Correlation between Magnetic Properties and Chemical Composition of Non-Oriented Electrical Steels Cut through Different Technologies

Abstract

1. Introduction

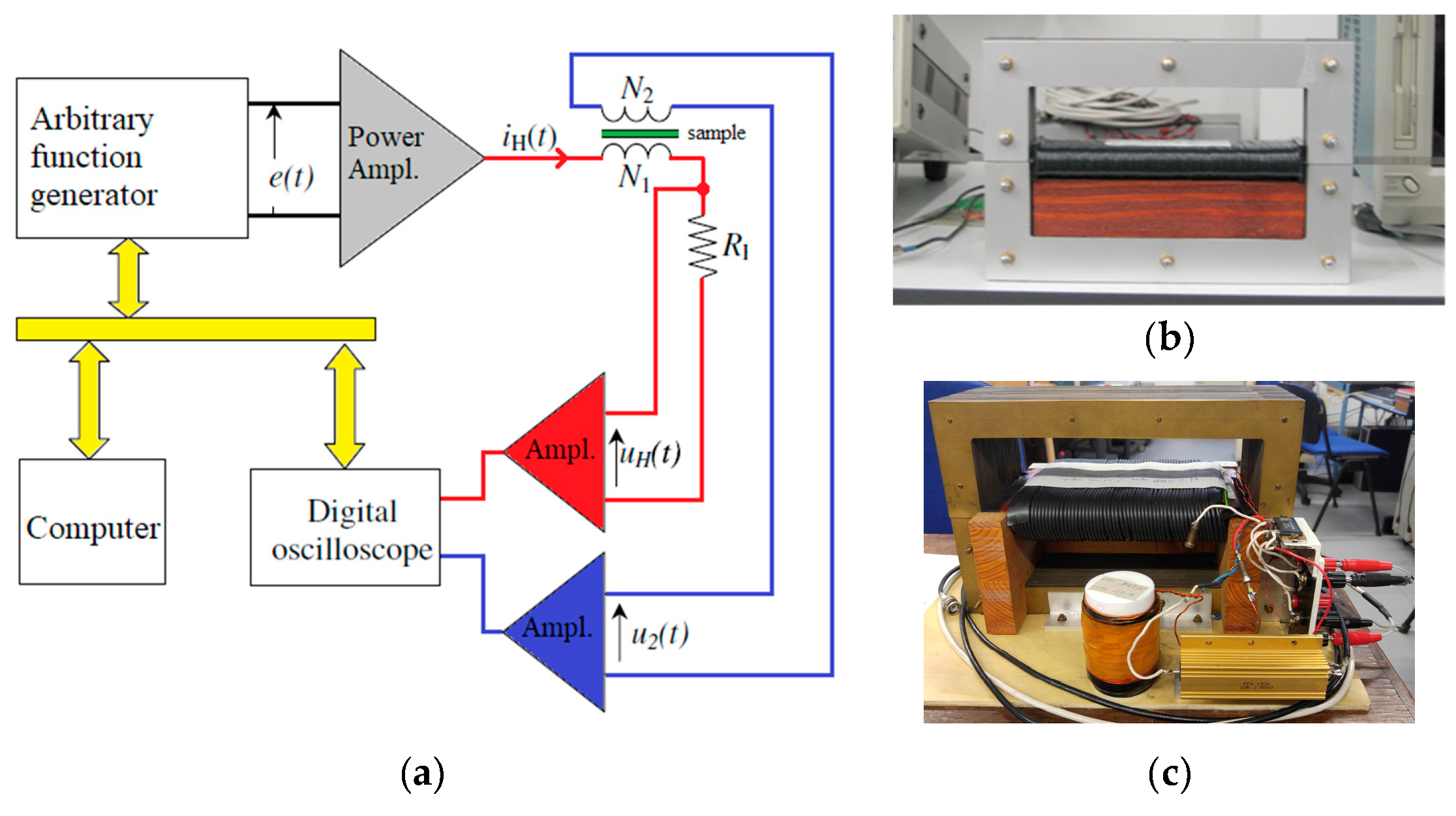

2. Materials and Methods

- -

- In the case of mechanical cutting, a Krrass Q11-2X2500 electric shearing machine (Nanjing Klaus CNC Machinery Co., Ltd. (KRRASS), Nanjing, China) was used. The device is a steel-welded and gate-type with a chain drive and it is adequate to cut strips of metals having less than 3 mm in thickness [23].

- -

- For the laser cut, a Trumpf TruFlow CO2 laser 3030 Classic (TRUMPF GmbH + Co. KG., Stuttgart, Germany) with a maximum power of 3200 W was used. The laser wavelength is 10.6 µm and the beam quality K 0.6. This machine has a correlation of 2% between beam stability and laser power. The generated cutting edge is extremely smooth and post-processing operations are not necessary. Usually, the final result is a micro-burr-free cutting sample [24].

- -

- A Maxiem 1530 (OMAX Corp., Kent, WA, USA) with the water-jet supplied by a high-pressure water pump, which uses a mixture of Garnet 80 mesh, was selected to cut the samples. This machine is equipped with a linear motion system, based on linear encoders, in order to provide a high-quality cut edge [25].

- -

- A Sodick Wire EDM VL600Q machine (Sodick Co., Ltd., Yokohama, Japan) was involved to cut the samples. This equipment has a rigid linear motor, which provides a good quality cut edge. It incorporates a ceramic material that has a high abrasion resistance and a low thermal expansion coefficient [26].

