The Influence of Laser Ablation Parameters on the Holes Structure of Laser Manufactured Graphene Paper Microsieves

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

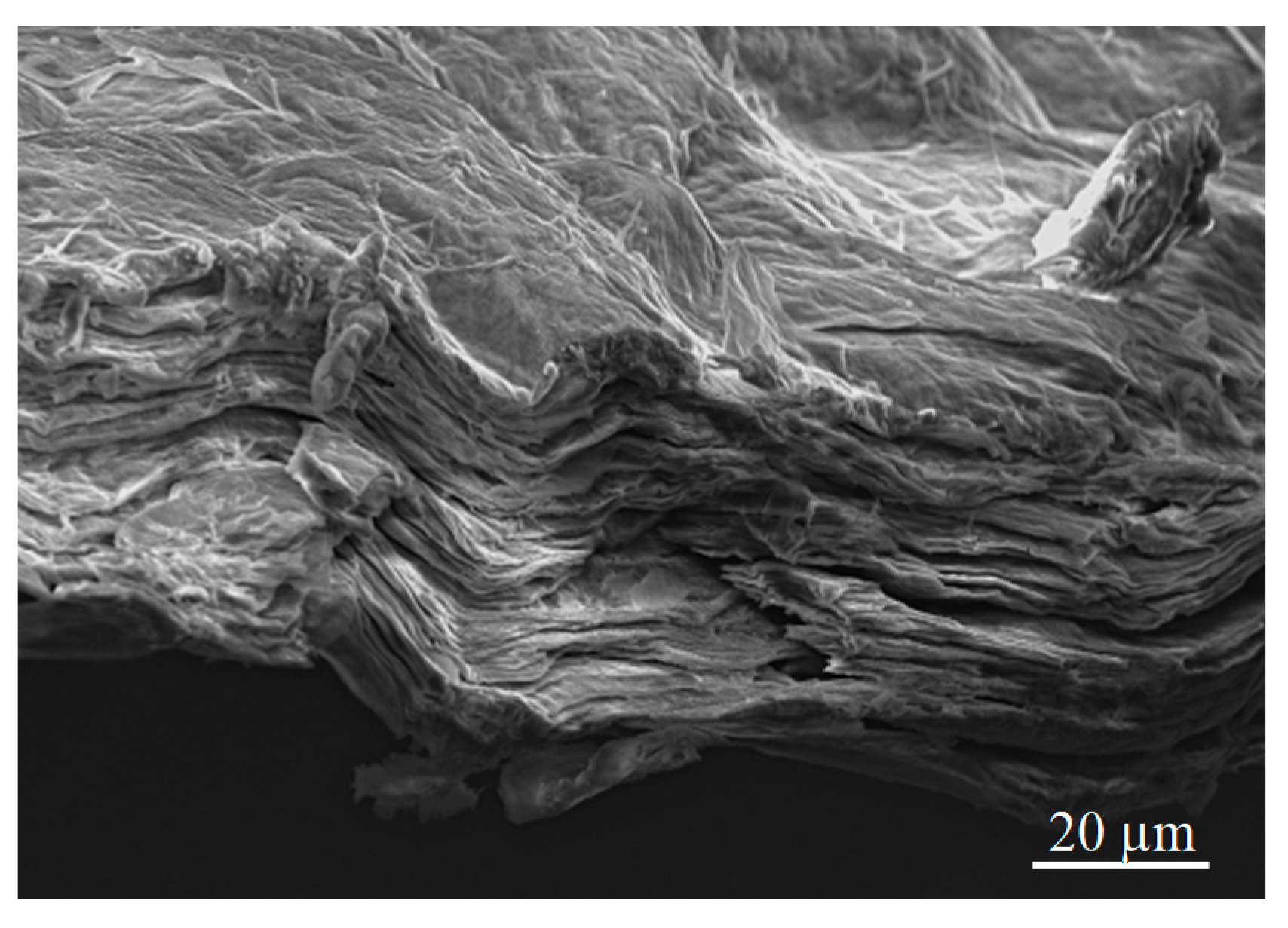

2.2. Characterization of Graphene Paper by Scanning Electron Microscopy

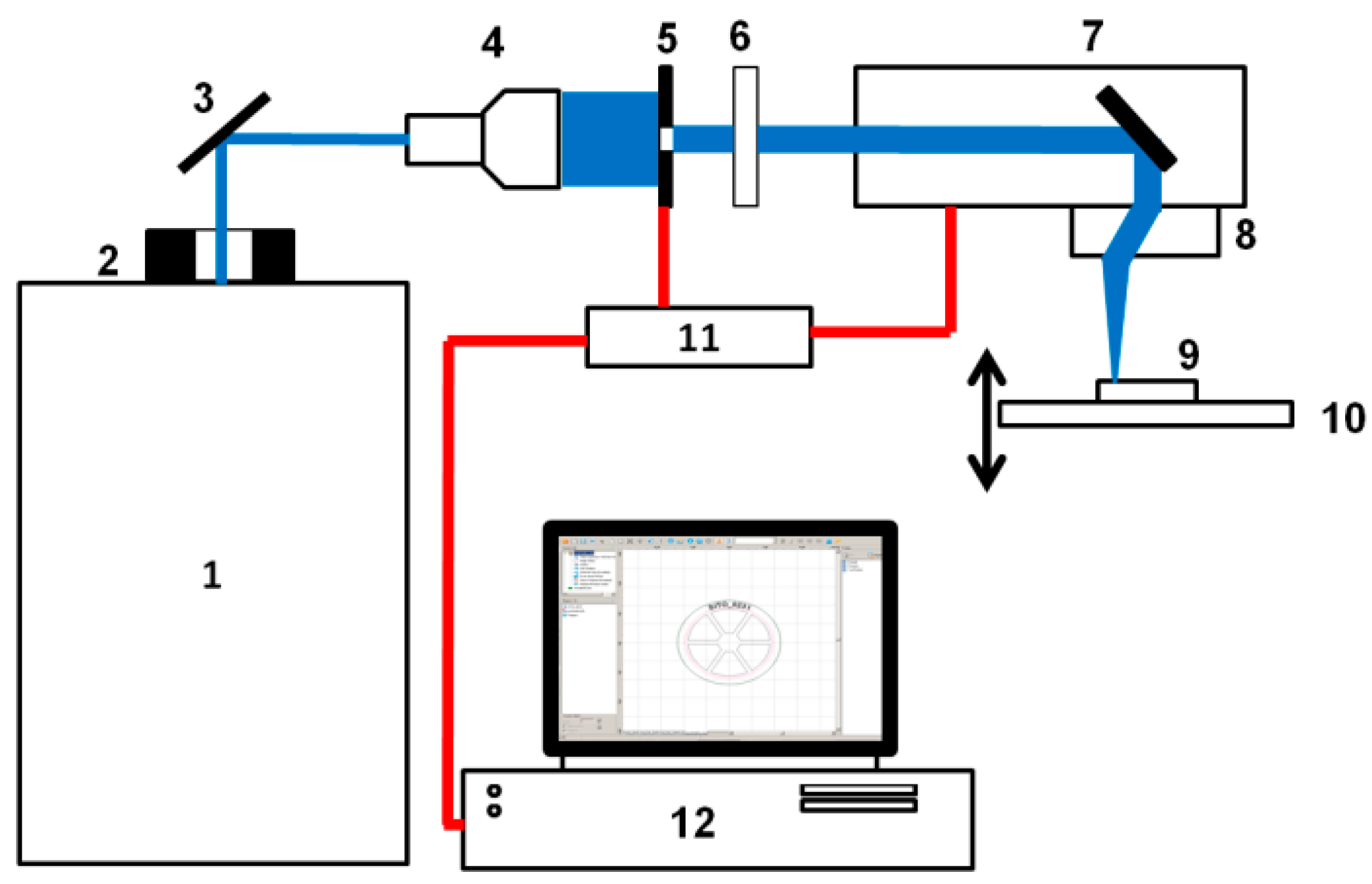

2.3. Laser Ablation

3. Results and Discussion

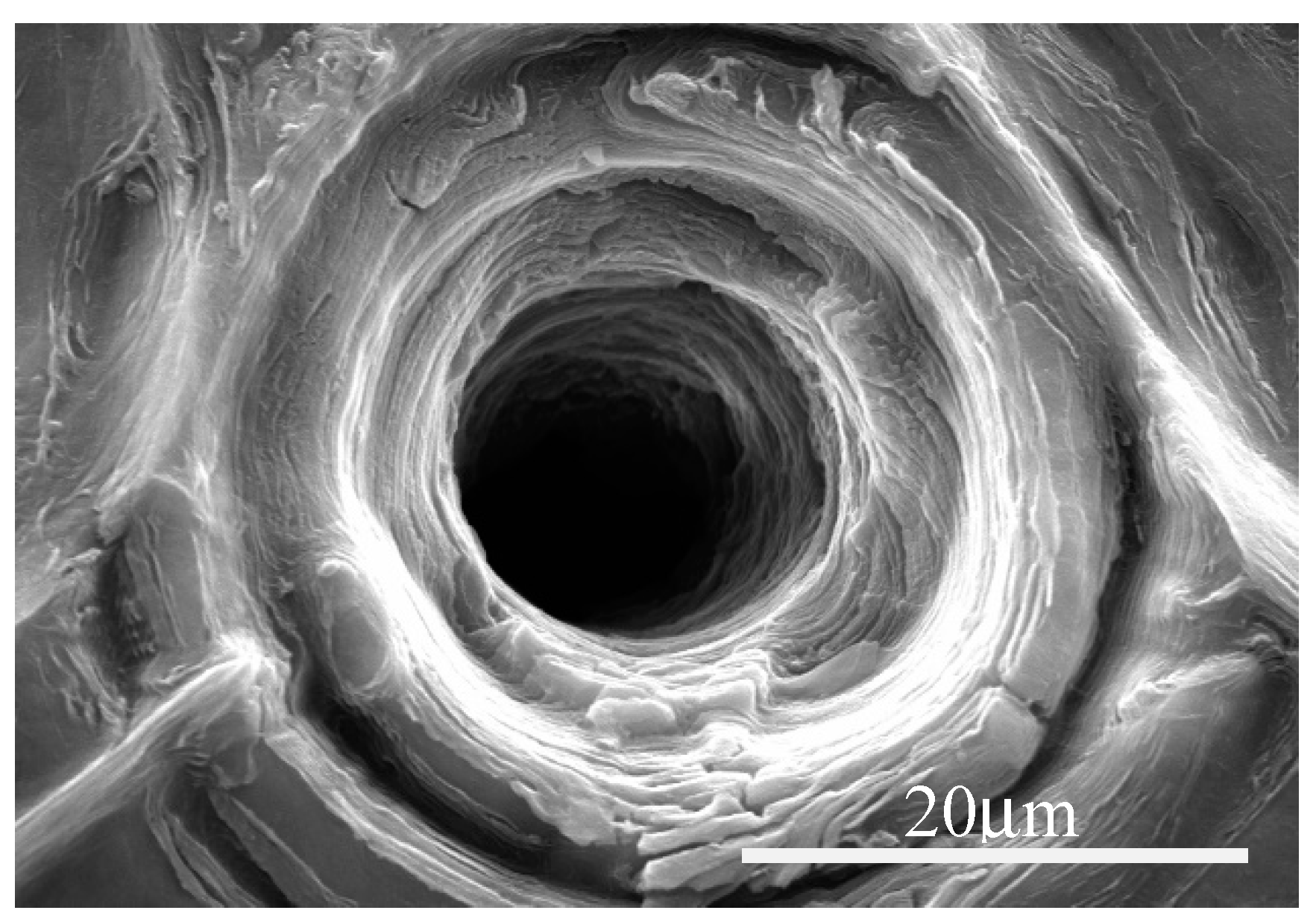

3.1. Graphene Paper Testing

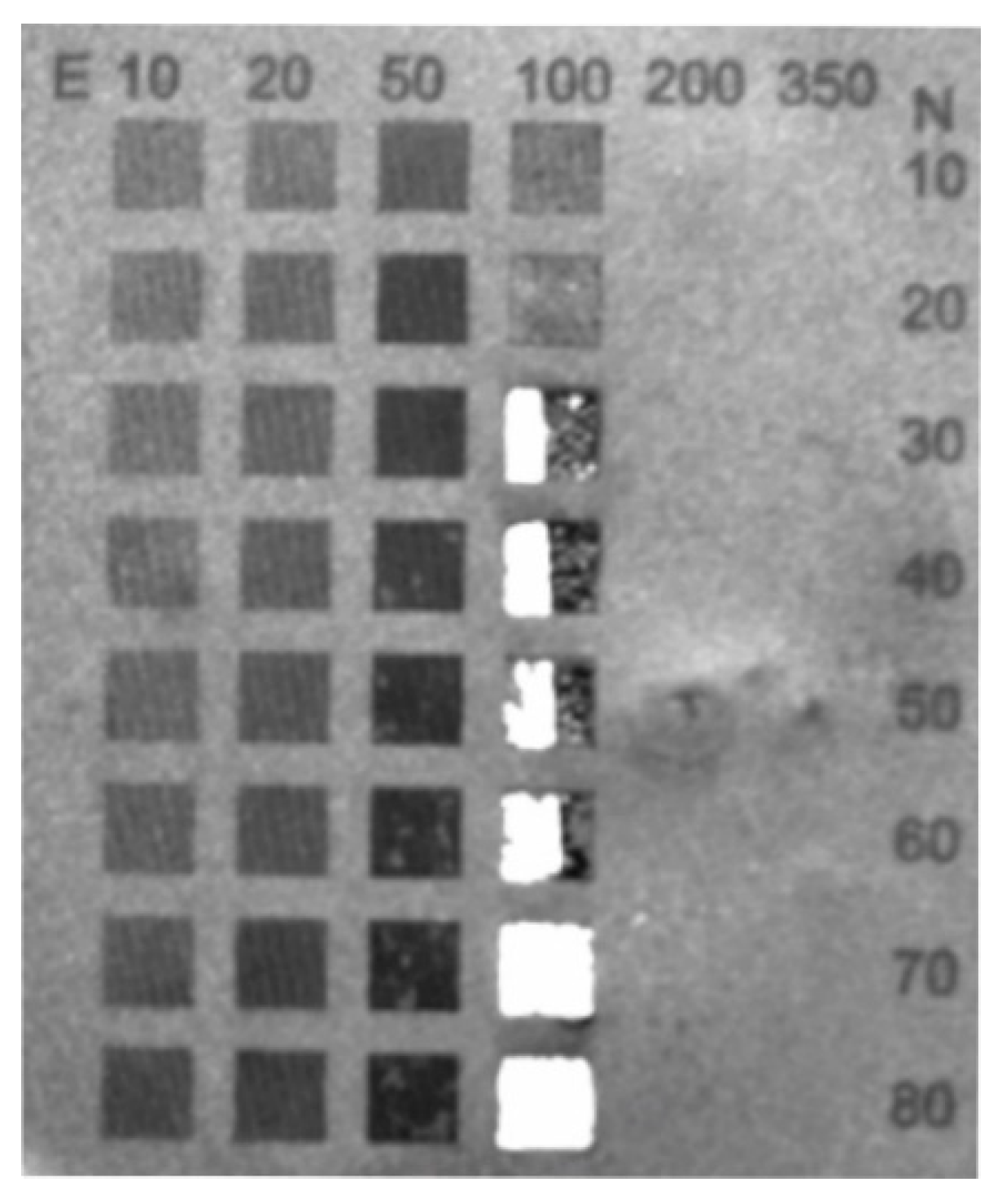

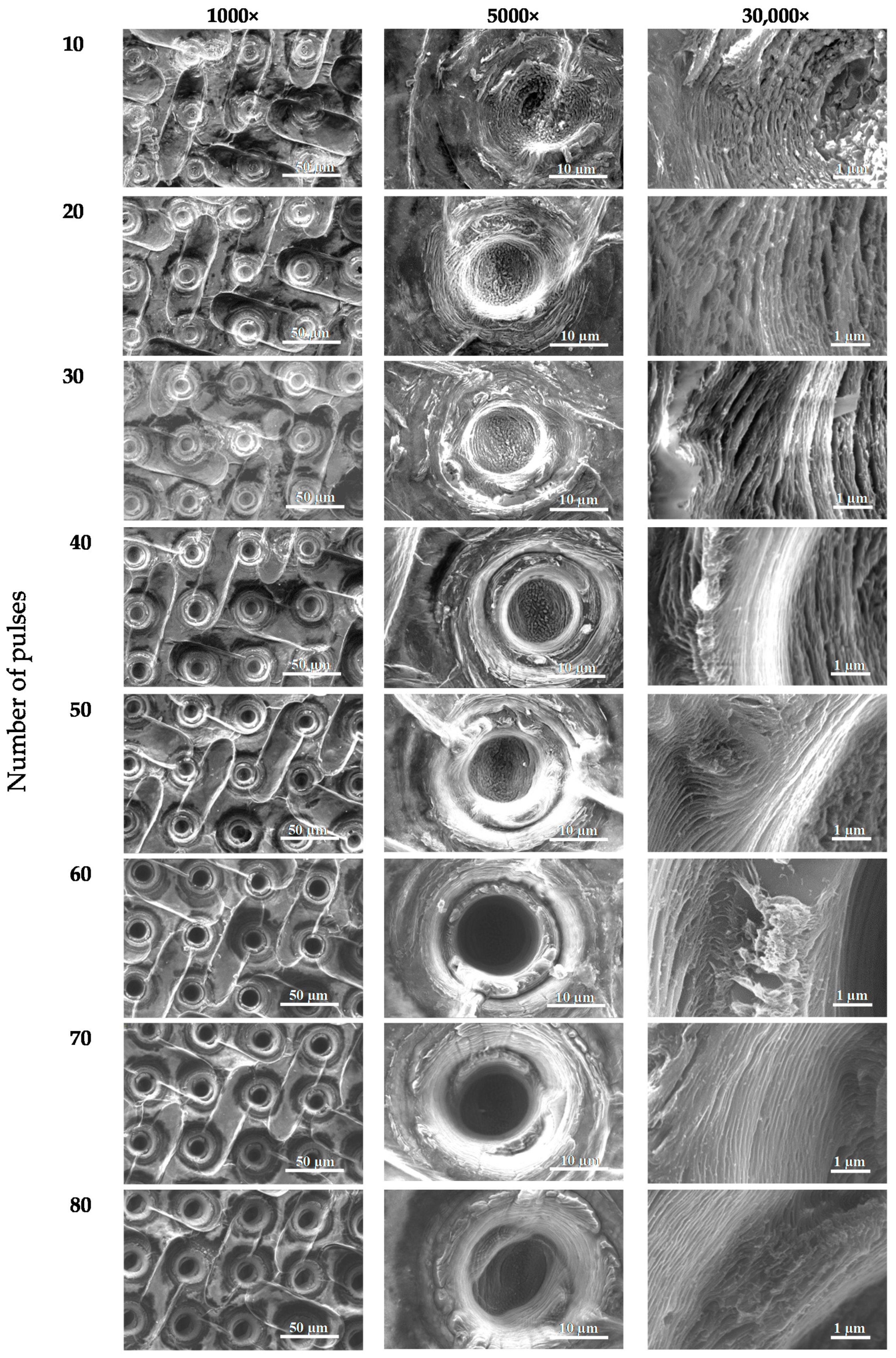

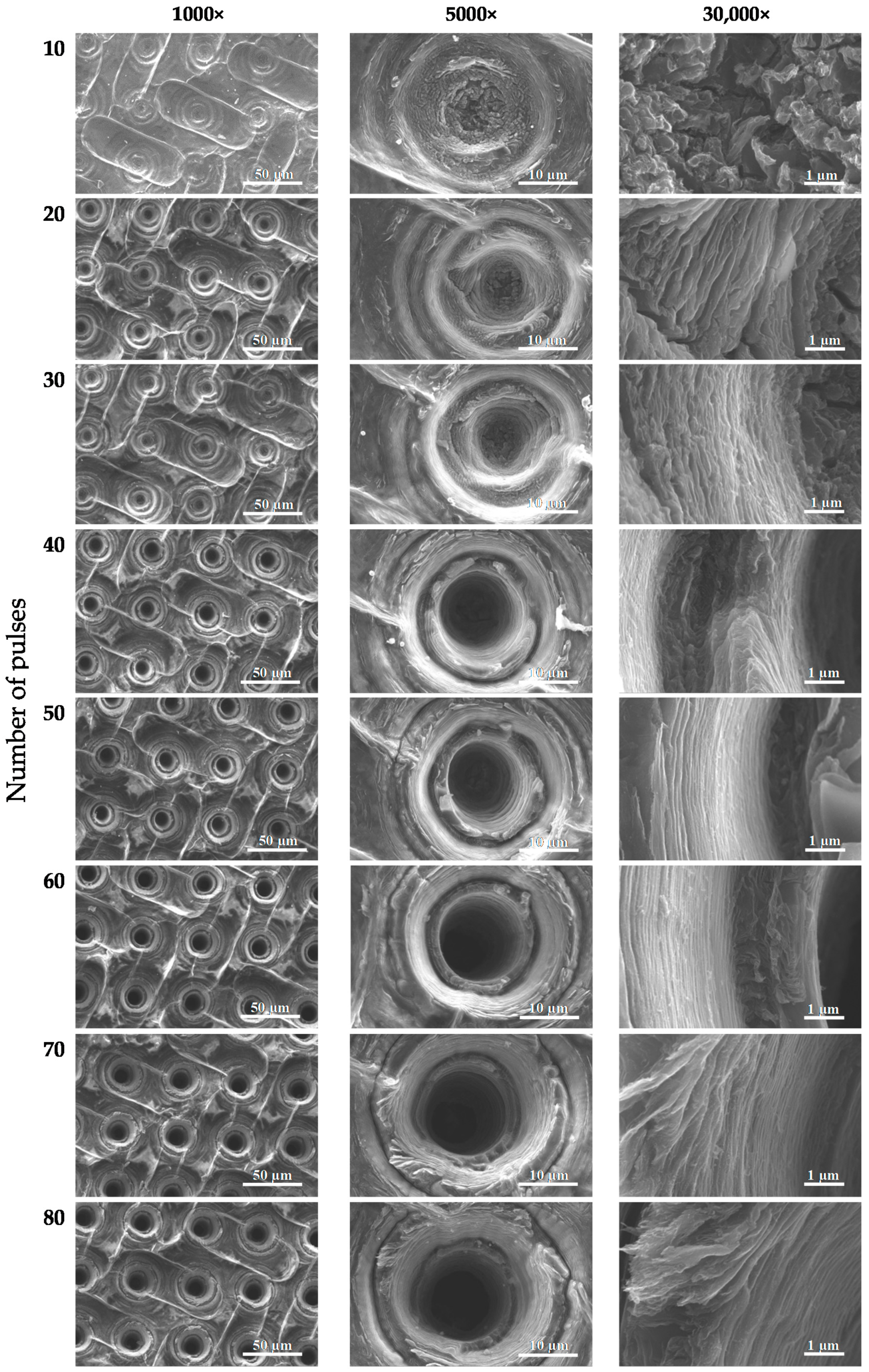

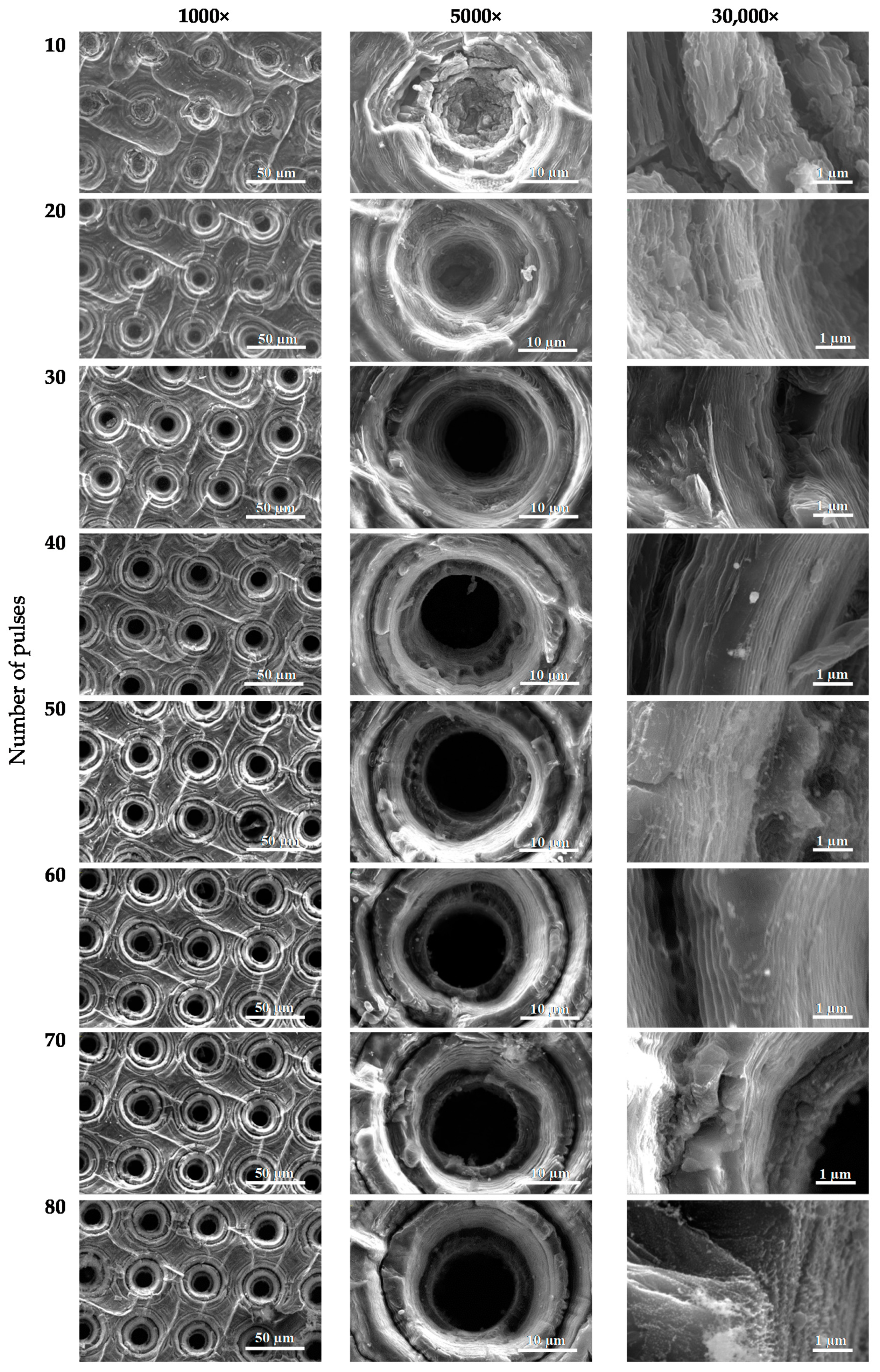

