Stability of a Melt Pool during 3D-Printing of an Unsupported Steel Component and Its Influence on Roughness

Abstract

1. Introduction

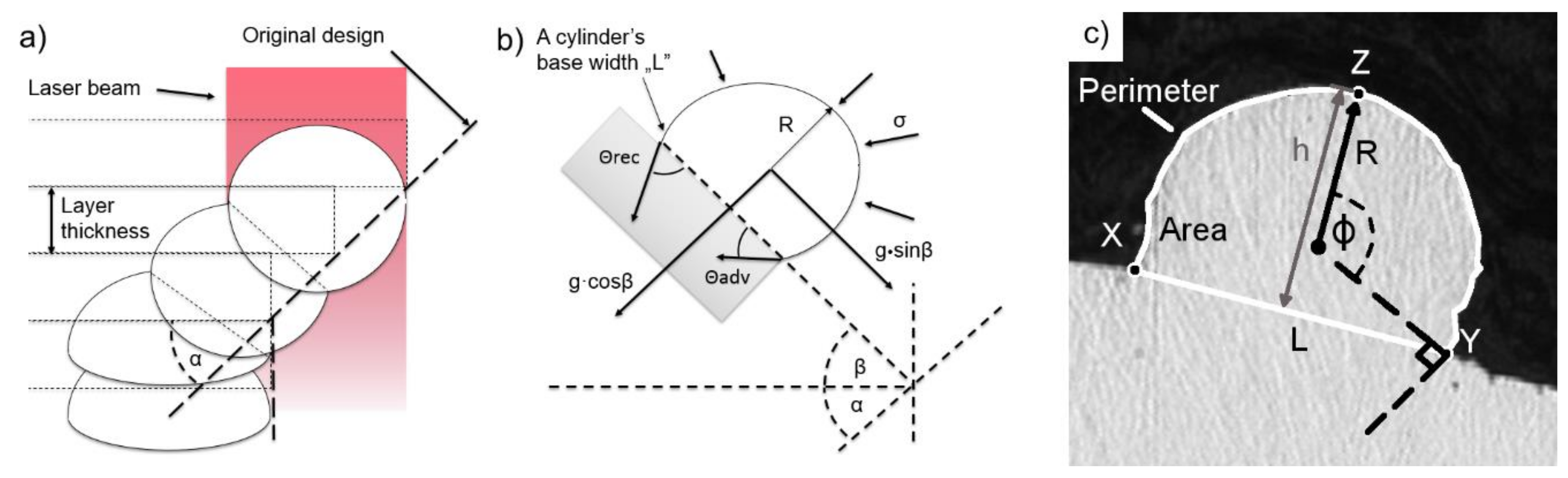

