1. Introduction

Lightweight concrete (LC) has been progressively used in structures such as large-span bridges, high-rise buildings and offshore oil platforms, owing to its superior characteristics in density, specific strength and durability [

1,

2]. Partially or entirely replacing normal weight concrete (NWC) with LC produces considerable benefits by reducing the dead load of structures [

3,

4]. Importantly, lightweight aggregate (LWA) is crucial for the properties of LC, since the main reason for the lightweight feature of LC was the light and porous LWA which differs from the denser structures of aggregates in NWC.

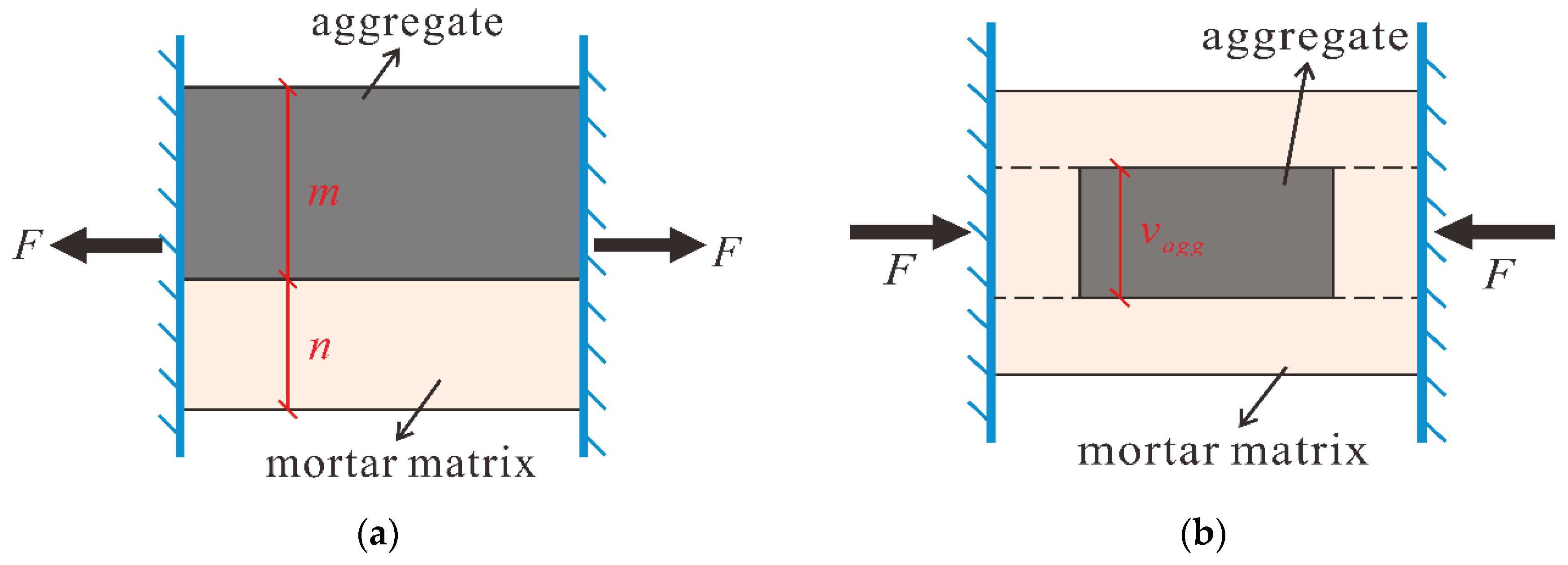

In addition to the filling role that aggregates play, the mechanical frame of concrete is also affected by aggregates [

5]. It is well known that the grading of aggregates in concrete affects the mechanical properties of NWC [

6,

7] in terms of the compaction and bond properties of concrete. One of main differences between LC and NWC is the ruptured LWA when subjected to tensile stress [

8], which means the fracture path in LC is different from that in NWC. Hence, the different aggregate size of LC could represent a different path of fracture, and then the properties of LC can be influenced. Moreover, several basic properties of LC were related to aggregate size. To date, the gradation of LWA has been proven to have significant influences on the quality of LC [

9]. Alengaram et al. [

10] investigated the effects of aggregate size and grading proportion of palm kernel shell (PKS) on the strength properties of LC. It was reported that PKS having sizes of 0–5 mm and 10–15 mm influenced the mechanical properties of LC, including compressive strength, splitting tensile strength and flexural strength. Karamloo et al. [

11] found that the increasing maximum aggregate size positively affected the fracture toughness and energy of LC. The expanded clay was used as LWA by Nahhab and Ketab to study the maximum size of aggregates on the properties of self-compacting LC [

12].

