Growth and Characterization of Cu2Zn1−xFexSnS4 Thin Films for Photovoltaic Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Precursor Solution

2.2. Thin-Films Synthesis

2.3. Characterization

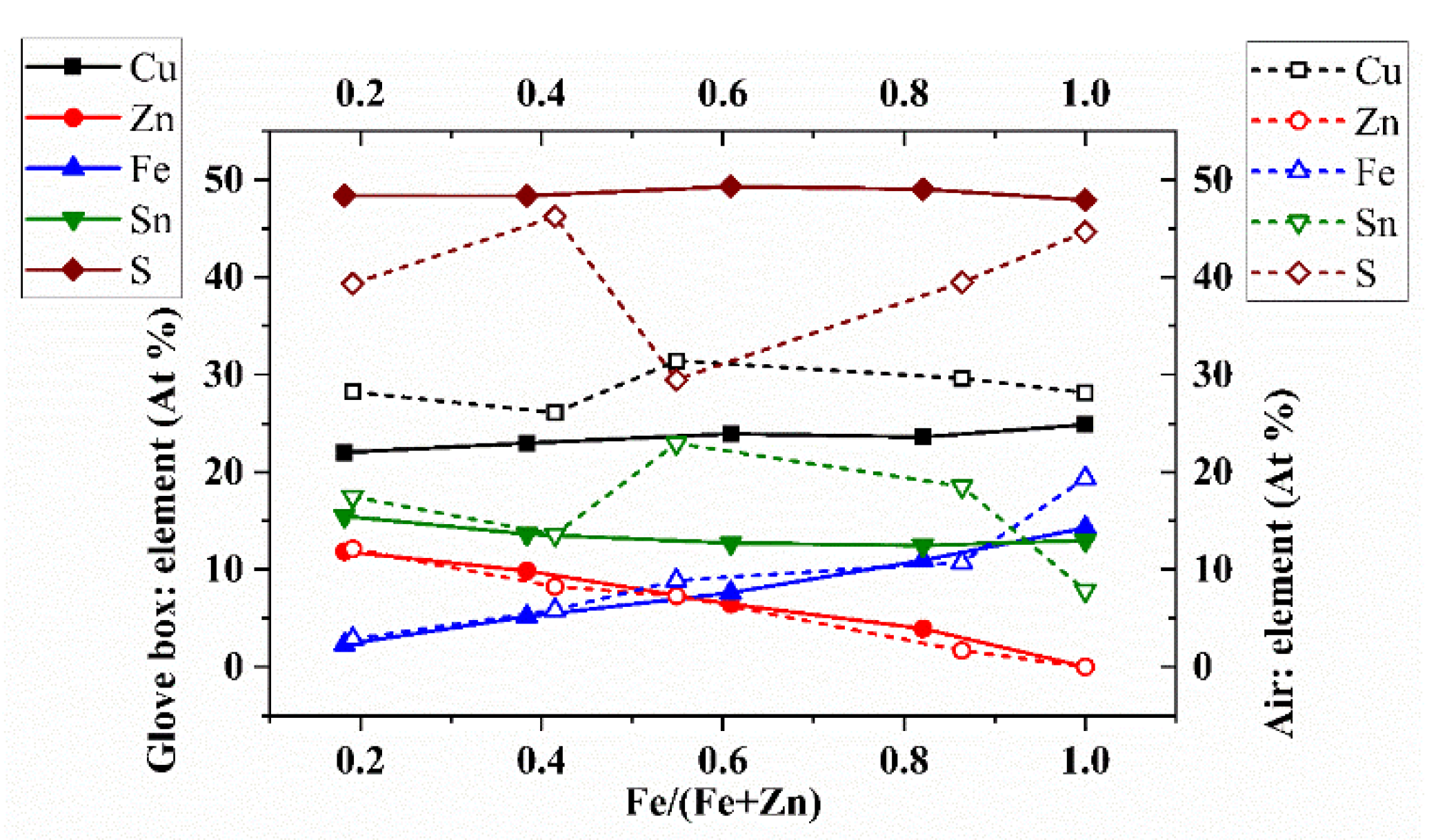

