Electronic Origin of α″ to β Phase Transformation in Ti-Nb-Based Thin Films upon Hf Microalloying

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Details

2.2. Computational Details

3. Results and Discussion

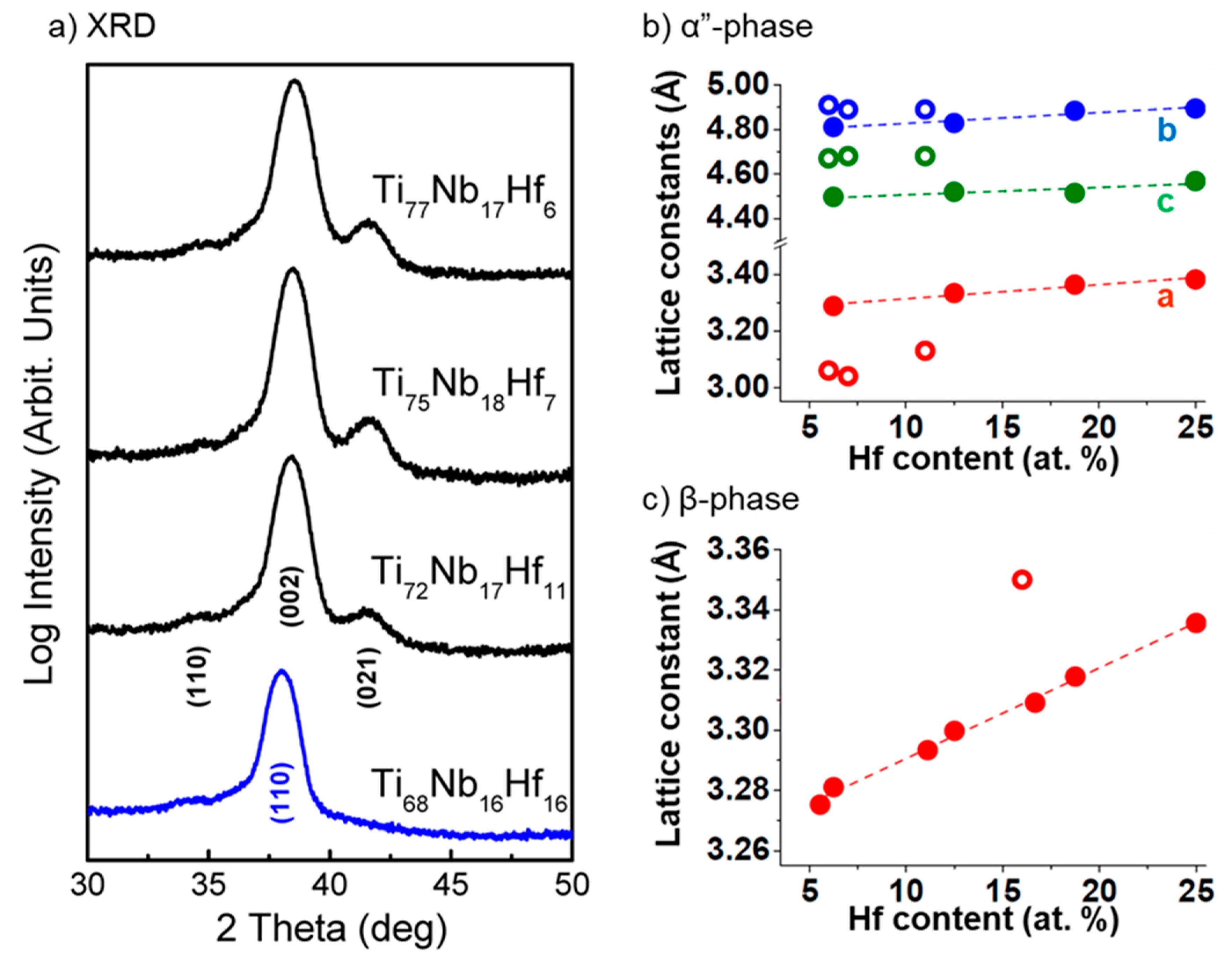

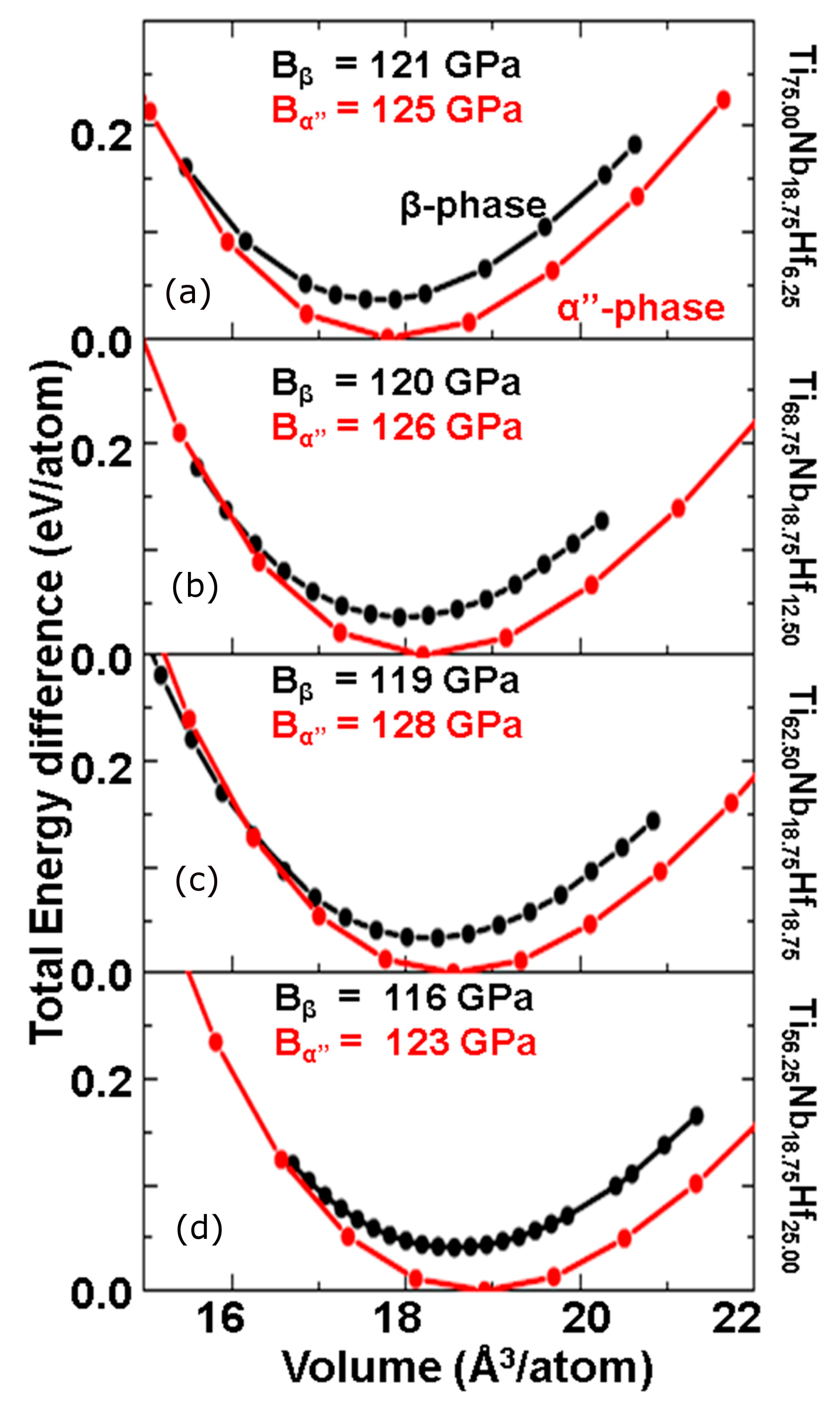

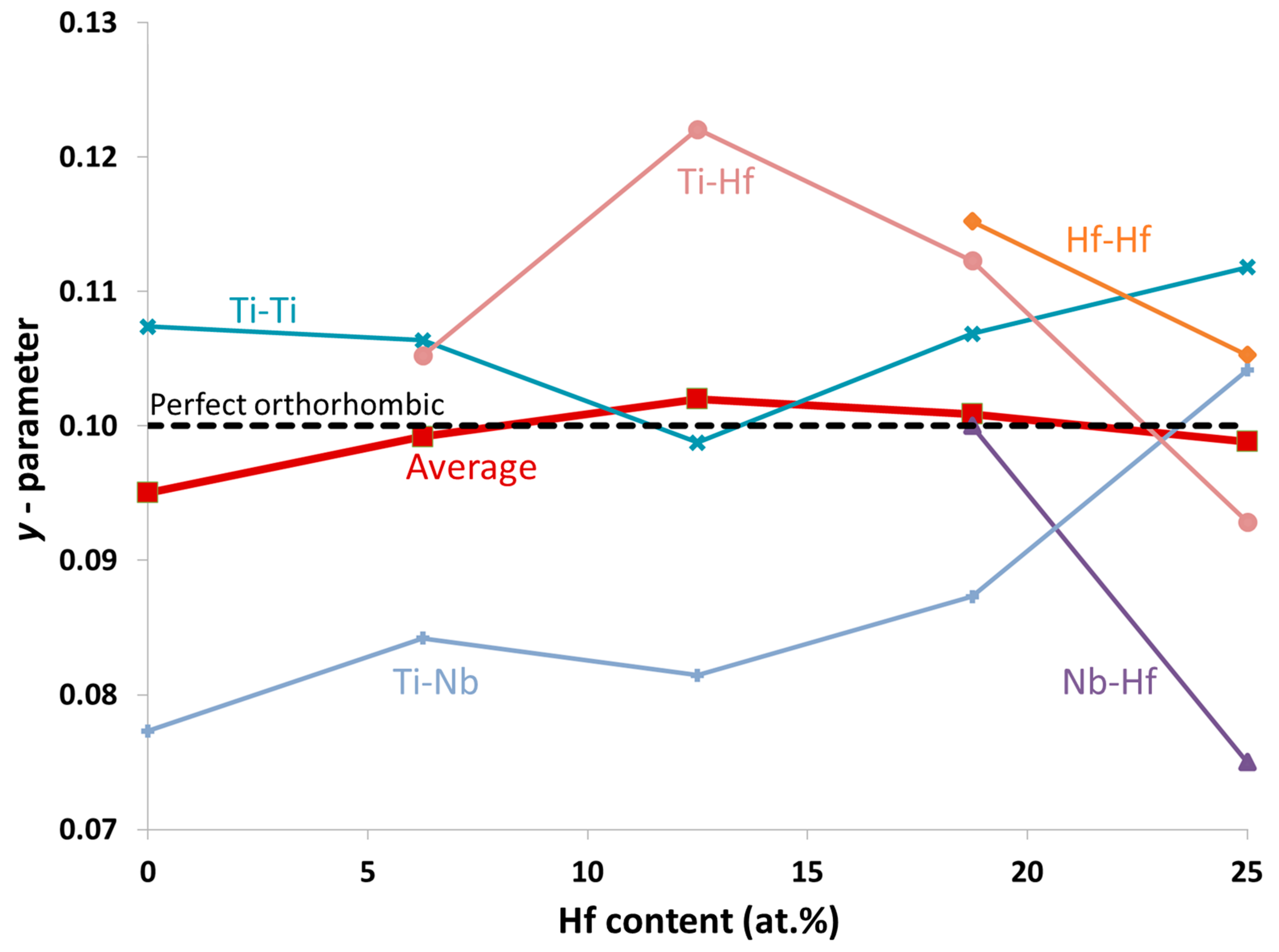

3.1. Structural Properties

3.1.1. X-Ray Diffraction Patterns

3.1.2. DFT Calculations

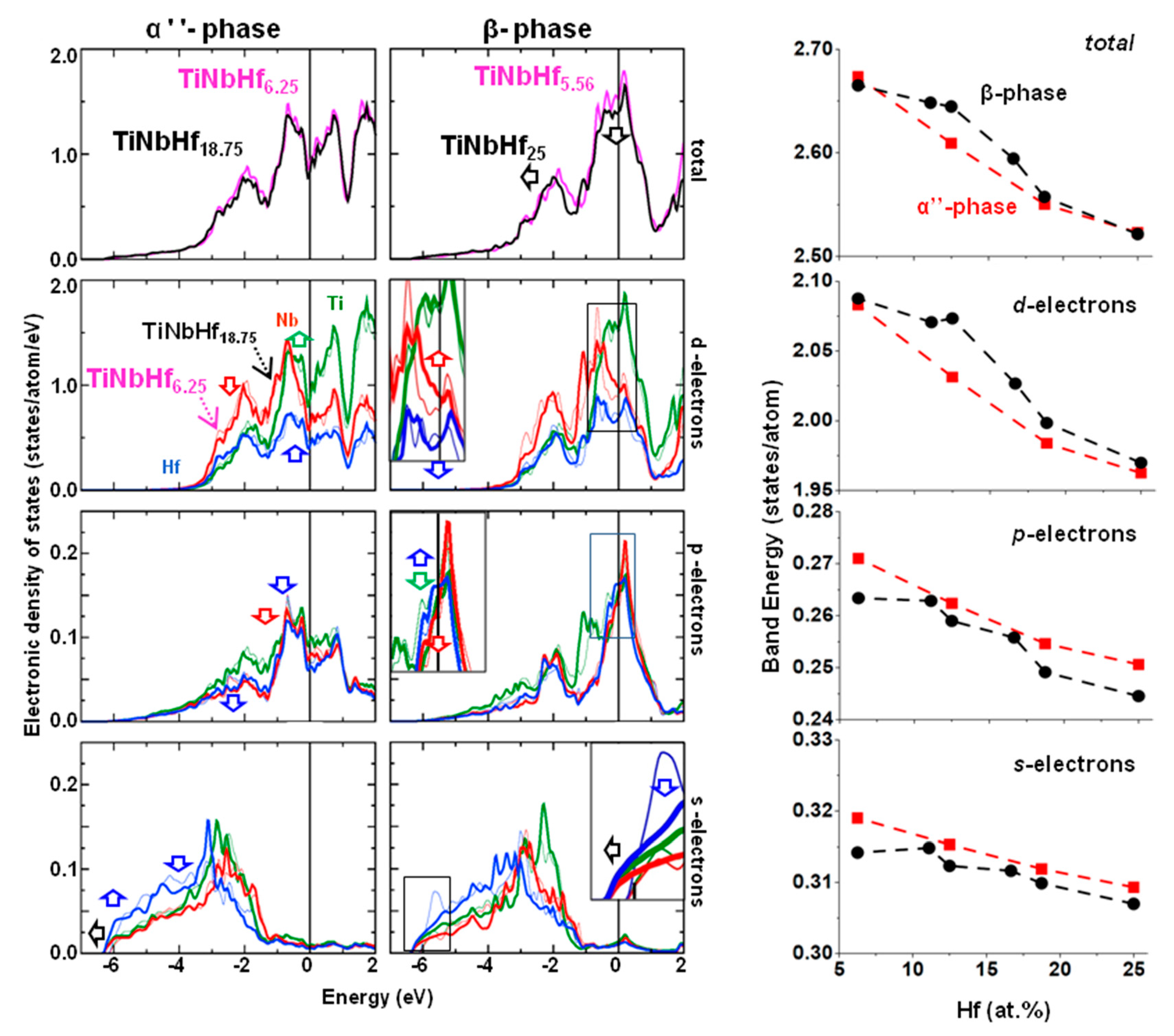

3.2. Electronic Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Niinomi, M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2008, 1, 30–42. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M. Recent metallic materials for biomedical applications. Metall. Mater. Trans. A 2002, 33, 477–486. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.; Asokamani, R.; Gogia, A. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Gutiérrez Moreno, J.J.; Papageorgiou, D.G.; Evangelakis, G.A.; Lekka, C.E. An ab initio study of the structural and mechanical alterations of Ti-Nb alloys. J. Appl. Phys. 2018, 124, 245102. [Google Scholar] [CrossRef]

- Ho, W.F.; Ju, C.P.; Chern Lin, J.H. Structure and properties of cast binary Ti–Mo alloys. Biomaterials 1999, 20, 2115–2122. [Google Scholar] [CrossRef]

- Oliveira, N.T.C.; Aleixo, G.; Caram, R.; Guastaldi, A.C. Development of Ti–Mo alloys for biomedical applications: Microstructure and electrochemical characterization. Mater. Sci. Eng. A 2007, 452–453, 727–731. [Google Scholar] [CrossRef]

- Brozek, C.; Sun, F.; Vermaut, P.; Millet, Y.; Lenain, A.; Embury, D.; Jacques, P.J.; Prima, F. A β-titanium alloy with extra high strain-hardening rate: Design and mechanical properties. Scr. Mater. 2016, 114, 60–64. [Google Scholar] [CrossRef]

- Hong, S.H.; Park, S.W.; Park, C.H.; Yeom, J.-T.; Kim, K. Relationship between phase stability and mechanical properties on near/metastable β-type Ti–Cr-(Mn) cast alloys. J. Alloy. Compd. 2020, 821, 153516. [Google Scholar] [CrossRef]

- Hong, S.H.; Hwang, Y.J.; Park, S.W.; Park, C.H.; Yeom, J.-T.; Park, J.M.; Kim, K. Low-cost beta titanium cast alloys with good tensile properties developed with addition of commercial material. J. Alloy. Compd. 2019, 793, 271–276. [Google Scholar] [CrossRef]

