Strontium- and Cobalt-Doped Multicomponent Mesoporous Bioactive Glasses (MBGs) for Potential Use in Bone Tissue Engineering Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Glass Synthesis

2.2. MBG Characterization

2.2.1. Thermal and Structural Characteristics

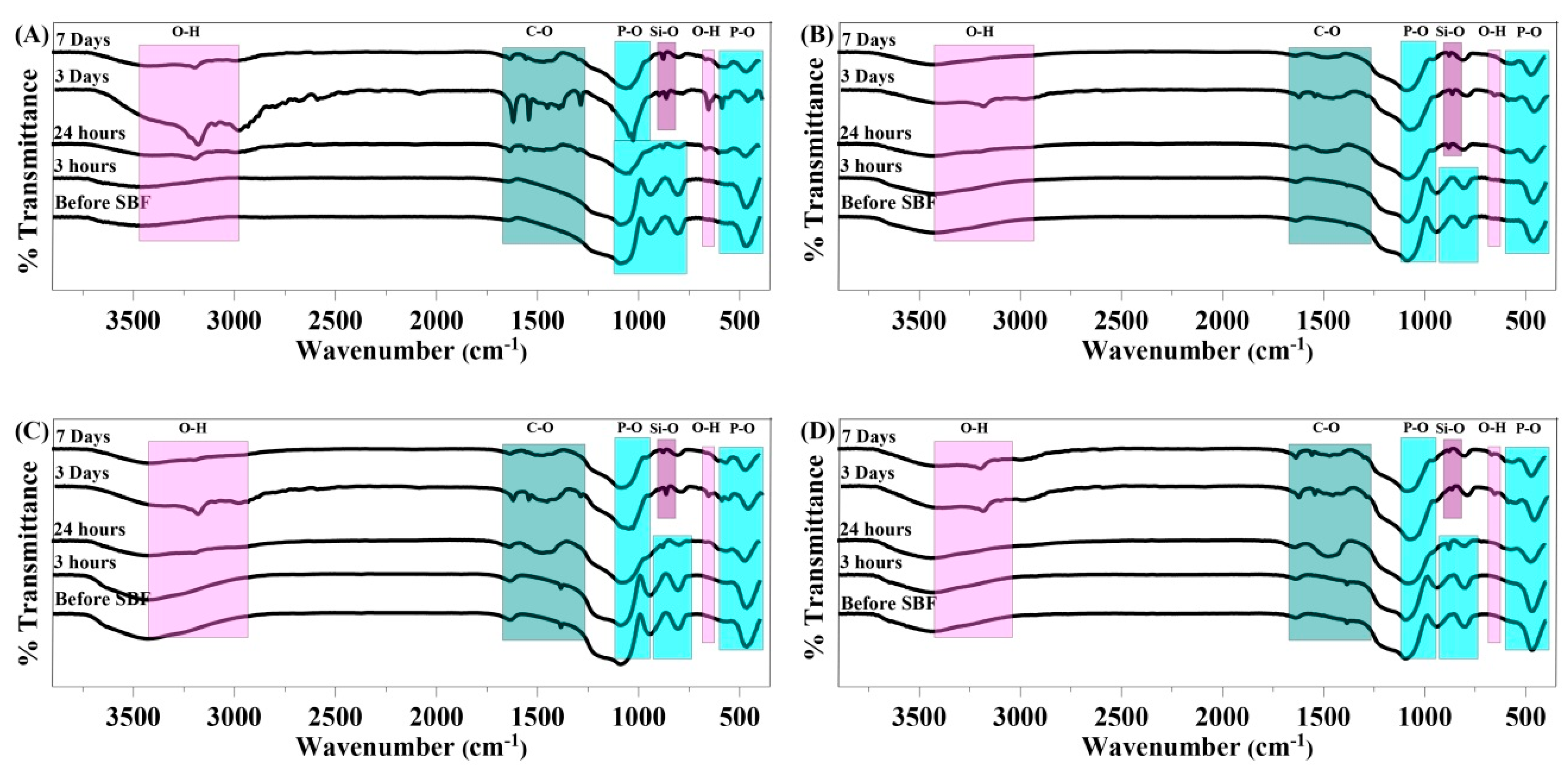

2.2.2. FTIR Analysis

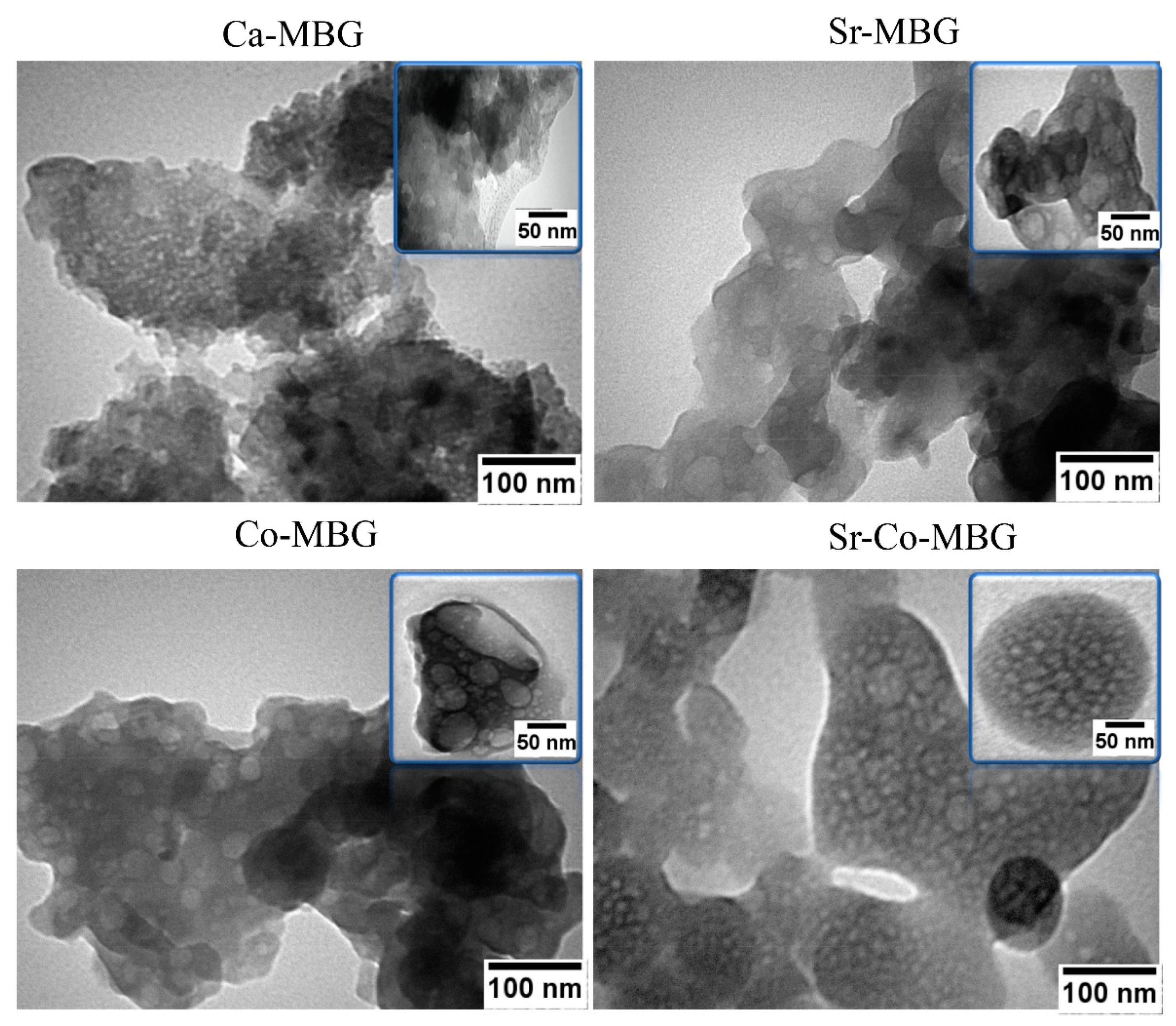

2.2.3. Microscopic Observations and Compositional Analysis

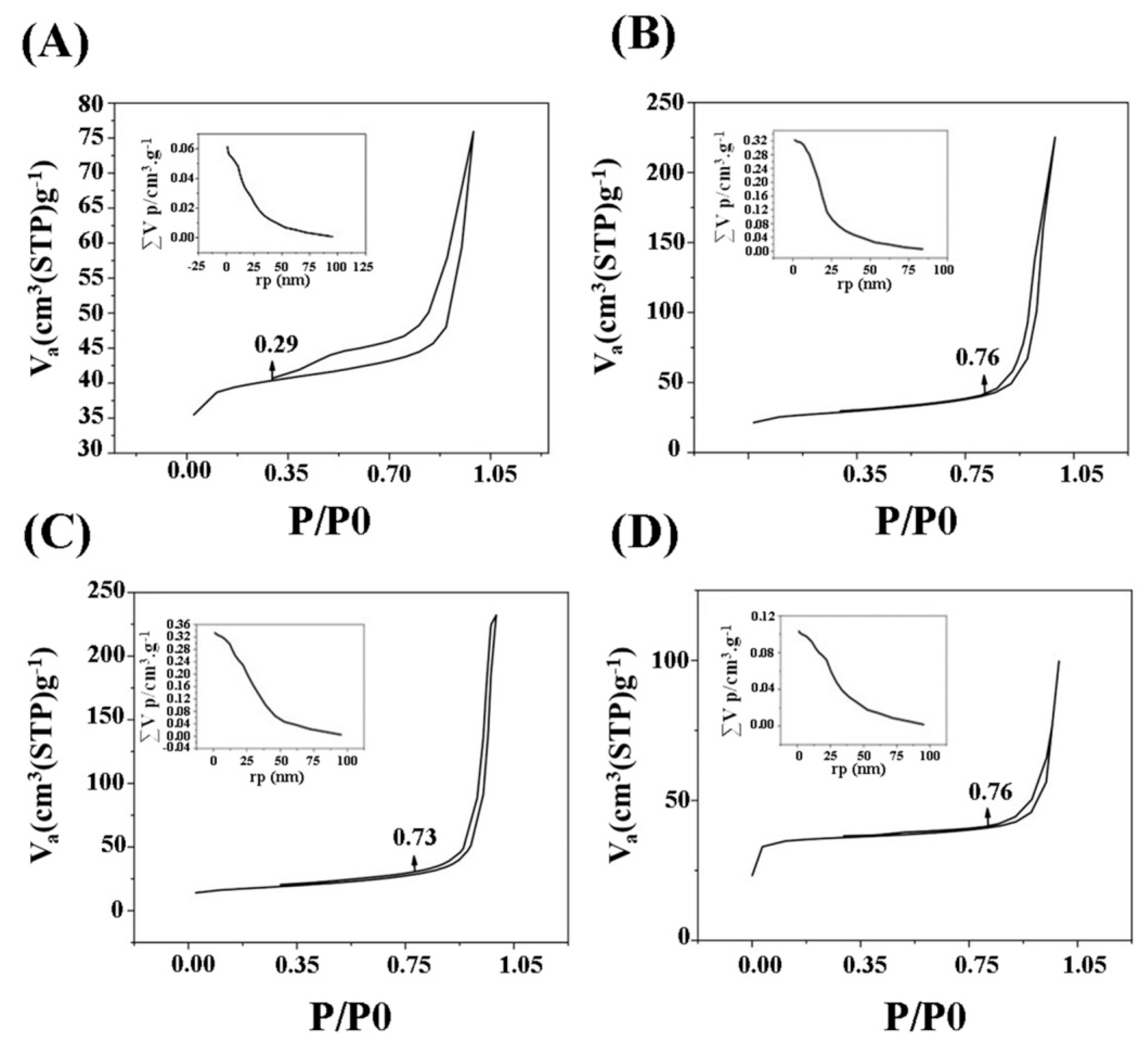

2.2.4. N2 Adsorption–Desorption Analysis

2.2.5. Size and Surface Charge Analyses

2.3. In Vitro Bioactivity Assessment

2.4. Evaluation of In Vitro Cellular Behavior

2.4.1. Cell Viability

2.4.2. Cell Attachment Study

2.4.3. In Vitro Mineralization

2.4.4. Cell Scratch Migration Assay

2.5. Statistical Evaluations

2.6. Image Treatment

3. Results

3.1. Thermal and Compositional Analysis

