3D Printing of ABS Barium Ferrite Composites

Abstract

1. Introduction

2. Materials and Methods

- Material selection

- Compounding and rheological characterization

- Filament extrusion

- Composite printing

- Specimen characterization

2.1. Material Selection and Characterization

2.2. Compounding and Rheological Characterization

2.3. Filament Extrusion

2.4. Composite Printing

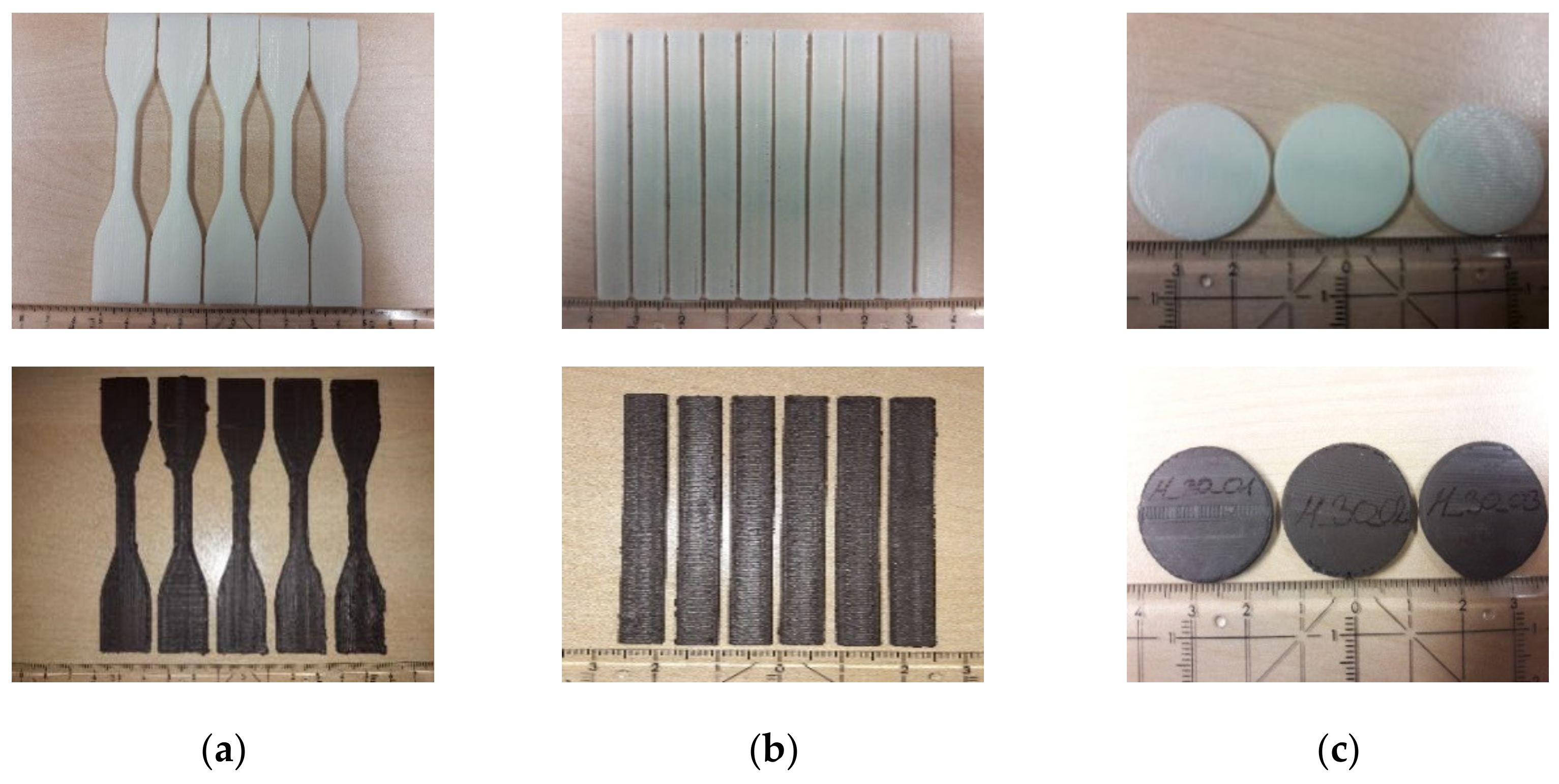

2.5. Specimen Characterization