3. Results

3.1. Chemical Composition of the Investigated Alloys

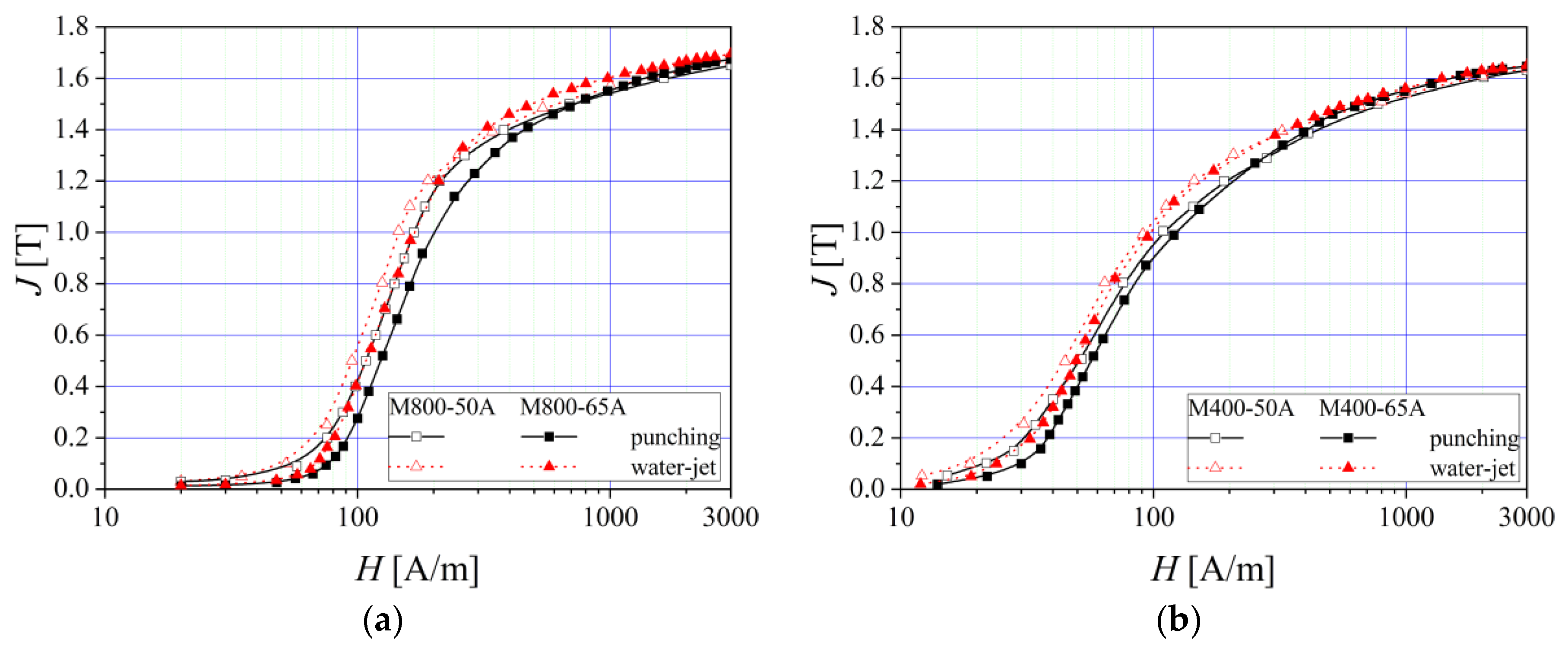

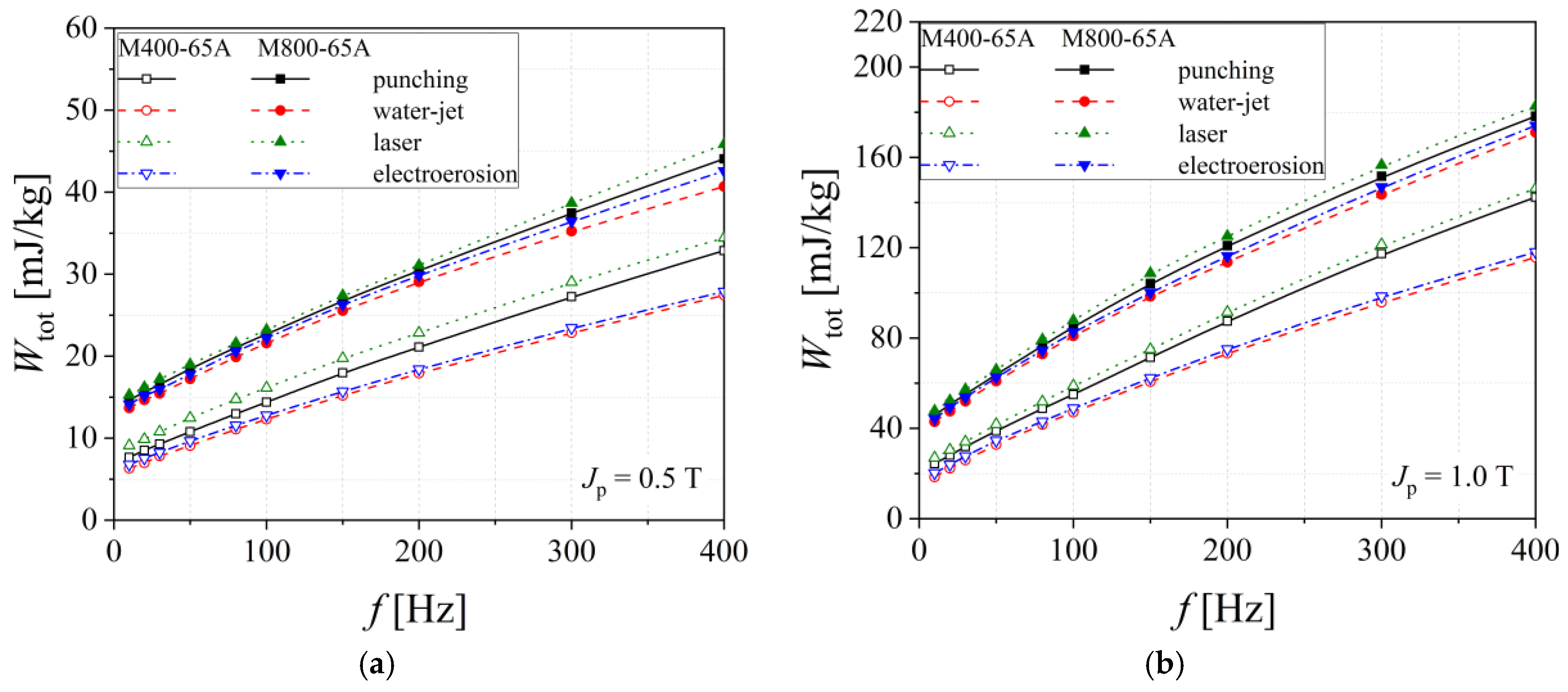

3.2. Influence of the Cutting Technology on the Normal Magnetization Curve, Energy Loss, and Magnetic Permeability Analysis