It was concluded that the increasing maximum aggregate size led to a decreased superplasticizer (SP) dosage requirement of 700–750 mm slump flow, and maximum size of 10 mm showed best enhancement on the compressive and flexural strengths [

12]. However, different types of LWA have different impacts on the mechanical properties of LC. The results from LWAs with low quality, such as PKS, may be not adapted to LWAs with high quality, such as expanded shale. Therefore, relevant research should be more specific.

The influence of LWA on the properties of LC is related to the interfacial transition zone (ITZ) apart from the inherent porous structure and lower strength. A prominent phenomenon, known as ‘internal curing’, substantially influences the structure of ITZ between LWA and the mortar matrix, while this change in the properties of ITZ enhances the bond performance of LWA. However, it was also suggested that the size of LWA affected the bond behavior in LC due to the effect of a varying specific surface [

12]. It is difficult to precisely reflect the effect of ITZ on the properties of concrete to date, and the influence of aggregate size on the properties of concrete is also hard to be quantitatively investigated at the microscale.

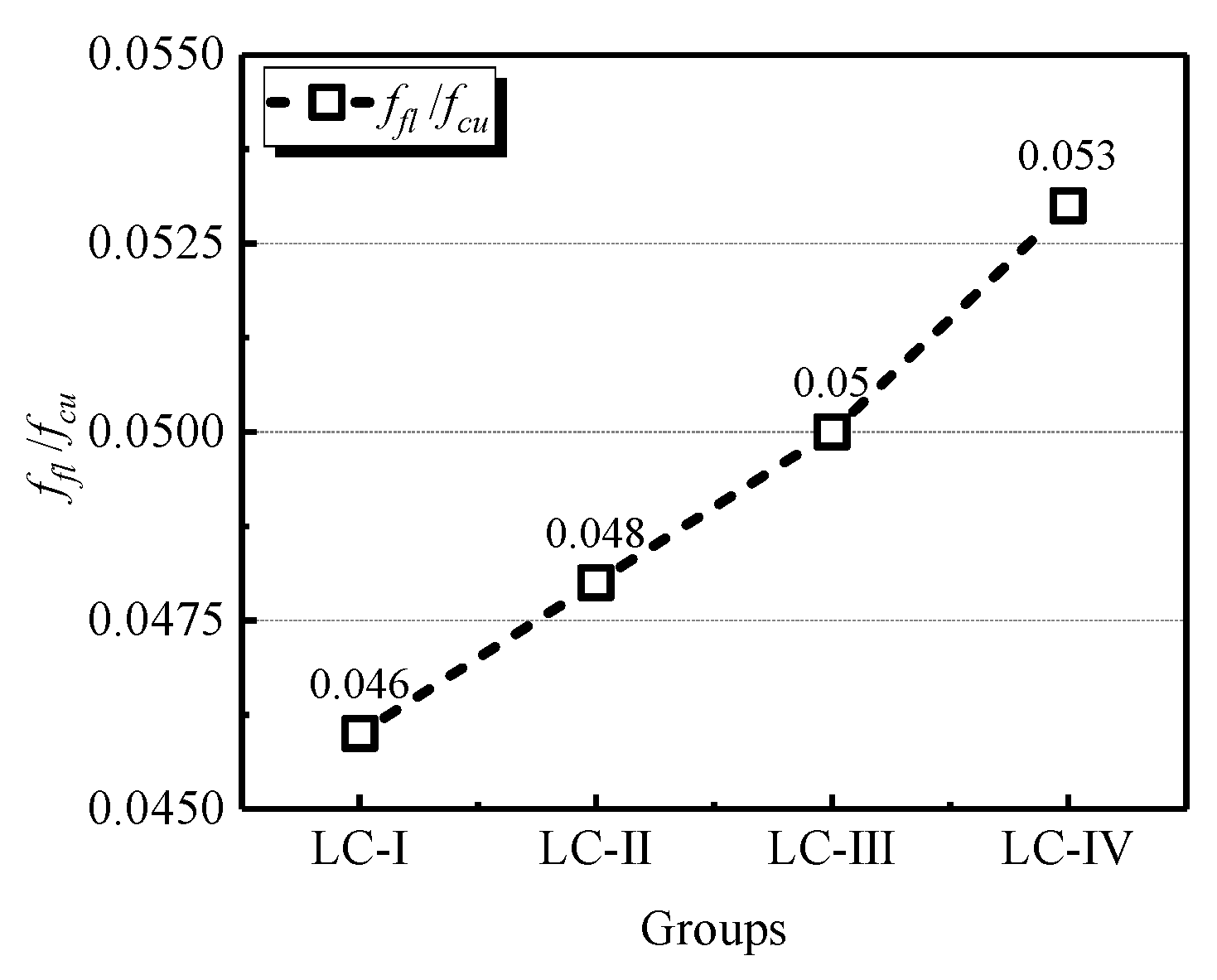

Therefore, the study of the effect of aggregate size on the mechanical properties of the LC is helpful to comprehensively control the structural performance of the LC. To this end, four groups of specimens having different sizes of LWAs were prepared to investigate the effect of aggregate size on the strength characteristics of LC. The compressive strength, splitting tensile strength and flexural strength of four groups of LCs were analyzed, and then, a simple estimation model for compressive strength considering effect of aggregate size was developed.

2. Methodology

2.1. Materials

2.1.1. Aggregates

The coarse LWA used in this work is grade 900 expanded shale with density, water absorption and cylinder compressive strength of 1512 kg/m3, 2.2 % and 6.9 MPa, respectively. The fine aggregate used is normal weight medium sands with a bulk density of 1510 kg/m3.

2.1.2. Cement and Admixtures

Ordinary Portland cement 42.5 [

13] was also used for all the mixes, and its chemical composition and physical properties are summarized in

Table 1. Additionally, the grade Ⅰ fly ash (FA) and silica fume (SF, produced by Elkem, Shanghai, China, 925U) were used as mineral admixture. Furthermore, BKS-199 polycarboxylic acid superplasticizer (SP, produced by Bok chemicals, Shandong, China), was used to produce the specimens.

