The Structure and Mechanical Properties of the Surface Layer of Polypropylene Polymers with Talc Additions

Abstract

1. Introduction

2. Materials and Methods

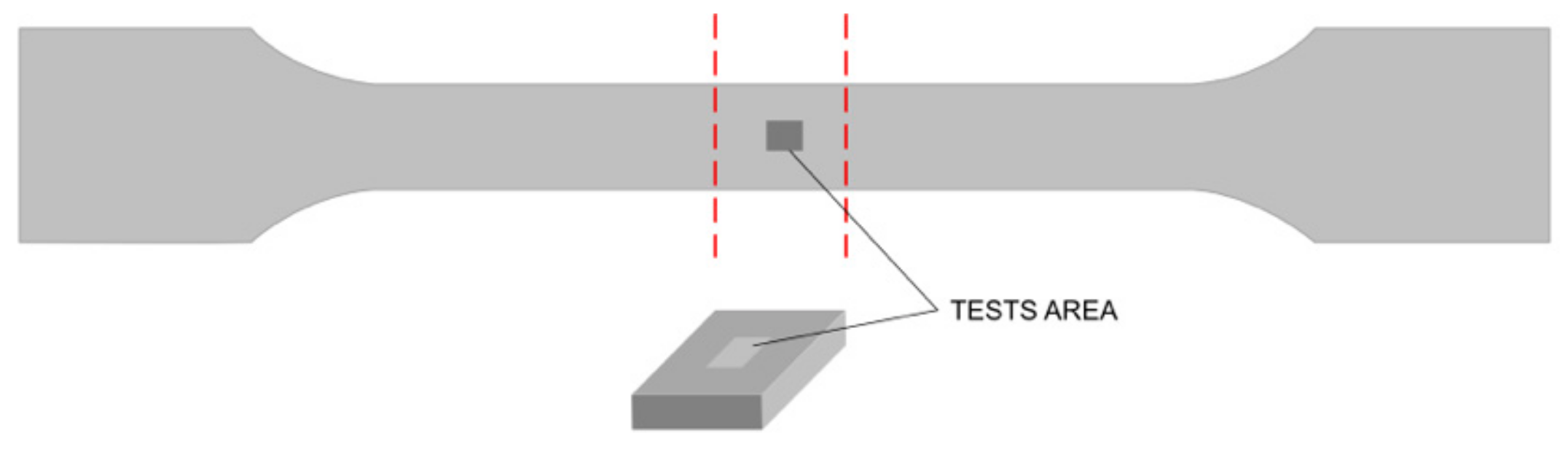

2.1. Sample Preparation

2.2. Methods

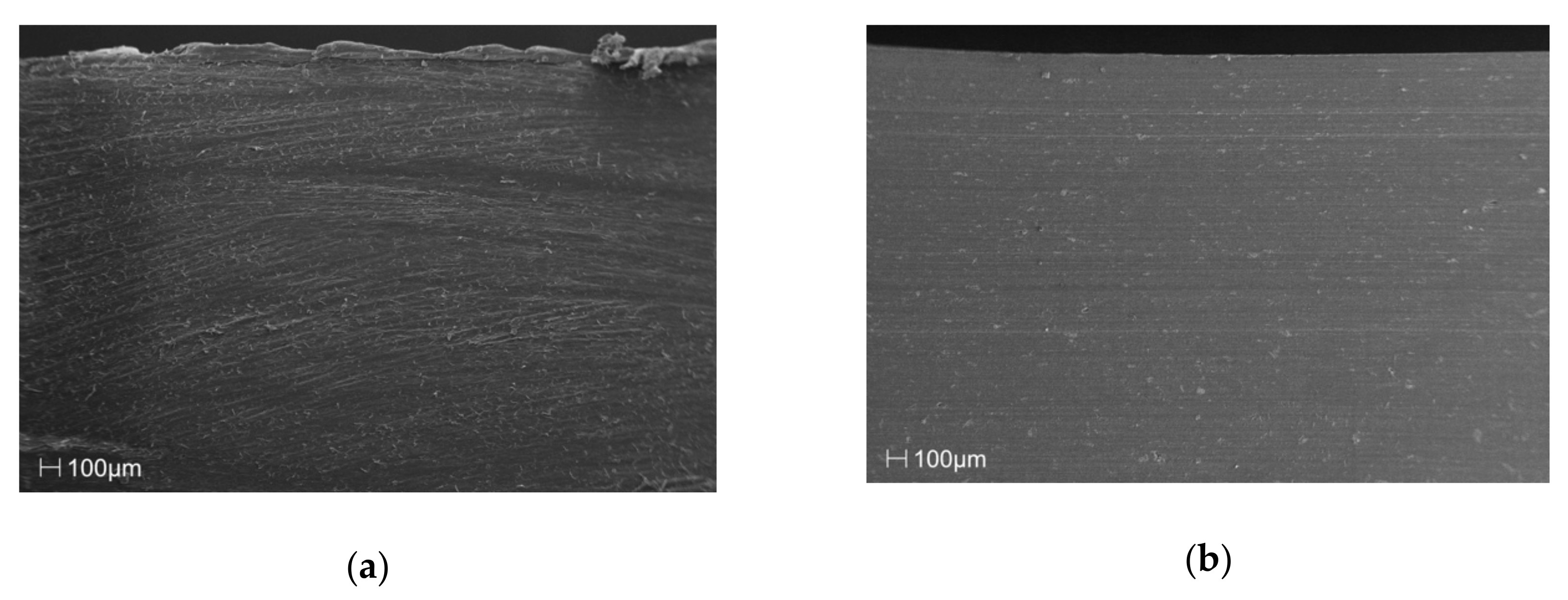

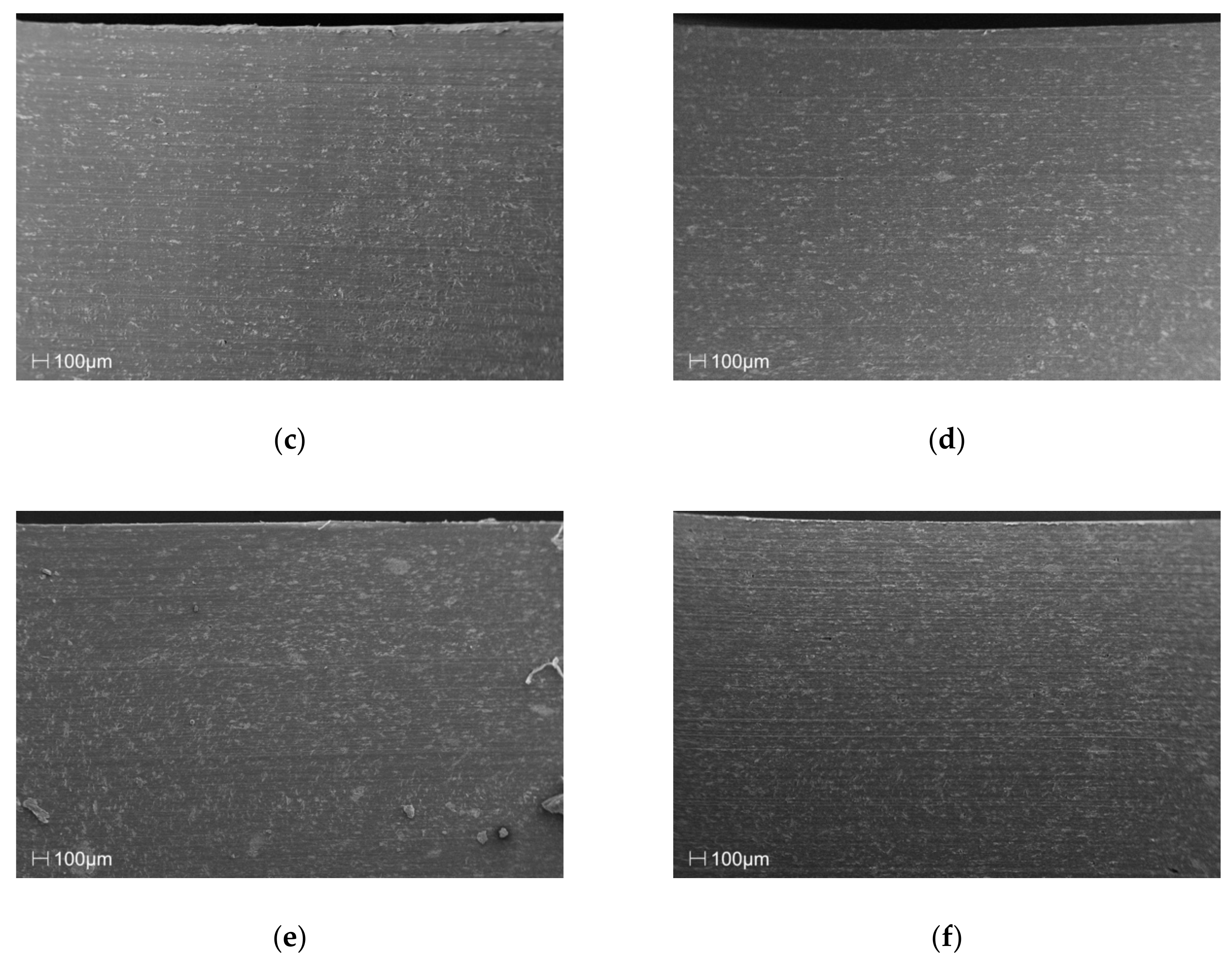

2.2.1. The Scanning Electron Microscope

