Cyclic-Dependent Damage Evolution in Self-Healing Woven SiC/[Si-B-C] Ceramic-Matrix Composites at Elevated Temperatures

Abstract

1. Introduction

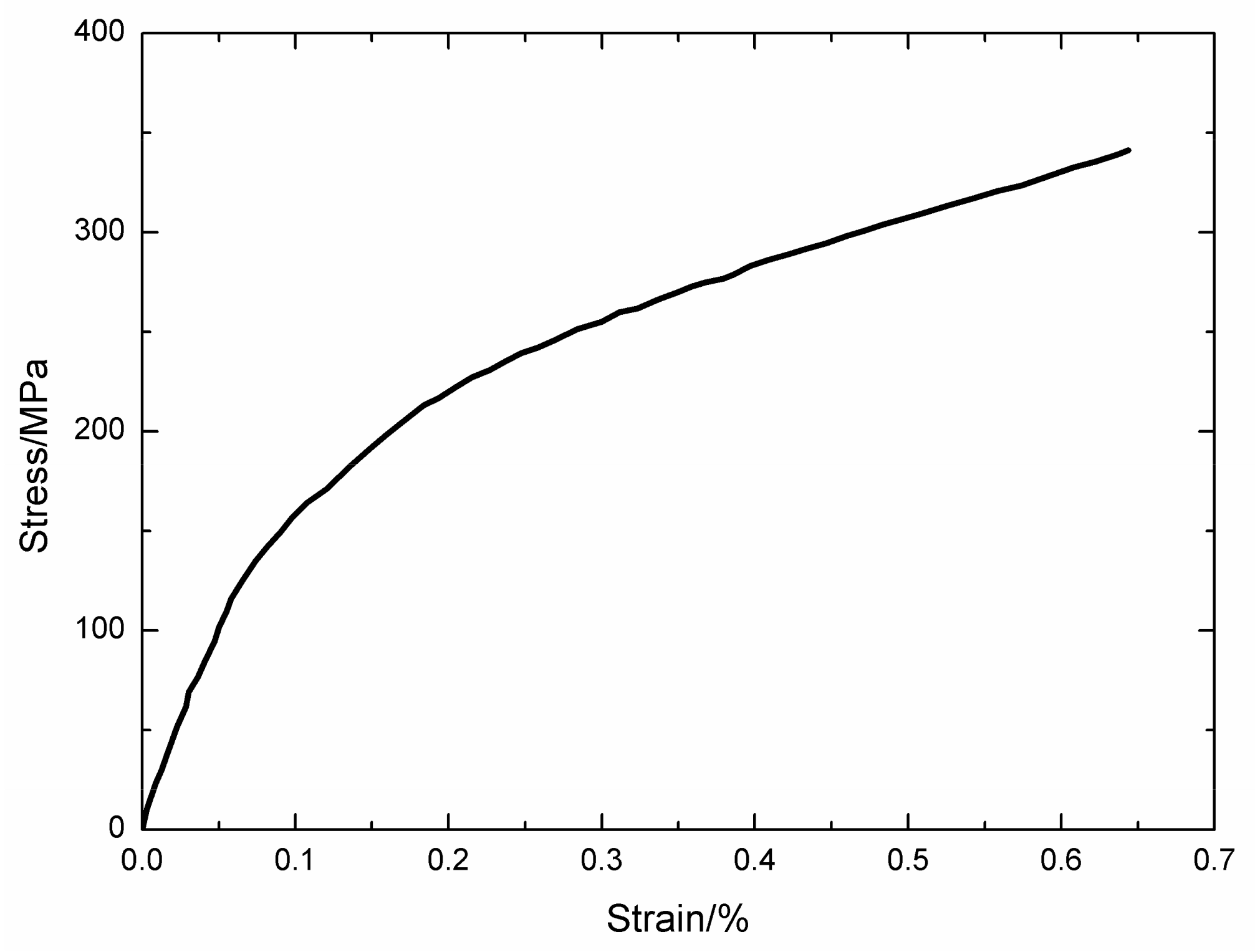

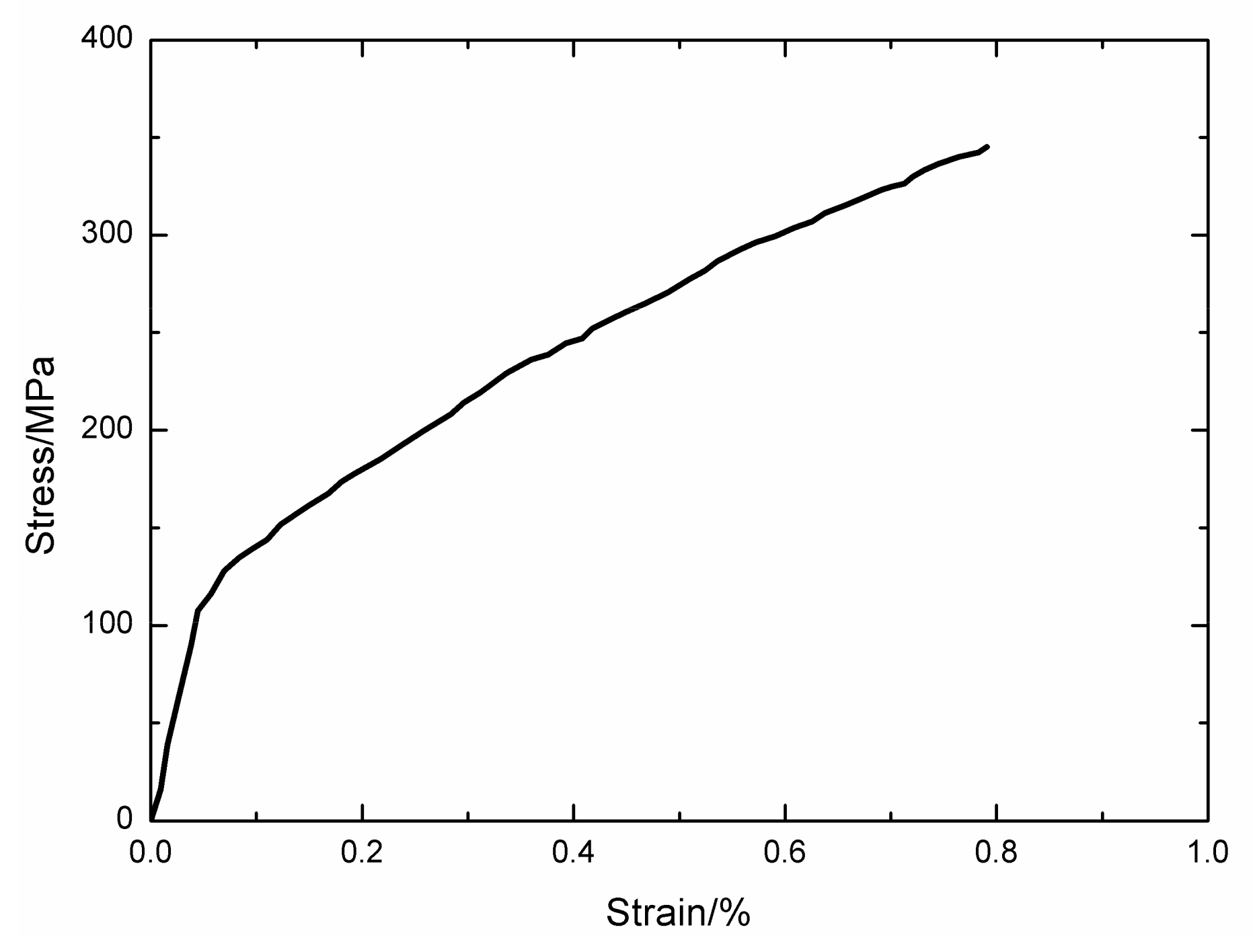

2. Materials and Experimental Procedures

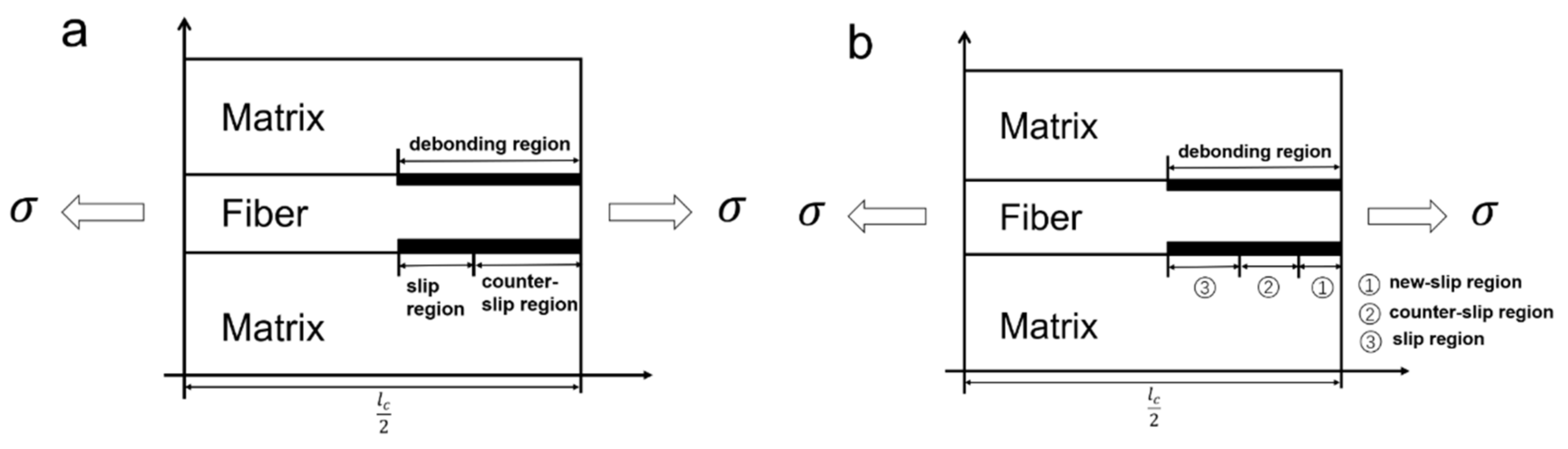

3. Theoretical Analysis

4. Experimental Comparisons

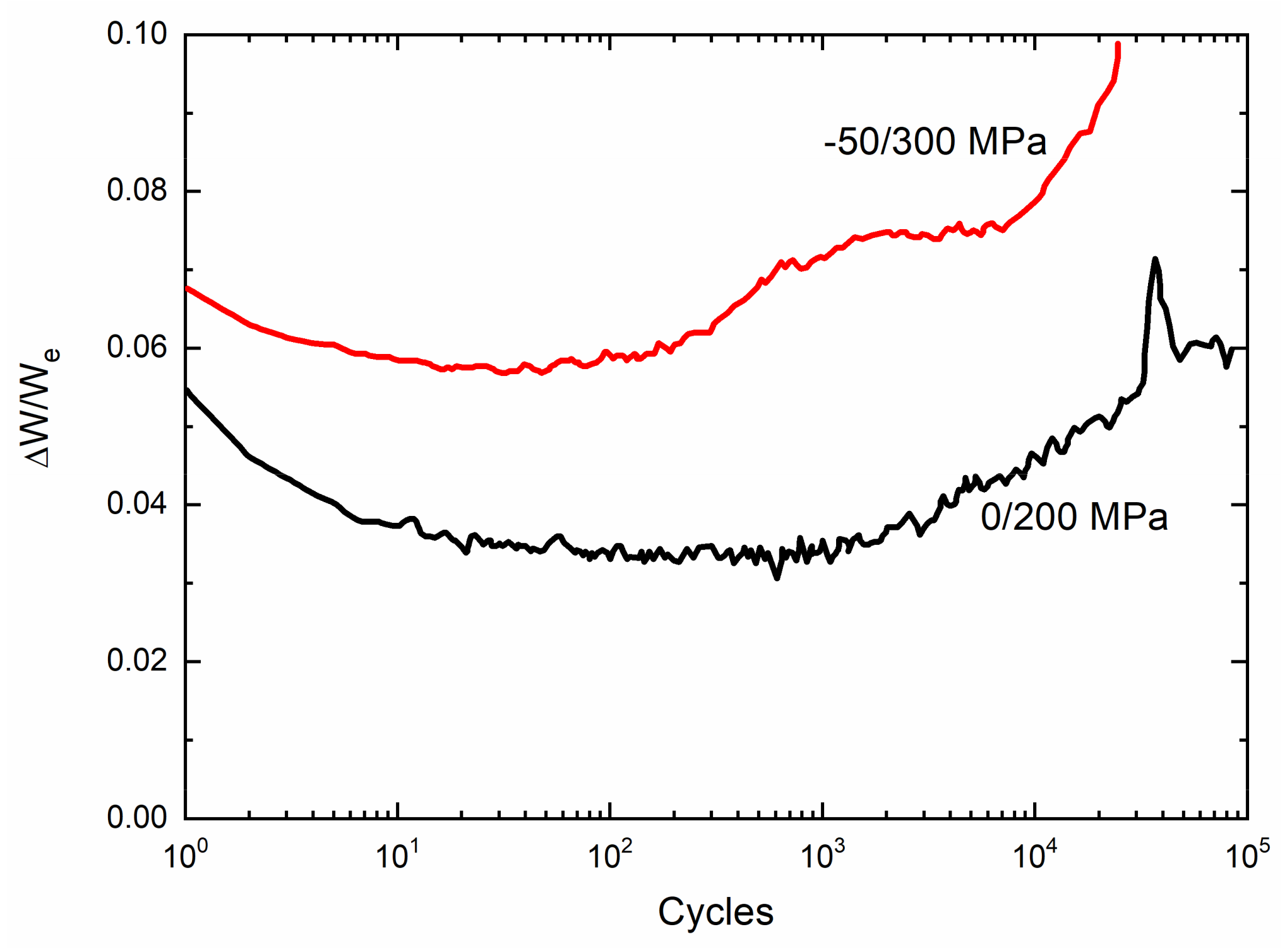

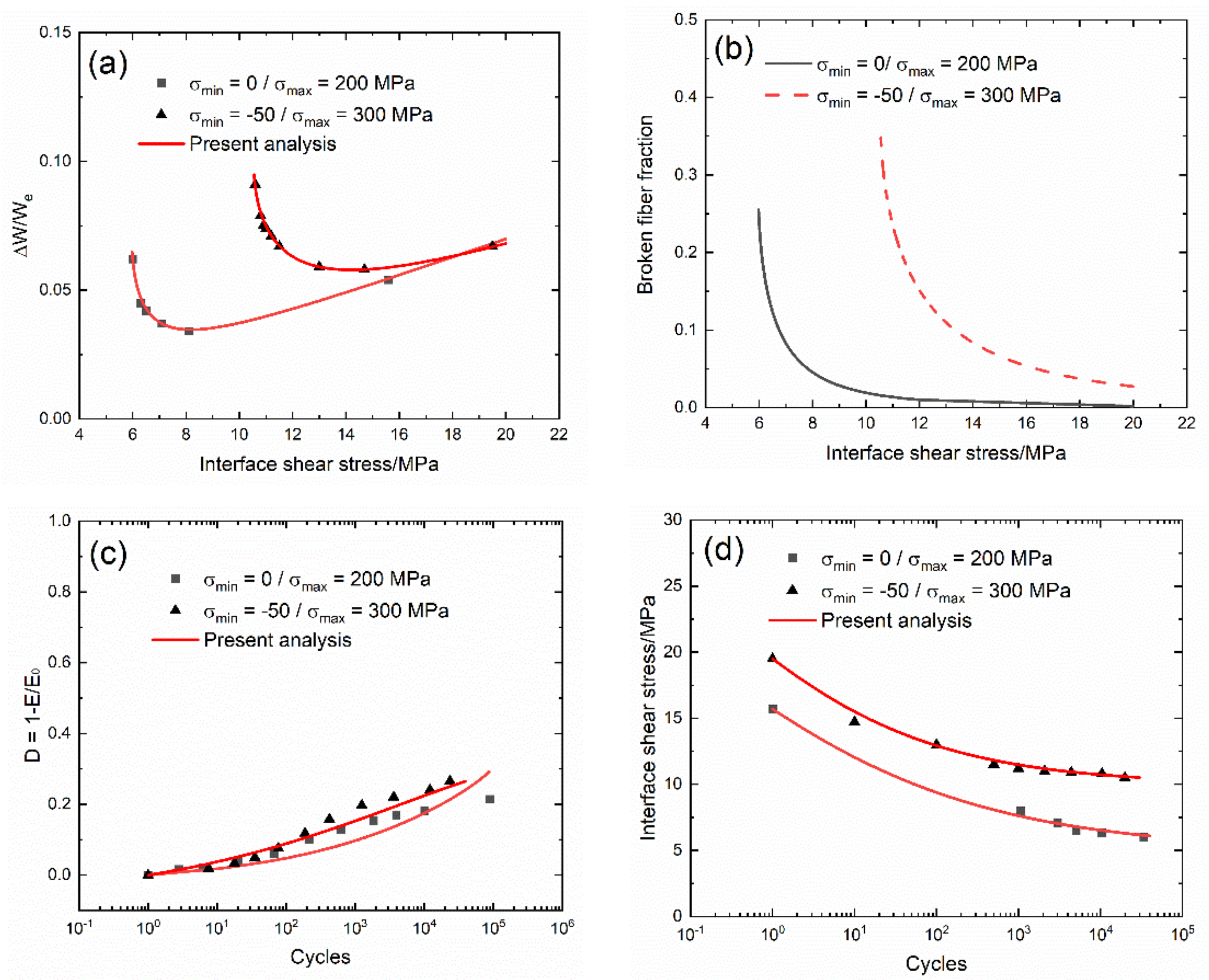

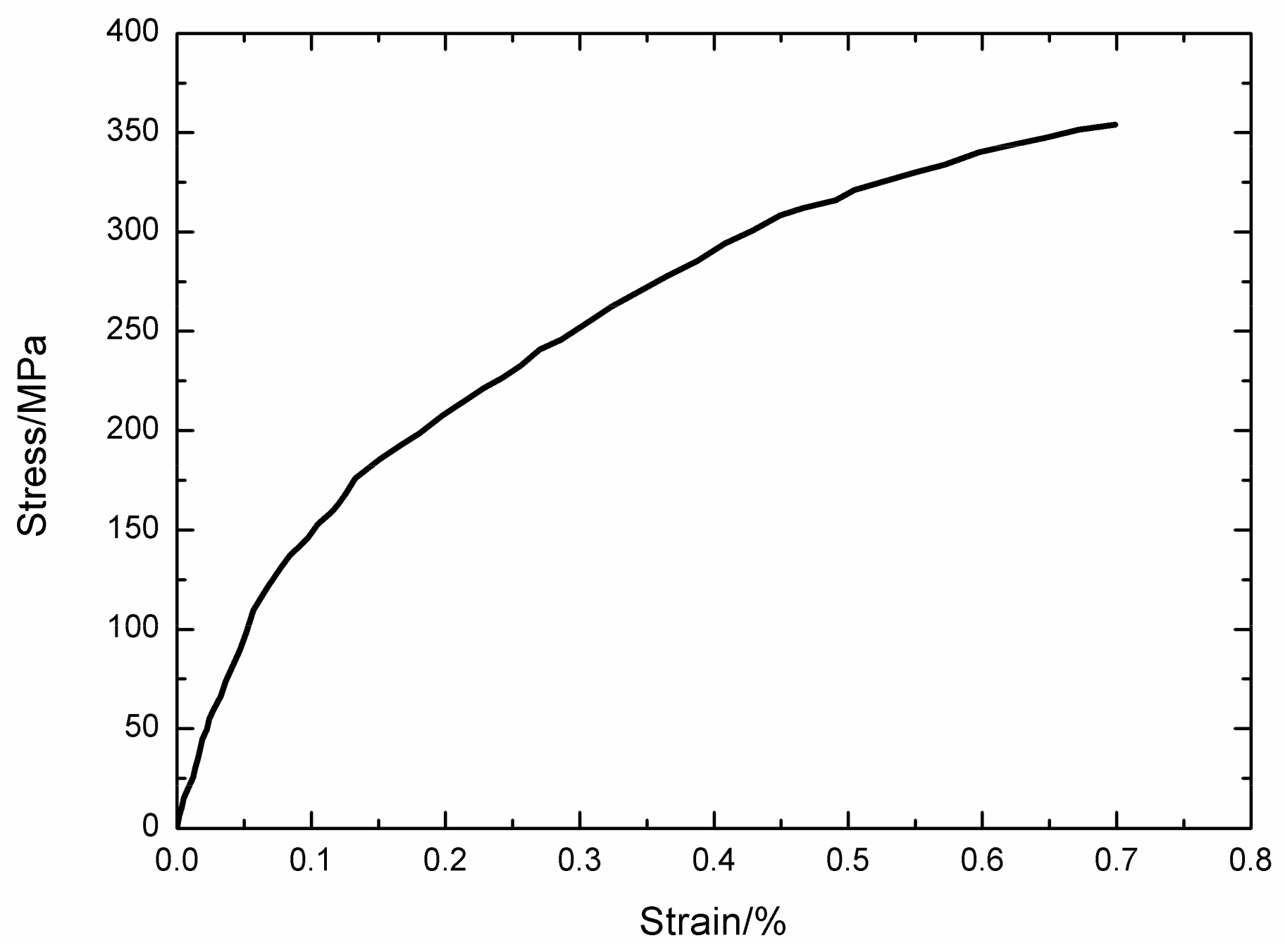

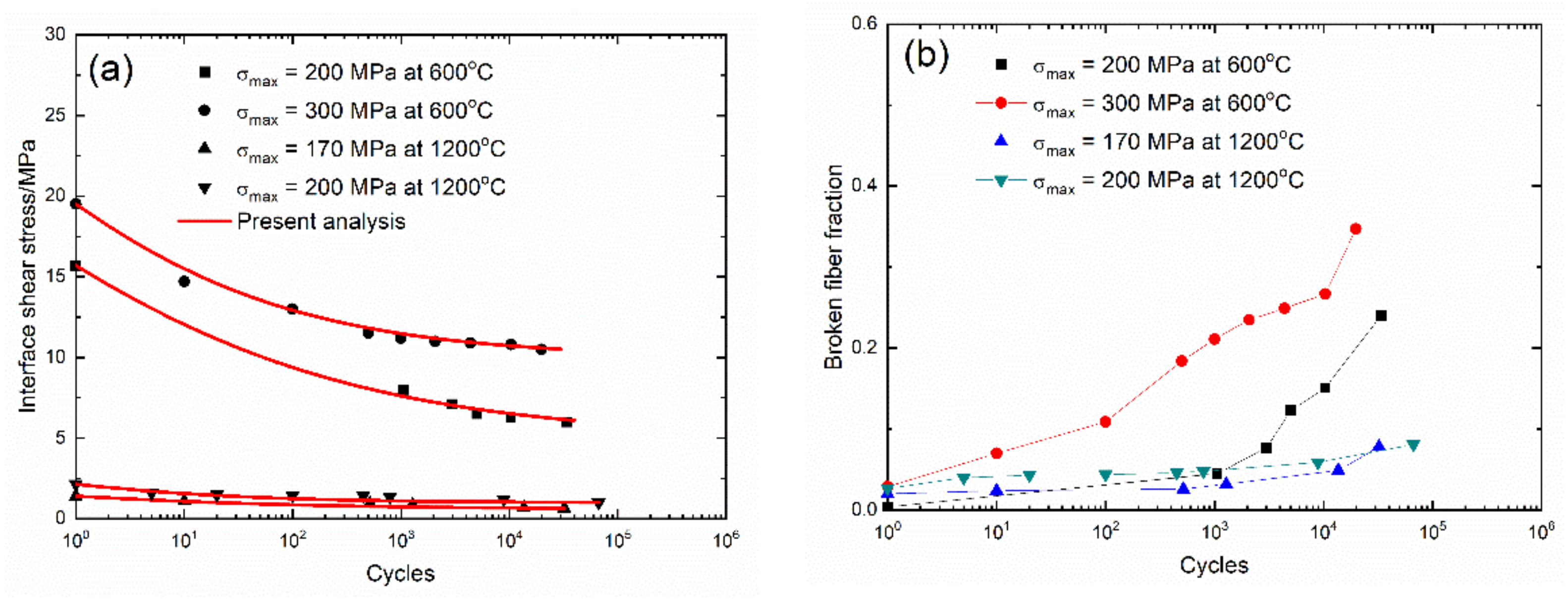

4.1. 2.5D Woven Hi-NicalonTM SiC/[Si-B-C] at 600 °C in an Air Atmosphere

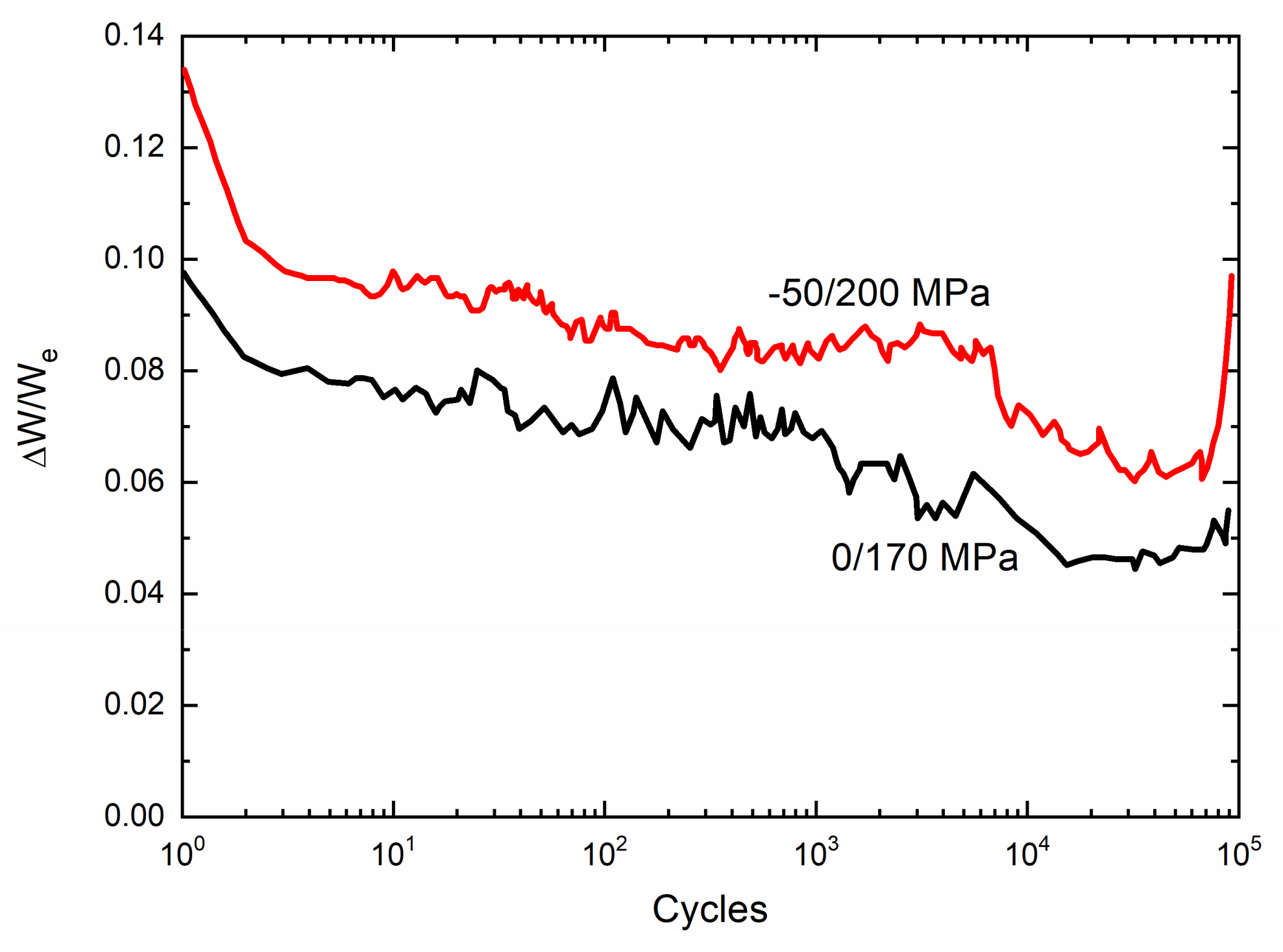

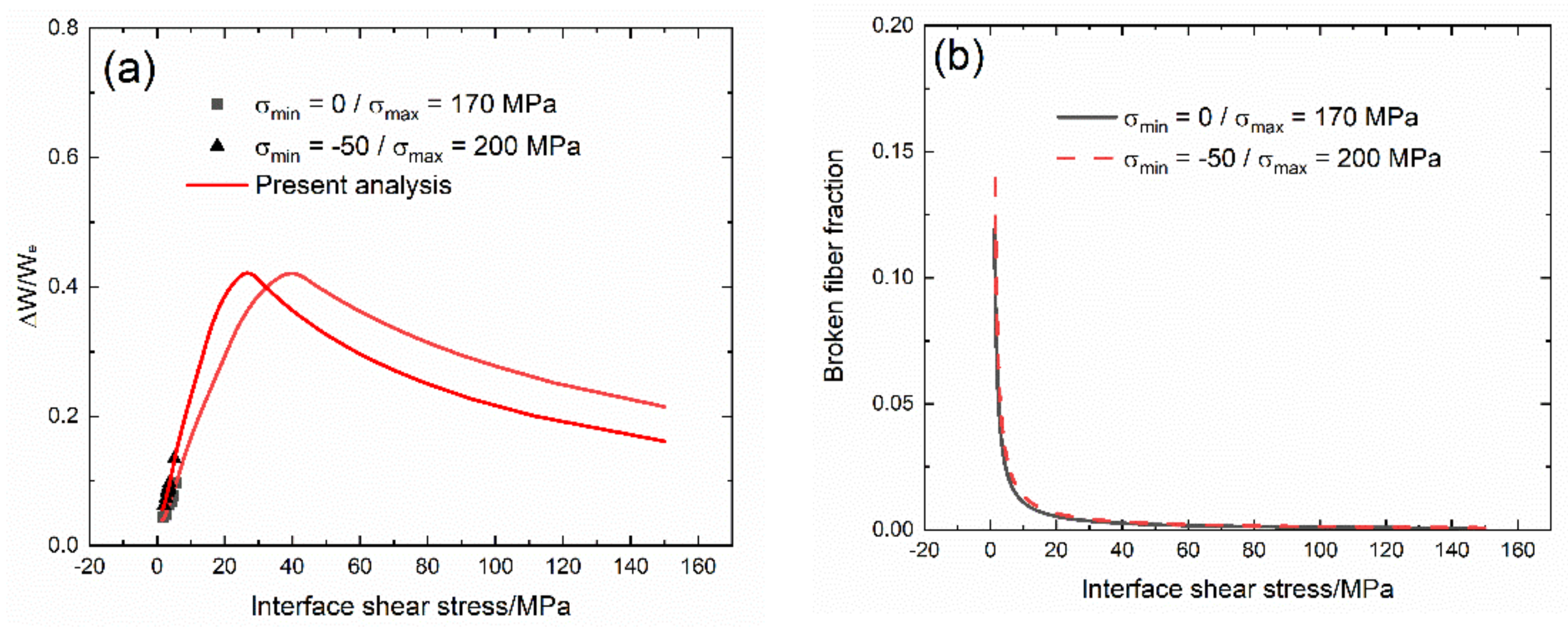

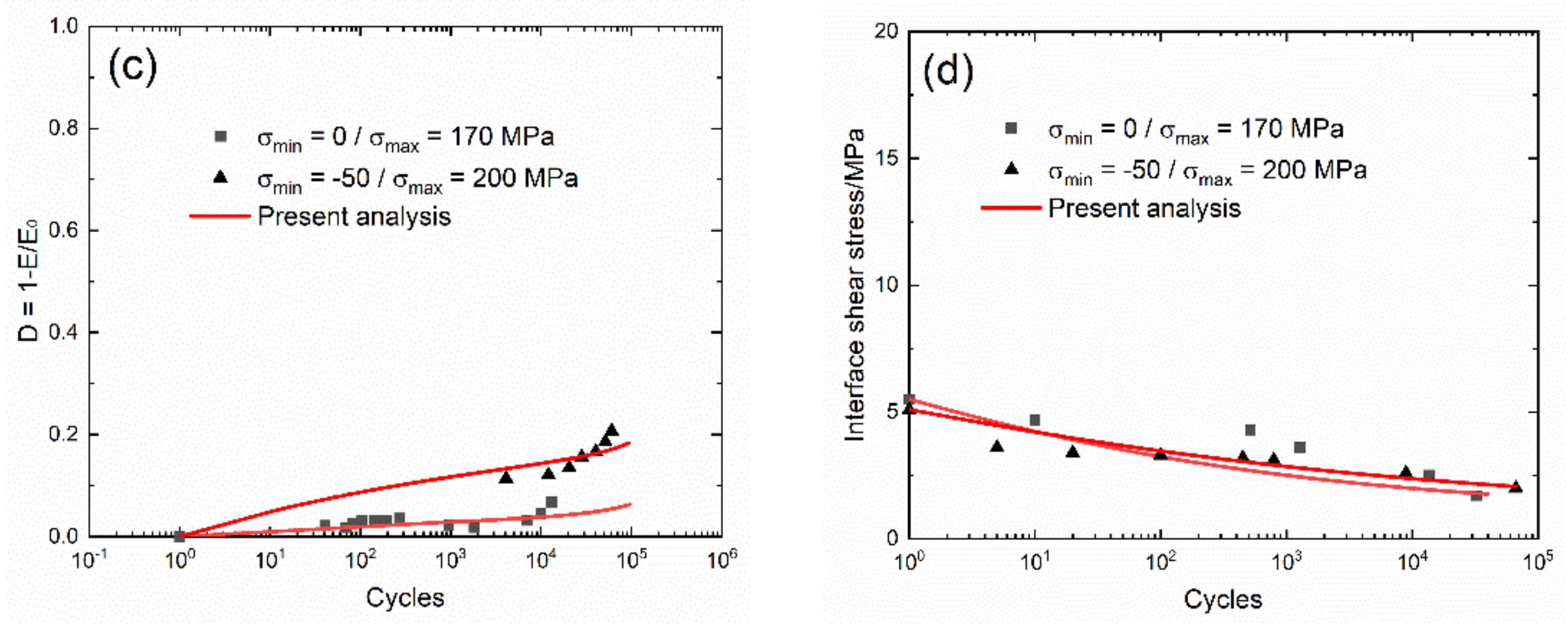

