C0.3N0.7Ti-SiC Toughed Silicon Nitride Hybrids with Non-Oxide Additives Ti3SiC2

Abstract

1. Introduction

2. Experimental Procedure

2.1. Preparation of Samples

2.2. Characterizations

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, W.; Yin, Z.; Yuan, J.; Wang, Z.; Fang, Y. Effects of sintering additives on mechanical properties and microstructure of Si3N4 ceramics by microwave sintering. Mater. Sci. Eng. A 2017, 684, 127–134. [Google Scholar] [CrossRef]

- Kandi, K.K.; Thallapalli, N.; Chilakalapalli, S.P.R. Development of silicon nitride-based ceramic radomes—A review. Int. J. Appl. Ceram. Technol. 2015, 12, 909–920. [Google Scholar] [CrossRef]

- Nishimura, T.; Xu, X.; Kimoto, K.; Hirosaki, N.; Tanaka, H. Fabrication of silicon nitride nanoceramics—Powder preparation and sintering: A review. Sci. Technol. Adv. Mater. 2007, 8, 635–643. [Google Scholar] [CrossRef]

- Luo, H.; Tan, Y.; Li, Y.; Xiao, P.; Deng, L.; Zeng, S.; Zhang, G.; Zhang, H.; Zhou, X.; Peng, S. Modeling for high-temperature dielectric behavior of multilayer Cf/Si3N4 composites in X-band. J. Eur. Ceram. Soc. 2017, 37, 1961–1968. [Google Scholar] [CrossRef]

- Bucio, T.D.; Bucio, T.D.; Lacava, C.; Clementi, M.; Faneca, J.; Skandalos, I.; Baldycheva, A.; Galli, M.; Debnath, K.; Petropoulos, P.; et al. Silicon nitride photonics for the near-infrared. IEEE J. Sel. Top. Quantum Electron. 2020, 26, 13. [Google Scholar] [CrossRef]

- Wen, Z.; Zhou, W.; Long, L.; Li, Y. Investigation on electromagnetic wave absorption of SiCw/Si3N4 composites exposed to short-time oxidation. J. Nanosci. Nanotechnol. 2020, 20, 1859–1865. [Google Scholar] [CrossRef]

- Kiani, K.M.; Frankis, H.C.; Mbonde, H.M.; Mateman, R.; Leinse, A.; Knights, A.P.; Bradley, J.D. Thulium-doped tellurium oxide waveguide amplifier with 7.6dB net gain on a silicon nitride chip. Opt. Lett. 2019, 44, 5788–5791. [Google Scholar] [CrossRef]

- Zanocco, M.; Marin, E.; Rondinella, A.; Boschetto, F.; Horiguchi, S.; Zhu, W.; McEntire, B.J.; Bock, R.M.; Bal, B.S.; Pezzotti, G. The role of nitrogen off-stoichiometry in the osteogenic behavior of silicon nitride bioceramics. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 105, 8. [Google Scholar] [CrossRef]

- Nikonam, M.R.; Pugh, M.D.; Drew, R.A.L. Microstructural evolution mechanism of porous reaction bonded silicon nitride ceramics heat-treated in two powder beds. Ceram. Int. 2019, 45, 21986–21997. [Google Scholar] [CrossRef]

- Liu, J.; Yang, J.; Zhu, S.; Cheng, J.; Yu, Y.; Qiao, Z.; Liu, W. Temperature-driven wear behavior of Si3N4-based ceramic reinforced by in situ formed TiC0.3N0.7 particles. J. Am. Ceram. Soc. 2019, 102, 4333–4343. [Google Scholar] [CrossRef]

- Ye, C.; Yue, X.; Ru, H.; Long, H.; Gong, X. Effect of addition of micron-sized TiC particles on mechanical properties of Si3N4 matrix composites. J. Alloy. Compd. 2017, 709, 165–171. [Google Scholar] [CrossRef]

- Bocanegra-Bernal, M.H.; Matovic, B. Mechanical properties of silicon nitride-based ceramics and its use in structural applications at high temperatures. Mater. Sci. Eng. A 2010, 527, 1314–1338. [Google Scholar] [CrossRef]

- Klemm, H. Silicon nitride for high-temperature applications. J. Am. Ceram. Soc. 2010, 93, 1501–1522. [Google Scholar] [CrossRef]

- Shi, C.; Zhu, Y.; Qian, H.; Lu, L. Fabrication of silicon nitride fiber-PMMA composite through free radical polymerization in batch. Mater. Res. Bull. 2014, 51, 161–166. [Google Scholar] [CrossRef]

- Eblagon, F.; Ehrle, B.; Graule, T.; Kuebler, J. Development of silicon nitride/silicon carbide composites for wood-cutting tools. J. Eur. Ceram. Soc. 2007, 27, 419–428. [Google Scholar] [CrossRef]

- Buzbee, M.; Lombardo, D.; Zhan, Q.; Hendrickson, J.; Sarangan, A.; Agha, I. Silicon nitride on-silicon 3-dimensional photonic circuits for integrated photodetection. In Advanced Photonics 2016 (IPR, NOMA, Sensors, Networks, SPPCom, SOF); Optical Society of America: Vancouver, BC, Canada, 2016. [Google Scholar]

