Self-Heating Graphene Nanocomposite Bricks: A Case Study in China

Abstract

:1. Introduction

2. Experimental

2.1. Materials

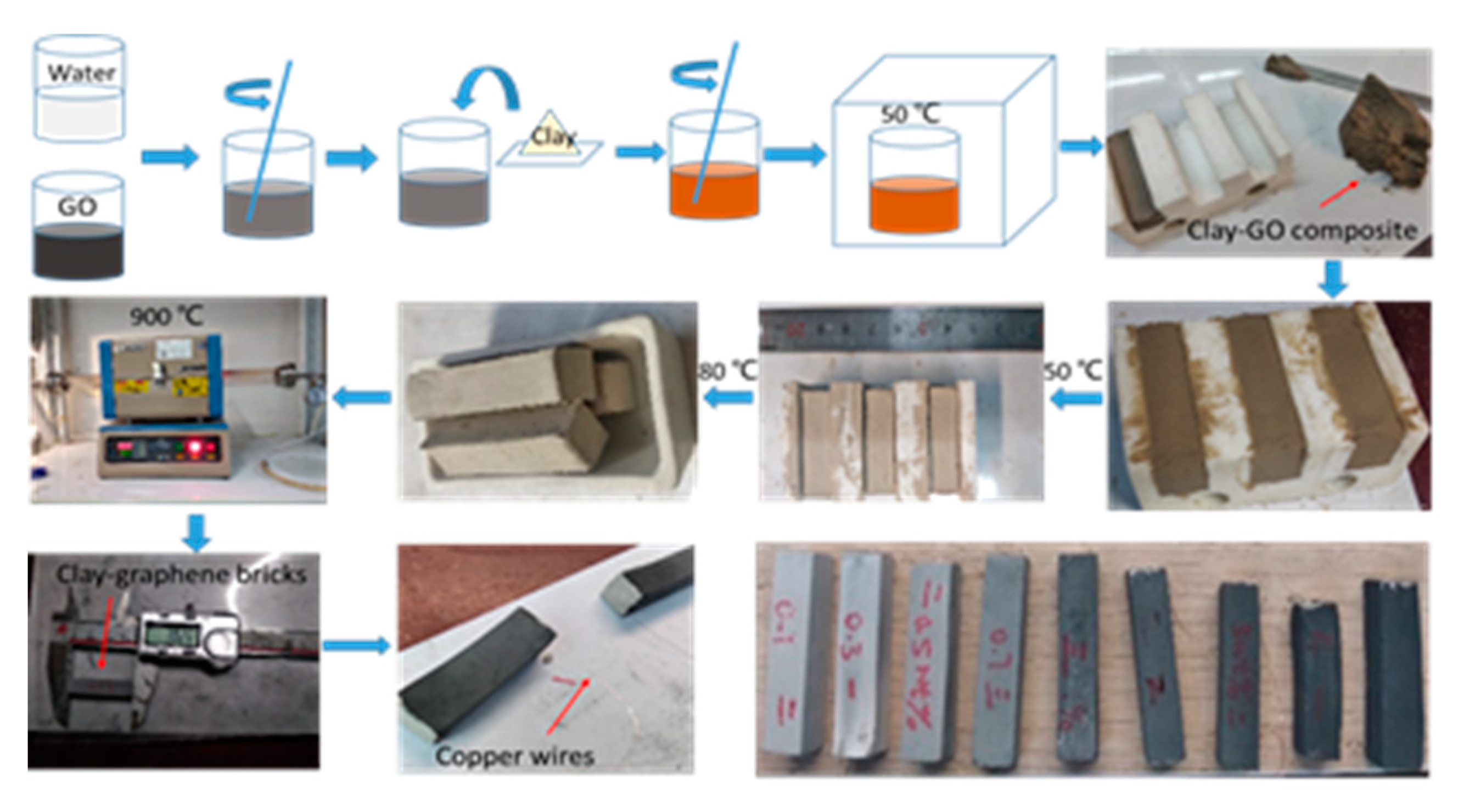

2.2. Preparation of Graphene Nanocomposite Bricks

2.3. Measurement of Resistivity

2.4. Heating Performance

2.5. Mechanical Properties

2.6. Advanced Characterization of Graphene Nanocomposite Bricks

3. Results and Discussion

4. Conclusions

- (1)

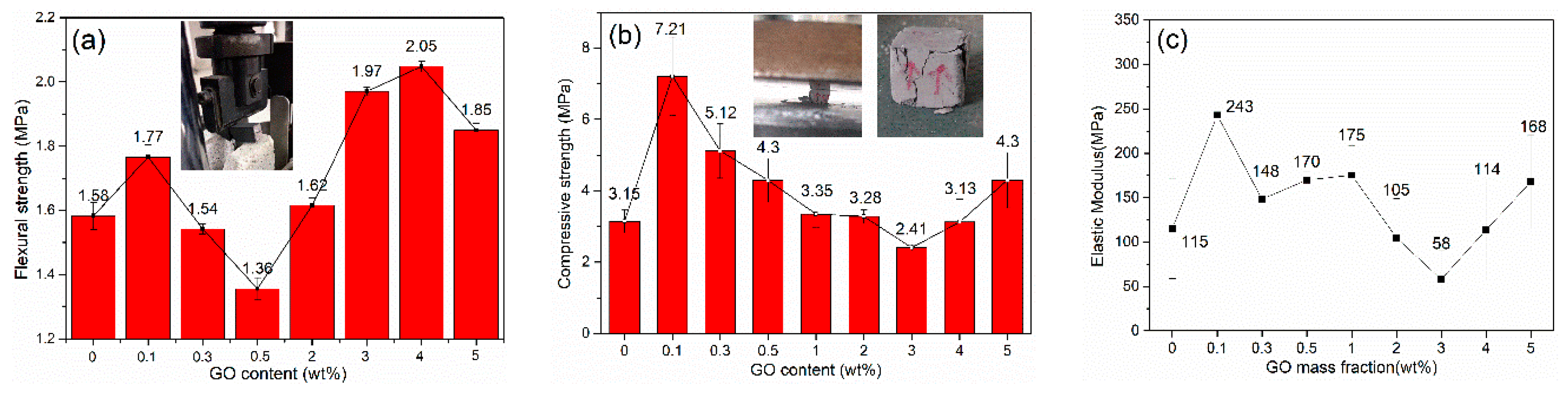

- High concentration GO is beneficial to the increment of compressive strength, flexural strength and elastic modulus of CGCB. Compressive strength, flexural strength, and elastic modulus showed similar increasing trend when the concentration of graphene was higher than 3 wt.%, indicating the recovery of the reinforcement effects of graphene.