4.2. 2.5D Woven Hi-NicalonTM SiC/[Si-B-C] at 1200 °C in an Air Atmosphere

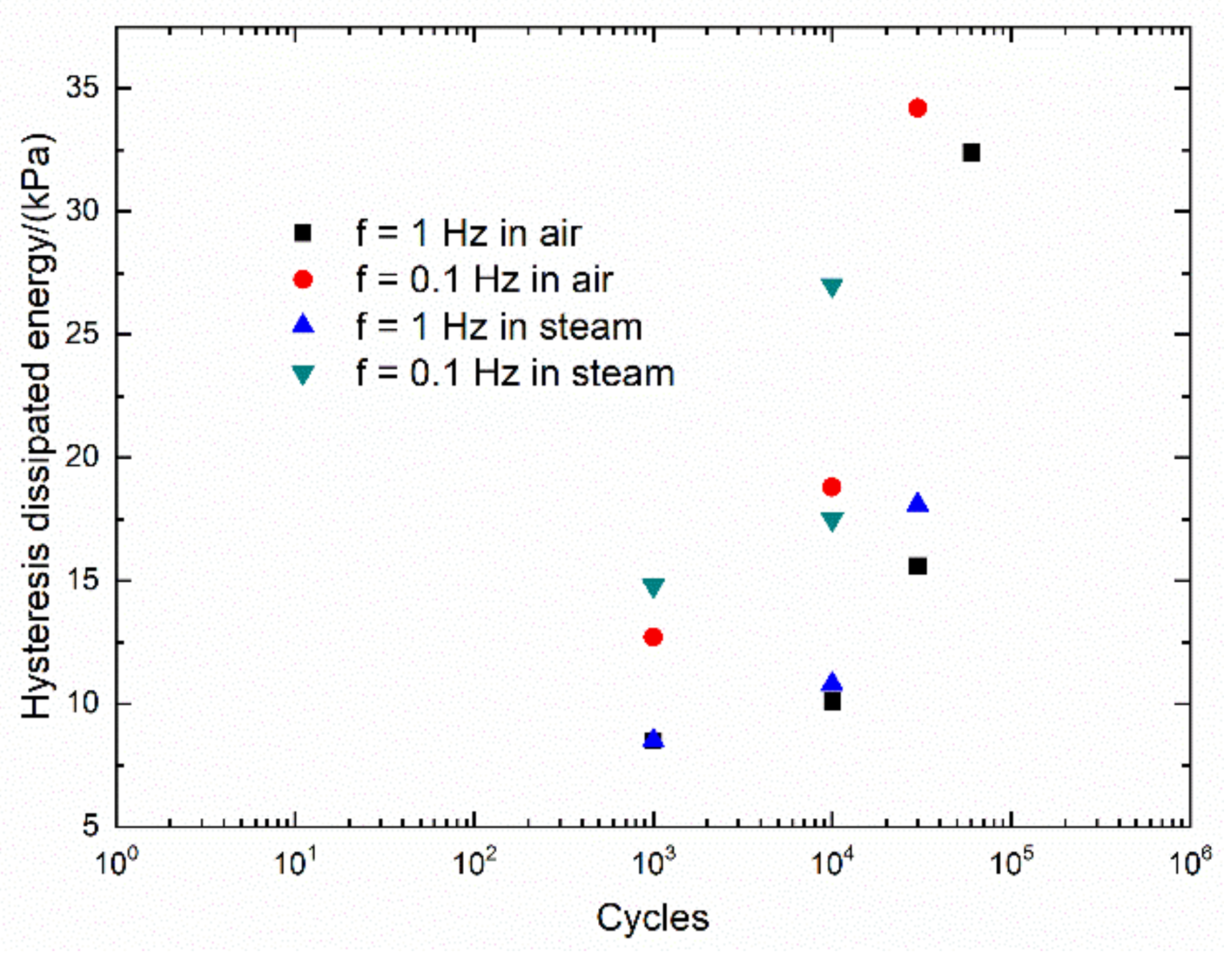

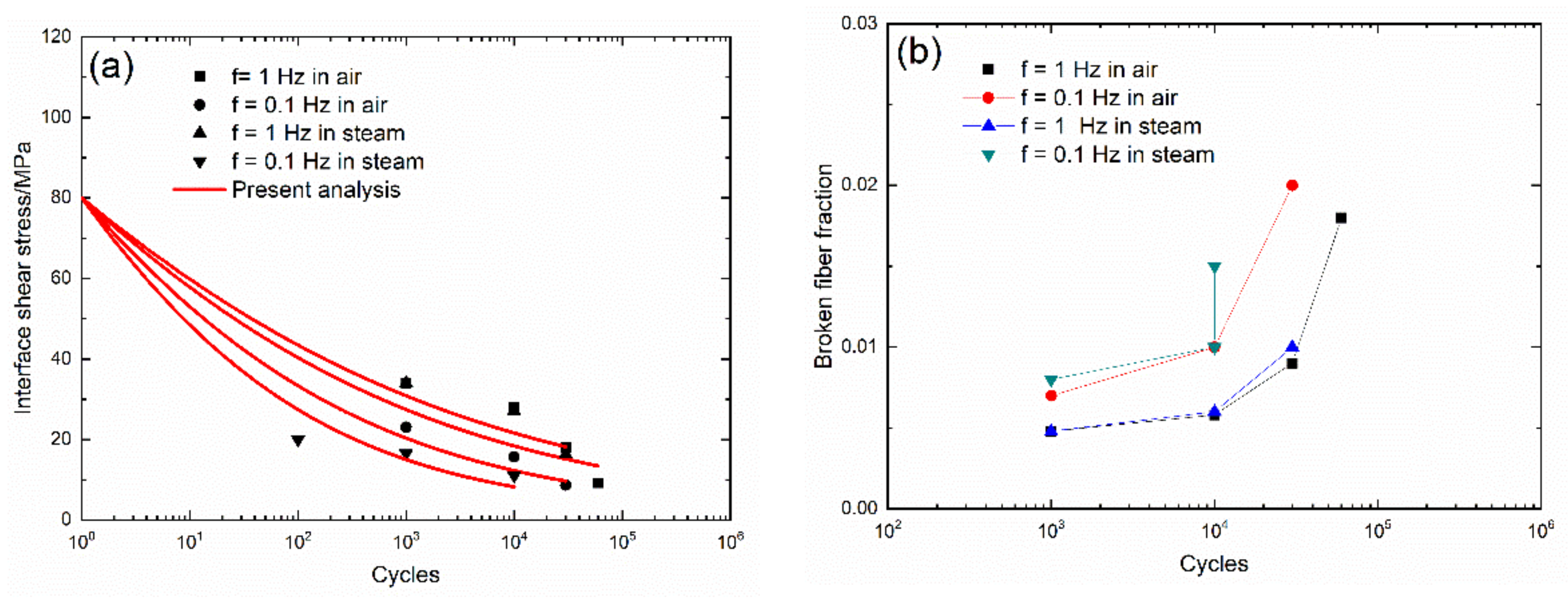

4.3. 2D Woven Self-healing Hi-NicalonTM SiC/[SiC-B4C] at 1200 °C in Air and in a Steam Atmospheres

4.4. Discussion

5. Conclusions

- (1)

- For 2.5D woven self-healing Hi-NicalonTM SiC/[Si-B-C] composite, temperature is a governing parameter for the fatigue process. At T = 600 °C in an air atmosphere, ∆W/We first decreases and then increases with cycle number; and at T = 1200 °C in an air atmosphere, ∆W/We decreases with cycle number. The degradation rate of the interface shear stress and broken fiber faction increases with peak stress.

- (2)