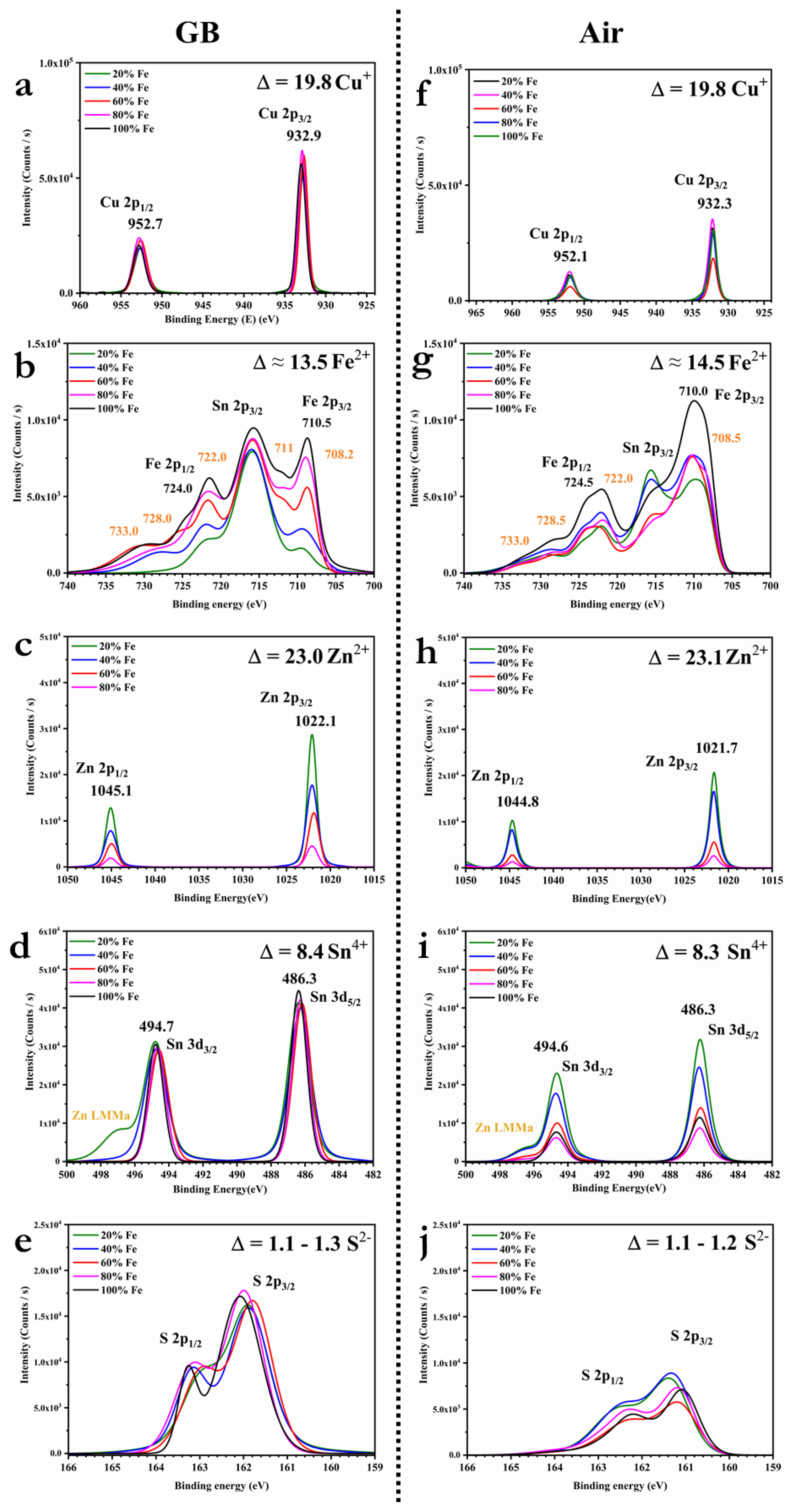

3. Results and Discussion

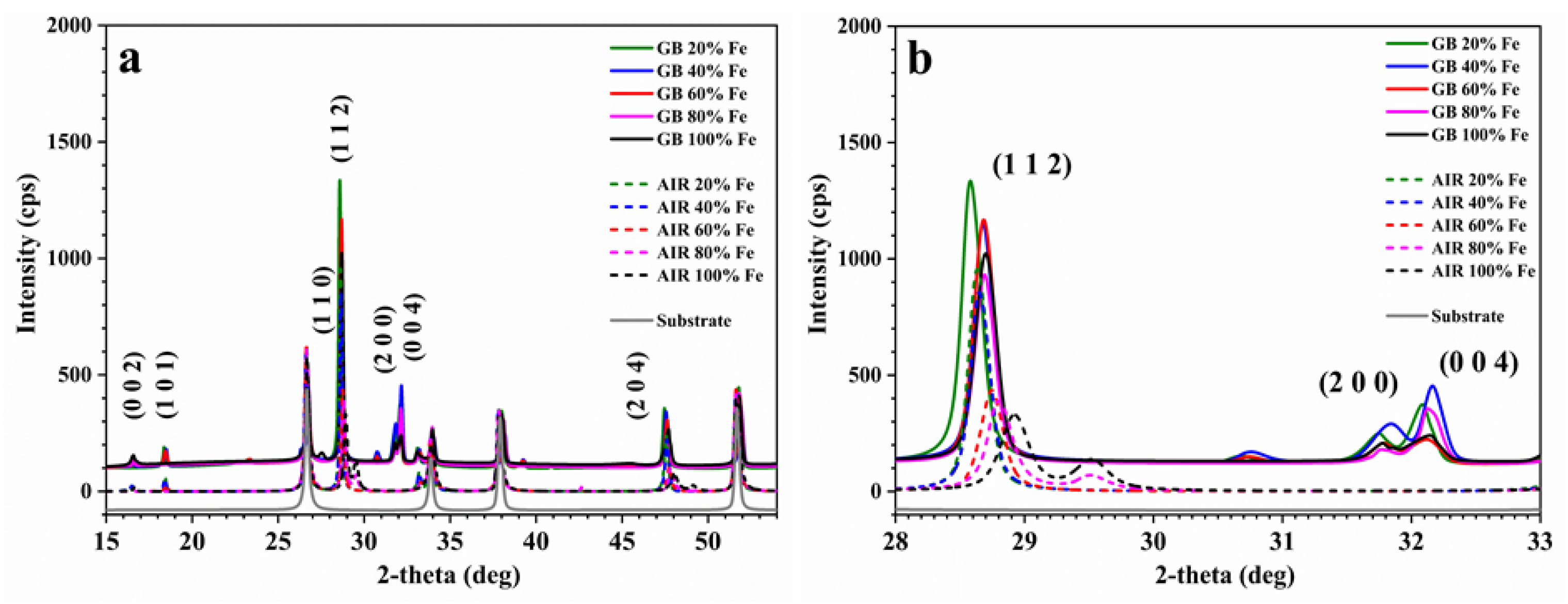

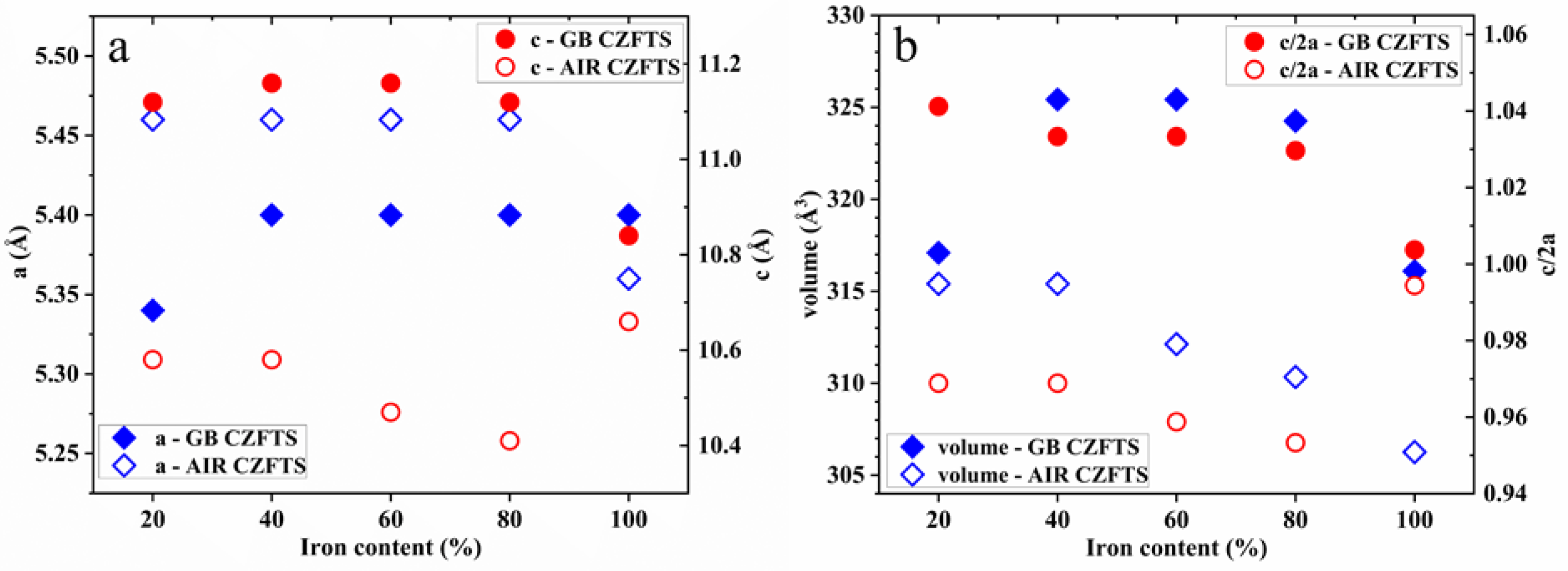

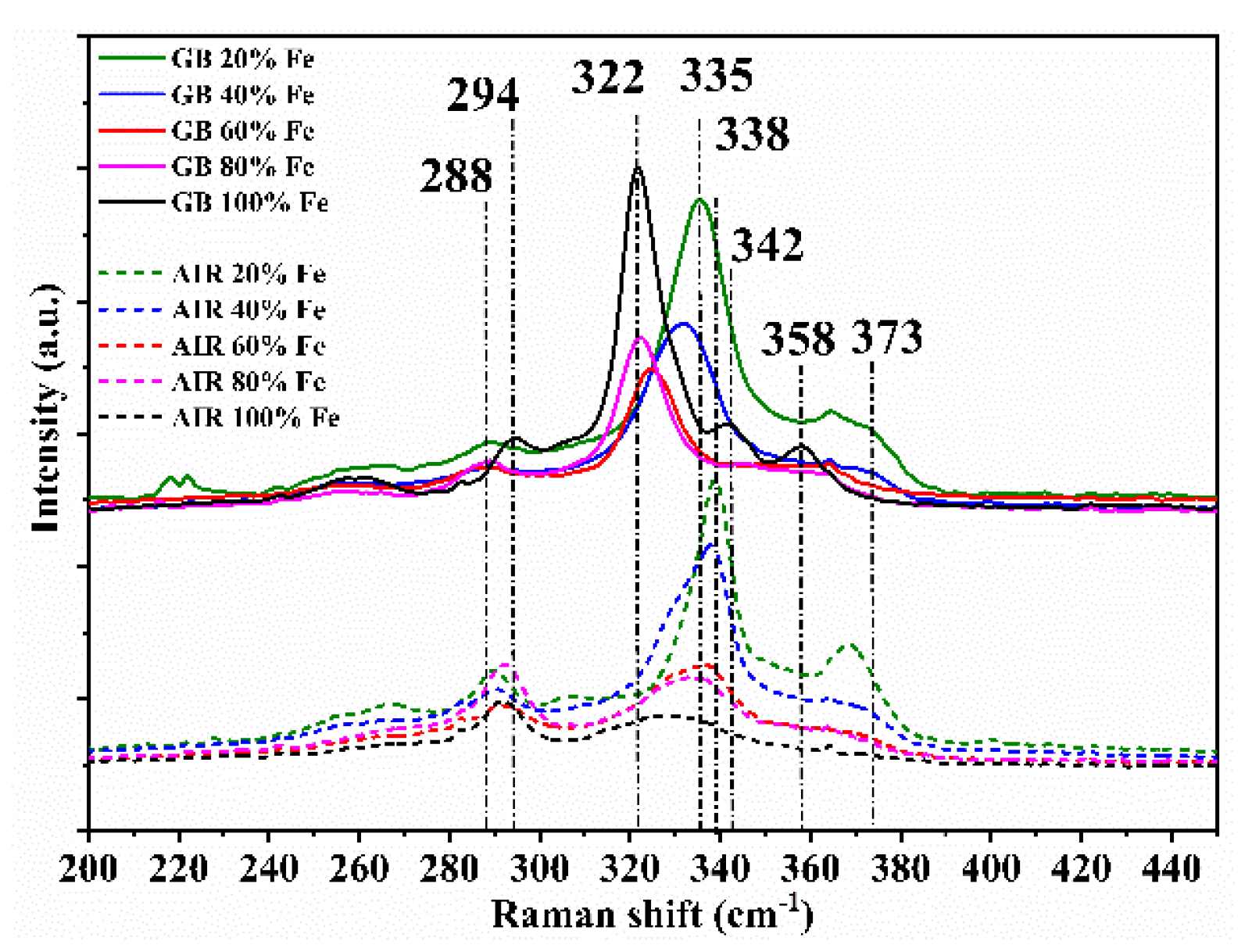

