Micro-Texture Analyses of a Cold-Work Tool Steel for Additive Manufacturing

Abstract

1. Introduction

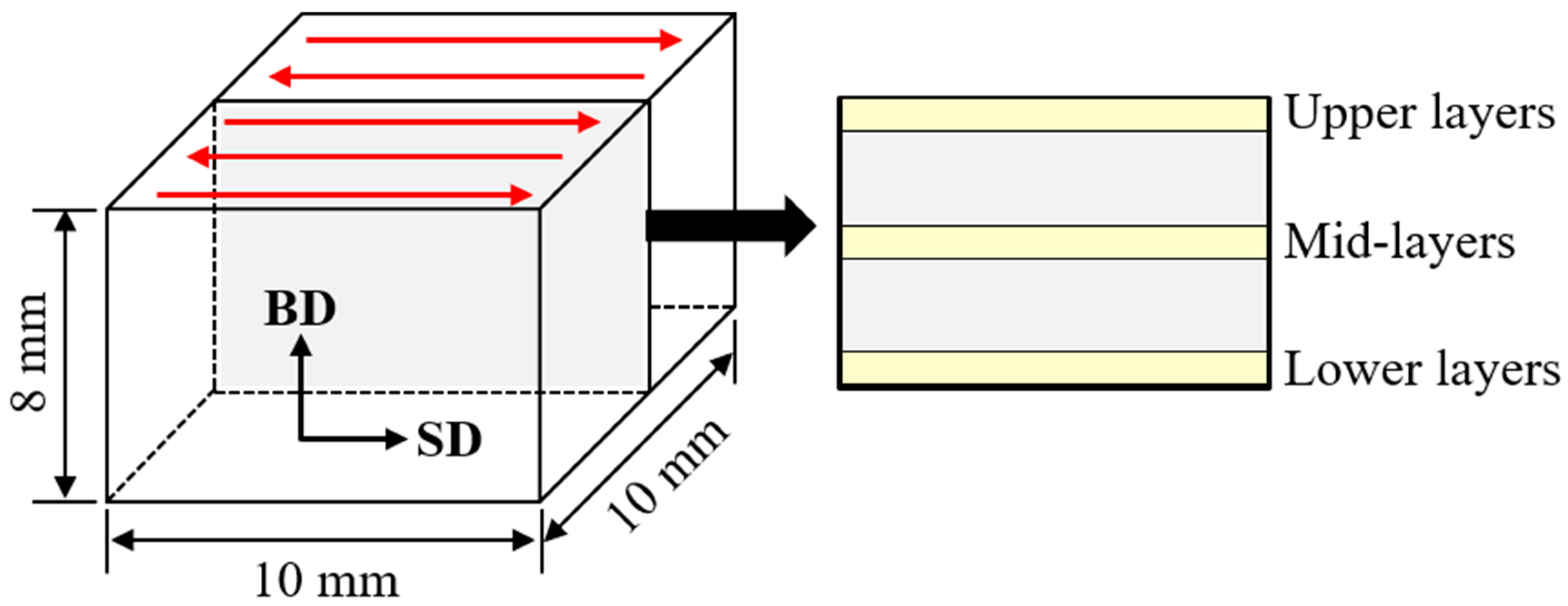

2. Material and Methods

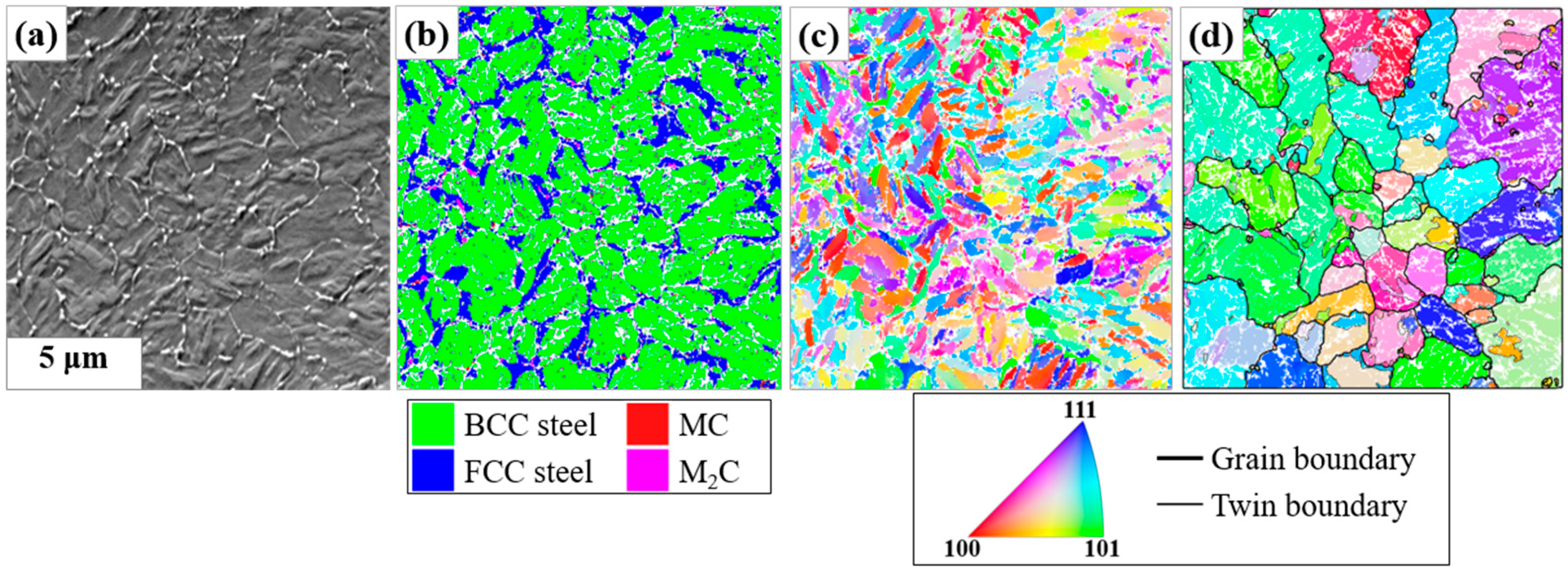

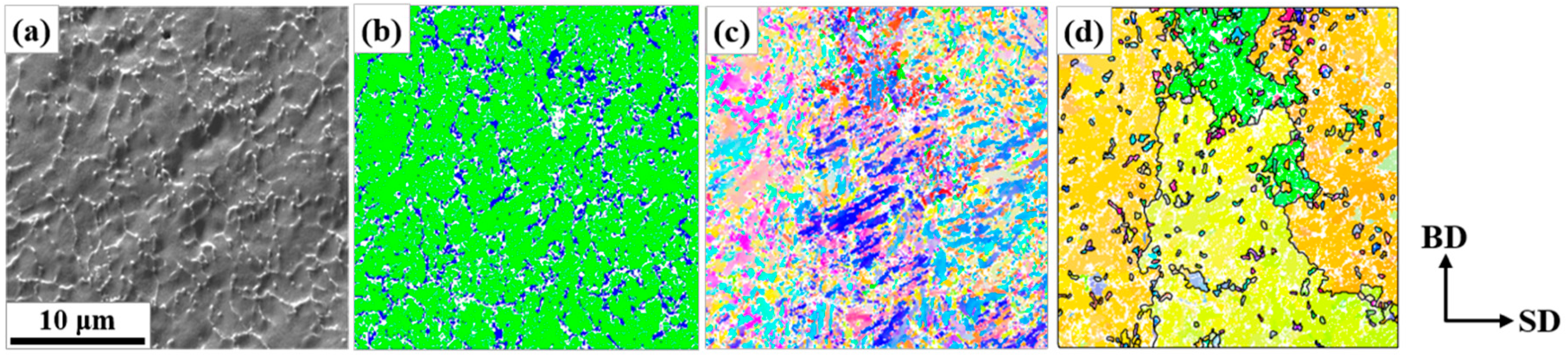

