As it was already mentioned, depending on the selected calculation method, numerical analyses of welding processes carried out in the SYSWELD environment can be divided into the following groups:

Local analysis: Used to determine the distribution of temperature fields, metallurgical phases as well as stresses and deformations within one welded joint;

In the case of welding, essentially the only load on the workpiece is the non-stationary distribution of the temperature field both on its surface and in many cases in thickness. Thus, the temperature in the model is determined by means of a variable function in time and dimensional space. Accurate determination of the temperature field distribution is, therefore, the basic and most important step in determining its influence on the metallurgical properties of the material and the stresses and deformation distributions of the welded structure. In order to refine the record of changes in temperature function in time and space, it is necessary to define a mathematical model of a heat source [

1]. This description, however, brings with it a lot of problems due to the complexity of the issue. There is a need to take into consideration many input parameters and apply some simplifications in the description of this model. When creating it, the influence of convection in the liquid metal pool, active elements, type of protective gas, wire diameter or method of transferring metal in the arc are not taken into account. Models of heat sources can be divided into three basic groups while defining the degree of complexity of the analyses carried out [

1]:

Three-dimensional.

Therefore, depending on the dimension of the heat source model used, point, linear or flat models of heat sources were used in the analyses. Their advantage was low “resource consumption” in the calculations. The limitations of these heat source models resulted primarily from the available computing power. Nowadays, when we have sufficient computing power, in most cases we almost exclusively use three-dimensional models [

5,

11,

12,

13,

14,

15,

16,

17,

18].