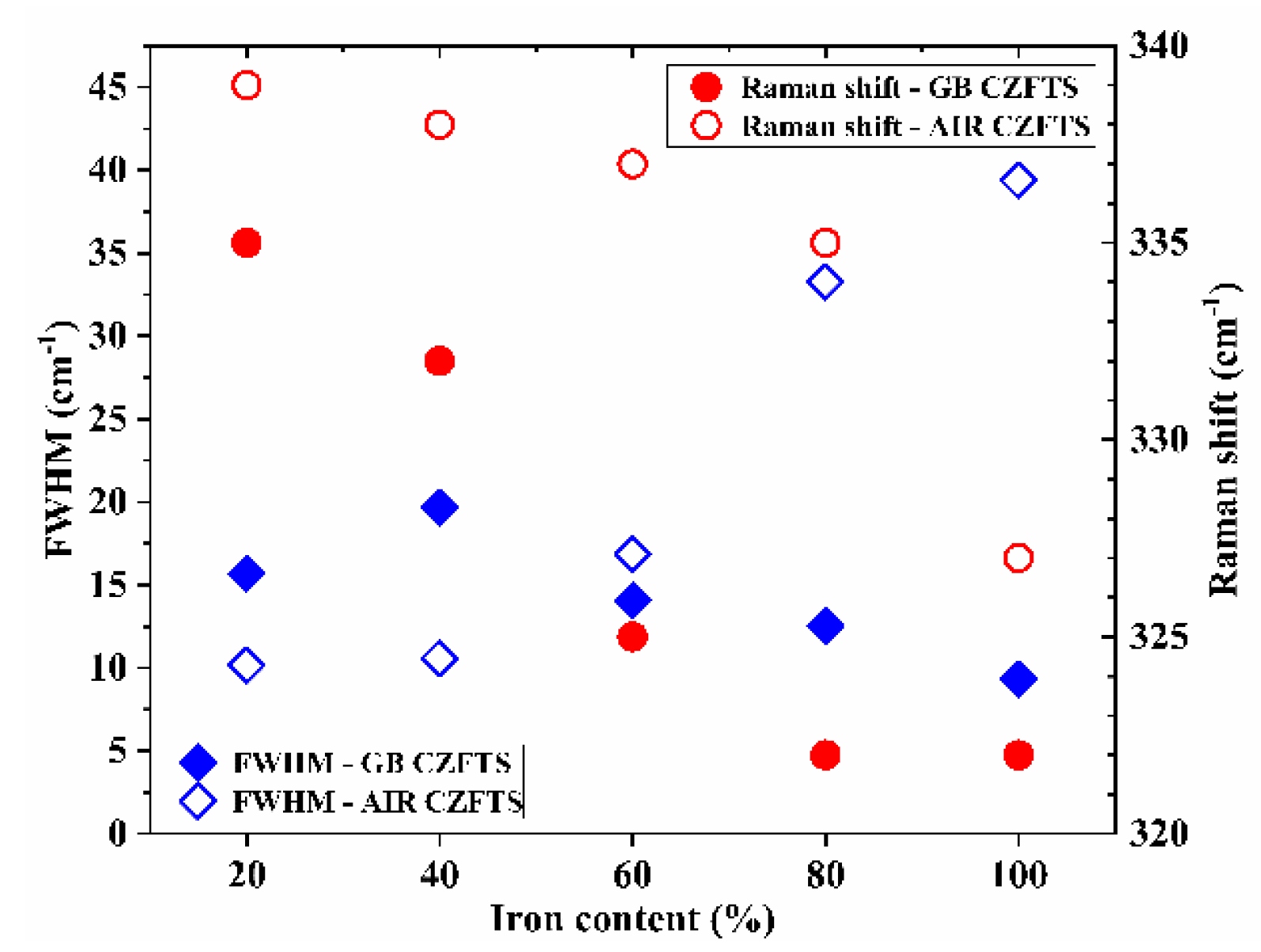

3.1. Phase Structure Analysis

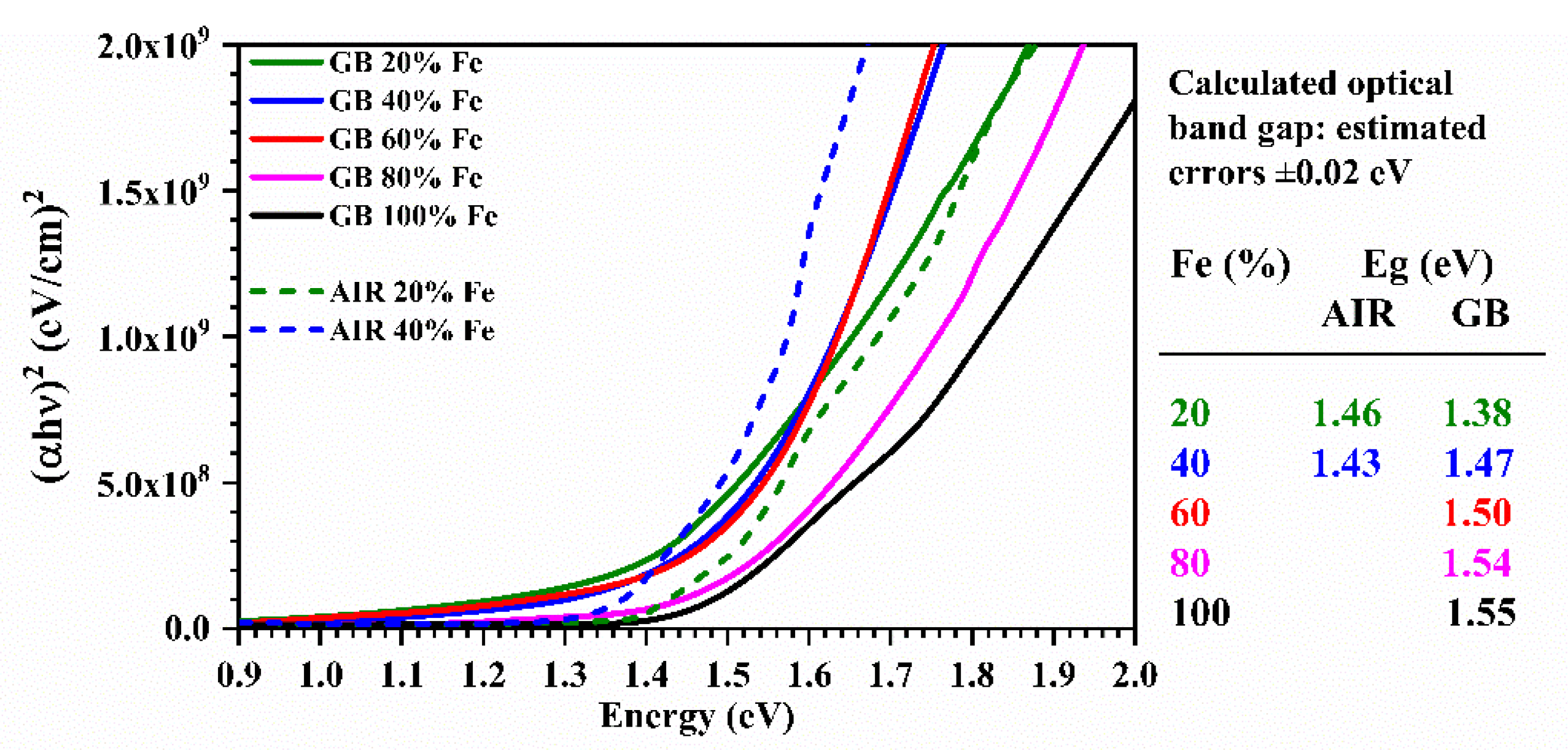

3.2. Energy Gap Tuning

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hoffert, M.I.; Caldeira, K.; Jain, A.K.; Haites, E.F.; Harvey, L.D.D.; Potter, S.D.; Schlesinger, M.E.; Schneider, S.H.; Watts, R.G.; Wigley, T.M.L.; et al. Energy implications of future stabilization of atmospheric CO2 content. Nature 1998, 395, 881–884. [Google Scholar] [CrossRef]

- REN21. Renewables 2019 Global Status Report; REN21 Secretariat: Paris, France, 2019; ISBN 978-3-9818911-7-1. Available online: http://www.ren21.net/gsr-2019/ (accessed on 16 January 2020).