- Moffat, D.; Larbalestier, D. The compctition between martensite and omega in quenched Ti-Nb alloys. Metall. Trans. A 1988, 19, 1677–1686. [Google Scholar] [CrossRef]

- Moffat, D.; Larbalestier, D. The compctition between the alpha and omega phases in aged Ti-Nb alloys. Metall. Mater. Trans. A 1988, 19, 1687–1694. [Google Scholar] [CrossRef]

- Moffat, D.; Kattner, U. The stable and metastable Ti-Nb phase diagrams. Metall. Mater. Trans. A 1988, 19, 2389–2397. [Google Scholar] [CrossRef]

- Lekka, C.E.; Gutierrez Moreno, J.; Calin, M. Electronic origin and structural instabilities of Ti-based alloys suitable for orthopaedic implants. J. Phys. Chem. Solids 2017, 102, 49–61. [Google Scholar] [CrossRef]

- Gutiérrez Moreno, J.; Bönisch, M.; Panagiotopoulos, N.; Calin, M.; Papageorgiou, D.; Gebert, A.; Eckert, J.; Evangelakis, G.; Lekka, C.E. Ab-initio and experimental study of phase stability of Ti-Nb alloys. J. Alloy. Compd. 2017, 696, 481–489. [Google Scholar] [CrossRef]

- Mardare, A.I.; Savan, A.; Ludwig, A.; Wieck, A.D.; Hassel, A.W. High-throughput synthesis and characterization of anodic oxides on Nb–Ti alloys. Electrochim. Acta 2009, 54, 5973–5980. [Google Scholar] [CrossRef]

- Photiou, D.; Panagiotopoulos, N.T.; Koutsokeras, L.; Evangelakis, G.A.; Constantinides, G. Microstructure and nanomechanical properties of magnetron sputtered Ti−Nb films. Surf. Coat. Technol. 2016, 302, 310–319. [Google Scholar] [CrossRef]

- Liu, X.; Chu, P.K.; Ding, C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater. Sci. Eng. R Rep. 2004, 47, 49–121. [Google Scholar] [CrossRef] [Green Version]

- Lorenzetti, M.; Pellicer, E.; Sort, J.; Baró, M.; Kovač, J.; Novak, S.; Kobe, S. Improvement to the corrosion resistance of Ti-based implants using hydrothermally synthesized nanostructured anatase coatings. Materials 2014, 7, 180–194. [Google Scholar] [CrossRef] [Green Version]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Massalski, T.; Subramanian, P.; Okamoto, H.; Kacprzak, L. Binary Alloy Phase Diagrams; ASM International: Materials Park, OH, USA, 1990. [Google Scholar]

- Cai, Z.; Koike, M.; Sato, H.; Brezner, M.; Guo, Q.; Komatsu, M.; Okuno, O.; Okabe, T. Electrochemical characterization of cast Ti–Hf binary alloys. Acta Biomater. 2005, 1, 353–356. [Google Scholar] [CrossRef]

- Mardare, A.I.; Ludwig, A.; Savan, A.; Wieck, A.D.; Hassel, A.W. High-throughput study of the anodic oxidation of Hf–Ti thin films. Electrochim. Acta 2009, 54, 5171–5178. [Google Scholar] [CrossRef]

- Zhou, Y.-L.; Niinomi, M.; Akahori, T. Changes in mechanical properties of Ti alloys in relation to alloying additions of Ta and Hf. Mater. Sci. Eng. A 2008, 483, 153–156. [Google Scholar] [CrossRef]

- Blaha, P.; Schwarz, K.; Madsen, G.; Kvasnicka, D.; Luitz, J. WIEN2k: An Augmented Plane Wave Plus Local Orbitals Program for Calculating Crystal Properties; Karlheinz Schwarz, Techn.: Universität Wien, Austria, 2001. [Google Scholar]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996, 77, 3865. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Söderlind, P.; Eriksson, O.; Wills, J.; Boring, A. Theory of elastic constants of cubic transition metals and alloys. Phys. Rev. B 1993, 48, 5844. [Google Scholar] [CrossRef]

- Chawla, V.; Jayaganthan, R.; Chawla, A.; Chandra, R. Microstructural characterizations of magnetron sputtered Ti films on glass substrate. J. Mater. Process. Technol. 2009, 209, 3444–3451. [Google Scholar] [CrossRef]