- (2)

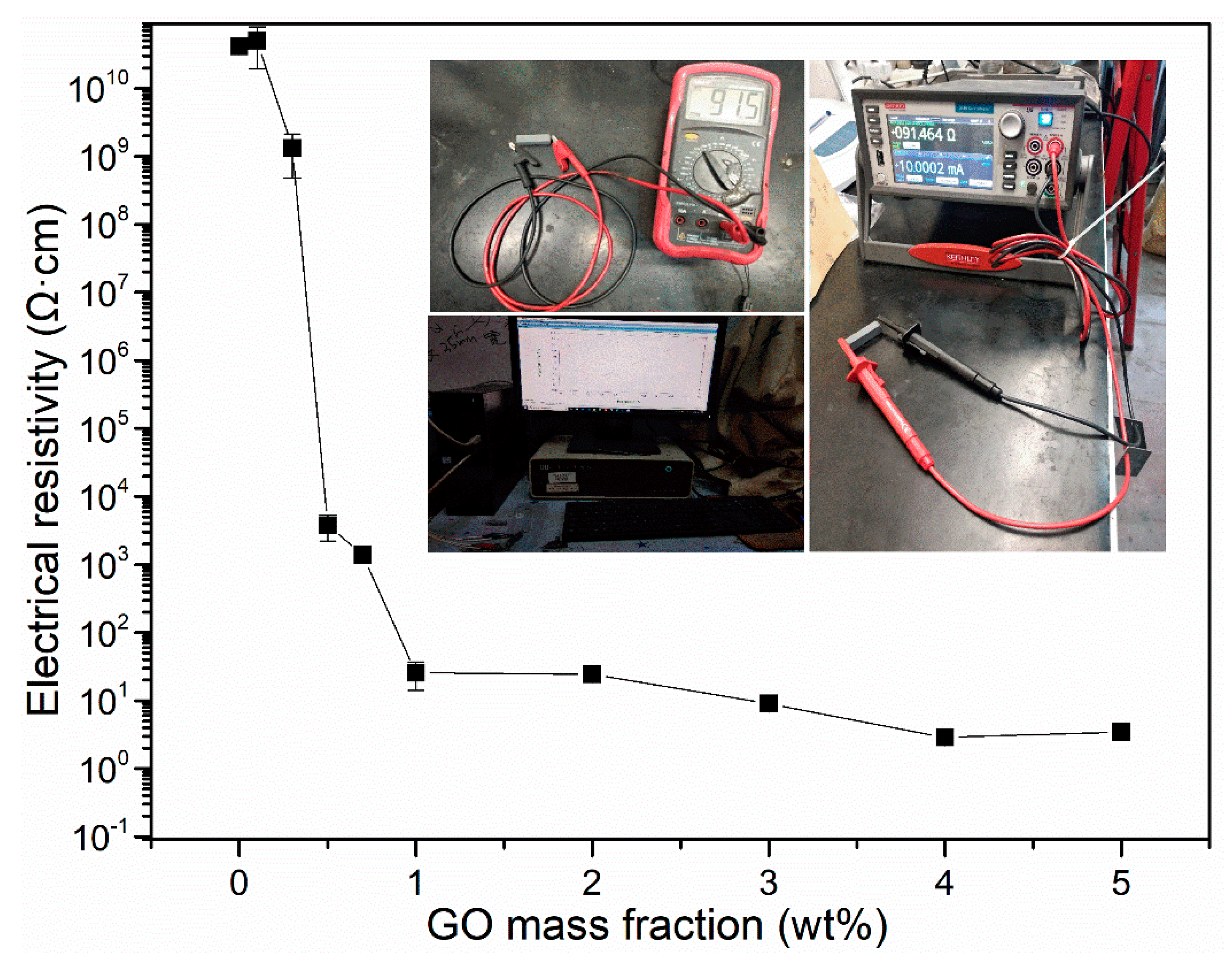

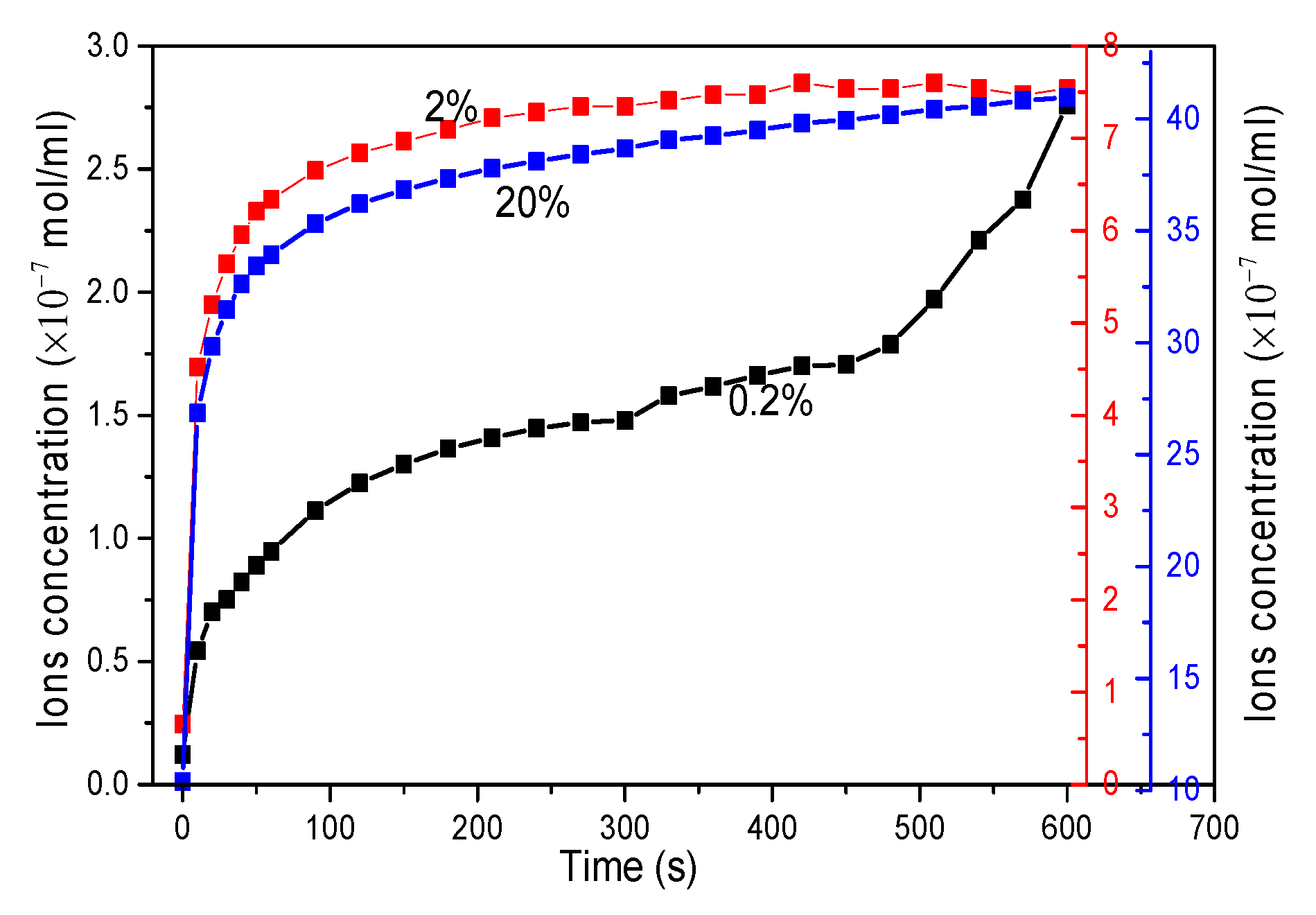

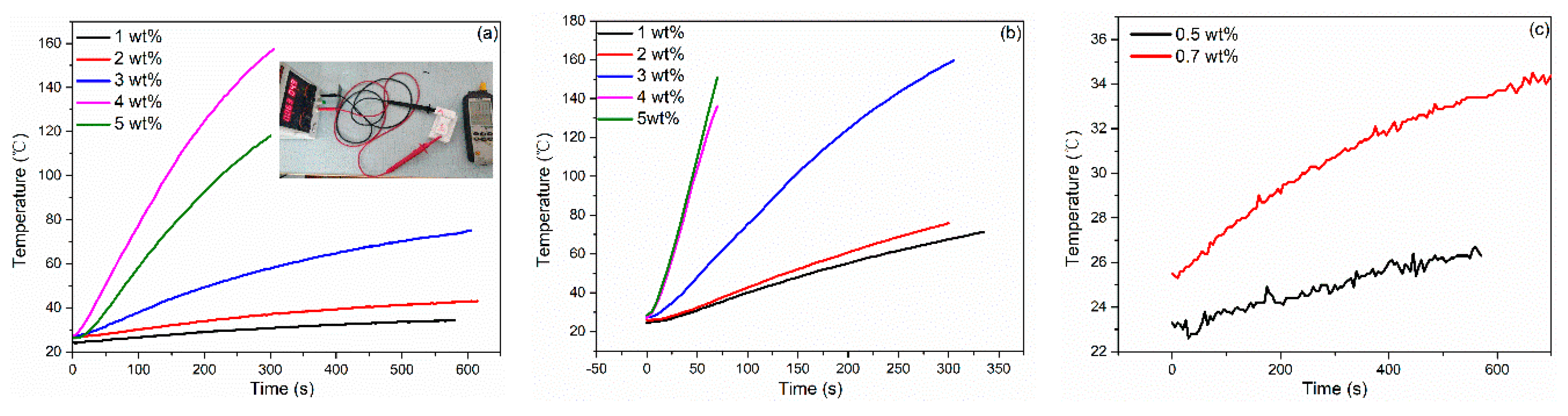

- There is a small time window that allows us to disperse GO uniformly in clay matrix before the ionic strength becomes too high. With the increase in graphene concentration and the electrical conductivity maintained at a stable level, the graphene network became more compacted with more distributed paths for heat generation and transfer, thus sharply enhancing the self-heating properties.

- (3)

- The temperature ramping curve is highly dependent on the graphene concentration under a given external voltage. For the samples with 1 wt.% graphene, the temperature only increases from 22 °C to 30 °C within 500 s, and then becomes saturated. When the graphene concentration increases to 3 wt.%, the sample can be heated quickly from room temperature to 73 °C in 600 s without any temperature saturation observed afterwards.