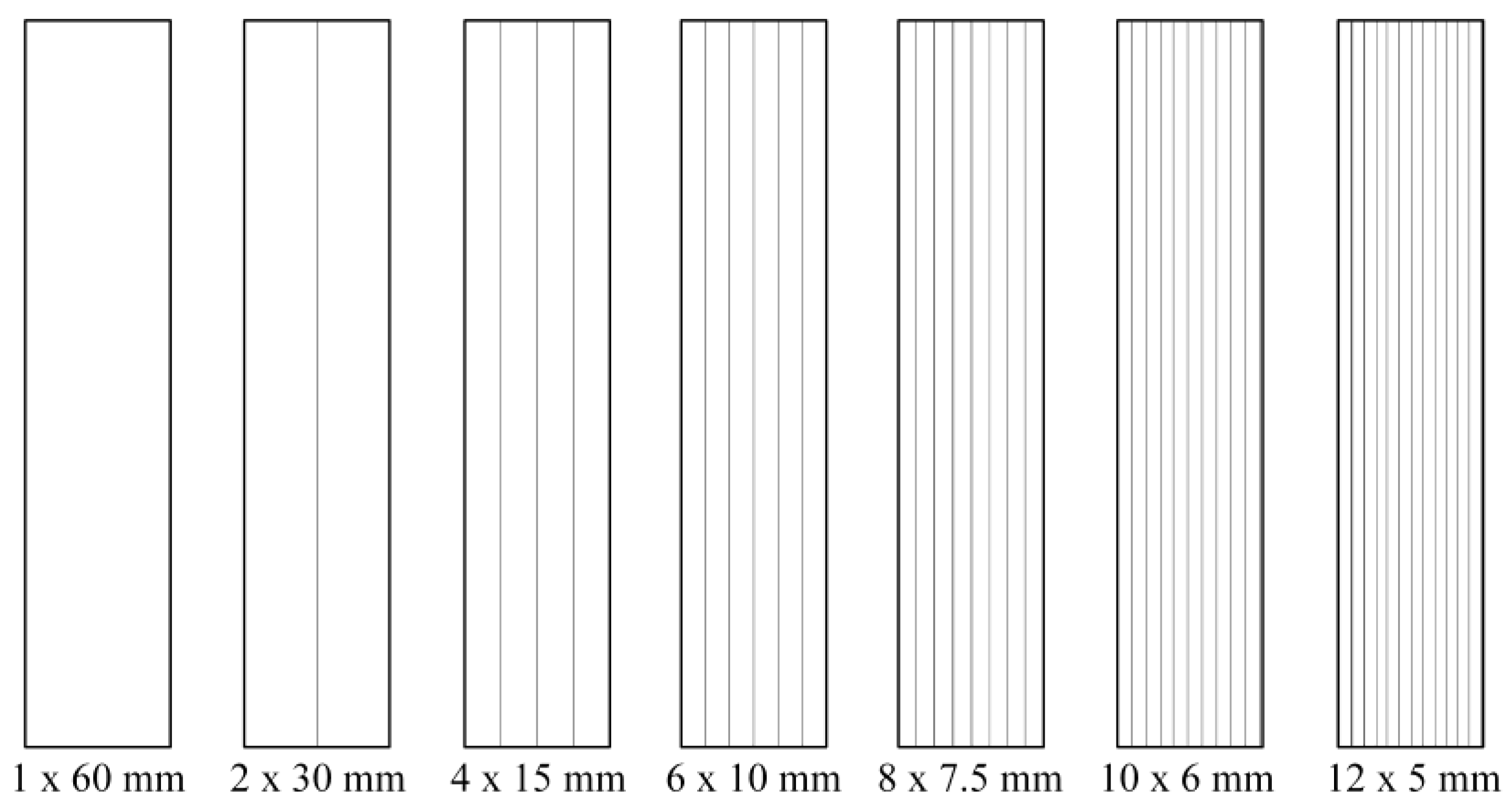

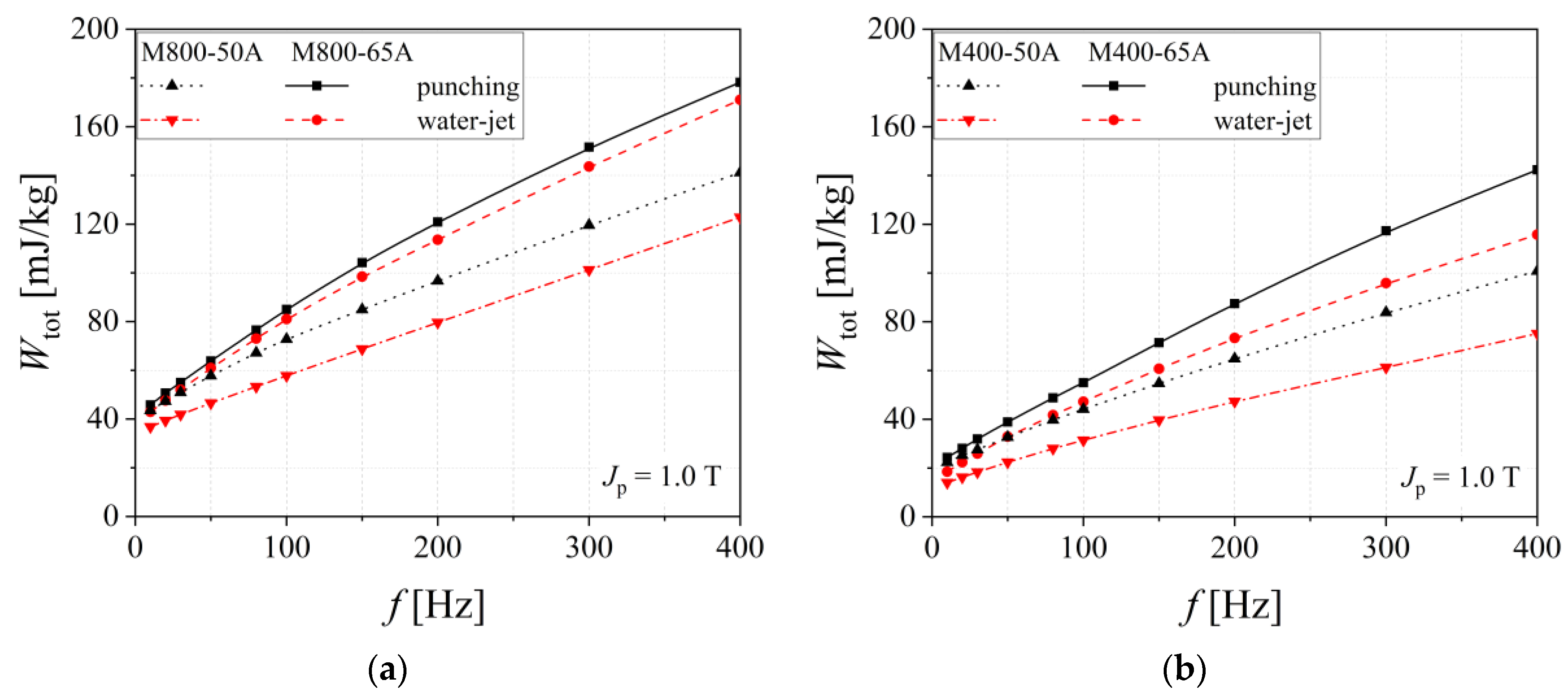

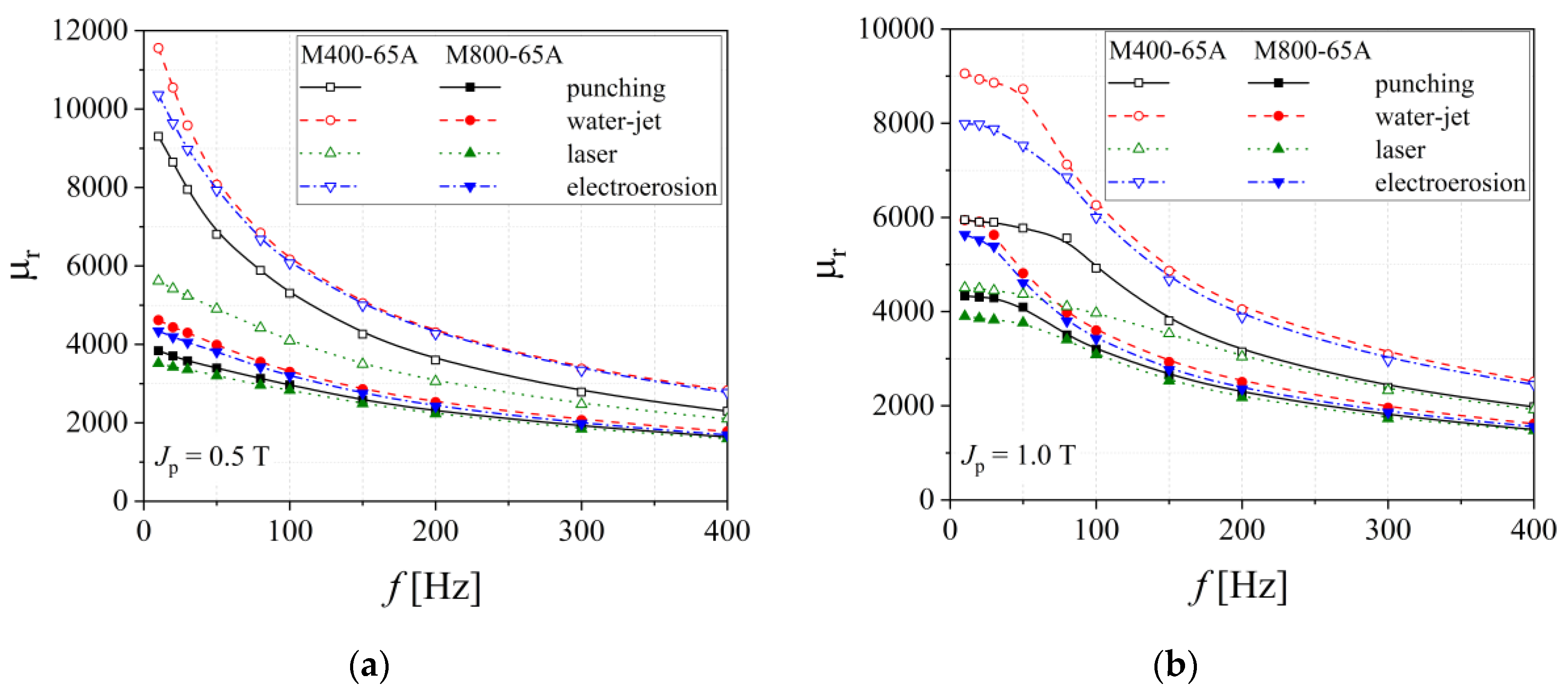

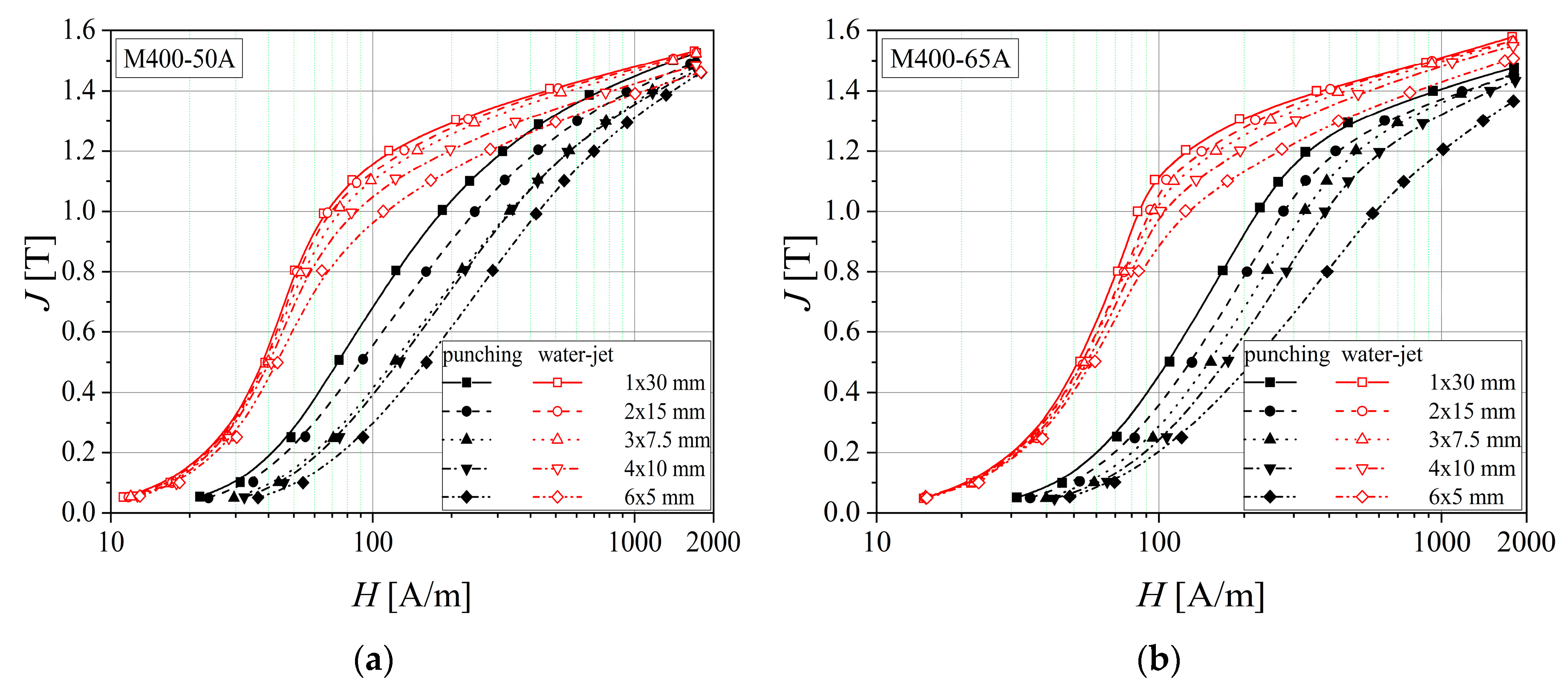

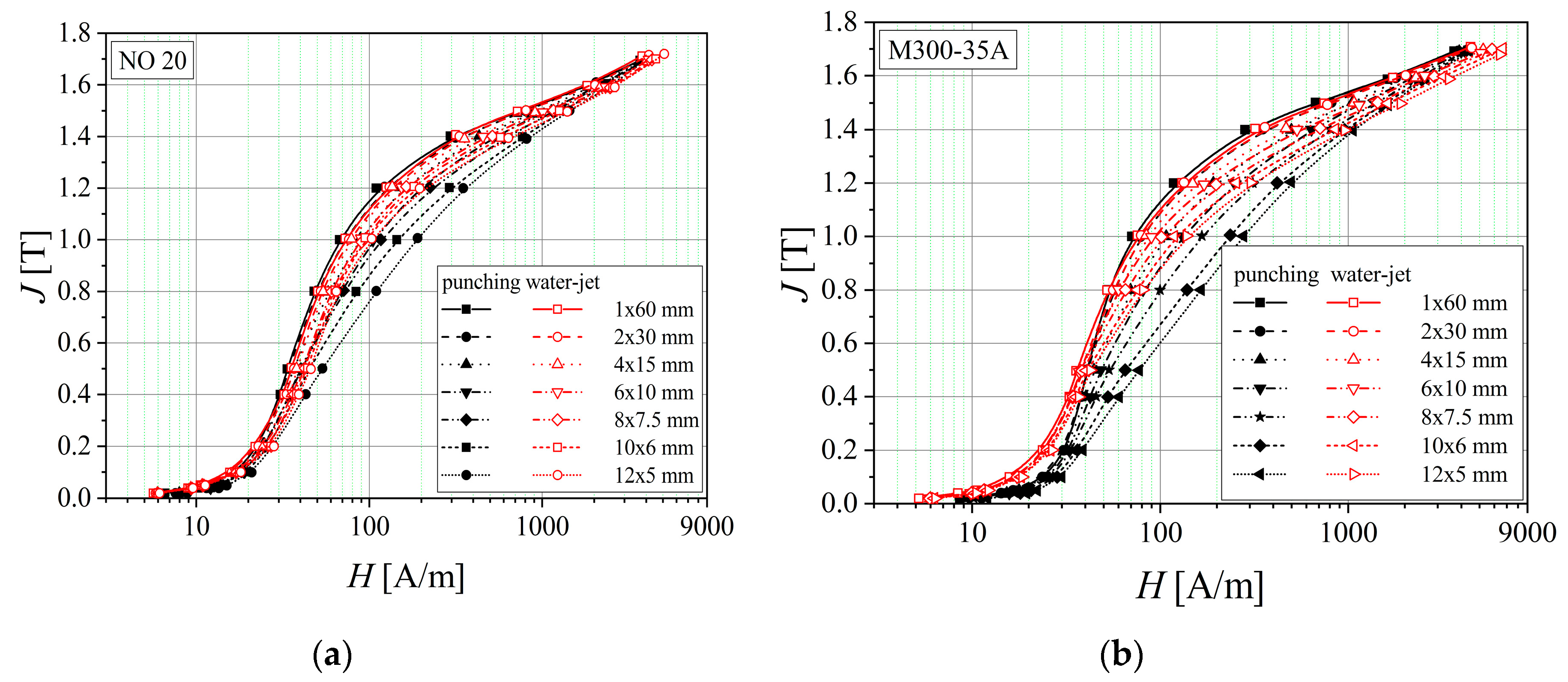

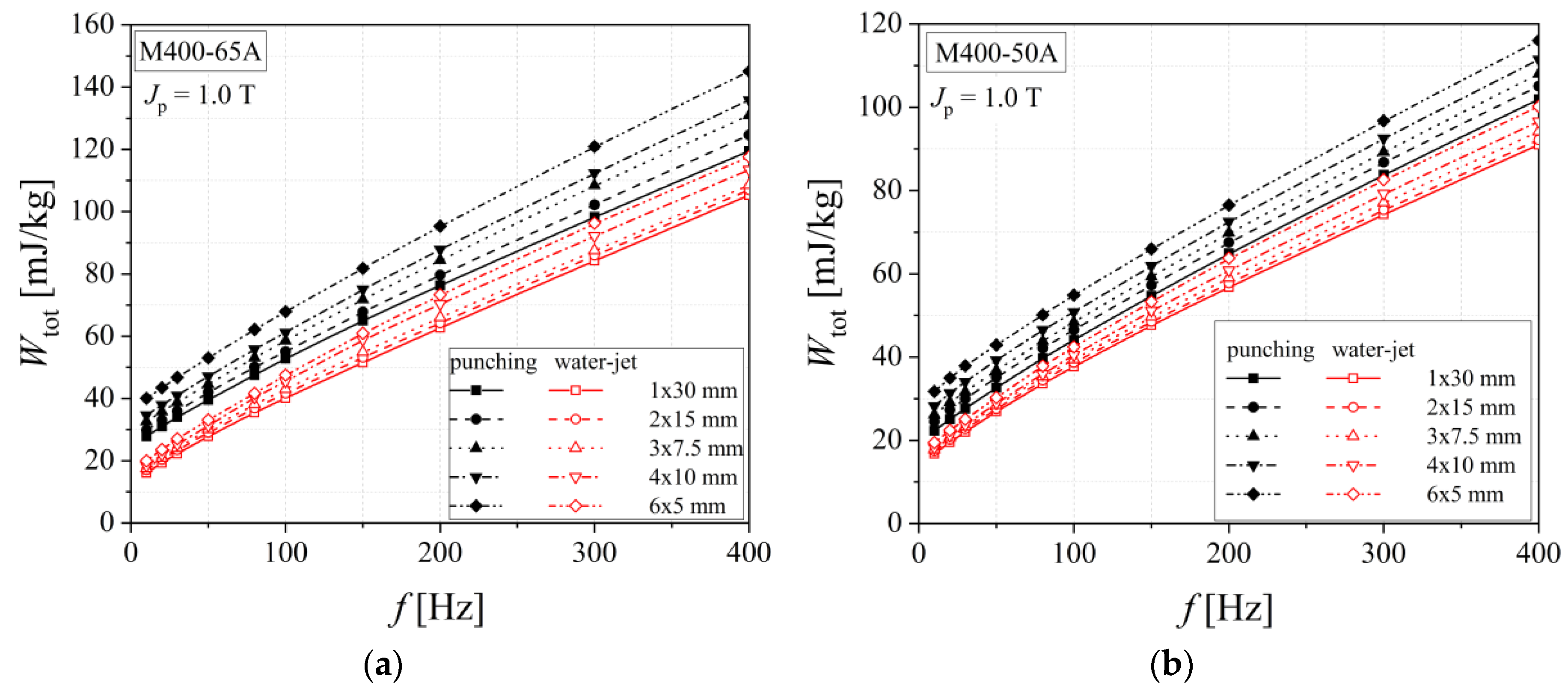

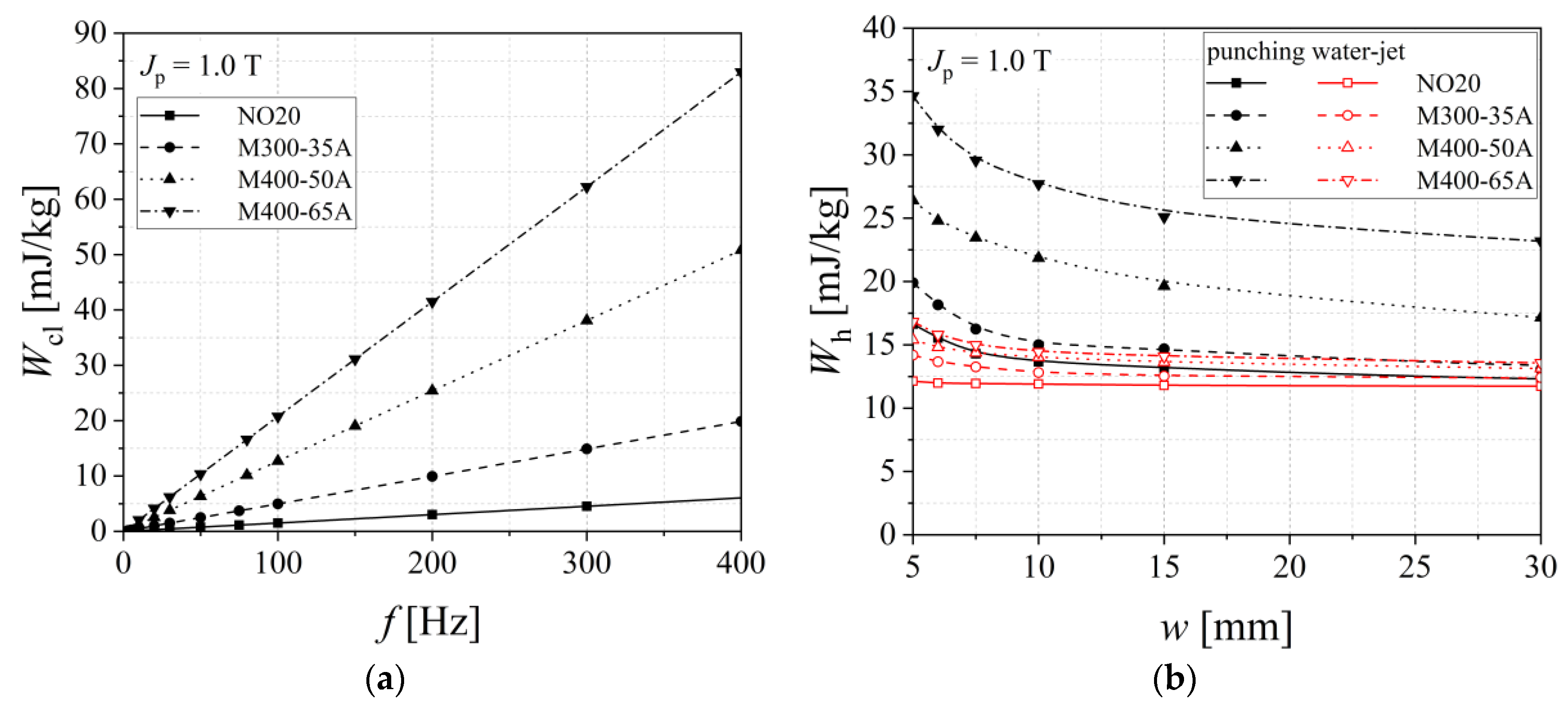

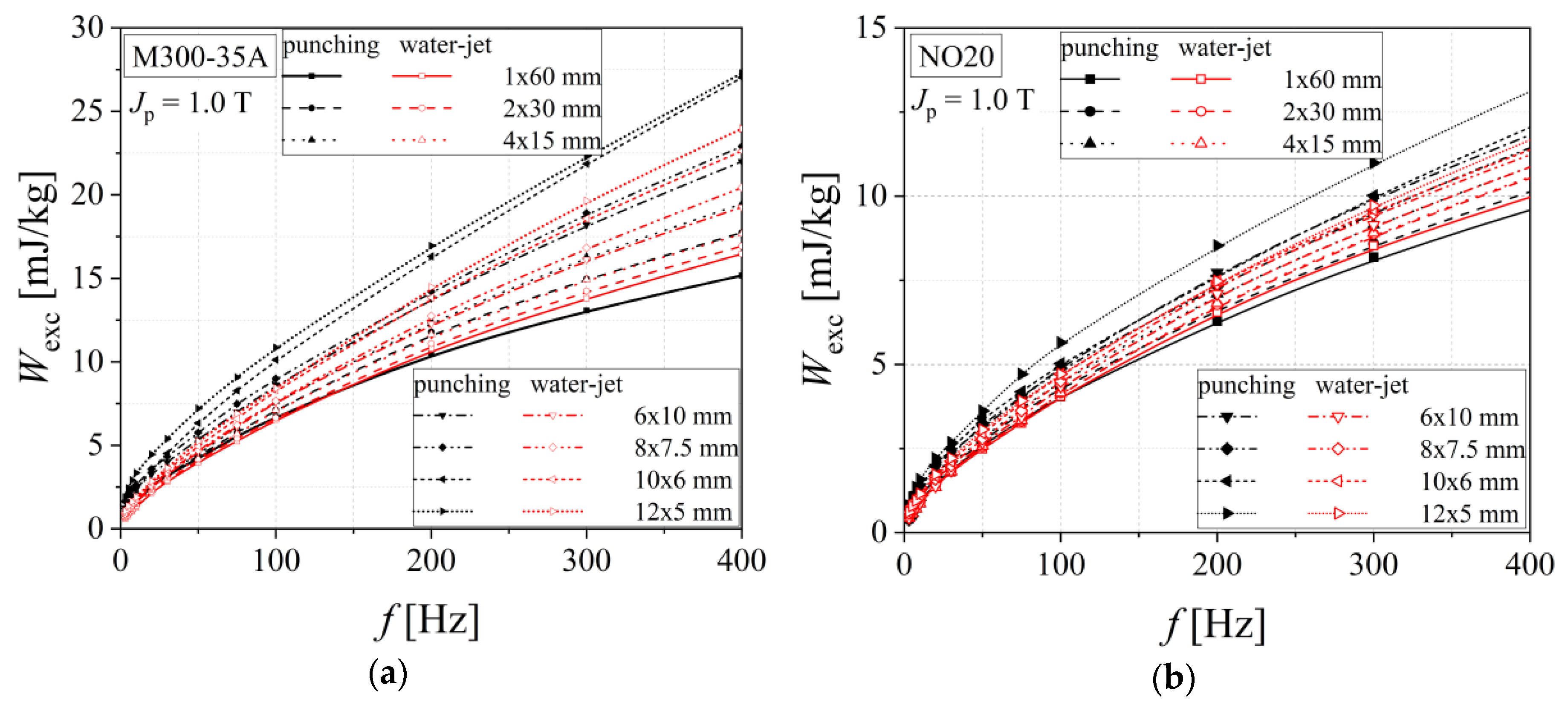

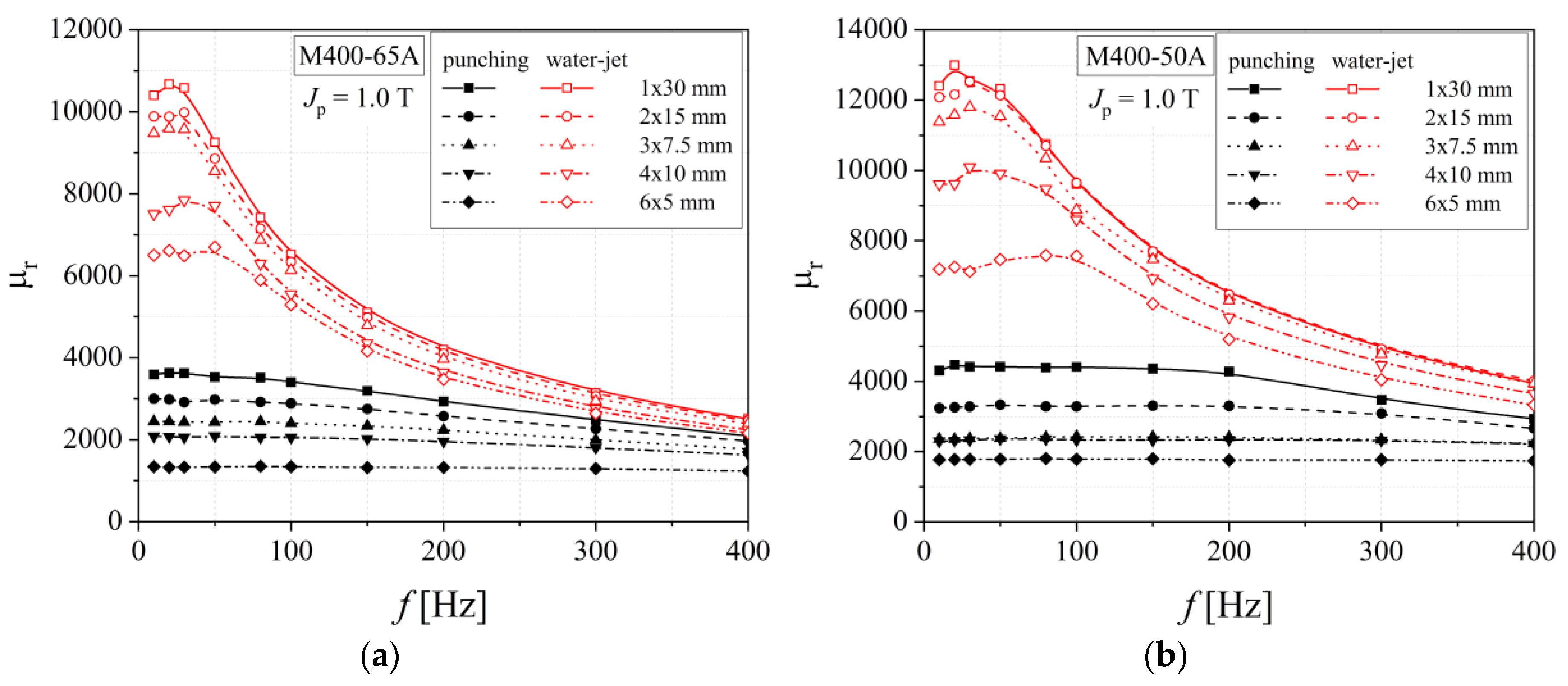

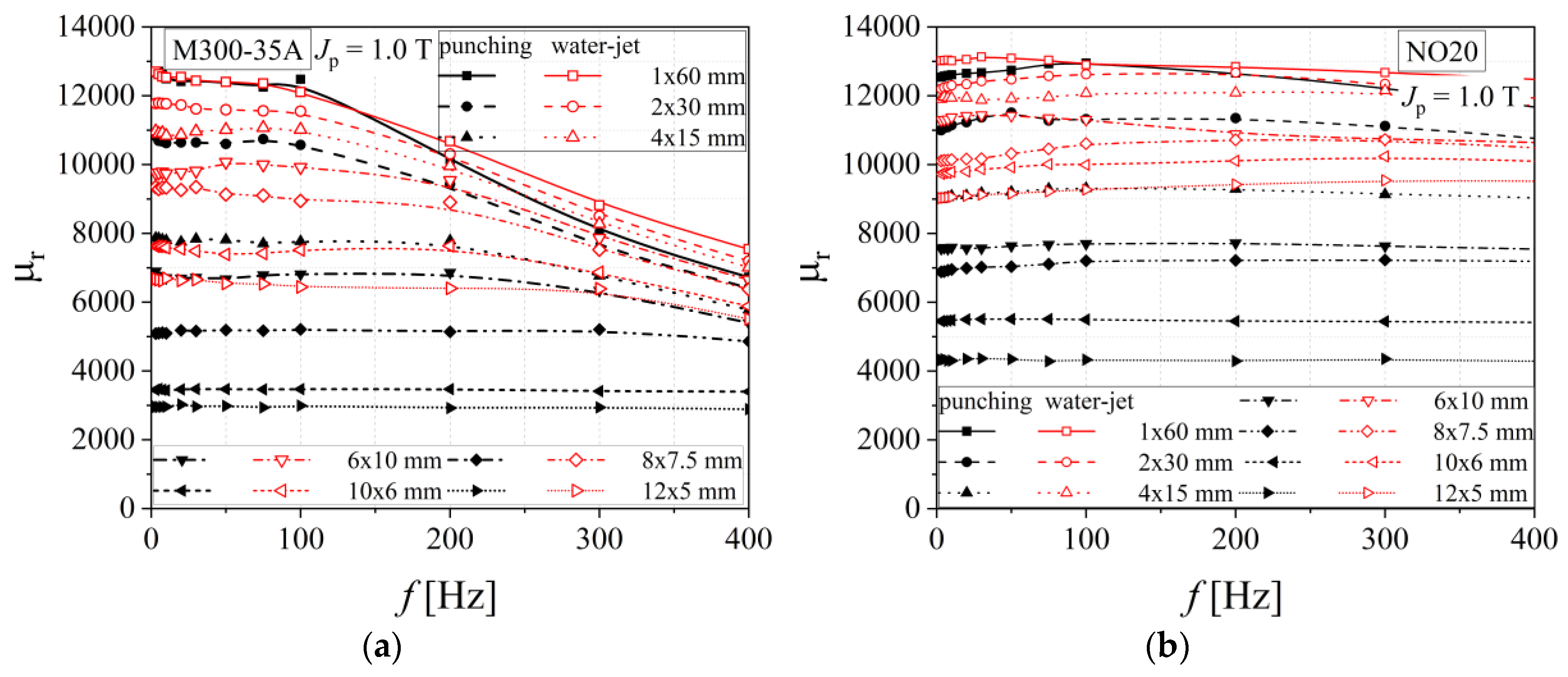

3.3. Influence of the Icreased Cutting Density on the Energy Losses and Magnetic Permeability Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bertoldi, P. EU Member States Energy Efficiency Policies for the industrial sector based on the NEEAPs analysis. In EEMODS 2017 Conference Proceedings, Rome, Italy, 6–8 September 2017; Publications Office of the European Union: Luxembourg, 2017; pp. 1–18. [Google Scholar]

- Miller, L.; Soulliere, K.; Sawyer-Beaulieu, S.; Tseng, S.; Tam, E. Challenges and Alternatives to Plastics Recycling in the Automotive Sector. Materials 2014, 7, 5883–5902. [Google Scholar] [CrossRef]

