Novel Poly(Caprolactone)/Epoxy Blends by Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Samples

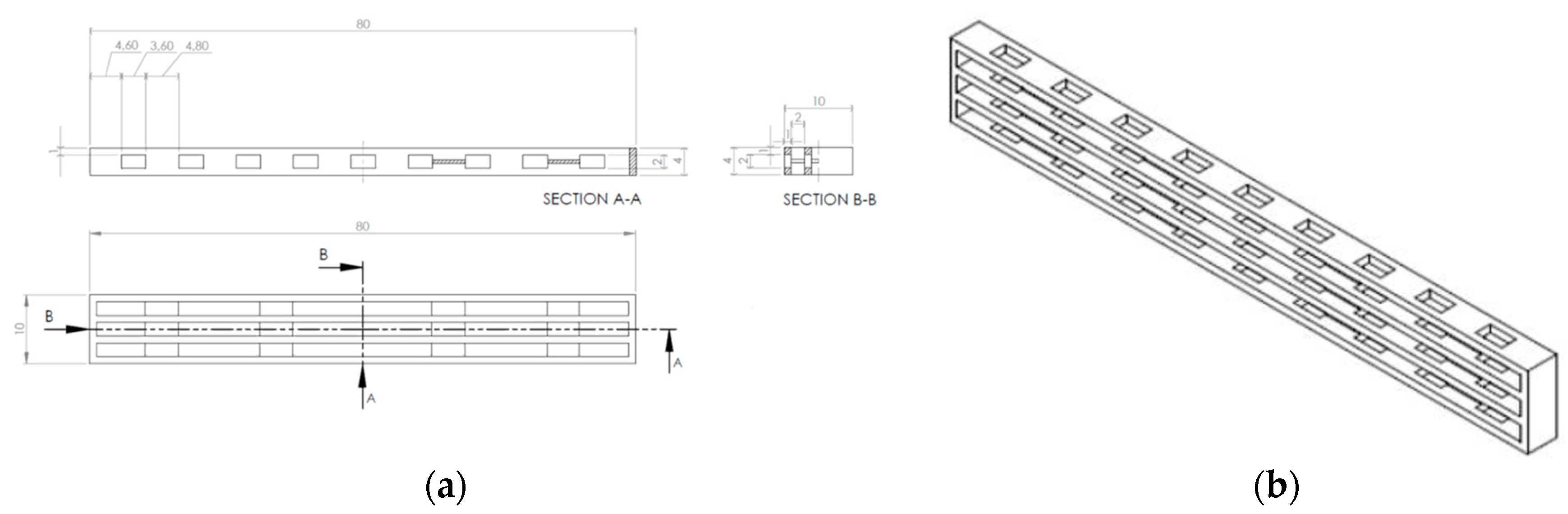

2.2.1. 3D Printed Poly(caprolactone)-Epoxy Blends

2.2.2. Melt-Mixed Poly(caprolactone)-Epoxy Blends

2.3. Experimental Techniques

2.3.1. Characterization of the Constituents

2.3.2. Evaluation of the Flexural and Fracture Behavior

