A New Approach in Surface Modification and Surface Hardening of Aluminum Alloys Using Friction Stir Process: Cu-Reinforced AA5083

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

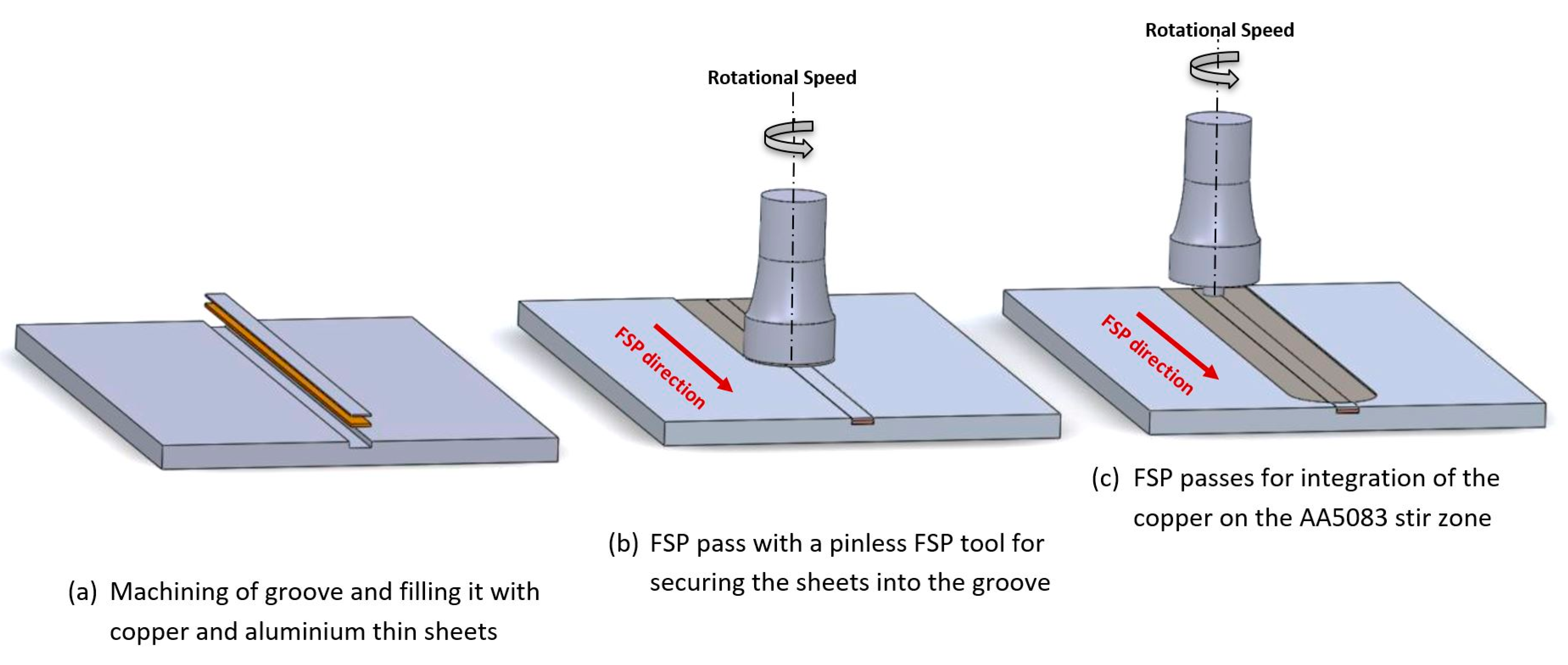