- Ramos, A.; Afonso Teixeira, C.; Rouboa, A. Environmental Analysis of Waste-to-Energy—A Portuguese Case Study. Energies 2018, 11, 548. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; Ferraz, M.; Teixeira, C.E.; Rozenfeld, H. The Deployment of Product-Related Environmental Legislation into Product Requirements. Sustainability 2016, 8, 332. [Google Scholar] [CrossRef]

- Ferrara, R. The Smart City and the Green Economy in Europe: A Critical Approach. Energies 2015, 8, 4724–4734. [Google Scholar] [CrossRef]

- Gómez, P.; Elduque, D.; Sarasa, J.; Pina, C.; Javierre, C. Influence of Composition on the Environmental Impact of a Cast Alluminum Alloy. Materials 2016, 9, 412. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez Aguilar, C.M.; Panameño, R.; Perez Velazquez, A.; Angel Álvarez, B.E.; Kiperstok, A.; César, S.F. Cleaner Production Applied in a Small Furniture Industry in Brazil: Addressing Focused Changes in Design to Reduce Waste. Sustainability 2017, 9, 1867. [Google Scholar] [CrossRef]

- Casamayor, J.L.; Su, D. Integration of eco-design tools into the development of eco-lighting products. J. Clean. Prod. 2013, 47, 32–42. [Google Scholar] [CrossRef]

- Grilli, M.L.; Bellezze, T.; Gamsjäger, E.; Rinaldi, A.; Novak, P.; Balos, S.; Piticescu, R.R.; Ruello, M.L. Solutions for Critical Raw Materials under Extreme Conditions: A Review. Materials 2017, 10, 285. [Google Scholar] [CrossRef]