- Xie, W.; Stöferle, T.; Raino, G.; Aubert, T.; Bisschop, S.; Zhu, Y.; Van Thourhout, D. On-chip integrated quantum-dot–silicon-nitride microdisk lasers. Adv. Mater. 2017, 29, 1604866-6. [Google Scholar] [CrossRef]

- Nishiyama, N.; Ishikawa, R.; Ohfuji, H.; Marquardt, H.; Kurnosov, A.; Taniguchi, T.; Kulik, E. Transparent polycrystalline cubic silicon nitride. Sci. Rep. 2017, 7, 44755. [Google Scholar] [CrossRef]

- Capelle, T.; Tsaturyan, Y.; Barg, A.; Schliesser, A. Polarimetric analysis of stress anisotropy in nanomechanical silicon nitride resonators. Appl. Phys. Lett. 2017, 110, 181106. [Google Scholar] [CrossRef]

- Yu, J.-J.; Guo, W.M.; Sun, S.K.; Lin, H.T.; Wang, C.Y. Graded Si3N4 ceramics with hard surface and tough core by two-step hot pressing. Ceram. Int. 2017, 43, 7948–7950. [Google Scholar] [CrossRef]

- Balázsi, C.; Fogarassy, Z.; Tapasztó, O.; Kailer, A.; Schröder, C.; Parchoviansky, M.; Balázsi, K. Si3N4 /graphene nanocomposites for tribological application in aqueous environments prepared by attritor milling and hot pressing. J. Eur. Ceram. Soc. 2017, 37, 3797–3804. [Google Scholar] [CrossRef]

- Xing, H.; Liu, B.; Sun, J.; Zou, B. Mechanical properties of Si3N4 ceramics from an in-situ synthesized a-Si3N4/β-Si3N4 composite powder. Ceram. Int. 2017, 43, 2150–2154. [Google Scholar] [CrossRef]

- Liang, H.; Zeng, Y.; Zuo, K.; Xia, Y.; Yao, D.; Yin, J. Mechanical properties and thermal conductivity of Si3N4 ceramics with YF3 and MgO as sintering additives. Ceram. Int. 2016, 42, 15679–15686. [Google Scholar] [CrossRef]

- Li, S.; Xie, Z.; Xue, W.; Luo, X.; An, L. Sintering of high-performance silicon nitride ceramics under vibratory pressure. J. Am. Ceram. Soc. 2015, 98, 698–701. [Google Scholar] [CrossRef]

- Mikijelj, B.; Nawaz, Z.; Kruzic, J.J.; Idrobo, J.; Swab, J.J.; Özcoban, H.; Liu, Y. Intergranular nanostructure effects on strength and toughness of Si3N4. J. Am. Ceram. Soc. 2015, 98, 1650–1657. [Google Scholar] [CrossRef]

- Zhou, M.Y.; Zhong, J.; Zhao, J.; Rodrigo, D.; Cheng, Y.B. Microstructures and properties of Si3N4/TiN composites sintered by hot pressing and spark plasma sintering. Mater. Res. Bull. 2013, 48, 1927–1933. [Google Scholar] [CrossRef]

- Kovalčíková, A.; Balko, J.; Balázsi, C.; Hvizdoš, P.; Dusza, J. Influence of hBN content on mechanical and tribological properties of Si3N4/BN ceramic composites. J. Eur. Ceram. Soc. 2014, 34, 3319–3328. [Google Scholar] [CrossRef]

- Shen, Z.; Zhao, Z.; Peng, H.; Nygren, M. Formation of tough interlocking microstructures in silicon nitride ceramics by dynamic ripening. Nature 2002, 417, 266. [Google Scholar] [CrossRef]

- Ahmad, N.; Sueyoshi, H. Microstructure and mechanical properties of silicon nitride-titanium nitride composites prepared by spark plasma sintering. Mater. Res. Bull. 2011, 46, 460–463. [Google Scholar] [CrossRef]

- Chockalingam, S.; Earl, D.A. Mechanical properties of 2.45GHz microwave sintered Si3N4–Y2O3–MgO–ZrO2 system. J. Eur. Ceram. Soc. 2009, 29, 2037–2043. [Google Scholar] [CrossRef]

- Shibata, N.; Pennycook, S.J.; Gosnell, T.R.; Painter, G.S.; Shelton, W.A.; Becher, P.F. Observation of rare-earth segregation in silicon nitride ceramics at subnanometre dimensions. Nature 2004, 428, 730–733. [Google Scholar] [CrossRef]

- Riley, F.L. Silicon nitride and related materials. J. Am. Ceram. Soc. 2010, 83, 245–265. [Google Scholar] [CrossRef]

- Lojanová, S.; Tatarko, P.; Chlup, Z.; Hnatko, M.; Dusza, J.; Lenčéš, Z.; Šajgalík, P. Rare-earth element doped Si3N4/SiC micro/nano-composites—RT and HT mechanical properties. J. Eur. Ceram. Soc. 2010, 30, 1931–1944. [Google Scholar] [CrossRef]

- Guo, W.-M.; Wu, L.X.; Ma, T.; You, Y.; Lin, H.T. Rapid fabrication of Si3N4 ceramics by reaction-bonding and pressureless sintering. J. Eur. Ceram. Soc. 2016, 36, 3919–3924. [Google Scholar] [CrossRef]

- Luo, H.; Xiao, P.; Hong, W. Dielectric behavior of laminate-structure Cf/Si3N4 composites in X-band. Appl. Phys. Lett. 2014, 105, 172903. [Google Scholar] [CrossRef]