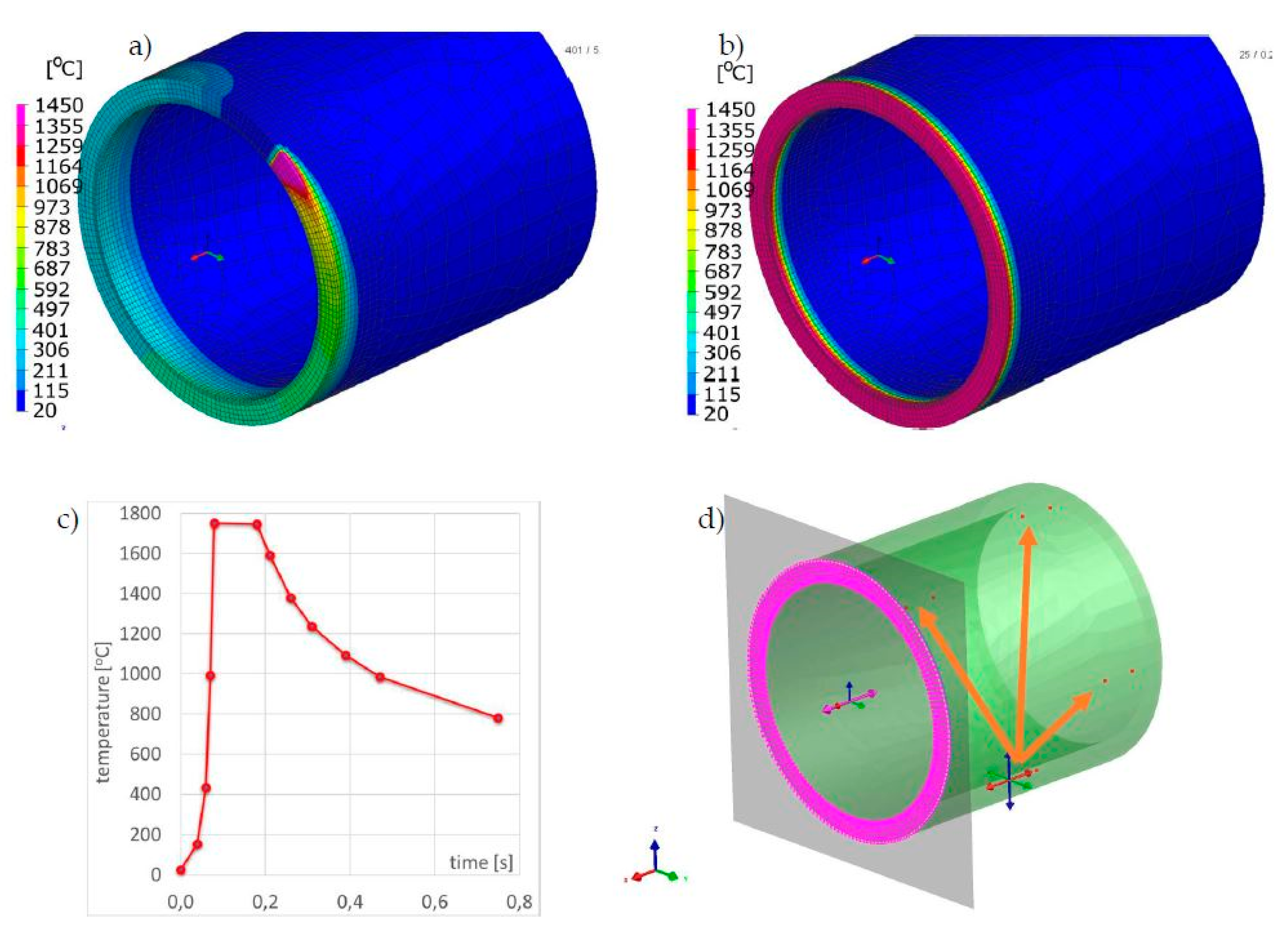

2.1. Transient Technique: Moving Heat Source

In the case of local analyses, when the moving heat source model is used, the calculations are carried out by the so-called “transient” technique, also called the “step-by-step” technique. Calculations are made in this case for each subsequent time increased by a given time step, which is automatically adjusted depending on the mesh density of the model or set by the user. The mathematical model of the heat source in this type of analysis moves along the line that determines the welding trajectory. The parameters used to describe the heat source model, in this case, are the actual welding process parameters, i.e., welding current, arc voltage, welding speed or thermal efficiency of the method, etc. So, this is mostly data that can be found, among others, at the Welding Procedure Specification Form (WPS) but also are part of the knowledge of every welding engineer. One of the most popular models used in current numerical analyses is the volumetric double ellipsoid model, also known as Goldak’s model [

1,

5,

15,

16,

17,

18,

19,

20]. It consists of two ellipsoids which, placed in two perpendicular planes, create an image of the weld pool in both horizontal and vertical space (

Figure 1). Transferred heat into a volume is described by Equations (1) and (2) [

1,

5,

19,

21]:

For the front part of the heat source model, the Equation is:

and for the rear part of the heat source model, the Equation is:

where

Qf,

Qr are volumetric heat flux density in front and rear part of the model [W/m

3];

Q is total power source;

a,

b,

cf,

cr are width, depth and length of the front and the rear part of the molten pool;

ff,

fr are constants which influence energy flow intensity into the material (

ff +

fr = 2); and k, l, m are coefficients enabling modification of the liquid metal pool shape.

The efficiency of the heat transfer into parent material is given by the applied welding method [

20]. For the proper heat source calibration, it is necessary to compare the results with experimentally determined and measured values. It is mainly the overall heat, the geometrical parameters of the molten pool and the efficiency of the heat transfer from the source into the material. After specifying the input parameters, it remains to add the constants

ff,

fr affecting the distribution of energy flow to the material and choose the coefficients k, l, m. Practice shows that we usually accept intercourse of

ff to

fr as 60:40. The choice of coefficients k, l, m is more complicated. If the unmodified heat source model is used, all three factors will be equal to three. The unmodified source is particularly suitable for simulated welding with coated electrodes. In the case of welding simulation, e.g., with the GMAW method, the model must be modified to obtain the correct shape of the liquid metal pool and the values of the coefficients chosen experimentally [

1,

5,

15,

16,

17,

18,

19,

20,

21,

22].