2.2. Friction Stir Process

2.3. Microstructural Characterization

2.4. Macrohardness Distribution Evaluation

3. Results and Discussion

3.1. Microstructural Characterization of the FSPed Specimens

3.1.1. Optical Microscopy Results

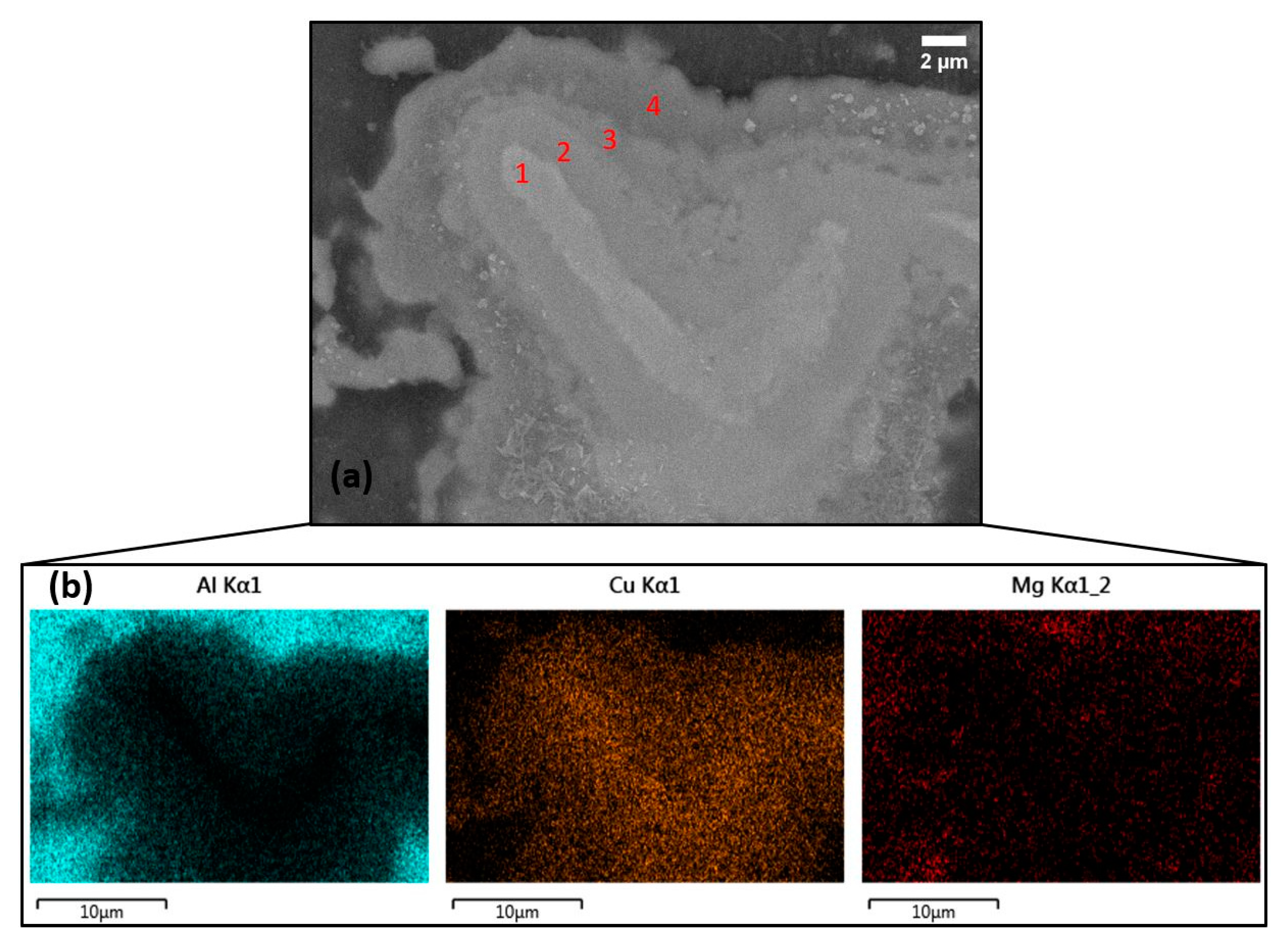

3.1.2. Scanning Electron Microscopy Results

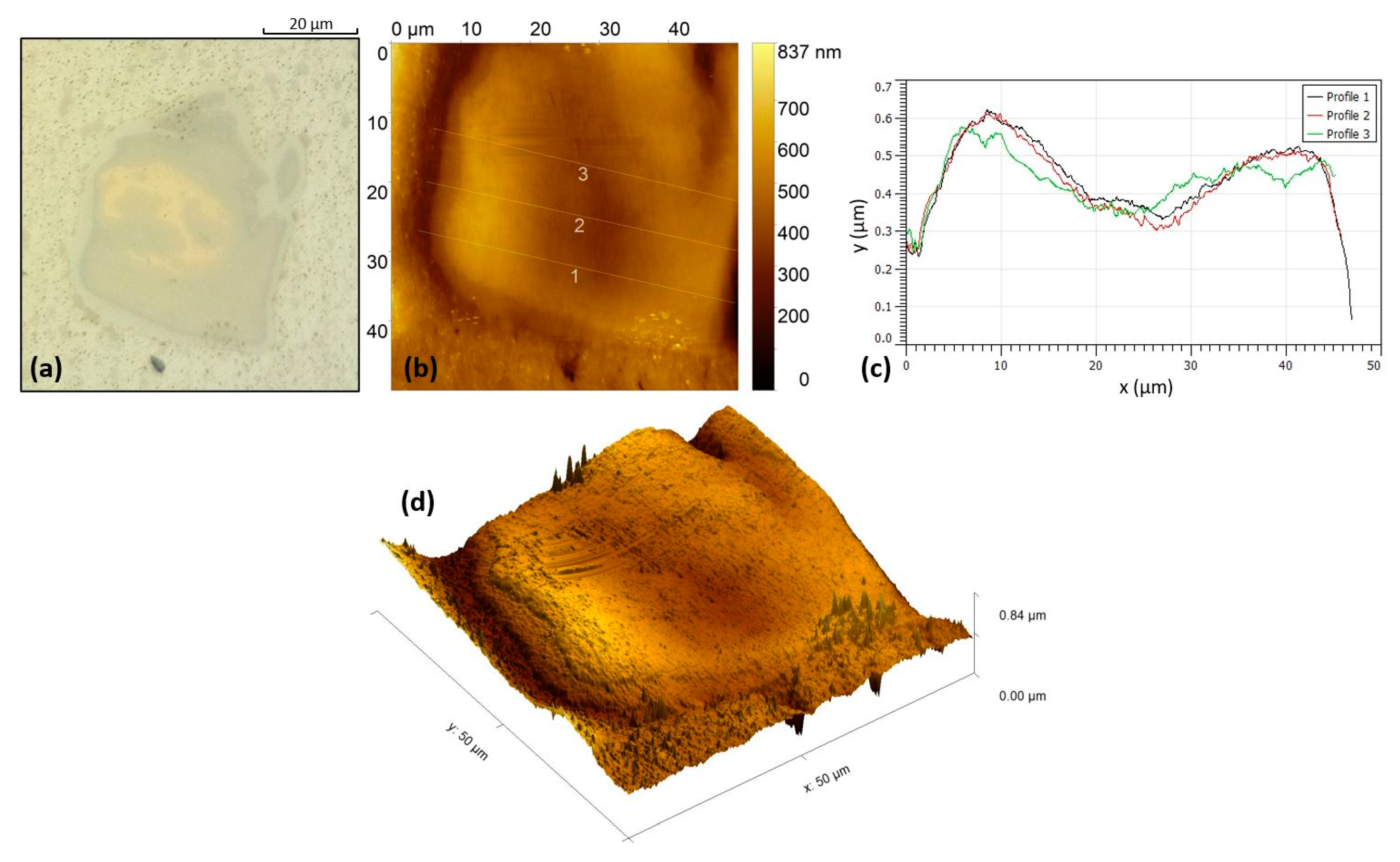

3.1.3. Atomic Force Microscopy Results

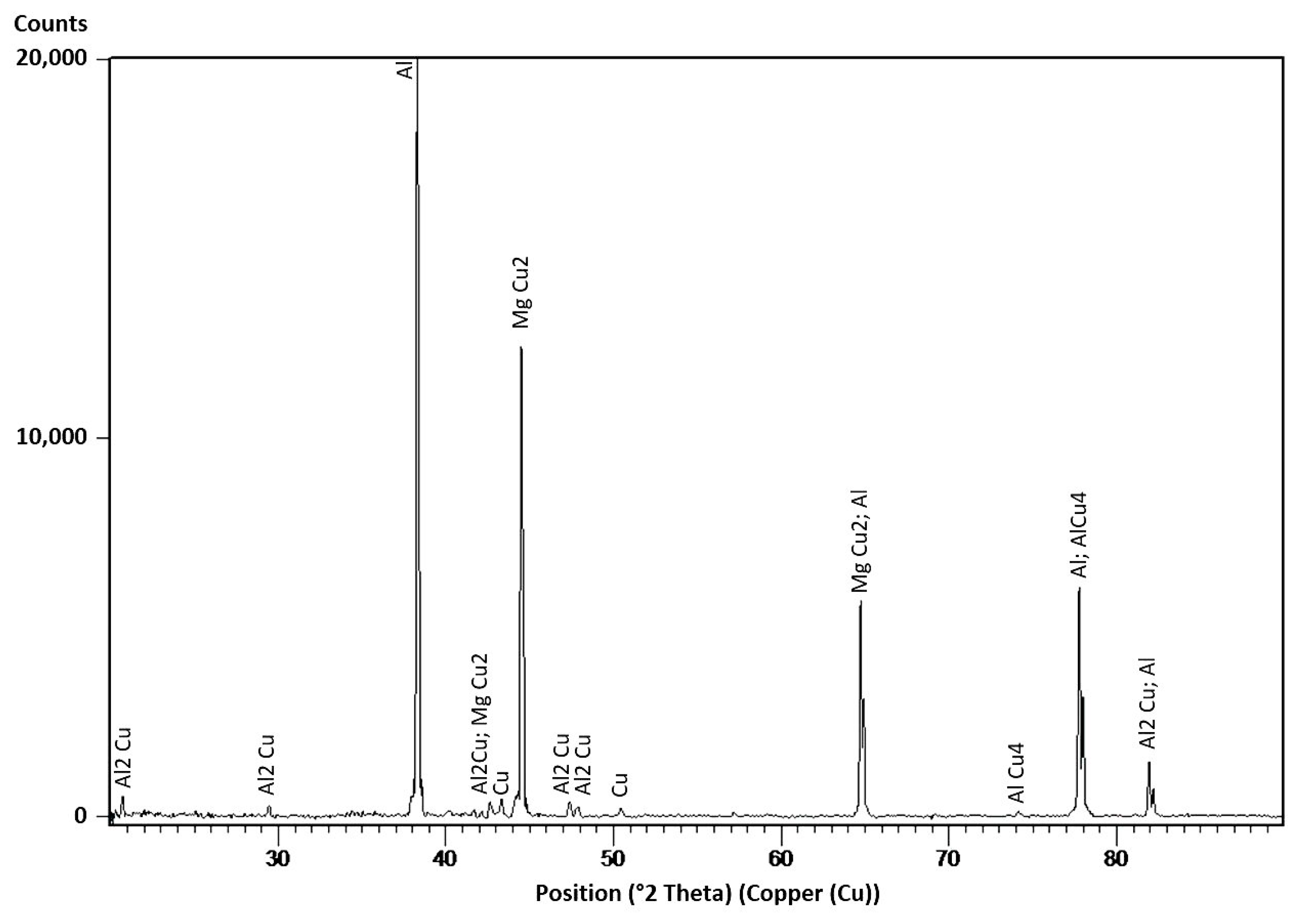

3.1.4. X-Ray Diffraction Analysis Results

3.2. Macrohardness Distribution Analysis

4. Discussion

5. Conclusions

- The scope of this study was successful in producing a Cu-reinforced AA5083 composite stir-zone.