- For 2D woven self-healing Hi-NicalonTM SiC/[SiC-B4C] composite at T = 1200 °C, loading frequency is a governing parameter for the fatigue process. ∆W increases with cycle number; under σmax = 140 MPa, at the same applied cycle number, the interface shear stress decreases with the loading frequency, and the interface shear stress in a steam atmosphere is lower than that in an air atmosphere, and the broken fiber fraction increases with decreasing loading frequency, and the broken fiber fraction in a steam atmosphere is higher than that in an air atmosphere.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| rf | fiber radius |

| lc | matrix crack spacing |

| ld | fiber/matrix interface debonding length |

| ly | fiber/matrix interface counter slip length |

| lz | fiber/matrix interface new slip length |

| σmax | fatigue peak stress |

| σmin | fatigue valley stress |

| ΦU | intact fiber stress upon unloading |

| ΦR | intact fiber stress upon reloading |

| εU | unloading composite strain |

| εR | reloading composite strain |

| τi | fiber/matrix interface shear stress |

| αf | fiber thermal expansional coefficient |

| αc | composite thermal expansional coefficient |

| ΔT | temperature difference between tested and fabricated temperature |

| Ef | fiber elastic modulus |

| We | maximum elastic energy stored during the cycle |

| ΔW | hysteresis dissipated energy |

| E0 | Young’s modulus of undamaged composite |

| E | mean slope of hysteresis loop |