2. Experimental Approach

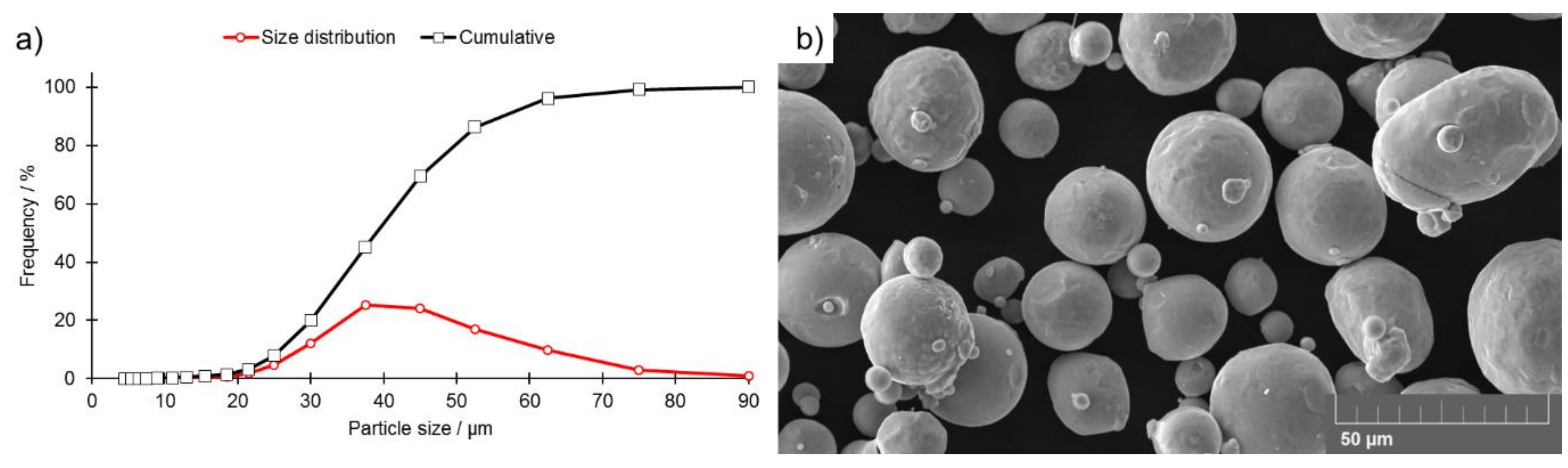

Base Material

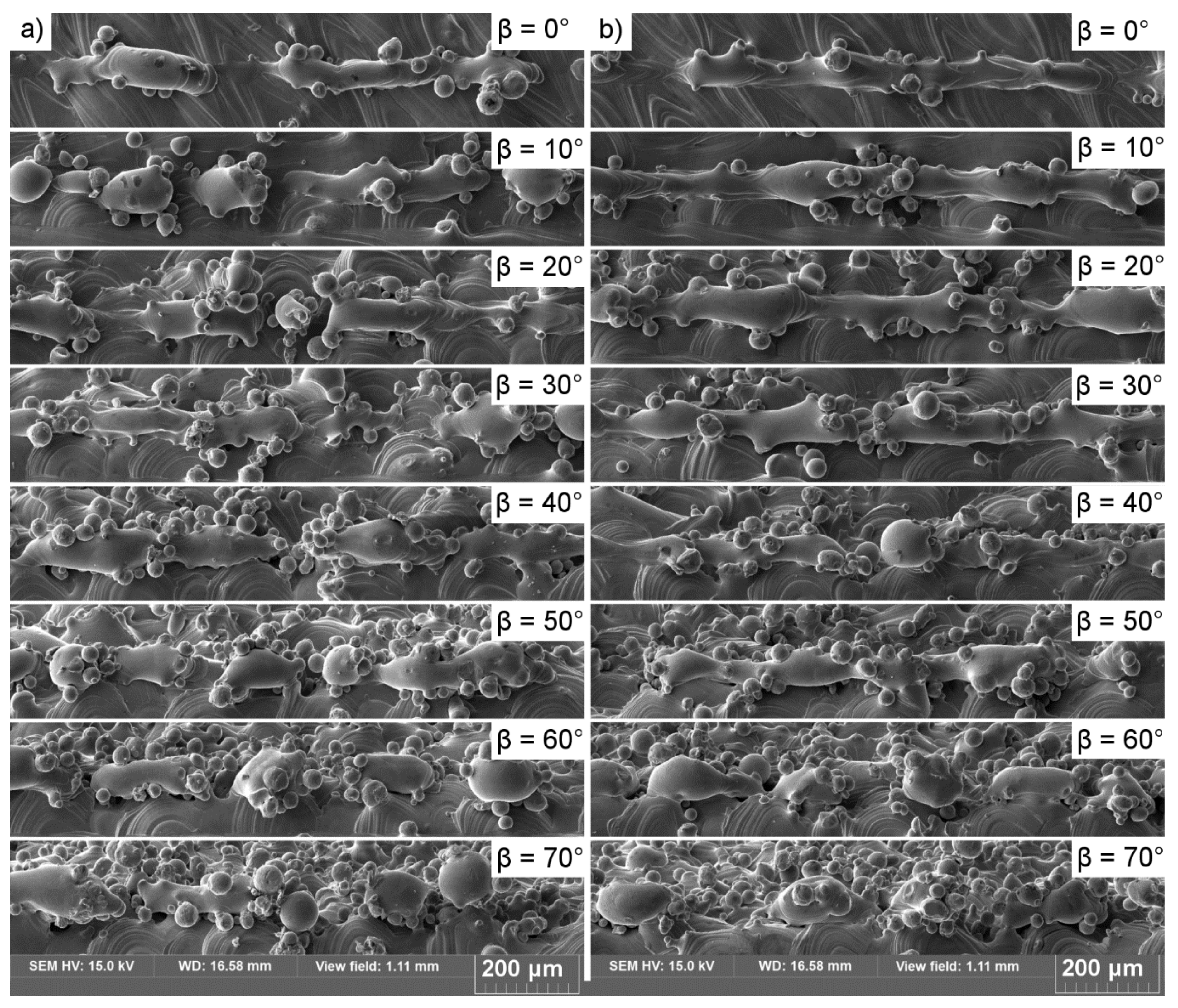

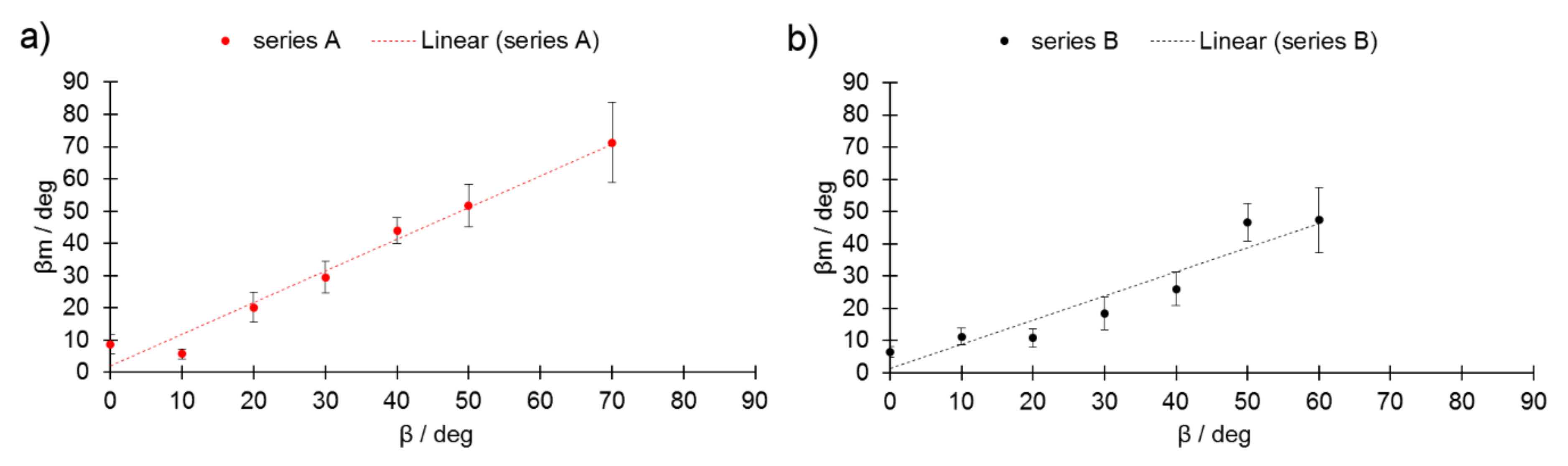

3. Results and Discussion