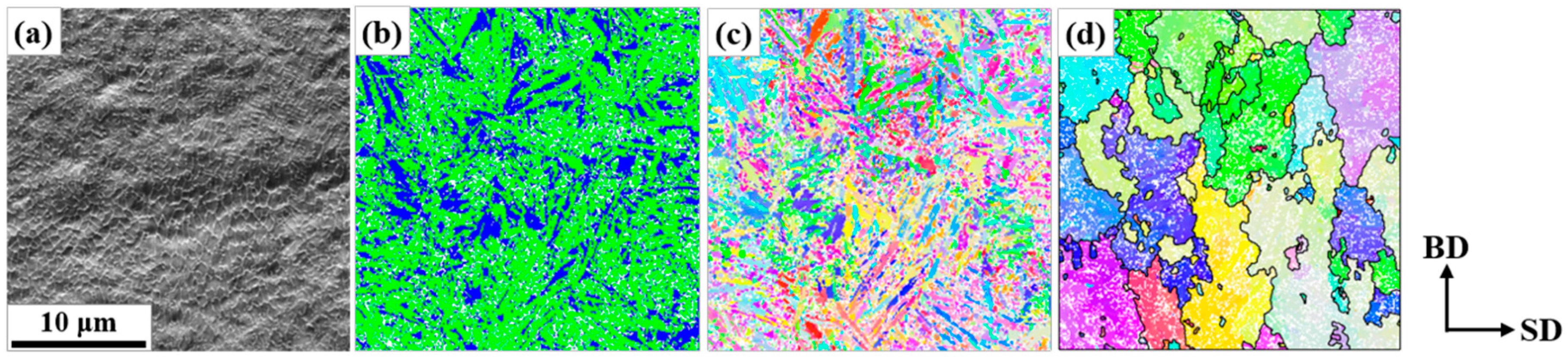

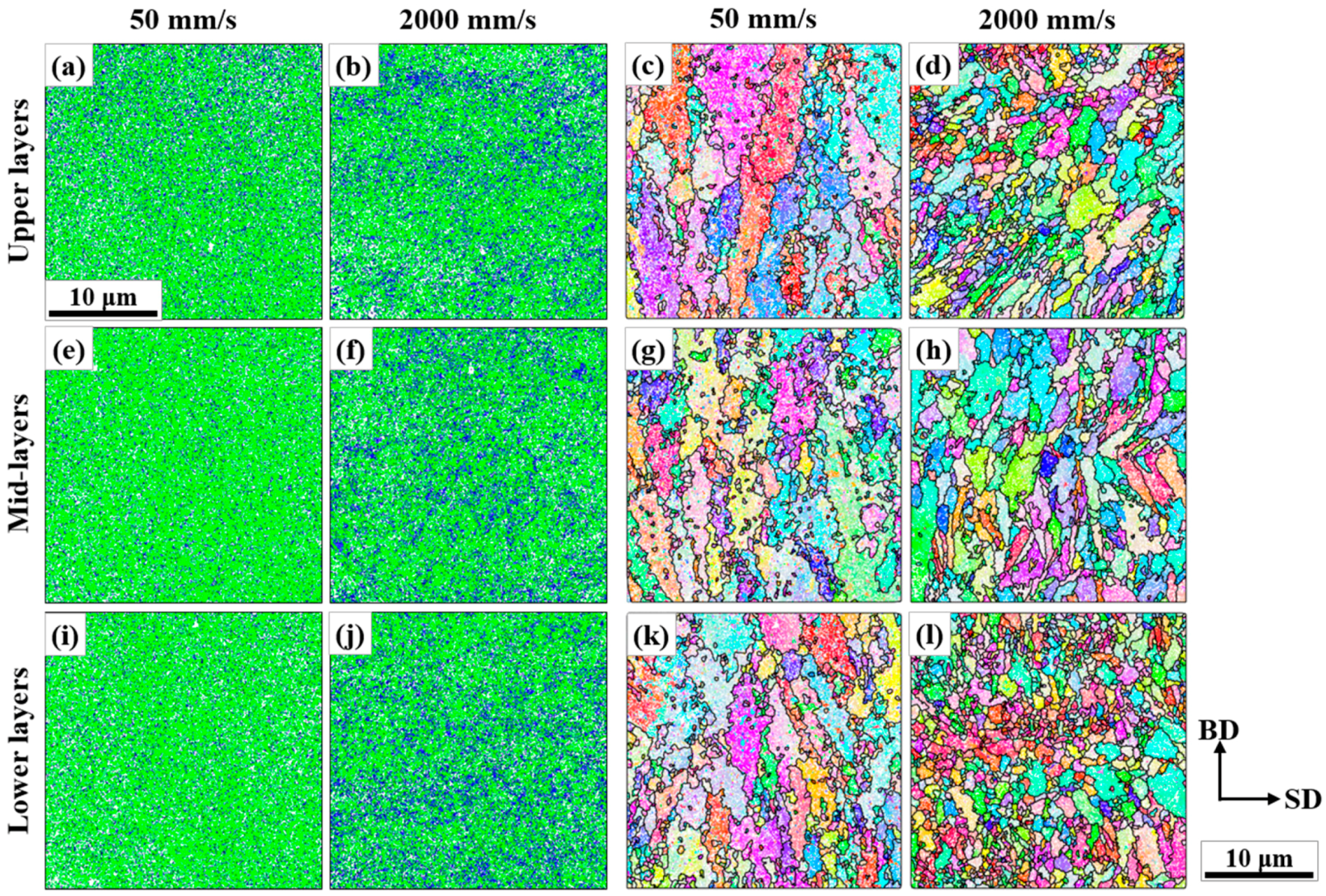

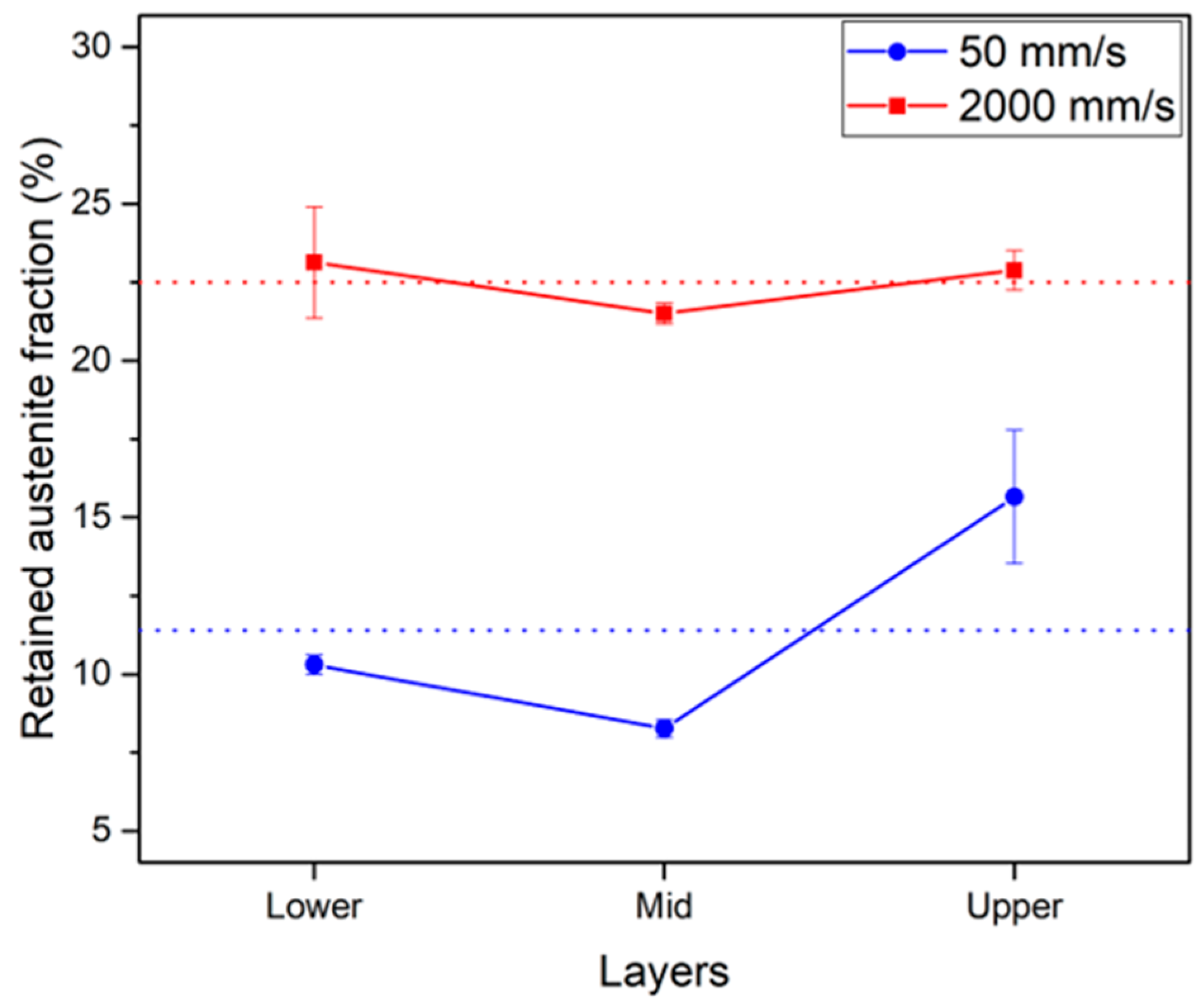

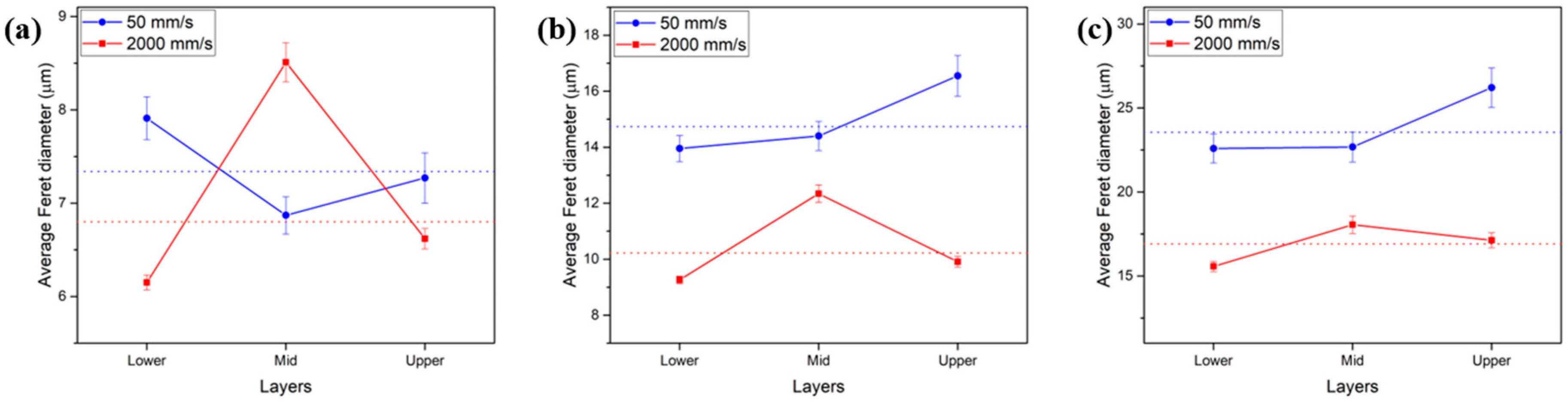

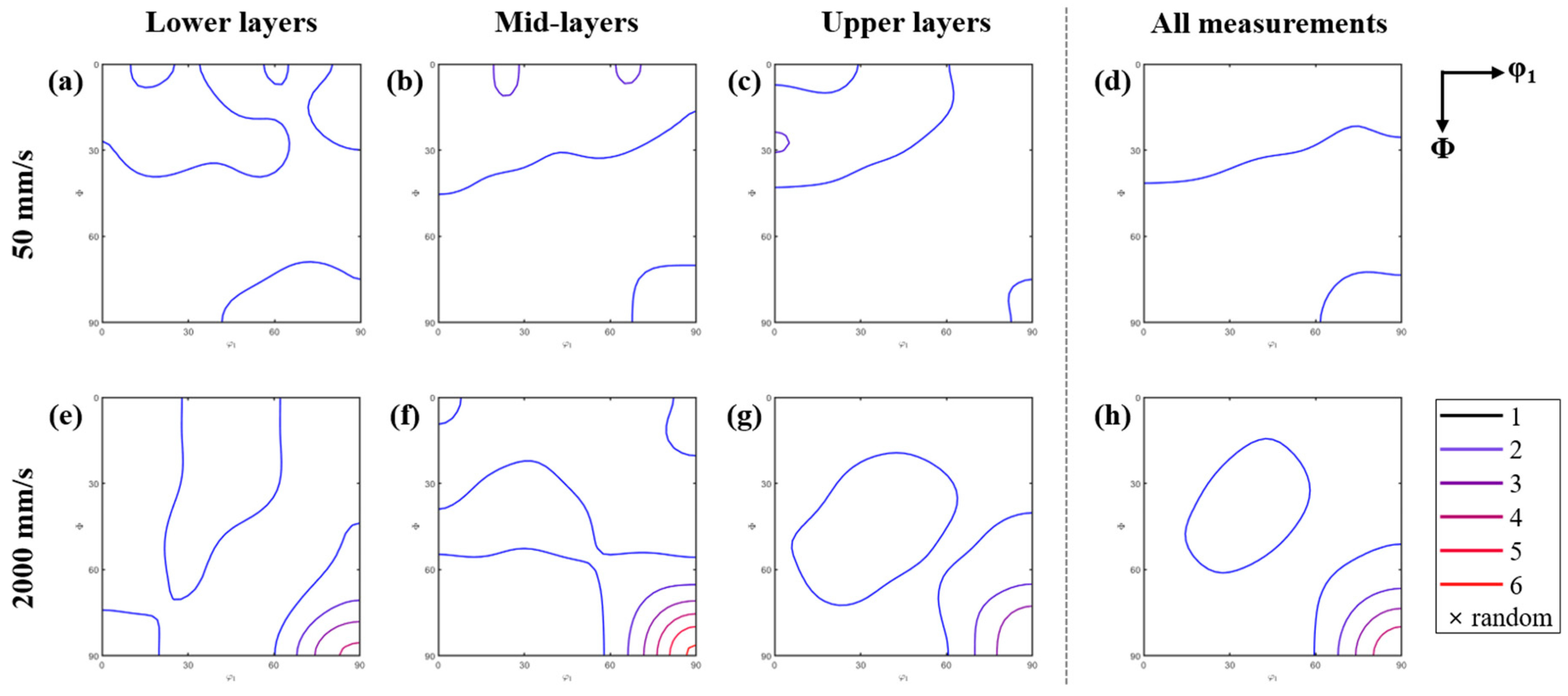

3. Results

4. Discussion

4.1. Carbide Networks and the Reconstructed Austenite Grain Structures

4.2. Retained Austenite Fraction and Thermal Cycles in the Parts of the AM Objects

4.3. Austenitic Grain Sizes and Thermal Cycles in the Parts of the AM Objects

4.4. Austenitic Textures and Thermal Cycles in the Parts of the AM Objects

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Niaki, M.K.; Nonino, F. Additive manufacturing management: A review and future research agenda. Int. J. Prod. Res. 2017, 55, 1419–1439. [Google Scholar] [CrossRef]

- Bourell, D.L. Perspectives on additive manufacturing. Annu. Rev. Mater. Res. 2016, 46, 1–18. [Google Scholar] [CrossRef]

- Murr, L.E. Frontiers of 3D printing/additive manufacturing: From human organs to aircraft fabrication. J. Mater. Sci. Technol. 2016, 32, 987–995. [Google Scholar] [CrossRef]

- Standard Terminology for Additive Manufacturing—General Principles—Terminology; ISO/ASTM 52900:2015(E); ASTM International: West Conshohocken, PA, USA, 2016.