| D | Kachanov’s damage parameter |

References

- Naslain, R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: An overview. Compos. Sci. Technol. 2004, 64, 155–170. [Google Scholar] [CrossRef]

- Bendnarcyk, B.A.; Mital, S.K.; Pineda, E.J.; Arnold, S.M. Multiscale modeling of ceramic matrix composites. In Proceedings of the 56th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar] [CrossRef]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804. [Google Scholar] [CrossRef] [PubMed]

- Steibel, J.; Blank, J.; Dix, B. Ceramic matrix composites at GE Aviation. In Proceedings of the Advanced Ceramic Matrix Composites: Science and Technology of Materials, Design, Applications, Performance and Integration, LaFonda on the Plaza, Santa Fe, NM, USA, 5–9 November 2017. [Google Scholar]

- Zhu, S.J.; Mizuno, M.; Kagawa, Y.; Mutoh, Y. Monotonic tension, fatigue and creep behavior of SiC-fiber-reinforced SiC-matrix composites: A review. Compos. Sci. Technol. 1999, 59, 833–851. [Google Scholar] [CrossRef]

- Ruggles-Wrenn, M.B.; Christensen, D.T.; Chamberlain, A.L.; Lane, J.E.; Cook, T.S. Effect of frequency and environment on fatigue behavior of a CVI SiC/SiC ceramic matrix composite at 1200 °C. Compos. Sci. Technol. 2011, 71, 190–196. [Google Scholar] [CrossRef]

- Ruggles-Wrenn, M.B.; Jones, T.P. Tension-tension fatigue of a SiC/SiC ceramic matrix composite at 1200°C in air and in steam. Int. J. Fatigue 2013, 47, 154–160. [Google Scholar] [CrossRef]