3.2. XRD Analysis

3.3. FTIR

3.4. Textural Properties

3.5. DLS, TEM and Zeta Potential Measurements

3.6. Bioactivity

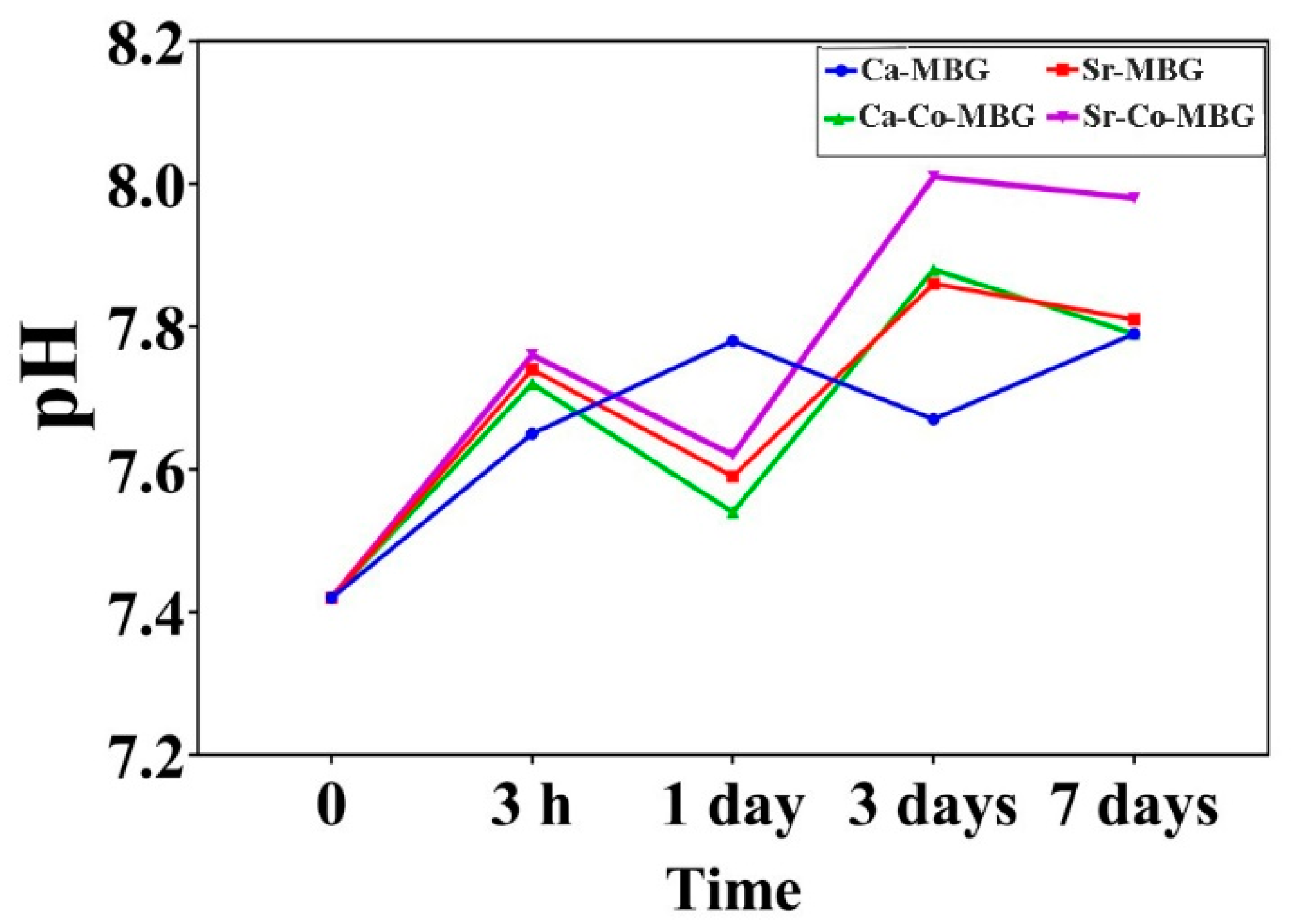

3.7. pH Measurement

3.8. Ion Release Profile

3.9. Cell Viability

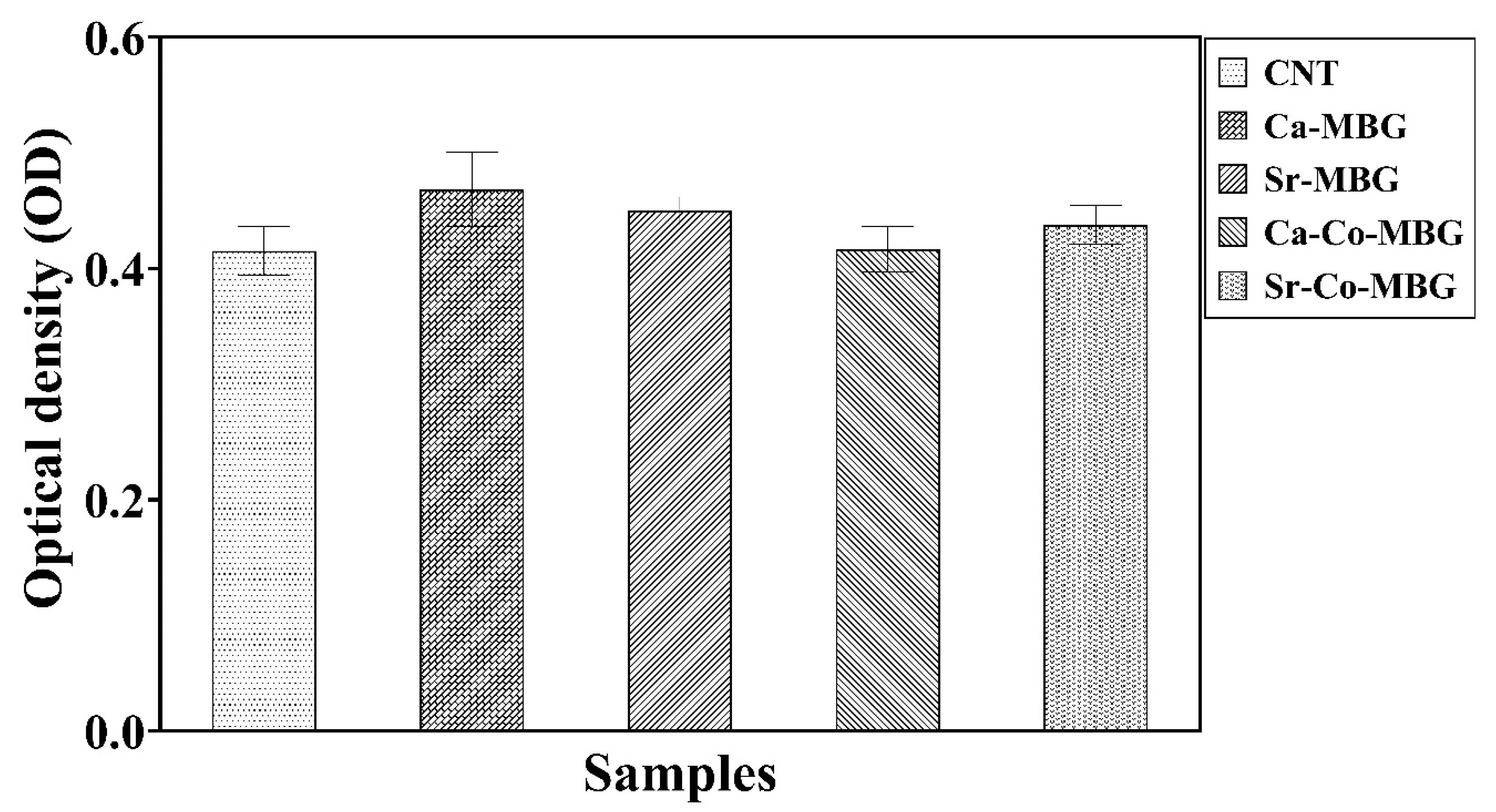

3.10. Cell Attachment Study

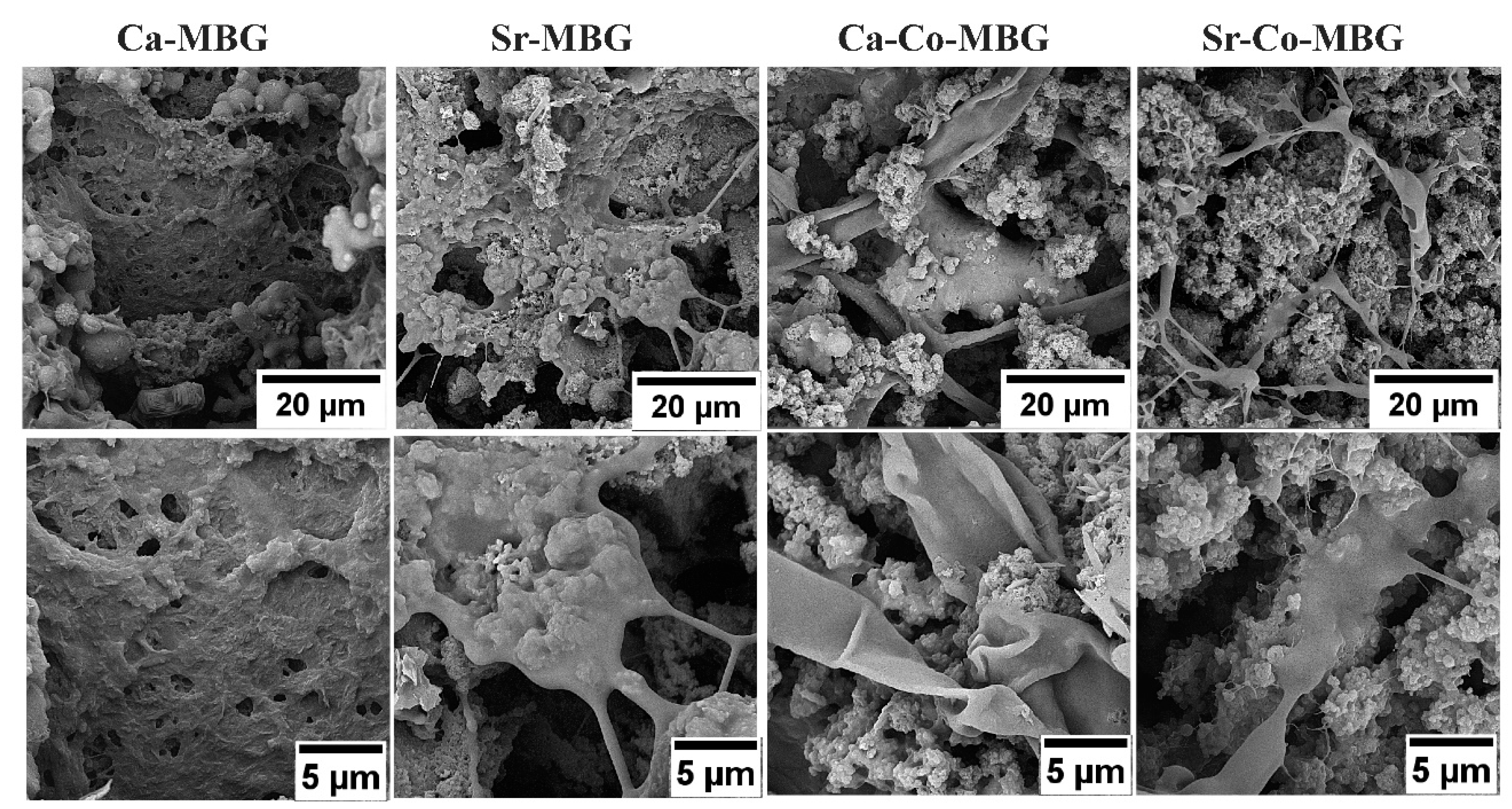

3.11. Bone Nodule Formation

3.12. In Vitro Angiogenesis Evaluation

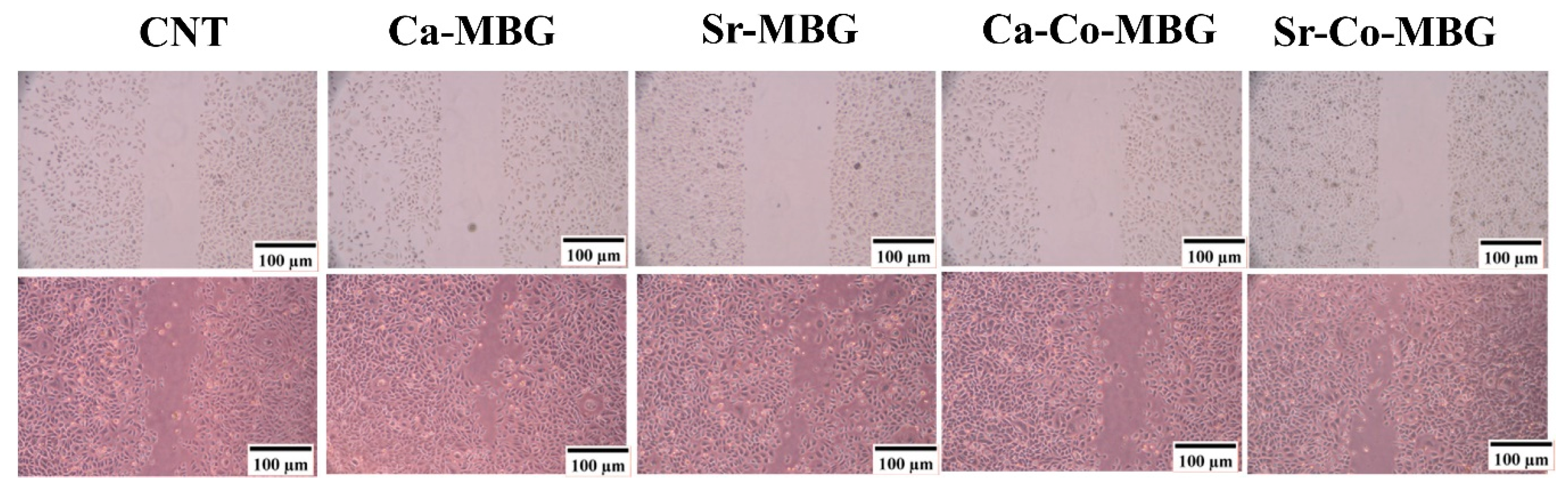

3.13. Correlation Matrix Presentation

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Massera, J. Bioactive glasses: Benefits and drawbacks for use in bone tissue engineering. Eng. Biomater. 2019, 153, 8. [Google Scholar]

- Varini, E.; Sánchez-Salcedo, S.; Malavasi, G.; Lusvardi, G.; Vallet-Regí, M.; Salinas, A. Cerium (III) and (IV) containing mesoporous glasses/alginate beads for bone regeneration: