Comprehensive Property Investigation of Mold Inhibitor Treated Raw Cotton and Ramie Fabric

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Anti-Mildew Treatment of Cotton and Ramie

2.3. Characterization and Measurement

3. Results

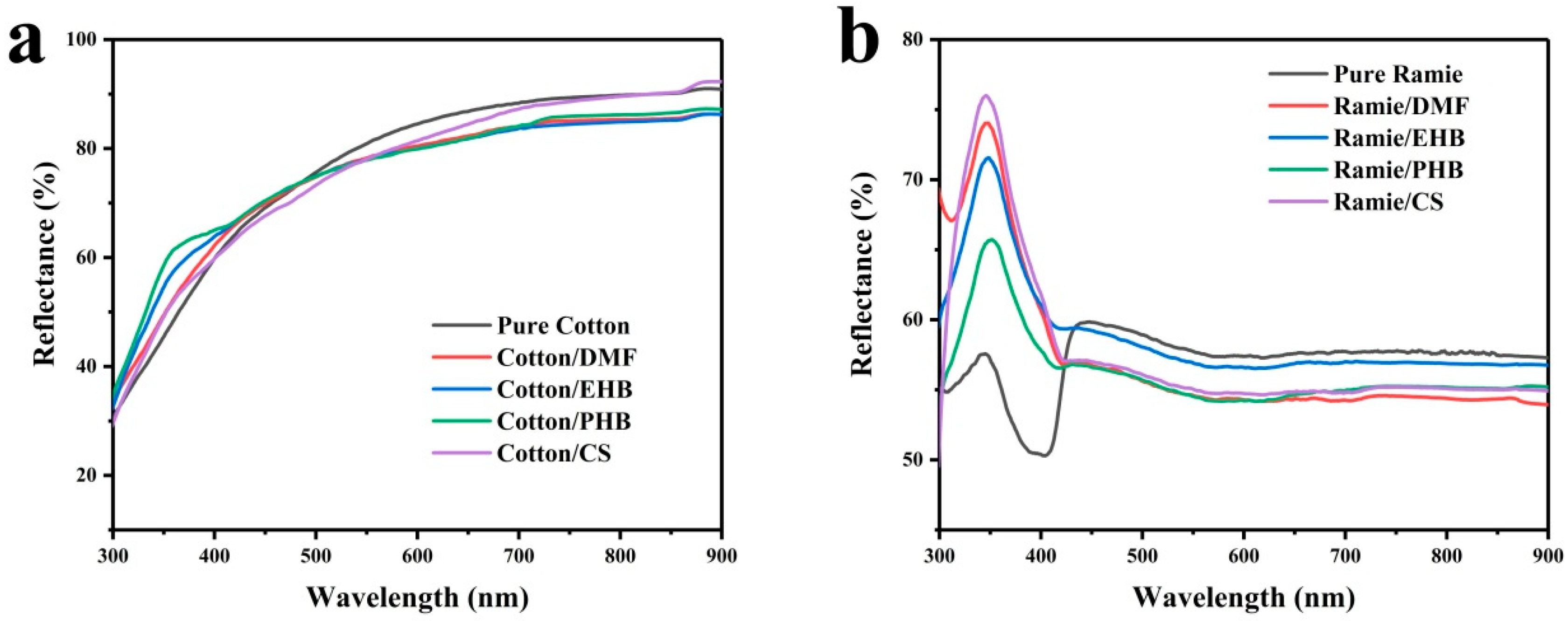

3.1. Optical Properties

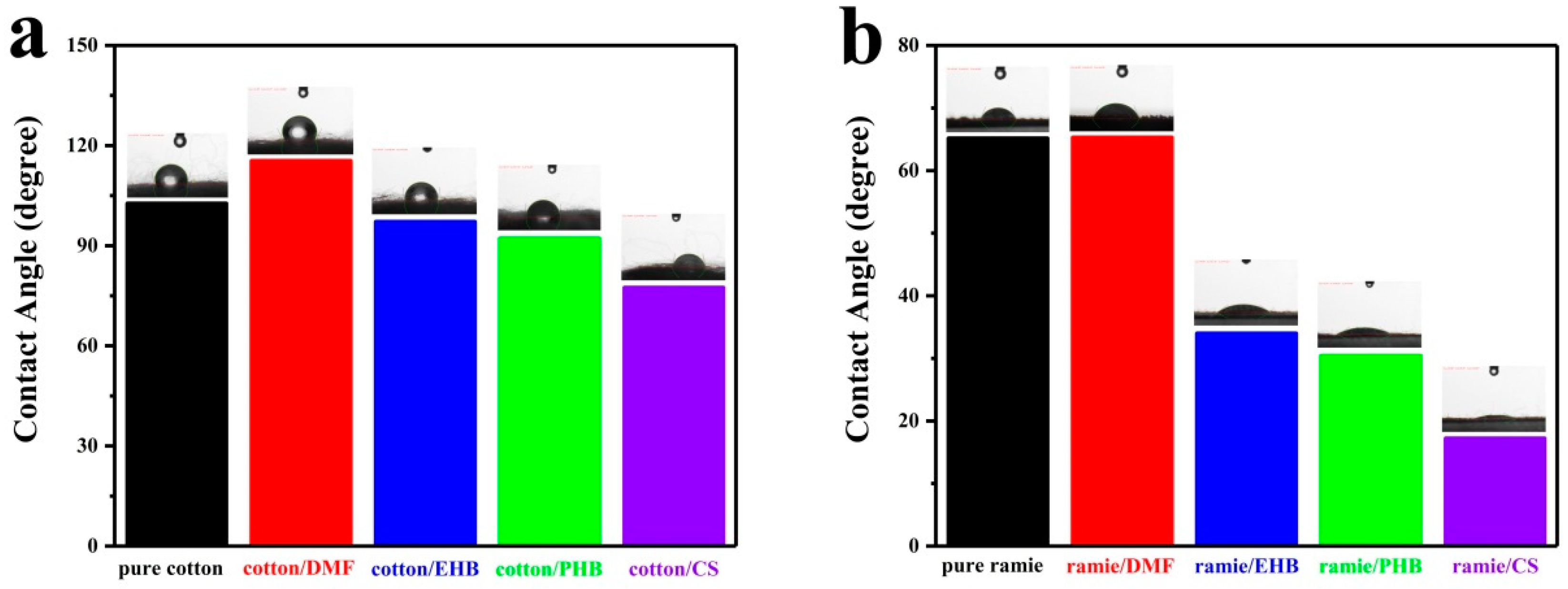

3.2. Wettability

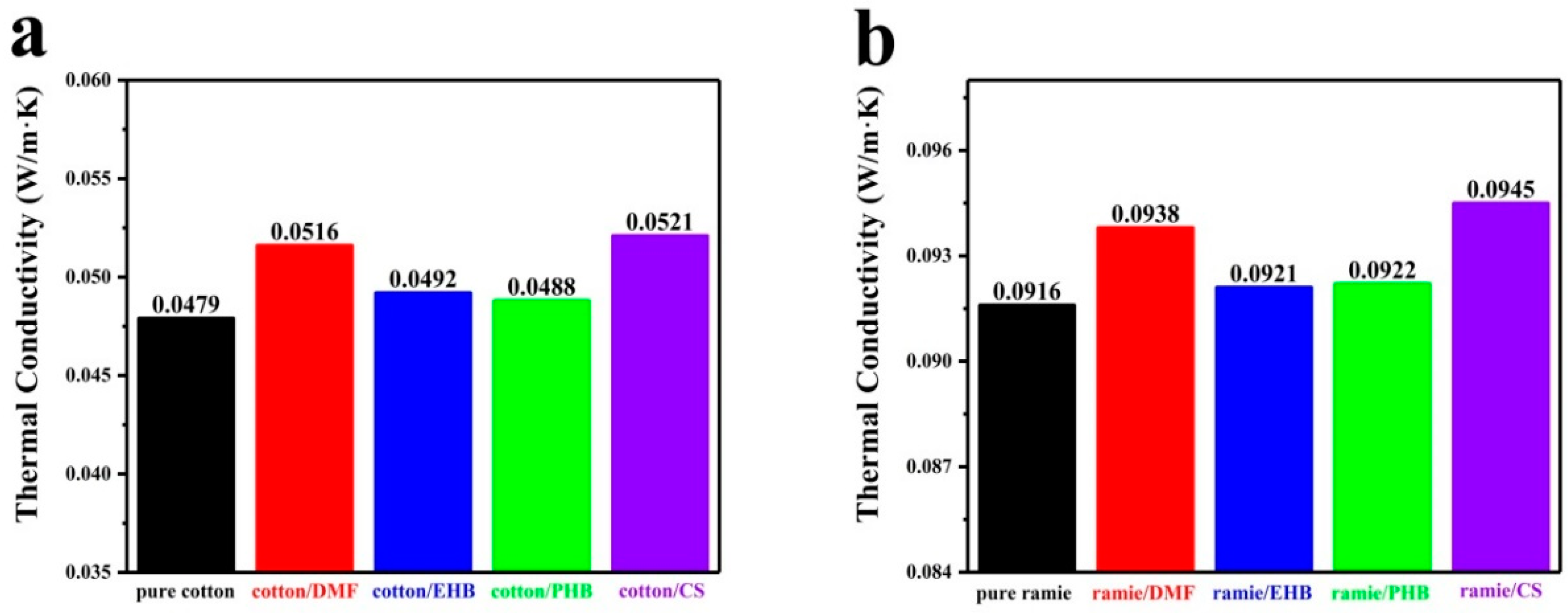

3.3. Thermal Conductivity

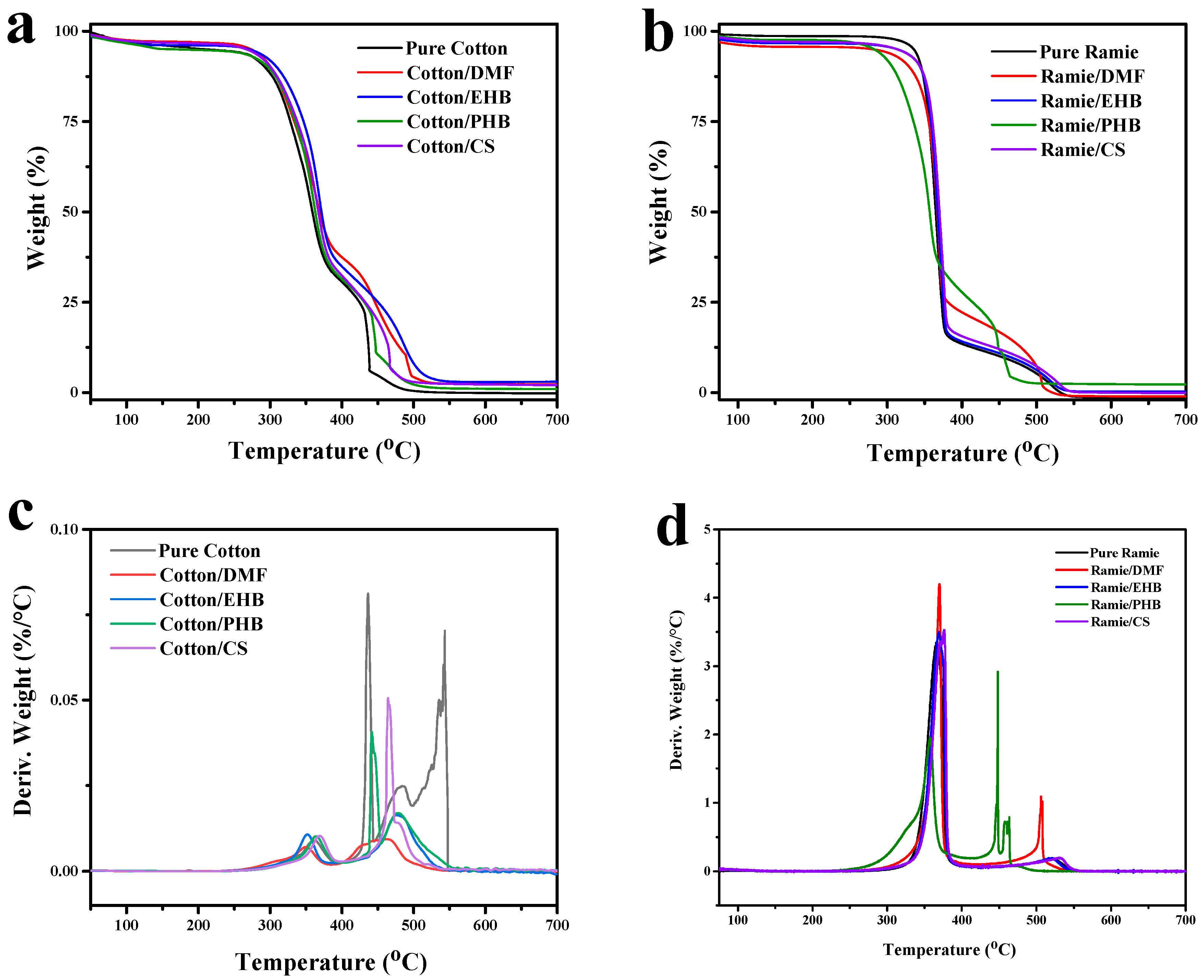

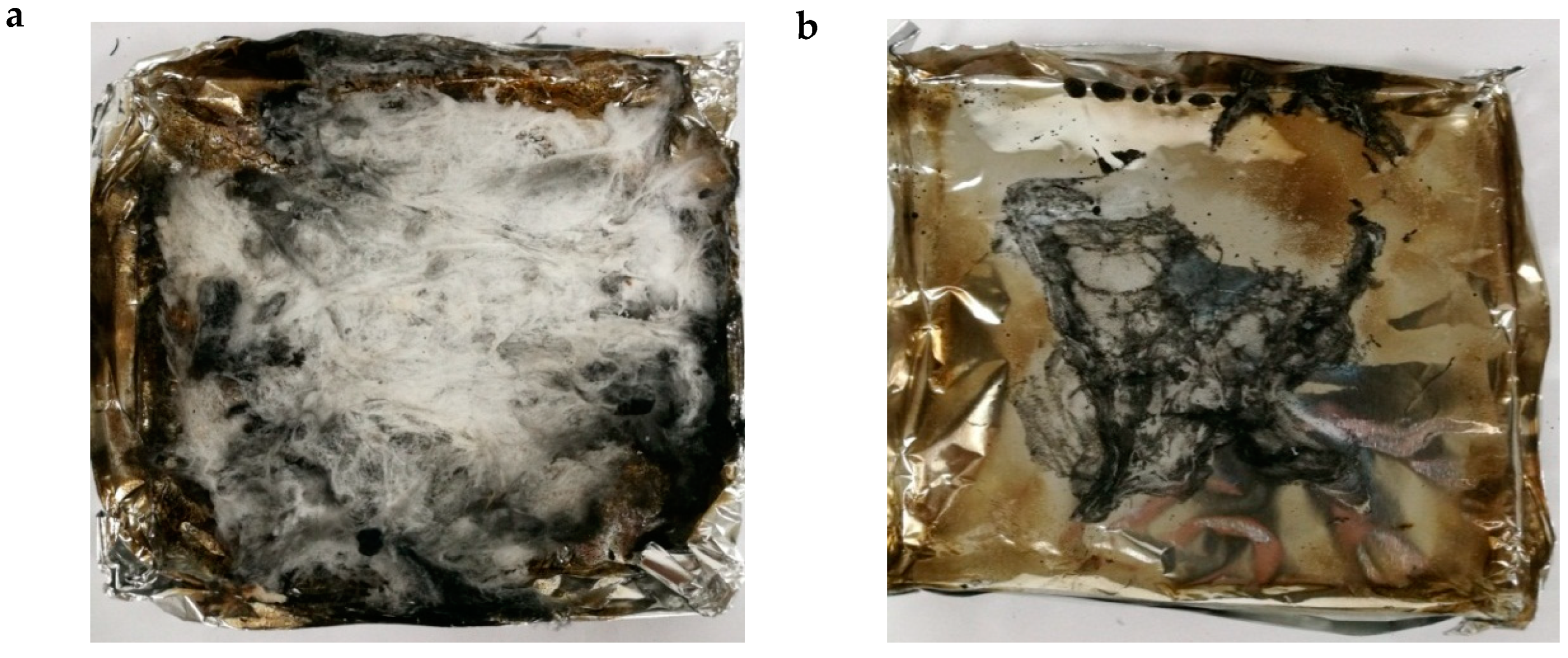

3.4. Thermal Stability and Combustion Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Staneva, D.; Vasileva-Tonkova, E.; Grabchev, I. A New Bioactive Complex between Zn(II) and a Fluorescent Symmetrical Benzanthrone Tripod for an Antibacterial Textile. Materials 2019, 12, 3473. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.H.; Hwang, E.K.; Kim, H.D. Colorimetric Assay and Antibacterial Activity of Cotton, Silk, and Wool Fabrics Dyed with Peony, Pomegranate, Clove, Coptis chinenis and Gallnut Extracts. Materials 2009, 2, 10–21. [Google Scholar] [CrossRef]

- Korica, M.; Persin, Z.; Trifunovic, S.; Mihajlovski, K.; Nikolic, T.; Maletic, S.; Zemljic, L.F.; Kostic, M.M. Influence of Different Pretreatments on the Antibacterial Properties of Chitosan Functionalized Viscose Fabric: TEMPO Oxidation and Coating with TEMPO Oxidized Cellulose Nanofibrils. Materials 2019, 12, 3144. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, B.; Vimont, A.; Desfosses-Foucault, E.; Daga, M.; Arora, G.; Fliss, I. Antifungal activity of lactic and propionic acid bacteria and their potential as protective culture in cottage cheese. Food Control 2017, 78, 350–356. [Google Scholar] [CrossRef]

- Vimont, A.; Fernandez, B.; Ahmed, G.; Fortin, H.-P.; Fliss, I. Quantitative antifungal activity of reuterin against food isolates of yeasts and moulds and its potential application in yogurt. Int. J. Food Microbiol. 2019, 289, 182–188. [Google Scholar] [CrossRef]

- Ma, N.; Wu, Y.; Xie, F.; Du, K.X.; Wang, Y.; Shi, L.X.; Ji, L.B.; Liu, T.Y.; Ma, X. Dimethyl fumarate reduces the risk of mycotoxins via improving intestinal barrier and microbiota. Oncotarget 2017, 8, 44625–44638. [Google Scholar] [CrossRef]