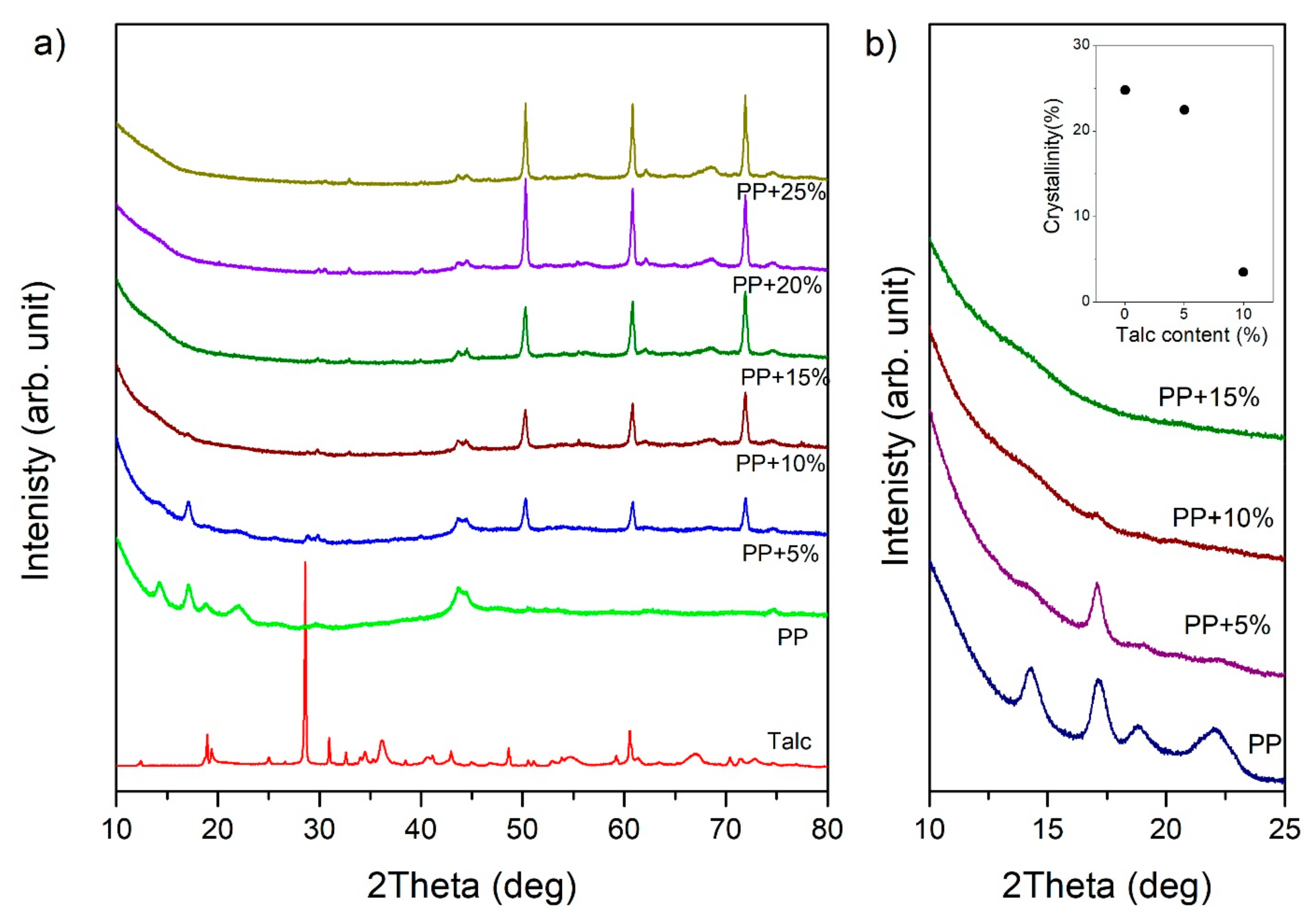

2.2.2. X-ray Diffraction

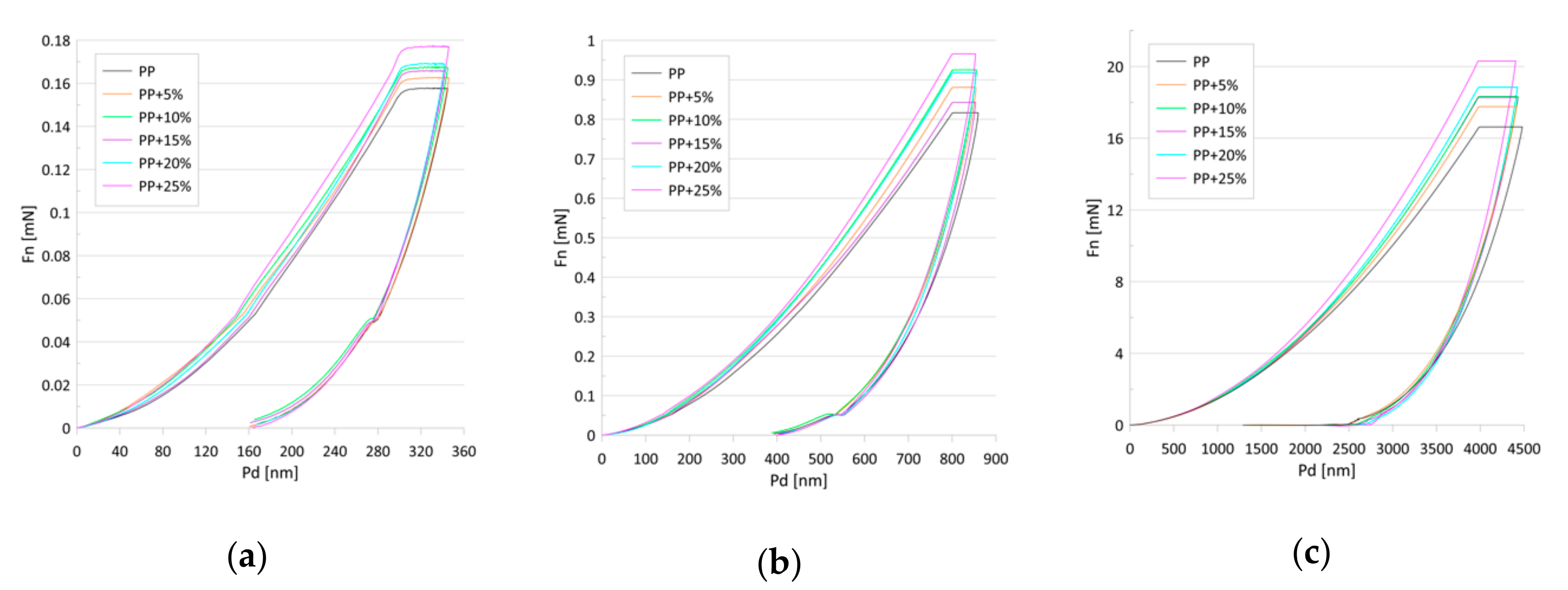

2.2.3. Nanoindentation

2.2.4. Nano-Scratch Tests

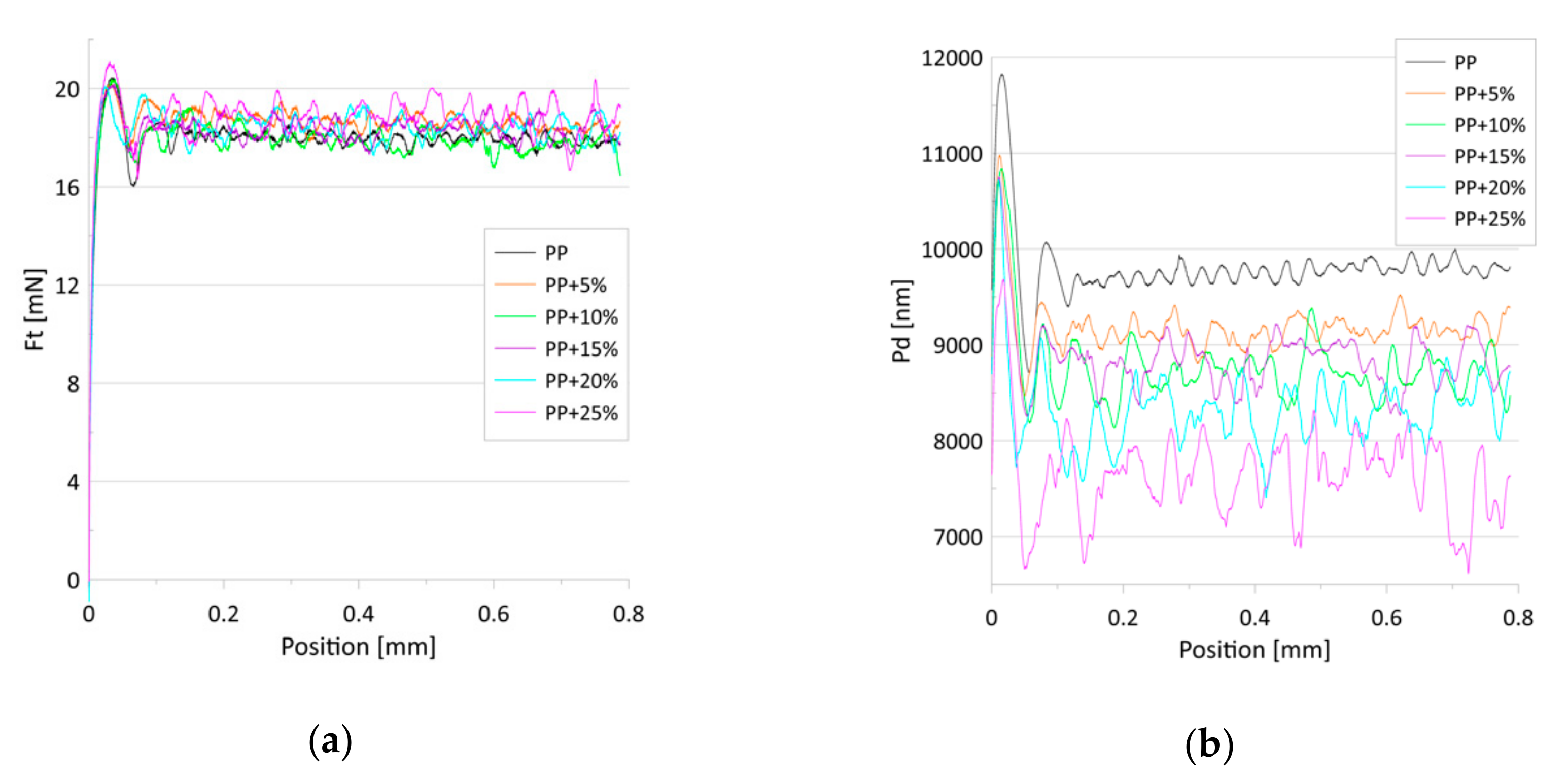

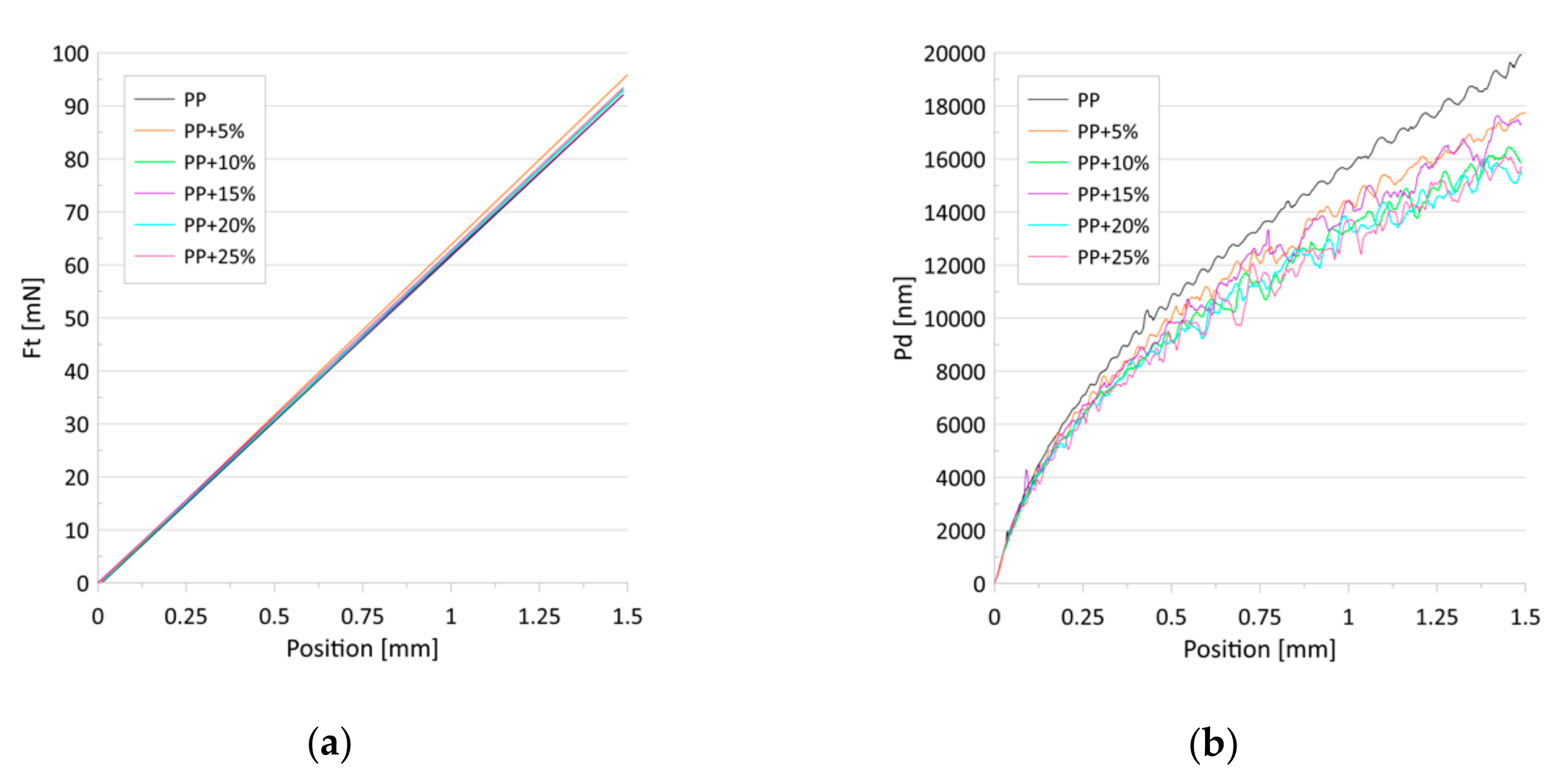

2.2.5. Statistics

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Silva, L.; Tognana, S.; Salgueiro, W. Study