Bioactivity, biocompatibility and reactive oxygen species activity. Mater. Sci. Eng. C 2019, 105, 109971. [Google Scholar] [CrossRef]

- Gómez-Cerezo, N.; Verron, E.; Montouillout, V.; Fayon, F.; Lagadec, P.; Bouler, J.; Bujoli, B.; Arcos, D.; Vallet-Regí, M. The response of pre-osteoblasts and osteoclasts to gallium containing mesoporous bioactive glasses. Acta Biomater. 2018, 76, 333–343. [Google Scholar] [CrossRef]

- Wilkesmann, S.; Fellenberg, J.; Nawaz, Q.; Reible, B.; Moghaddam, A.; Boccaccini, A.R.; Westhauser, F. Primary osteoblasts, osteoblast precursor cells or osteoblast-like cell lines: Which human cell types are (most) suitable for characterizing 45S5-Bioglass? J. Biomed. Mater. Res. Part A 2019, 108, 663–674. [Google Scholar] [CrossRef]

- Baino, F.; Fiume, E.; Barberi, J.; Kargozar, S.; Marchi, J.; Massera, J.; Verné, E. Processing methods for making porous bioactive glass-based scaffolds—A state-of-the-art review. Int. J. Appl. Ceram. Technol. 2019, 16, 1762–1796. [Google Scholar] [CrossRef]

- Baino, F.; Hamzehlou, S.; Kargozar, S. Bioactive glasses: Where are we and where are we going? J. Funct. Biomater. 2018, 9, 25. [Google Scholar] [CrossRef]

- Baino, F.; Fiume, E.; Miola, M.; Verné, E. Bioactive sol-gel glasses: Processing, properties, and applications. Int. J. Appl. Ceram. Technol. 2018, 15, 841–860. [Google Scholar] [CrossRef]

- Neščáková, Z.; Zheng, K.; Liverani, L.; Nawaz, Q.; Galusková, D.; Kaňková, H.; Michálek, M.; Galusek, D.; Boccaccini, A.R. Multifunctional zinc ion doped sol–gel derived mesoporous bioactive glass nanoparticles for biomedical applications. Bioact. Mater. 2019, 4, 312–321. [Google Scholar] [CrossRef]

- Kargozar, S.; Ramakrishna, S.; Mozafari, M. Chemistry of Biomaterials: Future Prospects. Curr. Opin. Biomed. Eng. 2019, 10, 181–190. [Google Scholar] [CrossRef]

- Kargozar, S.; Mozafari, M.; Hamzehlou, S.; Kim, H.-W.; Baino, F. Mesoporous bioactive glasses (MBGs) in cancer therapy: Full of hope and promise. Mater. Lett. 2019, 251, 241–246. [Google Scholar] [CrossRef]

- Kargozar, S.; Montazerian, M.; Hamzehlou, S.; Kim, H.-W.; Baino, F. Mesoporous bioactive glasses: Promising platforms for antibacterial strategies. Acta Biomater. 2018, 81, 1–19. [Google Scholar] [CrossRef]

- Polo, L.; Gómez-Cerezo, N.; García-Fernández, A.; Aznar, E.; Vivancos, J.L.; Arcos, D.; Vallet-Regí, M.; Martínez-Máñez, R. Mesoporous Bioactive Glasses Equipped with Stimuli-Responsive Molecular Gates for Controlled Delivery of Levofloxacin against Bacteria. Chem. A Eur. J. 2018, 24, 18944–18951. [Google Scholar] [CrossRef]

