Analysis of the Rolling Process of Alloy 6005 in a Three-High Skew Rolling Mill

Abstract

1. Introduction

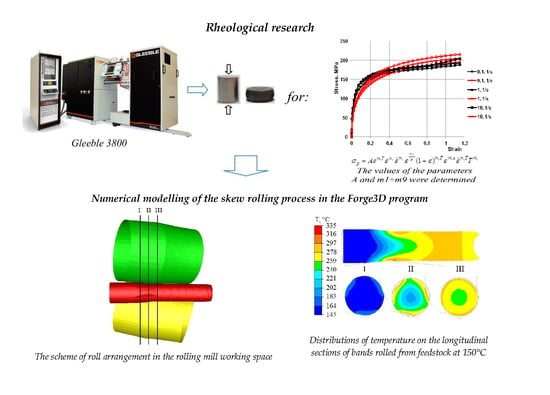

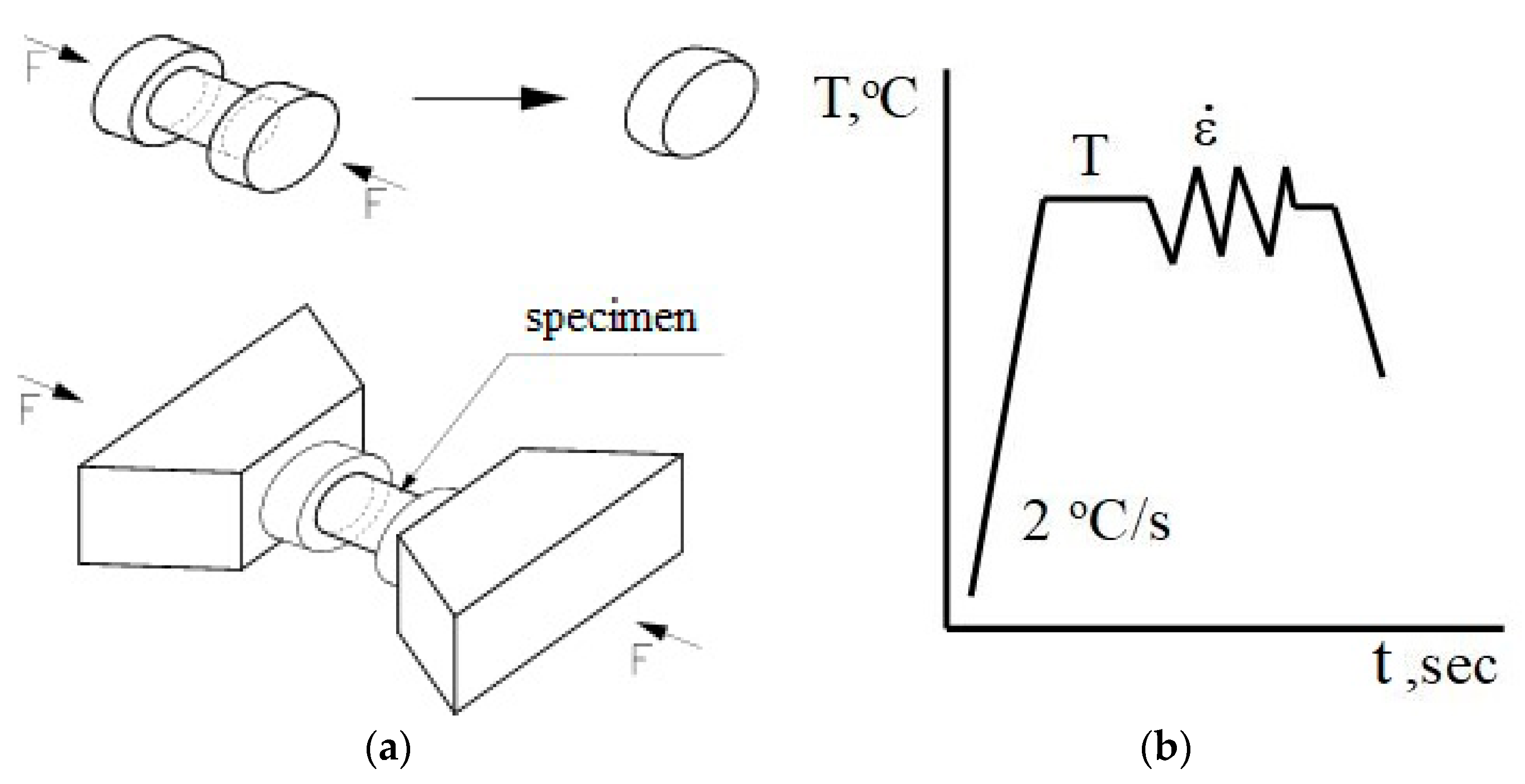

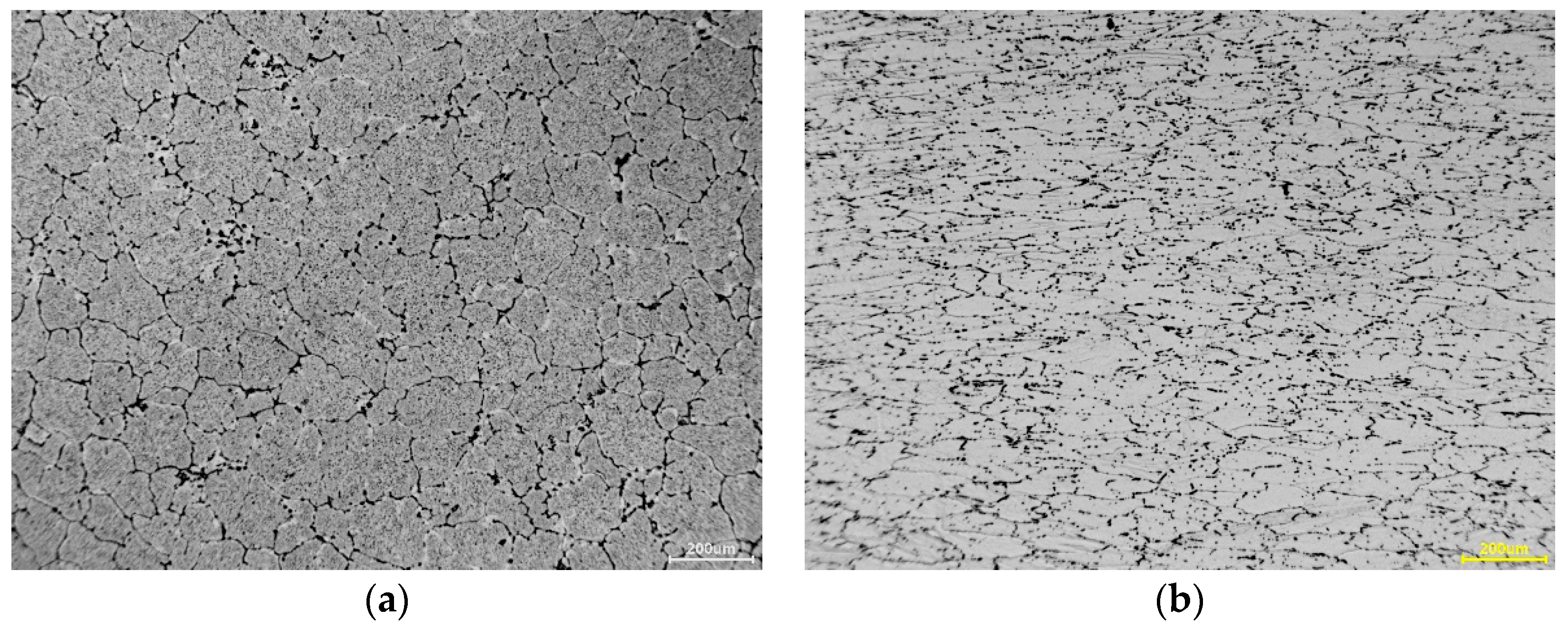

2. Materials and Methods

3. Results and Discussion

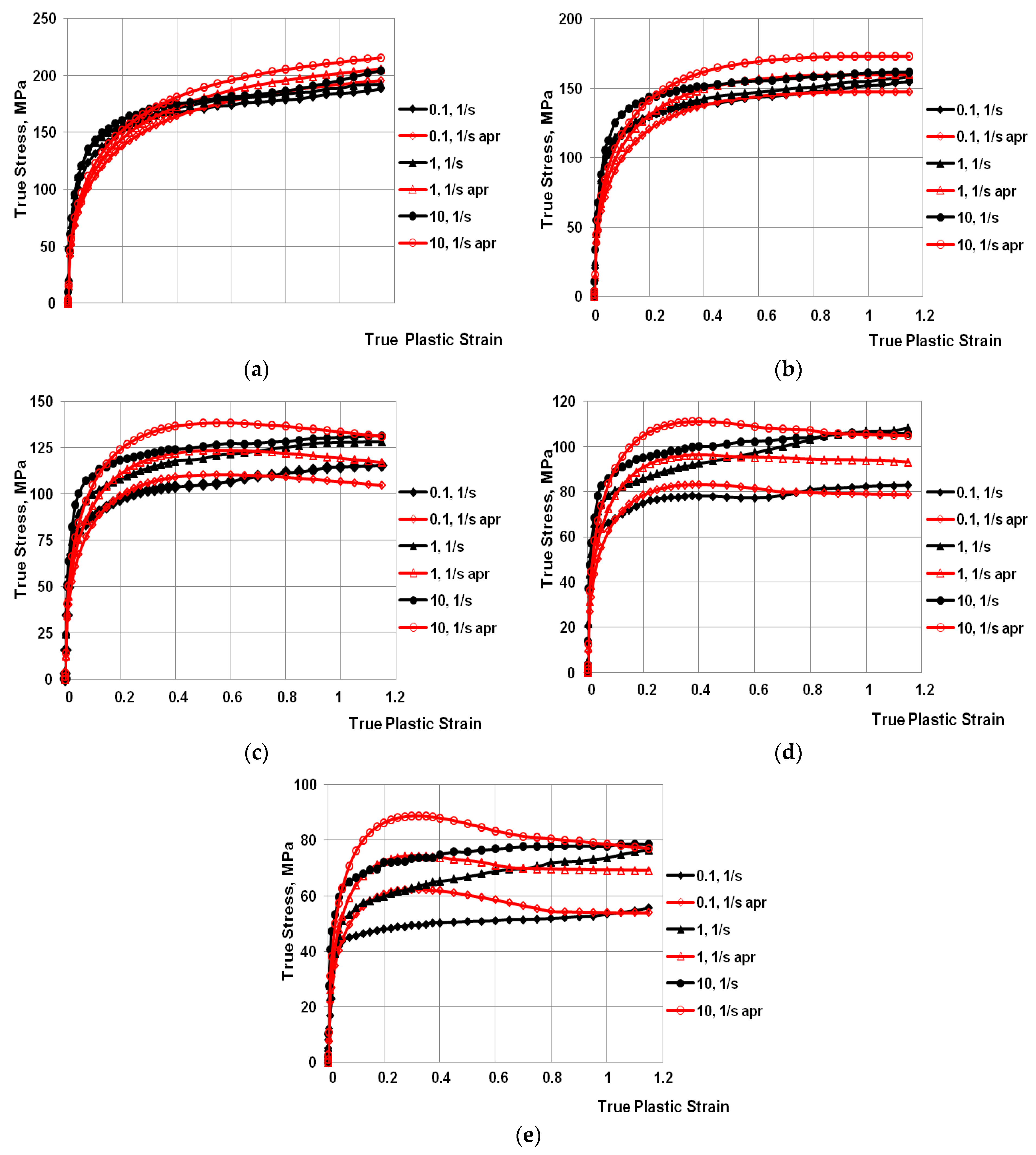

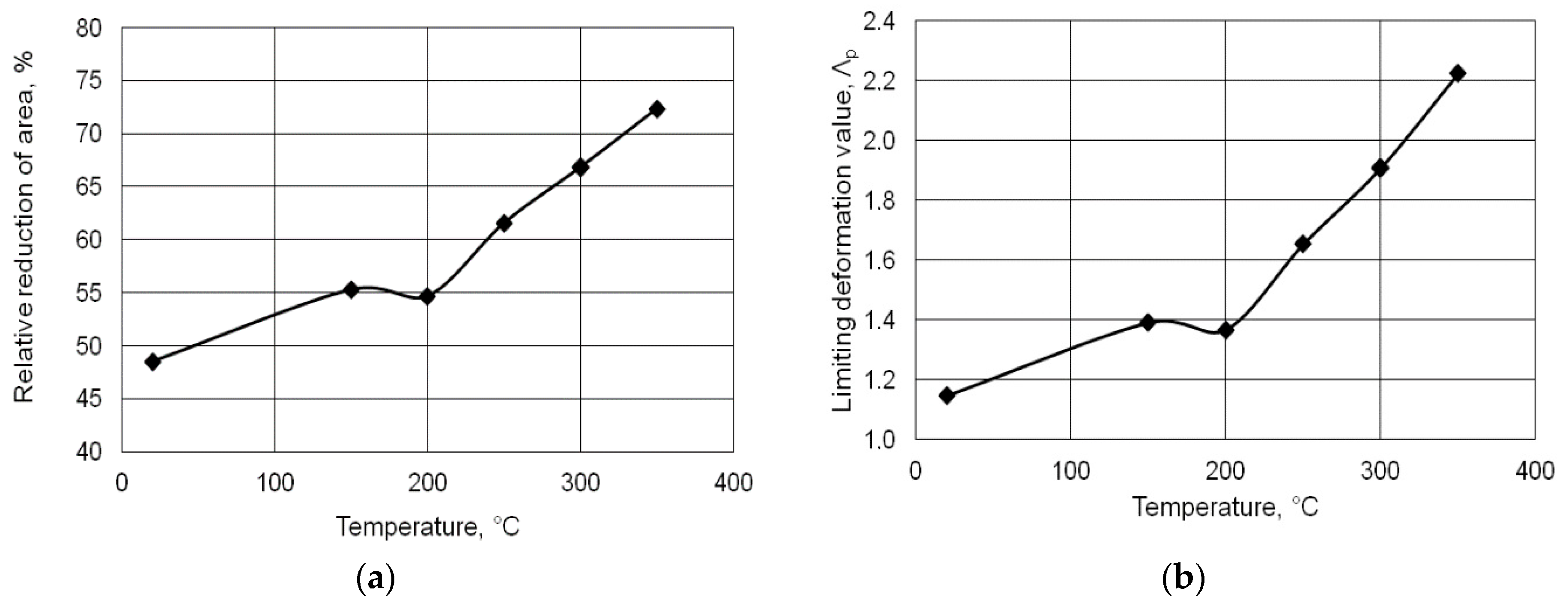

3.1. The Rheological Properties of Alloy 6005

3.2. Kolmogorov’s Criterion

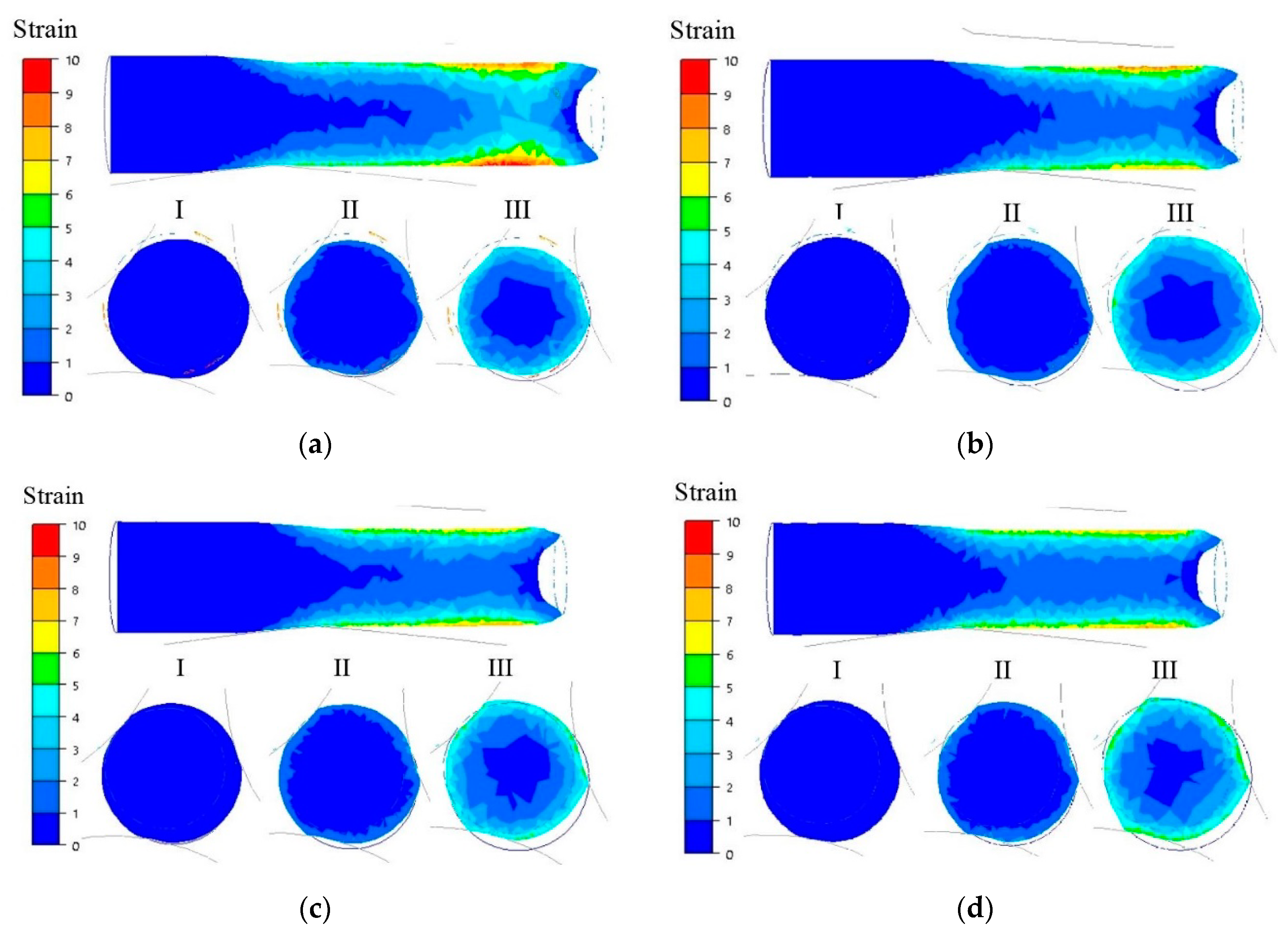

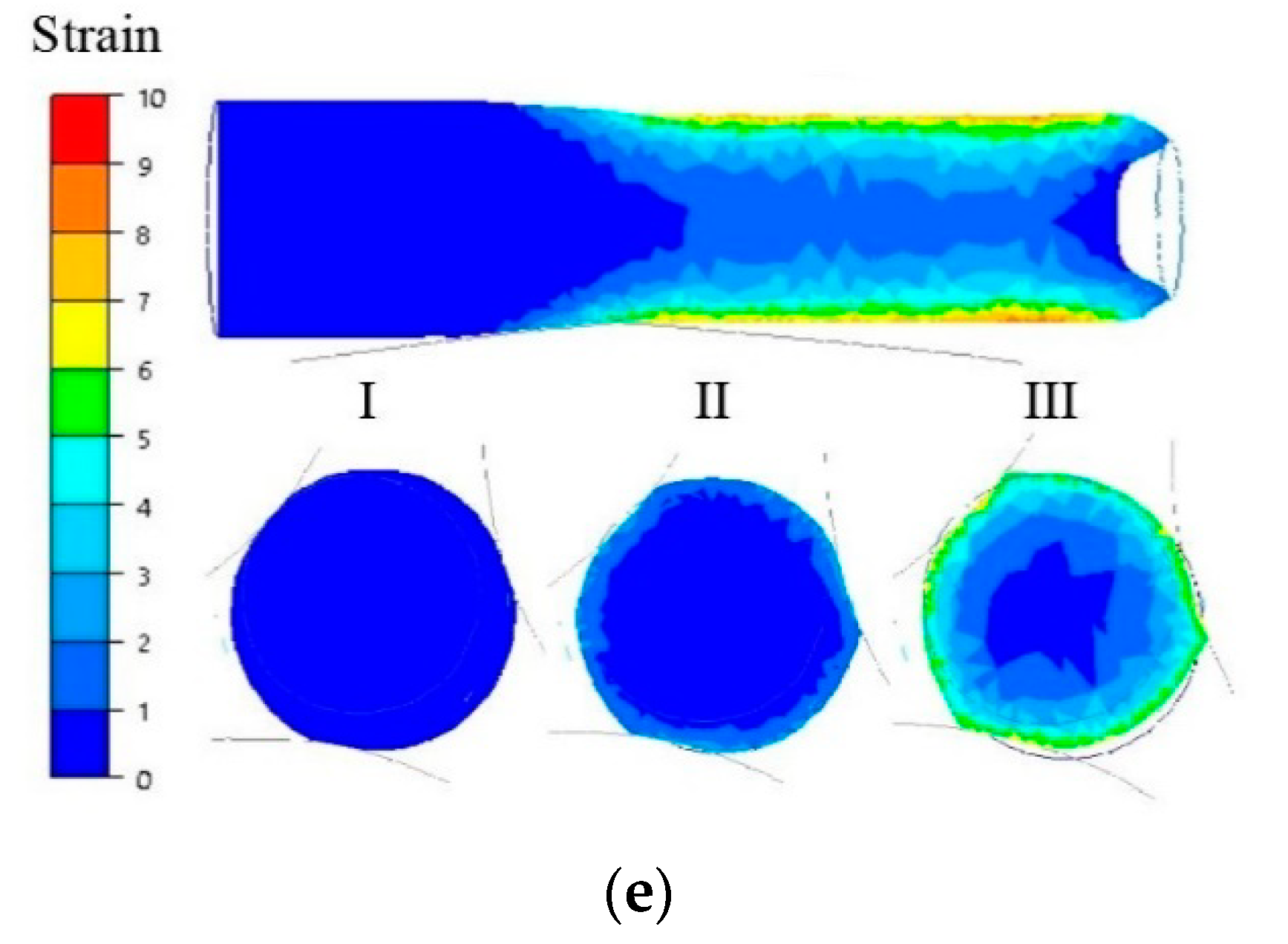

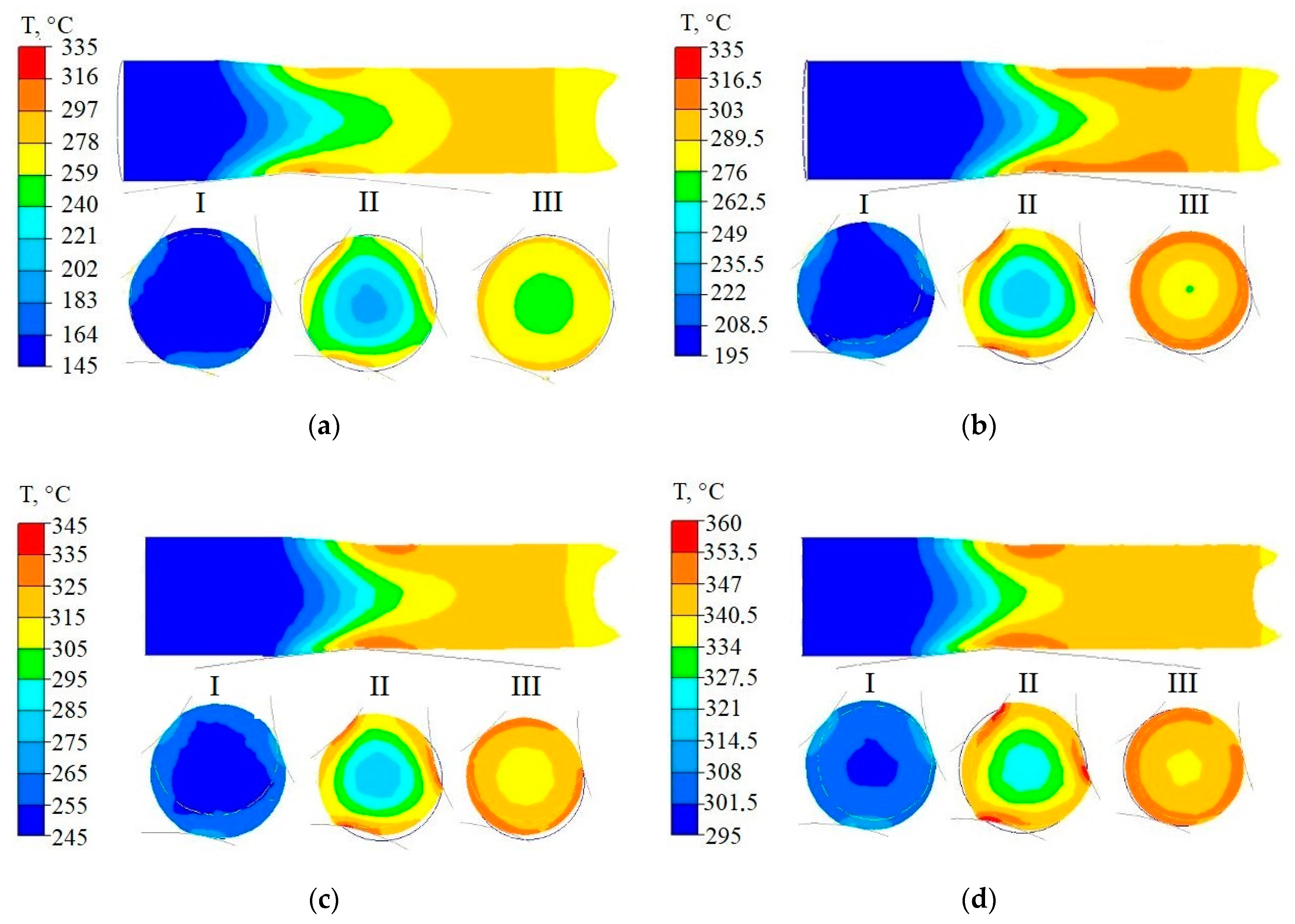

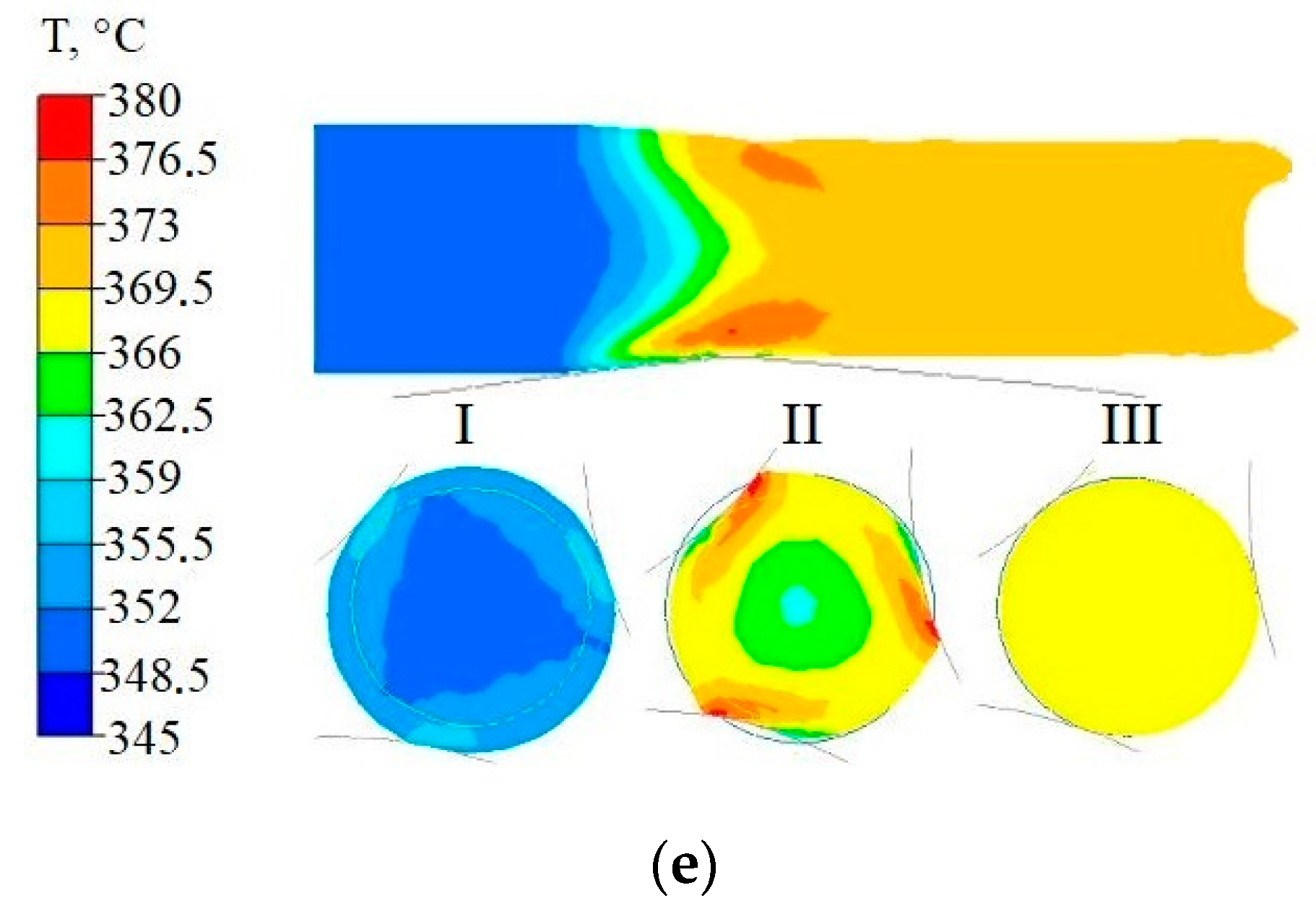

3.3. Numerical Modelling