- The proposed process with the utilization of 1000 rpm rotational speed combined with 13 mm/min transverse speed and three sequential FSP passes resulted in almost complete integration of the copper strip in the stir zone.

- The integration was done mainly in the form of coper-based intermetallic particles, and secondly, by copper diffusion in the AA5083 matrix.

- Microstructural analysis showed that the copper-based particles were composed by layers of different stoichiometric compositions. At the center of the particles, a pure copper layer/core was observed (mainly in large particles with diameters ranging from 30 to 80 μm).

- The main aluminum-copper intermetallic phases that were probed from the XRD analysis were the Al2C and AlCu4.

- The macrohardness distribution inside the Cu-reinforced stir-zone was highly increased from 77 HV to 138 HV.

- The high increment in macrohardness values in the stir-zone, compared to the FSPed sample without the copper addition, is attributed mainly to the high presence of the Al–Cu intermetallic compounds, and secondly to the diffused copper in the AA5083 matrix.

Author Contributions

Funding

Conflicts of Interest

References

- Glazoff, M.V.; Khvan, A.V.; Zolotorevsky, V.S.; Belov, N.A. Structure and Microstructure of Aluminum Alloys in As-Cast State. Cast. Aluminum Alloys 2019, 133–234. [Google Scholar] [CrossRef]

- Mishra, R.S.; Komarasamy, M. Friction Stir Welding of High Strength 7XXX Aluminum Alloys; Elsevier Inc.: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Kissell, J.R.; Ferry, R.L. Aluminum structures: A guide to their specifications and design; John Wiley & Son Inc.: New York, NY, USA, 2002. [Google Scholar]

- Cary, H.B.; Helzer, S.C. Modern welding technology; Pearson/Prentice Hall: Upper New Jersey River, NJ, USA, 2005. [Google Scholar]

- Mahoney, M.W.; Rhodes, C.G.; Flintoff, J.G.; Spurling, R.A.; Bingel, W.H. Properties of friction-stir-welded 7075 T651 aluminum. Met. Mater. Trans. A 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.; Sun, W.; McCartney, D.G. A review of friction stir welding of aluminium matrix composites. Mater. Des. 2015, 86, 61–71. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction Stir Welding and Processing II Article in Materials Science and Engineering R Reports. Mater. Sci. Eng. R 2014, 50, 1–78. [Google Scholar] [CrossRef]

- Jata, K.V.; Sankaran, K.K.; Ruschau, J.J. Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451. Met. Mater. Trans. A 2000, 31, 2181–2192. [Google Scholar] [CrossRef]

- Ma, Z.Y. Friction stir processing technology: A review. Met. Mater. Trans. A 2008, 39, 642–658. [Google Scholar] [CrossRef]

- Hutchings, I.; Shipway, P.; Hutchings, I.; Shipway, P. Surface engineering. Tribology 2017, 237–281. [Google Scholar] [CrossRef]

- Bauri, R.; Yadav, D. Metal matrix composites by friction stir processing; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Kurt, A.; Uygur, I.; Cete, E. Surface modification of aluminium by friction stir processing. J. Mater. Process. Technol. 2011, 211, 313–317. [Google Scholar] [CrossRef]

- Navazani, M.; Dehghani, K. Fabrication of Mg-ZrO2 surface layer composites by friction stir processing. J. Mater. Process. Technol. 2016, 229, 439–449. [Google Scholar] [CrossRef]