- Singh, S.; Ramakrishna, S.; Singh, R. Materials issues in additive manufacturing: A review. J. Manuf. Processes 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Ahn, D.-G. Direct metal additive manufacturing processes and their sustainable applications for green technology: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 381–395. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Epitaxy and microstructure evolution in metal additive manufacturing. Annu. Rev. Mater. Res. 2016, 46, 125–149. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Collins, P.C.; Brice, D.A.; Samimi, P.; Ghamarian, I.; Fraser, H.L. Microstructural control of additively manufactured metallic materials. Annu. Rev. Mater. Res. 2016, 46, 63–91. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Starr, T.; Stucker, B. Analysis of defect generation in Ti-6Al-4V parts made using powder bed fusion additive manufacturing processes. Addit. Manuf. 2014, 1, 87–98. [Google Scholar] [CrossRef]

- Sadowski, M.; Ladani, L.; Brindley, W.; Romano, J. Optimizing quality of additively manufactured Inconel 718 using powder bed laser melting process. Addit. Manuf. 2016, 11, 60–70. [Google Scholar] [CrossRef]

- Townsend, A.; Senin, N.; Blunt, L.; Leach, R.K.; Taylor, J.S. Surface texture metrology for metal additive manufacturing: A review. Precis. Eng. 2016, 46, 34–47. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Jelis, E.; Clemente, M.; Kerwien, S.; Ravindra, N.M.; Hespos, M.R. Metallurgical and mechanical evaluation of 4340 steel produced by direct metal laser sintering. JOM 2015, 67, 582–589. [Google Scholar] [CrossRef]

- Chae, H.; Huang, E.-W.; Jain, J.; Wang, H.; Woo, W.; Chen, S.-W.; Harjo, S.; Kawasaki, T.; Lee, S.Y. Plastic anisotropy and deformation-induced phase transformation of additive manufactured stainless steel. Mater. Sci. Eng. A 2019, 762, 138065. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Li, L. Direct additive laser manufacturing using gas- and water-atomised H13 tool steel powders. Int. J. Adv. Manuf. Technol. 2005, 25, 471–479. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Conlon, K.; Xue, L.; Rogge, R. Experimental study of residual stresses in laser clad AISI P20 tool steel onpre-hardened wrought P20 substrate. Mater. Sci. Eng. A 2010, 527, 7265–7273. [Google Scholar] [CrossRef]

- Xue, L.; Chen, J.; Wang, S.-H. Freeform laser consolidated H13 and CPM 9V tool steels. Metallogr. Microstruct. Anal. 2013, 2, 67–78. [Google Scholar] [CrossRef]

- Cottam, R.; Wang, J. Characterization of microstructure and residual stress in a 3D H13 tool steel component produced by additive manufacturing. J. Mater. Res. 2014, 29, 1978–1986. [Google Scholar] [CrossRef]

- Sander, J.; Hufenbach, J.; Giebeler, L.; Bleckmann, M.; Eckert, J.; Kühn, U. Microstructure, mechanical behavior, and wear properties of FeCrMoVC steel prepared by selective laser melting and casting. Scr. Mater. 2017, 126, 41–44. [Google Scholar] [CrossRef]

- Kang, J.-Y.; Yun, J.; Kim, H.; Kim, B.; Choe, J.; Yang, S.; Yu, J.-H.; Kim, Y.-J. Microstructures of powders and additively manufactured objects of an alloy tool steel for cold-work dies. J. Korean Powder Metall. Inst. 2017, 24, 202–209. [Google Scholar] [CrossRef]

- Additive Manufacturing with Steels 2019, SmarTech Analysis. 2019. Available online: http://www.smartechpublishing.com (accessed on 13 January 2020).

- Roberts, G.; Krauss, G.; Kennedy, R. Tool Steels, 5th ed.; ASM Int.: Cleveland, OH, USA, 1998. [Google Scholar]

- Nishiyama, Z. Martensitic Transformation; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Germain, L.; Gey, N.; Mercier, R.; Blaineau, P.; Humbert, M. An advanced approach to reconstructing parent orientation maps in the case of approximate orientation relations: Application to steels. Acta Mater. 2012, 60, 4551–4562. [Google Scholar] [CrossRef]

- Nyyssönen, T. Quenching and Partitioning of High-Aluminum Steels. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, 2017. [Google Scholar]

- Gomes, E.; Kestens, L.A.I. Fully automated orientation relationship calculation and prior austenite reconstruction by random walk clustering. IOP Conf. Ser. Mater. Sci. Eng. 2015, 82, 012059. [Google Scholar] [CrossRef]

- Kang, J.-Y.; Kim, H.; Son, D.; Lee, J.-J.; Yun, H.Y.; Lee, T.-H.; Park, S.-J.; Park, S.K. Effect of NbC carbide addition on mechanical properties of matrix-type cold-work tool steel. J. Korean Soc. Heat Treat. 2015, 28, 239–240. [Google Scholar] [CrossRef][Green Version]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture analysis with MTEX—Free and open source software toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- MTEX Toolbox. Available online: https://mtex-toolbox.github.io (accessed on 13 January 2020).