- Silva, M.M.; Lidon, F.C. Food preservatives - An overview on applications and side effects. Emir. J. Food Agric. 2016, 28, 366–373. [Google Scholar] [CrossRef]

- Ding, L.; Ji, J.; Khan, F.; Li, X.H.; Wan, S.A. Quantitative fire risk assessment of cotton storage and a criticality analysis of risk control strategies. Fire Mater. 2019, 10, 165–179. [Google Scholar] [CrossRef]

- El-Shafei, A.; ElShemy, M.; Abou-Okeil, A. Eco-friendly finishing agent for cotton fabrics to improve flame retardant and antibacterial properties. Carbohydr. Polym. 2015, 118, 83–90. [Google Scholar] [CrossRef]

- Kert, M.; Krkoc, V.; Gorjanc, M. Influence of Optical Brightening Agent Concentration on Properties of Cotton Fabric Coated with Photochromic Microcapsules Using a Pad-Dry-Cure Process. Polymers 2019, 11, 1919. [Google Scholar] [CrossRef]

- Zhu, B.; Liu, J.; Gao, W. Effects of Snailase Treatment on Wettability of Raw Cotton Yarns in Pre-Wetting Process of Foam Sizing. Appl. Biochem. Biotech. 2017, 182, 1065–1075. [Google Scholar] [CrossRef] [PubMed]

- Rosace, G.; Guido, E.; Colleoni, C.; Barigozzi, G. Influence of textile structure and silica based finishing on thermal insulation properties of cotton fabrics. Int. J. Polym. Sci. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Stohr, A.; Lindell, E.; Guo, L.; Persson, N.-K. Thermal Textile Pixels: The Characterisation of Temporal and Spatial Thermal Development. Materials 2019, 12, 3747. [Google Scholar] [CrossRef] [PubMed]