- (4)

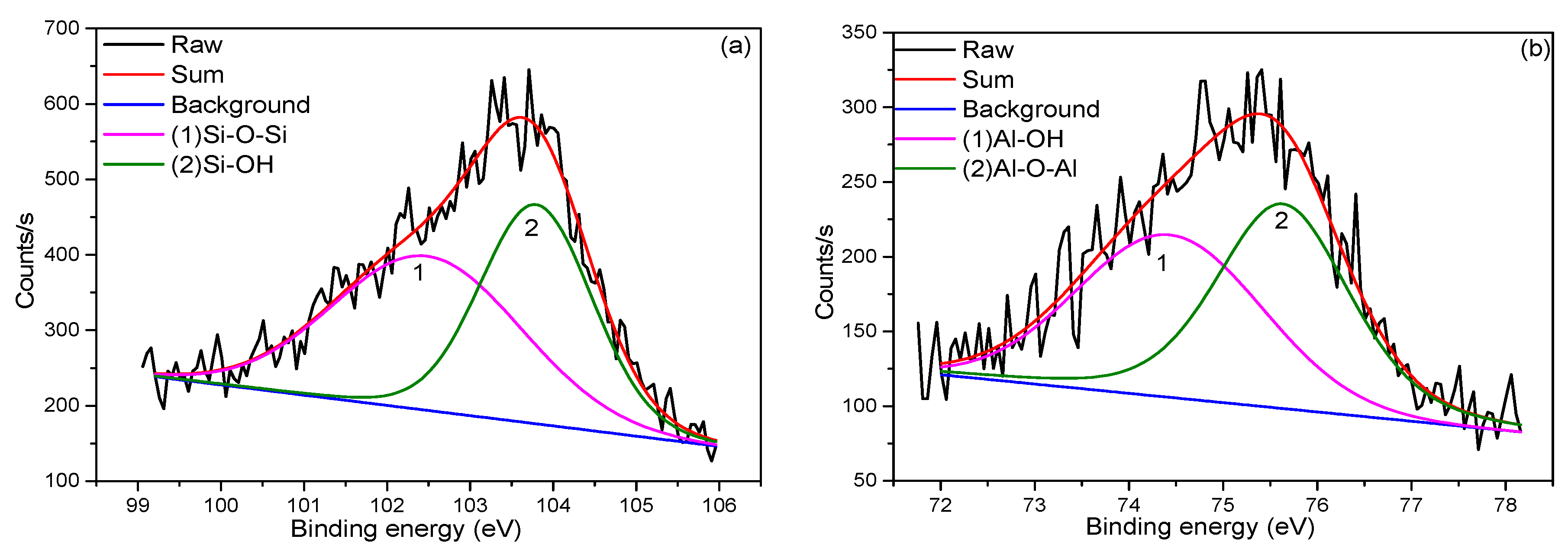

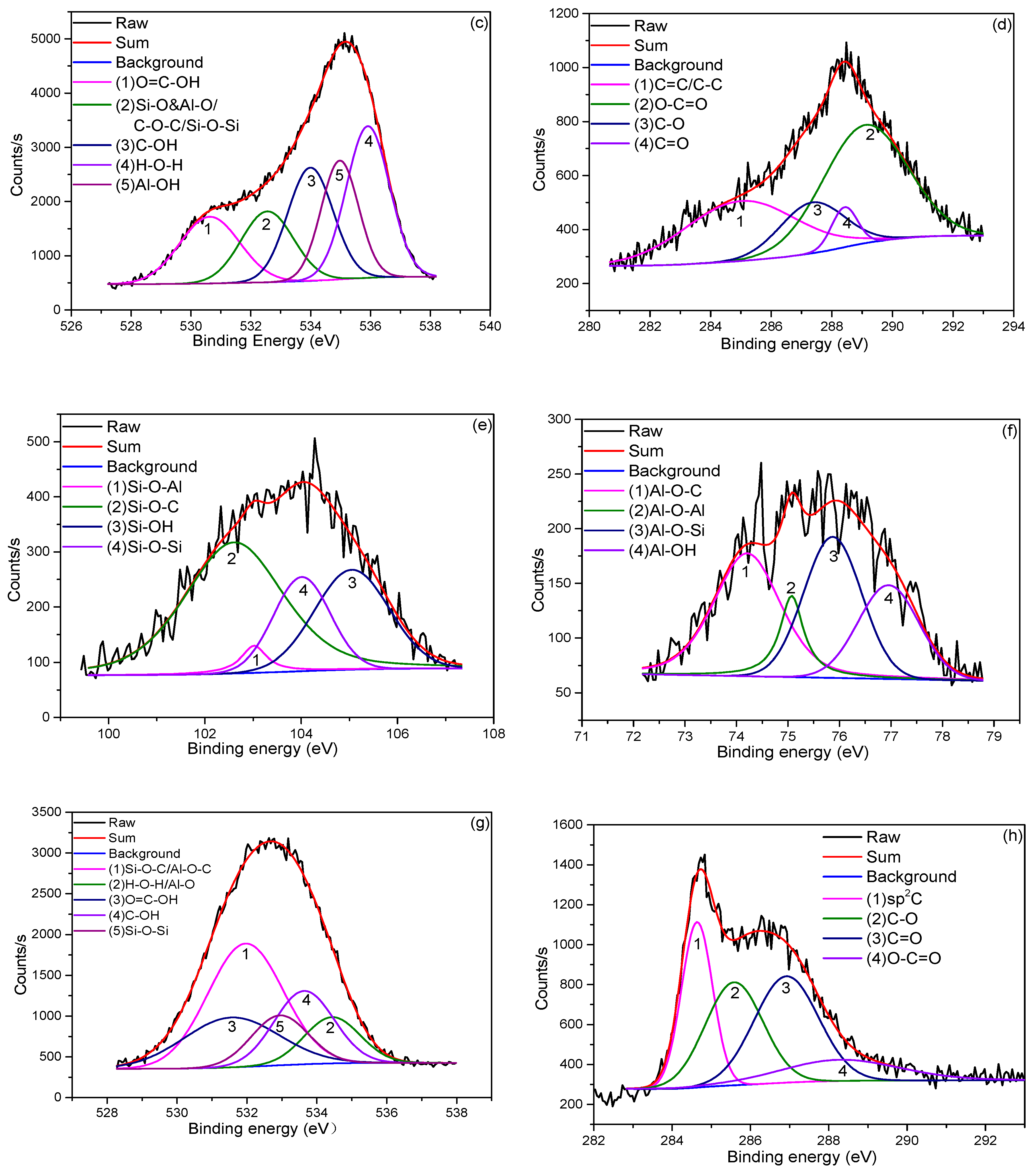

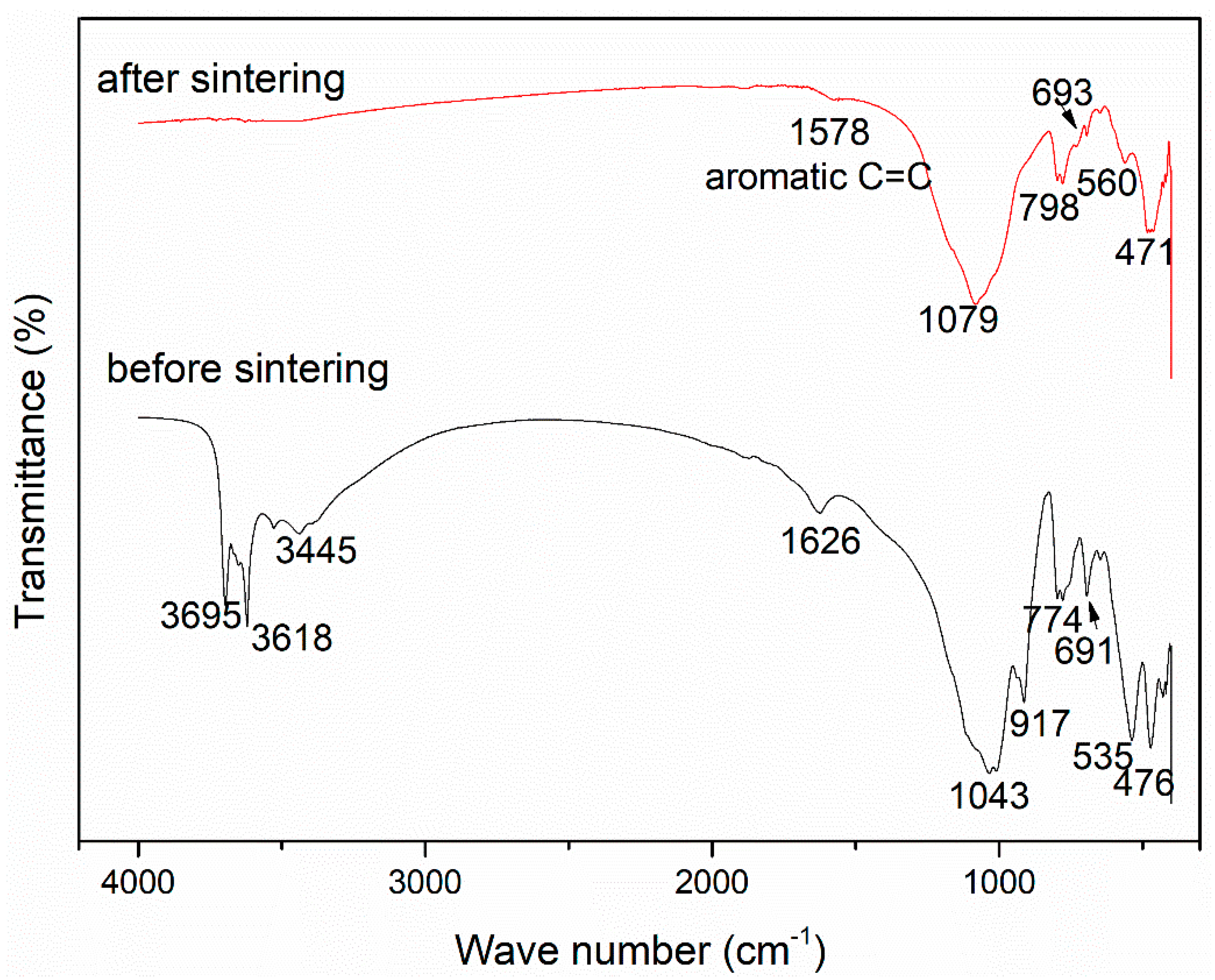

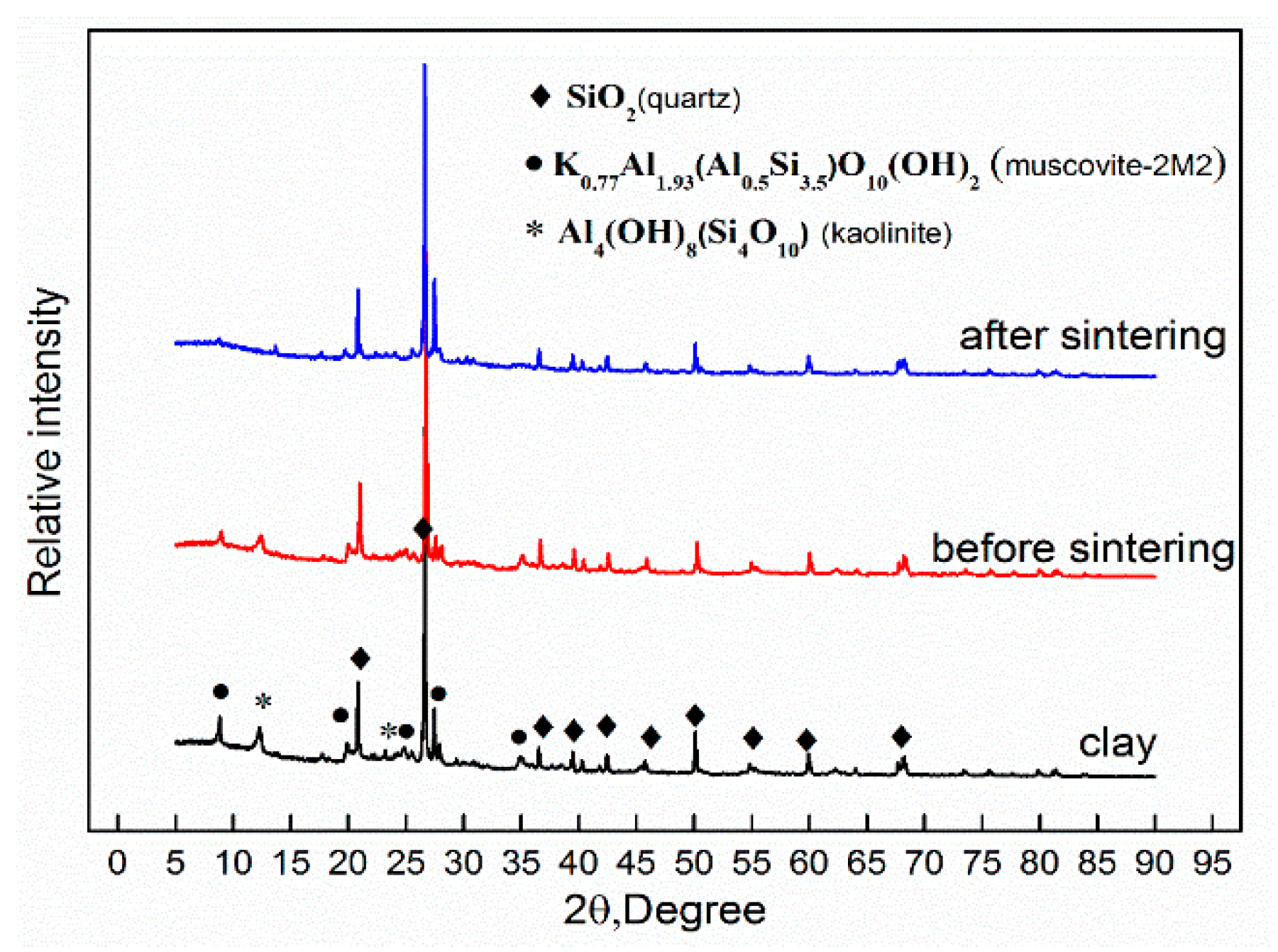

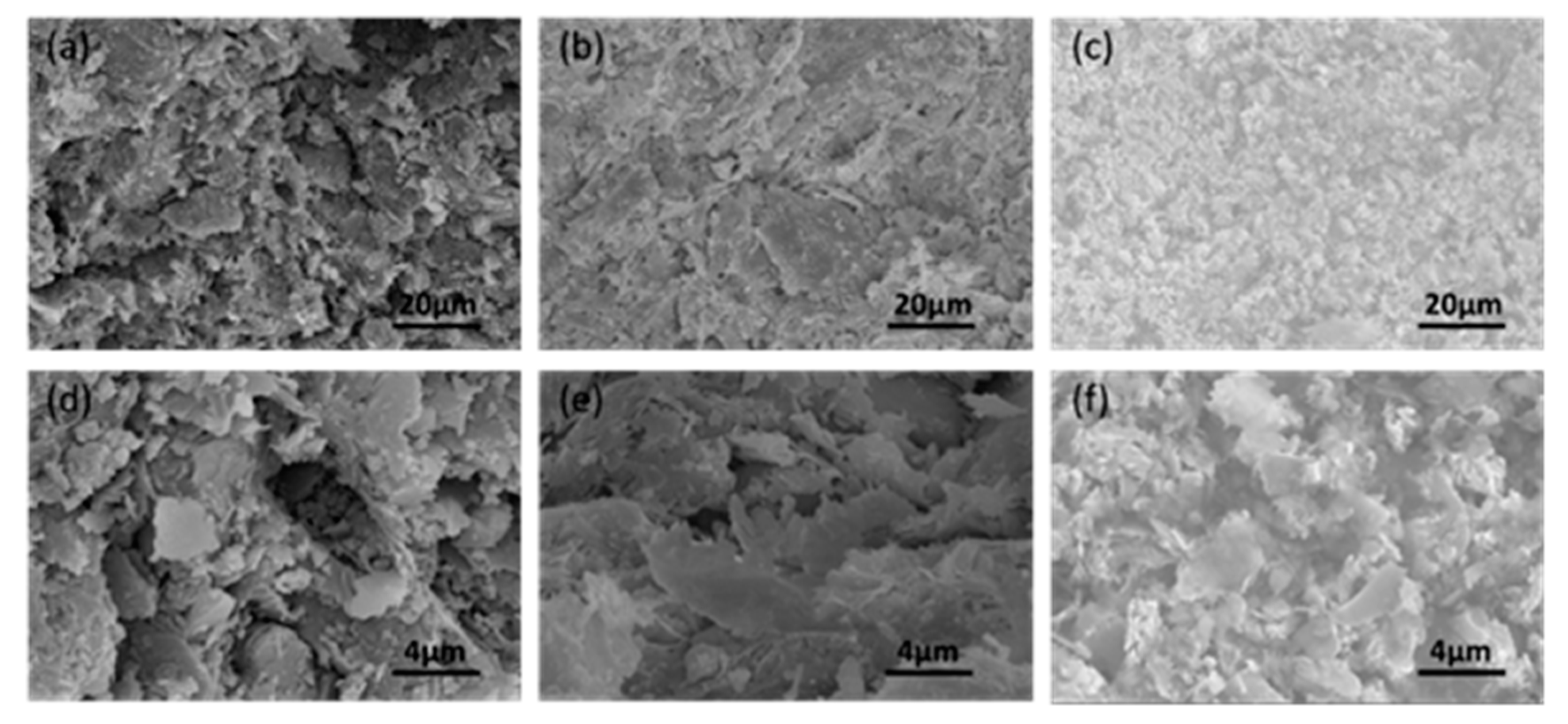

- The results from XRD, XPS, FT-IR and SEM proved that graphene was uniformly distributed across the whole matrix, and covalent bonding was formed between clay and GO. The thermal efficiency can reach up to 88% based on the applied voltage, measured resistance and temperature rise curves. The graphene nanocomposite bricks can serve as part of a smart building with using series connection method to share voltage to fit different circumstances, which also sheds lights on the development of intelligent buildings through promoting the combination of nanomaterials and building materials.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Yang, L.; Yan, H.; Lam, J.C. Thermal Comfort and Building Energy Consumption Implications—A Review. Appl. Energy 2014, 115, 164–173. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, Q.; Tian, Z.; He, B.; Jin, G. A Comprehensive Analysis on Definitions, Development, and Policies of Nearly Zero Energy Buildings in China. Renew. Sustain. Energy Rev. 2019, 114, 109314. [Google Scholar] [CrossRef]

