Study on the Relationship between Nano-Morphology Parameters and Properties of Bitumen during the Ageing Process

Abstract

1. Introduction

2. Test Design

2.1. Materials

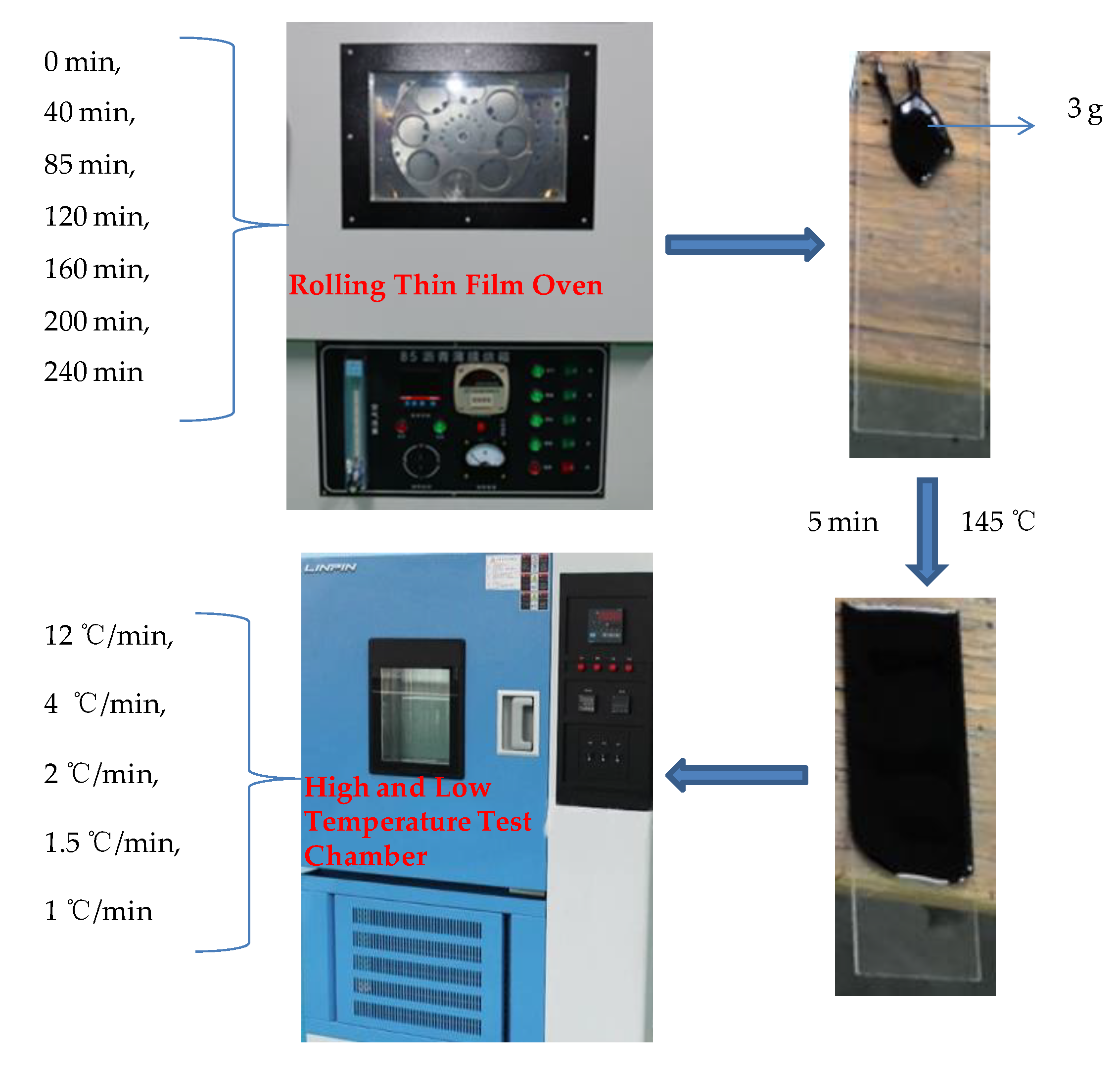

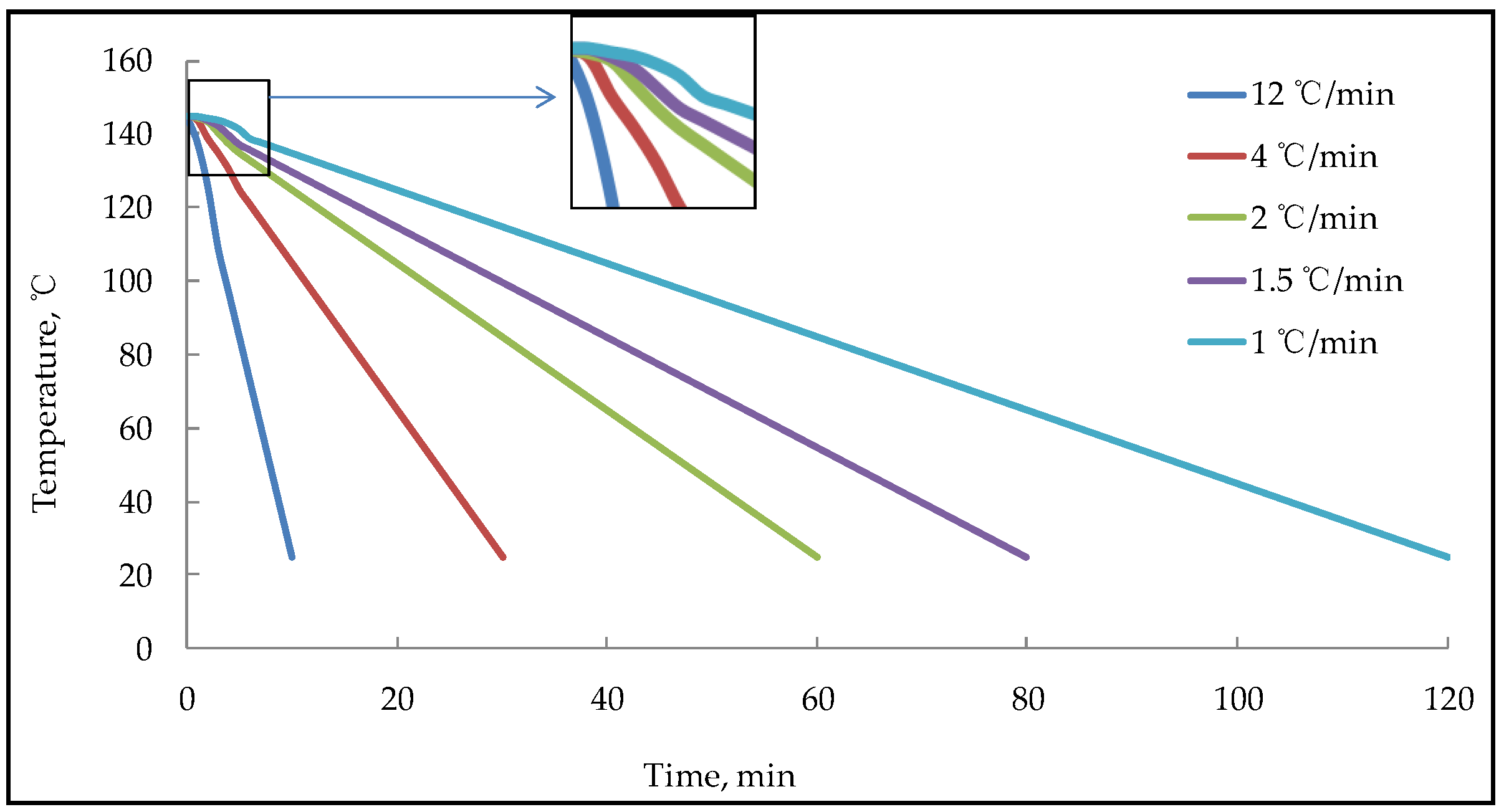

2.2. Test Design

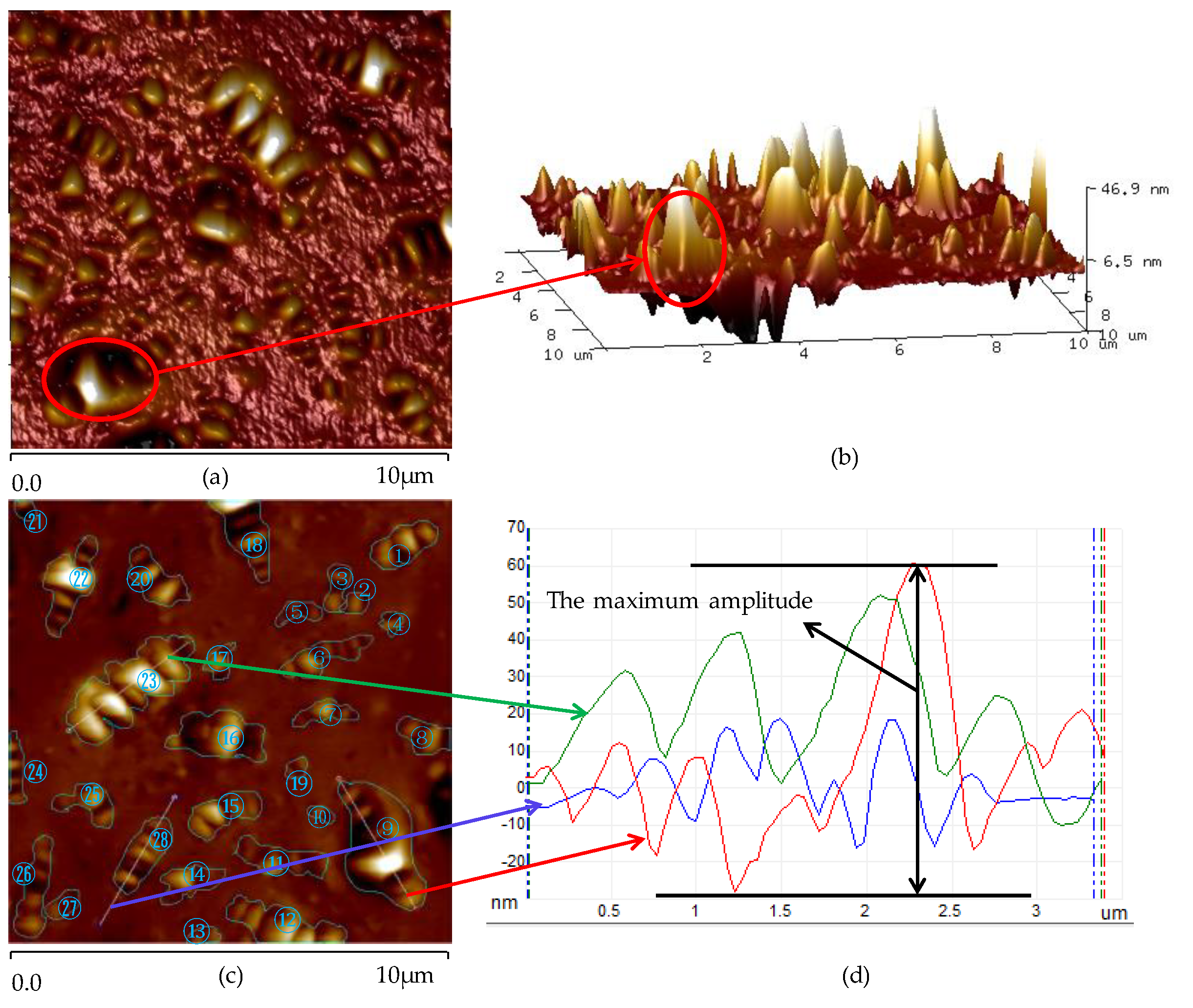

2.3. The Nano-Morphology Parameters

3. Results and Discussion

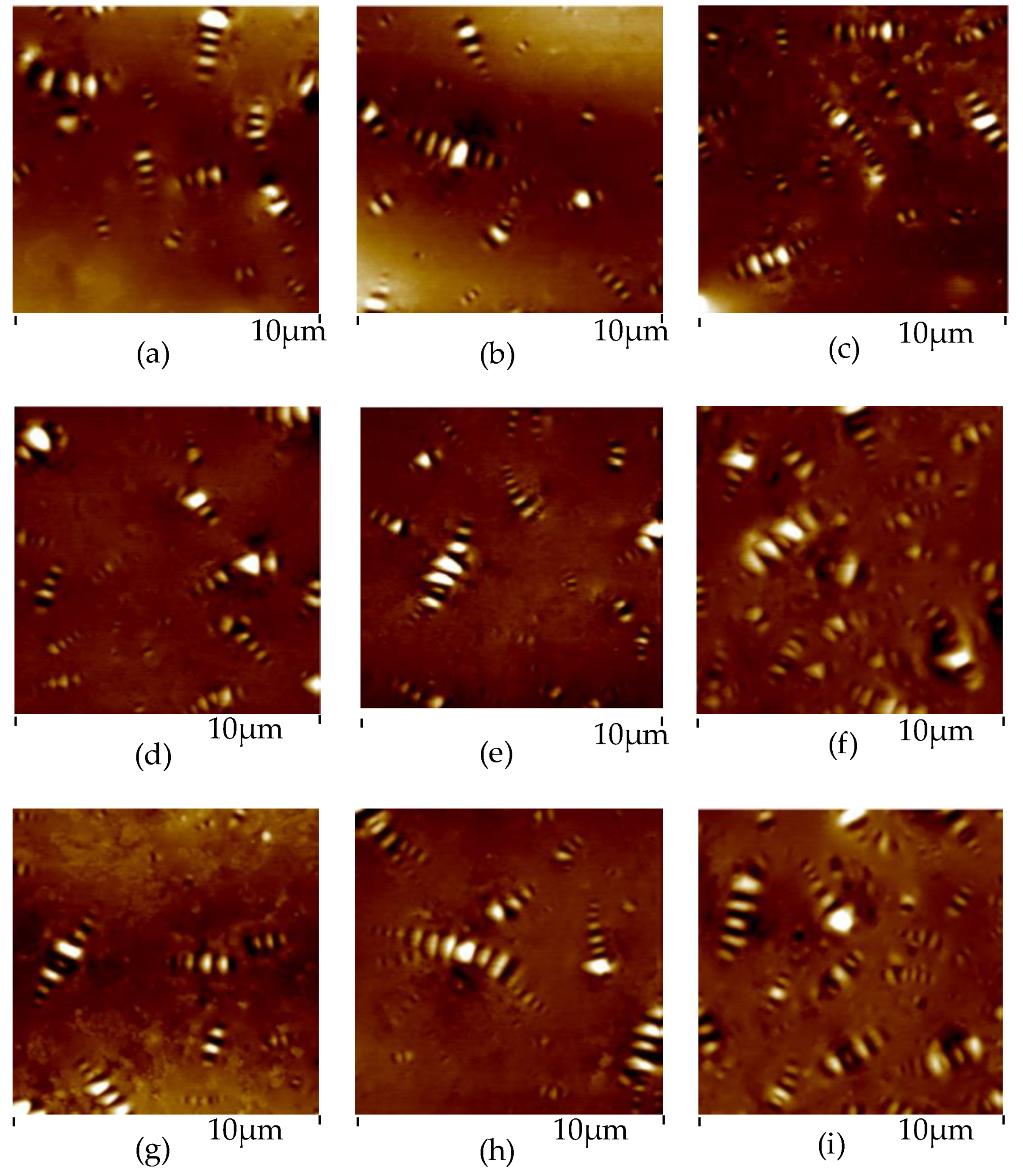

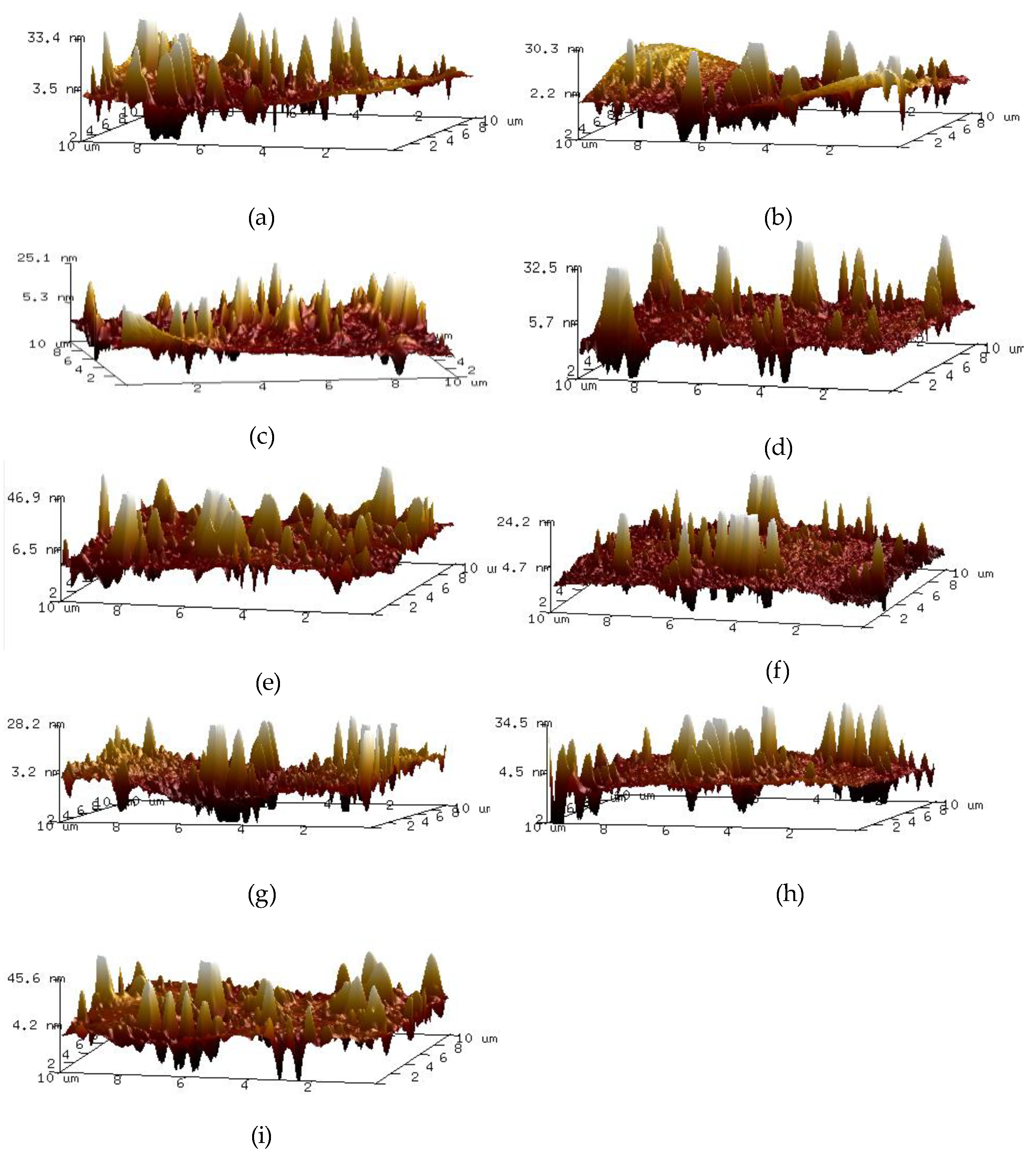

3.1. Effect of Ageing Time and Cooling Rate on Nano-Morphology of Bitumen

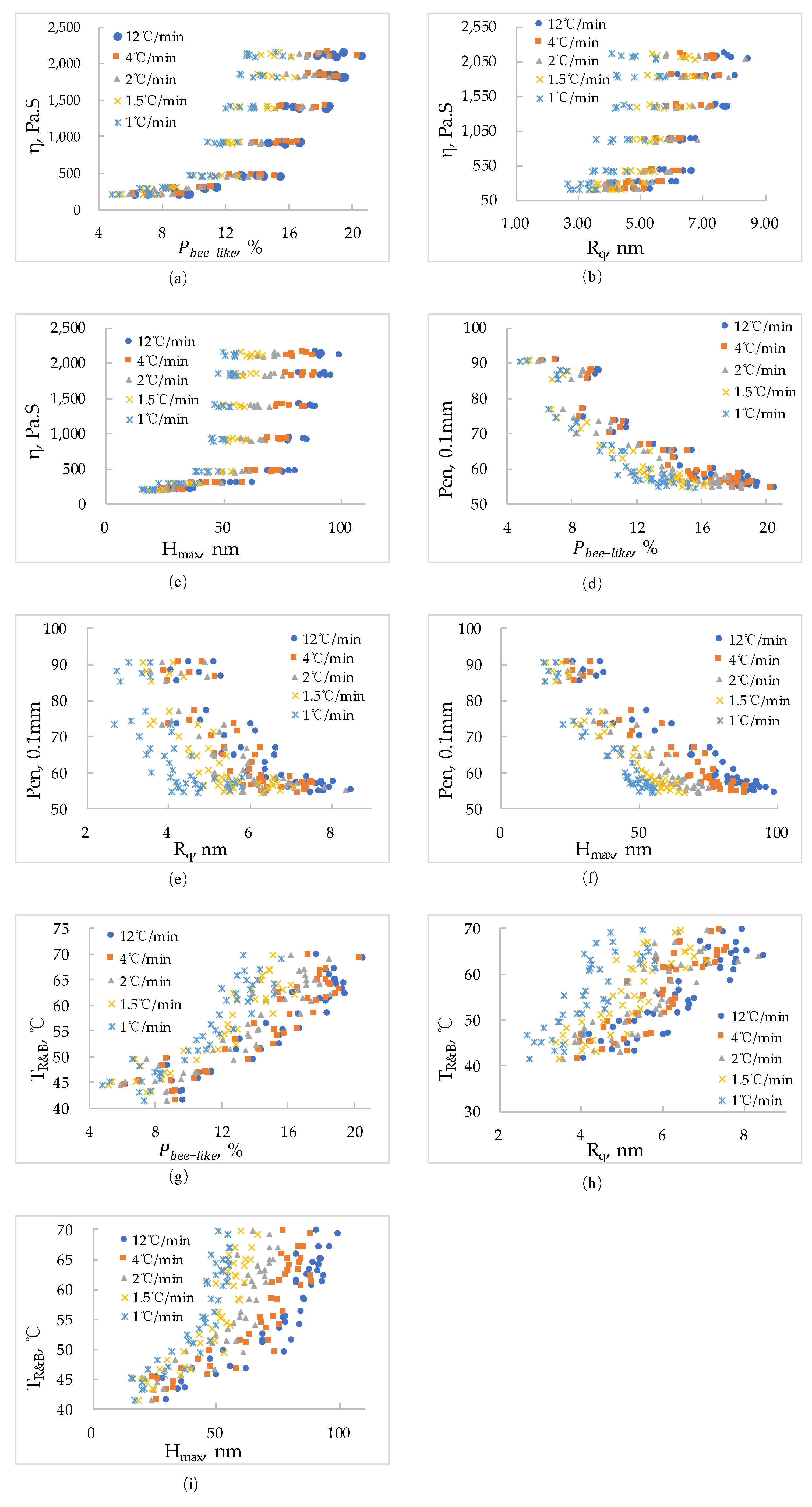

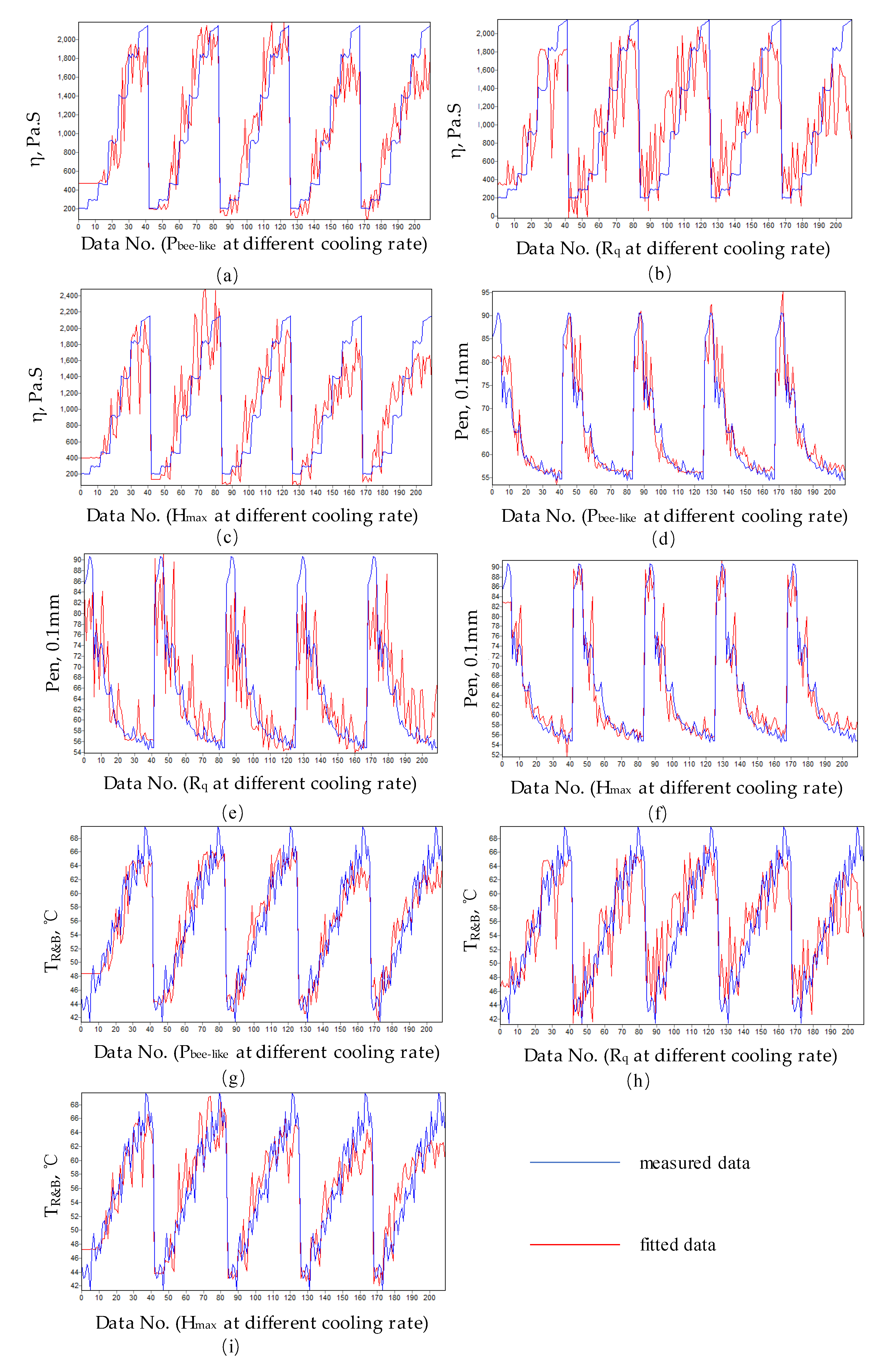

3.2. Relationship between the Nano-Morphology Parameters and the Bitumen Properties

4. Conclusions

- (1)

