Sound Absorption Performance of the Poplar Seed Fiber/PCL Composite Materials

Abstract

1. Introduction

2. Experiment

2.1. Materials and Equipment

2.2. Preparation of the Composite Materials

2.3. Testing of the Composite Materials

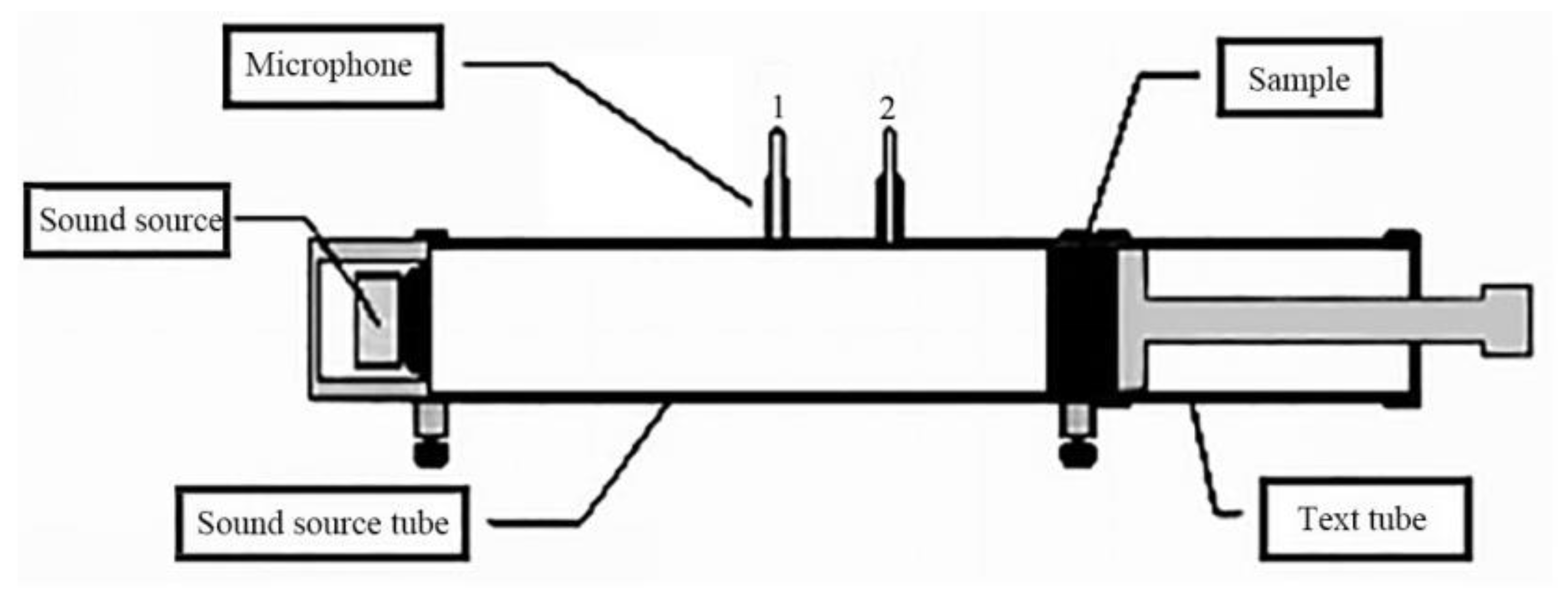

2.3.1. Testing of the Sound Absorption Coefficient