- Gómez-Cerezo, N.; Casarrubios, L.; Saiz-Pardo, M.; Ortega, L.; de Pablo, D.; Díaz-Güemes, I.; Fernández-Tomé, B.; Enciso, S.; Sánchez-Margallo, F.; Portolés, M. Mesoporous bioactive glass/ε-polycaprolactone scaffolds promote bone regeneration in osteoporotic sheep. Acta Biomater. 2019, 90, 393–402. [Google Scholar] [CrossRef]

- Gupta, N.; Santhiya, D.; Murugavel, S.; Kumar, A.; Aditya, A.; Ganguli, M.; Gupta, S. Effects of transition metal ion dopants (Ag, Cu and Fe) on the structural, mechanical and antibacterial properties of bioactive glass. Colloids Surf. A Physicochem. Eng. Asp. 2018, 538, 393–403. [Google Scholar] [CrossRef]

- Melchers, S.; Uesbeck, T.; Winter, O.; Eckert, H.; Eder, D. Effect of aluminum ion incorporation on the bioactivity and structure in mesoporous bioactive glasses. Chem. Mater. 2016, 28, 3254–3264. [Google Scholar] [CrossRef]

- Kargozar, S.; Lotfibakhshaiesh, N.; Ai, J.; Samadikuchaksaraie, A.; Hill, R.G.; Shah, P.A.; Milan, P.B.; Mozafari, M.; Fathi, M.; Joghataei, M.T. Synthesis, physico-chemical and biological characterization of strontium and cobalt substituted bioactive glasses for bone tissue engineering. J. Non-Cryst. Solids 2016, 449, 133–140. [Google Scholar] [CrossRef]

- Kargozar, S.; Lotfibakhshaiesh, N.; Ai, J.; Mozafari, M.; Milan, P.B.; Hamzehlou, S.; Barati, M.; Baino, F.; Hill, R.G.; Joghataei, M.T. Strontium-and cobalt-substituted bioactive glasses seeded with human umbilical cord perivascular cells to promote bone regeneration via enhanced osteogenic and angiogenic activities. Acta Biomater. 2017, 58, 502–514. [Google Scholar] [CrossRef]

- Bonnelye, E.; Chabadel, A.; Saltel, F.; Jurdic, P. Dual effect of strontium ranelate: Stimulation of osteoblast differentiation and inhibition of osteoclast formation and resorption in vitro. Bone 2008, 42, 129–138. [Google Scholar] [CrossRef]

- Gentleman, E.; Fredholm, Y.C.; Jell, G.; Lotfibakhshaiesh, N.; O’Donnell, M.D.; Hill, R.G.; Stevens, M.M. The effects of strontium-substituted bioactive glasses on osteoblasts and osteoclasts in vitro. Biomaterials 2010, 31, 3949–3956. [Google Scholar] [CrossRef]

- Kargozar, S.; Baino, F.; Hamzehlou, S.; Hill, R.G.; Mozafari, M. Bioactive glasses: Sprouting angiogenesis in tissue engineering. Trends Biotechnol. 2018, 36, 430–444. [Google Scholar] [CrossRef]

- Chai, Y.C.; Mendes, L.F.; van Gastel, N.; Carmeliet, G.; Luyten, F.P. Fine-tuning pro-angiogenic effects of cobalt for simultaneous enhancement of vascular endothelial growth factor secretion and implant neovascularization. Acta Biomater. 2018, 72, 447–460. [Google Scholar] [CrossRef]

- Roine, H.C.S.A. The Software. 2018. Available online: www.outotec.com/HSC (accessed on 23 April 2018).

- Kokubo, T.; Takadama, H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef]

- Nommeots-Nomm, A.; Labbaf, S.; Devlin, A.; Todd, N.; Geng, H.; Solanki, A.K.; Tang, H.M.; Perdika, P.; Pinna, A.; Ejeian, F. Highly degradable porous melt-derived bioactive glass foam scaffolds for bone regeneration. Acta Biomater. 2017, 57, 449–461. [Google Scholar] [CrossRef]

- Cacciotti, I.; Lombardi, M.; Bianco, A.; Ravaglioli, A.; Montanaro, L. Sol–gel derived 45S5 bioglass: Synthesis, microstructural evolution and thermal behaviour. J. Mater. Sci. Mater. Med. 2012, 23, 1849–1866. [Google Scholar] [CrossRef]

- Zheng, K.; Solodovnyk, A.; Li, W.; Goudouri, O.M.; Stähli, C.; Nazhat, S.N.; Boccaccini, A.R. Aging time and temperature effects on the structure and bioactivity of gel-derived 45S5 glass-ceramics. J. Am. Ceram. Soc. 2015, 98, 30–38. [Google Scholar] [CrossRef]

- Kermani, F.; Kargozar, S.; Tayarani-Najaran, Z.; Yousefi, A.; Beidokhti, S.M.; Moayed, M.H. Synthesis of nano HA/βTCP mesoporous particles using a simple modification in granulation method. Mater. Sci. Eng. C 2019, 96, 859–871. [Google Scholar] [CrossRef]

- Wu, C.; Chang, J. Multifunctional mesoporous bioactive glasses for effective delivery of therapeutic ions and drug/growth factors. J. Control. Release 2014, 193, 282–295. [Google Scholar] [CrossRef]

- García, A.; Izquierdo-Barba, I.; Colilla, M.; de Laorden, C.L.; Vallet-Regí, M. Preparation of 3-D scaffolds in the SiO2–P2O5 system with tailored hierarchical meso-macroporosity. Acta Biomater. 2011, 7, 1265–1273. [Google Scholar] [CrossRef]

- Wu, C.; Fan, W.; Zhu, Y.; Gelinsky, M.; Chang, J.; Cuniberti, G.; Albrecht, V.; Friis, T.; Xiao, Y. Multifunctional magnetic mesoporous bioactive glass scaffolds with a hierarchical pore structure. Acta Biomater. 2011, 7, 3563–3572. [Google Scholar] [CrossRef]

- Han, P.; Wu, C.; Chang, J.; Xiao, Y. The cementogenic differentiation of periodontal ligament cells via the activation of Wnt/β-catenin signalling pathway by Li+ ions released from bioactive scaffolds. Biomaterials 2012, 33, 6370–6379. [Google Scholar] [CrossRef]