- Qiu, S.; Liu, K.; Wang, D.; Ye, J.; Liang, F. A Comprehensive Review of Ocean Wave Energy Research and Development in China. Renew. Sustain. Energy Rev. 2019, 113, 109271. [Google Scholar] [CrossRef]

- Kuang, J.Z.; Qiu, T.S.; Shi, F. Effect of Heat Treatment on Kaolinite Structure Transformation and Activity. J. Nonferrous Metals 2012, 22, 258–264. [Google Scholar]

- Lu, X.; Liang, B.; Qu, J.P. Enhanced thermal conductivity of polyurethane/wood powder composite phase change materials via incorporating low loading of graphene oxide nanosheets for solar thermal energy storage. Solar Energy Mater. Solar Cells. 2020, 208, 110391. [Google Scholar] [CrossRef]

- Mahdi, M.; Abolhassan, I. Low-cost carbon foam as a practical support for organic phase change materials in thermal management. Appl. Energy. 2020, 258, 114108. [Google Scholar]

- Kluczek, A. An Energy-Led Sustainability Assessment of Production Systems – an Approach for Improving Energy Efficiency Performance. Int. J. Prod. Econ. 2019, 216, 190–203. [Google Scholar] [CrossRef]

- Chung, D.D.L. Self-heating structural materials. Smart Mater. Struct. 2004, 13, 562–565. [Google Scholar] [CrossRef]

- Riu, D.; Sautreuil, M.; Retière, N.; Sename, O. Control and Design of DC Grids for Robust Integration of Electrical Devices. Application to Aircraft Power Systems. Int. J. Electr. Power Energy Syst. 2014, 58, 181–189. [Google Scholar] [CrossRef]

- Buticchi, G.; Costa, L.F.; Liserre, M. Multi-Port DC/DC Converter for the Electrical Power Distribution System of the More Electric Aircraft. Math. Comput. Simulat. 2019, 158, 387–402. [Google Scholar] [CrossRef]

- Chang, C.; Ho, M.; Song, G.B.; Mo, Y.L.; Li, H. A Feasibility Study of Self-Heating Concrete Utilizing Carbon Nanofiber Heating Elements. Smart Mater. Struct. 2009, 18, 127001. [Google Scholar] [CrossRef]

- Hogancamp, J.; Grasley, Z. The Use of Microfine Cement to Enhance the Efficacy of Carbon Nanofibers with Respect to Drying Shrinkage Crack Resistance of Portland Cement Mortars. Cem. Concr. Compos. 2017, 83, 405–414. [Google Scholar] [CrossRef]

- Wang, H.; Gao, X.; Liu, J. Coupling Effect of Salt Freeze-Thaw Cycles and Cyclic Loading On Performance Degradation of Carbon Nanofiber Mortar. Cold Reg. Sci. Technol. 2018, 154, 95–102. [Google Scholar] [CrossRef]