2.3.2. Calculation of the Porosity

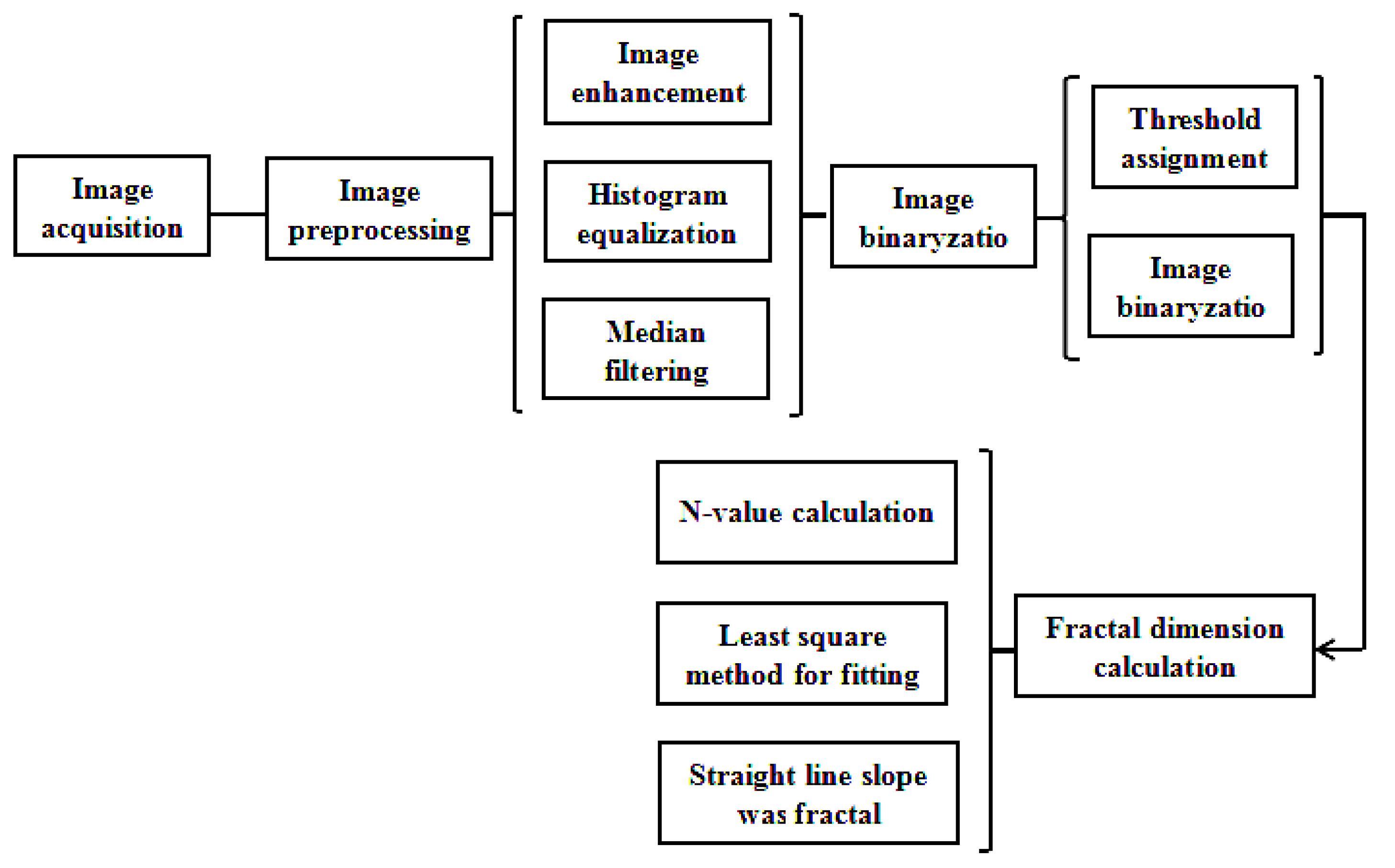

2.3.3. Fractal Characterization

3. Results and Discussion

3.1. Influence of the Technological Parameters on the Sound Absorption Coefficient

3.1.1. Influence of the Mass Fraction of Poplar Seed Fibers on the Sound Absorption Coefficient