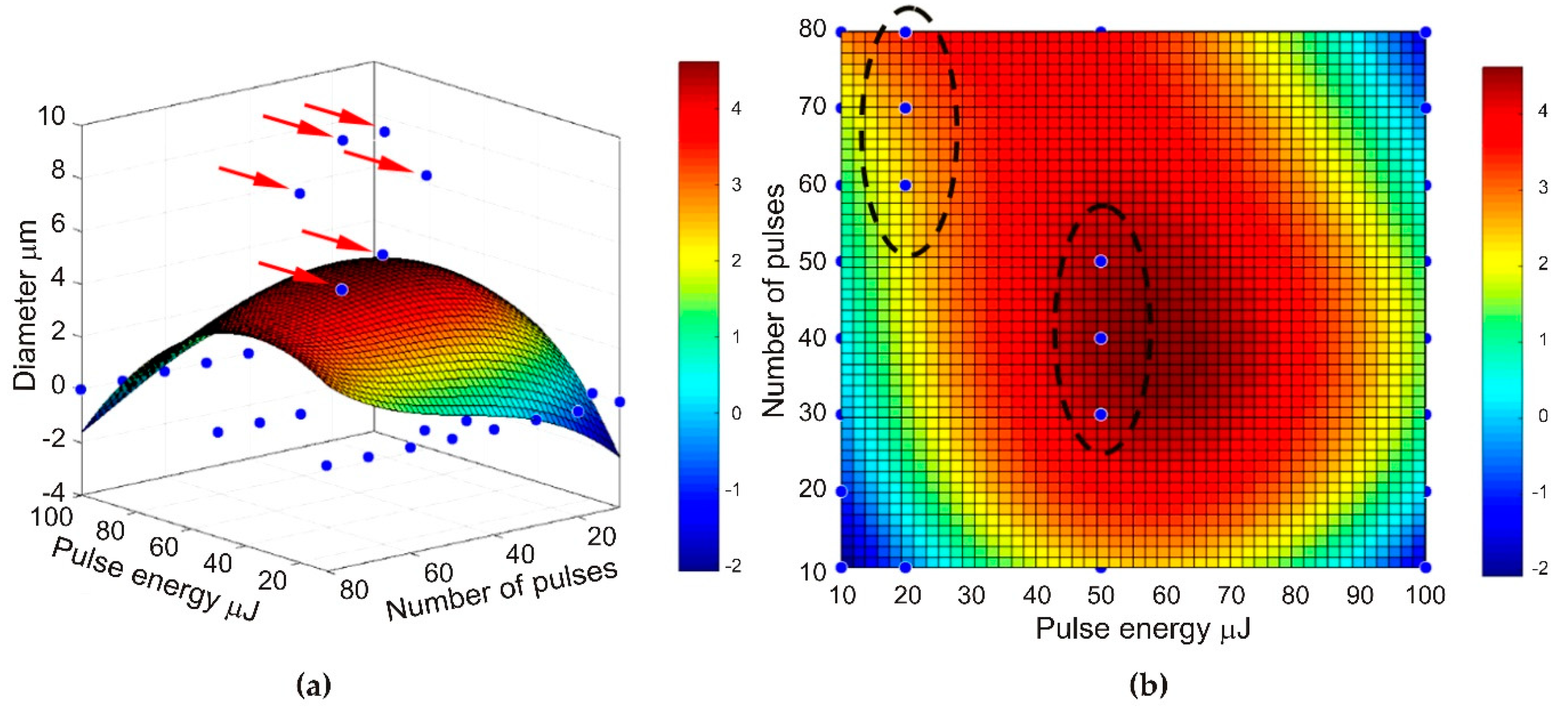

3.2. Selection of Laser Ablation Parameters

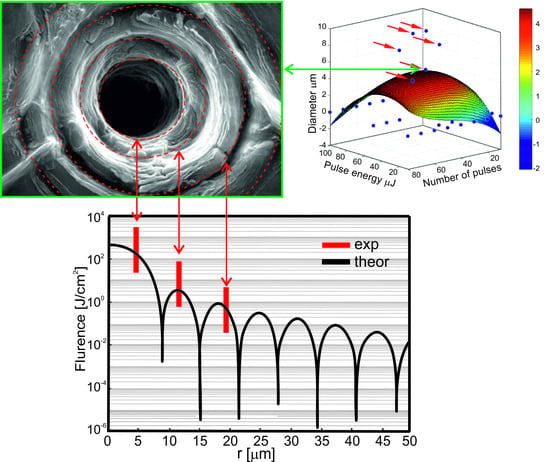

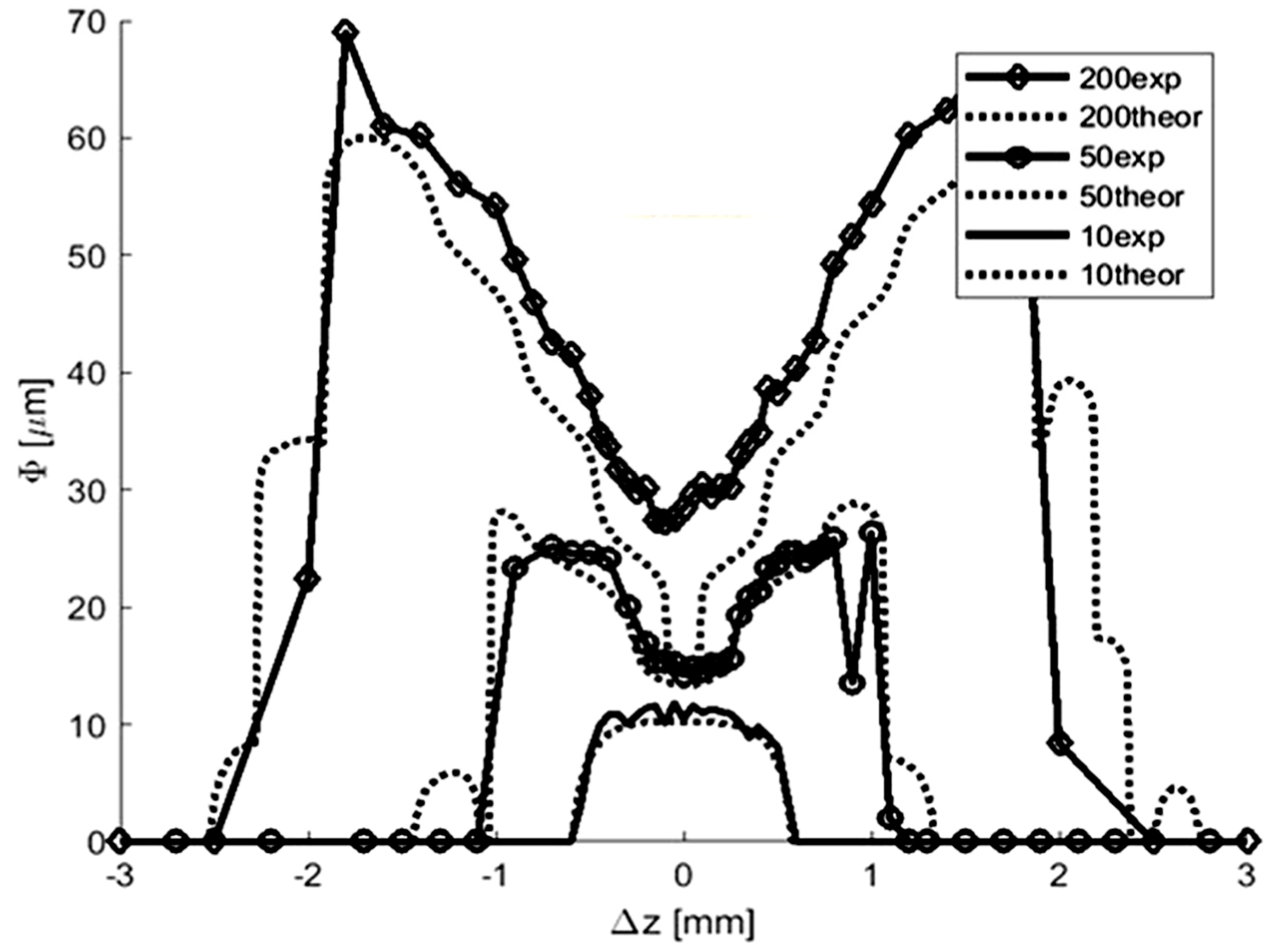

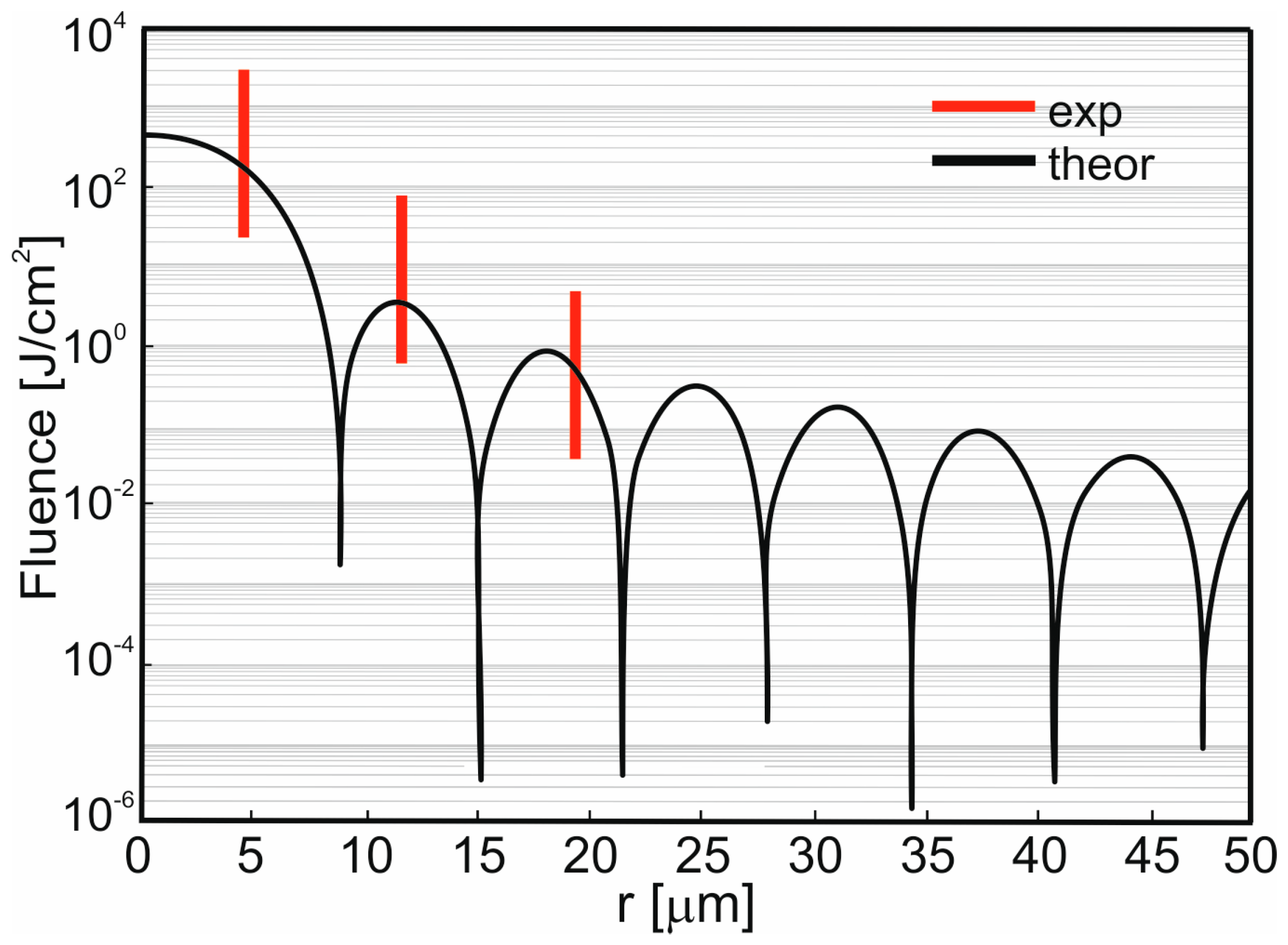

3.3. Distribution of Energy Density in Laser Beam

4. Conclusions

- Graphene paper morphology shown in the image taken on the microscope with the use of a scanning electron microscope (SEM) revealed multi-layered petals of graphene arranged in parallel. Typical lines in Raman spectra, i.e., D, G, D’, D + G, 2D, proved the presence of graphene oxide in the graphene paper;