4. Conclusions

- -

- for initial specimen temperatures higher than 250 °C, the reserve of material plasticity increased;

- -

- the thermal effect was determined correctly, as confirmed by plastometric tests;

- -

- for temperatures above 250 °C, a more uniform stress distribution occurred on the rolled bar cross-section, which contributed to better mechanical properties of finished products;

- -

- the application of the process of rolling in the three-high skew mill enabled the use of work of deformation for initiating transformations to occur within the material without heating the feedstock up to a high temperature. For alloy 6005, the value of the activation energy of hardening β″ phase precipitation was attained at the initial deformation condition after the feedstock was heated up to a temperature of 150 °C, owing to a thermal effect that occurred at this temperature;

- -

- using numerical modelling methods it was possible to determine the optimal technological conditions of the process of manufacturing bars of aluminum alloy 6005 in a three-high skew mill, which enabled a finished product of high mechanical properties to be obtained.

Author Contributions

Funding

Conflicts of Interest

References

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CIRP Ann. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Segal, V. Severe plastic deformation: simple shear versus pure shear. Mater. Sci. Eng. A 2002, 338, 331–344. [Google Scholar] [CrossRef]

- Segal, V.M. Equal channel angular extrusion: from macromechanics to structure formation. Mater. Sci. Eng. A 1999, 271, 322–333. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Dobatkin, S.V.; Bastarache, E.N.; Sakai, G.; Fujita, T.; Horita, Z.; Langdon, T.G. Grain refinement and superplastic flow in an aluminum alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2005, 408, 141–146. [Google Scholar] [CrossRef]