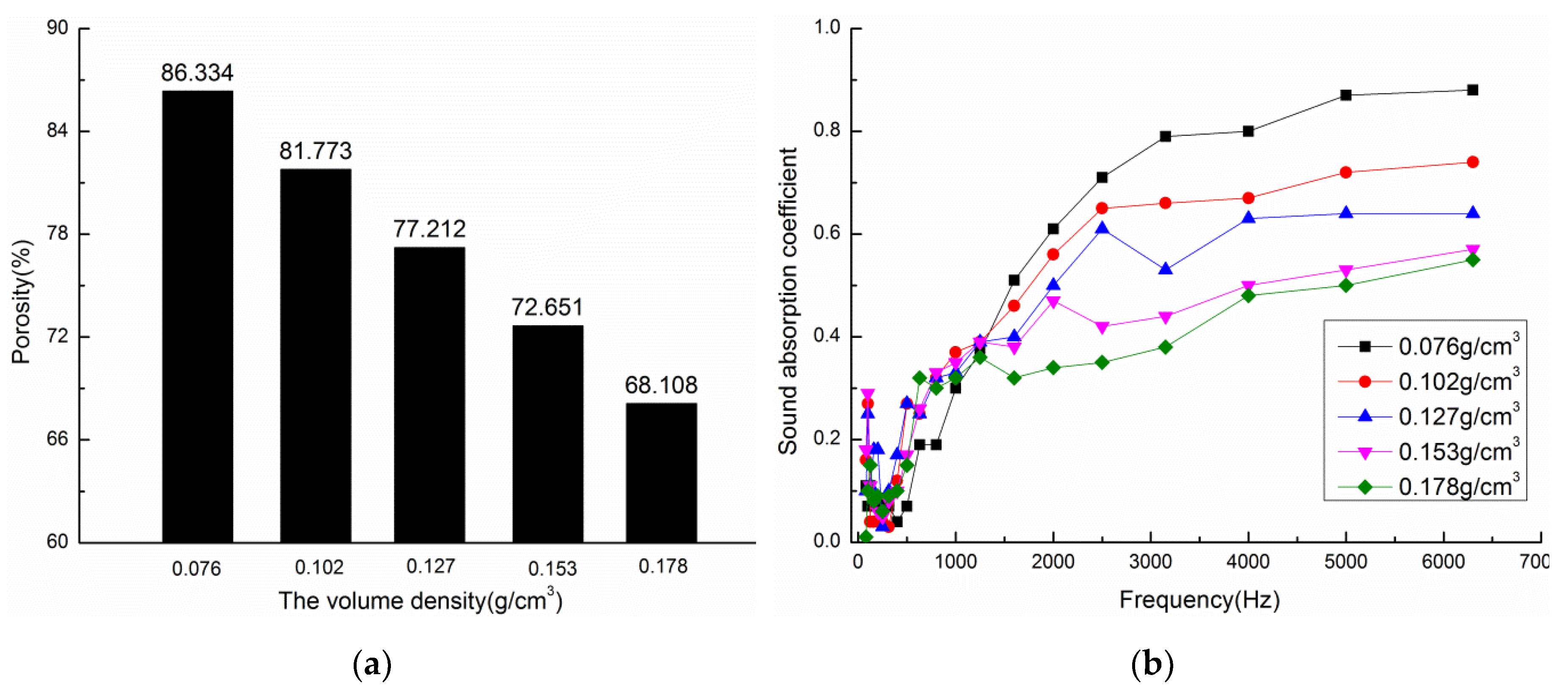

3.1.2. Influence of the Volume Density on the Sound Absorption Coefficient

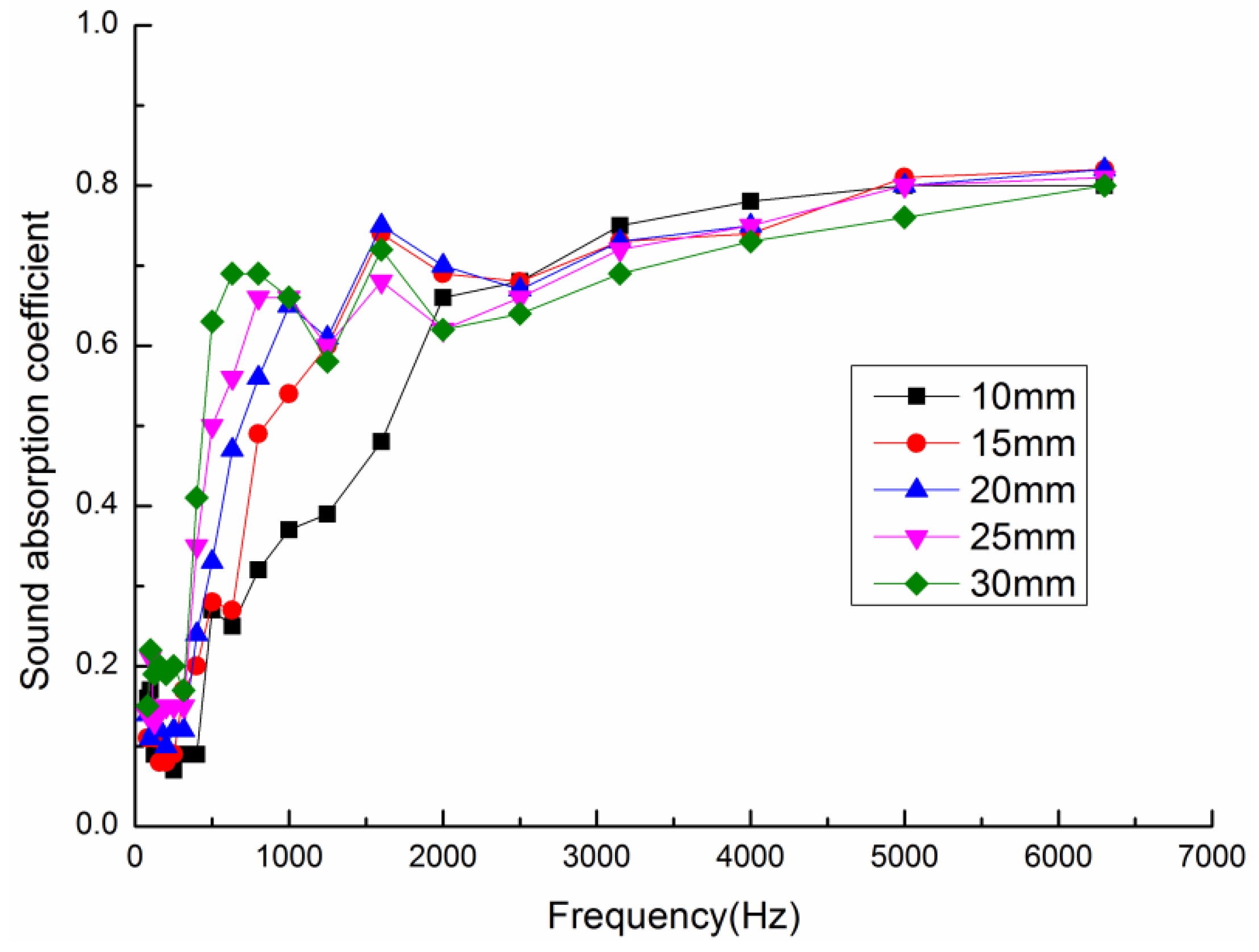

3.1.3. Influence of the Thickness on the Sound Absorption Coefficient

3.2. Fractal Characterization Results

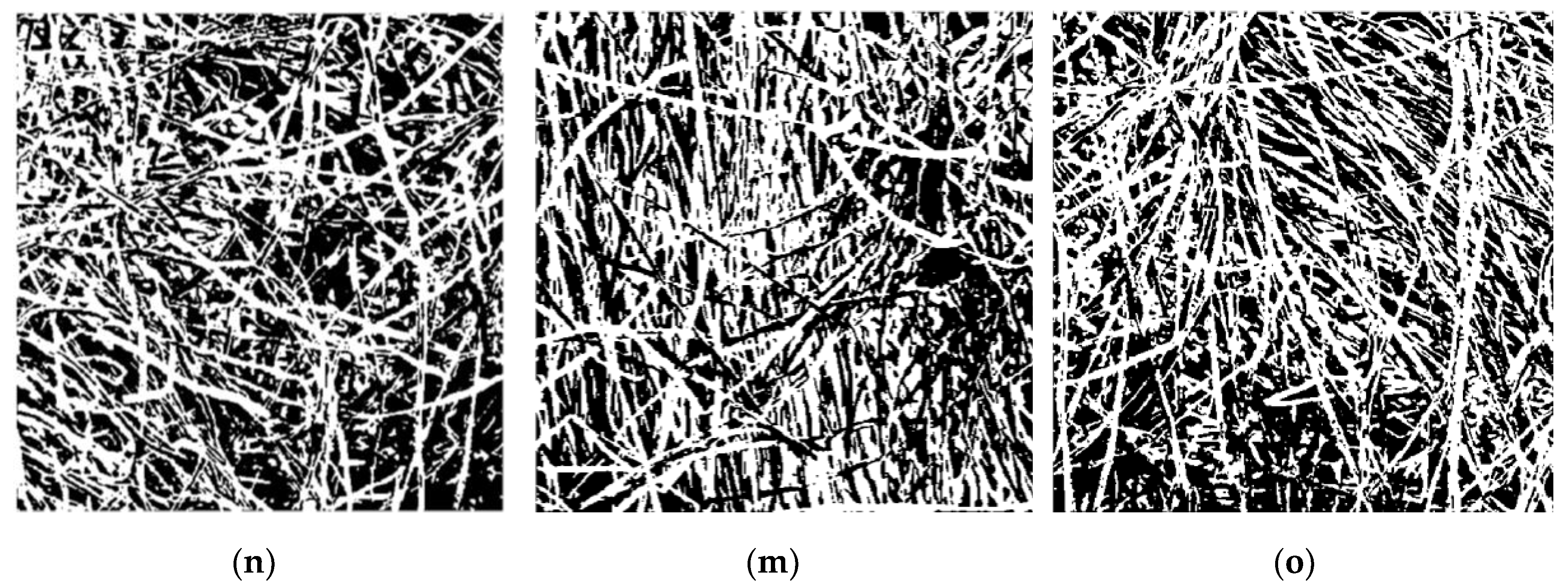

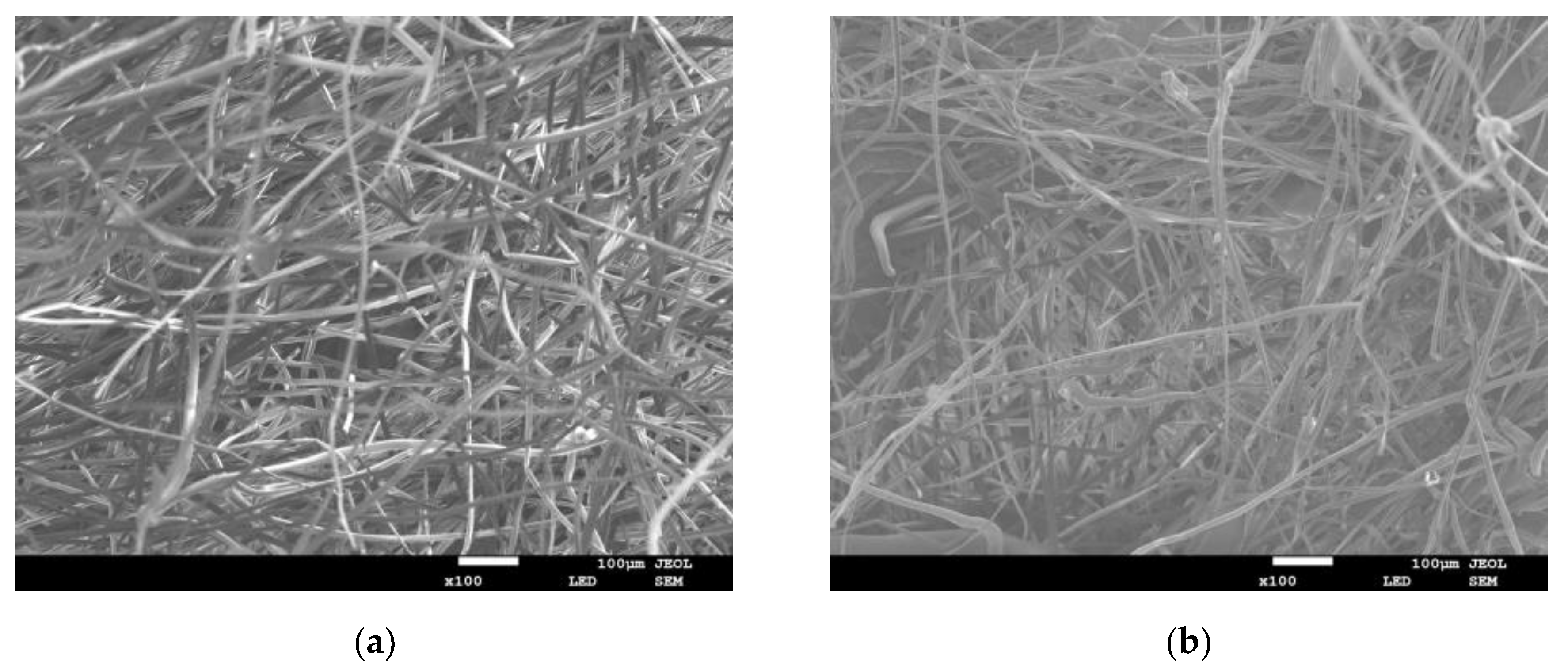