- The percentage of bee-like structure area, the maximum amplitude and the roughness will increase while the ageing degree of bitumen increases.

- (2)

- In the preparation process of AFM samples, the faster the cooling rate, the smaller the average area of the bee-like structure, but the larger the percentage of the bee-like structure area and the maximum amplitude and roughness.

- (3)

- While the percentage of the bee-like structure area, the maximum amplitude and roughness increase, the viscosity at 60 °C will increase, the penetration will decrease and the softening point will increase.

- (4)

- The relationship between the nano-morphology parameters of bitumen and the indexes of bitumen viscosity accords to .

Author Contributions

Funding

Conflicts of Interest

References

- Afra, S.; Nasr-El-Din, H.A.; Socci, D.; Cui, Z. Green phenolic amphiphile as a viscosity modifier and asphaltenes dispersant for heavy and extra-heavy oil. Fuel 2018, 220, 481–489. [Google Scholar] [CrossRef]

- Ji, X.; Hou, Y.; Zou, H.; Chen, B.; Jiang, Y. Study of surface microscopic properties of asphalt based on atomic force microscopy. Constr. Build. Mater. 2020, 242, 118025. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Y.X.; Jia, Z.; Wang, F.; Ding, L. Test method and material design of asphalt mixture with the function of photocatalytic decomposition of automobile exhaust. Constr. Build. Mater. 2019, 215, 298–309. [Google Scholar] [CrossRef]

- Zhang, W.; Jia, Z.; Wang, F. Effect and prediction of aromatic oil on swelling degree of direct-to-plant SBS modifier in bitumen. Pet. Sci. Technol. 2019, 37, 1033–1040. [Google Scholar] [CrossRef]

