Potato Starch Utilization in Ecological Loose-Fill Packaging Materials—Sustainability and Characterization

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

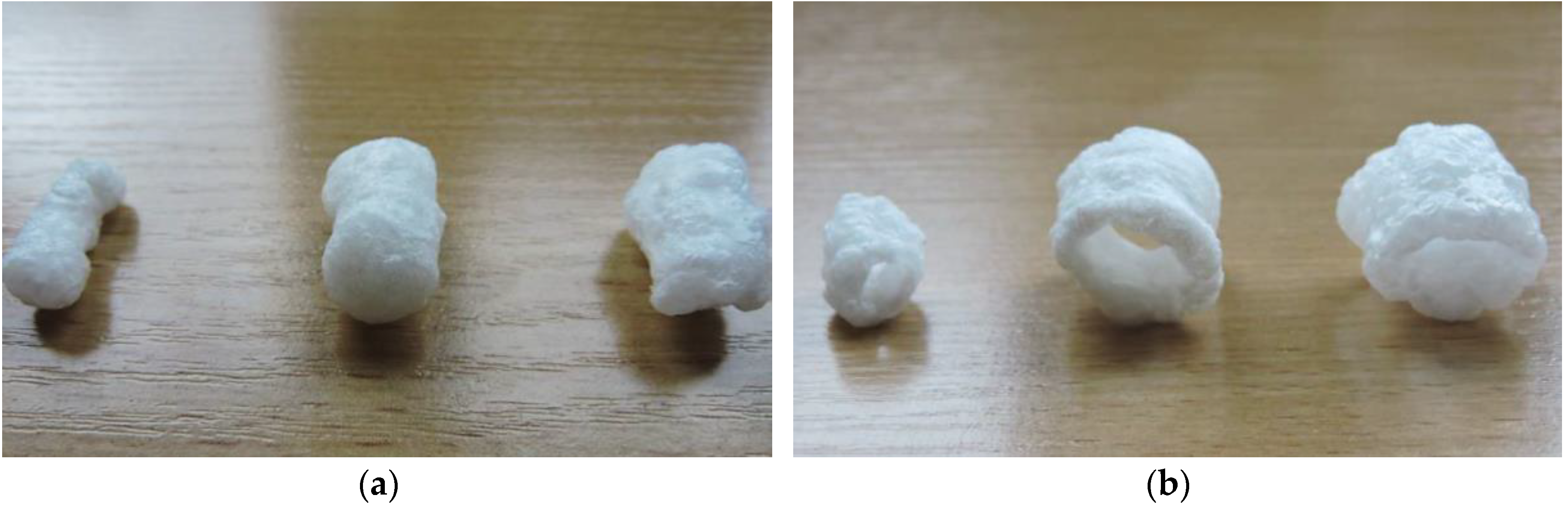

2.2. Processing of Foams

2.3. Evaluation of Process Efficiency

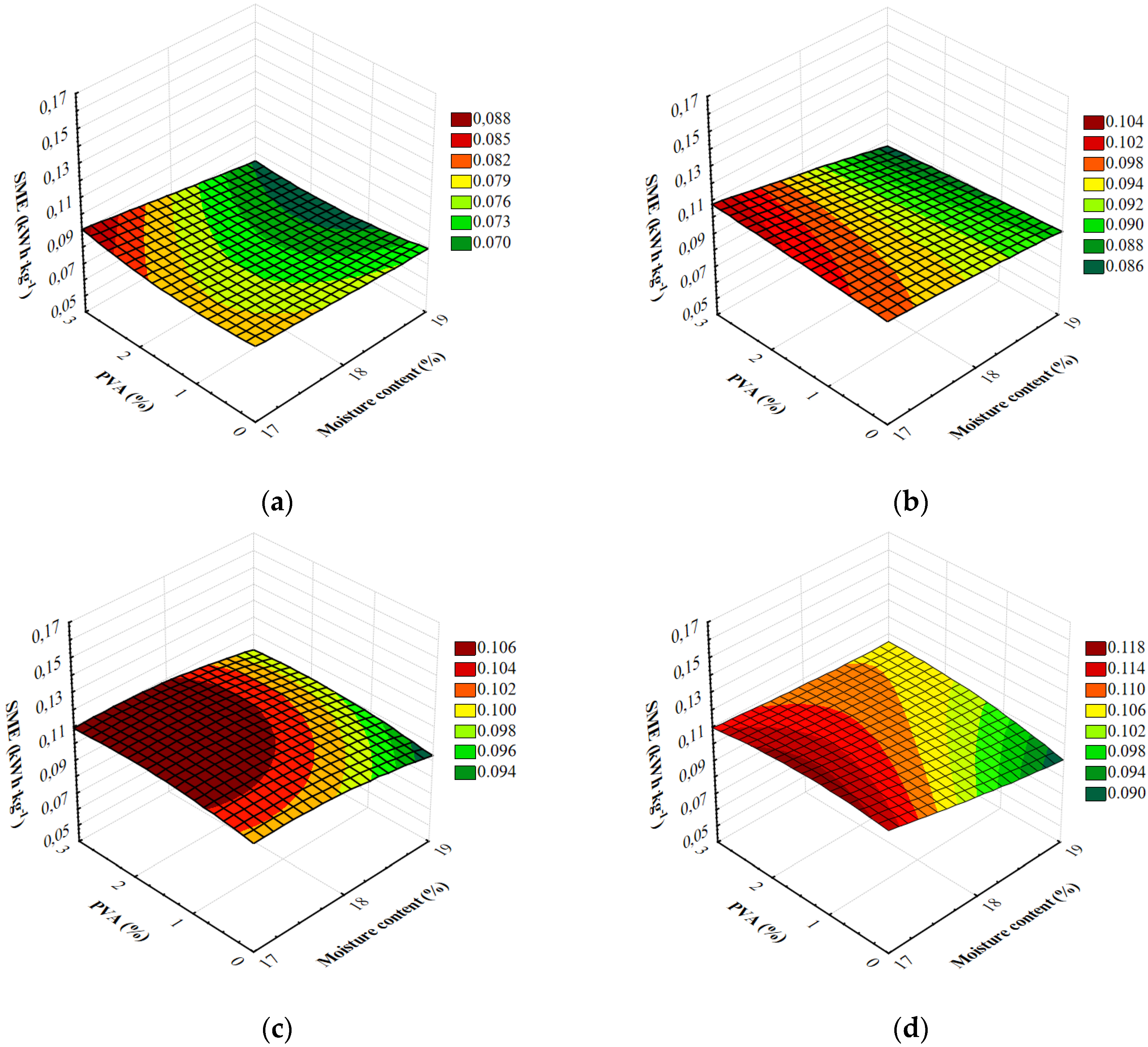