- Sabbaghianrad, S.; Kawasaki, M.; Langdon, T.G. Microstructural evolution and the mechanical properties of an aluminum alloy processed by high-pressure torsion. J. Mater. Sci. 2012, 47, 7789–7795. [Google Scholar] [CrossRef]

- Sakai, G.; Horita, Z.; Langdon, T.G. Grain refinement and superplasticity in an aluminum alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2005, 393, 344–351. [Google Scholar] [CrossRef]

- Huang, X.; Tsuji, N.; Hansen, N.; Minamino, Y. Microstructural evolution during accumulative roll-bonding of commercial purity aluminum. Mater. Sci. Eng. A 2003, 340, 265–271. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Bochniak, W.; Korbel, A. KOBO Type Forming: forging of metals under complex conditions of the process. J. Mater. Process. Technol. 2003, 134, 120–134. [Google Scholar] [CrossRef]

- Bochniak, W.; Marszowski, K.; Korbel, A. Theoretical and practical aspects of the production of thin-walled tubes by the KOBO method. J. Mater. Process. Technol. 2005, 169, 44–53. [Google Scholar] [CrossRef]

- Shurkin, P.K.; Akopyan, T.K.; Galkin, S.P.; Aleshchenko, A.S. Effect of Radial Shear Rolling on the Structure and Mechanical Properties of a New-Generation High-Strength Aluminum Alloy Based on the Al–Zn–Mg–Ni–Fe System. Met. Sci. Heat Treat. 2019, 60, 764–769. [Google Scholar] [CrossRef]

- Galkin, S.P. Radial shear rolling as an optimal technology for lean production. Steel Transl. 2014, 44, 61–64. [Google Scholar] [CrossRef]

- Kulakowska, A. Development of Properties of Aluminum AlZn5.5MgCu Bars in Three-High Rolling Mill; Czestochowa University of Technology: Czestochowa, Poland, 2017. [Google Scholar]

- Skripalenko, M.M.; Galkin, S.P.; Karpov, B.V.; Romantsev, B.A.; Kaputkina, L.M.; Danilin, A.V.; Skripalenko, M.N.; Patrin, P.V. Forming Features and Properties of Titanium alloy Billets after radial-shear rolling. Materials 2019, 12, 3179. [Google Scholar] [CrossRef]