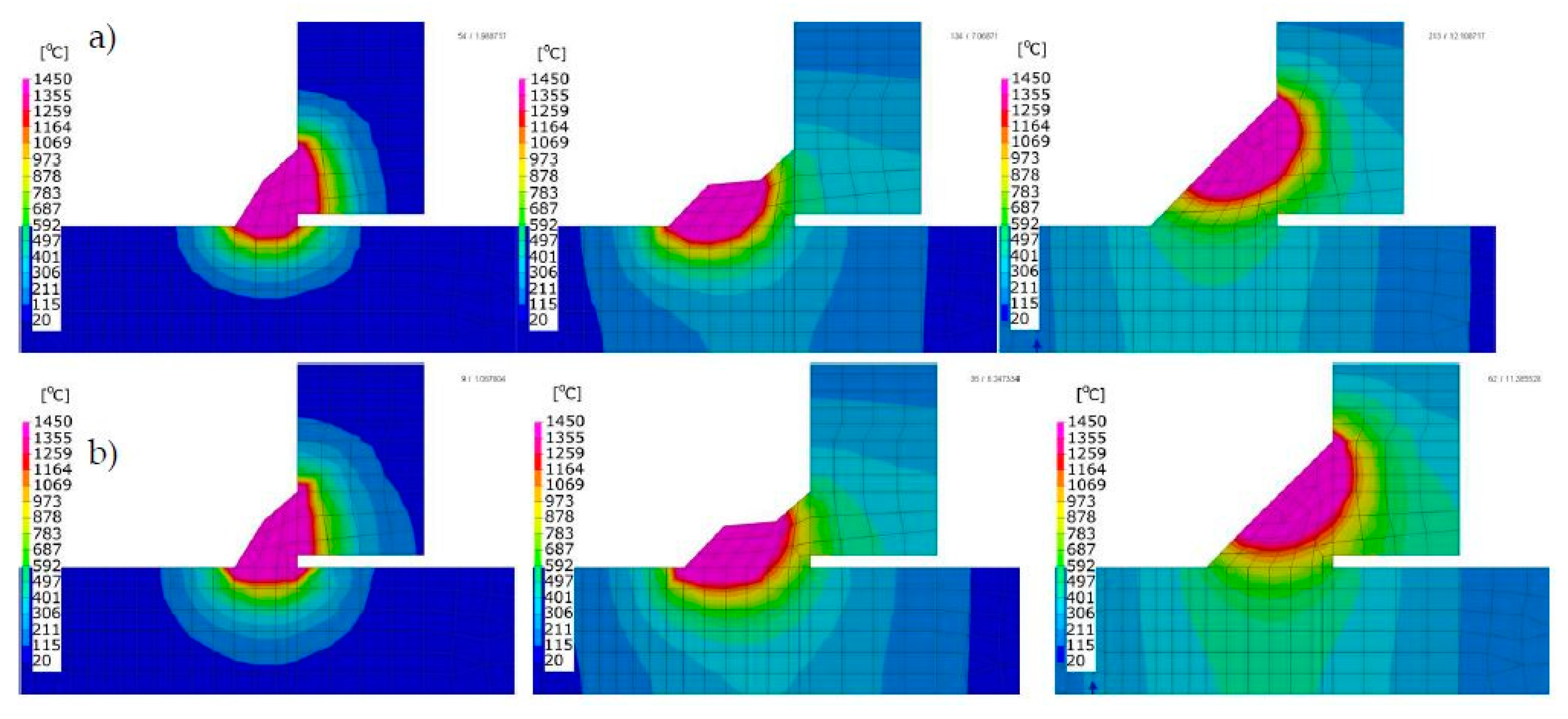

While Goldak’s source successfully covers the scope of numerical analyses of arc welding processes, in the case of laser or electron beam welding, the conical model with a Gaussian distribution is currently most commonly used. Its conical shape allows good reproduction of welding processes carried out using welding heat sources with a high concentration of energy (for example laser and electron beam welding). The mathematical description of this model can be represented by two Equations [

1,

5,

22]:

where

Q0 is the maximum value of volumetric heat flux density;

re,

ri are upper and lower 3D cone radius dimensions parameters;

ze,

zi are the 3D cone length parameters; and

x,

y,

z are point coordinates (

Figure 1).

Equation (3) describes the volumetric heat flow density into the material in the dependence of coordinate data. Equation (4) supplements Equation (3) by the definition of the radius change in the direction of the depth.