- Park, H.; Kim, H.-E.; Niihara, K. Microstructural evolution and mechanical properties of Si3N4 with Yb2O3 as a sintering additive. J. Am. Ceram. Soc. 1997, 80, 750–756. [Google Scholar] [CrossRef]

- Barsoum, M.W. The M N+1AX N phases: A new class of solids. Prog. Solid State Chem. 2000, 28, 201–281. [Google Scholar] [CrossRef]

- Sun, Z.M. Progress in research and development on MAX phases: A family of layered ternary compounds. Int. Mater. Rev. 2011, 56, 143–166. [Google Scholar] [CrossRef]

- Tzenov, N.V.; Barsoum, M.W. Synthesis and Characterization of Ti3AlC2. J. Am. Ceram. Soc. 2010, 83, 825–832. [Google Scholar] [CrossRef]

- Zhou, W.; Mei, B.; Zhu, J. Rapid synthesis of Ti3AlC2/TiB2 composites by the spark plasma sintering (SPS) technique. Ceram. Int. 2009, 35, 3507–3510. [Google Scholar]

- Li, M.; Li, C.; Li, J.; Zhou, Y. Oxidation behavior of a Ti3AlC2/TiB2 composite at 1000–1400 °C in Air. J. Am. Ceram. Soc. 2010, 93, 554–560. [Google Scholar] [CrossRef]

- Li, C.; Li, M.; Zhou, Y.; Zhang, J.; He, L. In situ synthesis and properties of Ti3AlC2/TiB2 composites. J. Am. Ceram. Soc. 2007, 90, 3615–3620. [Google Scholar] [CrossRef]

- Zhu, J.; Ye, L.; Wang, F. Fabrication of Ti3AlC2/Al2O3 nanocomposite by a novel method. Sci. Sinter. 2011, 43, 289–294. [Google Scholar] [CrossRef]

- Yeh, C.L.; Kuo, C.W.; Chu, Y.C. Formation of Ti3AlC2/Al2O3 and Ti3AlC2/Al2O3 composites by combustion synthesis in Ti–Al–C–TiO2 systems. J. Alloy. Compd. 2010, 494, 132–136. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, F.; Su, J.; Zhou, W.; Zhu, D. Mechanical, dielectric, and microwave-absorption properties of alumina ceramic containing dispersed Ti3SiC2. J. Electron. Mater. 2015, 44, 867–873. [Google Scholar] [CrossRef]

- Tan, Y.Q.; Tan, Y.Q.; Chen, C.; Li, F.Z.; Zhang, H.B.; Zhang, G.J.; Peng, S.M. Enhancement of sinterability and mechanical properties of B4C ceramics using Ti3AlC2 as a sintering aid. RSC Adv. 2015, 5, 76309–76314. [Google Scholar] [CrossRef]

- Tan, Y.; Luo, H.; Zhang, H.; Zhou, X.; Peng, S. Lightweight graphene nanoplatelet/boron carbide composite with high EMI shielding effectiveness. AIP Adv. 2016, 6, 035208. [Google Scholar] [CrossRef]

- Tan, Y.; Luo, H.; Zhang, H.; Zhou, X.; Peng, S. Fabrication of toughened B4C composites with high electrical conductivity using MAX phase as a novel sintering aid. Ceram. Int. 2016, 42, 7347–7352. [Google Scholar] [CrossRef]

- Tan, Y.; Luo, H.; Zhang, H.; Peng, S. Graphene nanoplatelet reinforced boron carbide composites with high electrical and thermal conductivity. J. Eur. Ceram. Soc. 2016, 36, 2679–2687. [Google Scholar] [CrossRef]

- Tan, Y.; Zhang, H.; Peng, S. Electrically conductive graphene nanoplatelet/boron carbide composites with high hardness and toughness. Scr. Mater. 2016, 114, 98–102. [Google Scholar] [CrossRef]

- Zhou, Y.; Hyuga, H.; Kusano, D.; Yoshizawa, Y.I.; Ohji, T.; Hirao, K. Development of high-thermal-conductivity silicon nitride ceramics. J. Asian Ceram. Soc. 2015. [Google Scholar] [CrossRef]

- Clarke, D.R. Densification of silicon nitride: Effect of chlorine impurities. J. Am. Ceram. Soc. 1982, 65. [Google Scholar] [CrossRef]

- Wu, E.; Riley, D.P.; Kisi, E.H.; Smith, R.I. In situ neutron powder diffraction study of Ti3SiC2 synthesis. J. Am. Ceram. Soc. 2004, 84, 2281–2288. [Google Scholar] [CrossRef]

- Racault, C.; Langlais, F.; Naslain, R. Solid-state synthesis and characterization of the ternary phase Ti3SiC2. J. Mater. Sci. 1994, 29, 3384–3392. [Google Scholar] [CrossRef]

- Mitomo, M.; Uenosono, S. Microstructural development during gas-pressure sintering of α-silicon nitride. J. Am. Ceram. Soc. 1992, 75, 103–107. [Google Scholar] [CrossRef]

- Biswas, S.K.; Riley, F.L. Gas pressure sintering of silicon nitride—Current status. Mater. Chem. Phys. 2001, 67, 175–179. [Google Scholar] [CrossRef]