- Calculated and measured distributions of the laser beam fluence show a good compliance. The tests conducted on the graphene paper laser ablation process demonstrated that the energy of a laser pulse is a crucial parameter decisive for the result of the processing. The lower the pulse energy, the smaller the diameter of the produced holes and the better the quality of their edges. Increasing the pulse energy decreases the number of the shots required to produce the hole. However, it decreases the quality of the processing and, moreover, causes uncontrolled failure of the processed material due to thermal conductivity and shock wave effects;

- The results of the test performed also show that after producing the holes, increasing the number of pulses does not significantly affect their diameter any longer;

- The analyses conducted proved that in order to successfully produce a microsieve from graphene paper, 50 to 70 pulses for one hole must be applied at energy levels of 20 µJ or 30 to 50 pulses at energy levels of 50 µJ.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Arshad, A.; Jabbal, M.; Yan, Y.; Reay, D. A review on graphene based nanofluids: Preparation, characterization and applications. J. Mol. Liq. 2019, 279, 444–484. [Google Scholar] [CrossRef]

- Sandhya, P.K.; Jose, J.; Sreekala, M.S.; Padmanabhan, M.; Thomas, S. Reduced graphene oxide and ZnO decorated graphene for biomedical applications. Ceram. Int. 2018, 44, 15092–15098. [Google Scholar] [CrossRef]

- Singh, R.; Sansare, S.; Shidhaye, S. Chapter 12: Biomedical application of graphenes. In Biomedical Applications of Nanoparticles; Elsevier Inc.: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Nasiłowska, B.; Kowalik, A.; Bogdanowicz, Z.; Sarzynski, A.; Hincza, K.; Gruszynski, K.; Woluntarski, M.; Mierczyk, Z.; Gózdz, S. Application of graphene paper laser ablation for separation of cancer cells. Proc. SPIE 2018, 10974, 109740B. [Google Scholar]