2.1.3. Gradation

To investigate the effect of aggregate size on the strength characteristics of LC, coarse lightweight aggregates were divided into three different size ranges: smaller than 4.75 mm, 4.75 to 9.5 mm and 9.5 to 16 mm. The aggregates in each range were applied for one type of concrete mixture; then, aggregates from the three ranges were combined to obtain a combination of gradation. The specific data for the four gradings are given in

Table 2.

2.1.4. Mix Proportions

In order to assess strength properties of high strength LC, the ratio of water to binder (W/B) content was taken as 0.27. To keep the only variable in the tests, i.e. the size of the aggregates, one mixture of LC was designed. The concrete mixture was designed according the volume of each raw material, while the volume fraction of LWA was kept as 40%, and the ratio of fine-to-all aggregates is 0.4, which means the sands content was adjusted when the aggregate size was changed. Owing to the lower water absorption of LWAs (2.2%), this was not taken into consideration in the design of the concrete mixture. Furthermore, due to the fact that the mixture was obtained according to the volumetric design method, the use of materials except LWA can be determined at once, while the mass of LWA was changed according to the particle density of LWAs with different sizes. Contents of materials except LWA and sands in the mixture are given in

Table 3. Note that despite the aggregates passing the 4.75 mm sieve being definable as the fine LWA, considering the purpose of present study, they were still categorized into the coarse LWA.

2.1.5. Designation of Specimens

Four groups of specimens were prepared and labeled as LC-Ⅰ, LC-Ⅱ, LC-Ⅲ and LC-Ⅳ, corresponding to the four gradings in

Table 2. Labels of specific uses in each group, such as compression test, splitting test and flexural test, were not distinguished.

2.2. Specimen Preparation

A series of experimental programs was conducted to determine the correlation between the aggregate size and the strength properties of LC, which includes compressive strength, splitting tensile strength and flexural strength tests. For specimens of each group, fifteen 100 mm × 100 mm × 100 mm concrete cubes for the 3-day, 7-day, 28-day, 90-day and 120-day compressive strength tests (three cubes for one curing period), another three 100 mm × 100 mm × 100 mm cubes for the 28-day splitting tensile strength test, and three 100 mm × 100 mm × 100 mm prisms for the 28-day flexural strength test, were cast.