- Khatri, S.; Cai, J.; Naraghi, M. Formation of Wavy Carbon Nanofibers and Nanocoils Via Precursor Constrained Microbuckling. J. Mech. Phys. Solids 2020, 134, 103763. [Google Scholar] [CrossRef]

- Kim, G.M.; Naeem, F.; Kim, H.K.; Lee, H.K. Heating and Heat-Dependent Mechanical Characteristics of CNT-embedded Cementitious Composites. Compos. Struct. 2016, 136, 162–170. [Google Scholar] [CrossRef]

- Sedaghatdoost, A.; Behfarnia, K. Mechanical Properties of Portland Cement Mortar Containing Multi-Walled Carbon Nanotubes at Elevated Temperatures. Constr. Build. Mater. 2018, 176, 482–489. [Google Scholar] [CrossRef]

- Alam, A.; Zhang, Y.; Kuan, H.; Lee, S.; Ma, J. Polymer Composite Hydrogels Containing Carbon Nanomaterials—Morphology and Mechanical and Functional Performance. Prog. Polym. Sci. 2018, 77, 1–18. [Google Scholar] [CrossRef]

- Masuki, K.; Pan, H.; Yoshihiro, I. Green Processing of Carbon Nanomaterials. Adv. Mater. 2017, 29, 11–18. [Google Scholar]

- Xu, P.; Shi, L.; Huang, J.; Wang, C.; Zhang, Y.; Xu, H. Methods of dispersion and stabilization of several nanomaterials in water. Ferroelectrics 2018, 527, 133–148. [Google Scholar] [CrossRef]