- Ziegler, G.; Heinrich, J.; Wötting, G. Relationships between processing, microstructure and properties of dense and reaction-bonded silicon nitride. J. Mater. Sci. 1987, 22, 3041–3086. [Google Scholar] [CrossRef]

- Pezzotta, M.; Zhang, Z.L. Effect of thermal mismatch induced residual stresses on grain boundary microcracking of titanium diboride ceramics. J. Mater. Sci. 2010, 45, 382–391. [Google Scholar] [CrossRef]

- Ma, H.-B.; Ma, H.B.; Zhang, G.J.; Liu, H.L.; Liu, J.X.; Lu, Y.; Xu, F.F. Effect of WC or ZrC addition on thermal residual stresses in ZrB2SiC ceramics. Mater. Des. 2016, 110, 340–345. [Google Scholar] [CrossRef]

- Iizuka, T.; Murao, T.; Yamamoto, H.; Kita, H. Microstructures and Properties of Mo5Si3-Particle-Reinforced Si3N4-Matrix Composites. J. Am. Ceram. Soc. 2002, 85, 954–960. [Google Scholar] [CrossRef]

- Fukasawa, T.; Goto, Y. Mechanical properties Of Si3N4 cerarnics reinforced with SiC whiskers and SiC platelets. J. Mater. Sci. 1998, 33, 1647–1651. [Google Scholar] [CrossRef]

- Hirosaki, N.; Akimune, Y.; Mitomo, M. Effect of grain growth of β-silicon nitride on strength, weibull modulus, and fracture toughness. J. Am. Ceram. Soc. 1993, 76, 1892–1894. [Google Scholar] [CrossRef]

- Kvetková, L.; Duszová, A.; Hvizdoš, P.; Dusza, J.; Kun, P.; Balázsi, C. Fracture toughness and toughening mechanisms in graphene platelet reinforced Si3N4 composites. Scr. Mater. 2012, 66, 793–796. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Lippmann, N.; Schmauder, S. Computational modeling of crack propagation in real microstructures of steels and virtual testing of artificially designed materials. Int. J. Fract. 2003, 120, 581–600. [Google Scholar] [CrossRef]

- Baik, D.S.; No, K.S.; Chun, J.S.S.; Yoon, Y.J. Mechanical properties of mica glass-ceramics. J. Am. Ceram. Soc. 1995, 78, 1217–1222. [Google Scholar] [CrossRef]