The concretes were mixed by a double-axis mixer (produced by Fangtai, Henan, China) under laboratory-conditions. The LWA was presoaked [

14]. Then, cementitious materials, sands and 3/4 of the total water were poured into the mixer. After 1–2 min mixing, the LWAs and the remaining water were added to the mix.

Subsequently, all specimens were cured, demolding was performed at 24 h, and the specimens were placed into a standard curing room maintained at 20 ± 2 °C and 95% ± 10% relative humidity until testing time.

2.3. Testing Methods

The oven-dried density, compressive strength, splitting tensile strength and flexural strength of four groups of LC were tested in this study. The test items and the dimensions of related specimens are summarized in

Table 4.

2.3.1. Oven-Dried Density

The density of oven-dried concrete was measured by using 100 mm × 100 mm × 100 mm specimens for 28-day compressive strength according to the relevant Chinese standard (JGJ51-2002) [

15].

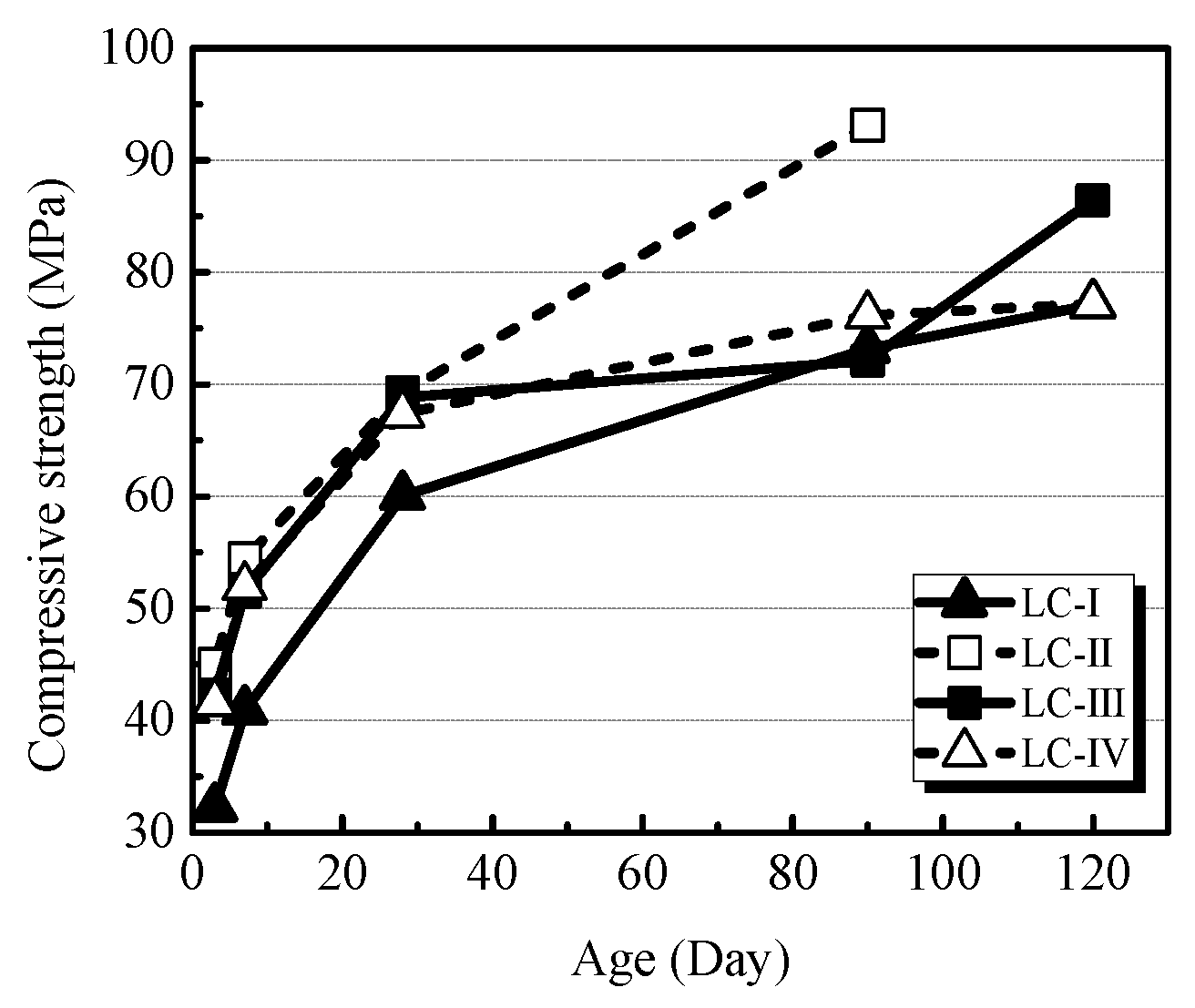

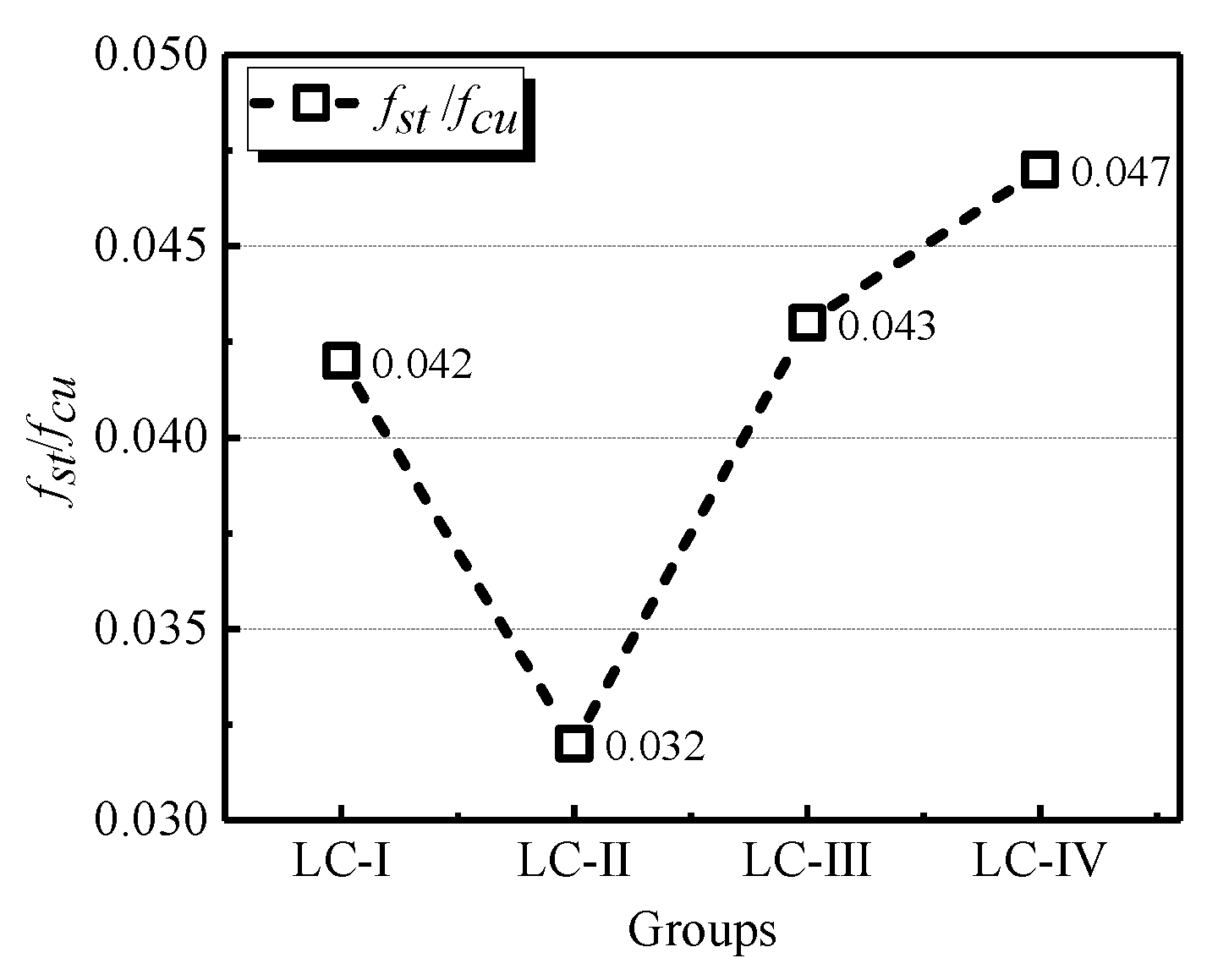

2.3.2. Compressive Strength

The compressive strengths of each group were determined at ages of 3 days, 7 days, 28 days, 90 days and 120 days by following GB/T 50081 [

16]. A load-control procedure was applied during the cubic compression strength test with a rate of 10 kN/s. The compression tests were conducted with an electric-hydraulic servo universal test machine having a maximum load capacity of 1000 kN.