- Bertotti, G.; Fiorillo, F. Crystalline Fe-Si, Fe-Al, and Fe-Si-Al alloys. In Landolt-Börnstein, Magnetic Properties of Metals; Wijn, H.P.J., Ed.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1994; Volume 19, pp. 33–143. ISBN 3-540-55590-0. [Google Scholar]

- Takahashi, N.; Suga, Y.; Kobayashi, H. Recent developments in grain-oriented silicon steel. J. Magn. Magn. Mater. 1996, 160, 98–101. [Google Scholar] [CrossRef]

- Takahashi, S.; Kobayashi, S.; Kikuchi, H.; Kamada, Y. Relationship between mechanical and magnetic properties in cold rolled low carbon steel. J. Appl. Phys. 2006, 100, 113908. [Google Scholar] [CrossRef]

- Fiorillo, F.; Kuepferling, M.; Appino, C. Magnetic hysteresis and Barkhausen noise in plastically deformed steel sheets. Metals 2018, 8, 15. [Google Scholar] [CrossRef]

- Bertotti, G. Hysteresis in Magnetism; Academic Press: San Diego, CA, USA, 1998. [Google Scholar]

- Kurosaki, Y.; Mogi, H.; Fujii, H.; Kubota, T.; Shiozaki, M. Importance of punching and workability in non-oriented electrical steel sheets. J. Magn. Magn. Mater. 2008, 320, 2474–2480. [Google Scholar] [CrossRef]