2.4. Specific Mechanical Energy Consumption

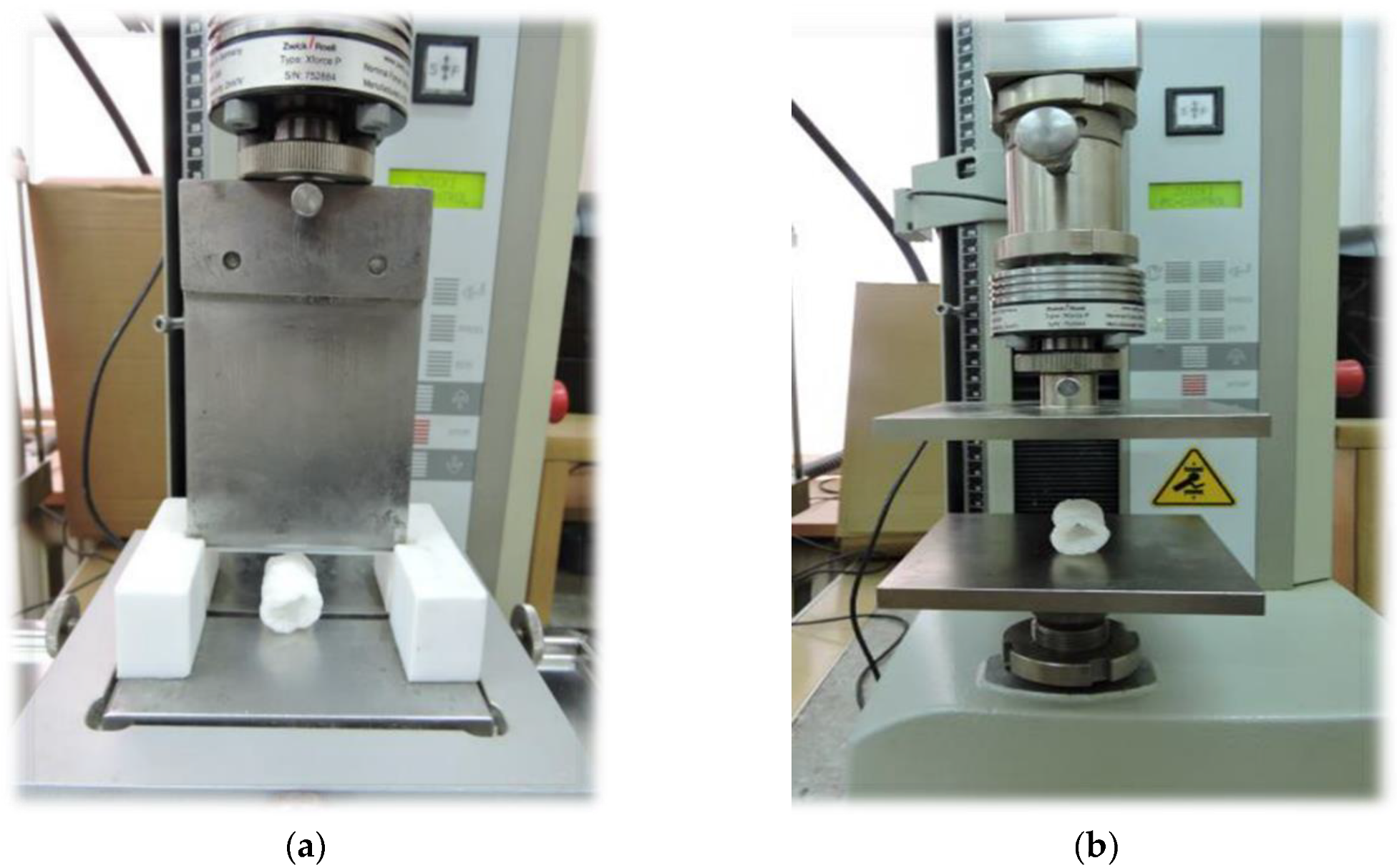

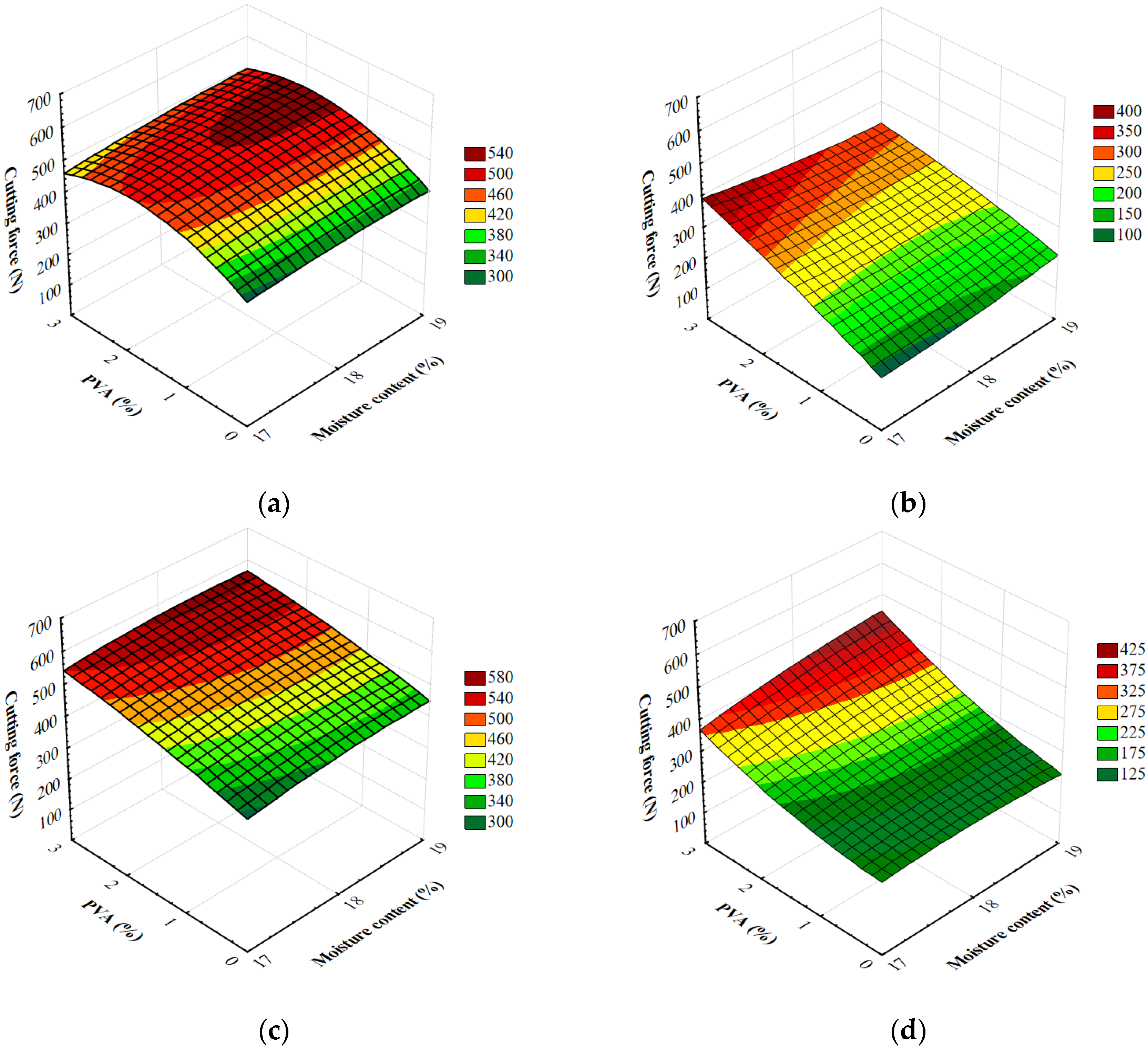

2.5. Cutting Force

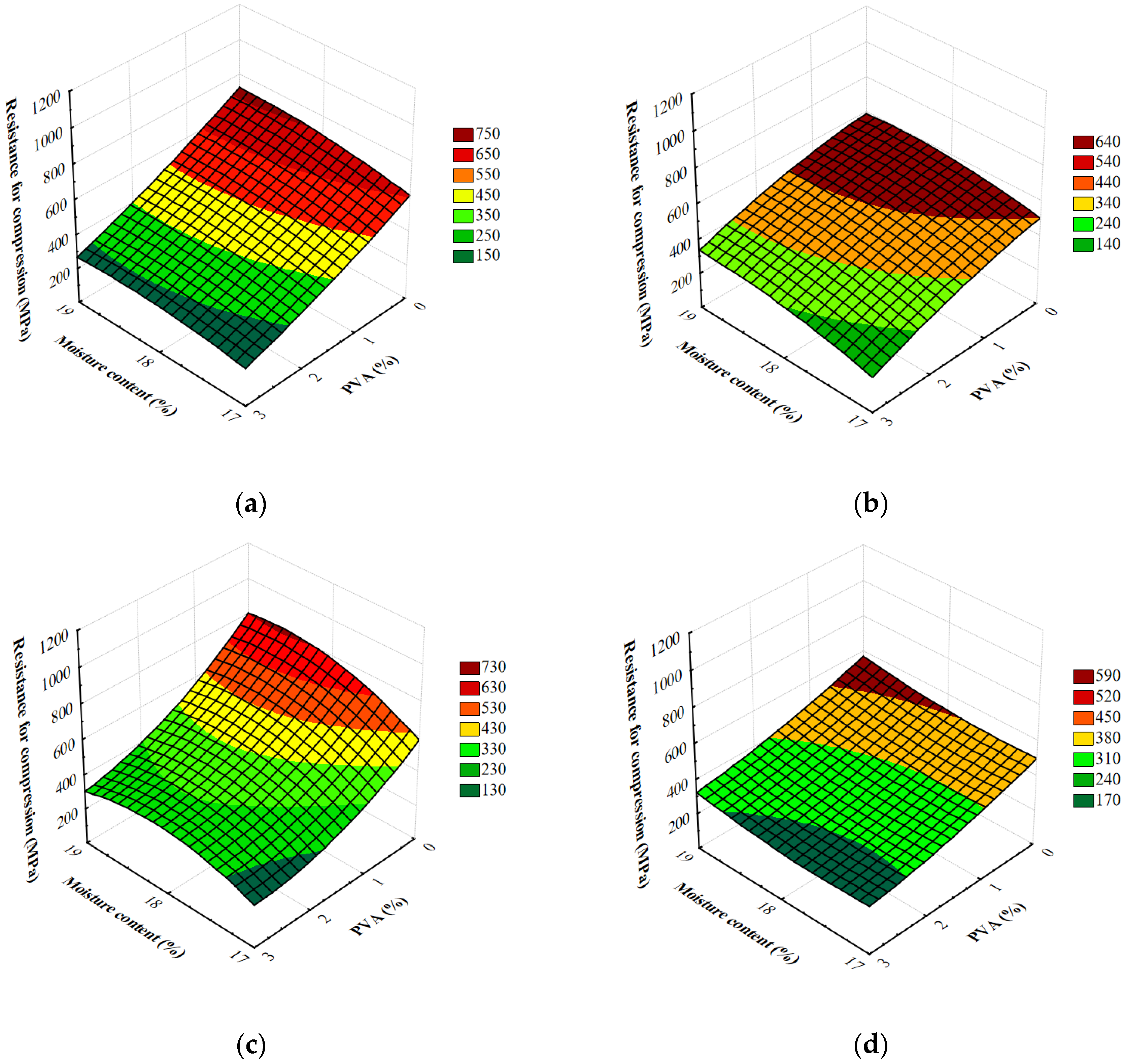

2.6. Compression Test

2.7. FTIR Analysis

2.8. Statistical Analysis

2.9. Principal Component Analysis (PCA) of FTIR Spectra