of the water absorption and its influence on the Young’s modulus in a commercial polyamide. Polym. Test. 2013, 32, 158–164. [Google Scholar] [CrossRef]

- Miri, V.; Persyn, O.; Lefebvre, J.-M.; Seguela, R. Effect of water absorption on the plastic deformation behavior of nylon 6. Eur. Polym. J. 2009, 45, 757–762. [Google Scholar] [CrossRef]

- Adriaensens, P.; Pollaris, A.; Rulkens, R.; Litvinov, V.M.; Gelan, J. Study of the water uptake of polyamide 46 based copolymers by magnetic resonance imaging relaxometry. Polymer 2004, 45, 2465–2473. [Google Scholar] [CrossRef]

- Deng, H.; Reynolds, C.T.; Cabrera, N.O.; Barkoula, N.-M.; Alcock, B.; Peijs, T. The water absorption behaviour of all-polypropylene composites and its effect on mechanical properties. Compos. Part B Eng. 2010, 41, 268–275. [Google Scholar] [CrossRef]

- Masaeli, E.; Morshed, M.; Tavanai, H. Study of the wettability properties of polypropylene nonwoven mats by low-pressure oxygen plasma treatment. Surf. Interface Anal. 2007, 39, 770–774. [Google Scholar] [CrossRef]