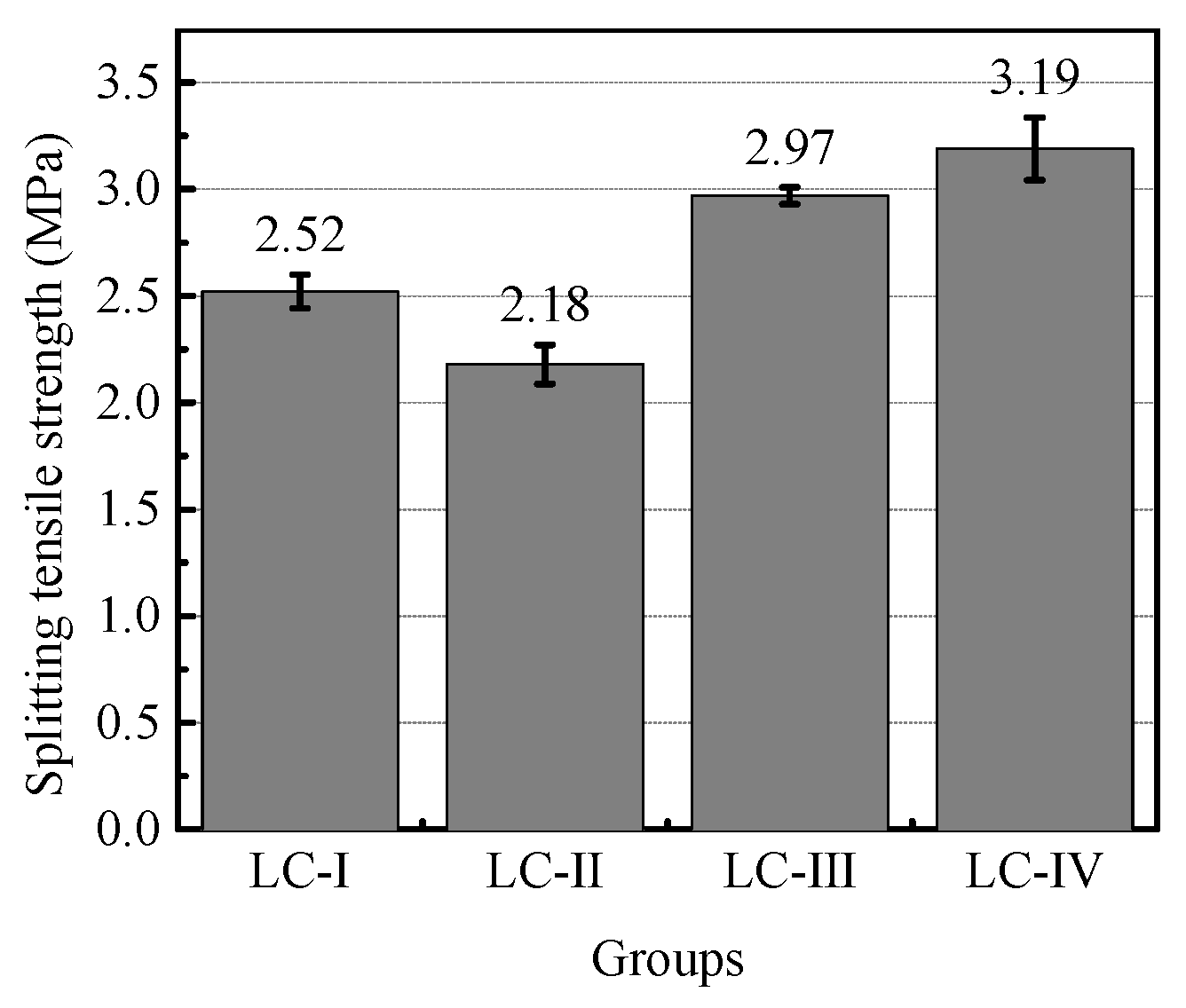

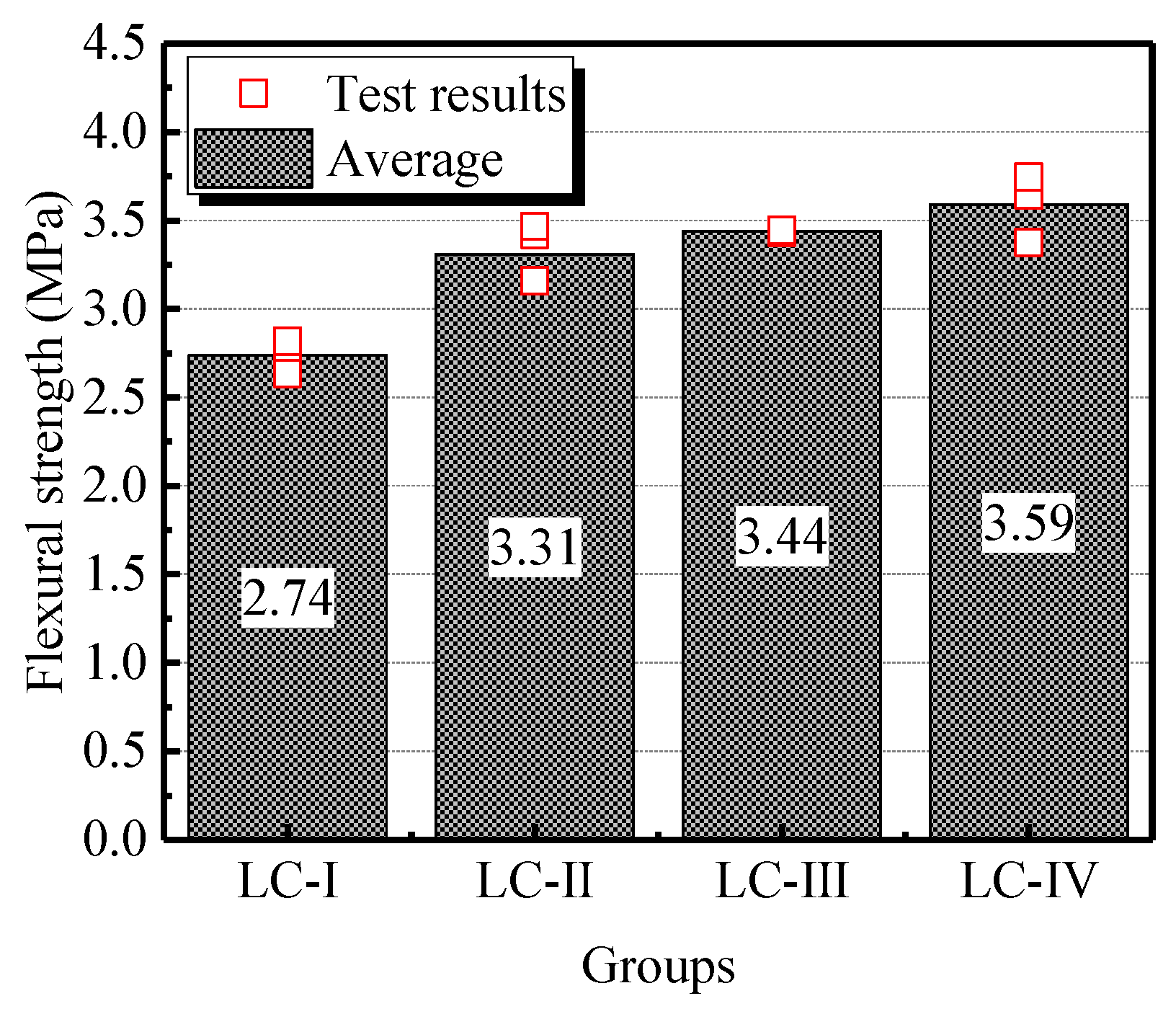

2.3.3. Splitting Tensile and Flexural Strength

The American Society for Testing and Materials (ASTM) C78/C78M-18 [

17] was followed to evaluate the 28 days flexural strength, and the splitting tensile strengths of four groups of specimens were obtained according to GB/T 50081 [

16].