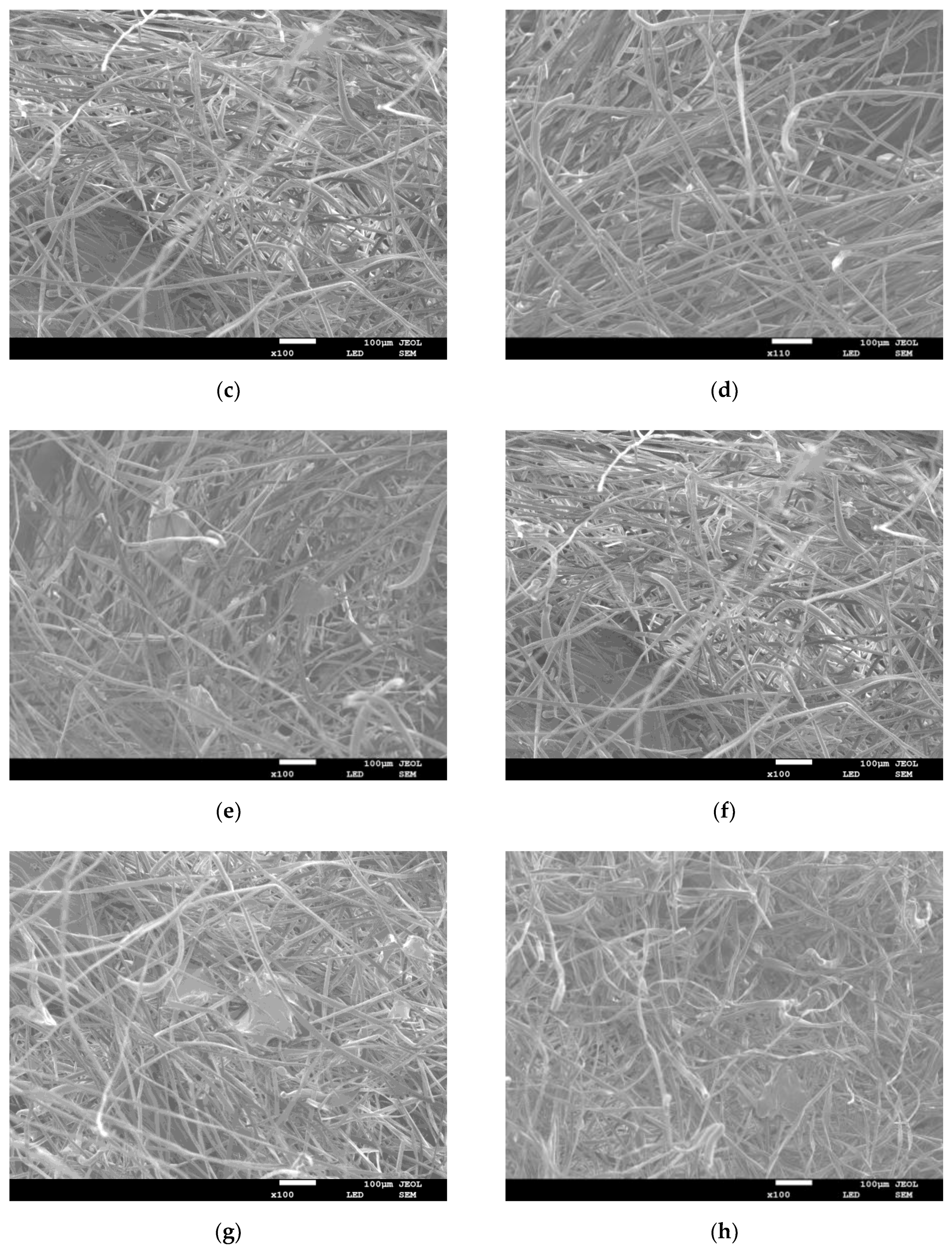

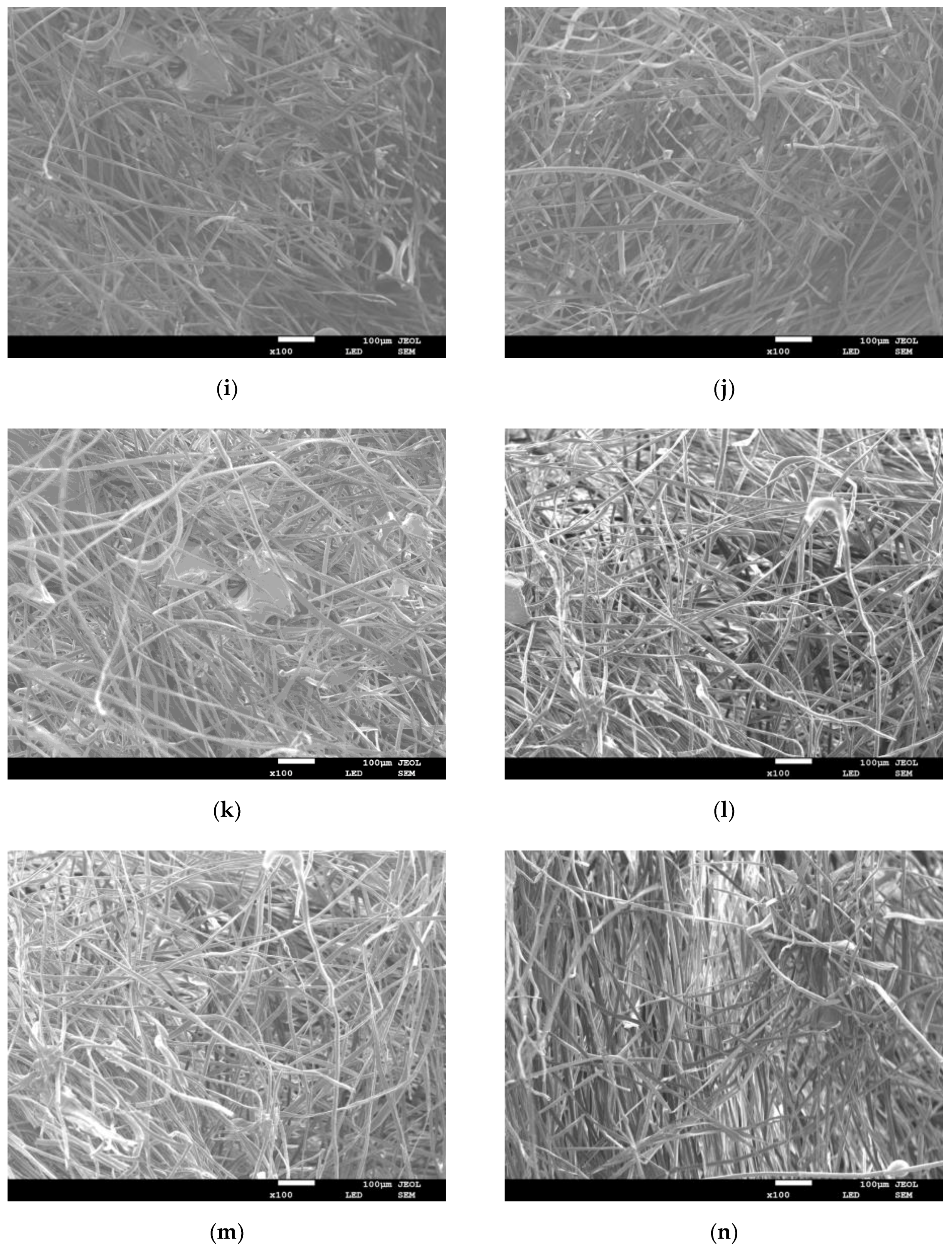

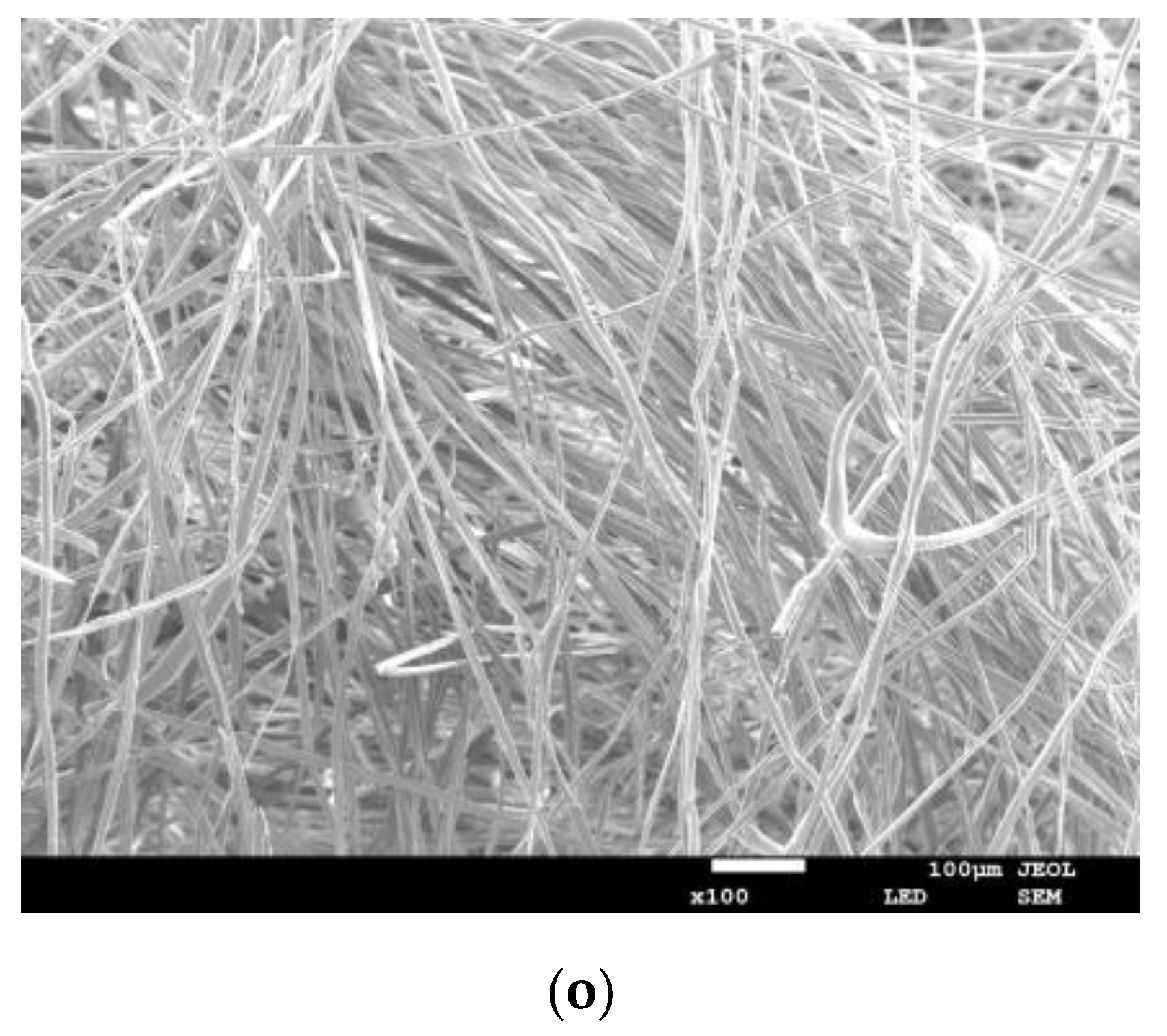

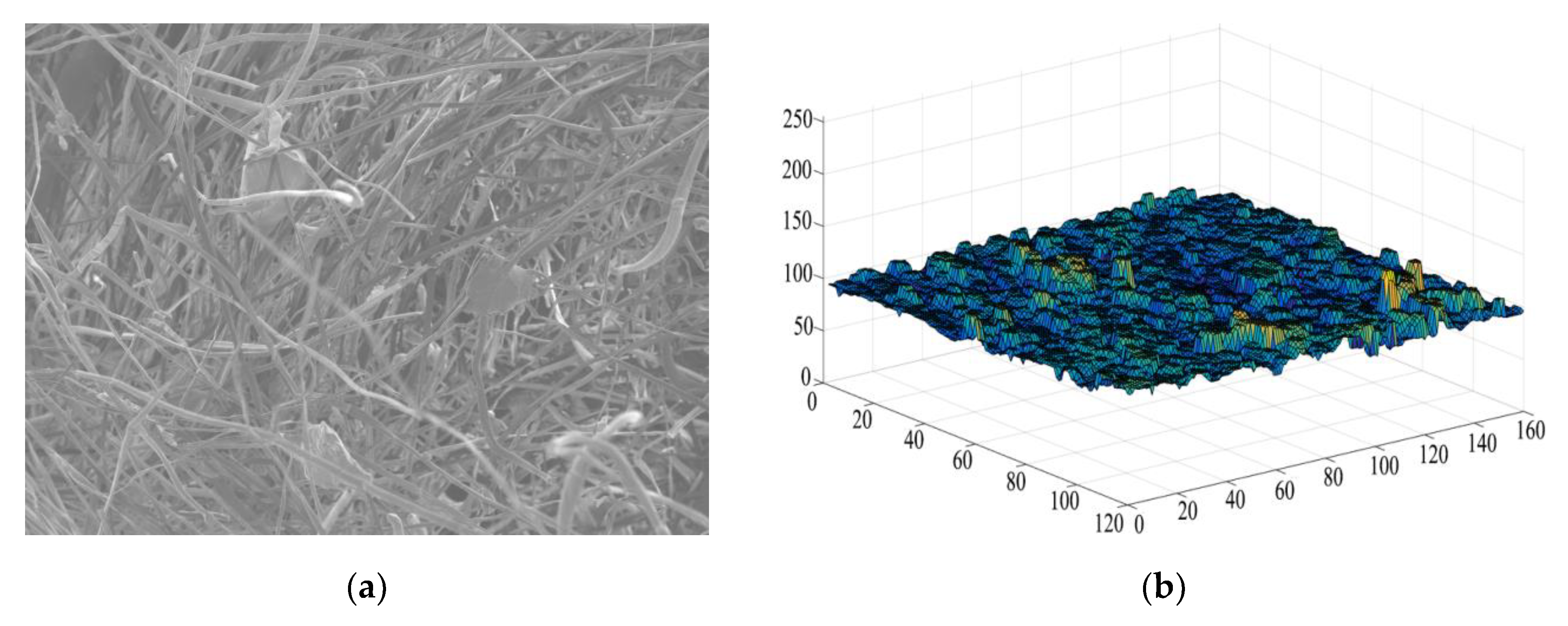

3.2.1. Image Acquisition of the Composite Materials

3.2.2. Pretreatment of the Images of the Composite Materials

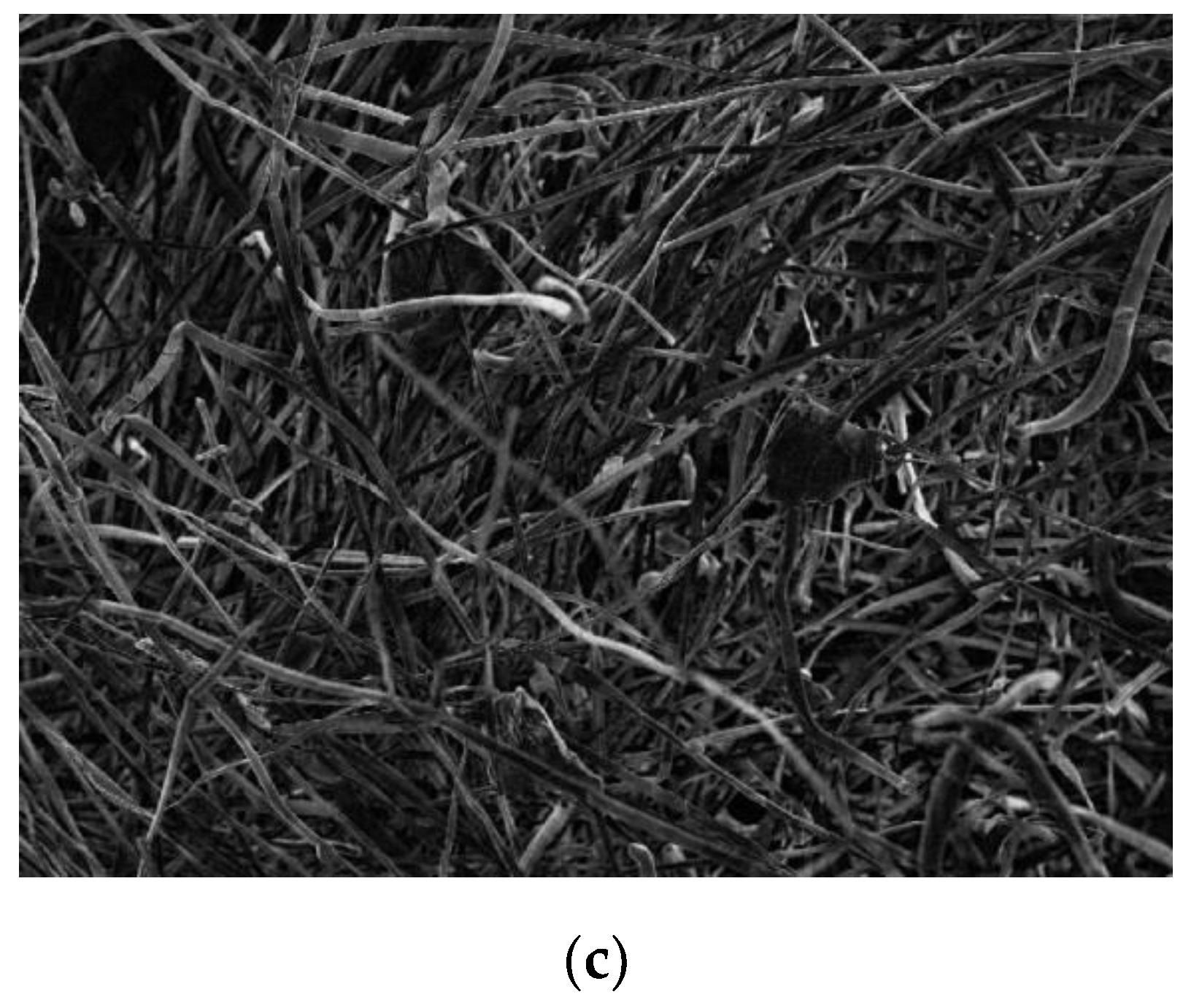