- Ashenai Ghasemi, F.; Ghasemi, I.; Menbari, S.; Ayaz, M.; Ashori, A. Optimization of mechanical properties of polypropylene/talc/graphene composites using response surface methodology. Polym. Test. 2016, 53, 283–292. [Google Scholar] [CrossRef]

- Leong, Y.W.; Ishak, Z.A.M.; Ariffin, A. Mechanical and thermal properties of talc and calcium carbonate filled polypropylene hybrid composites. J. Appl. Polym. Sci. 2004, 91, 3327–3336. [Google Scholar] [CrossRef]

- Srisawat, N.; Nithitanakul, M.; Srikulkit, K. Characterizations of Fibers Produced from Polypropylene/ Silica Composite. J. Met. Mater. Miner. 2009, 19, 53–58. [Google Scholar]

- Kaczmarek, H.; Królikowski, B.; Klimiec, E.; Kowalonek, J. New piezoelectric composites based on isotactic polypropylene filled with silicate. J. Mater. Sci. Mater. Electron. 2017, 28, 6435–6447. [Google Scholar] [CrossRef]

- Fu, S.; Yu, B.; Tang, W.; Fan, M.; Chen, F.; Fu, Q. Mechanical properties of polypropylene composites reinforced by hydrolyzed and microfibrillated Kevlar fibers. Compos. Sci. Technol. 2018, 163, 141–150. [Google Scholar] [CrossRef]

- Tang, G.; Claramunt, C.; Liu, C. Mechanical properties and characteristic of surface treated bamboo fiber reinforced PP/PS blends. Surf. Interface Anal. 2018, 50, 1–5. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Effects of maleated polypropylene on the morphology, thermal and mechanical properties of short carbon fiber reinforced polypropylene composites. Mater. Des. 2011, 32, 4069–4073. [Google Scholar] [CrossRef]

- Anozie, O.O.; Ifeanyi, N.D. Mathematical modelling of mechanical properties Polypropylene/Talc composites: Power equation approach. Int. J. Res. Adv. Eng. Technol. 2016, 2, 15–19. [Google Scholar]

- Lapcik, L.; Jindrova, P.; Lapcikova, B.; Tamblyn, R.; Greenwood, R.; Rowson, N. Effect of the Talc Filler Content on the Mechanical Properties of Polypropylene Composites. J. Appl. Polym. Sci. 2008, 10, 2742–2747. [Google Scholar] [CrossRef]

- Zihlif, A.M.; Ragosta, G. Mechanical properties of talc-polypropylene composites. Mater. Lett. 1991, 11, 368–372. [Google Scholar] [CrossRef]

- Wu, G.; Wen, B.; Hou, S. Preparation and structural study of polypropylene–talc gradient materials. Polym. Int. 2004, 53, 749–755. [Google Scholar] [CrossRef]

- Järvelä, P.A.; Enqvist, J.; Järvelä, P.K.; Tervala, O. Mechanical strength and thermal stability of magnesium silicate filled polypropylenes. Compos. Interfaces 2001, 8, 189–206. [Google Scholar] [CrossRef]

- Codolini, A.; Li, Q.M.; Wilkinson, A. Influence of machining process on the mechanical behaviour of injection-moulded specimens of talc-filled Polypropylene. Polym. Test. 2017, 62, 342–347. [Google Scholar] [CrossRef]

- Wong, M.; Moyse, A.; Lee, F.; Sue, H.-J. Study of surface damage of polypropylene under progressive loading. J. Mater. Sci. 2004, 39, 3293–3308. [Google Scholar] [CrossRef]

- Eriksen, E. The influence of surface roughness on the mechanical strength properties of machined short-fibre-reinforced thermoplastics. Compos. Sci. Technol. 2000, 60, 107–113. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, X.; Shi, S.; Liu, C.; Dai, K.; Yin, R.; Schubert, D.W.; Zheng, G.; Shen, C. Annealing Induced Mechanical Reinforcement of Injection Molded iPP Parts. Macromol. Mater. Eng. 2016, 301, 1468–1472. [Google Scholar] [CrossRef]

- Jiang, H.; Browning, R.; Sue, H.-J. Understanding of scratch-induced damage mechanisms in polymers. Polymer 2009, 50, 4056–4065. [Google Scholar] [CrossRef]

- Kim, B.-C.; Kim, H.-J.; Choi, B.-H.; Lee, H.-S. An experimental study of the scratch properties of poly(methyl methacrylate) as a function of the concentration of added slip agent. Tribol. Int. 2011, 44, 2035–2041. [Google Scholar] [CrossRef]

- Alisafaei, F.; Han, C.-S. Indentation Depth Dependent Mechanical Behavior in Polymers. Adv. Condens. Matter Phys. 2015, 2015, 1–20. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Fiori, L.; Pelillo, E. Nano-indentation of polymeric surfaces. J. Phys. D. Appl. Phys. 1998, 31, 2395–2405. [Google Scholar] [CrossRef]

- Chong, A.C.M.; Lam, D.C.C. Strain gradient plasticity effect in indentation hardness of polymers. J. Mater. Res. 1999, 14, 4103–4110. [Google Scholar] [CrossRef]