- Jae-Hyuck, Y.; Jung, B.I.; Jong, B.P.; Hojeong, J.; Costas, P.G. Graphene folds by femtosecond laser ablation. Appl. Phys. Lett. 2012, 100, 233124. [Google Scholar]

- Chen, K.; Wang, Q.; Niu, Z.; Chen, J. Graphene-based materials for flexible energy storage devices. J. Energy Chem. 2018, 27, 12–24. [Google Scholar] [CrossRef]

- Xu, T.; Chen, J.; Yuan, W.; Li, L.; Yang, L. Investigating the hydrogen storage capacity of surfactant modified graphene. Energy Procedia 2019, 158, 2112–2117. [Google Scholar] [CrossRef]

- Zhao, X.; Jiaqiang, E.; Wu, G.; Deng, Y.; Han, D.; Zhang, B.; Zhang, Z. A review of studies using graphenes in energy conversion, energy storage and heat transfer development. Energy Convers. Manag. 2019, 184, 581–599. [Google Scholar] [CrossRef]

- Li, Q.; Guo, X.; Zhang, Y.; Zhang, W.; Ge, C.; Zhao, L.; Wang, X.; Zhang, H.; Chen, J.; Wang, Z.; et al. Porous graphene paper for super capacitor applications. J. Mater. Sci. Technol. 2017, 33, 793–799. [Google Scholar] [CrossRef]

- Liu, S.; Ling, J.; Li, K.; Yao, F.; Oderinde, O.; Zhang, Z.; Fu, G. Bio-inspired and lanthanide-induced hierarchical sodium alginate/graphene oxide composite paper with enhanced physicochemical properties. Compos. Sci. Technol. 2017, 145, 62–70. [Google Scholar]