3.2.3. Eliminating the Background

3.2.4. Calculating a Gray Histogram and an Image After Gray Stretching

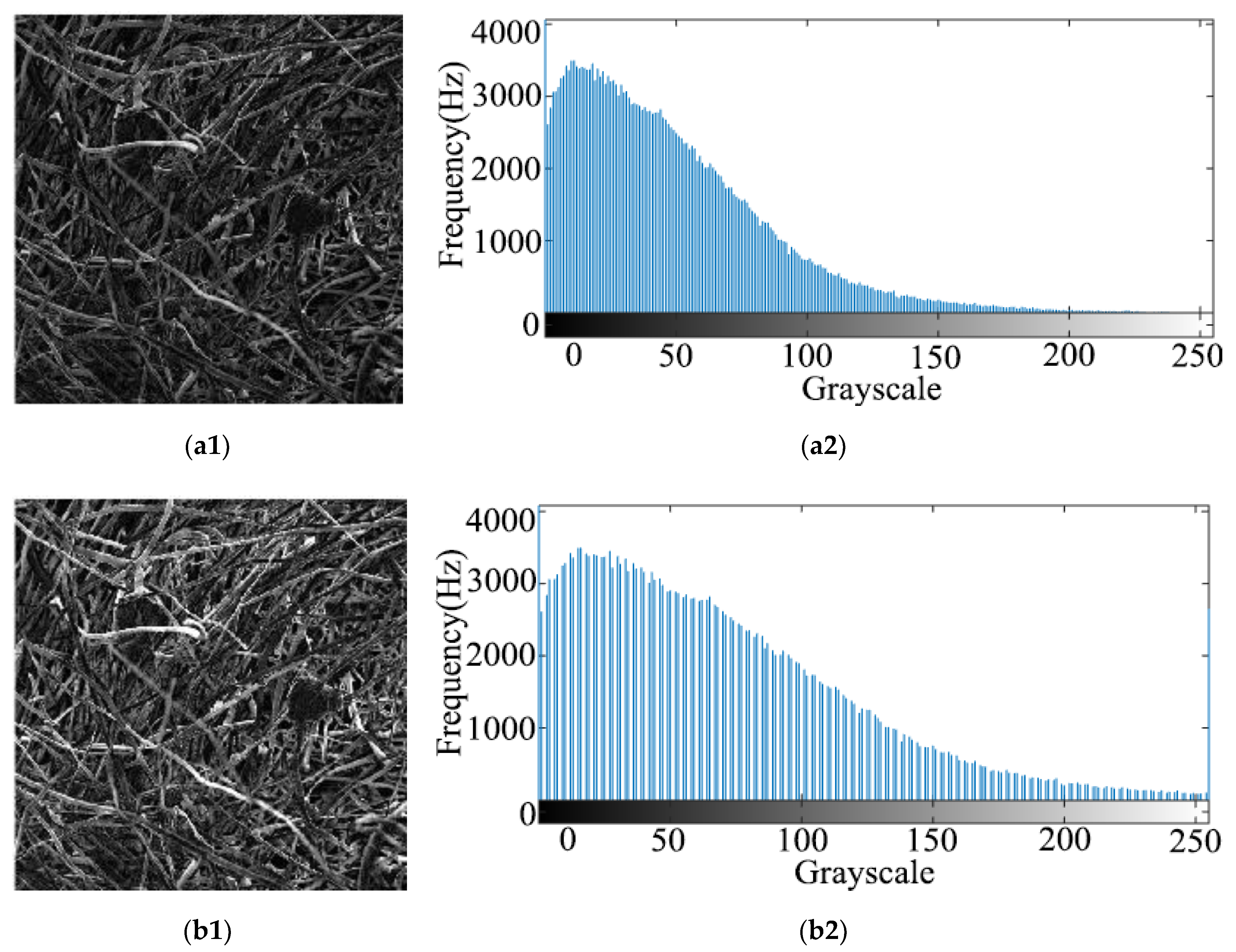

3.2.5. Median Filtering of the Images

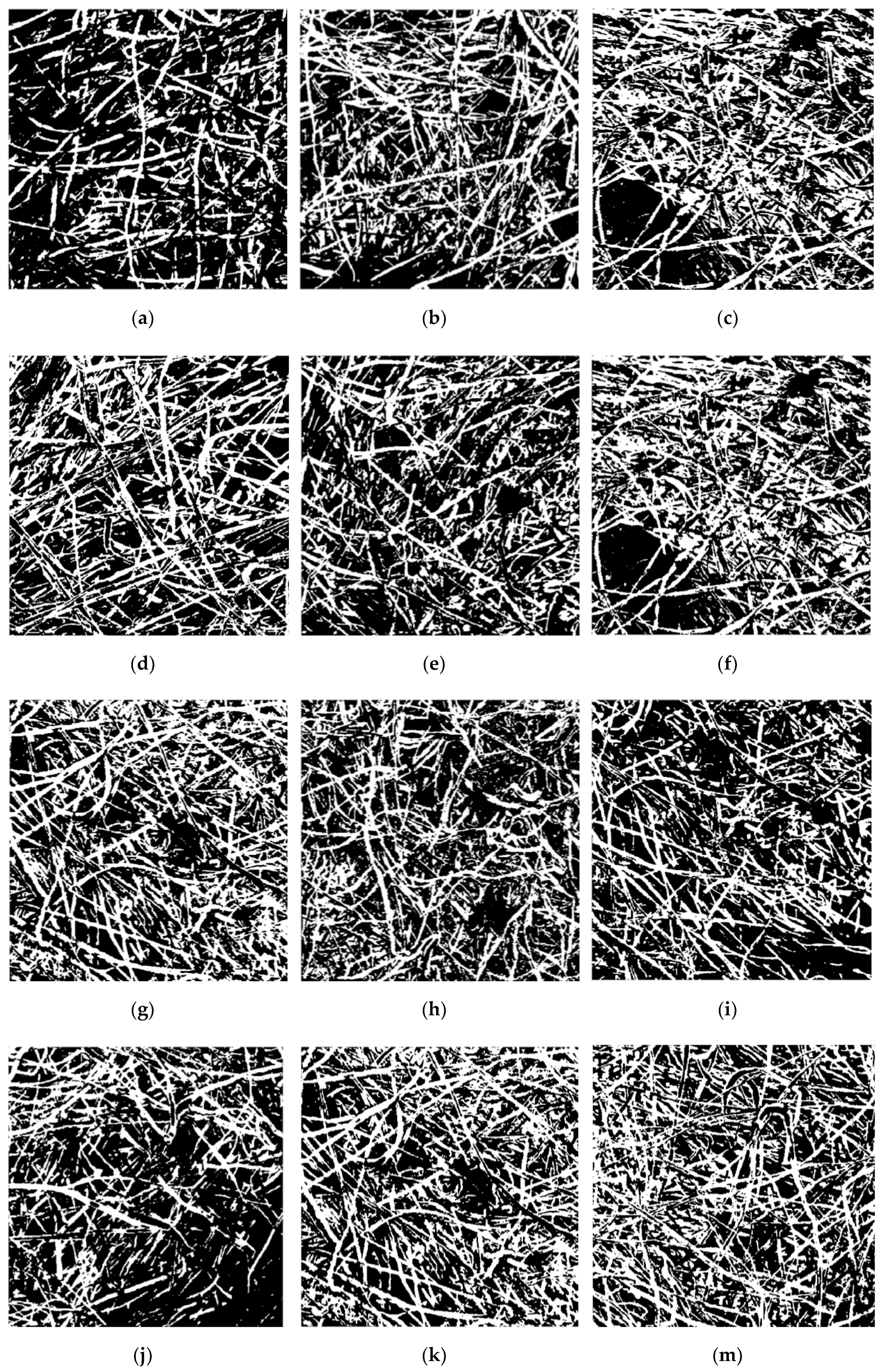

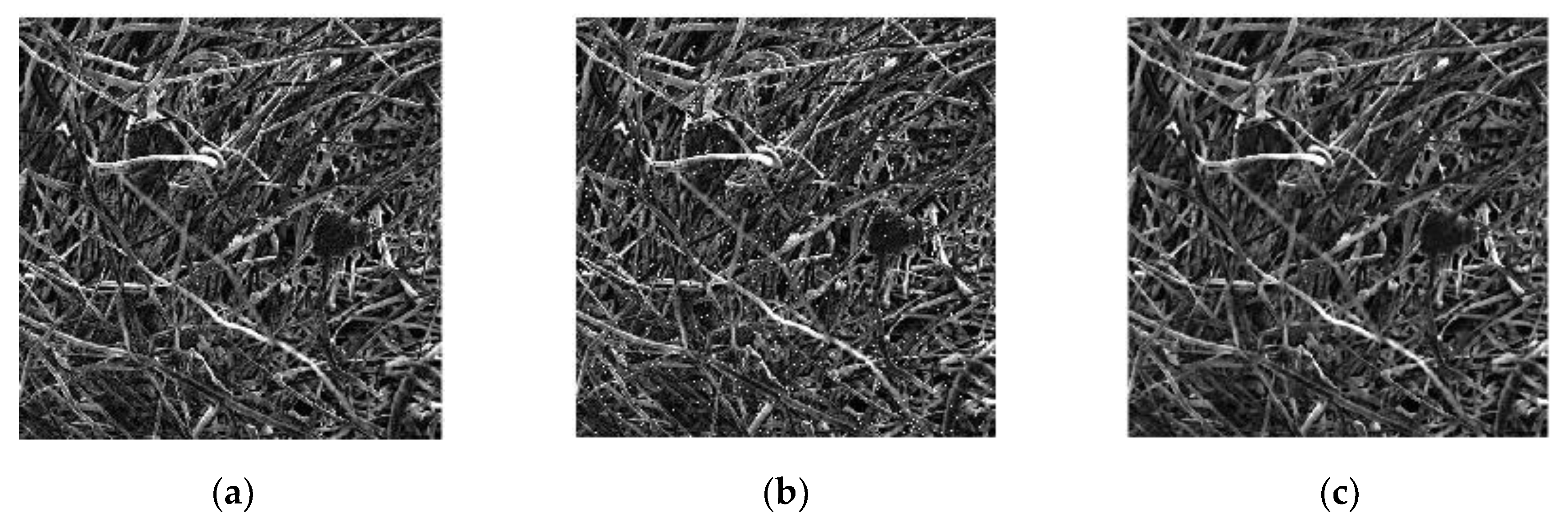

3.2.6. Binarization of the Images

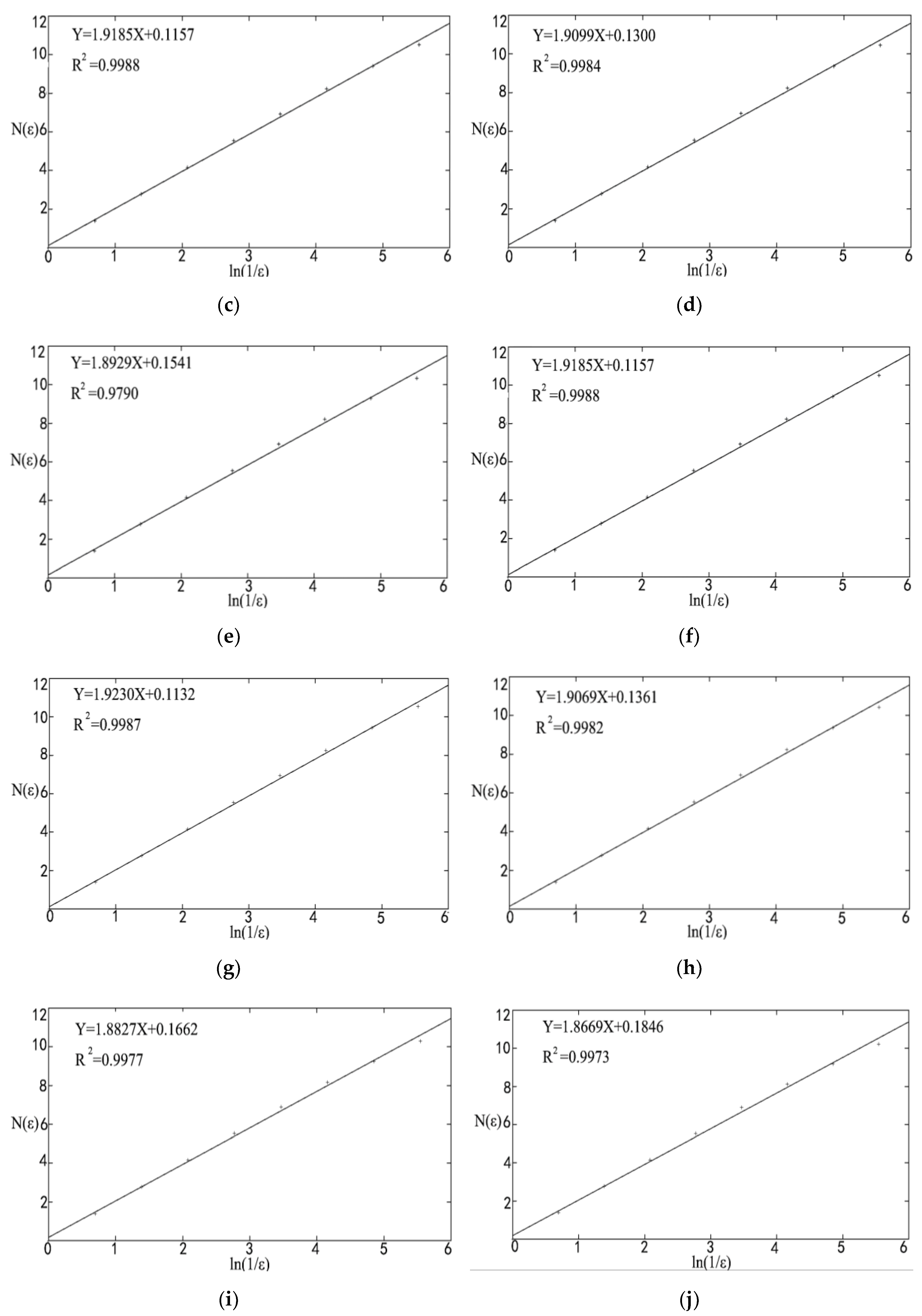