2.3.3. Evaluation of the Healing Behavior

2.3.4. Microstructrural Characterization

3. Results and Discussion

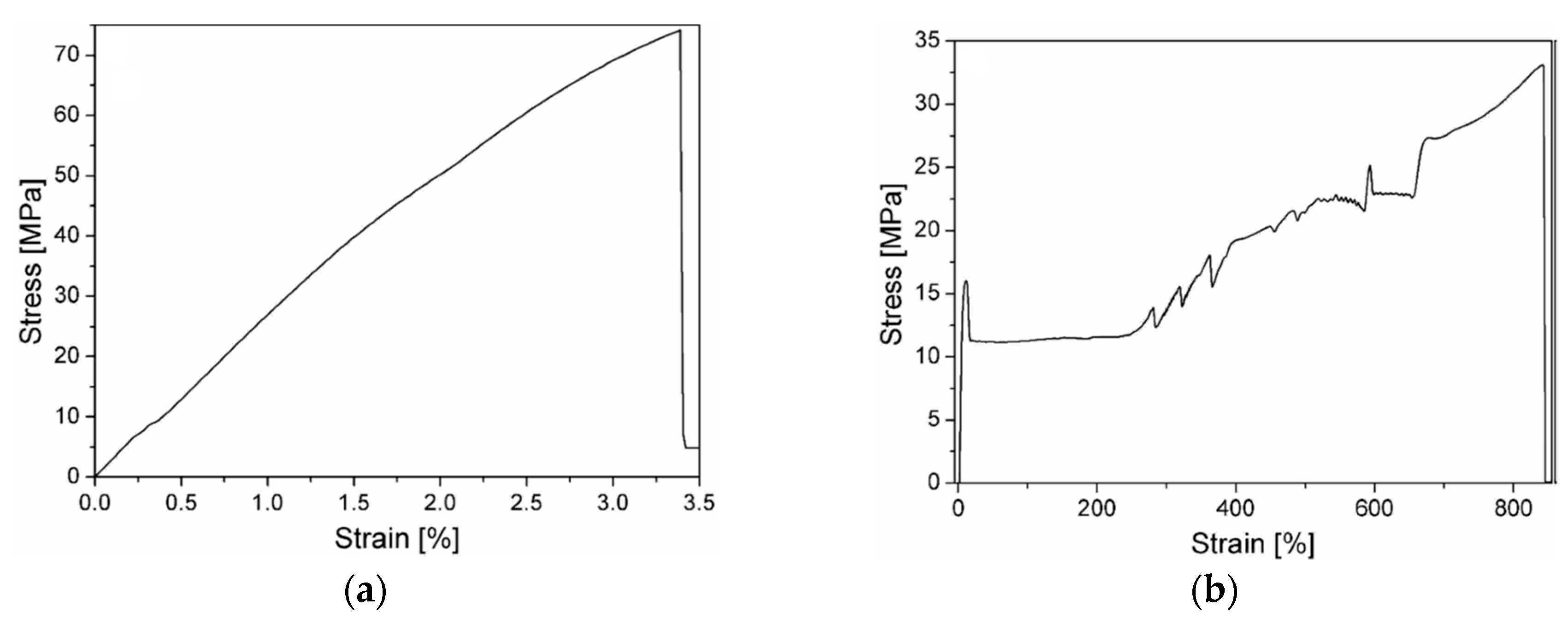

3.1. Characterization of the Constituents

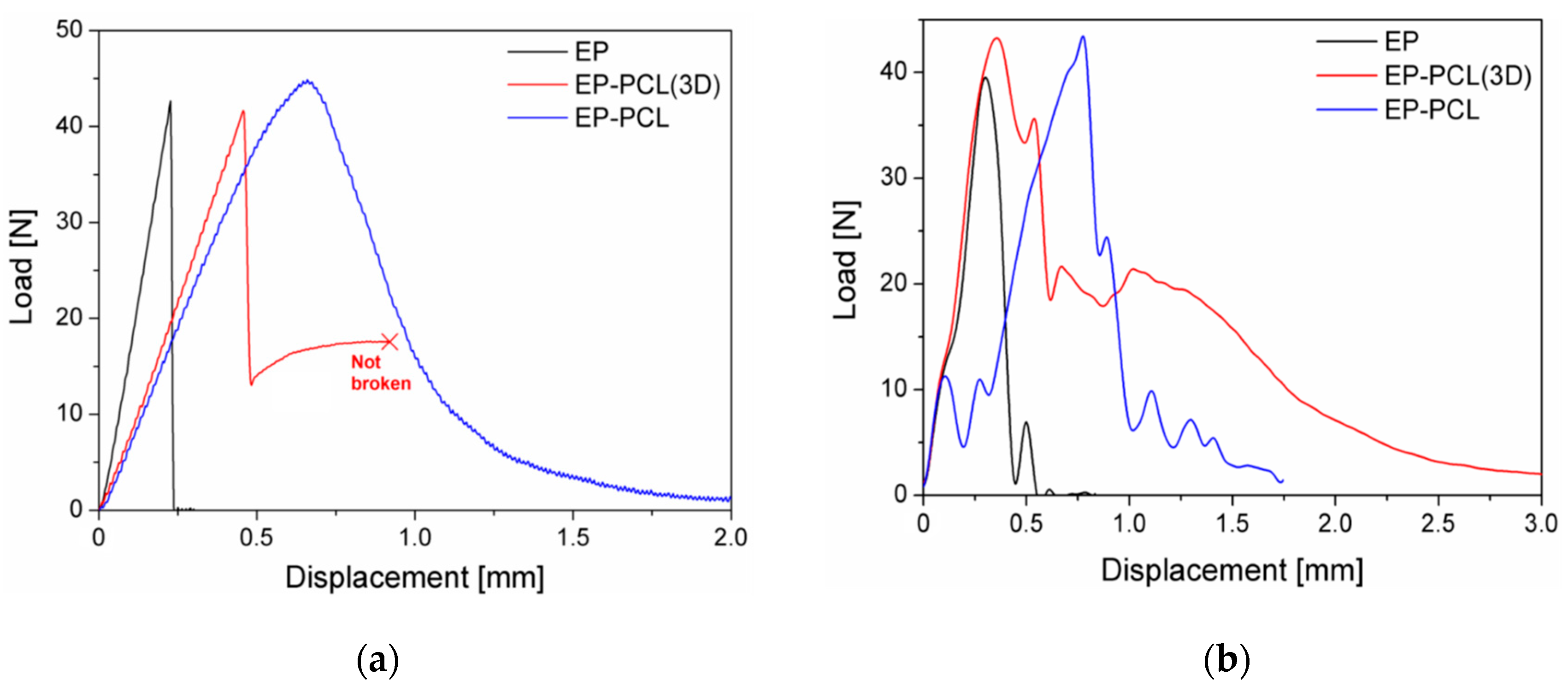

3.2. Evaluation of the Flexural and Fracture Behavior

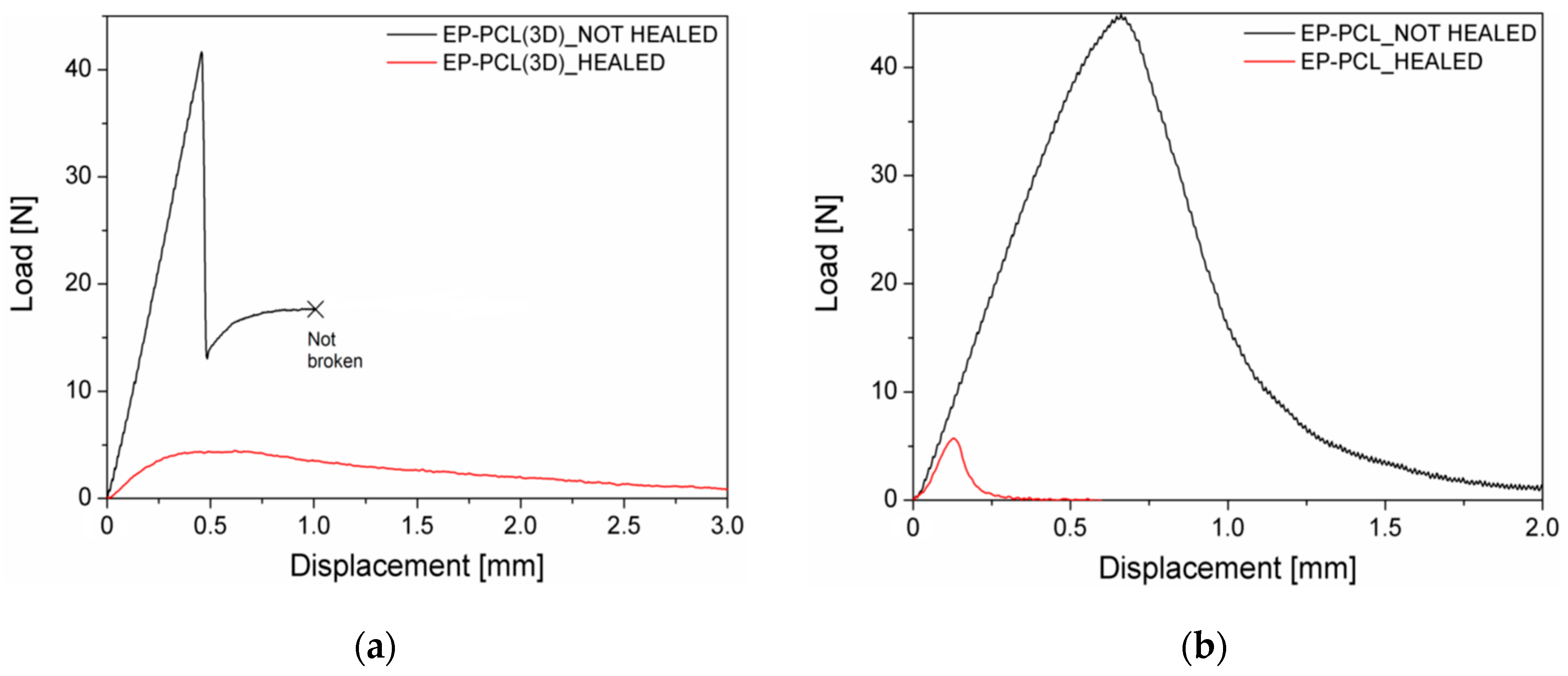