- An, Y.; Han, W.; Han, J.; Zhao, G.; Zhou, S.; Zhang, X. Synergistic effect on the mechanical behaviors of ternary graphene oxide-zirconium diboride-poly (vinyl alcohol) papers. Mater. Des. 2016, 112, 275–281. [Google Scholar] [CrossRef]

- Pérez-Mas, A.; Álvarez, P.; Campos, N.; Gómez, D.; Menéndez, R. Graphene patterning by nanosecond laser ablation: The effect of the substrate interaction with graphene. J. Phys. D Appl. Phys. 2016, 49, 305301. [Google Scholar] [CrossRef]

- Kalita, G.; Qi, L.; Namba, Y.; Wakita, K.; Umeno, M. Femtosecond laser induced micropatterning of graphene film. Mater. Lett. 2011, 65, 1569–1572. [Google Scholar] [CrossRef]

- Kiisk, V.; Kahro, T.; Kozlova, J.; Matisen, L.; Alles, H. Nanosecond laser treatment of graphene. Appl. Surf. Sci. 2013, 276, 133–137. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.K.; Singh, D.P.; Joanni, E.; Yadav, R.M.; Moshkalev, S.A. Laser-assisted synthesis, reduction and micro-patterning of graphene: Recent progress and applications. Coord. Chem. Rev. 2017, 342, 34–79. [Google Scholar] [CrossRef]

- Zhang, W.; Li, L.; Wang, Z.B.; Pena, A.A.; Whitehead, D.J.; Zhong, L.M.; Lin, Z.; Zhu, H.W. Ti: Sapphire femtosecond laser direct micro-cutting and profiling of graphene. Int. J. Appl. Phys. 2012, 109, 291–297. [Google Scholar]

- Sahin, R.; Simsek, E.; Akturk, S. Nanoscale patterning of graphene through femtosecond laser ablation. Appl. Phys. Lett. 2014, 104, 053118. [Google Scholar] [CrossRef]

- Dhar, S.; Barman, A.R.; Ni, G.X.; Wang, X.; Xu, X.F.; Zheng, Y.; Tripathy, S.; AriandoRusydi, A.; Loh, K.P.; Rubhausen, M.; et al. A new route to graphene layers by selective laser ablation. AIP Adv. 2011, 1, 022109. [Google Scholar] [CrossRef]

- Angus Mackenzie, D.M.; Buron, J.; Whelan, P.R.; Jessen, B.; Silajdźić, A.; Pesquera, A.; Centeno, A.; Zurutuza, A.; Bøggild, P.; Petersen, D.H. Fabrication of CVD graphene-based devices via laser ablation for wafer-scale characterization. 2D Mater. 2015, 2, 045003. [Google Scholar] [CrossRef]

- Łapiński, M.; Bogdanowicz, Z.; Marczak, J.; Rycyk, A.; Sarzyński, A.; Strzelec, M. Laser manufacturing of microsieves for bioengineering applications. Photonics Lett. Pol. 2015, 7, 60–62. [Google Scholar]

- Cao, G.; Gan, X.; Lin, H.; Jia, B. An accurate design of graphene oxide ultrathin flat lens based on Rayleigh-Sommerfeld theory. Opto-Electron. Adv. 2018, 1, 180012. [Google Scholar] [CrossRef]

- Koziński, R.; Wiliński, Z.; Librant, K.; Aksienionek, M.; Lipińska, L. Method of Preparing Graphene Paper. European Patent EP2842910A1, 8 August 2016. [Google Scholar]

- Hummers, W.S.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Pampaloni, F.; Enderlein, J. Gaussian, hermite-gaussian, and laguerre-gaussian beams: A primer. Am. J. Phys 2004, 1, 1–29. [Google Scholar]

| Number of pulses | Pulse Energy µJ | ||||

| 10 | 20 | 50 | 100 | ||

| 10 | 0 | 0 | 0 | 0 | |

| 20 | 0 | 0 | 0 | 0 | |

| 30 | 0 | 0 | 8.1 ± 0.5 | 0 | |

| 40 | 0 | 0 | 9.7 ± 0.4 | 0 | |

| 50 | 0 | 6.8 ± 0.6 | 9.8 ± 0.7 | 0 | |

| 60 | 0 | 7.1 ± 0.5 | 11.3 ± 1.2 | 0 | |

| 70 | 0 | 9.8 ± 0.5 | 13.2 ± 1.8 | 0 | |

| 80 | 0 | 10.5 ± 1.1 | 14.5 ± 2.3 | 0 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nasiłowska, B.; Bogdanowicz, Z.; Sarzyński, A.; Skrzeczanowski, W.; Djas, M.; Bartosewicz, B.; Jankiewicz, B.J.; Lipińska, L.; Mierczyk, Z. The Influence of Laser Ablation Parameters on the Holes Structure of Laser Manufactured Graphene Paper Microsieves. Materials 2020, 13, 1568. https://doi.org/10.3390/ma13071568

Nasiłowska B, Bogdanowicz Z, Sarzyński A, Skrzeczanowski W, Djas M, Bartosewicz B, Jankiewicz BJ, Lipińska L, Mierczyk Z. The Influence of Laser Ablation Parameters on the Holes Structure of Laser Manufactured Graphene Paper Microsieves. Materials. 2020; 13(7):1568. https://doi.org/10.3390/ma13071568

Chicago/Turabian StyleNasiłowska, Barbara, Zdzisław Bogdanowicz, Antoni Sarzyński, Wojciech Skrzeczanowski, Małgorzata Djas, Bartosz Bartosewicz, Bartłomiej J. Jankiewicz, Ludwika Lipińska, and Zygmunt Mierczyk. 2020. "The Influence of Laser Ablation Parameters on the Holes Structure of Laser Manufactured Graphene Paper Microsieves" Materials 13, no. 7: 1568. https://doi.org/10.3390/ma13071568

APA StyleNasiłowska, B., Bogdanowicz, Z., Sarzyński, A., Skrzeczanowski, W., Djas, M., Bartosewicz, B., Jankiewicz, B. J., Lipińska, L., & Mierczyk, Z. (2020). The Influence of Laser Ablation Parameters on the Holes Structure of Laser Manufactured Graphene Paper Microsieves. Materials, 13(7), 1568. https://doi.org/10.3390/ma13071568