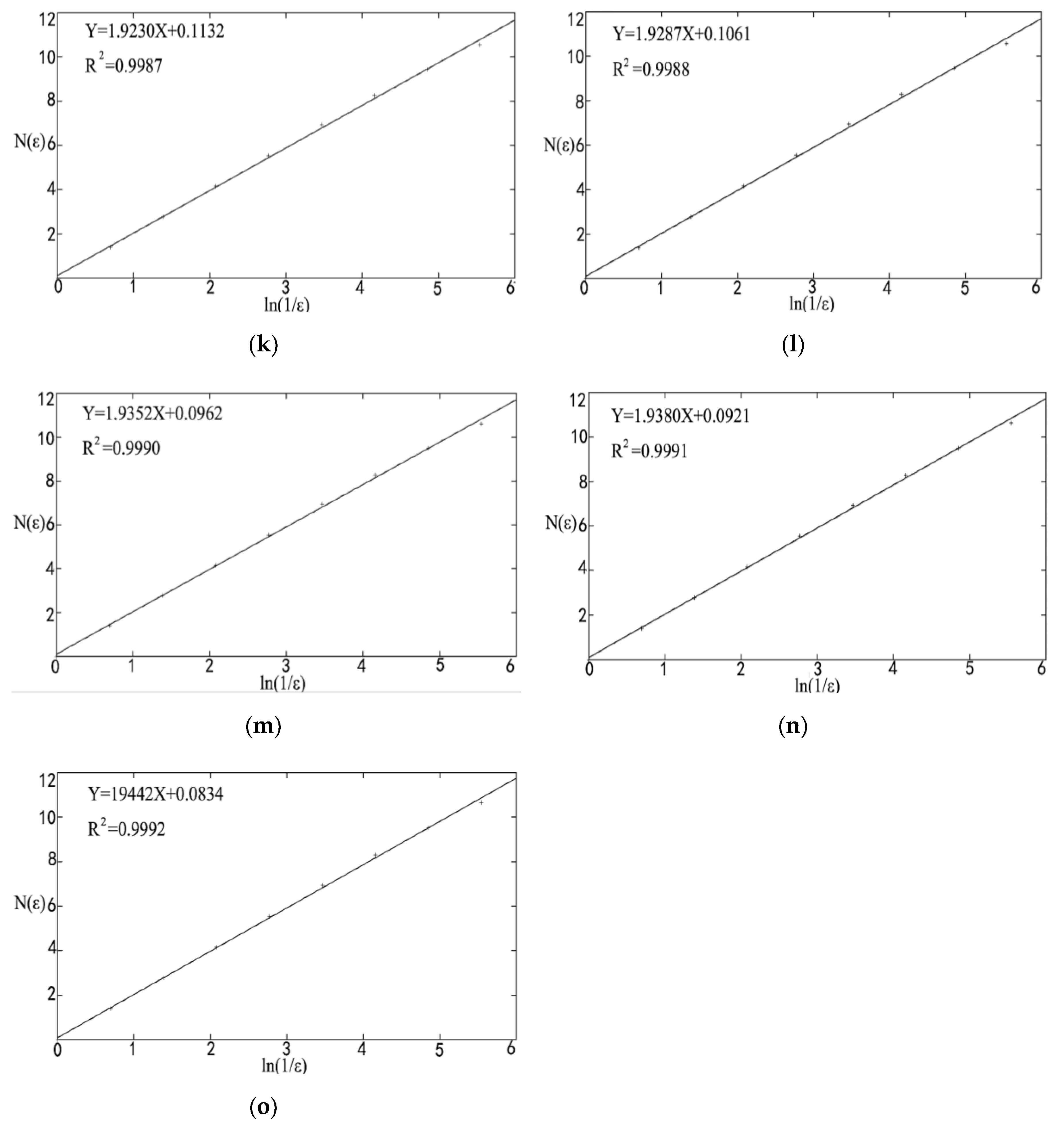

3.2.7. Calculation of the Fractal Dimension

3.2.8. Relationship Between Fractal Dimension and Various Factors

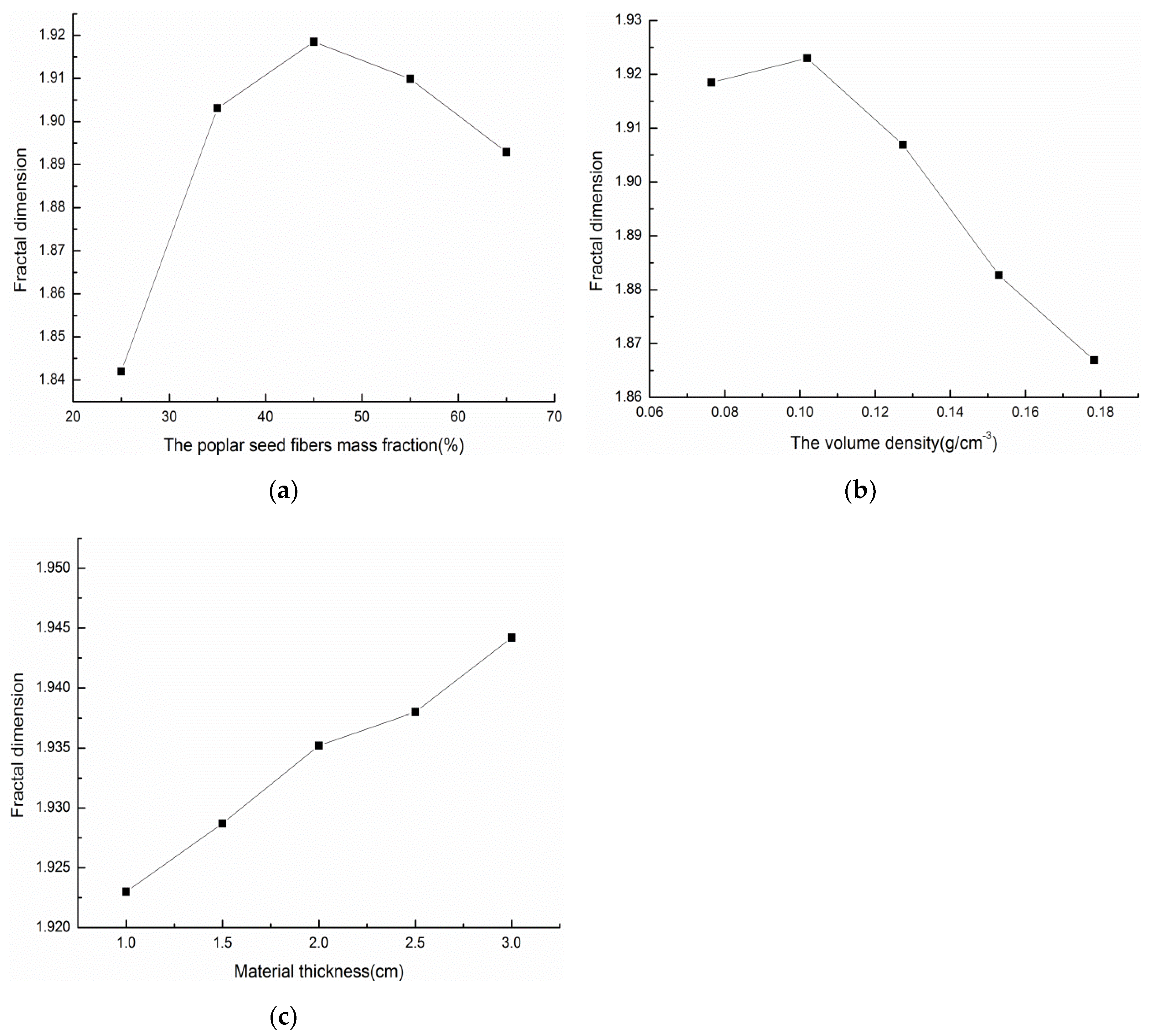

Relationship between the Fractal Dimension and the Mass Fraction of Poplar Seed Fibers, Material Density and Material Thickness