3. Results and Discussion

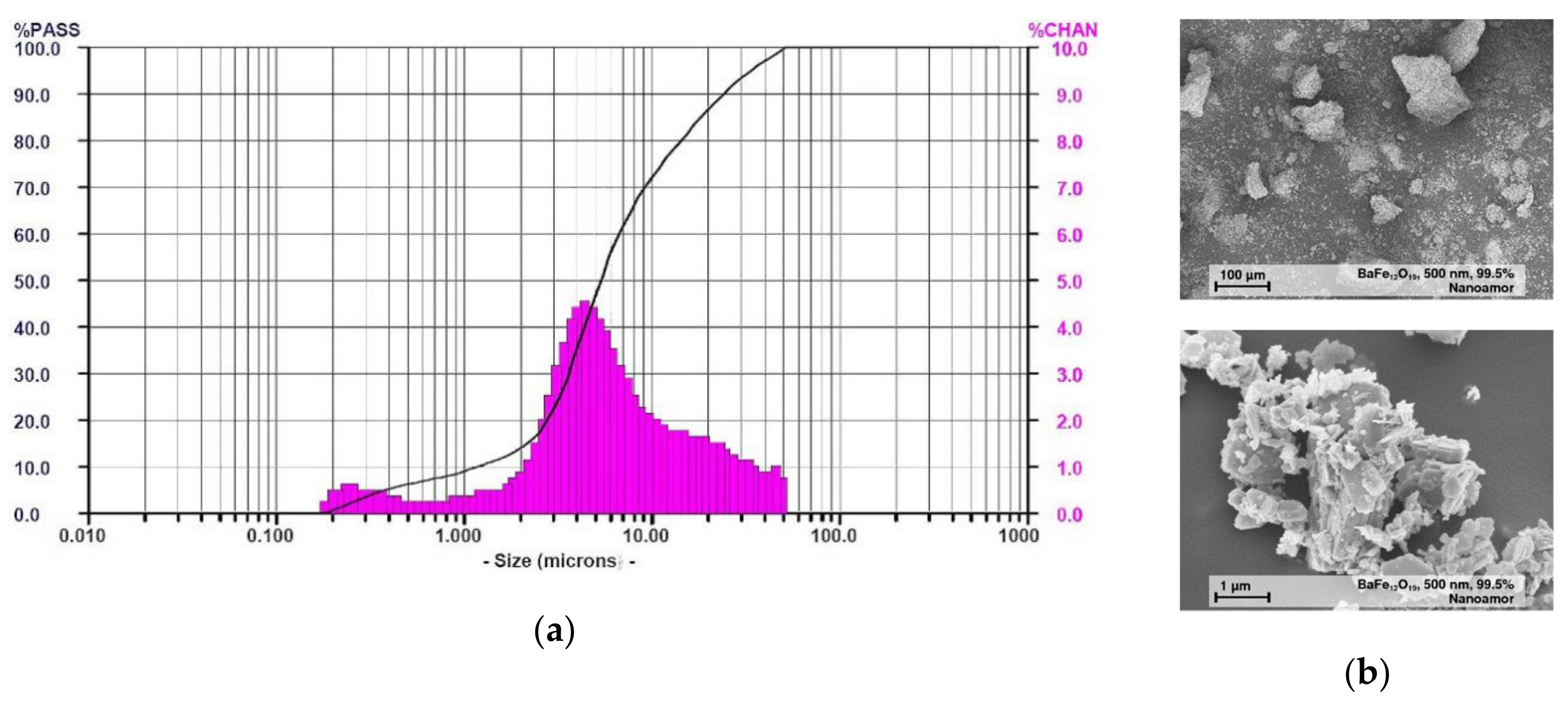

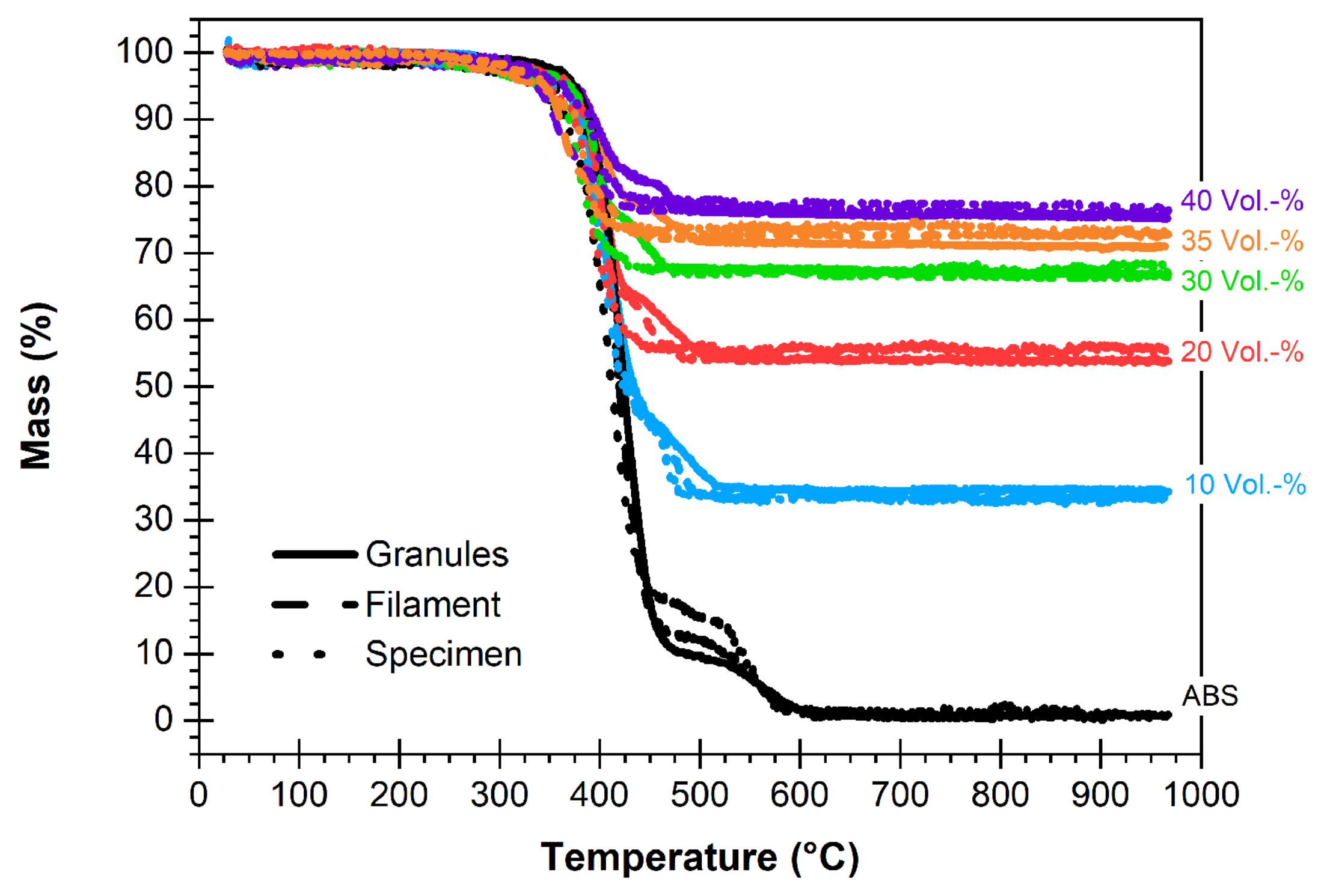

3.1. Material Properties and Characterization

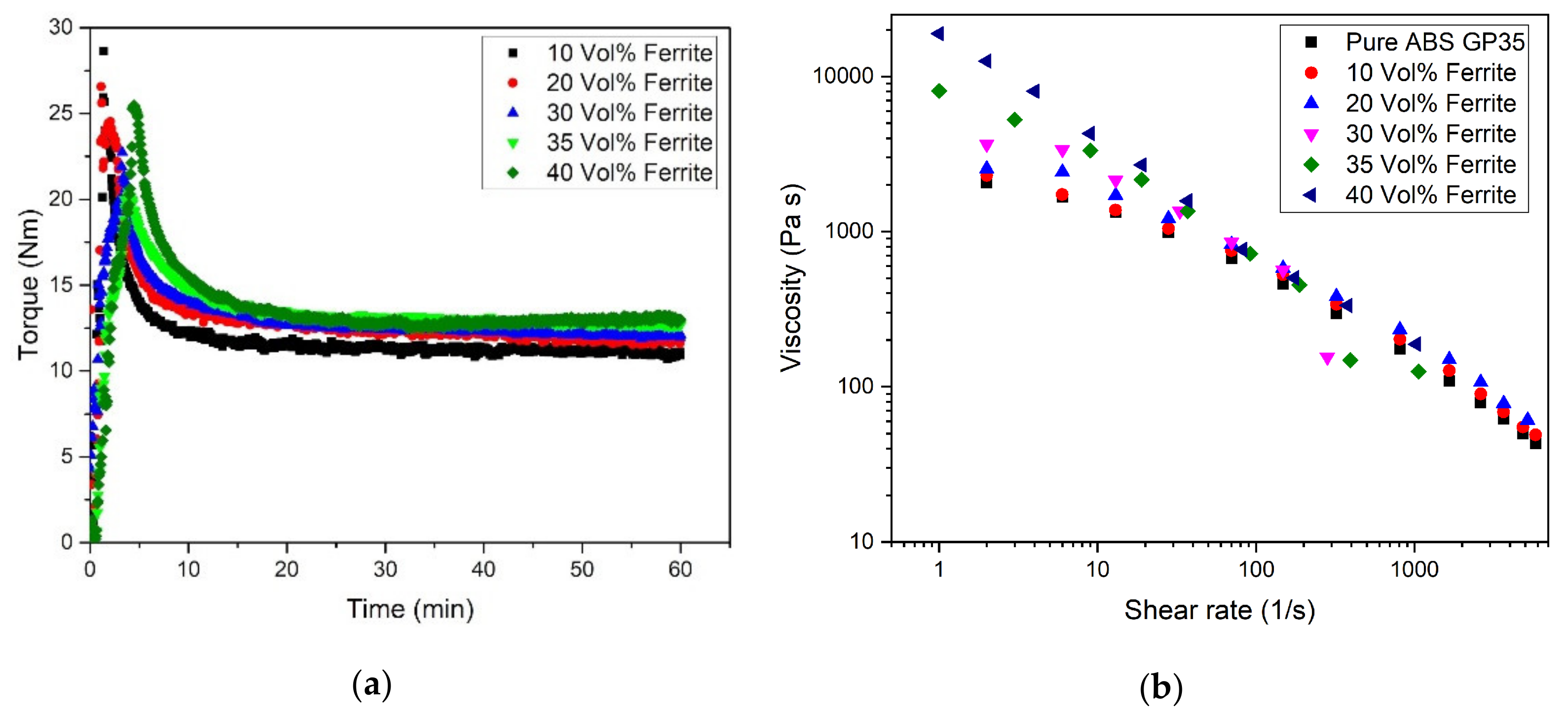