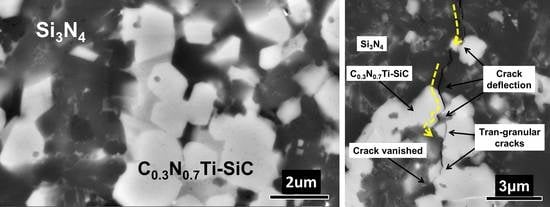

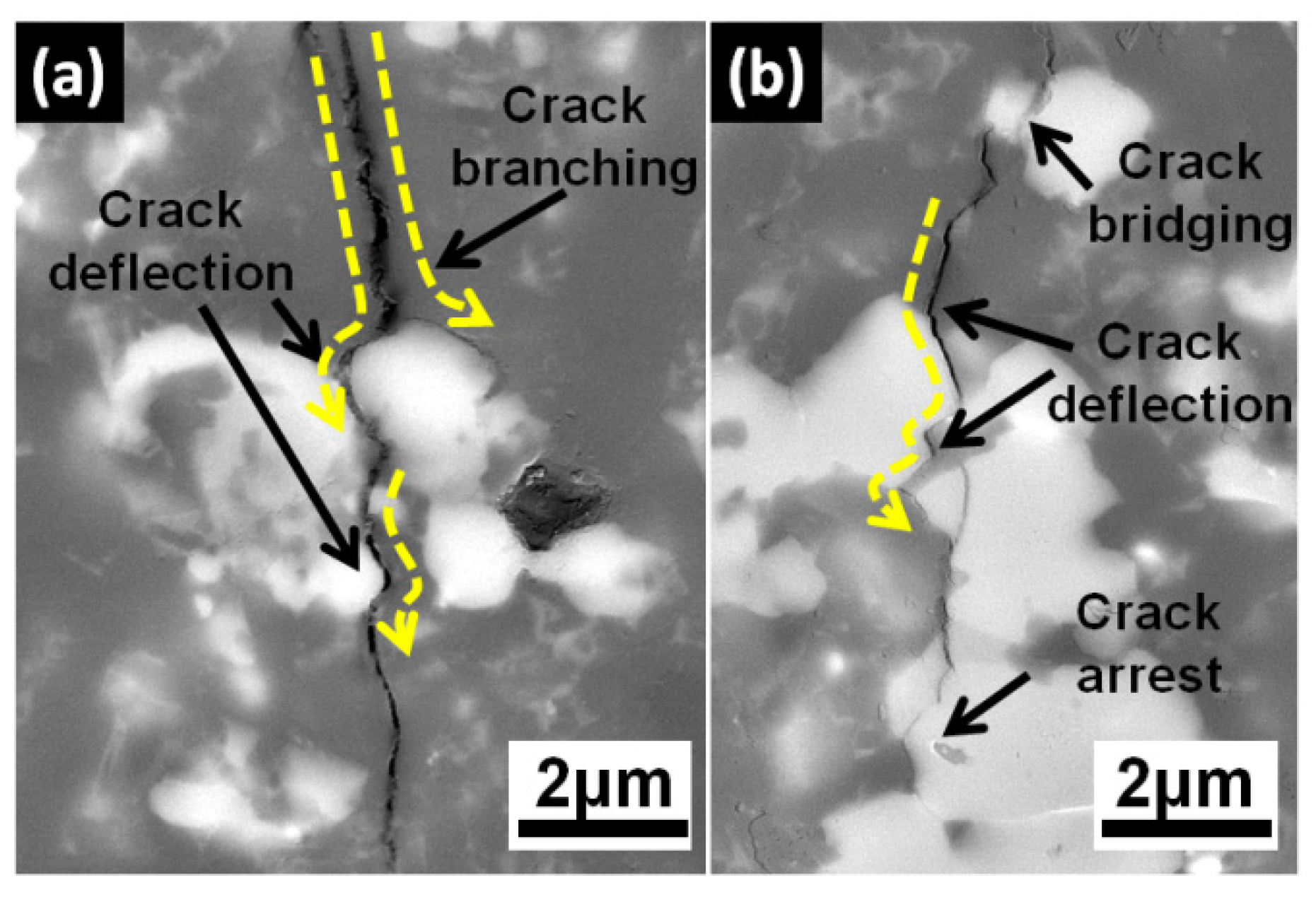

- Faber, K.T.; Evans, A.G. Intergranular crack-deflection toughening in silicon carbide. J. Am. Ceram. Soc. 1983, 66. [Google Scholar] [CrossRef]

- Nisar, A.; Balani, K. Synergistic reinforcement of carbon nanotubes and silicon carbide for toughening tantalum carbide based ultrahigh temperature ceramic. J. Mater. Res. 2016. [Google Scholar] [CrossRef]

- Wu, W.; Gui, J.; Wei, S.; Xue, W.; Xie, Z. Si3N4-SiCw composites as structural materials for cryogenic application. J. Eur. Ceram. Soc. 2016, 36, 2667–2672. [Google Scholar] [CrossRef]