- Chawla, V.; Jayaganthan, R.; Chawla, A.; Chandra, R. Morphological study of magnetron sputtered Ti thin films on silicon substrate. Mater. Chem. Phys. 2008, 111, 414–418. [Google Scholar] [CrossRef]

- Song, Y.; Cho, S.; Jung, C.; Bae, I.; Boo, J.; Kim, S. The structural and mechanical properties of Ti films fabricated by using RF magnetron sputtering. J. -Korean Phys. Soc. 2007, 51, 1152. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Georgarakis, K.; Yokoyama, Y.; Yavari, A. On the mechanical properties of TiNb based alloys. J. Alloy. Compd. 2013, 571, 25–30. [Google Scholar] [CrossRef]

- Banumathy, S.; Mandal, R.K.; Singh, A.K. Structure of orthorhombic martensitic phase in binary Ti–Nb alloys. J. Appl. Phys. 2009, 106, 093518. [Google Scholar] [CrossRef]

- Tobe, H.; Kim, H.; Inamura, T.; Hosoda, H.; Nam, T.; Miyazaki, S. Effect of Nb content on deformation behavior and shape memory properties of Ti–Nb alloys. J. Alloy. Compd. 2013, 577, S435–S438. [Google Scholar] [CrossRef]

- Bönisch, M.; Calin, M.; Waitz, T.; Panigrahi, A.; Zehetbauer, M.; Gebert, A.; Skrotzki, W.; Eckert, J. Thermal stability and phase transformations of martensitic Ti–Nb alloys. Sci. Technol. Adv. Mater. 2016, 14, 055004. [Google Scholar] [CrossRef] [PubMed]

- Morniroli, J.; Gantois, M. Investigation of the conditions for omega phase formation in Ti–Nb and Ti–Mo alloys. Mémoires Et Études Sci. De La Rev. De Métallurgie 1973, 70, 831–842. [Google Scholar]

- Li, C.-X.; Luo, H.-B.; Hu, Q.-M.; Yang, R.; Yin, F.-X.; Umezawa, O.; Vitos, L. Lattice parameters and relative stability of α ″phase in binary titanium alloys from first-principles calculations. Solid State Commun. 2013, 159, 70–75. [Google Scholar] [CrossRef]

- Ahmed, T.; Rack, H. Martensitic transformations in Ti-(16–26 at %) Nb alloys. J. Mater. Sci. 1996, 31, 4267–4276. [Google Scholar] [CrossRef]

- Gutiérrez Moreno, J.J.; Guo, Y.; Georgarakis, K.; Yavari, A.R.; Evangelakis, G.A.; Lekka, C.E. The role of Sn doping in the β-type Ti–25 at % Nb alloys: Experiment and ab initio calculations. J. Alloy. Compd. 2014, 615, S676–S679. [Google Scholar] [CrossRef]

- Calin, M.; Helth, A.; Gutierrez Moreno, J.J.; Bönisch, M.; Brackmann, V.; Giebeler, L.; Gemming, T.; Lekka, C.E.; Gebert, A.; Schnettler, R. Elastic softening of β-type Ti–Nb alloys by indium (In) additions. J. Mech. Behav. Biomed. Mater. 2014, 39, 162–174. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gutiérrez Moreno, J.J.; Panagiotopoulos, N.T.; Evangelakis, G.A.; Lekka, C.E. Electronic Origin of α″ to β Phase Transformation in Ti-Nb-Based Thin Films upon Hf Microalloying. Materials 2020, 13, 1288. https://doi.org/10.3390/ma13061288

Gutiérrez Moreno JJ, Panagiotopoulos NT, Evangelakis GA, Lekka CE. Electronic Origin of α″ to β Phase Transformation in Ti-Nb-Based Thin Films upon Hf Microalloying. Materials. 2020; 13(6):1288. https://doi.org/10.3390/ma13061288

Chicago/Turabian StyleGutiérrez Moreno, José Julio, Nikolaos T. Panagiotopoulos, Georgios A. Evangelakis, and Christina E. Lekka. 2020. "Electronic Origin of α″ to β Phase Transformation in Ti-Nb-Based Thin Films upon Hf Microalloying" Materials 13, no. 6: 1288. https://doi.org/10.3390/ma13061288

APA StyleGutiérrez Moreno, J. J., Panagiotopoulos, N. T., Evangelakis, G. A., & Lekka, C. E. (2020). Electronic Origin of α″ to β Phase Transformation in Ti-Nb-Based Thin Films upon Hf Microalloying. Materials, 13(6), 1288. https://doi.org/10.3390/ma13061288