3.2. Compounding and Rheological Characterization

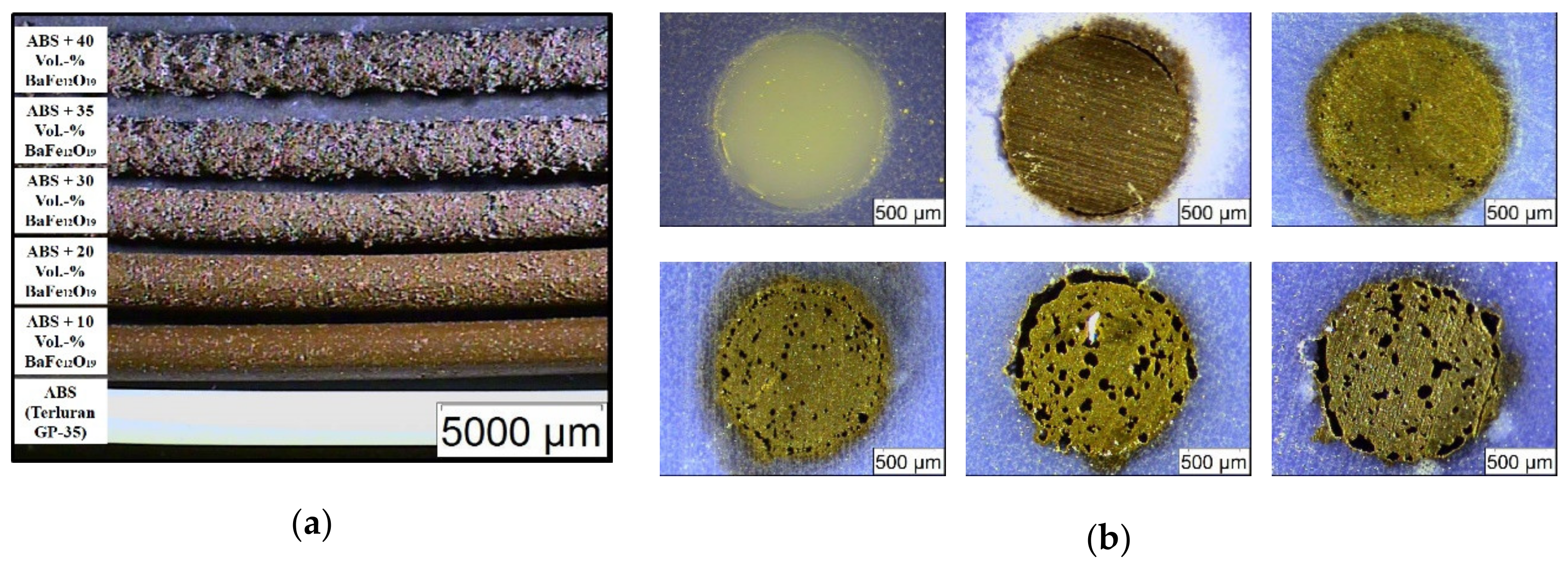

3.3. Filament Extrusion

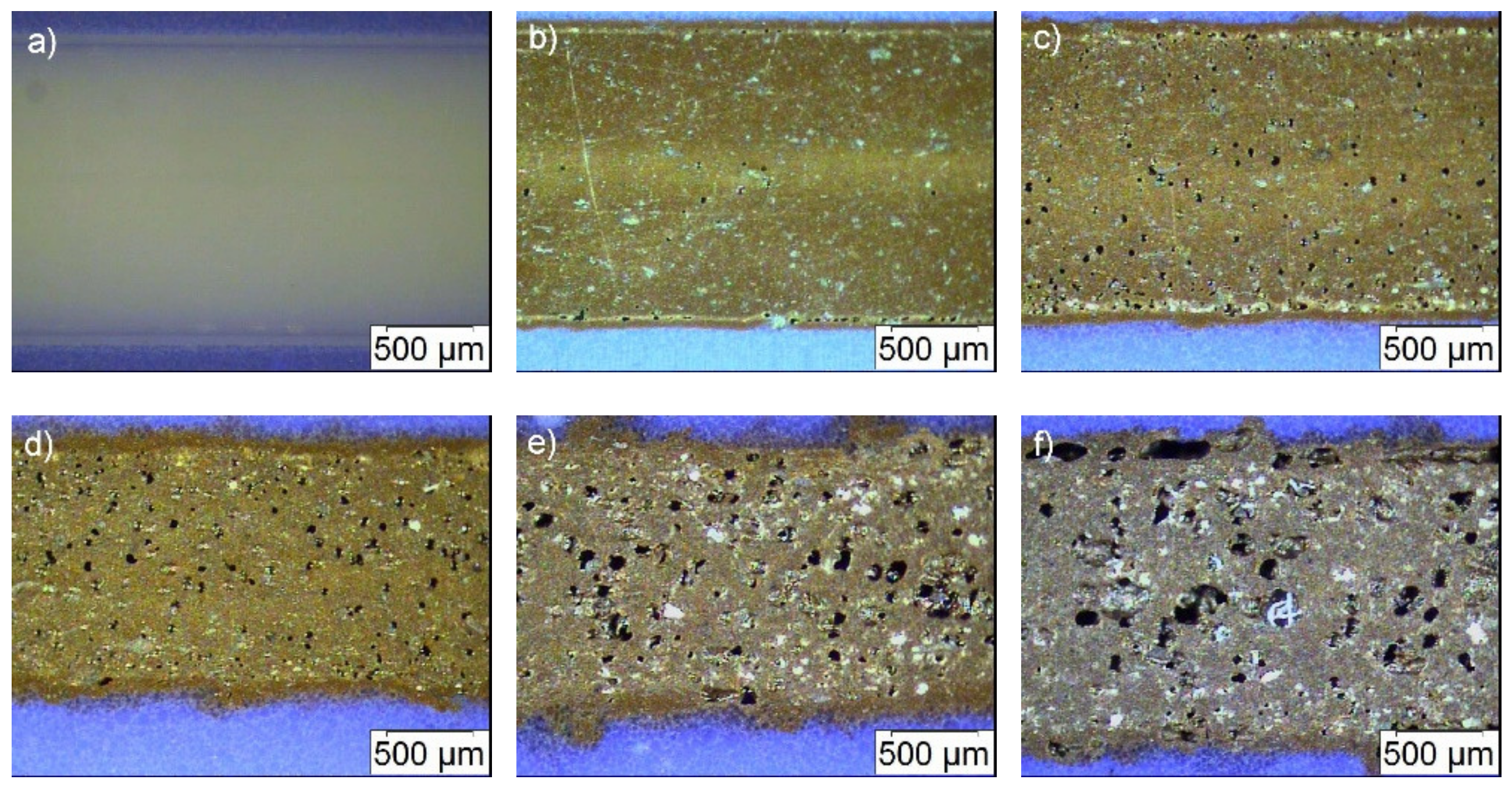

3.4. Composite Printing

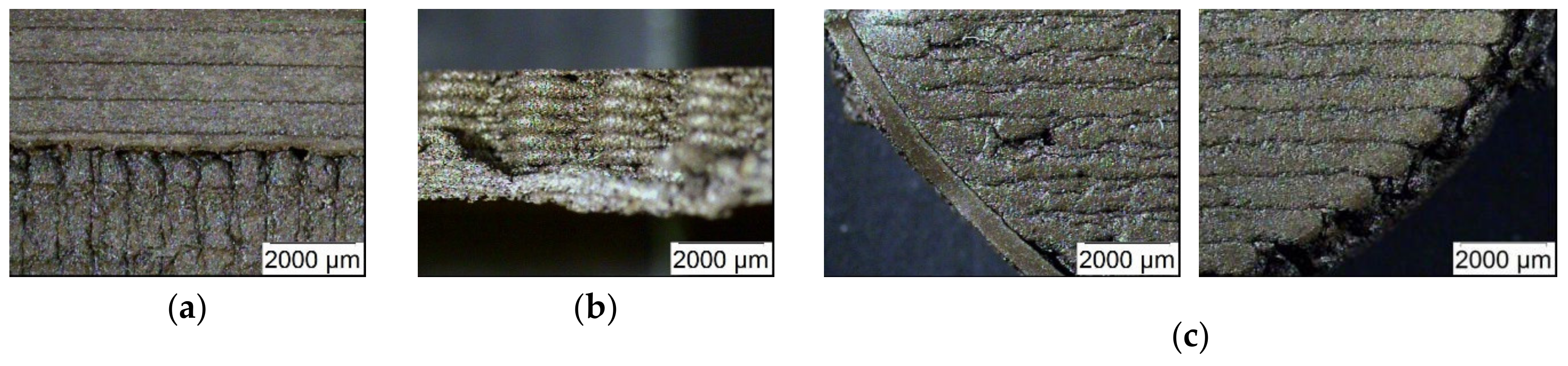