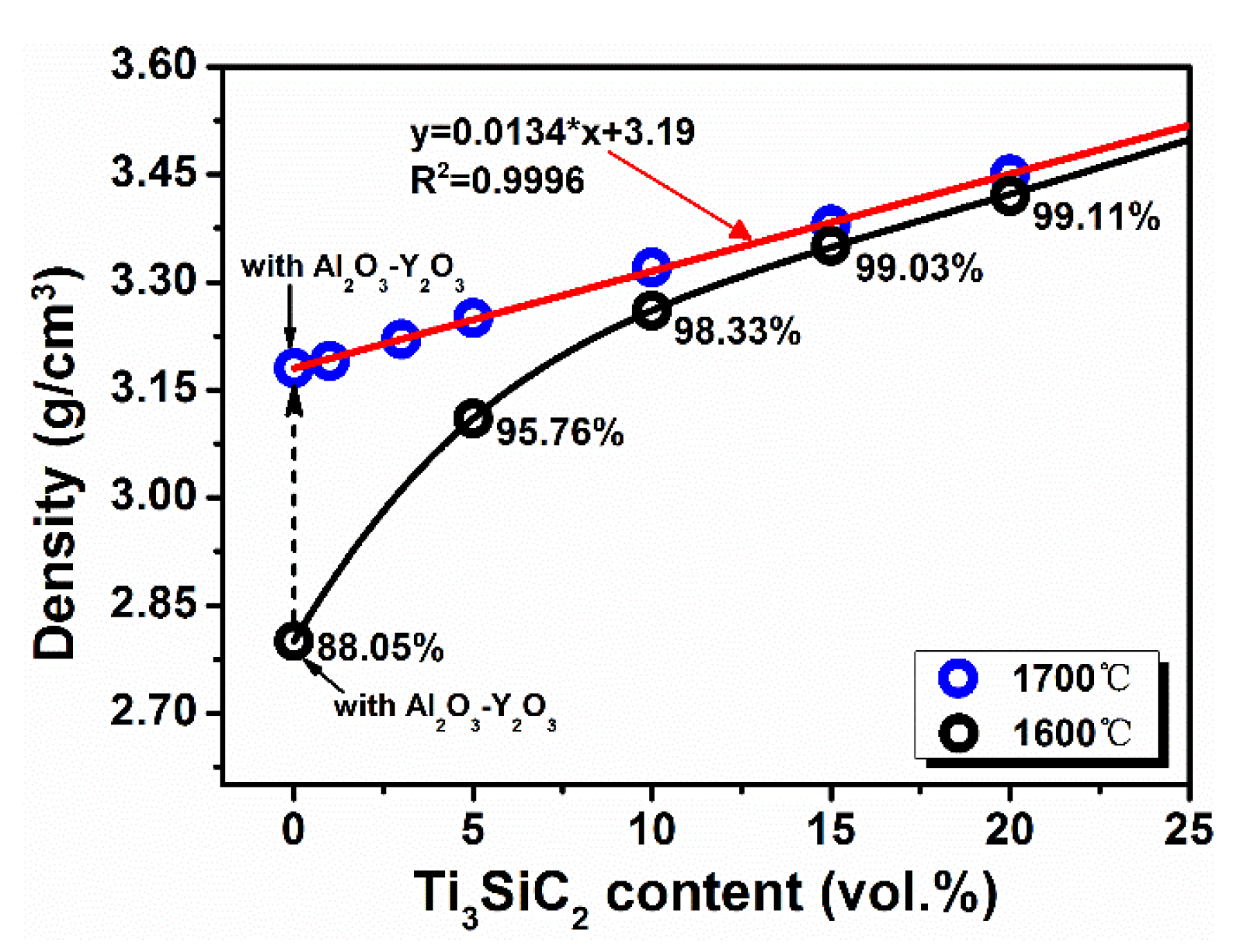

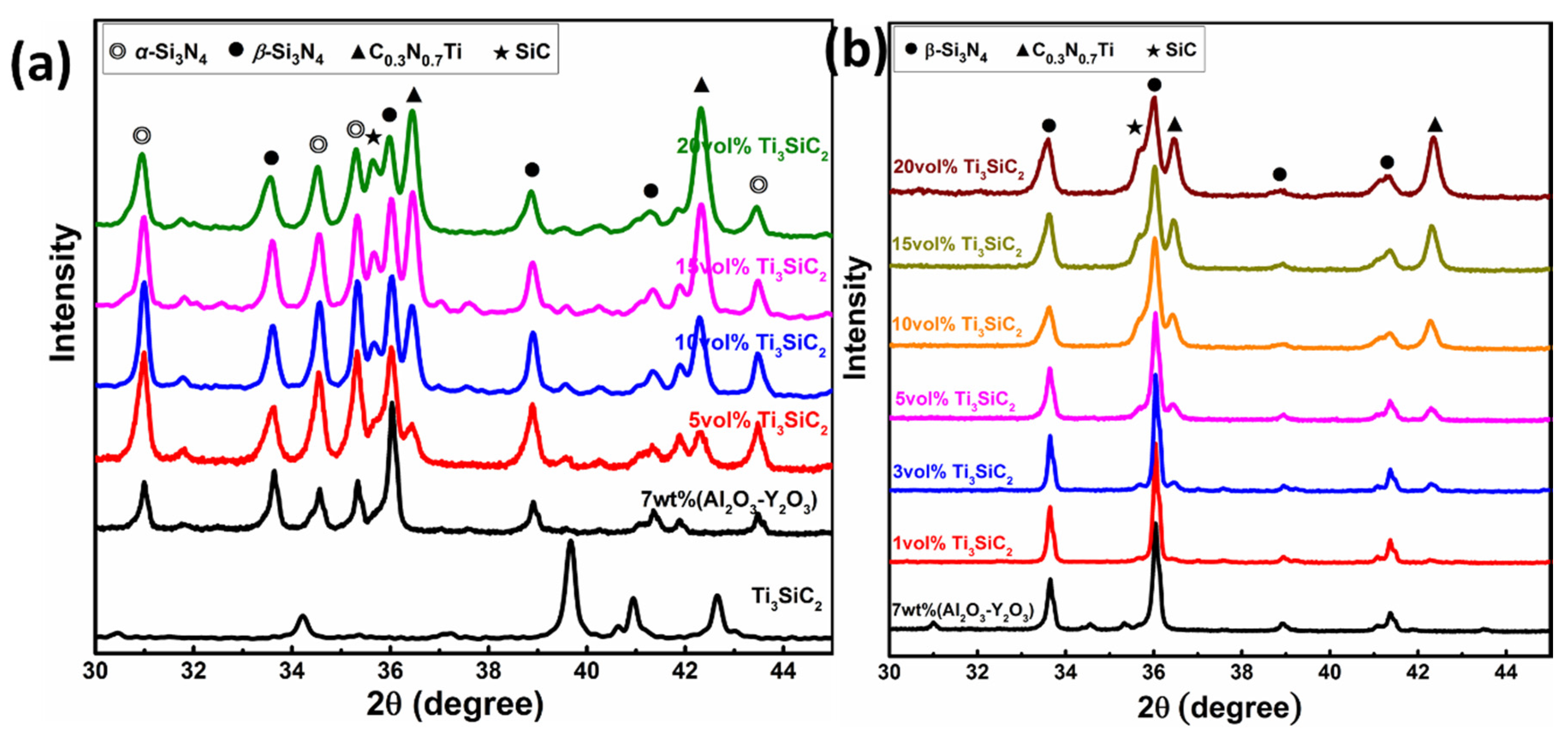

| Si3N4−x vol.% Ti3SiC2 | Weight Fraction | R Factor of Rietveld | Theoretical Density (g·cm−3) | Densification | ||