3. Results and Discussion

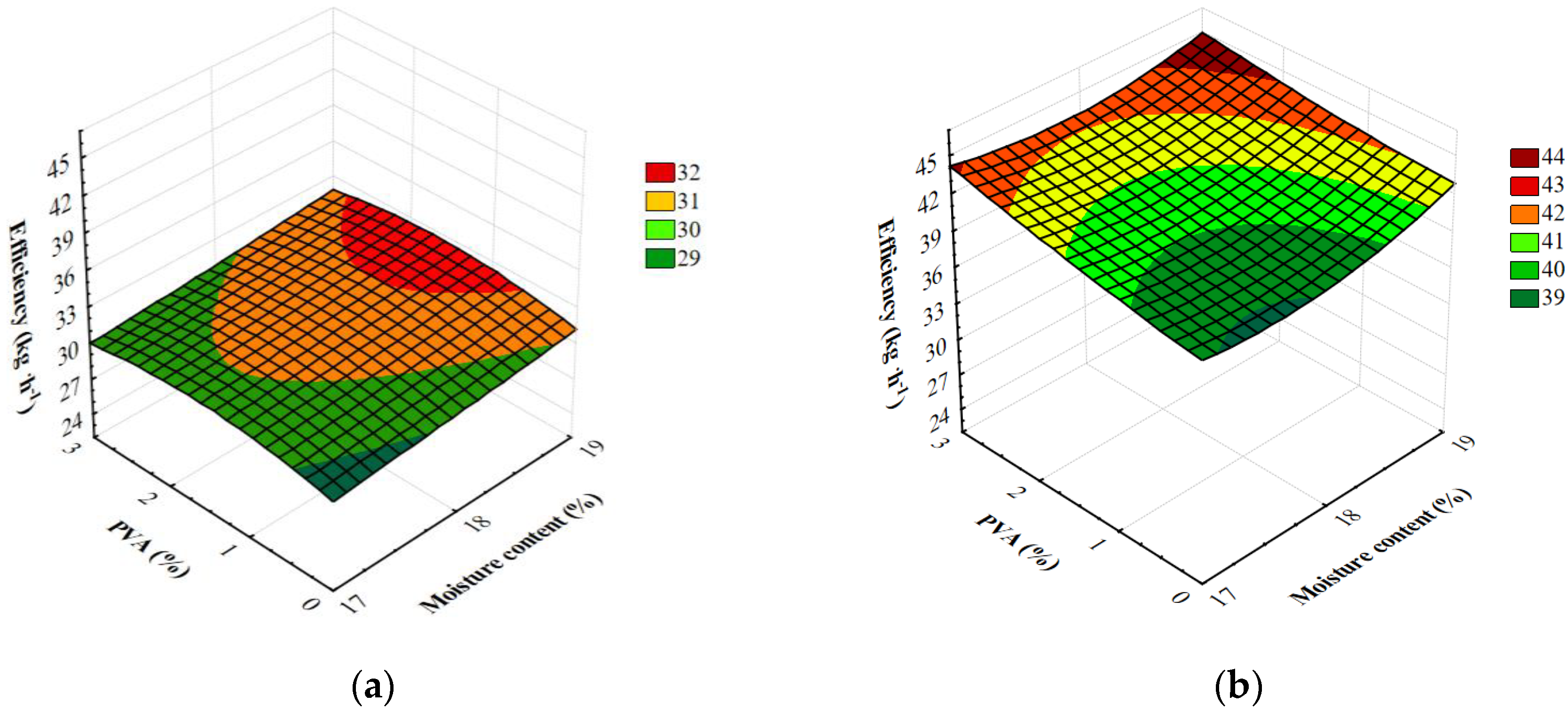

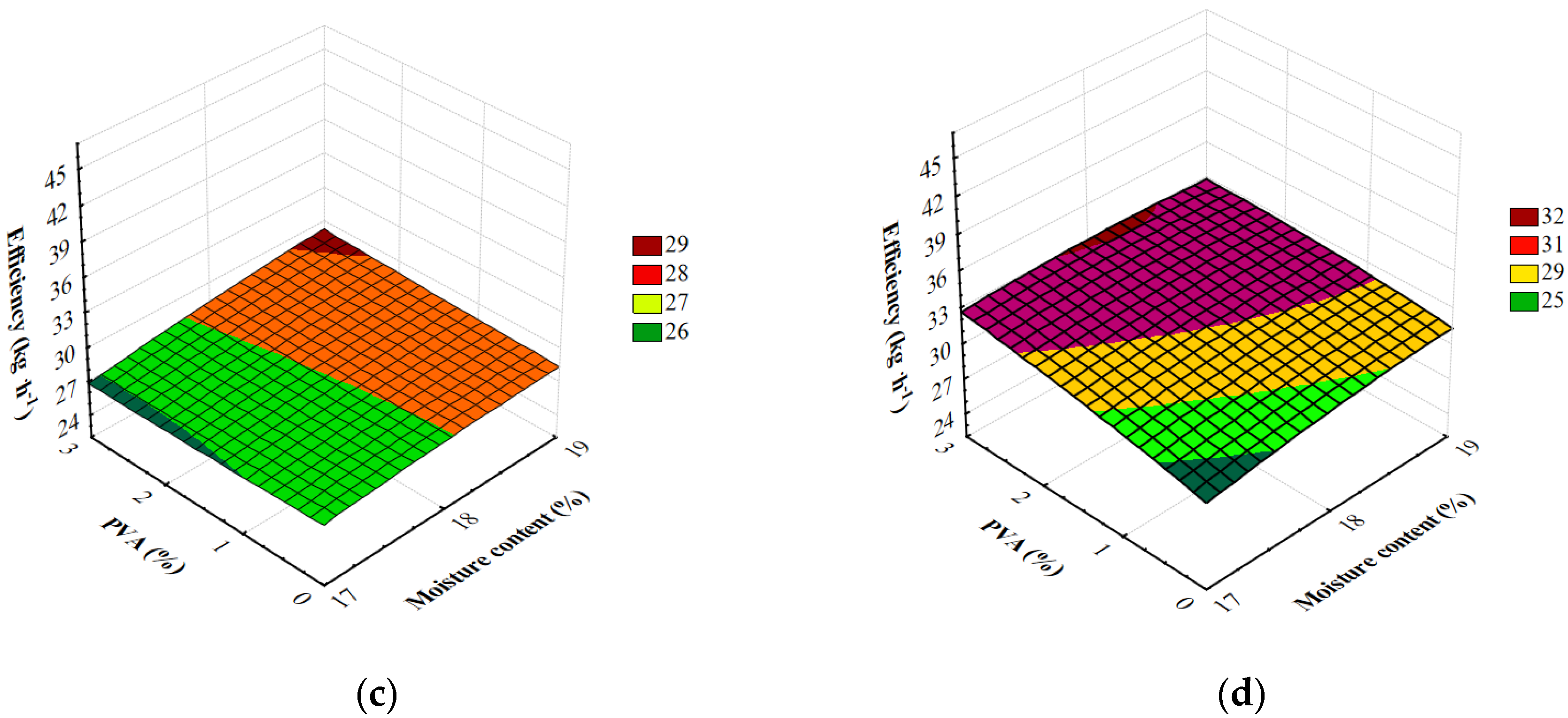

3.1. Processing Efficiency of Starch-Based Foams

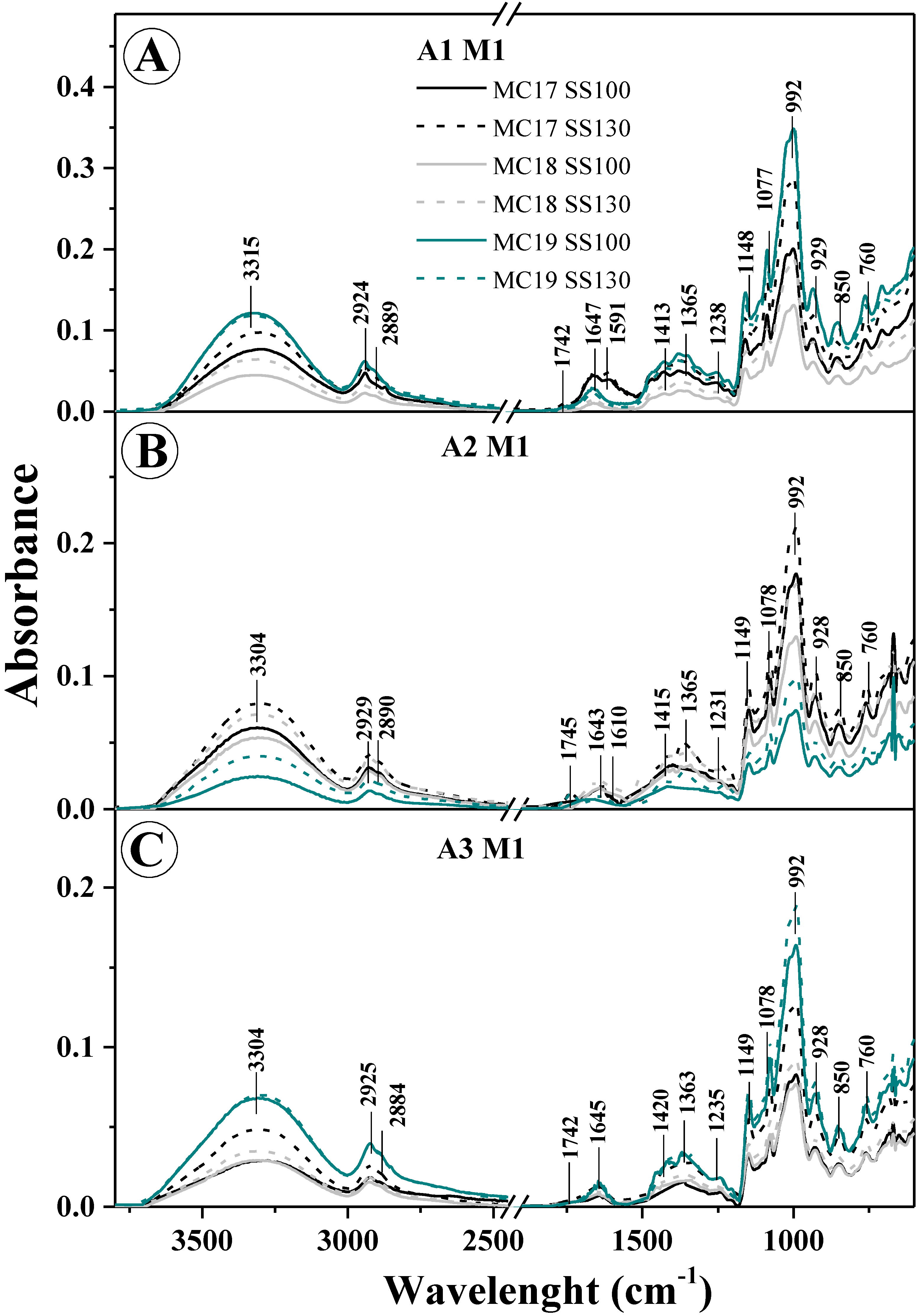

3.2. FTIR Characteristics of Foamed Starch-Based Materials

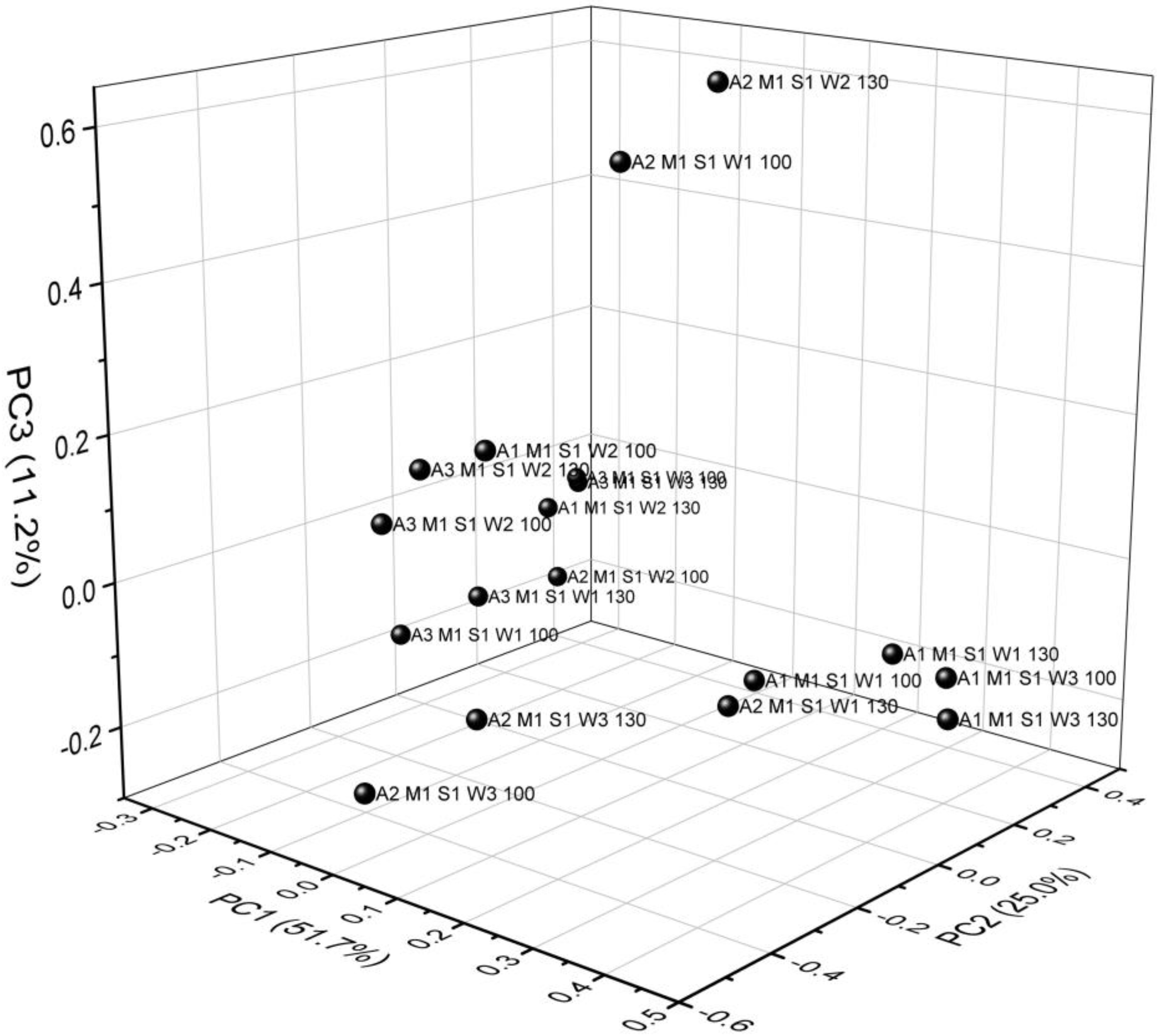