- Kedous-Lebouc, A.; Messal, O.; Youmssi, A. Joint punching and frequency effects on practical magnetic characteristics of electrical steels for high-speed machines. J. Magn. Magn. Mater. 2017, 426, 658–665. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Liu, H.; Li, C.; Cao, G.; Liu, Z.; Wang, G. Microstructure, texture and magnetic properties of strip-cast 1.3% Si non-oriented electrical steel. J. Magn. Magn. Mater. 2012, 324, 3328–3333. [Google Scholar] [CrossRef]

- Ghosh, P.; Chromik, R.R.; Knight, A.M.; Wakade, S.G. Effect of metallurgical factors on the bulk magnetic properties of non-oriented electrical steels. J. Magn. Magn. Mater. 2014, 324, 42–51. [Google Scholar] [CrossRef]

- Lee, K.M.; Huh, M.Y.; Lee, H.J.; Park, J.T.; Kim, J.S.; Shin, E.J.; Engler, O. Effect of hot band grain size on development of textures and magnetic properties in 2.0% Si non-oriented electrical steel sheet. J. Magn. Magn. Mater. 2015, 396, 53–64. [Google Scholar] [CrossRef]

- He, Y.; Hilinski, E.J. Texture and magnetic properties of non-oriented electrical steels processed by an unconventional cold rolling scheme. J. Magn. Magn. Mater. 2016, 405, 337–352. [Google Scholar] [CrossRef]