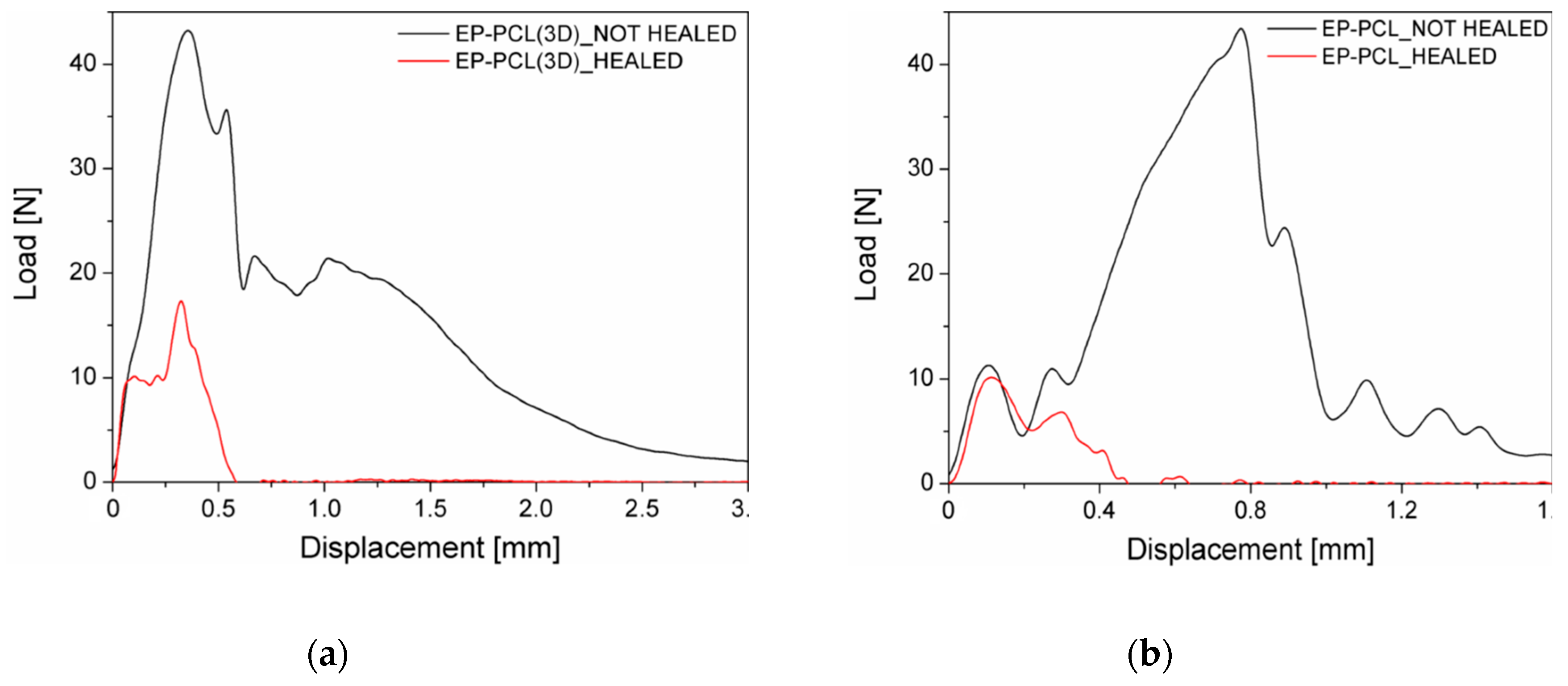

3.3. Evaluation of the Thermal Healing Behavior

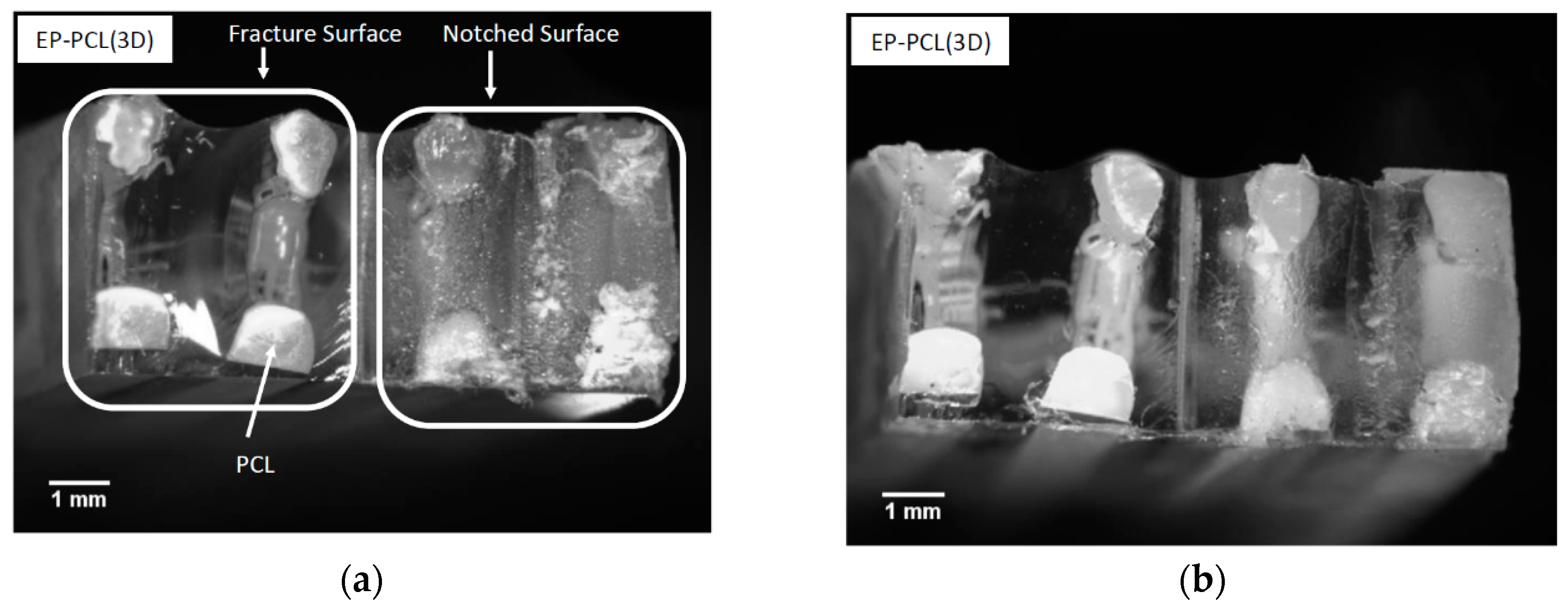

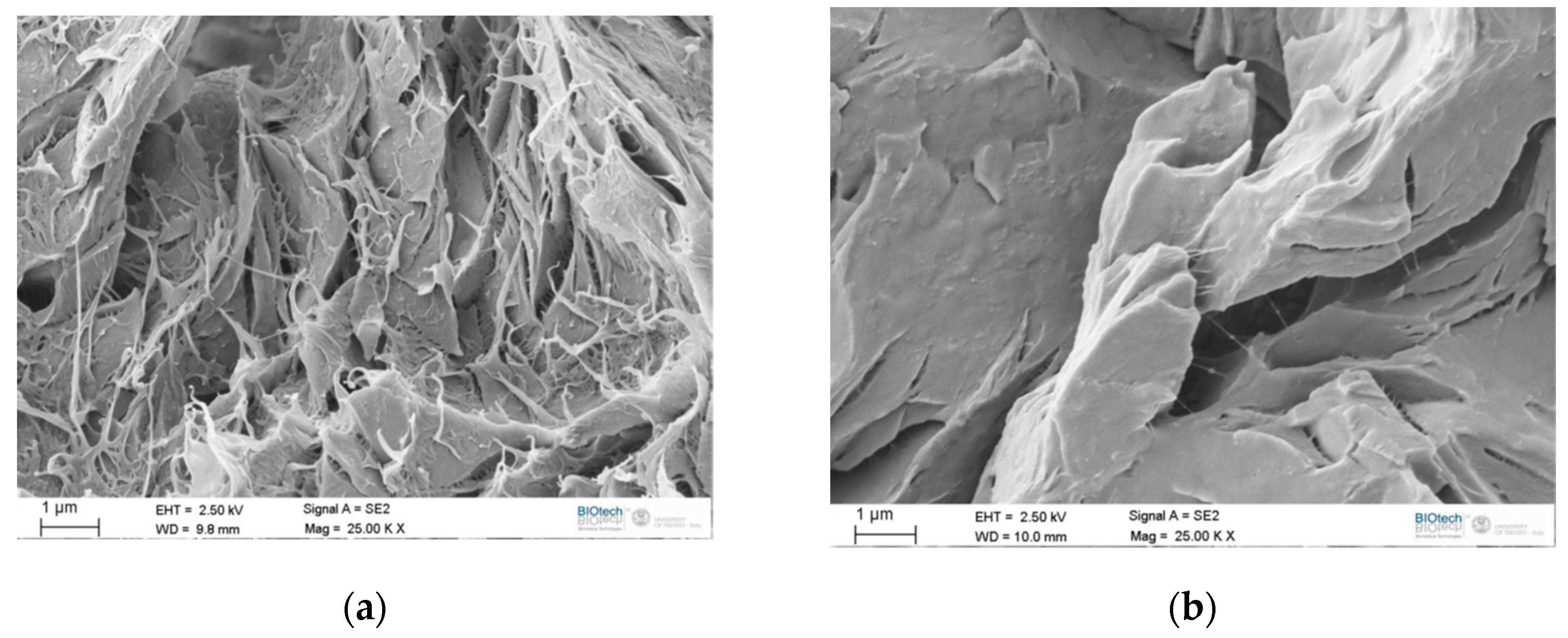

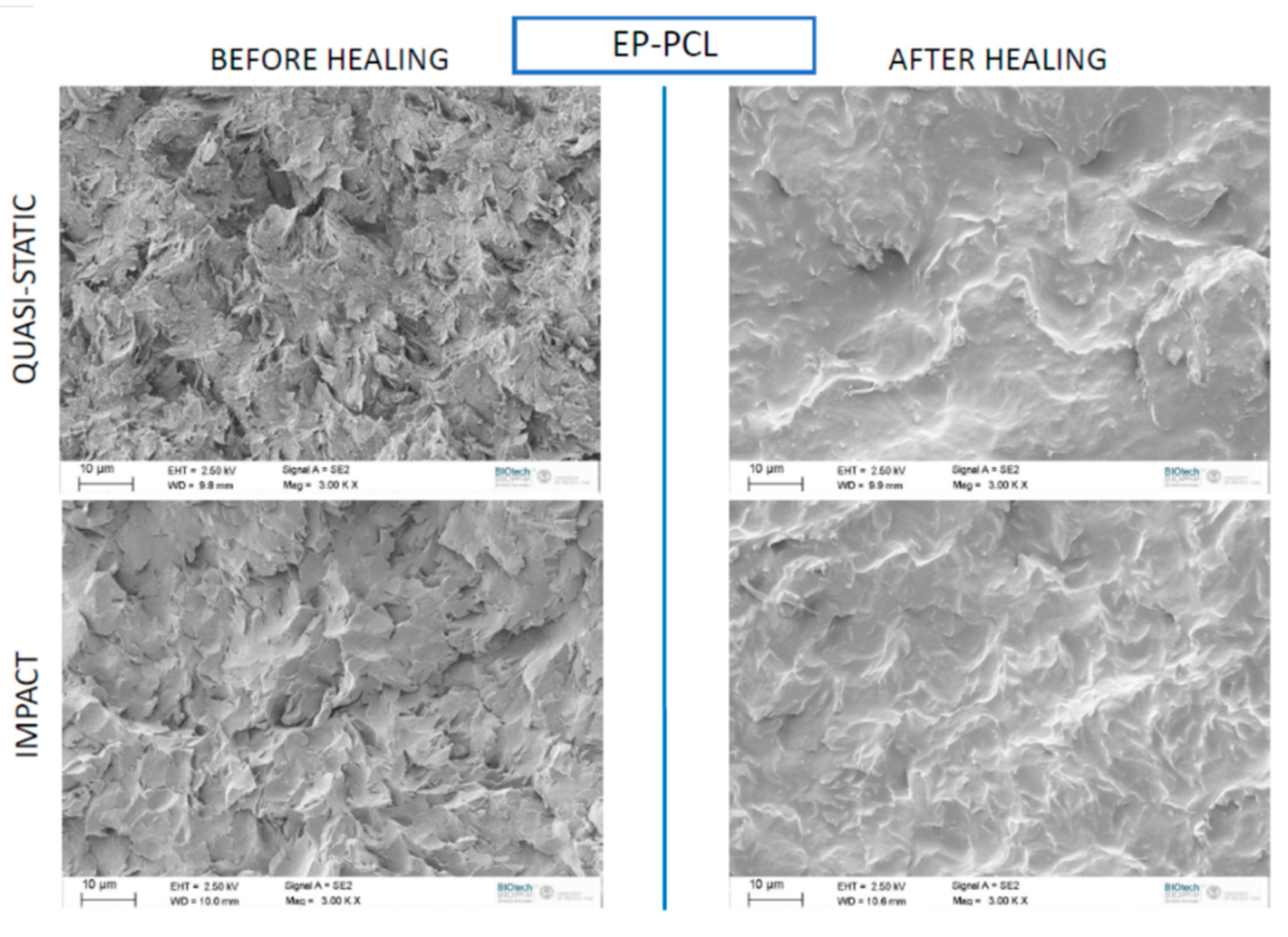

3.4. Microstructural Behavior

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Francis, B. Cure Kinetics of Epoxy/Thermoplastic Blends. In Handbook of Epoxy Blends; Parameswaranpillai, J., Hameed, N., Pionteck, J., Woo, E.M., Eds.; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Jagadeesh, K.S.; Gururaja Rao, J.; Shashikiran, K.; Suvarna, S.; Ambekar, S.Y.; Saletore, M.; Biswas, C.; Rajanna, A.V. Cure kinetics of multifunctional epoxies with 2,2′-dichloro-4,4′-diaminodiphenylmethane as hardener. J. Appl. Polym. Sci. 2000, 77, 2097–2103. [Google Scholar] [CrossRef]

- Wang, J.; Liu, R.; Jian, X. Introduction to Epoxy/Thermoplastic Blends. In Handbook of Epoxy Blends; Parameswaranpillai, J., Hameed, N., Pionteck, J., Woo, E.M., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 1–29. [Google Scholar]