|---|---|---|---|---|---|---|

| β-Si3N4 | C0.3N0.7Ti | SiC | ||||

| x = 1 | 97.3% | 0.9% | 1.8% | 4.76% | 3.21 | 99.26% |

| x = 3 | 97.1% | 0.9% | 2.1% | 4.55% | 3.21 | 99.89% |

| x = 5 | 92.8% | 4.1% | 3.1% | 3.46% | 3.25 | 99.92% |

| x = 10 | 87.3% | 7.6% | 5.1% | 3.42% | 3.30 | 99.73% |

| x = 15 | 82.3% | 11.7% | 6.0% | 3.47% | 3.35 | 99.98% |

| x = 20 | 78.4% | 14.6% | 7.0% | 4.07% | 3.39 | 99.79% |

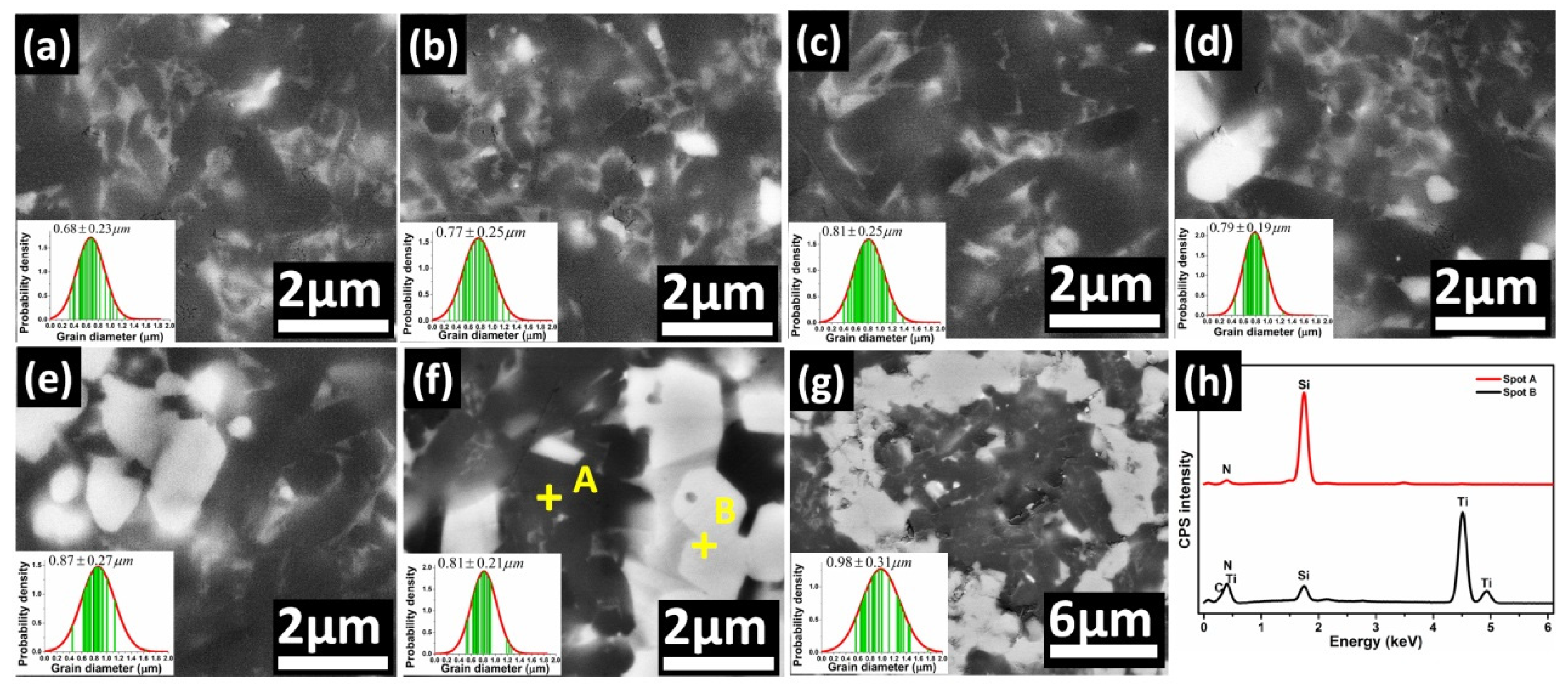

| Location | Si | N | O | Ti | C | Possible Phases |

|---|---|---|---|---|---|---|

| Spot A | 52.21 | 35.43 | 2.04 | 1.29 | 9.03 | Si3N4, SiC |

| Spot B | 5.10 | 27.18 | - | 50.13 | 17.59 | C0.3N0.7Ti, SiC |

| Composition | Sintering Conditions | Vickers Hardness (GPa) | Flexural Strength (MPa) | Fracture Toughness (MPa·m1/2) | Ref. |

|---|---|---|---|---|---|

| α-Si3N4 + 4 wt.% Al2O3 + 6 wt.% Y2O3 | Hot isostatic pressing at 1700 °C, 20 MPa, 3 h | 16.4 | 730 | 6.5 | [27] |

| α-Si3N4 + 5 wt.% Al2O3 + 5 wt.% Y2O3 | Hot press at 1800 °C, 30 MPa, 1.5 h | 16.1 | - | 5.2 | [20] |

| α-Si3N4 + 4 wt.% Al2O3 + 6 wt.% Y2O3 | Hot press at 1700 °C, 50 MPa, 1.5 h | 17.01 | - | - | [21] |

| α-Si3N4 + 30 vol.% β-Si3N4 whiskers + 5 wt.% Al2O3 + 5 wt.% Y2O3 + 5 wt.% CeO2 | Hot press at 1700 °C, 30 MPa, 30 min | 19.0 | 794 | 8.6 | [22] |

| α-Si3N4+4 wt.% Al2O3+4 wt.% Y2O3+15 vol.% SiC whiskers | Hot press at 1800 °C, 30 MPa, 30 min | 16 | 680 | 6.1 | [68] |

| α-Si3N4 + 5 wt.% Al2O3 + 4 wt.% Y2O3 + 3 wt.% TiC | Gas pressure sintering at 1750 °C, 2 MPa | 16.4 | 475 | 7.6 | [11] |