- Alisafaei, F.; Han, C.-S.; Lakhera, N. Characterization of indentation size effects in epoxy. Polym. Test. 2014, 40, 70–78. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Shojaei, A.; Mozaffari, N. Strain gradient plasticity for amorphous and crystalline polymers with application to micro- and nano-scale deformation analysis. Polymer 2014, 55, 4182–4198. [Google Scholar] [CrossRef]

- Han, C.-S.; Nikolov, S. Indentation size effects in polymers and related rotation gradients. J. Mater. Res. 2007, 22, 1662–1672. [Google Scholar] [CrossRef]

- Zhang, T.-Y.; Xu, W.-H.; Zhao, M.-H. The role of plastic deformation of rough surfaces in the size-dependent hardness. Acta Mater. 2004, 52, 57–68. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Munawar Chaudhri, M. Indentation of elastic solids with a rigid Vickers pyramidal indenter. Mech. Mater. 2006, 38, 1213–1228. [Google Scholar] [CrossRef]

- Homayounfar, S.Z.; Bagheri, R. Role of different compatibilizing approaches on the microstructure and mechanical properties of polypropylene/talc composites. AIP Conf. Proc. 2014, 1593, 428–431. [Google Scholar]

- Janssen, L.P.B.M.; Moscicki, L. Thermoplastic Starch: A Green Material for Various Industries; John Wiley & Sons: Oxford, UK, 2010. [Google Scholar]

- Edward, P.; Moore, J. Polypropylene Handbook; Hanser/Gardner Publications, Inc.: Cincinnati, OH, USA, 1996. [Google Scholar]

- Kogure, T. Stacking structure in disordered talc: Interpretation of its X-ray diffraction pattern by using pattern simulation and high-resolution transmission electron microscopy. Am. Mineral. 2006, 91, 1363–1370. [Google Scholar] [CrossRef]

- Hulleman, S.H.; Kalisvaart, M..; Janssen, F.H..; Feil, H.; Vliegenthart, J.F. Origins of B-type crystallinity in glycerol-plasticised, compression-moulded potato starches. Carbohydr. Polym. 1999, 39, 351–360. [Google Scholar] [CrossRef]

- Gradys, A.; Sajkiewicz, P.; Minakov, A.A.; Adamovsky, S.; Schick, C.; Hashimoto, T.; Saijo, K. Crystallization of polypropylene at various cooling rates. Mater. Sci. Eng. A 2005, 413, 442–446. [Google Scholar] [CrossRef]

- Velasco, J.I.; de Saja, J.A.; Martínez, A.B. Crystallization behavior of polypropylene filled with surface-modified talc. J. Appl. Polym. Sci. 1996, 61, 125–132. [Google Scholar] [CrossRef]

- Castillo, L.; Capiati, N.; Barbosa, S. Mechanical properties of polypropylene/talc composites: Role of the mineral morphology and particle surface modification. In Polypropylene: Synthesis, Applications and Environmental Concerns; Nova Science Publishers, Inc.: Lancaster, UK, 2013; pp. 145–160. [Google Scholar]

- Wang, K.; Bahlouli, N.; Addiego, F.; Ahzi, S.; Rémond, Y.; Ruch, D.; Muller, R. Effect of talc content on the degradation of re-extruded polypropylene/talc composites. Polym. Degrad. Stab. 2013, 98, 1275–1286. [Google Scholar] [CrossRef]

- Mastronardo, E.; Bonaccorsi, L.; Kato, Y.; Piperopoulos, E.; Lanza, M.; Milone, C. Thermochemical performance of carbon nanotubes based hybrid materials for MgO/H2O/Mg(OH)2 chemical heat pumps. Appl. Energy 2016, 181, 232–243. [Google Scholar] [CrossRef]

- Kumari, L.; Li, W.Z.; Vannoy, C.H.; Leblanc, R.M.; Wang, D.Z. Synthesis, characterization and optical properties of Mg(OH)2 micro-/nanostructure and its conversion to MgO. Ceram. Int. 2009, 35, 3355–3364. [Google Scholar] [CrossRef]

- Nemade, K.R.; Waghuley, S.A. Synthesis of MgO Nanoparticles by Solvent Mixed Spray Pyrolysis Technique for Optical Investigation. Int. J. Met. 2014, 2014, 1–4. [Google Scholar] [CrossRef]

- Barati, F.; Latifi, M.; Moayeri far, E.; Mosallanejad, M.H.; Saboori, A. Novel AM60-SiO2 Nanocomposite Produced via Ultrasound-Assisted Casting; Production and Characterization. Materials 2019, 12, 3976. [Google Scholar] [CrossRef] [PubMed]

- Ghayeb Zamharir, S.; Karimzadeh, R.; Aboutalebi, S.H. Laser-assisted tunable optical nonlinearity in liquid-phase exfoliated MoS2 dispersion. Appl. Phys. A 2018, 124, 692. [Google Scholar] [CrossRef]

- Ammar, O.; Bouaziz, Y.; Haddar, N.; Mnif, N. Talc as Reinforcing Filler in Polypropylene Compounds: Effect on Morphology and Mechanical Properties. Polym. Sci. 2017, 03, 1–7. [Google Scholar]

- Shelesh-Nezhad, K.; Taghizadeh, A. Shrinkage behavior and mechanical performances of injection molded polypropylene/talc composites. Polym. Eng. Sci. 2007, 47, 2124–2128. [Google Scholar] [CrossRef]