- Ramadan, R.; Ibrahim, S.A.; Farag, M.; Elzatahry, A.A.; Es-Saheb, M.H. Processing optimization and characterization of magnetic non-oriented electrical silicon steel. Int. J. Electrochem. Sci. 2012, 7, 3242–3251. [Google Scholar]

- Landgraf, F.J.G.; Teixeira, J.C.; Emura, M.; de Campos, M.F.; Muranaka, C.S. Separating components of the hysteresis loss of non-oriented electrical steels. Mater. Sci. Forum 1999, 302–303, 440–445. [Google Scholar] [CrossRef]

- Available online: https://www.krrasshvac.com/energy-saving-electric-shearing-machine/ (accessed on 9 February 2020).

- Available online: https://www.trumpf.com/en_INT/ (accessed on 9 February 2020).

- Available online: https://www.romax.com.ro/maxiem-products?product_id=13 (accessed on 9 February 2020).

- Available online: https://www.sodick.org/products/precision-wire-edm/vl600q.html (accessed on 9 February 2020).

- IEC 60404-3. Magnetic materials—Part 3: Methods of Measurement of the Magnetic Properties of Magnetic Sheet and Strip by Means of a Single Sheet Tester; International Electrotechnical Commission: Geneve, Switzerland, 1992. [Google Scholar]

- Available online: https://cogent-power.com/downloads (accessed on 9 February 2020).

- Available online: https://eramet.wixsite.com/ro-eramet (accessed on 9 February 2020).