3.5. Specimen Characterization

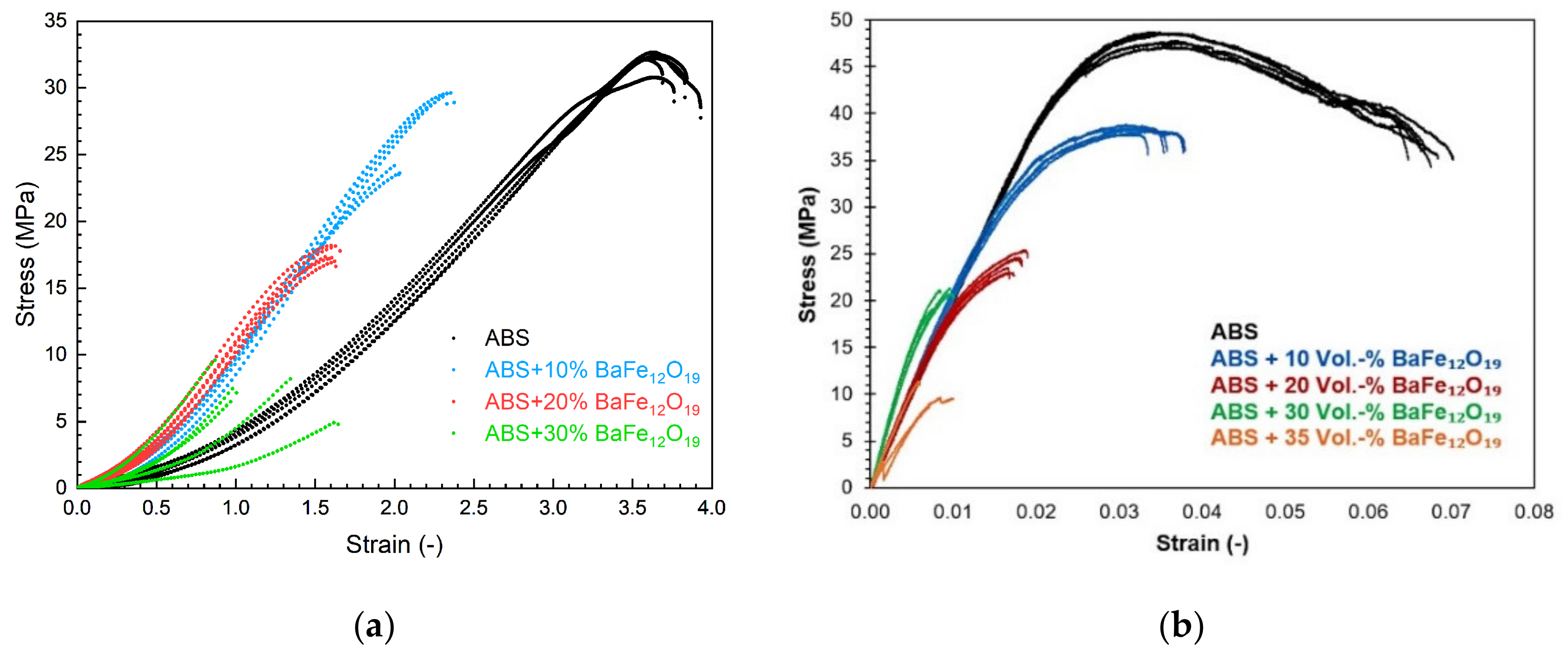

3.5.1. Mechanical Characterization

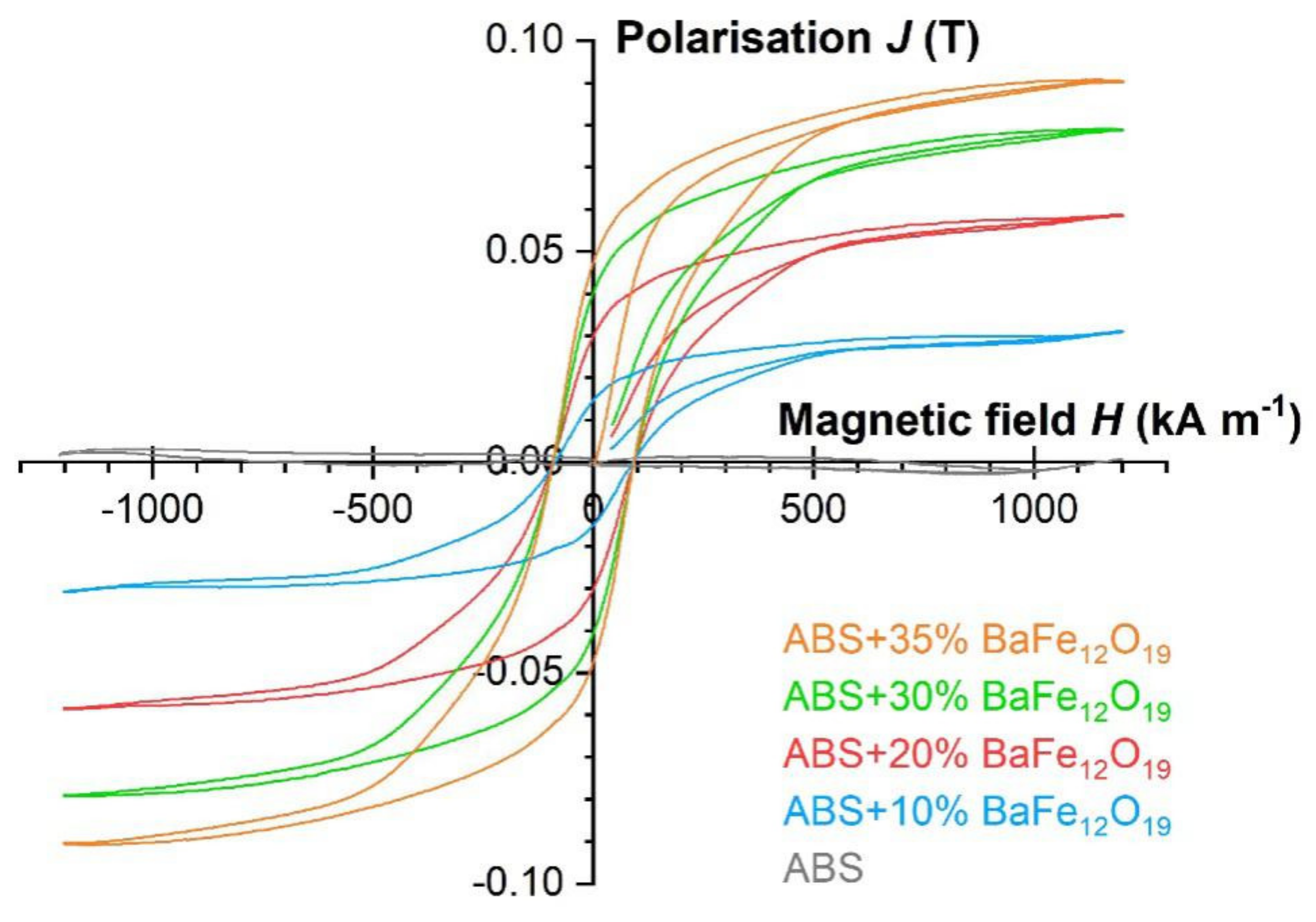

3.5.2. Magnetic Characterization

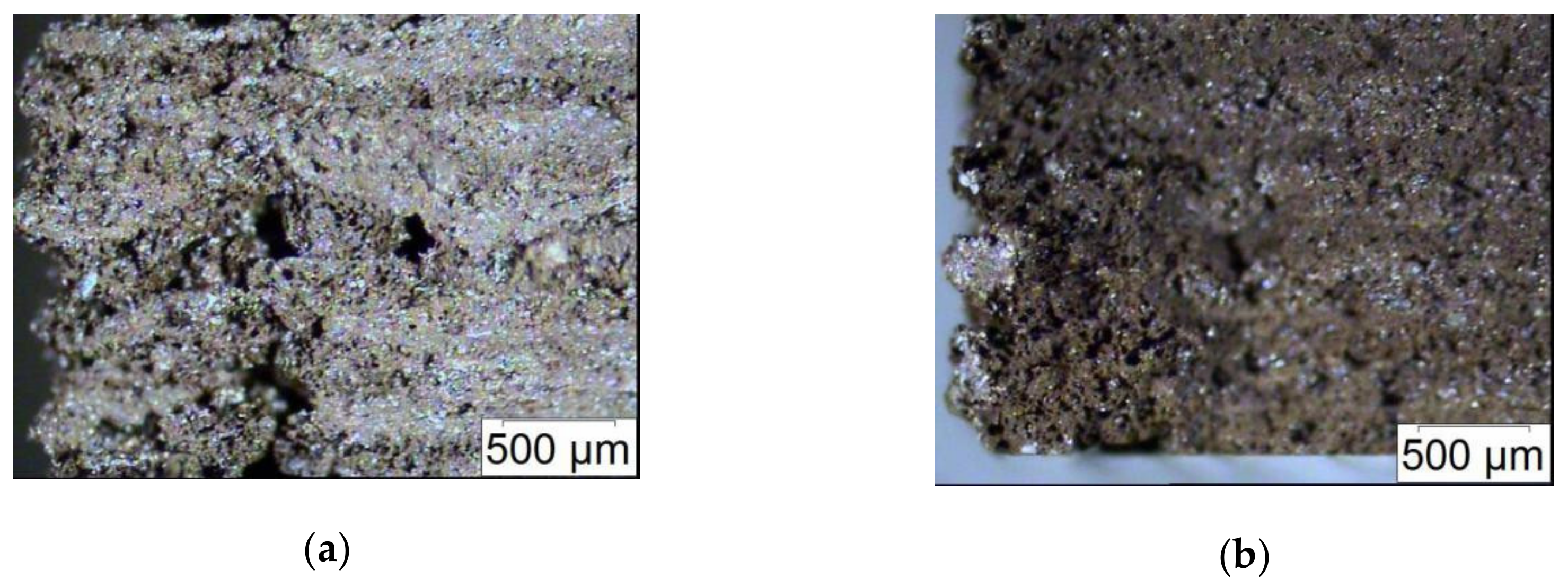

3.5.3. Process Characterization

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Additive Manufacturing—General Principles—Terminology; ISO/ASTM 52900; International Organization for Standardization: Geneva, Switzerland, 2015.