3.3. PCA of FTIR of M1 Sample with PVA Addition

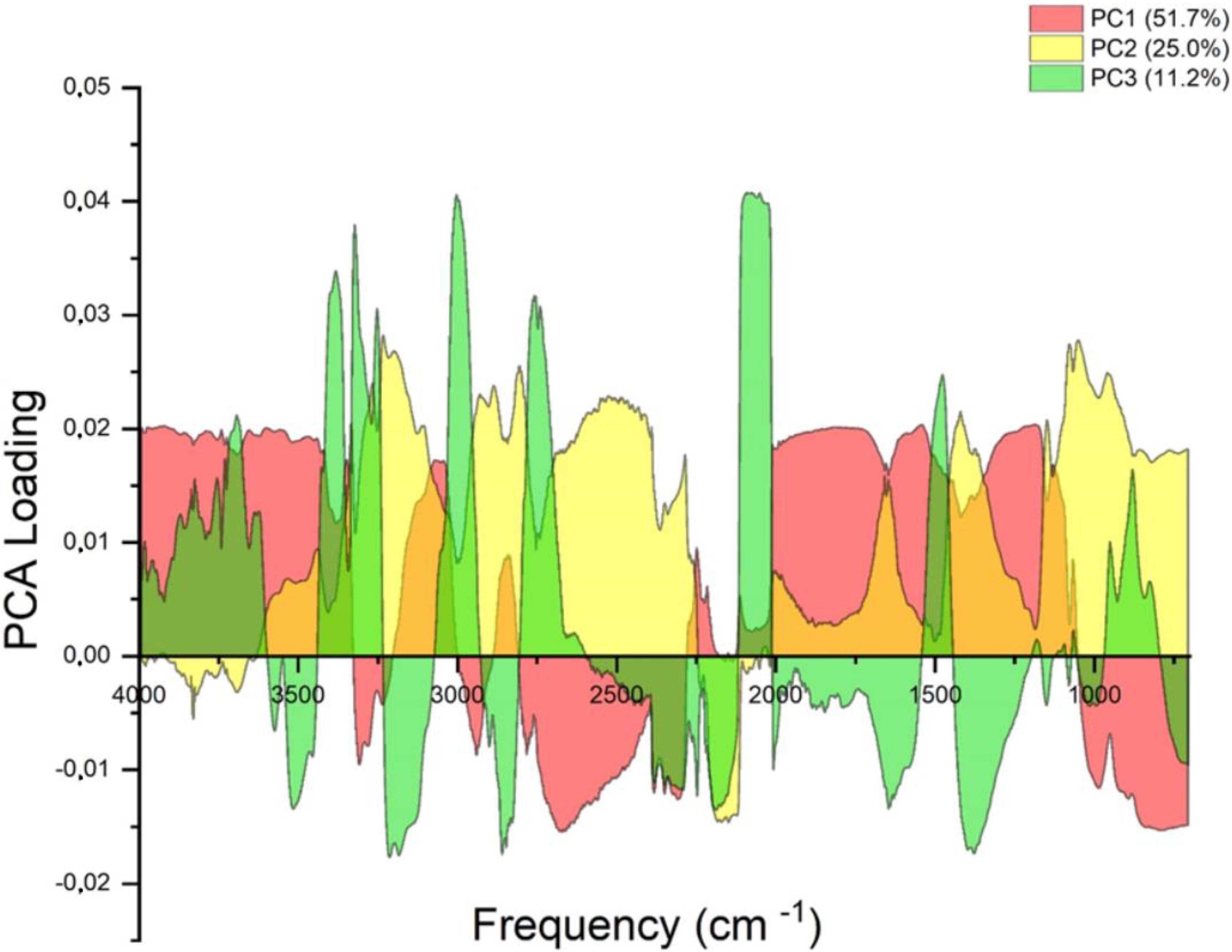

3.4. Loading Analysis of FTIR Spectra Samples M1 with Different PVA Content

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1999; pp. 352–407. [Google Scholar]

- Peisheng, L.; Guo-Feng, C. Porous Materials: Processing and Applications, 1st ed.; Butterworth-Heinemann, Tsinghua University: Beijing, China, 2014; pp. 245–279. [Google Scholar]

- Rosato, D.; Rosato, D.; Rosato, M. Plastic Product Material and Process Selection Handbook, 1st ed.; Elsevier Ltd.: Kidlington, Oxford, UK, 2004; pp. 124–178. [Google Scholar]