- Michaelides, E.E.S. Alternative Energy Sources; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Joshi, R.; Pathak, M. Decentralized grid-connected power generation potential in India: From perspective of energy efficient buildings. Energy Procedia 2014, 57, 716–724. [Google Scholar] [CrossRef] [Green Version]

- Kamada, R.; Yagioka, T.; Adachi, S.; Handa, A.; Tai, K.F.; Kato, T.; Sugimoto, H. New world record Cu(In,Ga)(Se,S)2 thin film solar cell efficiency beyond 22%. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; pp. 1287–1291. [Google Scholar]

- Le Donne, A.; Trifiletti, V.; Binetti, S. New earth-abundant thin film solar cells based on chalcogenides. Front. Chem. 2019, 7, 297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hall, S.R.; Szymanski, J.T.; Stewart, J.M. Kesterite, Cu2(Zn,Fe)SnS4, and stannite, Cu2(Fe,Zn)SnS4, structurally similar but distinct minerals. Can. Mineral. 1978, 16, 131–137. [Google Scholar]

- Vanalakar, S.A.; Patil, P.S.; Kim, J.H. Recent advances in synthesis of Cu2FeSnS4 materials for solar cell applications: A review. Sol. Energy Mater. Sol. Cells 2018, 182, 204–219. [Google Scholar] [CrossRef]

- Ito, K. Copper Zinc Tin Sulphide-Based Thin Film Solar Cells; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 2015. [Google Scholar]

- Yan, C.; Huang, J.; Sun, K.; Johnston, S.; Zhang, Y.; Sun, H.; Pu, A.; He, M.; Liu, F.; Eder, K.; et al. Cu2ZnSnS4 solar cells with over 10% power conversion efficiency enabled by heterojunction heat treatment. Nat. Energy 2018, 3, 764–772. [Google Scholar] [CrossRef]

- Huang, C.; Chan, Y.; Liu, F.; Tang, D.; Yang, J.; Lai, Y.; Li, J.; Liu, Y. Synthesis and characterization of multicomponent Cu2(FexZn1−x)SnS4 nanocrystals with tunable band gap and structure. J. Mater. Chem. A 2013, 1, 5402–5407. [Google Scholar] [CrossRef]

- Shibuya, T.; Goto, Y.; Kamihara, Y.; Matoba, M.; Yasuoka, K.; Burton, L.A.; Walsh, A. From kesterite to stannite photovoltaics: Stability and band gaps of the Cu2(Zn,Fe)SnS4 alloy. Appl. Phys. Lett. 2014, 104, 021912. [Google Scholar] [CrossRef] [Green Version]

- Shadrokh, Z.; Yazdani, A.; Eshghi, H. Solvothermal synthesis of Cu2Zn1−xFexSnS4 nanoparticles and the influence of annealing conditions on drop-casted thin films. Semicond. Sci. Technol. 2016, 31, 045004. [Google Scholar] [CrossRef]

- Hussein, H.; Yazdani, A. Investigation the influence of Fe(III) doping in Cu2ZnSnS4 semiconductor: Structural, optical and magnetic properties. Optik 2019, 179, 505–513. [Google Scholar] [CrossRef]

- Khadka, D.B.; Kim, J. Structural, optical and electrical properties of Cu2FeSnX4 (X = S, Se) thin films prepared by chemical spray pyrolysis. J. Alloy. Compd. 2015, 638, 103–108. [Google Scholar] [CrossRef]

- Gonce, M.; Aslan, E.; Ozel, F.; Patir, I. Dye-sensitized Cu2XSnS4 (X = Zn, Ni, Fe, Co, and Mn) nanofibers for efficient photocatalytic hydrogen evolution. ChemSusChem 2016, 9, 600–605. [Google Scholar] [CrossRef]

- Guan, H.; Shen, H.; Jiao, B.; Wang, X. Structural and optical properties of Cu2FeSnS4 thin film synthesized via a simple chemical method. Mater. Sci. Semicond. Process. 2014, 25, 159–162. [Google Scholar] [CrossRef]

- Giraldo, S.; Jehl, Z.; Placidi, M.; Izquierdo-Roca, V.; Pérez-Rodríguez, A.; Saucedo, E. Progress and perspectives of thin film kesterite photovoltaic technology: A critical review. Adv. Mater. 2019, 31, 1806692. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miao, X.; Chen, R.; Cheng, W. Synthesis and characterization of Cu2FeSnS4 thin films prepared by electrochemical deposition. Mater. Lett. 2017, 193, 183–186. [Google Scholar] [CrossRef]

- Trifiletti, V.; Mostoni, S.; Butrichi, F.; Acciarri, M.; Binetti, S.; Scotti, R. Study of precursor-inks designed for high-quality Cu2ZnSnS4 films for low-cost pv application. Chem. Sel. 2019, 4, 4905–4912. [Google Scholar]

- Cullity, B.D.; Stock, S.R. Elements of X-Ray Diffraction, 3rd ed.; Upper Saddle River: London, UK, 2001. [Google Scholar]

- Bonazzi, P.; Bindi, L.; Bernardini, G.; Menchetti, S. A model for the mechanism of incorporation of Cu, Fe and Zn in the stannite - kesterite series, Cu2FeSnS4-Cu2ZnSnS4. Can. Mineral. 2003, 41, 639–647. [Google Scholar] [CrossRef] [Green Version]

- Kevin, P.; Malik, M.A.; McAdams, S.; O’Brien, P. Synthesis of nanoparticulate alloys of the composition Cu2Zn1–xFexSnS4: Structural, optical, and magnetic properties. J. Am. Chem. Soc. 2015, 137, 15086–15089. [Google Scholar] [CrossRef]

- Chen, S.; Gong, X.G.; Walsh, A.; Wei, S.-H. Electronic structure and stability of quaternary chalcogenide semiconductors derived from cation cross-substitution of II-VI and I-III-VI2 compounds. Phys. Rev. B 2009, 79, 165211. [Google Scholar] [CrossRef]

- Khadka, D.B.; Kim, J. Study of structural and optical properties of kesterite Cu2ZnGeX4 (X = S, Se) thin films synthesized by chemical spray pyrolysis. Cryst. Eng. Comm 2013, 15, 10500–10509. [Google Scholar] [CrossRef]