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Rinaldi, M.; Ghidini, T.; Cecchini, F.; Brandao, A.; Nanni, F. Additive layer manufacturing of poly (ether ether ketone) via FDM. Compos. Part B Eng. 2018, 145, 162–172. [Google Scholar] [CrossRef]

- Roach, D.J.; Hamel, C.M.; Dunn, C.K.; Johnson, M.V.; Kuang, X.; Qi, H.J. The m4 3D printer: A multi-material multi-method additive manufacturing platform for future 3D printed structures. Addit. Manuf. 2019, 29, 100819. [Google Scholar] [CrossRef]

- Awad, A.; Trenfield, S.J.; Gaisford, S.; Basit, A.W. 3D printed medicines: A new branch of digital healthcare. Int. J. Pharm. 2018, 548, 586–596. [Google Scholar] [CrossRef]

- Bose, S.; Ke, D.; Sahasrabudhe, H.; Bandyopadhyay, A. Additive manufacturing of biomaterials. Prog. Mater. Sci. 2018, 93, 45–111. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Noetzel, D.; Eickhoff, R.; Hanemann, T. Fused filament fabrication of small ceramic components. Materials 2018, 11, 1463. [Google Scholar] [CrossRef] [PubMed]

- Lei, Z.; Chen, Z.; Zhou, Y.; Liu, Y.; Xu, J.; Wang, D.; Shen, Y.; Feng, W.; Zhang, Z.; Chen, H. Novel electrically conductive composite filaments based on Ag/saturated polyester/polyvinyl butyral for 3D-printing circuits. Compos. Sci. Technol. 2019, 180, 44–50. [Google Scholar] [CrossRef]

- Oztan, C.; Ballikaya, S.; Ozgun, U.; Karkkainen, R.; Celik, E. Additive manufacturing of thermoelectric materials via fused filament fabrication. Appl. Mater. Today 2019, 15, 77–82. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Fused deposition modeling of ABS-barium titanate composites: A simple route towards tailored dielectric devices. Polymers 2018, 10, 666. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Noetzel, D.; Pursche, K.; Hanemann, T. A 3D-printable polymer-metal soft-magnetic functional composite-development and characterization. Materials 2018, 11, 189. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Xiao, H.; Ding, S.; Huang, C. Effects of printing parameters of fused deposition modeling on mechanical properties, surface quality, and microstructure of PEEK. J. Mater. Process. Technol. 2019, 271, 62–74. [Google Scholar] [CrossRef]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical property of FDM printed ABS: Influence of printing parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Sonsalla, T.; Moore, A.L.; Meng, W.J.; Radadia, A.D.; Weiss, L. 3-D printer settings effects on the thermal conductivity of acrylonitrile butadiene styrene (ABS). Polym. Test. 2018, 70, 389–395. [Google Scholar] [CrossRef]

- Hanemann, T.; Syperek, D.; Noetzel, D. 3D-printed functional polymer-ceramic-composites. In Proceedings of the Mikrosystemtechnik Kongress 2019, Berlin, Germany, 28–30 October 2019; VDE Verlag GmbH: Berlin, Germany, 2019; pp. 603–606. [Google Scholar]

- Schumacher, B. Polymer Ceramic Composites with Optimized Dielectric Properties for Electronic Devices (In German). Ph.D. Thesis, University of Freiburg, Freiburg, Germany, 2010. Available online: https://freidok.uni-freiburg.de/data/7692 (accessed on 27 January 2020).

- Hanemann, T.; Heldele, R. Modern alchemy: Ceramic feedstock optimization by surfactant screening. Ceram. Forum Int. 2010, 87, E38–E40. [Google Scholar]

- Barnes, H.A. Review of the rheology of filled viscoelastic systems. Rheol. Rev. Br. Soc. Rheol. 2003, 1–36. [Google Scholar]

- Medesi, A.; Noetzel, D.; Hanemann, T. PVB/PEG-based feedstocks for injection molding of alumina microreactor components. Materials 2019, 12, 1219. [Google Scholar] [CrossRef] [PubMed]

- Noetzel, D.; Hanemann, T. Kleinbauteile aus Keramik und Metall aus dem FDM-Drucker. In Proceedings of the Fachtagung Werkstoffe und Additive Fertigung 2018, Potsdam, Germany, 25–26 April 2018. [Google Scholar]

- Abel, J.; Scheithauer, U.; Janics, T.; Hampel, S.; Cano, S.; Muller-Kohn, A.; Gunther, A.; Kukla, C.; Moritz, T. Fused Filament Fabrication (FFF) of metal-ceramic components. J. Vis. Exp. 2019, 143, e57693. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Gutierrez, J.; Arbeiter, F.; Schlauf, T.; Kukla, C.; Holzer, C. Tensile properties of sintered 17-4PH stainless steel fabricated by material extrusion additive manufacturing. Mater. Lett. 2019, 248, 165–168. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: A review and future perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Gutierrez, J.; Godec, D.; Guran, R.; Spoerk, M.; Kukla, C.; Holzer, C. 3D Printing conditions determination for feedstock used in fused filament fabrication (FFF) of 17-4PH stainless steel parts. Metalurgija 2018, 57, 117–120. [Google Scholar]