- Hung, A.M.; Fini, E.H. Absorption spectroscopy to determine the extent and mechanisms of aging in bitumen and asphaltenes. Fuel 2019, 242, 408–415. [Google Scholar] [CrossRef]

- Oldham, D.; Hung, A.; Parast, M.M.; Fini, E.H. Investigating bitumen rejuvenation mechanisms using a coupled rheometry-morphology characterization approach. Constr. Build. Mater. 2018, 159, 37–45. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, L.; Wang, D.; Guo, M.; Liu, P.; Yu, J. Characterization of bitumen micro-mechanical behaviors using AFM, phase dynamics theory and MD simulation. Materials 2017, 10, 208. [Google Scholar] [CrossRef]

- Wu, S.P.; Pang, L.; Mo, L.T.; Chen, Y.C.; Zhu, G.J. Influence of aging on the evolution of structure, morphology and rheology of base and SBS modified bitumen. Constr. Build. Mater. 2009, 23, 1005–1010. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Zhang, Z.; Zou, B.; Zhu, Z.; Lu, G.; Xu, W.; Yu, J.; Yu, H. Effect of aging on chemical and rheological properties of bitumen. Polymers 2018, 10, 1345. [Google Scholar] [CrossRef]

- Filippi, S.; Cappello, M.; Merce, M.; Polacco, G. Effect of Nanoadditives on Bitumen Aging Resistance: A Critical Review. J. Nanomater. 2018, 2018, 2469307. [Google Scholar] [CrossRef]

- Omairey, E.L.; Zhang, Y.; Al-Malaika, S.; Sheena, H.; Gu, F. Impact of anti-ageing compounds on oxidation ageing kinetics of bitumen by infrared spectroscopy analysis. Constr. Build. Mater. 2019, 223, 755–764. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, J.; Jia, Z. The UV anti-aging performance of TPS modified bitumen. Pet. Sci. Technol. 2018, 36, 1164–1169. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Molecular dynamics study of oxidative aging effect on asphalt binder properties. Fuel 2017, 188, 1–10. [Google Scholar] [CrossRef]

- Nivitha, M.R.; Prasad, E.; Krishnan, J.M. Ageing in modified bitumen using FTIR spectroscopy. Int. J. Pavement Eng. 2016, 17, 565–577. [Google Scholar] [CrossRef]

- Weigel, S.; Stephan, D. Differentiation of bitumen according to the refinery and ageing state based on FTIR spectroscopy and multivariate analysis methods. Mater. Struct. 2018, 51, 130. [Google Scholar] [CrossRef]