- Barreau, N.; Marsillac, S.; Albertini, D.; Bernède, J.C. Structural, optical and electrical properties of β-In2S3-3 xO3x thin films obtained by PVD. Thin Solid Film. 2002, 403, 331–334. [Google Scholar] [CrossRef]

- Fontané, X.; Izquierdo-Roca, V.; Saucedo, E.; Schorr, S.; Yukhymchuk, V.O.; Valakh, M.Y.; Pérez-Rodríguez, A.; Morante, J.R. Vibrational properties of stannite and kesterite type compounds: Raman scattering analysis of Cu2(Fe,Zn)SnS4. J. Alloy. Compd. 2012, 539, 190–194. [Google Scholar] [CrossRef]

- Boughriet, A.; Figueiredo, R.S.; Laureyns, J.; Recourt, P. Identification of newly generated iron phases in recent anoxic sediments: 57Fe Mössbauer and microRaman spectroscopic studies. J. Chem. Soc. Faraday Trans. 1997, 93, 3209–3215. [Google Scholar] [CrossRef]

- Fernandes, P.A.; Salomé, P.M.P.; da Cunha, A.F. Study of polycrystalline Cu2ZnSnS4 films by Raman scattering. J. Alloy. Compd. 2011, 509, 7600–7606. [Google Scholar] [CrossRef] [Green Version]

- Khare, A.; Himmetoglu, B.; Johnson, M.; Norris, D.J.; Cococcioni, M.; Aydil, E.S. Calculation of the lattice dynamics and Raman spectra of copper zinc tin chalcogenides and comparison to experiments. J. Appl. Phys. 2012, 111, 083707. [Google Scholar] [CrossRef]

- Dimitrievska, M.; Fairbrother, A.; Fontané, X.; Jawhari, T.; Izquierdo-Roca, V.; Saucedo, E.; Pérez-Rodríguez, A. Multiwavelength excitation Raman scattering study of polycrystalline kesterite Cu2ZnSnS4 thin films. Appl. Phys. Lett. 2014, 104, 021901. [Google Scholar] [CrossRef] [Green Version]

- Berg, D.M.; Djemour, R.; Gütay, L.; Siebentritt, S.; Dale, P.J.; Fontane, X.; Izquierdo-Roca, V.; Pérez-Rodriguez, A. Raman analysis of monoclinic Cu2SnS3 thin films. Appl. Phys. Lett. 2012, 100, 192103. [Google Scholar] [CrossRef]

- Scragg, J.J.S.; Choubrac, L.; Lafond, A.; Ericson, T.; Platzer-Björkman, C. A low-temperature order-disorder transition in Cu2ZnSnS4 thin films. Appl. Phys. Lett. 2014, 104, 041911. [Google Scholar] [CrossRef] [Green Version]

- Aldalbahi, A.; Mkawi, E.M.; Ibrahim, K.; Farrukh, M.A. Effect of sulfurization time on the properties of copper zinc tin sulfide thin films grown by electrochemical deposition. Sci. Rep. 2016, 6, 32431. [Google Scholar] [CrossRef] [Green Version]

- Altamura, G.; Wang, M.; Choy, K.-L. Influence of alkali metals (Na, Li, Rb) on the performance of electrostatic spray-assisted vapor deposited Cu2ZnSn(S,Se)4 solar cells. Sci. Rep. 2016, 6, 22109. [Google Scholar] [CrossRef] [PubMed]

- Azanza Ricardo, C.L.; Su’ait, M.S.; Müller, M.; Scardi, P. Production of Cu2(Zn,Fe)SnS4 powders for thin film solar cell by high energy ball milling. J. Power Sources 2013, 230, 70–75. [Google Scholar] [CrossRef]

- Gordillo, G.; Calderón, C.; Bartolo-Pérez, P. XPS analysis and structural and morphological characterization of Cu2ZnSnS4 thin films grown by sequential evaporation. Appl. Surf. Sci. 2014, 305, 506–514. [Google Scholar] [CrossRef]

- Hurtado, M.; Cruz, S.D.; Becerra, R.A.; Calderón, C.; Bartolo-Pérez, P.; Gordillo, G. XPS analysis and structural characterization of CZTS thin films prepared using solution and vacuum based deposition techniques. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 368–372. [Google Scholar]

- Xie, Y.; Zhang, C.; Yang, G.; Yang, J.; Zhou, X.; Ma, J. Highly crystalline stannite-phase Cu2XSnS4 (X = Mn, Fe, Co, Ni, Zn and Cd) nanoflower counter electrodes for ZnO-based dye-sensitised solar cells. J. Alloy. Compd. 2017, 696, 938–946. [Google Scholar] [CrossRef]

- Descostes, M.; Mercier, F.; Thromat, N.; Beaucaire, C.; Gautier-Soyer, M. Use of XPS in the determination of chemical environment and oxidation state of iron and sulfur samples: Constitution of a data basis in binding energies for Fe and S reference compounds and applications to the evidence of surface species of an oxidized pyrite in a carbonate medium. Appl. Surf. Sci. 2000, 165, 288–302. [Google Scholar]

- McIntyre, N.S.; Zetaruk, D.G. X-ray photoelectron spectroscopic studies of iron oxides. Anal. Chem. 1977, 49, 1521–1529. [Google Scholar] [CrossRef]