4. Conclusions

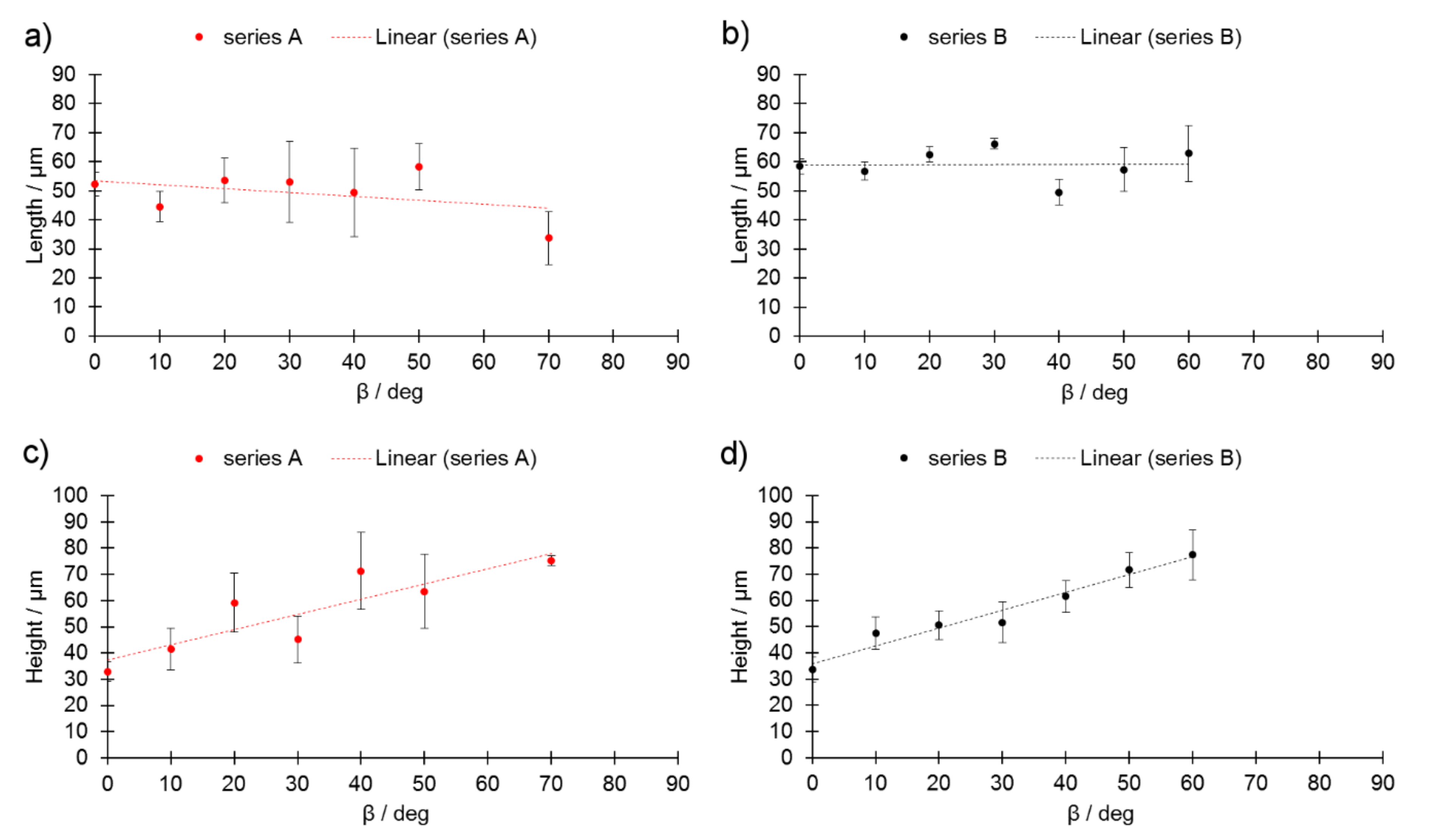

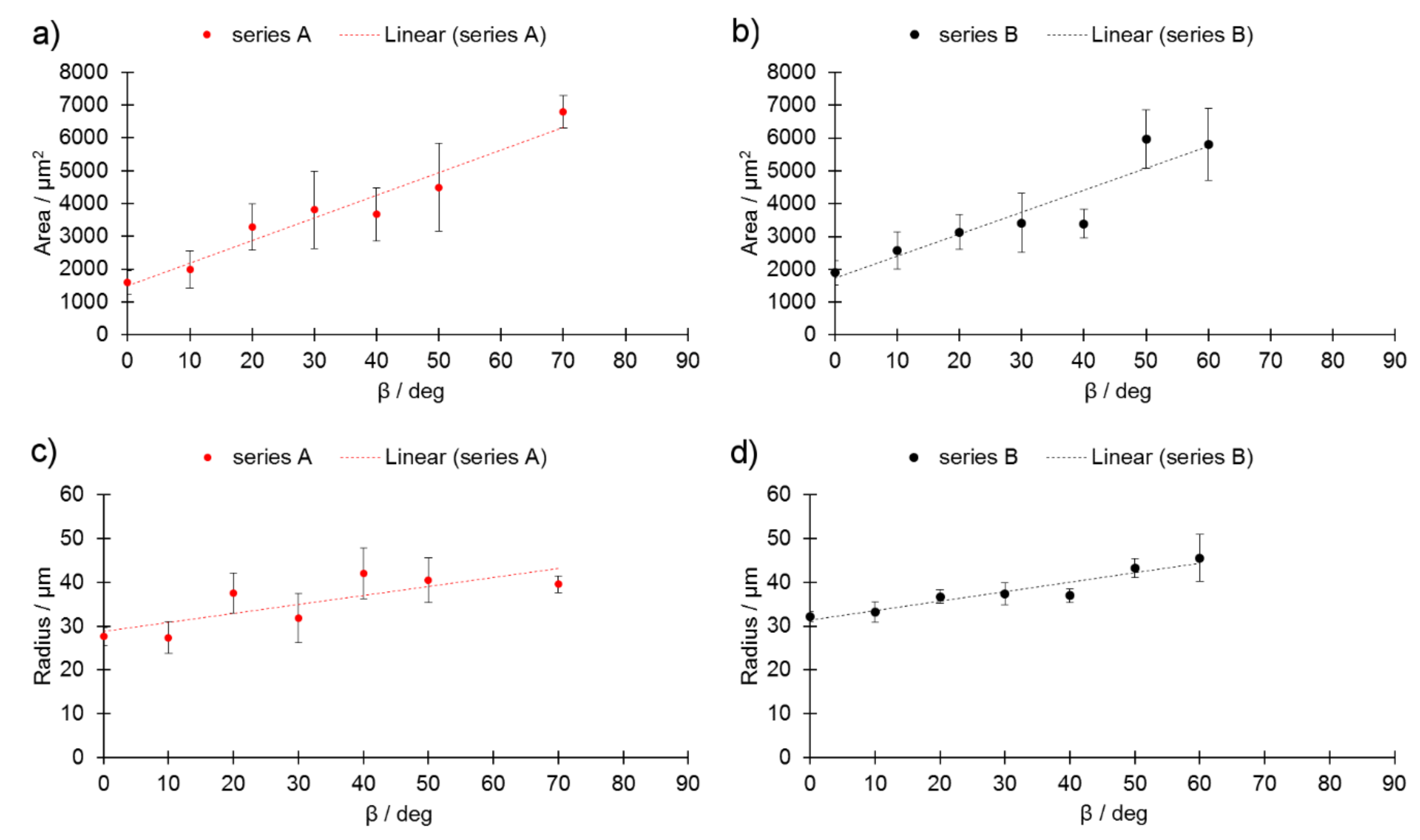

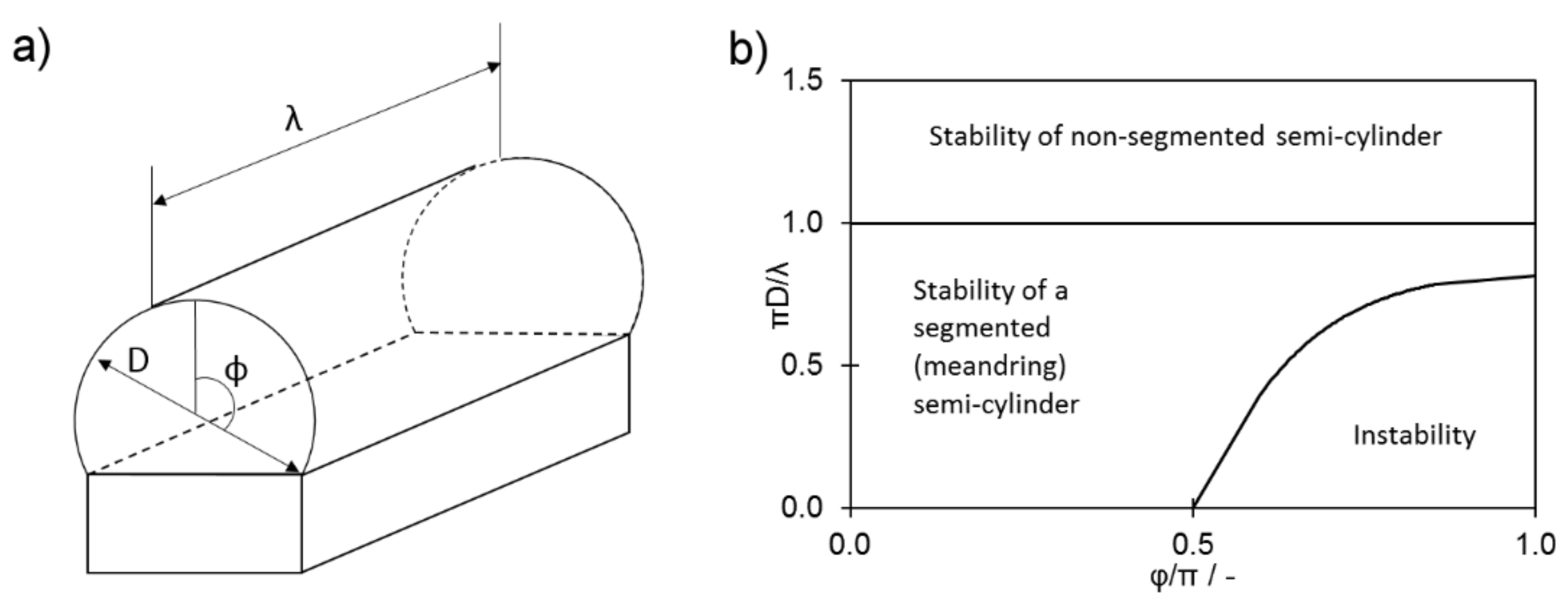

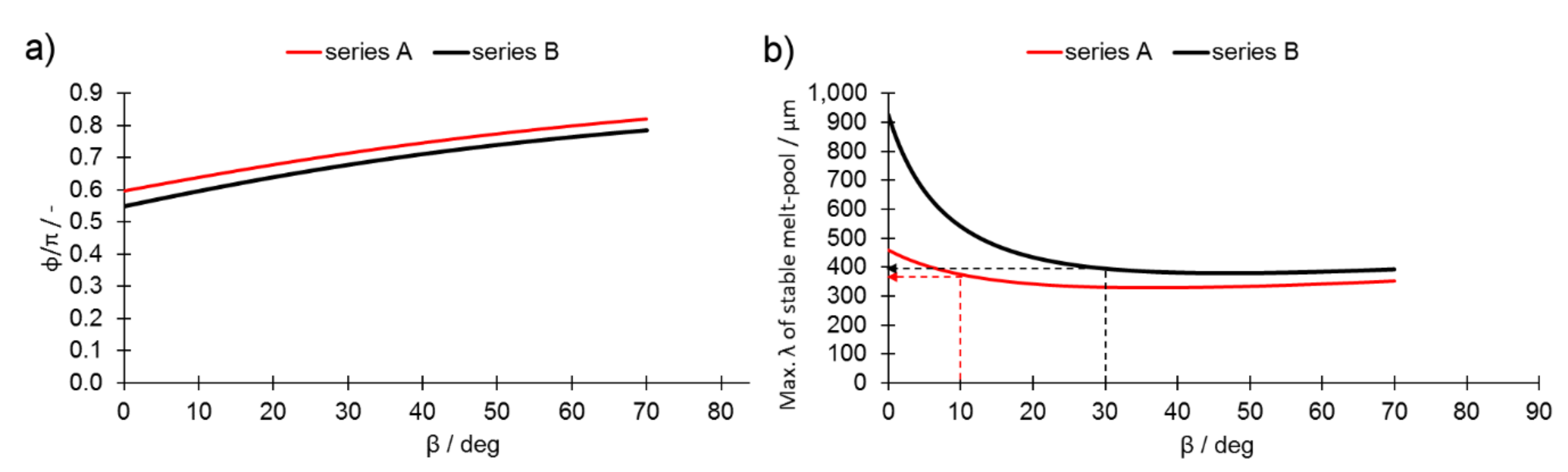