- Öksüz, M.; Eroglu, M.; Yıldırım, H. Effect of talc on the properties of polypropylene/ethylene/propylene/diene terpolymer blends. J. Appl. Polym. Sci. 2006, 101, 3033–3039. [Google Scholar] [CrossRef]

- Palutkiewicz, P.; Trzaskalska, M.; Bociąga, E. The influence of blowing agent addition, talc filler content, and injection velocity on selected properties, surface state, and structure of polypropylene injection molded parts. Cell. Polym. 2020, 39, 3–30. [Google Scholar] [CrossRef]

- Zhang, T.-Y.; Xu, W.-H. Surface Effects on Nanoindentation. J. Mater. Res. 2002, 17, 1715–1720. [Google Scholar] [CrossRef]

- Qin, S.; Song, J.; Yu, J.; Guo, J.; Hu, S. Scratch Hardness of Polypropylenes: Effect of Applied Normal Force. J. Macromol. Sci. Part B 2012, 51, 1100–1116. [Google Scholar] [CrossRef]

- Ferrage, E.; Martin, F.; Boudet, A.; Petit, S.; Fourty, G.; Jouffret, F.; Micoud, P.; De Parseval, P.; Salvi, S.; Bourgerette, C.; et al. Talc as nucleating agent of polypropylene: Morphology induced by lamellar particles addition and interface mineral-matrix modelization. J. Mater. Sci. 2002, 37, 1561–1573. [Google Scholar] [CrossRef]

- Chu, J.; Rumao, L.; Coleman, B. Scratch and mar resistance of filled polypropylene materials. Polym. Eng. Sci. 1998, 38, 1906–1914. [Google Scholar] [CrossRef]

| HIT (MPa) | p-Value (Linear) | |||

|---|---|---|---|---|

| Penetration Depth (nm) Talc Content (%) | 300 | 800 | 4000 | |

| 0 | 85 aA ± 8 | 71 aB ± 3 | 49 aC ± 5 | <0.001 |

| 5 | 88aA ± 12 | 78 bB ± 2 | 52 abC ± 2 | <0.001 |

| 10 | 91aA ± 4 | 81 bcB ± 3 | 53 abC ± 2 | <0.001 |

| 15 | 91 aA ± 11 | 81 bcB ± 4 | 52 abC ± 1 | <0.001 |

| 20 | 91 aA ± 18 | 79 bcB ± 4 | 54 bC ± 3 | <0.001 |

| 25 | 94 aA ± 20 | 83 cA ± 5 | 59 cB ± 5 | <0.001 |

| p-value (linear) | 0.012 | 0.002 | 0.012 | |

| EIT (GPa) | p-Value (Linear) | |||

|---|---|---|---|---|

| Penetration Depth (nm) Talc Content (%) | 300 | 800 | 4000 | |

| 0 | 1.43 aA ± 0.07 | 1.29 aB ± 0.03 | 0.96 aC ± 0.06 | <0.001 |

| 5 | 1.48 aA ± 0.11 | 1.39 bB ± 0.04 | 1.05 bC ± 0.03 | <0.001 |

| 10 | 1.52 aA ± 0.04 | 1.49 cA ± 0.05 | 1.10 bB ± 0.01 | <0.001 |

| 15 | 1.54 abcA ± 0.11 | 1.61 dA ± 0.02 | 1.11 bB ± 0.01 | <0.001 |

| 20 | 1.66 bcA ± 0,20 | 1.57 dA ± 0.08 | 1.24 cB ± 0.08 | <0.001 |

| 25 | 1.70 cA ± 0.25 | 1.64 dA ± 0.10 | 1.34 dC ± 0.11 | <0.001 |

| P-value (linear) | <0.001 | <0.001 | <0.001 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Świetlicki, M.; Chocyk, D.; Klepka, T.; Prószyński, A.; Kwaśniewska, A.; Borc, J.; Gładyszewski, G. The Structure and Mechanical Properties of the Surface Layer of Polypropylene Polymers with Talc Additions. Materials 2020, 13, 698. https://doi.org/10.3390/ma13030698

Świetlicki M, Chocyk D, Klepka T, Prószyński A, Kwaśniewska A, Borc J, Gładyszewski G. The Structure and Mechanical Properties of the Surface Layer of Polypropylene Polymers with Talc Additions. Materials. 2020; 13(3):698. https://doi.org/10.3390/ma13030698

Chicago/Turabian StyleŚwietlicki, Michał, Dariusz Chocyk, Tomasz Klepka, Adam Prószyński, Anita Kwaśniewska, Jarosław Borc, and Grzegorz Gładyszewski. 2020. "The Structure and Mechanical Properties of the Surface Layer of Polypropylene Polymers with Talc Additions" Materials 13, no. 3: 698. https://doi.org/10.3390/ma13030698

APA StyleŚwietlicki, M., Chocyk, D., Klepka, T., Prószyński, A., Kwaśniewska, A., Borc, J., & Gładyszewski, G. (2020). The Structure and Mechanical Properties of the Surface Layer of Polypropylene Polymers with Talc Additions. Materials, 13(3), 698. https://doi.org/10.3390/ma13030698