- Wu, C.; Zhou, Y.; Xu, M.; Han, P.; Chen, L.; Chang, J.; Xiao, Y. Copper-containing mesoporous bioactive glass scaffolds with multifunctional properties of angiogenesis capacity, osteostimulation and antibacterial activity. Biomaterials 2013, 34, 422–433. [Google Scholar] [CrossRef]

- Neves, N.; Linhares, D.; Costa, G.; Ribeiro, C.; Barbosa, M. In vivo and clinical application of strontium-enriched biomaterials for bone regeneration: A systematic review. Bone Joint Res. 2017, 6, 366–375. [Google Scholar] [CrossRef]

- Reginster, J.-Y. Cardiac concerns associated with strontium ranelate. Expert Opin. Drug Saf. 2014, 13, 1209–1213. [Google Scholar] [CrossRef]

- Donneau, A.-F.; Reginster, J.-Y. Cardiovascular Safety of Strontium Ranelate: Real-Life Assessment in Clinical Practice; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Lindsay, D.; Kerr, W. Cobalt close-up. Nat. Chem. 2011, 3, 494. [Google Scholar] [CrossRef]

- Kim, J.-J.; Kim, Y.-S.; Kumar, V. Heavy metal toxicity: An update of chelating therapeutic strategies. J. Trace Elem. Med. Biol. 2019, 54, 226–231. [Google Scholar] [CrossRef]

- Leyssens, L.; Vinck, B.; van der Straeten, C.; Wuyts, F.; Maes, L. Cobalt toxicity in humans—A review of the potential sources and systemic health effects. Toxicology 2017, 387, 43–56. [Google Scholar] [CrossRef]

- Sing, K.S.; Williams, R.T. Physisorption hysteresis loops and the characterization of nanoporous materials. Adsorpt. Sci. Technol. 2004, 22, 773–782. [Google Scholar] [CrossRef]

- Aali, H.; Azizi, N.; Baygi, N.J.; Kermani, F.; Mashreghi, M.; Youssefi, A.; Mollazadeh, S.; Khaki, J.V.; Nasiri, H. High antibacterial and photocatalytic activity of solution combustion synthesized Ni0. 5Zn0. 5Fe2O4 nanoparticles: Effect of fuel to oxidizer ratio and complex fuels. Ceram. Int. 2019, 45, 19127–19140. [Google Scholar] [CrossRef]

- Chen, D.; Huang, F.; Cheng, Y.B.; Caruso, R.A. Mesoporous anatase TiO2 beads with high surface areas and controllable pore sizes: A superior candidate for high-performance dye-sensitized solar cells. Adv. Mater. 2009, 21, 2206–2210. [Google Scholar] [CrossRef]

- Zheng, K.; Kang, J.; Rutkowski, B.; Gawęda, M.; Zhang, J.; Wang, Y.; Founier, N.; Sitarz, M.; Boccaccini, A.R. Towards highly dispersed mesoporous bioactive glass nanoparticles with high Cu concentration using Cu/ascorbic acid complex as precursor. Front. Chem. 2019, 7, 497. [Google Scholar] [CrossRef]

- Kargozar, S.; Kermani, F.; Beidokhti, S.M.; Hamzehlou, S.; Verné, E.; Ferraris, S.; Baino, F. Functionalization and Surface Modifications of Bioactive Glasses (BGs): Tailoring of the Biological Response Working on the Outermost Surface Layer. Materials 2019, 12, 3696. [Google Scholar] [CrossRef]

- Pourshahrestani, S.; Zeimaran, E.; Kadri, N.A.; Gargiulo, N.; Samuel, S.; Naveen, S.V.; Kamarul, T.; Towler, M.R. Gallium-containing mesoporous bioactive glass with potent hemostatic activity and antibacterial efficacy. J. Mater. Chem. B 2016, 4, 71–86. [Google Scholar] [CrossRef]

- Zhang, Y.; Luan, J.; Jiang, S.; Zhou, X.; Li, M. The effect of amino-functionalized mesoporous bioactive glass on MC3T3-E1 cells in vitro stimulation. Compos. Part B Eng. 2019, 172, 397–405. [Google Scholar] [CrossRef]

- Alkhraisat, M.H.; Moseke, C.; Blanco, L.; Barralet, J.E.; Lopez-Carbacos, E.; Gbureck, U. Strontium modified biocements with zero order release kinetics. Biomaterials 2008, 29, 4691–4697. [Google Scholar] [CrossRef]

- Mozafari, M.; Banijamali, S.; Baino, F.; Kargozar, S.; Hill, R.G. Calcium carbonate: Adored and ignored in bioactivity assessment. Acta Biomater. 2019, 91, 35–47. [Google Scholar] [CrossRef]

- Kermani, F.; Mollazadeh, S.; Khaki, J.V. A simple thermodynamics model for estimation and comparison the concentration of oxygen vacancies generated in oxide powders synthesized via the solution combustion method. Ceram. Int. 2019, 45, 13496–13501. [Google Scholar] [CrossRef]

- Sriranganathan, D.; Kanwal, N.; Hing, K.A.; Hill, R.G. Strontium substituted bioactive glasses for tissue engineered scaffolds: The importance of octacalcium phosphate. J. Mater. Sci. Mater. Med. 2016, 27, 39. [Google Scholar] [CrossRef]

- Kargozar, S.; Baino, F.; Lotfibakhshaiesh, N.; Hill, R.G.; Milan, P.B.; Hamzehlou, S.; Joghataei, M.T.; Mozafari, M. When size matters: Biological response to strontium-and cobalt-substituted bioactive glass particles. Mater. Today Proc. 2018, 5, 15768–15775. [Google Scholar] [CrossRef]

- Hench, L.L. Genetic design of bioactive glass. J. Eur. Ceram. Soc. 2009, 29, 1257–1265. [Google Scholar] [CrossRef]

- Romero-Sánchez, L.B.; Marí-Beffa, M.; Carrillo, P.; Medina, M.Á.; Díaz-Cuenca, A. Copper-containing mesoporous bioactive glass promotes angiogenesis in an in vivo zebrafish model. Acta Biomater. 2018, 68, 272–285. [Google Scholar] [CrossRef]