- Dorigato, A.; Pegoretti, A.; Bondioli, F.; Messori, M. Improving Epoxy Adhesives with Zirconia Nanoparticles. Compos. Interfaces 2010, 17, 873–892. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. The role of alumina nanoparticles in epoxy adhesives. J. Nanopart. Res. 2011, 13, 2429–2441. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A.; Quaresimin, M. Thermo-mechanical characterization of epoxy/clay nanocomposites as matrices for carbon/nanoclay/epoxy laminates. Mater. Sci. Eng. A 2011, 528, 6324–6333. [Google Scholar] [CrossRef]

- Rotrekl, J. Epoxy/PCL nanocomposites: Effect of layered silicate on structure and behavior. Express Polym. Lett. 2012, 6, 975–986. [Google Scholar] [CrossRef]

- Dorigato, A.; Morandi, S.; Pegoretti, A. Effect of nanoclay addition on the fiber/matrix adhesion in epoxy/glass composites. J. Compos. Mater. 2012, 46, 1439–1451. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Dorigato, A.; Pegoretti, A. Monitoring the Mechanical Behaviour of Electrically Conductive Polymer Nanocomposites under Ramp and Creep Conditions. J. Nanosci. Nanotechnol. 2012, 12, 4093–4102. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A.; Fambri, L.; Lonardi, C.; Slouf, M.; Kolarik, J. Linear low density polyethylene/cycloolefin copolymer blends. Express Polym. Lett. 2011, 5, 23–37. [Google Scholar] [CrossRef]

- Marouf, B.T.; Bagheri, R. Applications of Epoxy/Rubber Blends. In Handbook of Epoxy Blends; Parameswaranpillai, J., Hameed, N., Pionteck, J., Woo, E.M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 399–426. [Google Scholar]

- Rong, M.; Zeng, H. Polycarbonate/epoxy semi-interpenetrating polymer network: 1. Preparation, interaction and curing behaviour. Polymer 1996, 37, 2525–2531. [Google Scholar] [CrossRef]

- Vyas, A.; Iroh, J.O. In situ growth of multilayered crystals in amorphous matrix: Thermal, dynamic mechanical, and morphological analysis of nylon-6/epoxy composites. J. Appl. Polym. Sci. 2013, 130, 3319–3327. [Google Scholar] [CrossRef]

- Kulshreshtha, B.; Ghosh, A.K.; Misra, A. Crystallization kinetics and morphological behavior of reactively processed PBT/epoxy blends. Polymer 2003, 44, 4723–4734. [Google Scholar] [CrossRef]

- Jiang, X.; Huang, H.; Zhang, Y.; Zhang, Y. Dynamically cured polypropylene/epoxy blends. J. Appl. Polym. Sci. 2004, 92, 1437–1448. [Google Scholar] [CrossRef]

- Frigione, M.; Acierno, D.; Mascia, L. Miscibilization of low molecular weight functionalized polyethylenes in epoxy resins. I. Effects of composition and modifications chemistry. J. Appl. Polym. Sci. 1999, 73, 1457–1470. [Google Scholar] [CrossRef]

- Park, S.-J. Studies on cure behaviors, dielectric characteristics and mechanical properties of DGEBA/poly(ethylene terephthalate) blends. Macromol. Res. 2009, 17, 585–590. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, M.; Gan, W.; Tao, Q.; Li, S. Polymerization-Induced Viscoelastic Phase Separation in Polyethersulfone-Modified Epoxy Systems. J. Phys. Chem. B 2004, 108, 6208–6215. [Google Scholar] [CrossRef]

- Ishii, Y.; Ryan, A.J. Processing of Poly(2,6-dimethyl-1,4-phenylene ether) with Epoxy Resin. 1. Reaction-Induced Phase Separation. Macromolecules 2000, 33, 158–166. [Google Scholar] [CrossRef]

- Fan, W.; Zheng, S. Reaction-induced microphase separation in thermosetting blends of epoxy resin with poly(methyl methacrylate)-block-polystyrene block copolymers: Effect of topologies of block copolymers on morphological structures. Polymer 2008, 49, 3157–3167. [Google Scholar] [CrossRef]

- Jose, J.; Joseph, K.; Pionteck, J.; Thomas, S. PVT Behavior of Thermoplastic Poly(styrene-co-acrylonitrile)-Modified Epoxy Systems: Relating Polymerization-Induced Viscoelastic Phase Separation with the Cure Shrinkage Performance. J. Phys. Chem. B 2008, 112, 14793–14803. [Google Scholar] [CrossRef] [PubMed]

- Huang, P.; Zheng, S.; Huang, J.; Guo, Q.; Zhu, W. Miscibility and mechanical properties of epoxy resin/polysulfone blends. Polymer 1997, 38, 5565–5571. [Google Scholar] [CrossRef]

- George, S.M.; Puglia, D.; Kenny, J.M.; Parameswaranpillai, J.; Thomas, S. Reaction-Induced Phase Separation and Thermomechanical Properties in Epoxidized Styrene-block-butadiene-block-styrene Triblock Copolymer Modified Epoxy/DDM System. Ind. Eng. Chem. Res. 2014, 53, 6941–6950. [Google Scholar] [CrossRef]

- Goossens, S.; Groeninckx, G. Mutual Influence between Reaction-Induced Phase Separation and Isothermal Crystallization in POM/Epoxy Resin Blends. Macromolecules 2006, 39, 8049–8059. [Google Scholar] [CrossRef]

- Li, S.; Hsu, B.-L.; Li, F.; Li, C.Y.; Harris, F.W.; Cheng, S.Z. A study of polyimide thermoplastics used as tougheners in epoxy resins—Structure, property and solubility relationships. Thermochim. Acta 1999, 340, 221–229. [Google Scholar] [CrossRef]