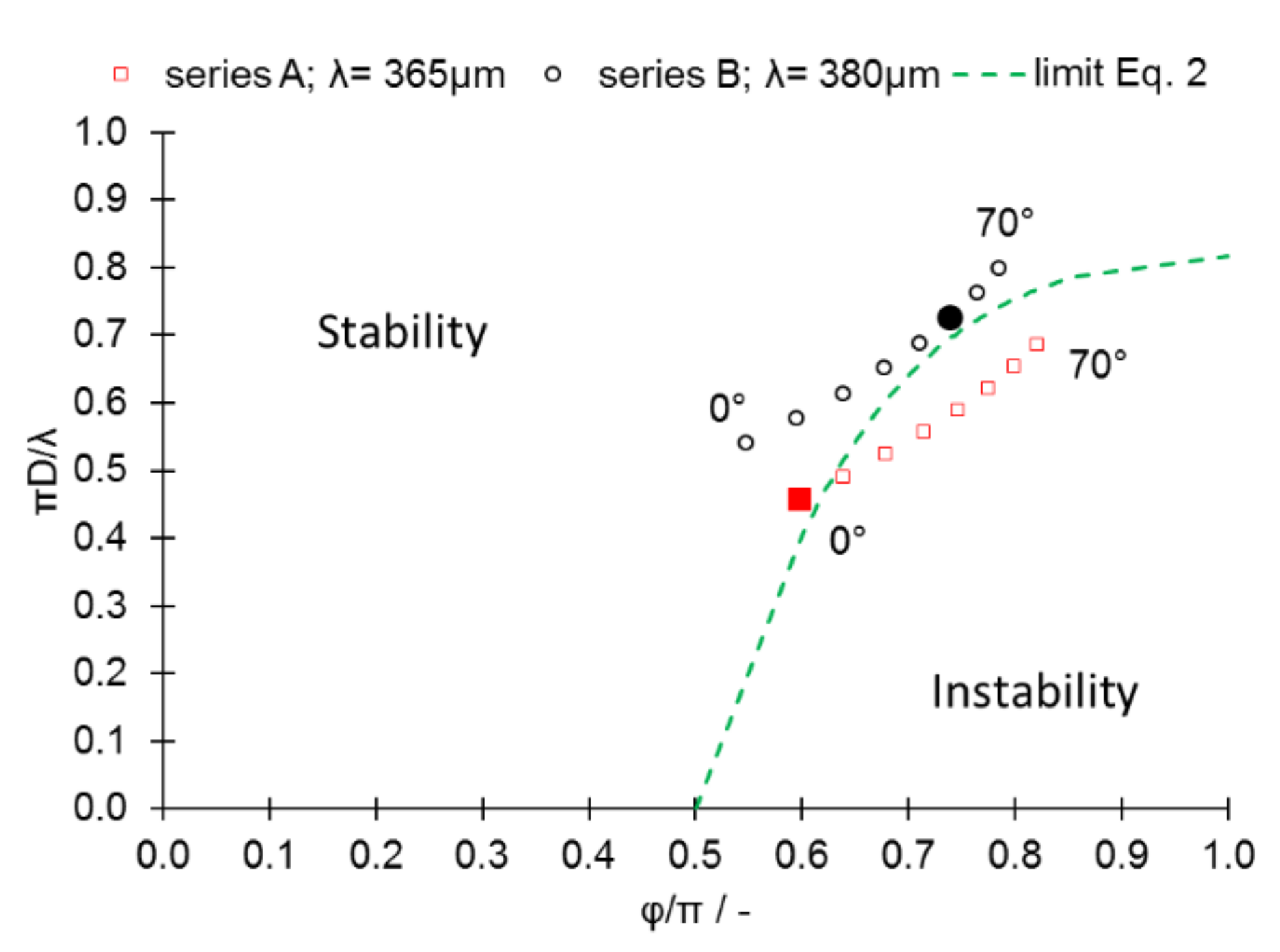

- the area of the melt-pool cross-section increased with the inclination angle due to the availability of extra powder. A constant increase in the radius of the melt track coupled with a constant value of the melt-track width “L” contributed to the melt-pool instability, segmentation, and, finally, balling.