- Sivertsen, K. Polymer Foams. Polymer Physics, 1st ed.; Spring, Massachusetts Institute of Technology: Cambridge, MA, USA, 2007; pp. 3–17. [Google Scholar]

- Bhatnagar, S.; Hanna, M.A. Starch-based plastic foams from various starch sources. Cereal Chem. 1996, 73, 601–604. [Google Scholar]

- Mitrus, M. Starch protective loose-fill foams. In Thermoplastic Elastomers, 1st ed.; El-Sonbati, A.Z., Ed.; Intech Open: Rijeka, Croatia, 2012; pp. 79–94. [Google Scholar]

- Pushpadass, H.A.; Suresh Babu, S.G.; Weber, R.W.; Hanna, M.A. Extrusion of starch-based loose-fill packaging foams: Effects of temperature, moisture and talc on physical properties. Packag. Technol. Sci. 2008, 21, 171–183. [Google Scholar] [CrossRef]

- Guan, J.; Eskridge, K.M.; Hanna, M.A. Acetylated starch-polylactic acid loose-fill packaging materials. Ind. Crop. Prod. 2005, 22, 109–123. [Google Scholar] [CrossRef]

- Zhang, J.F.; Sun, X. Biodegradable foams of poly (lactic acid)/starch I. Extrusion condition and cellular size distribution. J. Appl. Polym. Sci. 2007, 106, 857–862. [Google Scholar] [CrossRef]

- Soykeabkaew, N.; Supaphol, P.; Rujiravanit, R. Preparation and characterization of jute- and flax-reinforced starch-based composite foams. Carb. Polym. 2004, 58, 53–63. [Google Scholar] [CrossRef]

- Xu, Y.X.; Dzenis, Y.; Hanna, M.A. Water solubility, thermal characteristics and biodegradability of extruded starch acetate foams. Ind. Crop. Prod. 2005, 21, 361–368. [Google Scholar] [CrossRef]

- Elizondo, N.J.; Sobral, P.J.A.; Menegalli, F.C. Development of films based on blends of Amaranthus cruentus flour and poly (vinyl alcohol). Carb. Polym. 2009, 75, 592–598. [Google Scholar] [CrossRef]

- Combrzyński, M.; Matysiak, A.; Wójtowicz, A.; Oniszczuk, T.; Kupryaniuk, K.; Żelizko, K.; Kuboń, M.; Mazurkiewicz, J.; Mitrus, M. Effect of foaming agent addition on starch foam properties. Przem. Chem. 2018, 97, 682–685. [Google Scholar]

- Combrzyński, M.; Mościcki, L.; Kwaśniewska, A.; Oniszczuk, T.; Wójtowicz, A.; Kręcisz, M.; Sołowiej, B.; Gładyszewska, B.; Muszyński, S. Effect of PVA and PDE on selected structural characteristics of extrusion-cooked starch foams. Polimeros 2018, 28, 76–83. [Google Scholar] [CrossRef]

- Chaudhary, A.L.; Miler, M.; Torley, P.J.; Sopade, P.A.; Halley, P.J. Amylose content and chemical modification effects on the extrusion of thermoplastic starch from maize. Carb. Polym. 2008, 74, 907–913. [Google Scholar] [CrossRef]

- Lui, W.B.; Peng, J. Physical, mechanical, biodegradable properties and energy absorption behavior of corn grit-polyvinyl alcohol cushioning extrudates. J. Food. Eng. 2005, 71, 73–84. [Google Scholar] [CrossRef]

- Yang, Z.; Graiver, D.; Narayan, R. Extrusion of humidity-resistant starch foam sheets. Polym. Eng. Sci. 2013, 53, 857–867. [Google Scholar] [CrossRef]

- Arif, S.; Burgess, G.; Narayan, R.; Harte, B. Evaluation of a biodegradable foam for protective packaging applications. Packag. Tech. Sci. 2007, 20, 413–419. [Google Scholar] [CrossRef]

- Lee, S.Y.; Eskridge, K.M.; Koh, W.Y.; Hanna, M.A. Evaluation of ingredient effects on extruded starch-based foams using a supersaturated split-plot design. Ind. Crop. Prod. 2009, 29, 427–436. [Google Scholar] [CrossRef]

- De Graaf, R.A.; Janssen, L.P.B.M. The production of a new partially biodegradable starch plastic by reactive extrusion. Polym. Eng. Sci. 2000, 40, 2086–2094. [Google Scholar] [CrossRef]

- Oniszczuk, T.; Wójtowicz, A.; Mościcki, L.; Mitrus, M.; Kupryaniuk, K.; Kusz, A.; Bartnik, G. Effect of natural fibres on the mechanical properties of thermoplastic starch. Int. Agrophys. 2016, 30, 211–218. [Google Scholar] [CrossRef]

- Chocyk, D.; Gładyszewska, B.; Ciupak, A.; Oniszczuk, T.; Mościcki, L.; Rejak, A. Influence of water addition on mechanical properties of thermoplastic starch foils. Int. Agrophys. 2015, 29, 267–275. [Google Scholar] [CrossRef]

- Oniszczuk, T.; Pilawka, R. Effect of cellulose fibers on thermal strength of thermoplastic starch. Przem. Chem. 2013, 92, 265–269. [Google Scholar]

- Patel, M.; Bastioli, C.; Marini, L.; Würd-Inger, E. Life-cycle assessment of bio-based polymers and natural fiber composites. Biopolym. Online 2005, 10, 1–59. [Google Scholar]

- Obayi, C.S.; Tolouei, R.; Paternoster, C.; Turgeon, S.; Okorie, B.C.; Obikwelu, D.; Cassar, G.; Buhagiar, J.; Mantovani, D. Influence of cross-rolling on the micro-texture and biodegradation of pure iron as biodegradable material for medical implants. Acta Biomater. 2015, 17, 68–77. [Google Scholar] [CrossRef]

- Niaounakis, M. Biopolymers: Processing and Products, 1st ed.; Elsevier Inc.: Kidlington, Oxford, UK, 2014; pp. 354–399. [Google Scholar]

- Zhou, J.; Song, J.; Parker, R. Structure and properties of starch-based foams prepared by microwave heating from extruded pellets. Carb. Polym. 2006, 63, 466–475. [Google Scholar] [CrossRef]

- Neumann, P.E.; Seib, P.A. Starch-Based Biodegradable Packaging Filler and Method of Preparing Same. U.S. Patent No. 5,248,702, 28 September 1993. [Google Scholar]

- Lacourse, N.L.; Altieri, P.A. Biodegradable Packaging Material and the Method of Preparation Thereof. U.S. Patent No. 4,863,655, 5 September 1989. [Google Scholar]

- Lacourse, N.L.; Altieri, P.A. Biodegradable Shaped Products and the Method of Preparation Thereof. U.S. Patent No. 5,043,196, 27 August 1991. [Google Scholar]

- Combrzyński, M.; Wójtowicz, A.; Klimek, M.; Mościcki, L.; Oniszczuk, T.; Juśko, S. Specific mechanical energy consumption of extrusion-cooking of wheat foamed packaging materials. Agric. Eng. 2015, 1, 25–34. [Google Scholar]

- Stojceska, V.; Ainsworth, P.; Plunkett, A.; İbanoğlu, E.; İbanoğlu, S. Cauliflower by-products as a new source of dietary fibre, antioxidants and proteins in cereal based ready-to-eat expanded snacks. J. Food Eng. 2008, 87, 554–563. [Google Scholar] [CrossRef]

- Stojceska, V.; Ainsworth, P.; Plunkett, A.; İbanoğlu, S. The advantage of using extrusion processing for increasing dietary fibre level in gluten-free products. Food Chem. 2010, 121, 156–164. [Google Scholar] [CrossRef]