- Sreelekshmi, B.; Hunashyal, A.M.; Quadri, S.S.; Banapurmath, N.R.; Hallad, S.A.; Ganachari, S.V. Study of crack filling nano-cement composite material for structural application. Mater. Focus 2017, 6, 407–411. [Google Scholar] [CrossRef]

- Zhong, J.; Zhou, G.; He, P.; Yang, Z.; Jia, D. 3D Printing Strong and Conductive Geo-Polymer Nanocomposite Structures Modified by Graphene Oxide. Carbon 2017, 117, 421–426. [Google Scholar] [CrossRef]

- Orsu, P.; Koyyada, A. Recent Progresses and Challenges in Graphene Based Nano Materials for Advanced Therapeutical Applications: A Comprehensive Review. Mater. Today Commun. 2020, 22, 100823. [Google Scholar] [CrossRef]

- Korkmaz, S.; Kariper, İ.A. Graphene and Graphene Oxide Based Aerogels: Synthesis, Characteristics and Supercapacitor Applications. J. Energy Storage 2020, 27, 101038. [Google Scholar] [CrossRef]

- Wang, J.T.; Wang, Q.H.; Chen, S.L.; Yuan, L.; Li, Y.W. Comparison of Corrosion Resistance of High Chromia Brick, High Zirconia Brick, Fused AZS Brick and Si3N4 Bonded SiC Brick Against Coal Slag. Ceram. Int. 2020. [Google Scholar] [CrossRef]

- Cultrone, G.; Aurrekoetxea, I.; Casado, C.; Arizzi, A. Sawdust Recycling in the Production of Lightweight Bricks: How the Amount of Additive and the Firing Temperature Influence the Physical Properties of the Bricks. Constr. Build. Mater. 2020, 235, 117436. [Google Scholar] [CrossRef]

- Kovtyukhova, N.-I.; Ollivier, P.-J.; Martin, B.-R.; Mallouk, T.-E.; Chizhik, S.-A.; Buzaneva, E.-V. Layer-by-layer assembly of ultrathin composite films from micron-sized graphite oxide sheets and polycations. Chem. Mater. 1999, 11, 771–778. [Google Scholar] [CrossRef]

- Liu, X.X.; Liu, X.W.; Hu, Y.H. Investigation of the Thermal Behaviour and Decomposition Kinetics of Kaolinite. Clay Miner. 2015, 50, 199–209. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Q. Molecular dynamic simulation of mechanical behavior of RGO produced by thermal reduction method. Micro Nano Lett. 2017, 12, 638–642. [Google Scholar] [CrossRef]

- Narayanan, D.P.; Gopalakrishnan, A.; Yaakob, Z.; Sugunan, S.; Narayanan, B.N. A Facile Synthesis of Clay – Graphene Oxide Nanocomposite Catalysts for Solvent Free Multicomponent Biginelli Reaction. Arab. J. Chem. 2020, 13, 318–334. [Google Scholar] [CrossRef]

- Tironi, A.; Cravero, F.; Scian, A.N.; Irassar, E.F. Pozzolanic Activity of Calcined Halloysite-Rich Kaolinitic Clays. Appl. Clay Sci. 2017, 147, 11–18. [Google Scholar] [CrossRef]

- Peng, S.; Qiao, X.-C.; Yu, J.-G. Influence of Mechanochemical Effect on Al-(O,OH) Polyhedron of Kaolinite. J. Wuhan Univ. Technol. 2011, 33, 22–26. [Google Scholar]

- Zhang, S.; Zhang, Z.; Liu, J. Structural Modification in Swift Heavy Ion Irradiated Muscovite Mica. Chin. Phys. B English Version 2017, 26, 321–325. [Google Scholar] [CrossRef]

- Wen, M.; Sun, X.; Su, L.; Shen, J.; Li, J.; Guo, S. The Electrical Conductivity of Carbon Nanotube/Carbon Black/Polypropylene Composites Prepared through Multistage Stretching Extrusion. Polymer 2012, 53, 1602–1610. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, C.; Duan, Z.; Wang, B.; Li, Q.; Chung, K.L.; Zhang, J.; Chen, S. Influences of Multi-Walled Carbon Nanotube (MCNT) Fraction, Moisture, Stress/Strain Level On the Electrical Properties of MCNT Cement-Based Composites. Sens. Actuators A Phys. 2018, 280, 413–421. [Google Scholar] [CrossRef]

- Su, Y.; Gao, B.; Mao, L. Concurrent Agglomeration and Straining Govern the Transport of 14C-labeled Few-Layer Graphene in Saturated Porous Media. Water Res. 2017, 115, 84–93. [Google Scholar] [CrossRef] [PubMed]

| Composition (wt.%) | SiO2 | Al2O3 | K2O | Fe2O3 | CaO | Other |

|---|---|---|---|---|---|---|

| Clay | 66.9 | 28.3 | 3.9 | 0.4 | 0.2 | 0.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Z.; Lu, D.; Gong, J.; Shi, X.; Zhong, J. Self-Heating Graphene Nanocomposite Bricks: A Case Study in China. Materials 2020, 13, 714. https://doi.org/10.3390/ma13030714

Tang Z, Lu D, Gong J, Shi X, Zhong J. Self-Heating Graphene Nanocomposite Bricks: A Case Study in China. Materials. 2020; 13(3):714. https://doi.org/10.3390/ma13030714

Chicago/Turabian StyleTang, Zhuo, Dong Lu, Jing Gong, Xianming Shi, and Jing Zhong. 2020. "Self-Heating Graphene Nanocomposite Bricks: A Case Study in China" Materials 13, no. 3: 714. https://doi.org/10.3390/ma13030714

APA StyleTang, Z., Lu, D., Gong, J., Shi, X., & Zhong, J. (2020). Self-Heating Graphene Nanocomposite Bricks: A Case Study in China. Materials, 13(3), 714. https://doi.org/10.3390/ma13030714