- Li, L.B. Damage and failure of fiber-reinforced ceramic-matrix composites subjected to cyclic fatigue, dwell fatigue and thermomechanical fatigue. Ceram. Int. 2017, 43, 13978–13996. [Google Scholar] [CrossRef]

- Racle, E.; Godin, N.; Reynaud, P.; Fantozzi, G. Fatigue lifetime of ceramic matrix composites at intermediate temperature by acoustic emission. Materials 2017, 10, 658. [Google Scholar] [CrossRef]

- Ikarashi, Y.; Ogasawara, T.; Aoki, T. Effects of cyclic tensile loading on the rupture behavior of orthogonal 3-D woven SiC fiber/SiC matrix composites at elevated temperatures in air. J. Eur. Ceram. Soc. 2019, 39, 806–812. [Google Scholar] [CrossRef]

- Murthy, L.N.; Nemeth, N.N.; Brewer, D.N.; Mital, S. Probabilistic analysis of a SiC/SiC ceramic matrix composite turbine vane. Compos. Part B Eng. 2008, 39, 694–703. [Google Scholar] [CrossRef]

- Santhosh, U.; Ahmad, J.; John, R.; Ojard, G.; Miller, R.; Gowayed, Y. Modeling of stress concentration in ceramic matrix composites. Compos. Part B Eng. 2013, 45, 1156–1163. [Google Scholar] [CrossRef]

- Li, L.B. Advanced SiC/SiC composite system. In Comprehensive Composite Materials II; Beaumont, P.W.R., Zweben, C.H., Eds.; Academic Press: Oxford, UK, 2018; Volume 5, pp. 41–85. [Google Scholar] [CrossRef]

- Lamouroux, F.; Camus, G.; Thebault, J. Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: I, Experimental approach. J. Am. Ceram. Soc. 1994, 77, 2049–2057. [Google Scholar] [CrossRef]

- Hay, R.S.; Chater, R.J. Oxidation kinetics strength of Hi-NicalonTM-S SiC fiber after oxidation in dry and wet air. J. Am. Ceram. Soc. 2017, 100, 4110–4130. [Google Scholar] [CrossRef]

- Viricelle, J.P.; Goursat, P.; Bahloul-Hourlier, D. Oxidation behavior of a multi-layered ceramic-matrix composite (SiC)f/C/(SiBC)m. Compos. Sci. Technol. 2001, 61, 607–614. [Google Scholar] [CrossRef]

- Bouillon, E.; Abbe, F.; Goujard, S.; Pestourie, E.; Habarou, G. Mechanical and thermal properties of a self-sealing matrix composite and determination of the life time duration. Ceram. Eng. Sci. Proc. 2002, 21, 459–467. [Google Scholar] [CrossRef]

- Ruggles-Wrenn, M.B.; Delapasse, J.; Chamberlain, A.L.; Lane, J.E.; Cook, T.S. Fatigue behavior of a Hi-NicalonTM/SiC-B4C composite at 1200 °C in air and in steam. Mater. Sci. Eng. A 2012, 534, 119–128. [Google Scholar] [CrossRef]

- Ruggles-Wrenn, M.B.; Kurtz, G. Notch sensitivity of fatigue behavior of a Hi-NicalonTM/SiC-B4C composite at 1200 °C in air and in steam. Appl. Compos. Mater. 2013, 20, 891–905. [Google Scholar] [CrossRef]

- Ruggles-Wrenn, M.B.; Lee, M.D. Fatigue behavior of an advanced SiC/SiC composite with a self-healing matrix at 1300 °C in air and in steam. Mater. Sci. Eng. A 2016, 677, 438–445. [Google Scholar] [CrossRef]

- Reynaud, P.; Rouby, D.; Fantozzi, G. Cyclic fatigue behaviour at high temperature of a self-healing ceramic matrix composite. Ann. Chim. Sci. Mater. 2005, 30, 649–658. [Google Scholar] [CrossRef]

- Carrere, P.; Lamon, J. Fatigue behavior at high temperature in air of a 2D woven SiC/SiBC with a self healing matrix. Key Eng. Mater. 1999, 164–165, 321–324. [Google Scholar] [CrossRef]

- Forio, P.; Lamon, J. Fatigue behavior at high temperatures in air of a 2D SiC/Si-B-C composite with a self-healing multilayered matrix. Adv. Ceram. Matrix Compos. VII 2001. [Google Scholar] [CrossRef]

- Simon, C.; Rebillat, F.; Camus, G. Electrical resistivity monitoring of a SiC/[Si-B-C] composite under oxidizing environments. Acta Mater. 2017, 132, 586–597. [Google Scholar] [CrossRef]

- Simon, C.; Rebillat, F.; Herb, V.; Camus, G. Monitoring damage evolution of SiCf/[Si-B-C]m composites using electrical resistivity: Crack density-based electromechanical modeling. Acta Mater. 2017, 124, 579–587. [Google Scholar] [CrossRef]

- Moevus, M.; Reynaud, P.; R’Mili, M.; Godin, N.; Rouby, D.; Fantozzi, G. Static fatigue of a 2.5D SiC/[Si-B-C] composite at intermediate temperature under air. Adv. Sci. Technol. 2006, 50, 141–146. [Google Scholar] [CrossRef]

- Reynaud, P. Cyclic fatigue of ceramic-matrix composites at ambient and elevated temperatures. Compos. Sci. Technol. 1996, 56, 809–814. [Google Scholar] [CrossRef]

- Dalmaz, A.; Reynaud, P.; Rouby, D.; Fantozzi Abbe, F. Mechanical behavior and damage development during cyclic fatigue at high-temperature of a 2.5D carbon/sic composite. Compos. Sci. Technol. 1998, 58, 693–699. [Google Scholar] [CrossRef]

- Fantozzi, G.; Reynaud, P. Mechanical hysteresis in ceramic matrix composites. Mater. Sci. Eng. Part A Struct. 2009, 521–522, 18–23. [Google Scholar] [CrossRef]

- Li, L.B. A hysteresis dissipated energy-based damage parameter for life prediction of carbon fiber-reinforced ceramic-matrix composites under fatigue loading. Compos. Part B Eng. 2015, 82, 108–128. [Google Scholar] [CrossRef]

- Li, L.B. Damage monitoring and life prediction of carbon fiber-reinforced ceramic-matrix composites at room and elevated temperatures using hysteresis dissipated energy-based damage parameter. Compos. Interface 2018, 25, 335–356. [Google Scholar] [CrossRef]

- Li, L.B.; Reynaud, P.; Fantozzi, G. Mechanical hysteresis and damage evolution in C/SiC composites under fatigue loading at room and elevated temperatures. Int. J. Appl. Ceram. Technol. 2019, 16, 2214–2228. [Google Scholar] [CrossRef]

- Li, L.B. Failure analysis of long-fiber-reinforced ceramic-matrix composites subjected to in-phase thermomechanical and isothermal cyclic loading. Eng. Fail. Anal. 2019, 104, 856–872. [Google Scholar] [CrossRef]

- Penas Olivia. Etude de Composites SiC/SiBC à Matrice Multiséquencée en Fatigue Cyclique à Hautes Températures Sous Air. Ph.D. Thesis, INSA de Lyon, Villeurbanne, France, 2002.