- Belov, N.A.; Korotkova, N.O.; Akopyan, T.K.; Pesin, A.M. Phase composition and mechanical properties of Al–1.5%Cu–1.5%Mn–0.35%Zr(Fe,Si) wire alloy. J. Alloys Compd. 2019, 782, 735–746. [Google Scholar] [CrossRef]

- Dobatkin, S.; Galkin, S.; Estrin, Y.; Serebryany, V.; Diez, M.; Martynenko, N.; Lukyanova, E.; Perezhogin, V. Grain refinement, texture, and mechanical properties of a magnesium alloy after radial-shear rolling. J. Alloys Compd. 2019, 774, 969–979. [Google Scholar] [CrossRef]

- Gryc, A.; Bajor, T.; Dyja, H. The analysis of influence the parameters of rolling process in three high skew rolling mill of AZ31 magnesium alloy bars on temperature distribution. Metalurgija 2016, 55, 772–774. [Google Scholar]

- Sawicki, S.; Dyja, H.; Kawałek, A.; Laber, K.; Wiśniewska-Weinert, H. Zmiany właściwości reologicznych wybranych stopów AlMg w próbie ściskania. Obróbka Plast. Met. 2017, 28, 59–74. [Google Scholar]

- Laber, K.; Kawałek, A.; Sawicki, S.; Dyja, H.; Borowski, J.; Lesniak, D.; Jurczak, H. Investigations of Plasticity of Hard-Deformed Aluminium Alloys of 5xxx Series Using Torsion Plastometer. Arch. Metall. Mater. 2016, 61, 1853–1860. [Google Scholar] [CrossRef]

- Dyja, H.; Gałkin, A.; Knapinski, M. Reologia Metali Odkształconych Plastycznie; Czestochowa University of Technology: Czestochowa, Poland, 2010; ISBN 978-83-7193-471-1. [Google Scholar]

- Lukács, J.; Kuzsella, L.; Koncsik, Z.; Gáspár, M.; Meilinger, Á. Role of the Physical Simulation for the Estimation of the Weldability of High Strength Steels and Aluminum Alloys. Mater. Sci. Forum. 2015, 812, 149–154. [Google Scholar] [CrossRef]

- Polish Standard, P.N. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; PKN: Warsaw, Poland, 2016; Volume 82. [Google Scholar]

- Spittel, A.; Hensel, T. Kraft- und Arbeitsbedarf Bildsamer Formgebungsverfahren; Deutscher Verlag für Grundstoffindustrie: Lipsk, Germany, 1978. [Google Scholar]

- Mrówka-Nowotnik, G.; Sieniawski, J.; Wierzbińska, M.; Nowotnik, A. Precipitation processes of strengthening phases’ particles from supersaturated AlMgSi alloys. Inżynieria Mater. 2015, 1, 376–380. [Google Scholar]

- Kolmogorov, V.L. Stresses, Strains, Fracture; Metallurgia: Moscow, Russia, 1970. [Google Scholar]

- Kolmogorov, V.L. Plasticity and Fracture; Metallurgia: Moscow, Russia, 1977. [Google Scholar]

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 6005 | 0.40 | 0.175 | 0.05 | 0.05 | 0.675 | 0.05 | 0.05 | 0.05 | R |

| Rp0.2, MPa | Rm, MPa | A, % | Z, % |

|---|---|---|---|

| 33.00 | 104.09 | 17.12 | 48.48 |

| Kind of Test | Temperature (T), °C | Strain Rate (), s−1 | Number of Specimen for Each Variant |

|---|---|---|---|

| Compression test | 150, 200, 250, 300, 350 | 0.1, 1, 10 | 5 |

| Tensile test | 150, 200, 250, 300, 350 | According to [24] | 5 |

| Aluminum | The Values of the Parameters Obtained from the Approximation of Equation (1) | Average Approx. Error A [%] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | m1 | m2 | m3 | m4 | m5 | m7 | m8 | m9 | ||

| 6005 | 6.304367 | −0.00654 | 0.381576 | −0.03346 | −0.00017 | −0.00560 | 0.265601 | 0.000317 | 0.963414 | 6.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bajor, T.; Kulakowska, A.; Dyja, H. Analysis of the Rolling Process of Alloy 6005 in a Three-High Skew Rolling Mill. Materials 2020, 13, 1114. https://doi.org/10.3390/ma13051114

Bajor T, Kulakowska A, Dyja H. Analysis of the Rolling Process of Alloy 6005 in a Three-High Skew Rolling Mill. Materials. 2020; 13(5):1114. https://doi.org/10.3390/ma13051114

Chicago/Turabian StyleBajor, Teresa, Anna Kulakowska, and Henryk Dyja. 2020. "Analysis of the Rolling Process of Alloy 6005 in a Three-High Skew Rolling Mill" Materials 13, no. 5: 1114. https://doi.org/10.3390/ma13051114

APA StyleBajor, T., Kulakowska, A., & Dyja, H. (2020). Analysis of the Rolling Process of Alloy 6005 in a Three-High Skew Rolling Mill. Materials, 13(5), 1114. https://doi.org/10.3390/ma13051114