- MTEX Forum. Available online: https://groups.google.com/forum/#!forum/mtexmail (accessed on 13 January 2020).

- Dongen, S.M. Graph Clustering by Flow Simulation. Ph.D. Thesis, Universiteit Utrecht, Utrecht, The Netherlands, 2001. [Google Scholar]

- Schaeffer, S.E. Graph clustering. Comput. Sci. Rev. 2007, 1, 27–64. [Google Scholar] [CrossRef]

- Goss, N.P. New development in electrical strip steels characterized by fine grain structure approaching the properties of a single crystal. Trans. Am. Soc. Met. 1935, 23, 511–531. [Google Scholar]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Oxford, UK, 2004. [Google Scholar]

- Kim, H.; Kang, J.-Y.; Son, D.; Lee, T.-H.; Cho, K.-M. Evolution of carbides in cold-work tool steels. Mater. Charact. 2015, 107, 376–385. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloys, 2nd ed.; Chapman & Hall: London, UK, 1992. [Google Scholar]

- Leslie, W.C. The Physical Metallurgy of Steels; International Student Edition; McGraw-Hill Kogakusha: Tokyo, Japan, 1982. [Google Scholar]

- Białobrzeska, B.; Konat, Ł.; Jasiński, R. The influence of austenite grain size on the mechanical properties of low-alloy steel with boron. Metals 2017, 7, 26–45. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly anisotropic steel processed by selective laser melting. Metall. Mater. Trans. B 2013, 44, 794–796. [Google Scholar] [CrossRef]

- Wei, H.L.; Mazumder, J.; DebRoy, T. Evolution of solidification texture during additive manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef] [PubMed]

- Yan, F.; Xiong, W.; Faierson, E.J. Grain structure control of additively manufactured metallic materials. Materials 2017, 10, 1260. [Google Scholar] [CrossRef]

- Im, Y.-D.; Kim, K.-H.; Jung, K.-H.; Lee, Y.-K.; Song, K.-H. Anisotropic mechanical behavior of additive manufactured AISI 316L steel. Metall. Mater. Trans. A 2019, 50, 2014–2021. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Mo | Nb | V | W | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.89 | 0.20 | 0.30 | 5.29 | 0.17 | 2.78 | 1.22 | 0.42 | 0.19 | 0.19 | Bal. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, J.-Y.; Yun, J.; Kim, B.; Choe, J.; Yang, S.; Park, S.-J.; Yu, J.-H.; Kim, Y.-J. Micro-Texture Analyses of a Cold-Work Tool Steel for Additive Manufacturing. Materials 2020, 13, 788. https://doi.org/10.3390/ma13030788

Kang J-Y, Yun J, Kim B, Choe J, Yang S, Park S-J, Yu J-H, Kim Y-J. Micro-Texture Analyses of a Cold-Work Tool Steel for Additive Manufacturing. Materials. 2020; 13(3):788. https://doi.org/10.3390/ma13030788

Chicago/Turabian StyleKang, Jun-Yun, Jaecheol Yun, Byunghwan Kim, Jungho Choe, Sangsun Yang, Seong-Jun Park, Ji-Hun Yu, and Yong-Jin Kim. 2020. "Micro-Texture Analyses of a Cold-Work Tool Steel for Additive Manufacturing" Materials 13, no. 3: 788. https://doi.org/10.3390/ma13030788

APA StyleKang, J.-Y., Yun, J., Kim, B., Choe, J., Yang, S., Park, S.-J., Yu, J.-H., & Kim, Y.-J. (2020). Micro-Texture Analyses of a Cold-Work Tool Steel for Additive Manufacturing. Materials, 13(3), 788. https://doi.org/10.3390/ma13030788