- Mondal, M.I.H.; Saha, J. Antimicrobial, UV resistant and thermal comfort properties of chitosan-and Aloe vera-modified cotton woven fabric. J. Polym. Environ. 2019, 27, 405–420. [Google Scholar] [CrossRef]

- Perera, S.; Bhushan, B.; Bandara, R.; Rajapakse, G.; Rajapakse, S.; Bandara, C. Morphological, antimicrobial, durability, and physical properties of untreated and treated textiles using silver-nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2013, 436, 975–989. [Google Scholar] [CrossRef]

- Ghoranneviss, M.; Shahidi, S. Effect of various metallic salts on antibacterial activity and physical properties of cotton fabrics. J. Ind. Text. 2013, 42, 193–203. [Google Scholar] [CrossRef]

- Üreyen, M.E.; Gürkan, P.; Namligöz, E.S.; Armakan, D.M.; Doğan, A. Antibacterial and Physical Properties of Knitted Cotton Fabrics Treated with Antibacterial Finishes. AATCC Rev. 2010, 10, 48–54. [Google Scholar]

- Darwish, R.M.; Bloomfield, S.F. The effect of co-solvents on the antibacterial activity of paraben preservatives. Int. J. Pharm. 1995, 119, 183–192. [Google Scholar] [CrossRef]

- Wang, H.-H.; Sun, D.-W.; Kuang, R. Inhibition of Escherichia coli by dimethyl fumarate. Int. J. Food Microbiol. 2001, 65, 125–130. [Google Scholar] [CrossRef]

- Lück, E. Food applications of sorbic acid and its salts. Food Addit. Contam. 1990, 7, 711–715. [Google Scholar] [CrossRef]

- Bunger, J.R.; Ekanayake, A. Antimicrobial Combinations of A Sorbate Preservative, Natamycin and A Dialkyl Dicarbonate Useful in Treating Beverages and Other Food Products and Process of Making. Google Patents: 6,136,356, 24 October 2000. [Google Scholar]

- Reaction-to-Fire Tests-Heat Release, Smoke Production and Mass Loss Rate-Part 1: Heat Release Rate (Cone Calorimeter Method), ISO 5660-1; ISO: Geneva, Switzerland, 2002.

- Hu, X.; Zhang, Q.; Yu, H.; Zhao, D.; Dong, S.; Zhou, W.; Tang, Z. Quantitative Analysis of Naturally Colored Cotton and White Cotton Blends by UV–VIS Diffuse Reflectance Spectroscopy. J. Appl. Spectrosc. 2015, 81, 949–955. [Google Scholar] [CrossRef]

- Li, S.; Huang, J.; Chen, Z.; Chen, G.; Lai, Y. A review on special wettability textiles: Theoretical models, fabrication technologies and multifunctional applications. J. Mater. Chem. A 2017, 5, 31–55. [Google Scholar] [CrossRef]

- Lin, J.; Zheng, C.; Ye, W.J.; Wang, H.Q.; Feng, D.Y.; Li, Q.Y.; Huan, B.W. A Facile Dip-Coating Approach to Prepare SiO2/Fluoropolymer Coating for Superhydrophobic and Superoleophobic Fabrics with Self-Cleaning Property. J. Appl. Polym. Sci. 2015, 132, 41458. [Google Scholar] [CrossRef]

- Avramescu, R.E.; Ghica, M.V.; Dinu-Pirvu, C.; Prisada, R.; Popa, L. Superhydrophobic Natural and Artificial Surfaces-A Structural Approach. Materials 2018, 11, 866. [Google Scholar] [CrossRef] [PubMed]

- Efimov, V.B.; Makova, M.K.; Mezhov-Deglin, L.P. Thermal conductivity of organic superconductors. Phys. C Supercond. 1997, 282–287, 1903–1904. [Google Scholar] [CrossRef]

- Gong, F.; Meng, C.; He, J.; Dong, X. Fabrication of highly conductive and multifunctional polyester fabrics by spray-coating with PEDOT:PSS solutions. Prog. Org. Coat. 2018, 121, 89–96. [Google Scholar] [CrossRef]