- Mirjavadi, S.S.; Alipour, M.; Hamouda, A.M.S.; Matin, A.; Kord, S.; Afshari, B.M.; Koppad, P.G. Effect of multi-pass friction stir processing on the microstructure, mechanical and wear properties of AA5083/ZrO2 nanocomposites. J. Alloys Compd. 2017, 726, 1262–1273. [Google Scholar] [CrossRef]

- Gangil, N.; Siddiquee, A.N.; Maheshwari, S. Aluminium based in-situ composite fabrication through friction stir processing: A review. J. Alloys Compd. 2017, 715, 91–104. [Google Scholar] [CrossRef]

- Zohoor, M.; Besharati-Givi, M.K.; Salami, P. Effect of processing parameters on fabrication of Al–Mg/Cu composites via friction stir processing. Mater. Des. 2012, 39, 358–365. [Google Scholar] [CrossRef]

- Liu, G.; Gong, M.; Xie, D.; Wang, J. Structures and Mechanical Properties of Al-Al 2 Cu Interfaces. JOM 2019, 71, 1200–1208. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, W.; Xie, J.; Sun, S.; Wang, L.; Qian, Y.; Meng, Y.; Wei, Y. Microstructure and mechanical properties of aluminum 5083 weldments by gas tungsten arc and gas metal arc welding. Mater. Sci. Eng. A 2012, 549, 7–13. [Google Scholar] [CrossRef]

- Papantoniou, I.G.; Kyriakopoulou, H.P.; Pantelis, D.I.; Athanasiou-Ioannou, A.; Manolakos, D.E. Manufacturing process of AA5083/nano-γAl2O3 localized composite metal foam fabricated by friction stir processing route (FSP) and microstructural characterization. J. Mater. Sci. 2018, 53, 3817–3835. [Google Scholar] [CrossRef]

- Papantoniou, I.G.; Kyriakopoulou, H.P.; Pantelis, D.I.; Manolakos, D.E. Fabrication of MWCNT-reinforced Al composite local foams using friction stir processing route. Int. J. Adv. Manuf. Technol. 2018, 97, 675–686. [Google Scholar] [CrossRef]

- Dai, J.; Jiang, B.; Zhang, J.; Yang, Q.; Jiang, Z.; Dong, H.; Pan, F. Diffusion Kinetics in Mg-Cu Binary System. J. Phase Equilibria Diffus. 2015, 36, 613–619. [Google Scholar] [CrossRef]

| Element | Al | Si | Fe | Cu | Mn | Cr | Mg | Ti | Others Total |

|---|---|---|---|---|---|---|---|---|---|

| Weight % | 94.42 | 0.11 | 0.26 | 0.01 | 0.62 | 0.09 | 4.45 | 0.01 | 0.03 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papantoniou, I.G.; Markopoulos, A.P.; Manolakos, D.E. A New Approach in Surface Modification and Surface Hardening of Aluminum Alloys Using Friction Stir Process: Cu-Reinforced AA5083. Materials 2020, 13, 1278. https://doi.org/10.3390/ma13061278

Papantoniou IG, Markopoulos AP, Manolakos DE. A New Approach in Surface Modification and Surface Hardening of Aluminum Alloys Using Friction Stir Process: Cu-Reinforced AA5083. Materials. 2020; 13(6):1278. https://doi.org/10.3390/ma13061278

Chicago/Turabian StylePapantoniou, Ioannis G., Angelos P. Markopoulos, and Dimitrios E. Manolakos. 2020. "A New Approach in Surface Modification and Surface Hardening of Aluminum Alloys Using Friction Stir Process: Cu-Reinforced AA5083" Materials 13, no. 6: 1278. https://doi.org/10.3390/ma13061278

APA StylePapantoniou, I. G., Markopoulos, A. P., & Manolakos, D. E. (2020). A New Approach in Surface Modification and Surface Hardening of Aluminum Alloys Using Friction Stir Process: Cu-Reinforced AA5083. Materials, 13(6), 1278. https://doi.org/10.3390/ma13061278