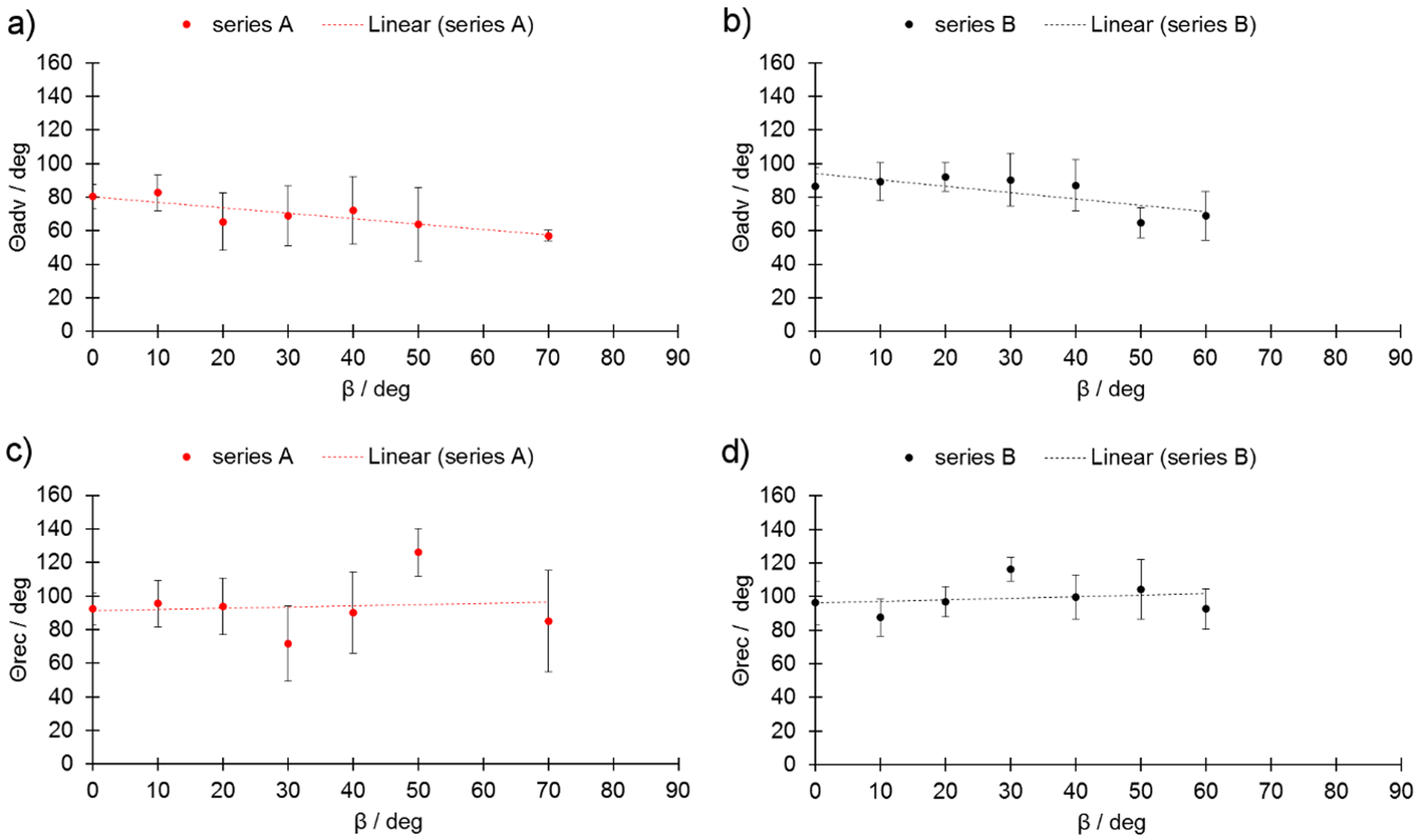

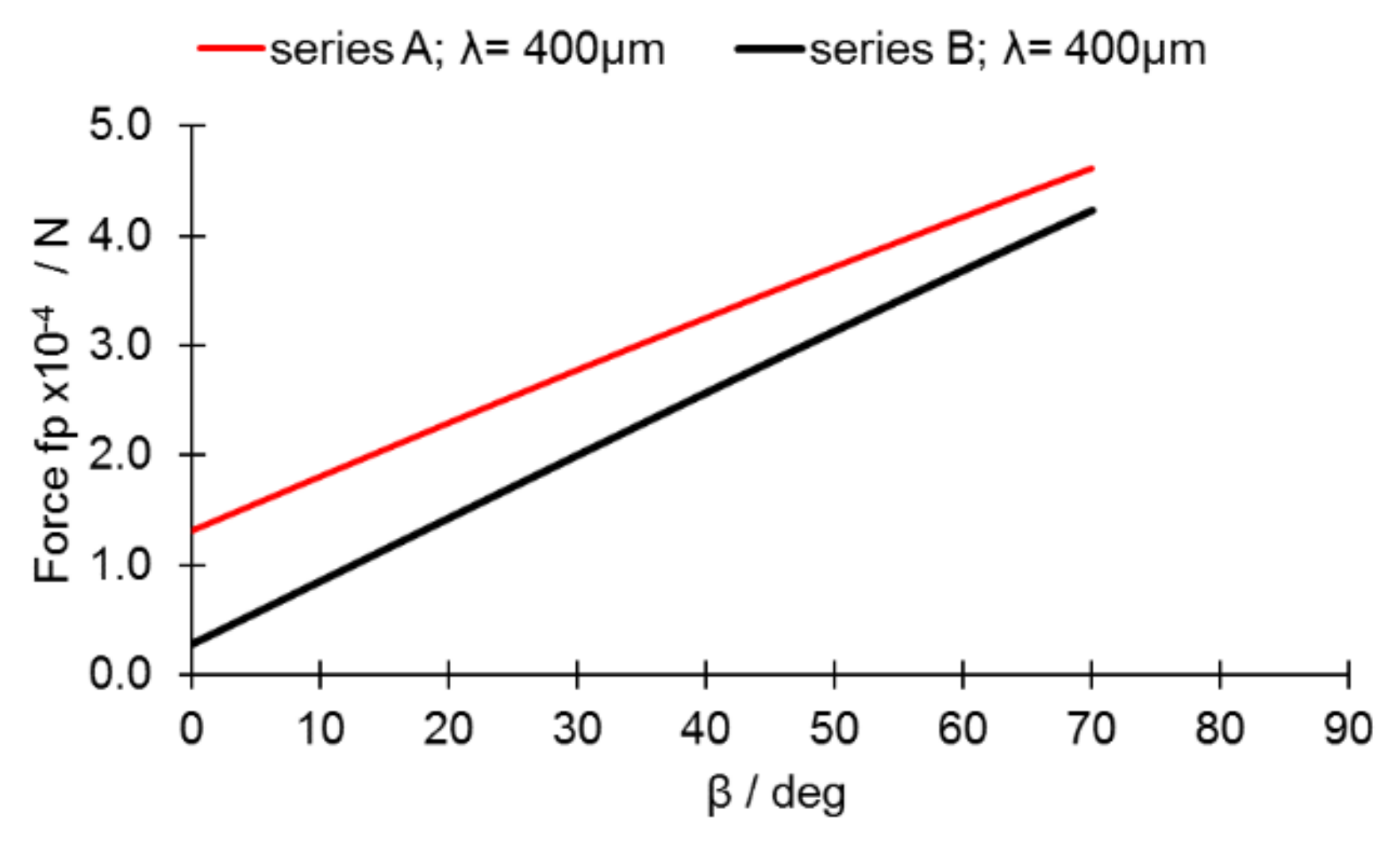

- surface tension forces are the main cause of melt-pool balling rather than gravitational pull; the influence of the latter is limited due to the limited slippage of molten metal.

- the stability of a melt pool can be increased by improving the connection between the melt pool and a previously formed layer and by increasing its radius as much as possible. Shortening the melt-pool length can increase its stability on an incline. The stability of the melt pool should be considered when unsupported, inclined surfaces are being printed. In industrial applications, these results would suggest that the printing parameters for the outline have to be modified along the decreasing inclination angle, i.e., the laser power has to be continuously decreased, while the spot speed should be continuously increased at the same time.