- Singh, B.; Saboo, N.; Kumar, P. Use of Fourier transform infrared spectroscopy to study ageing characteristics of asphalt binders. Pet. Sci. Technol. 2017, 35, 1648–1654. [Google Scholar] [CrossRef]

- Hofko, B.; Porot, L.; Cannone, A.F.; Poulikakos, L.; Huber, L.; Lu, X.; Mollenhauer, K.; Grothe, H. FTIR spectral analysis of bituminous binders: Reproducibility and impact of ageing temperature. Mater. Struct. 2018, 51, 45. [Google Scholar] [CrossRef]

- Hofko, B.; Alavi, M.Z.; Grothe, H.; Jones, D.; Harvey, J. Repeatability and sensitivity of FTIR ATR spectral analysis methods for bituminous binders. Mater. Struct. 2017, 50, 187. [Google Scholar] [CrossRef]

- Nivitha, M.R.; Prasad, E.; Krishnan, J.M. Transitions in unmodified and modified bitumen using FTIR spectroscopy. Mater. Struct. 2019, 52, 7. [Google Scholar] [CrossRef]

- Teltayev, B.B.; Rossi, C.O.; Ashimova, S.Z. Composition and rheological characteristics of bitumen in short-term and long-term aging. Mag. Civ. Eng. 2018, 81, 93–101. [Google Scholar] [CrossRef]

- Chen, J.S.; Lee, C.T.; Lin, Y.Y. Characterization of a Recycling Agent for Restoring Aged Bitumen. J. Mater. Civ. Eng. 2018, 30, 05018003. [Google Scholar] [CrossRef]

- Baqersad, M.; Ali, H. Rheological and chemical characteristics of asphalt binders recycled using different recycling agents. Constr. Build. Mater. 2019, 228, 116738. [Google Scholar] [CrossRef]

- Gong, X.; Dong, Z.; Wang, H.; Ma, X.; Yu, H.; Hu, K. Rheological Characterization of Asphalt Fine Aggregate Matrix Using Dynamic Shear Rheometer. Polymers 2019, 11, 1273. [Google Scholar] [CrossRef] [PubMed]

- Gawel, I.; Czechowski, F.; Kosno, J. An environmental friendly anti-ageing additive to bitumen. Constr. Build. Mater. 2016, 110, 42–47. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Wang, D.; Porot, L.; Hofko, B. Impact of asphalt aging temperature on chemo-mechanics. RSC Adv. 2019, 9, 11602–11613. [Google Scholar] [CrossRef]

- Gümüştekin, Ş.; Topal, A.; Şengöz, B. Texture analysis of polymer modified bitumen images. Int. J. Mater. Res. 2011, 102, 513–520. [Google Scholar] [CrossRef]

- Su, J.F.; Schlangen, E.; Wang, Y.Y. Investigation the self-healing mechanism of aged bitumen using microcapsules containing rejuvenator. Constr. Build. Mater. 2015, 85, 49–56. [Google Scholar] [CrossRef]

- Zhang, W.; Jia, Z.; Zhang, Y.; Hu, K.; Ding, L.; Wang, F. The effect of direct-to-plant styrene-butadiene-styrene block copolymer components on bitumen modification. Polymers 2019, 11, 140. [Google Scholar] [CrossRef]

- Zhu, J.; Balieu, R.; Lu, X.; Kringos, N. Microstructure evaluation of polymer-modified bitumen by image analysis using two-dimensional fast Fourier transform. Mater. Des. 2018, 137, 164–175. [Google Scholar] [CrossRef]

- Vassaux, S.; Gaudefroy, V.; Boulangé, L.; Soro, L.J.; Pévère, A.; Michelet, A.; Barragan-Montero, V.; Mouillet, V. Study of remobilization phenomena at reclaimed asphalt binder/virgin binder interphases for recycled asphalt mixtures using novel microscopic methodologies. Constr. Build. Mater. 2018, 165, 846–858. [Google Scholar] [CrossRef]

- Dehouche, N.; Kaci, M.; Mouillet, V. The effects of mixing rate on morphology and physical properties of bitumen/organo-modified montmorillonite nanocomposites. Constr. Build. Mater. 2016, 114, 76–86. [Google Scholar] [CrossRef]

- Geçkil, T. Physical, chemical, microstructural and rheological properties of reactive terpolymer-modified bitumen. Materials 2019, 12, 921. [Google Scholar] [CrossRef]

- Bo, L.; Yujiao, C.; Xiang, L.; Hailian, L.; Xiaomin, L. Effect of material composition on nano-adhesive characteristics of styrene-butadiene-styrene copolymer-modified bitumen using atomic force microscope technology. Int. J. Adhes. Adhes. 2019, 89, 168–173. [Google Scholar] [CrossRef]

- Holcombe, E.W.; Nazzal, M.D.; Mogawer, W.; Austerman, A.J.; Kaya, S. Evaluating asphalt binders prepared with different processes to meet the same performance grade: Use of atomic force microscope. Transp. Res. Rec. 2017, 2632, 99–109. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, F.; Shi, J.; Li, Z.; Liang, X. Experimental study on nano-parameters of styrene-butadiene-styrene block copolymer modified bitumen based on atomic force microscopy. Polymers 2019, 11, 989. [Google Scholar] [CrossRef] [PubMed]

- Santos dos, S.; Partl, M.N.; Poulikakos, L.D. Newly observed effects of water on the microstructures of bitumen surface. Constr. Build. Mater. 2014, 71, 618–627. [Google Scholar] [CrossRef]