- Pricop, V.; Helerea, E.; Calin, M.D. Influence of alloy elements on magnetic properties of electrical steels. In ICATE 2016 Conference Proceedings, Craiova, Romania, 6–8 October 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Barros, J.; Ros-Yanez, T.; Vandenbossche, L.; Dupre, L.; Melkebeek, J.; Houbaert, Y. The effect of Si and Al concentration gradients on the mechanical and magnetic properties of electrical steel. J. Magn. Magn. Mater. 2005, 290–291, 1457–1460. [Google Scholar] [CrossRef]

- Beckley, P. Electrical Steels for Rotating Machines; The Institution of Electrical Engineers: London, UK, 2002. [Google Scholar]

- Pyrhonen, J.; Jokinen, T.; Hrabovcova, V. Design of Rotating Electrical Machines; Wiley: West Sussex, UK, 2009. [Google Scholar]

- Tumanski, S. Magnetic Materials from Handbook of Magnetic Measurements; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- You, D.; Park, H. Developmental trajectories in electrical steel technology using patent information. Sustainability 2018, 10, 2728. [Google Scholar] [CrossRef]

- Cardelli, E.; Faba, A.; Pompei, M.; Quondam Antonio, S. Magnetic losses in Si-Fe alloys for avionic applications. AIP Adv. 2017, 7, 056112. [Google Scholar] [CrossRef]

- Belhadj, A.; Baudouin, P.; Breaban, F.; Deffontaine, A.; Dewulf, M.; Houbaert, Y. Effect of laser cutting on microstructure and on magnetic properties of grain non-oriented electrical steels. J. Magn. Magn. Mater. 2003, 256, 20–31. [Google Scholar] [CrossRef]

- Hofmann, M.; Naumoski, H.; Herr, U.; Herzog, H.-G. Magnetic properties of electrical steel sheets in respect of cutting: Micromagnetic analysis and macromagnetic modeling. IEEE Trans. Magn. 2016, 52, 2000114. [Google Scholar] [CrossRef]

- Calvillo, N.; Soria, M.J.; Salinas, A.; Gutierrez, E.J.; Reyes, I.A.; Carrillo, F.R. Influence of thickness and chemical composition of hot-rolled bands on the final microstructure and magnetic properties of non-oriented electrical steel sheets subjected to two different decarburizing atmospheres. Metals 2017, 7, 229. [Google Scholar] [CrossRef]

- Paltanea, G.; Paltanea, V.; Gavrila, H. Energy losses prediction in non-oriented silicon iron sheets. Rev. Roum. Sci. Techn. Electrotechn. Energ. 2013, 58, 53–62. [Google Scholar]

- Marra, K.M.; Marra, L.C.; Buono, V.T.L. Effect of aluminum addition on the magnetic properties of a semi-processed electrical steel. Mater. Res. 2016, 19, 1162–1166. [Google Scholar]

- Klancnik, G.; Medved, J.; Nagode, A.; Novak, G.; Petrovic, D.S. Influence of Mn on the solidification of Fe-Si-Al alloy for non-oriented electrical steel. J. Therm. Anal. Calorim. 2013, 116, 295–302. [Google Scholar] [CrossRef]

- Lee, S.; De Cooman, C. Effect of phosphorus on the magnetic losses of non-oriented 2% Si steel. ISIJ Int. 2012, 52, 1162–1170. [Google Scholar] [CrossRef]

- Bertotti, G.; Di Schino, G.; Ferro Milone, A.; Fiorillo, F. On the effect of grain size on magnetic losses of 3% non-oriented SiFe. J. Phys. 1985, 46, C6385–C6388. [Google Scholar] [CrossRef]

- Zhao, H.; Ferrara, E.; Manescu (Paltanea), V.; Paltanea, G.; Gavrila, H.; Fiorillo, F. Effect of punching and water-jet cutting methods on magnetization curve and energy losses of non-oriented magnetic steel sheets. Int. J. Appl. Electrom. 2017, 55, 69–76. [Google Scholar] [CrossRef]

- Manescu-Paltanea, V.; Paltanea, G.; Nemoianu, I.V. Degradation of static and dynamic magnetic properties of non-oriented steel sheets by cutting. IEEE Trans. Magn. 2018, 54, 2001705. [Google Scholar] [CrossRef]

- Manescu-Paltanea, V.; Paltanea, G.; Ferrara, E.; Nemoianu, I.V.; Fiorillo, F.; Gavrila, H. Influence of mechanical and water-jet cutting on the dynamic magnetic properties of NO Fe-Si steels. J. Magn. Magn. Mater. 2020, 499, 166257. [Google Scholar] [CrossRef]

| Sample Grade | Mass Density [g/cm3] | Electrical Resistivity [Ωm] | Thickness [mm] |

|---|---|---|---|

| M800-65A | 7.80 | 25 × 10−8 | 0.65 |

| M800-50A | 7.80 | 23 × 10−8 | 0.50 |

| M400-65A | 7.65 | 44 × 10−8 | 0.65 |

| M400-50A | 7.70 | 42 × 10−8 | 0.50 |

| M300-35A | 7.65 | 50 × 10−8 | 0.35 |

| NO20 | 7.65 | 52 × 10−8 | 0.20 |

| Sample Grade | Chemical Element | ||||||

|---|---|---|---|---|---|---|---|

| Fe [%] | Si [%] | Mn [%] | Al [%] | P [%] | S [%] | C [%] | |

| M800-65A | 96.4 | 1.43 | 0.58 | 0.215 | 0.049 | 0.005 | 0.033 |

| M800-50A | 98.3 | 1.177 | 0.213 | 0.129 | 0.043 | 0.005 | 0.0095 |

| M400-65A | 96.8 | 2.19 | 0.146 | 0.401 | 0.021 | 0.003 | 0.0095 |

| M400-50A | 97.1 | 1.99 | 0.183 | 0.376 | 0.021 | 0.003 | 0.0094 |

| M300-35A | 96.7 | 1.95 | 0.251 | 0.458 | 0.029 | 0.004 | 0.0094 |

| NO20 | 96.5 | 2.31 | 0.185 | 0.341 | 0.033 | 0.004 | 0.0120 |

| Sample Grade | Punching | EP | Water | Ew | ||

|---|---|---|---|---|---|---|

| Wtot-5mm | Wtot-30mm | [%] | Wtot-5mm | Wtot-30mm | [%] | |

| M400-65A | 53.041 | 39.541 | 25.452 | 36.636 | 31.297 | 14.573 |

| M400-50A | 42.909 | 32.658 | 23.890 | 25.671 | 22.429 | 12.629 |

| M300-35A | 29.292 | 19.869 | 32.169 | 21.865 | 18.771 | 14.150 |

| NO20 | 20.992 | 15.566 | 25.847 | 15.951 | 15.024 | 5.811 |

| Sample Grade | <s> [µm] |

|---|---|

| M400-65A | 127 |

| M400-50A | 92 |

| M300-35A | 86 |

| NO20 | 122 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paltanea, G.; Manescu, V.; Stefanoiu, R.; Nemoianu, I.V.; Gavrila, H. Correlation between Magnetic Properties and Chemical Composition of Non-Oriented Electrical Steels Cut through Different Technologies. Materials 2020, 13, 1455. https://doi.org/10.3390/ma13061455

Paltanea G, Manescu V, Stefanoiu R, Nemoianu IV, Gavrila H. Correlation between Magnetic Properties and Chemical Composition of Non-Oriented Electrical Steels Cut through Different Technologies. Materials. 2020; 13(6):1455. https://doi.org/10.3390/ma13061455

Chicago/Turabian StylePaltanea, Gheorghe, Veronica Manescu (Paltanea), Radu Stefanoiu, Iosif Vasile Nemoianu, and Horia Gavrila. 2020. "Correlation between Magnetic Properties and Chemical Composition of Non-Oriented Electrical Steels Cut through Different Technologies" Materials 13, no. 6: 1455. https://doi.org/10.3390/ma13061455

APA StylePaltanea, G., Manescu, V., Stefanoiu, R., Nemoianu, I. V., & Gavrila, H. (2020). Correlation between Magnetic Properties and Chemical Composition of Non-Oriented Electrical Steels Cut through Different Technologies. Materials, 13(6), 1455. https://doi.org/10.3390/ma13061455

.png)