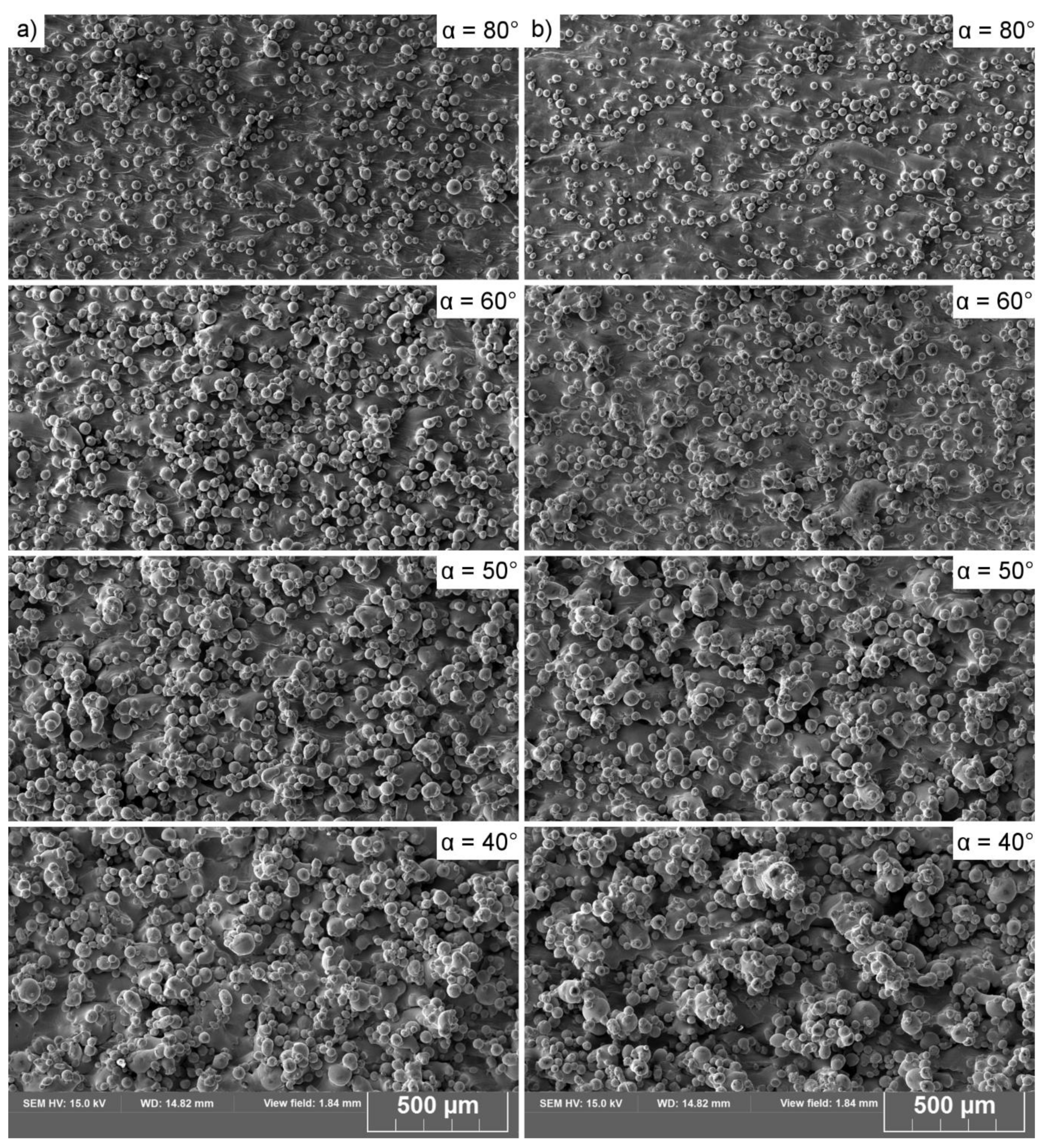

- The use of higher amounts of laser power may result in lowered downskin roughness, but only if the melt track is stable. On the other hand, the instability of the melt track causes a significant increase in roughness with respect to the counterpart factor of lower laser power. The results of this study show that the laser power should be adjusted and consequently lowered as the printing angles become increasingly steeper, mainly to avoid melting the powder that has been placed beneath the overhang.

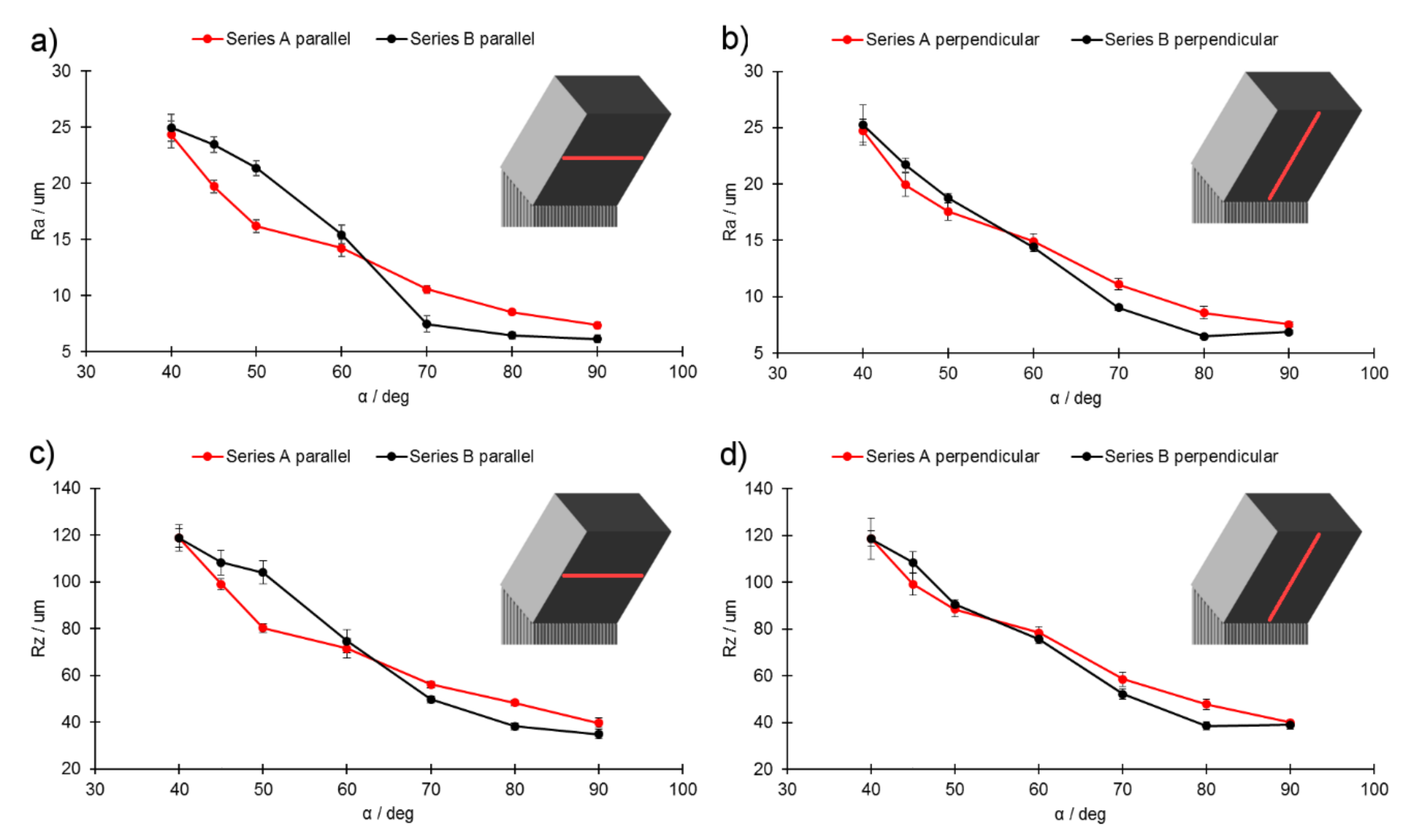

- The factor of melt-pool instability was mainly found to influence the downskin roughness in the direction parallel to the X–Y printing plane, as the perpendicular direction was subjected to re-melting effects as the subsequent layers were built.