- Kukla, C.; Gonzalez-Gutierrez, J.; Burkhardt, C.; Holzer, C. The production of magnets by FFF—Fused Filament Fabrication. In Proceedings of the EuroPM-Conference 2017, Mailand, Italy, 1–5 October 2017. [Google Scholar]

- Gonzalez-Gutierrez, J.; Duretek, I.; Holzer, C.; Arbeiter, F.; Kukla, C. Filler content and properties of highly filled filaments for fused filament fabrication of magnets. In Proceedings of the Antec Conference, Anaheim, CA, USA, 8–10 May 2017. [Google Scholar]

- Huber, C.; Cano, S.; Teliban, I.; Schuschnigg, S.; Groenefeld, M.; Suess, D. Polymer-bonded anisotropic SrFe12O19 filaments for fused filament fabrication. J. Appl. Phys. 2020, 127, 063904. [Google Scholar] [CrossRef]

- Wei, X.; Liu, Y.; Zhao, D.; Mao, X.; Jiang, W.; Ge, S.S. Net-shaped barium and strontium ferrites by 3D printing with enhanced magnetic performance from milled powders. J. Magn. Magn. Mater. 2020, 493, 165664. [Google Scholar] [CrossRef]

- Palmero, E.M.; Casaleiz, D.; Jimenez, N.A.; Rial, J.; de Vicente, J.; Nieto, A.; Altimira, R.; Bollero, A. Magnetic-polymer composites for bonding and 3D printing of permanent magnets. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big area additive manufacturing of high performance bonded NdFeB magnets. Sci. Rep. 2016, 6, 36212. [Google Scholar] [CrossRef]

- Nagarajan, B.; Eufracio Aguilera, A.F.; Wiechmann, M.; Qureshi, A.J.; Mertiny, P. Characterization of magnetic particle alignment in photosensitive polymer resin: A preliminary study for additive manufacturing processes. Addit. Manuf. 2018, 22, 528–536. [Google Scholar] [CrossRef]

- Nilsén, F.; Ituarte, I.F.; Salmi, M.; Partanen, J.; Hannula, S.-P. Effect of process parameters on non-modulated Ni-Mn-Ga alloy manufactured using powder bed fusion. Addit. Manuf. 2019, 28, 464–474. [Google Scholar] [CrossRef]

| Feature | Tensile Tests | Bending Tests | Magnetic Measurement |

|---|---|---|---|

| Applied standard | ASTM D638 Type IV | ASTM D790 | DIN IC 60404-5 |

| Specimen geometry | length × height × width 115 × 3.2 × 19 (mm3) | length × height × width 72 × 6.5 × 27.3 (mm3) | Diameter × height 25 × 2 (mm2) |

| Gauge length | 25 mm | n.a. | n.a. |

| Gauge width | 6 mm | n.a. | n.a. |

| Measuring speed | 5 ± 1.25 mm/min | 1 mm/min | n.a. |

| Temperature | 25 ± 2 °C | 25 ± 2 °C | 23.5 ± 0.4 °C |

| Relative humidity | 50 ± 5% | 50 ± 5% | n.a. |

| Composition | Tensile Stress (MPa) | Number of Samples | Bending Stress (MPa) | Number of Samples |

|---|---|---|---|---|

| ABS | 32.3 ± 2.0 | 10 | 35.3 ± 0.8 | 10 |

| ABS/10 vol.% Ferrite | 26.5 ± 3.3 | 6 | 35.8 ± 0.2 | 7 |

| ABS/20 vol.% Ferrite | 17.5 ± 0.6 | 7 | 23.3 ± 0.9 | 6 |

| ABS/30 vol.% Ferrite | 7.5 ± 1.8 | 5 | 20.3 ± 0.9 | 6 |

| ABS/35 vol.% Ferrite | - | - | 9.7 ± 1.2 | 3 |

| Composition | Hmax (kA/m) | Jmax (mT) | Bremn (mT) | Hcoer (kA/m) | (BH)max (kJ/m3) |

|---|---|---|---|---|---|

| Without sample | 1201 | 2 | 0.4 | 0.4 | 0 |

| ABS | 1201 | 1 | 0.6 | 0.4 | 0 |

| ABS/10 vol.% Ferrite | 1201 | 31 | 15 | 11 | 0.04 |

| ABS/20 vol.% Ferrite | 1202 | 59 | 30 | 20 | 15 |

| ABS/30 vol.% Ferrite | 1201 | 79 | 40 | 25 | 26 |

| ABS/35 vol.% Ferrite | 1202 | 91 | 47 | 29 | 35 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hanemann, T.; Syperek, D.; Nötzel, D. 3D Printing of ABS Barium Ferrite Composites. Materials 2020, 13, 1481. https://doi.org/10.3390/ma13061481

Hanemann T, Syperek D, Nötzel D. 3D Printing of ABS Barium Ferrite Composites. Materials. 2020; 13(6):1481. https://doi.org/10.3390/ma13061481

Chicago/Turabian StyleHanemann, Thomas, Diana Syperek, and Dorit Nötzel. 2020. "3D Printing of ABS Barium Ferrite Composites" Materials 13, no. 6: 1481. https://doi.org/10.3390/ma13061481

APA StyleHanemann, T., Syperek, D., & Nötzel, D. (2020). 3D Printing of ABS Barium Ferrite Composites. Materials, 13(6), 1481. https://doi.org/10.3390/ma13061481