- Li, L.B. Time-dependent damage and fracture of fiber-reinforced ceramic-matrix composites at elevated temperatures. Compos. Interfaces 2019, 26, 963–988. [Google Scholar] [CrossRef]

- Budiansky, B.; Hutchinson, J.W.; Evans, A.G. Matrix fracture in fiber-reinforced ceramics. J. Mech. Phys. Solids 1986, 34, 167–189. [Google Scholar] [CrossRef]

- Evans, A.G. Design and life prediction issues for high-temperature engineering ceramics and their composites. Acta Mater. 1997, 45, 23–40. [Google Scholar] [CrossRef]

| Materials | |

|---|---|

| Fiber | Hi-NicalonTM |

| Interphase | Pyrolytic Carbon (PyC) |

| Matrix | Multilayer [Si-B-C] |

| Fiber preform | 2.5D |

| Fiber volume/(%) | 35 |

| Fabrication method | Chemical Vapor Infiltration (CVI) |

| Manufacturer | SNECMA Propulsion Solide |

| Experimental Procedures | |

| Specimen shape | Dog bone-shaped |

| Specimen dimension | 200 mm length 5 mm thickness 16 mm width |

| Testing machine | INSTRON Model 8502 servo hydraulic load-frame |

| Loading frequency/(Hz) | 0.25 |

| Maximum cycle number | 1000000 |

| Temperature/(°C) | 600, 1200 |

| Environment | air |

| σmin/σmax (MPa) | 0/200, −50/300 at 600 °C 0/170, −50/200 at 1200 °C |

| Materials | |

|---|---|

| Fiber | Hi-NicalonTM |

| Interphase | Pyrolytic Carbon Boron carbide |

| Matrix | Multilayer [SiC-B4C] |

| Fiber preform | 2D |

| Fiber volume/(%) | 34.8 |

| Fabrication method | Chemical Vapor Infiltration (CVI) |

| Manufacturer | Hyper-Therm High-Temperature Composites, Inc. |

| Experimental Procedures | |

| Specimen shape | Dog bone-shaped |

| Specimen dimension | 152 mm length 3.5 mm thickness 10 mm wide |

| Testing machine | MTS 810 servo hydraulic load-frame |

| Loading frequency/(Hz) | 0.1 and 1 |

| Maximum cycle number | 100,000 for f = 0.1 Hz 200,000 for f = 1 Hz |

| Temperature/(°C) | 1200 |

| Environment | air and steam |

| σmin/σmax (MPa) | 7/140 |

| Case | Interface Debonding Condition | Interface Counter Slip Condition | Interface New Slip Condition |

|---|---|---|---|

| Case 1 | ld(σmax) < lc/2 | ly(σmin) = ld(σmax) | lz(σmax) = ld(σmax) |

| Case 2 | ld(σmax) < lc/2 | ly(σmin) < ld(σmax) | lz(σmax) < ld(σmax) |

| Case 3 | ld(σmax) = lc/2 | ly(σmin) < lc/2 | lz(σmax) < lc/2 |

| Case 4 | ld(σmax) = lc/2 | ly(σmin) = lc/2 | lz(σmax) = lc/2 |

| 0/200 MPa at 600 °C in Air Atmosphere | |||

|---|---|---|---|

| Cycle number | ∆W/We | τi/MPa | P/% |

| 1 | 0.054 | 15.7 | 0.4 |

| 1055 | 0.034 | 8.0 | 4.5 |

| 2993 | 0.037 | 7.1 | 7.7 |

| 5041 | 0.042 | 6.5 | 12.3 |

| 10,343 | 0.045 | 6.3 | 15.1 |

| 33,788 | 0.062 | 6 | 24.0 |

| −50/300 MPa at 600 °C in Air Atmosphere | |||

| Cycle number | ∆W/We | τi/MPa | P/% |

| 1 | 0.067 | 19.5 | 2.9 |

| 10 | 0.058 | 14.7 | 7.0 |

| 100 | 0.059 | 13.0 | 10.9 |

| 500 | 0.067 | 11.5 | 18.4 |

| 1000 | 0.071 | 11.2 | 21.1 |

| 2080 | 0.074 | 11.0 | 23.5 |

| 4410 | 0.075 | 10.9 | 24.9 |

| 10,406 | 0.079 | 10.8 | 26.7 |

| 19,812 | 0.091 | 10.5 | 34.7 |

| 0/170 MPa at 1200 °C in Air Atmosphere | |||

|---|---|---|---|

| Cycle number | ∆W/We | τi/MPa | P/% |

| 1 | 0.097 | 5.5 | 2.0 |

| 10 | 0.076 | 4.7 | 2.4 |

| 517 | 0.068 | 4.3 | 2.6 |

| 1281 | 0.062 | 3.6 | 3.2 |

| 13,700 | 0.047 | 2.5 | 4.9 |

| 32,334 | 0.044 | 1.7 | 7.8 |

| −50/200 MPa at 1200 °C in Air Atmosphere | |||

| Cycle number | ∆W/We | τi/MPa | P/% |

| 1 | 0.133 | 5.1 | 2.7 |

| 5 | 0.096 | 3.6 | 4.0 |

| 20 | 0.090 | 3.4 | 4.3 |

| 100 | 0.087 | 3.3 | 4.4 |

| 450 | 0.085 | 3.2 | 4.6 |

| 790 | 0.082 | 3.1 | 4.8 |

| 8910 | 0.073 | 2.6 | 5.9 |

| 66,794 | 0.061 | 2.0 | 8.1 |

| σmax = 140 MPa and f = 1.0 Hz at 1200 °C in Air Atmosphere | |||

|---|---|---|---|

| Cycle number | ∆W/kPa | τi/MPa | P/% |

| 1000 | 8.5 | 34 | 0.48 |

| 10,000 | 10.1 | 28 | 0.58 |

| 30,000 | 15.6 | 18 | 0.9 |

| 60,000 | 32.4 | 9.2 | 1.8 |

| σmax = 140 MPa and f = 0.1 Hz at 1200 °C in Air Atmosphere | |||

| Cycle number | ∆W/kPa | τi/MPa | P/% |

| 1000 | 12.7 | 23 | 0.7 |

| 10,000 | 18.8 | 15.7 | 1 |

| 30,000 | 34.2 | 8.7 | 2 |

| σmax = 140 MPa and f = 1.0 Hz at 1200 °C in Steam Atmosphere | |||

| Cycle number | ∆W/kPa | τi/MPa | P/% |

| 1000 | 8.5 | 34 | 0.48 |

| 10,000 | 10.8 | 27.1 | 0.6 |

| 30,000 | 18.1 | 16.3 | 1 |

| σmax = 140 MPa and f = 0.1 Hz at 1200 °C in Steam Atmosphere | |||

| Cycle number | ∆W/kPa | τi/MPa | P/% |

| 1000 | 14.8 | 20 | 0.8 |

| 10,000 | 17.5 | 16.5 | 1 |

| 10,000 | 27 | 11 | 1.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Reynaud, P.; Fantozzi, G. Cyclic-Dependent Damage Evolution in Self-Healing Woven SiC/[Si-B-C] Ceramic-Matrix Composites at Elevated Temperatures. Materials 2020, 13, 1478. https://doi.org/10.3390/ma13061478

Li L, Reynaud P, Fantozzi G. Cyclic-Dependent Damage Evolution in Self-Healing Woven SiC/[Si-B-C] Ceramic-Matrix Composites at Elevated Temperatures. Materials. 2020; 13(6):1478. https://doi.org/10.3390/ma13061478

Chicago/Turabian StyleLi, Longbiao, Pascal Reynaud, and Gilbert Fantozzi. 2020. "Cyclic-Dependent Damage Evolution in Self-Healing Woven SiC/[Si-B-C] Ceramic-Matrix Composites at Elevated Temperatures" Materials 13, no. 6: 1478. https://doi.org/10.3390/ma13061478

APA StyleLi, L., Reynaud, P., & Fantozzi, G. (2020). Cyclic-Dependent Damage Evolution in Self-Healing Woven SiC/[Si-B-C] Ceramic-Matrix Composites at Elevated Temperatures. Materials, 13(6), 1478. https://doi.org/10.3390/ma13061478