- Burke, G.M.; Wurster, D.E.; Berg, M.J.; Veng-Pedersen, P.; Schottelius, D.D. Surface characterization of activated charcoal by X-ray photoelectron spectroscopy (XPS): Correlation with phenobarbital adsorption data. Pharm. Res. 1992, 9, 126–130. [Google Scholar] [CrossRef]

- Song, N.; Green, M.A.; Huang, J.; Hu, Y.; Hao, X. Study of sputtered Cu2ZnSnS4 thin films on Si. Appl. Surf. Sci. 2018, 459, 700–706. [Google Scholar] [CrossRef]

- Bär, M.; Schubert, B.-A.; Marsen, B.; Krause, S.; Pookpanratana, S.; Unold, T.; Weinhardt, L.; Heske, C.; Schock, H.-W. Native oxidation and Cu-poor surface structure of thin film Cu2ZnSnS4 solar cell absorbers. Appl. Phys. Lett. 2011, 99, 112103. [Google Scholar] [CrossRef]

- Aono, M.; Yoshitake, K.; Miyazaki, H. XPS depth profile study of CZTS thin films prepared by spray pyrolysis. Phys. Status Solidi C 2013, 10, 1058–1061. [Google Scholar] [CrossRef]

- Pankove, J. Optical Processes in Semiconductors; Dover Publications: New York, NY, USA, 1975. [Google Scholar]

- Chatterjee, S.; Pal, A.J. A solution approach to p-type Cu2FeSnS4 thin-films and pn-junction solar cells: Role of electron selective materials on their performance. Sol. Energy Mater. Sol. Cells 2017, 160, 233–240. [Google Scholar] [CrossRef]

- Shockley, W.; Queisser, H.J. Detailed balance limit of efficiency of p-n junction solar cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Goetzberger, A.; Hoffmann, V.U. Photovoltaic Solar Energy Generation; Springer: Berlin, Germany, 2005. [Google Scholar]

| Fe (%) | Method | Cu 2p (eV) | Zn 2p (eV) | Fe 2p (eV) | Sn 3d (eV) | S 2p (eV) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 3/2 | 1/2 | 3/2 | 1/2 | 3/2 | 1/2 | 3/2 | 1/2 | 3/2 | ||

| 20 | AIR | 951.99 | 932.29 | 1044.69 | 1021.69 | 723.99 | 709.79 | 494.69 | 486.29 | 162.49 | 161.39 |

| GB | 952.68 | 932.78 | 1045.08 | 1022.08 | 723.88 | 709.68 | 494.78 | 486.38 | 162.98 | 161.88 | |

| 40 | AIR | 951.65 | 932.16 | 1044.76 | 1021.66 | 724.16 | 710.14 | 494.66 | 486.26 | 162.36 | 161.36 |

| GB | 952.68 | 932.78 | 1044.98 | 1022.08 | 723.88 | 709.48 | 494.78 | 486.28 | 163.18 | 161.88 | |

| 60 | AIR | 951.81 | 932.11 | 1044.61 | 1021.71 | 724.21 | 710.19 | 494.61 | 486.21 | 162.21 | 161.21 |

| GB | 952.58 | 932.68 | 1044.98 | 1021.88 | 725.28 | 710.98 | 494.58 | 486.18 | 162.88 | 161.78 | |

| 80 | AIR | 951.99 | 932.09 | 1044.76 | 1021.66 | 724.09 | 710.29 | 494.69 | 486.29 | 162.29 | 161.19 |

| GB | 952.78 | 932.88 | 1045.08 | 1022.08 | 724.08 | 710.48 | 494.68 | 486.28 | 163.08 | 161.98 | |

| 100 | AIR | 951.85 | 932.05 | / | / | 723.85 | 709.95 | 494.65 | 486.25 | 162.25 | 161.05 |

| GB | 952.78 | 933.08 | / | / | 724.48 | 710.48 | 494.78 | 486.38 | 163.28 | 162.08 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trifiletti, V.; Tseberlidis, G.; Colombo, M.; Spinardi, A.; Luong, S.; Danilson, M.; Grossberg, M.; Fenwick, O.; Binetti, S. Growth and Characterization of Cu2Zn1−xFexSnS4 Thin Films for Photovoltaic Applications. Materials 2020, 13, 1471. https://doi.org/10.3390/ma13061471

Trifiletti V, Tseberlidis G, Colombo M, Spinardi A, Luong S, Danilson M, Grossberg M, Fenwick O, Binetti S. Growth and Characterization of Cu2Zn1−xFexSnS4 Thin Films for Photovoltaic Applications. Materials. 2020; 13(6):1471. https://doi.org/10.3390/ma13061471

Chicago/Turabian StyleTrifiletti, Vanira, Giorgio Tseberlidis, Marco Colombo, Alberto Spinardi, Sally Luong, Mati Danilson, Maarja Grossberg, Oliver Fenwick, and Simona Binetti. 2020. "Growth and Characterization of Cu2Zn1−xFexSnS4 Thin Films for Photovoltaic Applications" Materials 13, no. 6: 1471. https://doi.org/10.3390/ma13061471

APA StyleTrifiletti, V., Tseberlidis, G., Colombo, M., Spinardi, A., Luong, S., Danilson, M., Grossberg, M., Fenwick, O., & Binetti, S. (2020). Growth and Characterization of Cu2Zn1−xFexSnS4 Thin Films for Photovoltaic Applications. Materials, 13(6), 1471. https://doi.org/10.3390/ma13061471