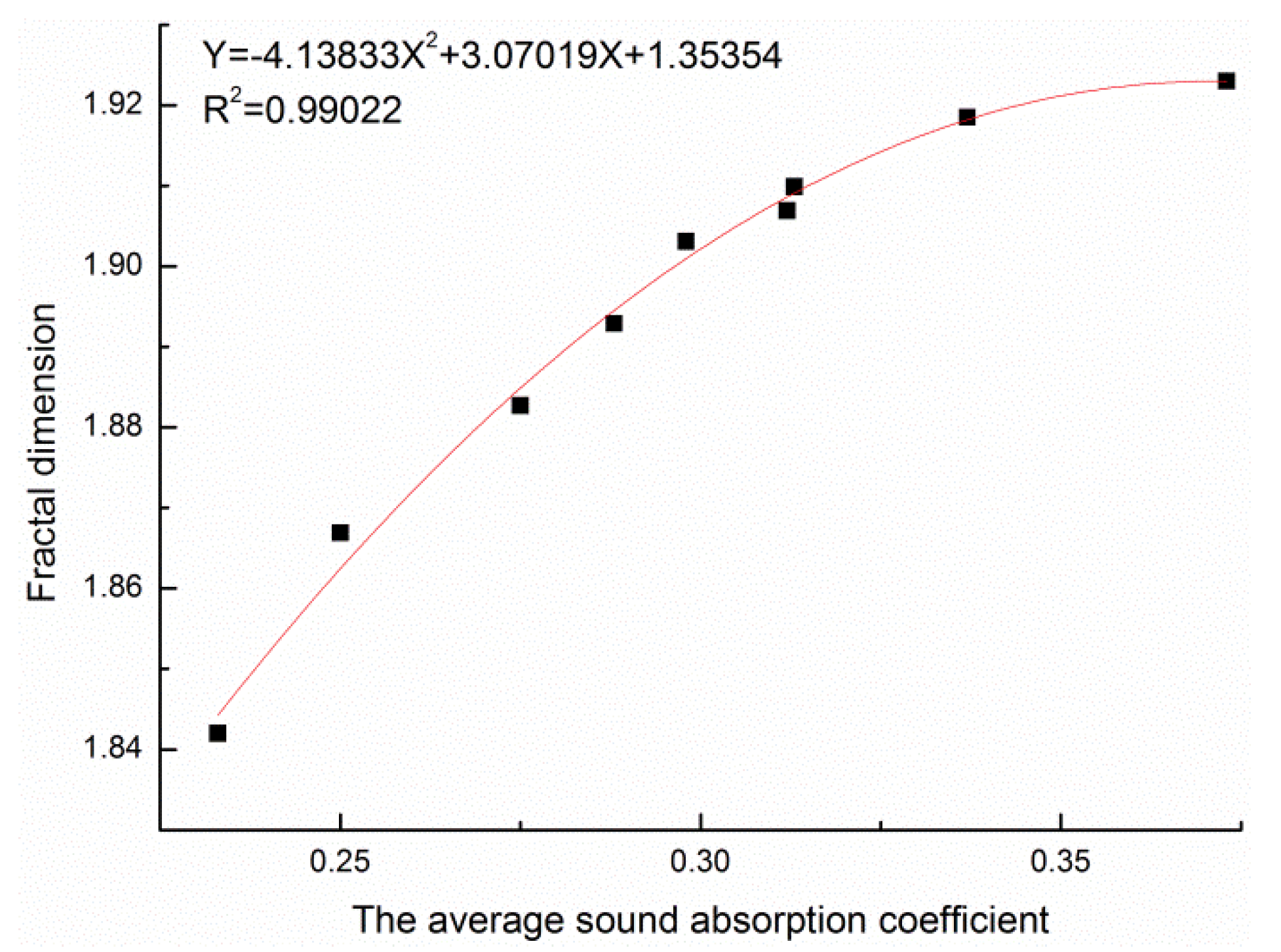

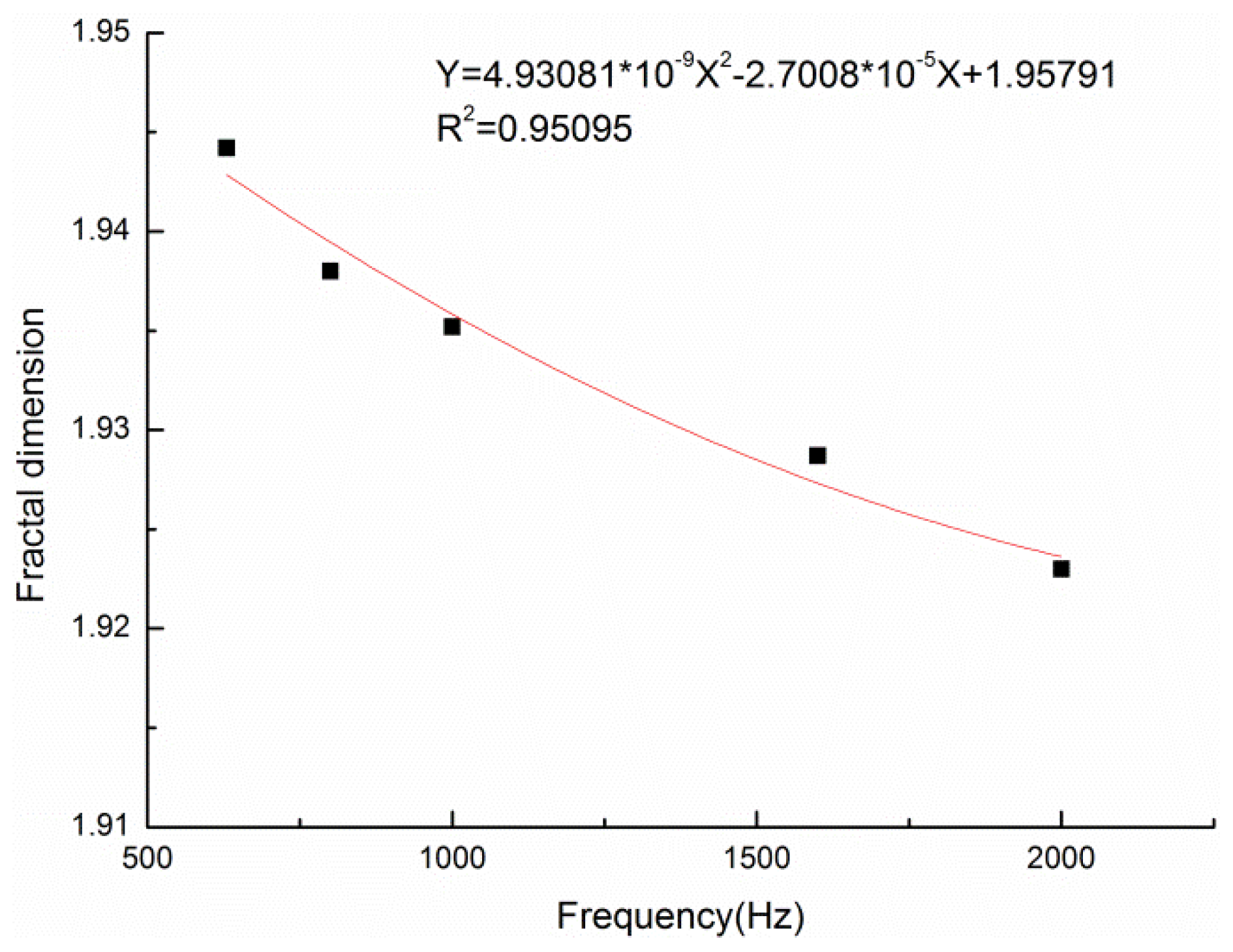

Relationship between Fractal Dimension and Sound Absorption Performance of Materials

4. Conclusions

- (1)

- The sound absorption properties of the composite materials were studied by the transfer function method. The effects of the mass fraction of poplar seed fibers, volume density, and material thickness of the composite materials on their sound absorption performance were studied. At a hot pressing temperature of 90 °C, a hot pressing pressure of 10 MPa, and a hot pressing time of 20 min., the results of single-factor experiments showed that the optimized technological conditions were: a mass fraction of poplar seed fibers of 45%, a volume density of the composite materials of 0.102 g/cm3, and a thickness of the composite materials of 30 mm. The sound absorption coefficient of the composite material that was prepared under the optimal process conditions was higher than 0.7, and the sound absorption frequency band was wide.

- (2)

- Using box-counting dimension method that was based on fractal theory, the fractal dimensions of the composite materials were calculated while using the Matlab program, and the relationships between the fractal dimensions and mass fractions of poplar seed fibers, the volume densities, and thicknesses of the composite materials were analyzed. Subsequently, quantitative relationships between the average sound absorption coefficient and the fractal dimension, and between the resonant sound absorption frequency and the fractal dimension were deduced. The fractal dimension was fitted to the average sound absorption coefficient of the composite materials, and the quantitative relationship was: Y = 4.13833X2 + 3.07019X + 1.35354, with a correlation coefficient of 0.99. The fractal dimension was fitted to the resonance absorption frequency and the fitting curve was: Y = 4.93081 × 10−9X2−2.7008 × 10−5X + 1.95791, with a correlation coefficient of 0.95. By fitting the relationships between the average sound absorption coefficient and the fractal dimension, and between the resonant sound absorption frequency and the fractal dimension, a quantitative relationship of fitting curves was obtained, providing a theoretical basis and an important guide for studying and designing better sound-absorbing composite materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Fang, S.Z. Silviculture of poplar plantation in China: A review. Chin. J. Appl. Ecol. 2008, 19, 2308–2316. [Google Scholar]

- Yin, J.H.; Lv, Y.C.; Zhang, J.Y.; Cai, Y.J. Property and collection application of poplar down fiber. Cotton Text. Technol. 2011, 39, 65–68. [Google Scholar]

- Chen, X.J. Harm of poplar seed fibers and its solution. Modern Agric. Technol. 2014, 43, 155–156. [Google Scholar]

- Guo, Q.L. Harm of poplar seed fibers and its solution. Friends Farms Get. Rich 2019, 63, 203. [Google Scholar]