- Kręcisz, M.; Wójtowicz, A.; Oniszczuk, A. Effect of selected parameters on process efficiency and energy consumption during the extrusion-cooking of corn-rice instant grits. Agric. Agric. Sci. Procedia 2015, 7, 139–145. [Google Scholar] [CrossRef][Green Version]

- Jin, Z.; Hsiehl, F.; Huff, H.E. Effects of soy fiber, salt, sugar and screw speed on physical properties and microstructure of corn meal extrudate. J. Cereal Sci. 1995, 22, 185–194. [Google Scholar] [CrossRef]

- Filli, K.; Sjöqvist, M.; Öhgren, C.; Stading, M.; Rigdahl, M. Development and characterization of extruded biodegradable foams based on zein and pearl millet flour. Annu. Trans. Nord. Rheol. Soc. 2011, 19, 139–145. [Google Scholar]

- İbanoğlu, Ş.; Ainsworth, P.; Özer, E.A.; Plunkett, A. Physical and sensory evaluation of a nutritionally balanced gluten-free extruded snack. J. Food Eng. 2006, 75, 469–472. [Google Scholar] [CrossRef]

- Mitrus, M.; Moscicki, L. Extrusion-cooking of starch protective loose-fill foams. Chem. Eng. Res. Des. 2014, 92, 778–783. [Google Scholar] [CrossRef]

- Combrzyński, M.; Wójtowicz, A.; Mitrus, M.; Oniszczuk, T.; Matwijczuk, A.; Pawelczyk, P.; Mościcki, L. Effect of starch type and screw speed on mechanical properties of extrusion-cooked starch-based foams. Int. Agrophys. 2019, 33, 233–240. [Google Scholar] [CrossRef]

- Willett, J.L.; Shogren, R.L. Processing and properties of extruded starch/polymer foams. Polymer 2002, 43, 5935–5947. [Google Scholar] [CrossRef]

- Akdogan, H. Pressure, torque and energy responses of a twin screw extruder at high moisture contents. Food Res. Int. 1996, 29, 423–429. [Google Scholar] [CrossRef]

- Gropper, M.; Moraru, C.I.; Kokini, J.L. Effect of specific mechanical energy on properties of extruded protein-starch mixtures. Cereal Chem. 2002, 79, 429–433. [Google Scholar] [CrossRef]

- Chaudhary, A.L.; Torley, P.J.; Halley, P.J.; McCaffery, N.; Chaudhary, D.S. Amylose content and chemical modification effects on thermoplastic starch from maize—Processing and characterisation using conventional polymer equipment. Carb. Polym. 2009, 78, 917–925. [Google Scholar] [CrossRef]

- Oniszczuk, T.; Combrzyński, M.; Matwijczuk, A.; Oniszczuk, A.; Gładyszewska, B.; Podleśny, J.; Czernel, G.; Karcz, D.; Niemczynowicz, A.; Wójtowicz, A. Physical assessment, spectroscopic and chemometric analysis of starch-based foils with selected functional additives. PLoS ONE 2019, 14. [Google Scholar] [CrossRef] [PubMed]

- Lancuški, A.; Ammar, A.A.; Avrahami, R.; Vilensky, R.; Vasilyev, G.; Zussman, E. Design of starch-formate compound fibers as encapsulation platform for biotherapeutics. Carb. Polym. 2017, 158, 68–76. [Google Scholar] [CrossRef]

- Kaushik, A.; Singh, M.; Verma, G. Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carb. Polym. 2010, 82, 337–345. [Google Scholar] [CrossRef]

- Kizil, R.; Irudayaraj, J.; Seetharaman, K. Characterization of irradiated starches by using FT-Raman and FTIR spectroscopy. J. Agric. Food Chem. 2002, 50, 3912–3918. [Google Scholar] [CrossRef]

- Brereton, R.G. Chemometrics: Data Analysis for the Laboratory and Chemical Plant; John Wiley: Chichester, UK, 2003; pp. 203–356. [Google Scholar]

- Abdi, H.; Williams, L.J. Principal component analysis. Wires Comput. Stat. 2010, 2, 433–459. [Google Scholar] [CrossRef]

- Xu, C.J.; Liang, Y.Z.; Chau, F.T.; Heyden, Y.V. Pretreatments of chromatographic fingerprints for quality control of herbal medicines. J. Chromatogr. A 2006, 1134, 253–259. [Google Scholar] [CrossRef]

- Li, Y.Q.; Kong, D.X.; Wu, H. Analysis and evaluation of essential oil components of cinnamon barks using GC–MS and FTIR spectroscopy. Ind. Crop. Prod. 2013, 41, 269–278. [Google Scholar] [CrossRef]

| Parameter | Forming Die | Screw Speed (rpm) | Model Fitted |

|---|---|---|---|

| Efficiency (kg h−1) | M1 | 100 | E = 41.118−2.119MC+1.510A+0.084MC2+0.005MCA−0.464A2 |

| 130 | E = 436.168−45.329MC+6.344A+1.296MC2−0.317MCA+0.136A2 | ||

| M2 | 100 | E = −48.549+7.922MC-3.726A-.204MC2+0.206MCA+0.036A2 | |

| 130 | E = −97.566+13.166MC+7.026A−0.336MC2−0.322MCA−0.136A2 | ||

| SME (kWh kg−1) | M1 | 100 | SME = 0.2007−0.0103MC+0.0271A+0.0002MC2−0.0018MCA+0.0016A2 |

| 130 | SME = −0.0154+0,0173MC+0.0368A−0.0006MC2−0.002MCA−0.0001A2 | ||

| M2 | 100 | SME = −1.0122+0.1293MC+0.0002A−0.0037MC2+0.0004MCA−0.0016A2 | |

| 130 | SME = 0.6545−0.051MC−0.0427A+0.0011MC2+0.0028MCA−0.0016A2 | ||

| Cutting force (N) | M1 | 100 | CF = −2028.02+263.12MC+53.84A-7.11MC2+3.87MCA−32.28A2 |

| 130 | CF = 2860.28−319.26MC+384.05A+9.46MC2−17.41MCA−4.60A2 | ||

| M2 | 100 | CF = −3592.86+430.68MC+92.52A−11.48MC2-2.02MCA−5.14A2 | |

| 130 | CF = -3275.19+392.57MC−229.01A-10.96MC2+14.09MCA+11.72A2 | ||

| Resistance for compression (MPa) | M1 | 100 | RC = −9553.83+1079.09MC+43.37A-28.33MC2−11.76MCA+9.15A2 |