- Golubev, Y.A.; Kovaleva, O.V.; Yushkin, N.P. Observations and morphological analysis of supermolecular structure of natural bitumens by atomic force microscopy. Fuel 2008, 87, 32–38. [Google Scholar] [CrossRef]

- Pizzorno, B.S.; Dourado, E.R.; Moraes, M.D.; Simão, R.A.; Leite, L.F.M. Segregation and crystallization of waxes on the surface of asphalt binders as observed by atomic force microscopy. Pet. Sci. Technol. 2014, 32, 2738–2745. [Google Scholar] [CrossRef]

- Yu, X.; Burnham, N.A.; Granados-Focil, S.; Tao, M. Bitumen’s microstructures are correlated with its bulk thermal and rheological properties. Fuel 2019, 254, 115509. [Google Scholar] [CrossRef]

- Fischer, H.R.; Dillingh, E.C.; Hermse, C.G.M. On the microstructure of bituminous binders. Road Mater. Pavement Des. 2014, 15, 1–15. [Google Scholar] [CrossRef]

- Blom, J.; Soenen, H.; Katsiki, A.; Van den Brande, N.; Rahier, H.; van den Bergh, W. Investigation of the bulk and surface microstructure of bitumen by atomic force microscopy. Constr. Build. Mater. 2018, 177, 158–169. [Google Scholar] [CrossRef]

- Zhang, H.L.; Yu, J.Y.; Feng, Z.G.; Xue, L.H.; Wu, S.P. Effect of aging on the morphology of bitumen by atomic force microscopy. J. Microsc. 2012, 246, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Jiang, Y.; Zou, H.; Cao, F.; Hou, Y. Application of numerical simulation method to improve shear strength and rutting resistance of asphalt mixture. Int. J. Pavement Eng. 2020, 21, 112–121. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.V.J.M.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- The Ministry of Communications Highway Science Institute. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; JTG E20-2011; China Communications Press: Beijing, China, 2011. [Google Scholar]

- Zhang, W.; Zou, L.; Jia, Z.; Wang, F.; Li, Y.; Shi, P. Effect of Thermo-Oxidative Ageing on Nano-Morphology of Bitumen. Appl. Sci. 2019, 9, 3027. [Google Scholar] [CrossRef]

- Yin, C. Hazard assessment and regionalization of highway flood disasters in china. Nat. Hazards 2020, 200, 1–16. [Google Scholar] [CrossRef]

| Test Items | Value | |

|---|---|---|

| Penetration, 25 °C, 0.1 mm | 88.1 | |

| Ductility, 15 °C, cm | 101.9 | |

| Viscosity at 60 °C, Pa·s | 202.411 | |

| Softening point, °C | 43.7 | |

| RTFOT 1 | Penetration ratio, % | 71.9 |

| Residual ductility, 15 °C, cm | 33.7 | |

| Mass loss, % | 0.3 | |

| No. | a | b | c | d | e | f | g | R2, % | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Equation (6) | 2266.6 | −0.0006 | 0.02 | −0.18 | 0.39 | 35.1 | 51.94 | 95.04 | ||

| Equation (7) | 2455.2 | −0.006 | 0.07 | −0.08 | −0.44 | 52.8 | −289.7 | 88.26 | ||

| Equation (8) | 3359.3 | −0.00003 | 0.0004 | −0.01 | 0.06 | 27.5 | 61.4 | 92.23 | ||

| Equation (9) | −38.83 | 0.0004 | −0.02 | 0.43 | −1.6 | −1.1 | 94.24 | 96.83 | ||

| Equation (10) | −63.70 | 0.003 | −0.08 | 0.63 | −0.79 | −2.4 | 115.12 | 89.13 | ||

| Equation (11) | −43.14 | 0.00002 | −0.0001 | 0.05 | −0.53 | −1.1 | 95.15 | 97.85 | ||

| Equation (12) | 25.62 | −0.0003 | 0.01 | 0.02 | −0.28 | 0.6 | 41.77 | 98.26 | ||

| Equation (13) | 32.23 | −0.002 | −0.002 | 0.3 | −0.57 | 0.9 | −35.9 | 89.31 | ||

| Equation (14) | 33.83 | −0.00001 | 0.001 | 0.01 | −0.21 | 0.4 | 42.03 | 93.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Wang, X.; Zhang, W.; Ding, L. Study on the Relationship between Nano-Morphology Parameters and Properties of Bitumen during the Ageing Process. Materials 2020, 13, 1472. https://doi.org/10.3390/ma13061472

Zhang M, Wang X, Zhang W, Ding L. Study on the Relationship between Nano-Morphology Parameters and Properties of Bitumen during the Ageing Process. Materials. 2020; 13(6):1472. https://doi.org/10.3390/ma13061472

Chicago/Turabian StyleZhang, Mengyuan, Xuancang Wang, Wengang Zhang, and Longting Ding. 2020. "Study on the Relationship between Nano-Morphology Parameters and Properties of Bitumen during the Ageing Process" Materials 13, no. 6: 1472. https://doi.org/10.3390/ma13061472

APA StyleZhang, M., Wang, X., Zhang, W., & Ding, L. (2020). Study on the Relationship between Nano-Morphology Parameters and Properties of Bitumen during the Ageing Process. Materials, 13(6), 1472. https://doi.org/10.3390/ma13061472