- Zhong, Z.; Zheng, S.; Huang, J.; Cheng, X.; Guo, Q.; Wei, J. Phase behaviour and mechanical properties of epoxy resin containing phenolphthalein poly(ether ether ketone). Polymer 1998, 39, 1075–1080. [Google Scholar] [CrossRef]

- Soares, B.G.; Livi, S. Novel Techniques for the Preparation of Different Epoxy/Rubber Blends. In Handbook of Epoxy Blends; Parameswaranpillai, J., Hameed, N., Pionteck, J., Woo, E.M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 29–67. [Google Scholar]

- Cai, C.; Shi, Q.; Li, L.; Zhu, L.; Yin, J. Grafting acrylic acid onto polypropylene by reactive extrusion with pre-irradiated PP as initiator. Radiat. Phys. Chem. 2008, 77, 370–372. [Google Scholar] [CrossRef]

- Abbate, M.; Martuscelli, E.; Musto, P.; Ragosta, G.; Scarinzi, G. Toughening of a highly cross-linked epoxy resin by reactive blending with bisphenol A polycarbonate. I. FTIR spectroscopy. J. Polym. Sci. Part B Polym. Phys. 1994, 32, 395–408. [Google Scholar] [CrossRef]

- Barone, L.; Carciotto, S.; Cicala, G.; Recca, A. Thermomechanical properties of epoxy/poly(ε-caprolactone) blends. Polym. Eng. Sci. 2006, 46, 1576–1582. [Google Scholar] [CrossRef]

- Williams, R.J.J.; Rozenberg, B.A.; Pascault, J.-P. Reaction-induced phase separation in modified thermosetting polymers. In Polymer Analysis Polymer Physics; Springer: Berlin/Heidelberg, Germany, 1997; pp. 95–156. [Google Scholar]

- Funabashi, M.; Ninomiya, F.; Kunioka, M. Biodegradation of Polycaprolactone Powders Proposed as Reference Test Materials for International Standard of Biodegradation Evaluation Method. J. Polym. Environ. 2007, 15, 7–17. [Google Scholar] [CrossRef]

- Fabbri, P.; Cannillo, V.; Sola, A.; Dorigato, A.; Federica, C. Highly porous polycaprolactone-45S5 Bioglass® scaffolds for bone tissue engineering. Compos. Sci. Technol. 2010, 70, 1869–1878. [Google Scholar] [CrossRef]

- Koenig, M.F.; Huang, S.J. Biodegradable blends and composites of polycaprolactone and starch derivatives. Polymer 1995, 36, 1877–1882. [Google Scholar] [CrossRef]

- Matzinos, P.; Tserki, V.; Kontoyiannis, A.; Panayiotou, C. Processing and characterization of starch/polycaprolactone products. Polym. Degrad. Stab. 2002, 77, 17–24. [Google Scholar] [CrossRef]

- Rudnik, E. Properties and applications. In Compostable Polymer Materials; Rudnik, E., Ed.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 38–69. [Google Scholar]

- Jones, A.R.; Watkins, C.A.; White, S.R.; Sottos, N.R. Self-healing thermoplastic-toughened epoxy. Polymer 2015, 74, 254–261. [Google Scholar] [CrossRef]

- Karger-Kocsis, J. Self-healing properties of epoxy resins with poly(ε-caprolactone) healing agent. Polym. Bull. 2016, 73, 3081–3093. [Google Scholar] [CrossRef]

- Mahmood, H.; Dorigato, A.; Pegoretti, A. Thermal mending in novel epoxy/cyclic olefin copolymer blends. Express Polym. Lett. 2020, 14, 368–383. [Google Scholar] [CrossRef]

- Li, G.; Meng, H. Overview of crack self-healing. In Recent Advances in Smart Self-healing Polymers and Composites; Li, G., Meng, H., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 1–19. [Google Scholar]

- Ji, G.; Zhang, P.; Nji, J.; John, M.; Li, G. Shape memory polymer-based self-healing composites. In Recent Advances in Smart Self-Healing Polymers and Composites; Woodhead Publishing: Cambridge, UK, 2015; pp. 293–363. [Google Scholar]

- Nji, J.; Li, G. Damage healing ability of a shape-memory-polymer-based particulate composite with small thermoplastic contents. Smart Mater. Struct. 2012, 21, 025011. [Google Scholar] [CrossRef]

- Fejős, M.; Molnár, K.; Karger-Kocsis, J. Epoxy/Polycaprolactone Systems with Triple-Shape Memory Effect: Electrospun Nanoweb with and without Graphene Versus Co-Continuous Morphology. Materials 2013, 6, 4489–4504. [Google Scholar] [CrossRef]

- Arias, M.A.L.; Frontini, P.M.; Williams, R.J.J. Analysis of the damage zone around the crack tip for two rubber-modified epoxy matrices exhibiting different toughenability. Polymer 2003, 44, 1537–1546. [Google Scholar] [CrossRef]

- Brooker, R.D.; Kinloch, A.J.; Taylor, A.C. The Morphology and Fracture Properties of Thermoplastic-Toughened Epoxy Polymers. J. Adhes. 2010, 86, 726–741. [Google Scholar] [CrossRef]

- Pearson, R.A.; Yee, A.F. Toughening mechanisms in thermoplastic-modified epoxies: 1. Modification using poly(phenylene oxide). Polymer 1993, 34, 3658–3670. [Google Scholar] [CrossRef]

- Dorigato, A.; Moretti, V.; Dul, S.; Unterberger, S.; Pegoretti, A. Electrically conductive nanocomposites for fused deposition modelling. Synth. Met. 2017, 226, 7–14. [Google Scholar] [CrossRef]