- Wang, J.H.; Chen, S.C.; Shao, J.L.; Chou, L.M.; Guo, L. Current situation, problems and prospects of poplar and willow flying floc control in Beijing. Landsc. Arch. Beijing 2011, 27, 48–50. [Google Scholar]

- Chen, H.; Mei, C.T.; Luo, W.; Xu, M.S.; Ren, Y.; Yin, W.X. Comparative study on microstructure of flocculant/catkin with natural fiber. Spectrosc. Spect. Anal. 2018, 38, 929–932. [Google Scholar]

- Liu, J.; Xu, Z.L.; Zeng, B.N.; Chen, W. Morphology analysis of the poplar seed hair fibers and characterization and preparation as a thermal insulation material. J. Wuhan Univ. Sci. Eng. 2016, 29, 3–7. [Google Scholar]

- Xu, Y.F.; Su, Q.C.; Shen, H.; Xu, G. Physicochemical and sorption characteristics of poplar seed fiber as a natural oil sorbent. Text. Res. J. 2019, 89, 4186–4194. [Google Scholar] [CrossRef]

- Sebeia, N.; Jabli, M.; Ghith, A.; El Ghoul, Y.; Alminderej, F.M. Populus tremula, nerium oleander and pergularia tomentosa seed fibers as sources of cellulose and lignin for the bio-sorption of methylene blue. Int. J. Biol. Macromol. 2018, 121, 655–665. [Google Scholar] [CrossRef]

- Li, M.M.; Li, Y.Z.; An, Q.D.; Gong, Y.M.; Liu, Y.F.; Guo, J. Green planting silver nanoparticles on populus fibers and the catalytic application. Res. Chem. Intermed. 2018, 44, 5669–5691. [Google Scholar] [CrossRef]

- Wang, X.D.; Liu, Y.J.; Li, F.J.; Zhi, L.L. Poplar catkin: A natural biomaterial for highly specific and efficient enrichment of sialoglycopeptides. Chin. Chem. Lett. 2017, 28, 1018–1026. [Google Scholar] [CrossRef]

- Li, L.; Hu, T.; Sun, H.; Zhang, J.; Wang, A. Correction to “Pressure-Sensitive and Conductive Carbon Aerogels from Poplars Catkins for Selective Oil Absorption and Oil/Water Separation”. ACS Appl. Mater. Inter. 2017, 9, 18001–18007. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.L.; Yang, Z.; Wang, Z.J.; Zhang, F.Q.; You, F.; Yao, C. Preparation and sound absorption properties of a barium titanate/nitrile butadiene rubber-polyurethane foam composite with multilayered structure. Materials 2018, 11, 474. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.I.; Mohammad, J.; Jesuarockiam, N. Void content, tensile, vibration and acoustic properties of kenaf/bamboo fiber reinforced epoxy hybrid composites. Materials 2019, 12, 2094. [Google Scholar]

- Han, L. Properties of kapok fiber and its application suggestion in spinning and weaving. Cotton Text. Technol. 2010, 38, 61–64. [Google Scholar]

- Shen, J.; Xiang, H.F.; Zhang, X.Y.; Xiao, H.; Zhang, X.L.; Shi, M.W.; Xu, J. Sound Absorption and Noise Reduction Material and Application Thereof. CN101593515A, 2 December 2009. [Google Scholar]

- Chen, Y. Study on Fractal Properties and Production Process Design of Microfiber Nonwovens. Ph.D. Thesis, Tianjin Polytechnic University, Tianjin, China, May 2016. [Google Scholar]

- Wang, Y.H. Porosity Detection of T700/BMI and Fractal Study on Pore Morphology Characteristics. Master’s Thesis, Nanchang Hangkong University, Nanchang, Hongkong, December 2018. [Google Scholar]

- Lyu, L.H.; Liu, Y.J.; Bi, J.H.; Guo, J. Sound absorption properties of DFs/EVA composites. Polymers 2019, 11, 811. [Google Scholar] [CrossRef]

- Yang, S.; Li, M.S. Relationship between fractal structure and warmth retention properties of wool fiber assembly. J. Text. Res. 2017, 38, 11–15. [Google Scholar]

- Yang, X.H. Expression and Fractal Simulation of Morphologic Structures of Nonwovens. Ph.D. Thesis, Soochow University, Soochow, China, August 2013. [Google Scholar]

- Lyu, L.H.; Li, C.W.; Wu, C.X. Preparation of discarded peanut shell/EVA composite and its sound absorption properties. Adv. Text. Technol. 2018, 33, 12–16. [Google Scholar]

- Qian, J.M.; Li, X.X. Sound absorption mechanism of polymer based composite foams. Noise Vib. Control 2000, 5, 41–43. [Google Scholar]

- Su, W.; Li, X.Y.; Liu, S.S. Discussion on feasibility of nonwoven sound-absorbing materials used for road noise-deafening barrier. J. Zhejiang Fashion Inst. Technol. 2009, 2, 8–12. [Google Scholar]

- Ma, Y.X. Study on the Sound Absorption Properties of Composite Needle-Punched Nonwovens. Master’s Thesis, Donghua University, Shanghai, China, January 2010. [Google Scholar]

- Liu, Y.F.; Jing, D.S. Pore Structure of grain-size fractal granular material. Materials. 2019, 12, 2053. [Google Scholar] [CrossRef] [PubMed]

- Li, Y. Historical architecture facade dimensional algorithm and evolution research. Shanxi Architect. 2020, 11, 36–38. [Google Scholar]

- Yang, S. Study of Structural Characteristics and Acoustic Properties of Fiber. Ph.D. Thesis, Donghua University, Shanghai, China, 2010.

- Li, H.T.; Zheng, Y. MATLAB Programming Tutorial; Higher Education Press: Beijing, China, 2002. [Google Scholar]

- Zhao, M. Mechanical Vibration and Noise; Science Press: Beijing, China, 2004; pp. 221–223. [Google Scholar]

- Peng, L.M.; Wang, J.F.; Fu, F.; Wang, D.; Zhu, G.Y. Experimental study on sound absorption of wood fiber/polyester fiber composite materials. J. Build. Mater. 2015, 18, 172–176. [Google Scholar]

- Yang, S.; Yu, W.D.; Pan, N. Effect of fractal dimension of voids on sound absorption properties of nonwovens. J. Text. Res. 2010, 31, 28–32. [Google Scholar]

- Yang, H.; Luo, T.; Li, L.; Rao, Y.; Li, W.; Liu, K.W.; Qiu, Z. Research on drilling bit positioning strategy based on SINS MWD system. IEEE Access 2019, 7, 109398–109410. [Google Scholar] [CrossRef]

| Mass Fraction (%) | 125 Hz | 250 Hz | 500 Hz | 1000 Hz | 2000 Hz | 4000 Hz | NRC | Average Sound Absorption Coefficient |

|---|---|---|---|---|---|---|---|---|

| 25 | 0.07 | 0.04 | 0.07 | 0.16 | 0.30 | 0.76 | 0.143 | 0.233 |

| 35 | 0.12 | 0.09 | 0.08 | 0.21 | 0.47 | 0.82 | 0.213 | 0.298 |

| 45 | 0.11 | 0.08 | 0.07 | 0.30 | 0.61 | 0.85 | 0.265 | 0.337 |

| 55 | 0.07 | 0.07 | 0.06 | 0.36 | 0.56 | 0.76 | 0.263 | 0.313 |

| 65 | 0.13 | 0.11 | 0.13 | 0.31 | 0.39 | 0.66 | 0.235 | 0.288 |

| Volume Density (g/cm3) | 125 Hz | 250 Hz | 500 Hz | 1000 Hz | 2000 Hz | 4000 Hz | NRC | Average Sound Absorption Coefficient |

|---|---|---|---|---|---|---|---|---|

| 0.076 | 0.11 | 0.08 | 0.07 | 0.30 | 0.61 | 0.80 | 0265 | 0.337 |

| 0.102 | 0.09 | 0.07 | 0.27 | 0.37 | 0.66 | 0.78 | 0.343 | 0.373 |

| 0.127 | 0.11 | 0.03 | 0.27 | 0.37 | 0.50 | 0.63 | 0.283 | 0.312 |

| 0.153 | 0.11 | 0.05 | 0.17 | 0.35 | 0.47 | 0.50 | 0.260 | 0.275 |

| 0.178 | 0.15 | 0.06 | 0.15 | 0.32 | 0.34 | 0.48 | 0.218 | 0.250 |

| Material Thicknesses (mm) | 125 Hz | 250 Hz | 500 Hz | 1000 Hz | 2000 Hz | 4000 Hz | NRC | Average Sound Absorption Coefficient |

|---|---|---|---|---|---|---|---|---|

| 10 | 0.09 | 0.07 | 0.27 | 0.37 | 0.66 | 0.78 | 0.343 | 0.373 |

| 15 | 0.11 | 0.09 | 0.28 | 0.54 | 0.69 | 0.74 | 0.400 | 0.408 |

| 20 | 0.12 | 0.12 | 0.33 | 0.65 | 0.70 | 0.75 | 0.450 | 0.442 |

| 25 | 0.13 | 0.15 | 0.50 | 0.66 | 0.62 | 0.75 | 0.483 | 0.468 |

| 30 | 0.19 | 0.20 | 0.63 | 0.66 | 0.62 | 0.73 | 0.528 | 0.505 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Lyu, L.; Guo, J.; Wang, Y. Sound Absorption Performance of the Poplar Seed Fiber/PCL Composite Materials. Materials 2020, 13, 1465. https://doi.org/10.3390/ma13061465

Liu Y, Lyu L, Guo J, Wang Y. Sound Absorption Performance of the Poplar Seed Fiber/PCL Composite Materials. Materials. 2020; 13(6):1465. https://doi.org/10.3390/ma13061465

Chicago/Turabian StyleLiu, Yingjie, Lihua Lyu, Jing Guo, and Ying Wang. 2020. "Sound Absorption Performance of the Poplar Seed Fiber/PCL Composite Materials" Materials 13, no. 6: 1465. https://doi.org/10.3390/ma13061465

APA StyleLiu, Y., Lyu, L., Guo, J., & Wang, Y. (2020). Sound Absorption Performance of the Poplar Seed Fiber/PCL Composite Materials. Materials, 13(6), 1465. https://doi.org/10.3390/ma13061465