- Deng, Z.; Lin, B.; Jiang, Z.; Huang, W.; Li, J.; Zeng, X.; Wang, H.; Wang, D.; Zhang, Y. Hypoxia-Mimicking Cobalt-Doped Borosilicate Bioactive Glass Scaffolds with Enhanced Angiogenic and Osteogenic Capacity for Bone Regeneration. Int. J. Biol. Sci. 2019, 15, 1113. [Google Scholar] [CrossRef]

| Sample | SiO2 | P2O5 | CaO | SrO | CoO | Na2O | MgO | K2O |

|---|---|---|---|---|---|---|---|---|

| Ca-MBG | 41.20 | 5.06 | 36.14 | - | - | 7.17 | 3.26 | 7.17 |

| Sr-MBG | 41.20 | 5.06 | 30.14 | 6.00 | - | 7.17 | 3.26 | 7.17 |

| Ca-Co-MBG | 41.20 | 5.06 | 35.64 | - | 0.50 | 7.17 | 3.26 | 7.17 |

| Sr-Co-MBG | 41.20 | 5.06 | 29.64 | 6.00 | 0.50 | 7.17 | 3.26 | 7.17 |

| Glass | Rietveld Refinement Study | ||||

|---|---|---|---|---|---|

| Sample | Times | Crystallinity (%) | Hydroxyapatite (wt.%) | Silica gel (wt.%) | Average Crystallite Size (nm) |

| Ca-MBG | Before SBF | <5 | - | - | - |

| 3 h | 8 | - | - | - | |

| 24 h | 16 | - | - | - | |

| 3 days | 33.5 | 97 | <5 | 327 ± 58 | |

| 7 days | 45 | 98 | <5 | 198 ± 28 | |

| Glass | Rietveld Refinement Study | ||||

|---|---|---|---|---|---|

| Sample | Times | Crystallinity (%) | Hydroxyapatite (wt.%) | Silica gel (wt.%) | Average Crystallite Size (nm) |

| Sr-MBG | Before SBF | <5 | - | - | - |

| 3 h | 9 | - | - | - | |

| 24 h | 18 | - | - | - | |

| 3 days | 33.0 | 98 | <5 | 318 ± 21 | |

| 7 days | 48 | 95 | 5 | 178 ± 13 | |

| Glass | Rietveld Refinement Study | ||||

|---|---|---|---|---|---|

| Sample | Times | Crystallinity (%) | Hydroxyapatite (wt.%) | Silica gel (wt.%) | Average Crystallite Size (nm) |

| Ca-Co-MBG | Before SBF | <5 | - | - | - |

| 3 h | 7 | - | - | - | |

| 24 h | 16 | - | - | - | |

| 3 days | 31.0 | 81 | 19 | 316 ± 29 | |

| 7 days | 46 | 90 | 10 | 201 ± 9 | |

| Glass | Rietveld Refinement Study | ||||

|---|---|---|---|---|---|

| Sample | Times | Crystallinity (%) | Hydroxyapatite (wt.%) | Silica gel (wt.%) | Average Crystallite Size (nm) |

| Sr-Co-MBG | Before SBF | <5 | - | - | - |

| 3 h | <5 | - | - | - | |

| 24 h | 19 | - | - | - | |

| 3 days | 28 | 98 | <5 | 226 ± 9 | |

| 7 days | 53 | 89 | 11 | 185 ± 24 | |

| Sample | SΒET (m2.g−1) | Range of Pore Radius (nm) | Volume of Pore (Vm [cm3·g−1·(STP)] | P/P0 |

|---|---|---|---|---|

| Ca-MBG | 151.01 | 2–10 | 0.0612 | 0.29 |

| Sr-Ca-MBG | 99.56 | 5–12 | 0.3223 | 0.75 |

| Co-Ca-MBG | 62.36 | 12–23 | 0.3335 | 0.70 |

| Sr-Co-MBG | 131.97 | 10–20 | 0.1033 | 0.74 |

| Sample | Time | Ca | P | Si | Sr | Co |

|---|---|---|---|---|---|---|

| Ca-MBG | 24 h | 113.45 | 2.00 | 7.90 | - | - |

| 7 days | 208.81 | 11.65 | 31.91 | - | - | |

| Sr-MBG | 24 h | 151.4 | 1.65 | 22.53 | 70.00 | - |

| 7 days | 204.70 | 8.93 | 30.00 | 52.00 | - | |

| Ca-Co-MBG | 24 h | 179.569 | 1.33 | 22.15 | - | 0.276 |

| 7 days | 193.28 | 6.47 | 44.10 | - | 0.306 | |

| Sr-Co-MBG | 24 h | 175.24 | 2.23 | 37.60 | 69.00 | 0.432 |

| 7 days | 200.80 | 8.10 | 41.40 | 57.00 | 0.573 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kermani, F.; Mollazadeh Beidokhti, S.; Baino, F.; Gholamzadeh-Virany, Z.; Mozafari, M.; Kargozar, S. Strontium- and Cobalt-Doped Multicomponent Mesoporous Bioactive Glasses (MBGs) for Potential Use in Bone Tissue Engineering Applications. Materials 2020, 13, 1348. https://doi.org/10.3390/ma13061348

Kermani F, Mollazadeh Beidokhti S, Baino F, Gholamzadeh-Virany Z, Mozafari M, Kargozar S. Strontium- and Cobalt-Doped Multicomponent Mesoporous Bioactive Glasses (MBGs) for Potential Use in Bone Tissue Engineering Applications. Materials. 2020; 13(6):1348. https://doi.org/10.3390/ma13061348

Chicago/Turabian StyleKermani, Farzad, Sahar Mollazadeh Beidokhti, Francesco Baino, Zahra Gholamzadeh-Virany, Masoud Mozafari, and Saeid Kargozar. 2020. "Strontium- and Cobalt-Doped Multicomponent Mesoporous Bioactive Glasses (MBGs) for Potential Use in Bone Tissue Engineering Applications" Materials 13, no. 6: 1348. https://doi.org/10.3390/ma13061348

APA StyleKermani, F., Mollazadeh Beidokhti, S., Baino, F., Gholamzadeh-Virany, Z., Mozafari, M., & Kargozar, S. (2020). Strontium- and Cobalt-Doped Multicomponent Mesoporous Bioactive Glasses (MBGs) for Potential Use in Bone Tissue Engineering Applications. Materials, 13(6), 1348. https://doi.org/10.3390/ma13061348