- Wang, F.; Lai, D.; Shi, W.; Fu, M. Effects of fabric thickness and material on apparent ‘wet’ conductive thermal resistance of knitted fabric ‘skin’ on sweating manikins. J. Therm. Biol. 2017, 70, 69–76. [Google Scholar] [CrossRef]

- Chu, F.K.; Hou, Y.B.; Liu, L.X.; Qiu, S.L.; Cai, W.; Xu, Z.M.; Song, L.; Hu, W.Z. Hierarchical Structure: An effective Strategy to Enhance the Mechanical Performance and Fire Safety of Unsaturated Polyester Resin. ACS Appl. Mater. Interfaces 2019, 11, 29436–29447. [Google Scholar] [CrossRef]

- Ouajai, S.; Shanks, R.A. Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym. Degrad. Stabil. 2005, 89, 327–335. [Google Scholar] [CrossRef]

- Cai, W.; Hu, Y.; Pan, Y.; Zhou, X.; Chu, F.; Han, L.; Mu, X.; Zhuang, Z.; Wang, X.; Xing, W. Self-assembly followed by radical polymerization of ionic liquid for interfacial engineering of black phosphorus nanosheets: Enhancing flame retardancy, toxic gas suppression and mechanical performance of polyurethane. J. Colloid Interface Sci. 2020, 561, 32–45. [Google Scholar] [CrossRef]

- Cai, W.; Cai, T.; He, L.; Chu, F.; Mu, X.; Han, L.; Hu, Y.; Wang, B.; Hu, W. Natural antioxidant functionalization for fabricating ambient-stable black phosphorus nanosheets toward enhancing flame retardancy and toxic gases suppression of polyurethane. J. Hazard. Mater. 2020, 387, 121971–121985. [Google Scholar] [CrossRef]

- Liu, L.X.; Huang, Z.C.; Pan, Y.; Wang, X.; Song, L.; Hu, Y. Finishing of cotton fabrics by multi-layered coatings to improve their flame retardancy and water repellency. Cellulose 2018, 25, 4791–4803. [Google Scholar] [CrossRef]

- Deng, J.; Kang, F.R.; Xiao, Y.; Shu, C.M.; Wang, W.F.; Bin, L.W.; Liu, Z.C. Effects of platinum compounds/superfine aluminum hydroxide/ultrafine calcium carbonate on the flame retardation and smoke suppression of silicone foams. J. Appl. Polym. Sci. 2020, 137, 47679. [Google Scholar] [CrossRef]

- Beaugendre, A.; Lemesle, C.; Bellayer, S.; Degoutin, S.; Duquesne, S.; Casetta, M.; Pierlot, C.; Jaime, F.; Kim, T.; Jimenez, M. Flame retardant and weathering resistant self-layering epoxy-silicone coatings for plastics. Prog. Org. Coat. 2019, 136, 105269. [Google Scholar] [CrossRef]

- Pan, Y.; Zhao, H.T. A novel blowing agent polyelectrolyte for fabricating intumescent multilayer coating that retards fire on cotton fabric. J. Appl. Polym. Sci. 2018, 135, 8. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Cai, W.; Song, L.; Mu, X.; Hu, Y. Comprehensive Property Investigation of Mold Inhibitor Treated Raw Cotton and Ramie Fabric. Materials 2020, 13, 1105. https://doi.org/10.3390/ma13051105

Zhao Z, Cai W, Song L, Mu X, Hu Y. Comprehensive Property Investigation of Mold Inhibitor Treated Raw Cotton and Ramie Fabric. Materials. 2020; 13(5):1105. https://doi.org/10.3390/ma13051105

Chicago/Turabian StyleZhao, Zhixin, Wei Cai, Lei Song, Xiaowei Mu, and Yuan Hu. 2020. "Comprehensive Property Investigation of Mold Inhibitor Treated Raw Cotton and Ramie Fabric" Materials 13, no. 5: 1105. https://doi.org/10.3390/ma13051105

APA StyleZhao, Z., Cai, W., Song, L., Mu, X., & Hu, Y. (2020). Comprehensive Property Investigation of Mold Inhibitor Treated Raw Cotton and Ramie Fabric. Materials, 13(5), 1105. https://doi.org/10.3390/ma13051105