- Rigotti, D.; Dorigato, A.; Pegoretti, A. 3D printable thermoplastic polyurethane blends with thermal energy storage/release capabilities. Mater. Today Commun. 2018, 15, 228–235. [Google Scholar] [CrossRef]

- Valentini, F.; Dorigato, A.; Rigotti, D.; Pegoretti, A. Polyhydroxyalkanoates/Fibrillated Nanocellulose Composites for Additive Manufacturing. J. Polym. Environ. 2019, 27, 1333–1341. [Google Scholar] [CrossRef]

- Nadgorny, M.; Ameli, A. Functional Polymers and Nanocomposites for 3D Printing of Smart Structures and Devices. ACS Appl. Mater. Interfaces 2018, 10, 17489–17507. [Google Scholar] [CrossRef] [PubMed]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Szebenyi, G.; Czigany, T.; Magyar, B.; Karger-Kocsis, J. 3D printing-assisted interphase engineering of polymer composites&58; Concept and feasibility. Express Polym. Lett. 2017, 11, 525–530. [Google Scholar]

- Belter, J.T.; Dollar, A.M. Strengthening of 3D Printed Fused Deposition Manufactured Parts Using the Fill Compositing Technique. PLoS ONE 2015, 10, e0122915. [Google Scholar] [CrossRef]

- Plastics—Determination of Charpy Impact Properties; ISO 179-2; ISO: Geneva, Switzerland, 1997.

- Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials; ASTM D5045-14; ASTM: West Conshohocken, PA, USA, 2014.

- Plastics—Determination of Tensile Properties; ISO 527-1; ISO: Geneva, Switzerland, 2012.

- Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM D790-17; ASTM: West Conshohocken, PA, USA, 2017.

- Pavan, A. Determination of fracture toughness (GIC and KIC) at moderately high loading rates. In European Structural Integrity Society; Moore, D.R., Pavan, A., Williams, J.G., Eds.; Elsevier: Oxford, UK, 2001; Volume 28, pp. 27–58. [Google Scholar]

- Wunderlich, B. Structure and Properties of Materials. In Thermal Analysis of Polymeric Materials; Springer: Berlin/Heidelberg, Germany, 2005; pp. 455–590. [Google Scholar]

- McKeen, L.W. Introduction to Use of Plastics in Food Packaging. In Plastic Films in Food Packaging; Ebnesajjad, S., Ed.; William Andrew: Oxford, UK, 2013; pp. 1–15. [Google Scholar]

- Ashby, M.F.; Johnson, K. Materials and Design: The Art and Science of Material Selection in Product Design, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2014; pp. 1–389. [Google Scholar]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Enhancement of fracture toughness, mechanical and thermal properties of rubber/epoxy composites by incorporation of graphene nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2016, 87, 10–22. [Google Scholar] [CrossRef]

- Kunz-Douglass, S.; Beaumont, P.W.R.; Ashby, M.F. A model for the toughness of epoxy-rubber particulate composites. J. Mater. Sci. 1980, 15, 1109–1123. [Google Scholar] [CrossRef]

- Cohades, A.; Manfredi, E.; Plummer, C.J.G.; Michaud, V. Thermal mending in immiscible poly(ε-caprolactone)/epoxy blends. Eur. Polym. J. 2016, 81, 114–128. [Google Scholar] [CrossRef]

| Sample | E (MPa) | σy (MPa) | σb (MPa) | εb (%) |

|---|---|---|---|---|

| EP | 2749 ± 39 | - | 69.4 ± 7.7 | 3.1 ± 0.5 |

| PCL(3D) | 421 ± 12 | 16.6 ± 0.5 | 33.7 ± 2.9 | 853.0 ± 25.0 |

| Sample | EB (MPa) | σfB (MPa) | εfB (%) |

|---|---|---|---|

| EP | 3070 ± 99 | 108.0 ± 5.0 | 4.0 ± 0.2 |

| EP-PCL(3D) | 1709 ± 109 | 55.8 ± 6.3 | 3.6 ± 0.3 |

| EP-PCL | 1541 ± 24 | 47.1 ± 1.5 | 6.2 ± 0.5 |

| Sample | KIC,v (MPa·m0.5) | KIC,h (MPa·m0.5) | ηh (%) |

|---|---|---|---|

| Quasi-static tests | |||

| EP-PCL(3D) | 1.12 ± 0.12 | 0.16 ± 0.02 | 15 ± 2 |

| EP-PCL | 1.28 ± 0.12 | 0.23 ± 0.07 | 18 ± 5 |

| Impact tests | |||

| EP-PCL(3D) | 1.15 ± 0.10 | 0.39 ± 0.11 | 34 ± 9 |

| EP-PCL | 1.35 ± 0.11 | 0.36 ± 0.07 | 27 ± 6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dorigato, A.; Rigotti, D.; Pegoretti, A. Novel Poly(Caprolactone)/Epoxy Blends by Additive Manufacturing. Materials 2020, 13, 819. https://doi.org/10.3390/ma13040819

Dorigato A, Rigotti D, Pegoretti A. Novel Poly(Caprolactone)/Epoxy Blends by Additive Manufacturing. Materials. 2020; 13(4):819. https://doi.org/10.3390/ma13040819

Chicago/Turabian StyleDorigato, Andrea, Daniele Rigotti, and Alessandro Pegoretti. 2020. "Novel Poly(Caprolactone)/Epoxy Blends by Additive Manufacturing" Materials 13, no. 4: 819. https://doi.org/10.3390/ma13040819

APA StyleDorigato, A., Rigotti, D., & Pegoretti, A. (2020). Novel Poly(Caprolactone)/Epoxy Blends by Additive Manufacturing. Materials, 13(4), 819. https://doi.org/10.3390/ma13040819