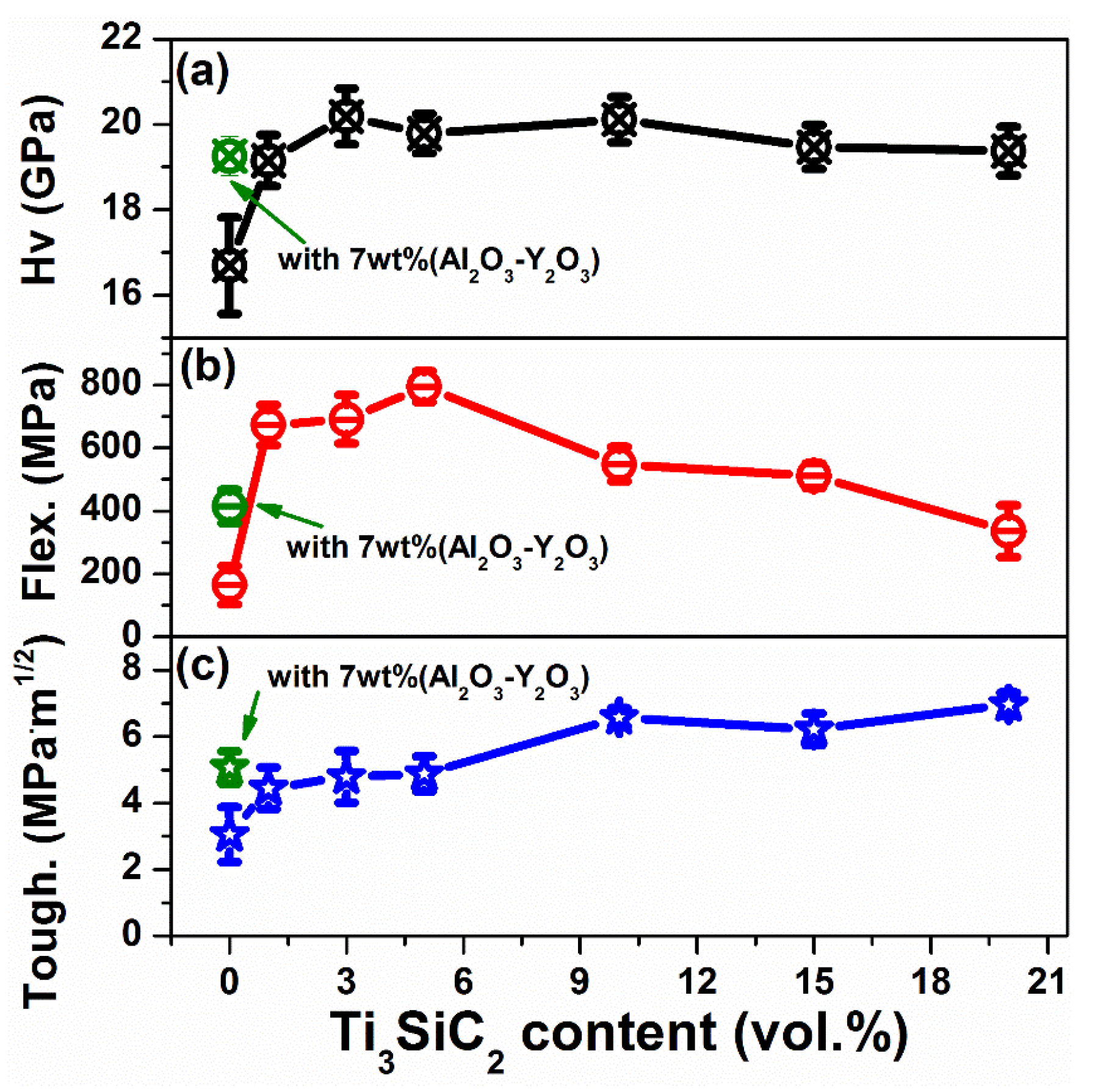

| α-Si3N4 + 5 vol.% Ti3SiC2 | Hot-pressed at 1700 °C for 90 min | 19.78 | 795 | 4.88 | This work |

| α-Si3N4 + 20 vol.% Ti3SiC2 | Hot-pressed at 1700 °C for 90 min | 20.11 | 549 | 6.58 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Li, C.; Deng, L.; Li, Y.; Xiao, P.; Zhang, H. C0.3N0.7Ti-SiC Toughed Silicon Nitride Hybrids with Non-Oxide Additives Ti3SiC2. Materials 2020, 13, 1428. https://doi.org/10.3390/ma13061428

Luo H, Li C, Deng L, Li Y, Xiao P, Zhang H. C0.3N0.7Ti-SiC Toughed Silicon Nitride Hybrids with Non-Oxide Additives Ti3SiC2. Materials. 2020; 13(6):1428. https://doi.org/10.3390/ma13061428

Chicago/Turabian StyleLuo, Heng, Chen Li, Lianwen Deng, Yang Li, Peng Xiao, and Haibin Zhang. 2020. "C0.3N0.7Ti-SiC Toughed Silicon Nitride Hybrids with Non-Oxide Additives Ti3SiC2" Materials 13, no. 6: 1428. https://doi.org/10.3390/ma13061428

APA StyleLuo, H., Li, C., Deng, L., Li, Y., Xiao, P., & Zhang, H. (2020). C0.3N0.7Ti-SiC Toughed Silicon Nitride Hybrids with Non-Oxide Additives Ti3SiC2. Materials, 13(6), 1428. https://doi.org/10.3390/ma13061428