| 130 | RC = −11425.17+1289.41MC−187.74A−34.59MC2+7.64MCA−14.04A2 | ||

| M2 | 100 | RC = -30643.98+3380.90MC+242.65A-90.84MC2−27.26MCA+36.21A2 | |

| 130 | RC = 8347.24−906.55MC−58.97A+26.16MC2−3.08MCA+11.93A2 |

| Variation Source | df | Sum of Squares | Mean Squares | F0 Test | p (F > F0) |

|---|---|---|---|---|---|

| A | 6 | 637.08 | 106.18 | 162.05 | <0.05 |

| M | 1 | 9786.55 | 9786.55 | 14936.30 | <0.05 |

| MC | 2 | 887.46 | 443.73 | 677.22 | <0.05 |

| S | 1 | 18315.90 | 18315.90 | 27953.90 | <0.05 |

| A*M | 6 | 162.12 | 27.02 | 41.24 | <0.05 |

| A*MC | 12 | 395.04 | 32.92 | 50.24 | <0.05 |

| A*S | 6 | 511.23 | 85.20 | 130.04 | <0.05 |

| M*MC | 2 | 7.71 | 3.85 | 5.88 | <0.05 |

| M*S | 1 | 454.97 | 454.97 | 694.38 | <0.05 |

| MC*S | 2 | 9.09 | 4.55 | 6.94 | <0.05 |

| Variation Source | df | Sum of Squares | Mean Squares | F0 test | p (F > F0) |

|---|---|---|---|---|---|

| A | 6 | 0.0042 | 0.0007 | 135.31 | <0.05 |

| M | 1 | 0.1026 | 0.1026 | 19669.70 | <0.05 |

| MC | 2 | 0.0308 | 0.0154 | 2955.75 | <0.05 |

| S | 1 | 0.0068 | 0.0068 | 1297.34 | <0.05 |

| A*M | 6 | 0.0285 | 0.0028 | 54.88 | <0.05 |

| A*MC | 12 | 0.0017 | 0.0001 | 56.09 | <0.05 |

| A*S | 6 | 0.0035 | 0.0003 | 99.17 | <0.05 |

| M*MC | 2 | 0.0025 | 0.0001 | 30.77 | <0.05 |

| M*S | 1 | 0.0001 | 0.0001 | 331.60 | <0.05 |

| MC*SS | 2 | 0.0002 | 0.0001 | 16.30 | <0.05 |

| Variation Source | df | Sum of Squares | Mean Squares | F0 test | p (F > F0) |

|---|---|---|---|---|---|

| A | 6 | 20835591.86 | 3472598.64 | 842.40 | <0.05 |

| M | 1 | 16537802.65 | 16537802.65 | 4011.82 | <0.05 |

| MC | 2 | 44607.10 | 22303.55 | 5.41 | <0.05 |

| S | 1 | 398.41 | 398.41 | 0.10 | 0.76 |

| A*M | 6 | 1382125.77 | 230354.29 | 55.88 | <0.05 |

| A*MC | 12 | 328018.80 | 27334.90 | 6.63 | <0.05 |

| A*S | 6 | 805109.31 | 134184.88 | 32.55 | <0.05 |

| M*MC | 2 | 21191.76 | 10595.88 | 2.57 | 0.08 |

| M*S | 1 | 212836.72 | 212836.72 | 51.63 | <0.05 |

| MC*S | 2 | 42746.38 | 21373.19 | 5.18 | <0.05 |

| Variation Source | df | Sum of Squares | Mean Squares | F0 test | p (F > F0) |

|---|---|---|---|---|---|

| A | 6 | 44380113.23 | 7396685.54 | 976.75 | <0.05 |

| M | 1 | 1722479.66 | 1722479.66 | 227.46 | <0.05 |

| MC | 2 | 1864091.80 | 932045.90 | 123.08 | <0.05 |

| S | 1 | 2489633.17 | 2489633.17 | 328.76 | <0.05 |

| A*M | 6 | 1276493.15 | 212748.86 | 28.09 | <0.05 |

| A*MC | 12 | 498540.48 | 41545.04 | 5.49 | <0.05 |

| A*S | 6 | 810771.30 | 135128.55 | 17.84 | <0.05 |

| M*MC | 2 | 148377.25 | 74188.63 | 9.8 | <0.05 |

| M*S | 1 | 678894.86 | 678894.86 | 89.65 | <0.05 |

| MC*S | 2 | 164722.48 | 82361.24 | 10.88 | <0.05 |

| Position o Maximum (cm−1) | ||||||||

|---|---|---|---|---|---|---|---|---|

| M1 S1 | M2 S1 | M1 S1 | M2 S1 | Type of Vibrations | ||||

| A1 | A2 | A3 | A1 | A2 | A3 | |||

| 3308 | 3308 | 3315 | 3304 | 3304 | 3317 | 3307 | 3300 | ν(-OH) with absorber water |

| 2925 | 2925 | 2924 | 2929 | 2925 | 2927 | 2927 | 2926 | νst(C-H) and ν(C-H) in CH2 / CH3 group |

| 2887 | 2887 | 2889 | 2890 | 2884 | 2887 | 2886 | 2885 | |

| 1742/5 | 1742/5 | 1742/5 | 1742/5 | 1742/5 | 1742/5 | 1742/5 | 1742/5 | ν(C=O) |

| 1647 | 1645 | 1647 | 1643 | 1645 | 1645 | 1647 | 1640 | δm(O-H) (absorber water) |

| nd | nd | 1591 | 1610 | nd | nd | 1609 | Nd | δ(C-H) or δ(CH2) in plane |

| 1417 | 1418 | 1413 | 1415 | 1420 | 1417 | 1417 | 1415 | C-H bending and wagging or δ(COH) |

| 1363 | 1363 | 1365 | 1365 | 1363 | 1367 | 1360 | 1363 | |

| 1241 | 1239 | 1238 | 1231 | 1235 | 1240 | 1241 | 1242 | δ(O-H) or C-O |

| 1148 | 1147 | 1148 | 1149 | 1149 | 1149 | 1147 | 1147 | anhydroglucose ring C–O stretch of C–O–H in starch and C-O-C antisymmetric bridge |

| 1077 | 1078 | 1077 | 1078 | 1078 | 1078 | 1078 | 1078 | |

| 990 | 990 | 992 | 992 | 992 | 993 | 992 | 992 | ν (C-O) and ν(C-O-C or C-O-H) |

| 927 | 927 | 929 | 928 | 928 | 927 | 928 | 928 | ν (C-C) and ν (C-O) or C-O-C bend or O-H deformation (broadened by water) |

| 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 | |

| 757 | 760 | 760 | 760 | 760 | 760 | 760 | 760 | |

| 757 | 760 | 760 | 760 | 760 | 760 | 760 | 760 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Combrzyński, M.; Matwijczuk, A.; Wójtowicz, A.; Oniszczuk, T.; Karcz, D.; Szponar, J.; Niemczynowicz, A.; Bober, D.; Mitrus, M.; Kupryaniuk, K.; et al. Potato Starch Utilization in Ecological Loose-Fill Packaging Materials—Sustainability and Characterization. Materials 2020, 13, 1390. https://doi.org/10.3390/ma13061390

Combrzyński M, Matwijczuk A, Wójtowicz A, Oniszczuk T, Karcz D, Szponar J, Niemczynowicz A, Bober D, Mitrus M, Kupryaniuk K, et al. Potato Starch Utilization in Ecological Loose-Fill Packaging Materials—Sustainability and Characterization. Materials. 2020; 13(6):1390. https://doi.org/10.3390/ma13061390

Chicago/Turabian StyleCombrzyński, Maciej, Arkadiusz Matwijczuk, Agnieszka Wójtowicz, Tomasz Oniszczuk, Dariusz Karcz, Jarosław Szponar, Agnieszka Niemczynowicz, Dariusz Bober, Marcin Mitrus, Karol Kupryaniuk, and et al. 2020. "Potato Starch Utilization in Ecological Loose-Fill Packaging Materials—Sustainability and Characterization" Materials 13, no. 6: 1390. https://doi.org/10.3390/ma13061390

APA StyleCombrzyński, M., Matwijczuk, A., Wójtowicz, A., Oniszczuk, T., Karcz, D., Szponar, J., Niemczynowicz, A., Bober, D., Mitrus, M., Kupryaniuk, K., Stasiak, M., Dobrzański, B., & Oniszczuk, A. (2020). Potato Starch Utilization in Ecological Loose-Fill Packaging Materials—Sustainability and Characterization. Materials, 13(6), 1390. https://doi.org/10.3390/ma13061390