- Linear energy is not a factor that is suitable for comparing varying laser parameters.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Krishnan, M.; Atzeni, E.; Canali, R.; Calignano, F.; Manfredi, D.; Paola Ambrosio, P.; Iuliano, L. On the effect of process parameters on properties of AlSi10Mg parts produced by DMLS. Rapid Prototyp. J. 2014, 20, 449–458. [Google Scholar] [CrossRef]

- Tolochko, N.K.; Arshinov, M.K.; Gusarov, A.V.; Titov, V.I.; Laoui, T.; Froyen, L. Mechanisms of selective laser sintering and heat transfer in Ti powder. Rapid Prototyp. J. 2003, 9, 314–326. [Google Scholar] [CrossRef]

- Van Elsen, M.; Baelmans, M.; Mercelis, P.; Kruth, J.-P. Solutions for modelling moving heat sources in a semi-infinite medium and applications to laser material processing. Int. J. Heat Mass Trans. 2007, 50, 4872–4882. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Kruth, J.-P. Modelling of radiation transfer in metallic powders at laser treatment. Int. J. Heat Mass Trans. 2005, 48, 3423–3434. [Google Scholar] [CrossRef]

- Kovaleva, I.; Kovalev, O.; Smurov, I. Model of heat and mass transfer in random packing layer of powder particles in selective laser melting. Phys. Procedia 2014, 56, 400–410. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Kovalev, E.P. Model of thermal conductivity in powder beds. Phys. Rev. B 2009, 80, 024202. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Smurov, I. Modeling the interaction of laser radiation with powder bed at selective laser melting. Phys. Procedia 2010, 5, 381–394. [Google Scholar] [CrossRef]

- Anestiev, L.A.; Froyen, L. Model of primary rearrangement processes at liquid phase sintering and selective laser sintering due to biparticle interactions. J. Appl. Phys. 1999, 86, 4008–4017. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Laoui, T.; Froyen, L.; Titov, V.I. Contact thermal conductivity of a powder bed in selective laser sintering. Int. J. Heat Mass Trans. 2003, 46, 1103–1109. [Google Scholar] [CrossRef]

- Baillis, D.; Sacadura, J.-F. Thermal radiation properties of dispersed media: Theoretical prediction and experimental characterization. J. Quant. Spectrosc. RA 2000, 67, 327–363. [Google Scholar] [CrossRef]

- Wang, D.; Yang, Y.; Liu, R.; Xiao, D.; Sun, J. Study on the designing rules and processability of porous structure based on selective laser melting (SLM). J. Mater. 2013, 213, 1734–1742. [Google Scholar] [CrossRef]

- Panwisawas, C.; Qiu, C.L.; Sovani, Y.; Brooks, J.W.; Attallah, M.M.; Basoalto, H.C. On the role of thermal fluid dynamics into the evolution of porosity during selective laser melting. Scr. Mater. 2015, 105, 14–17. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A. Mesoscopic simulation model of selective laser melting of stainless steel powder. J. Mater. 2014, 214, 2627–2636. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Matthews, M.J.; Guss, G.; Khairallah, S.A.; Rubenchik, A.M.; Depond, P.J.; King, W.E. Denudation of metal powder layers in laser powder bed fusion processes. Acta Mater. 2016, 114, 33–42. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Kurian, A.; Arivazhagan, N.; Senthilkumaran, K. Numerical and experimental investigations on laser melting of stainless steel 316L metal powders. J. Manuf. Process. 2014, 16, 345–355. [Google Scholar] [CrossRef]

- Levich, V.G. Physicochemical Hydrodynamics; Prentice-Hall: Englewood Cliffs, NJ, USA, 1962. [Google Scholar]

- Boley, C.D.; Mitchell, S.C.; Rubenchik, A.M.; Wu, S.S.Q. Metal powder absorptivity: Modelling and experiment. Appl. Opt. 2016, 55, 6496–6500. [Google Scholar] [CrossRef]

- Lee, Y.S.; Zhang, W. Modeling of heat transfer, fluid flow and solidification microstructure of nickel-base superalloy fabricated by laser powder bed fusion. Addit. Manuf. 2016, 12, 178–188. [Google Scholar] [CrossRef]

- Extand, C.W.; Kumagai, Y. Liquid drops on an inclined plane: The relation between contact angles, drop shape, and retentive force. J. Colloid Interface Sci. 1995, 170, 515–521. [Google Scholar] [CrossRef]

- Kim, C.S. Thermophysical Properties of Stainless Steels; ANL-75-55; Argonne National Laboratory: Argonne, IL, USA, 1975; p. 60439. [Google Scholar]

- Yadroitsev, I.; Bertrand, P.H.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Smurov, I.; Ostendorf, A. Lasers in Manufacturing; Graf, T., Petring, D., Otto, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; p. 807. [Google Scholar]

| Element | C | Cr | Cu | Fe | Mn | Mo | N | Ni | O | P | S | Si |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wt. % | 0.03 | 17.5–18.0 | <0.5 | Bal. | <2.0 | 2.25–2.50 | <0.1 | 12.5–13.0 | <0.1 | <0.025 | <0.01 | <0.75 |

| Area of the Cross-Section | Beam Function | Remarks | Series A | Series B | ||

|---|---|---|---|---|---|---|

| Lp | Ls | Lp | Ls | |||

| Infill Parameters | Hatching | 90 µm of hatching distance. Layer thickness = 20 μm. | 160 | 960 | 160 | 960 |

| Contour Parameters | Standard | n/a | 100 | 770 | 100 | 770 |

| Up Skin | n/a | 160 | 790 | 160 | 790 | |

| Down Skin | n/a | 70 | 990 | 85 | 1200 | |

| Edge | Beam offset = 0 | 50 | 200 | 50 | 200 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skalon, M.; Meier, B.; Gruberbauer, A.; Amancio-Filho, S.d.T.; Sommitsch, C. Stability of a Melt Pool during 3D-Printing of an Unsupported Steel Component and Its Influence on Roughness. Materials 2020, 13, 808. https://doi.org/10.3390/ma13030808

Skalon M, Meier B, Gruberbauer A, Amancio-Filho SdT, Sommitsch C. Stability of a Melt Pool during 3D-Printing of an Unsupported Steel Component and Its Influence on Roughness. Materials. 2020; 13(3):808. https://doi.org/10.3390/ma13030808

Chicago/Turabian StyleSkalon, Mateusz, Benjamin Meier, Andreas Gruberbauer, Sergio de Traglia Amancio-Filho, and Christof Sommitsch. 2020. "Stability of a Melt Pool during 3D-Printing of an Unsupported Steel Component and Its Influence on Roughness" Materials 13, no. 3: 808. https://doi.org/10.3390/ma13030808

APA StyleSkalon, M., Meier, B., Gruberbauer, A., Amancio-Filho, S. d. T., & Sommitsch, C. (2020). Stability of a Melt Pool during 3D-Printing of an Unsupported Steel Component and Its Influence on Roughness. Materials, 13(3), 808. https://doi.org/10.3390/ma13030808