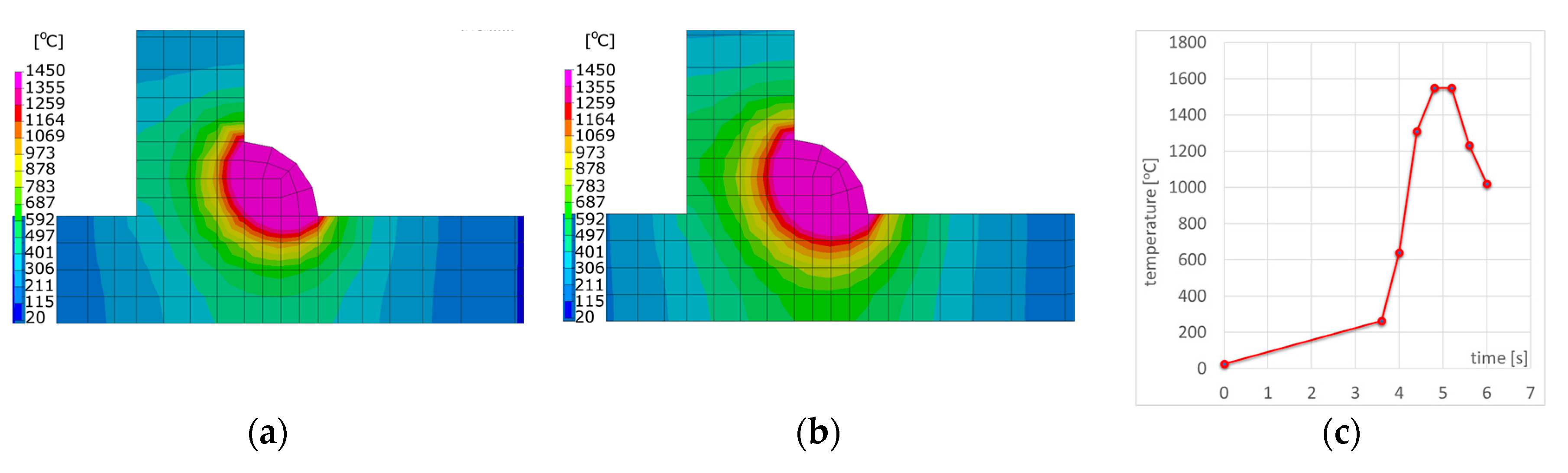

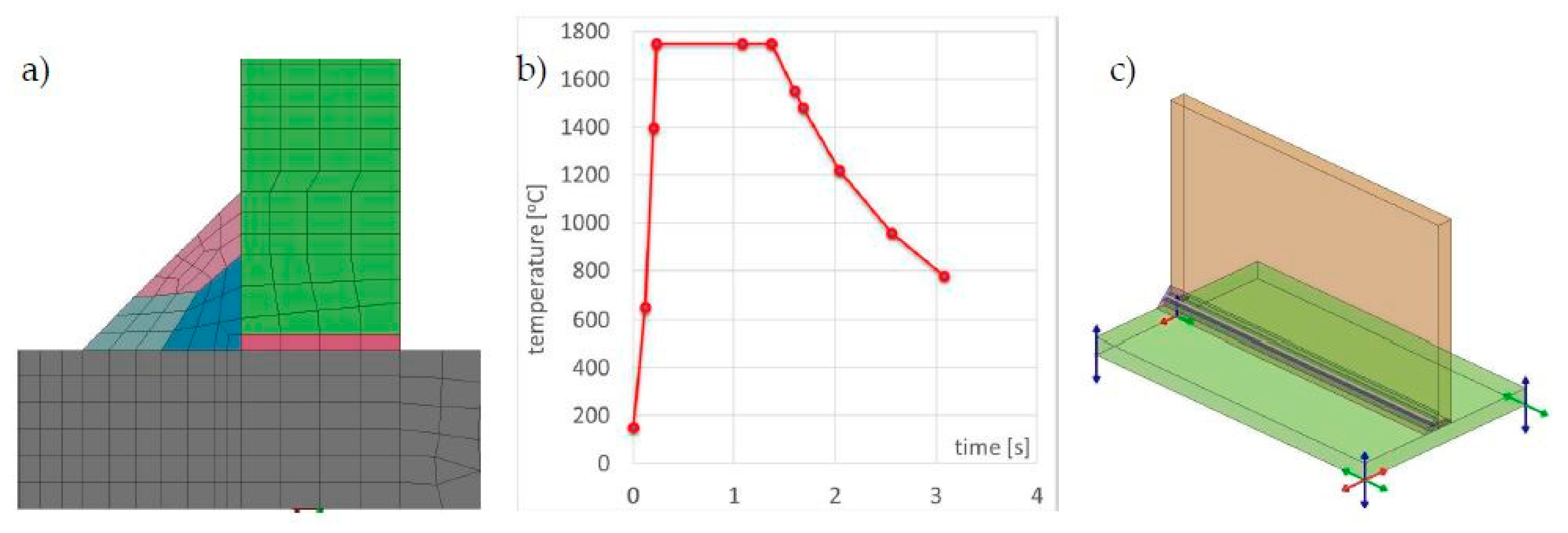

This way of defining a heat source model and conducting numerical analyses based on a moving heat source requires its appropriate calibration procedure (

Figure 2). Only in this case will it be possible to recreate with it the actual distribution of temperature fields that affect the metallurgical transformations, stress and deformation distributions that occur. It is a long-term process but can be carried out on partially simplified models (including 2D cross-section models). Incorrect calibration of the heat source model leads to duplication of errors during this stage and simulation, which in turn leads to incorrect results.

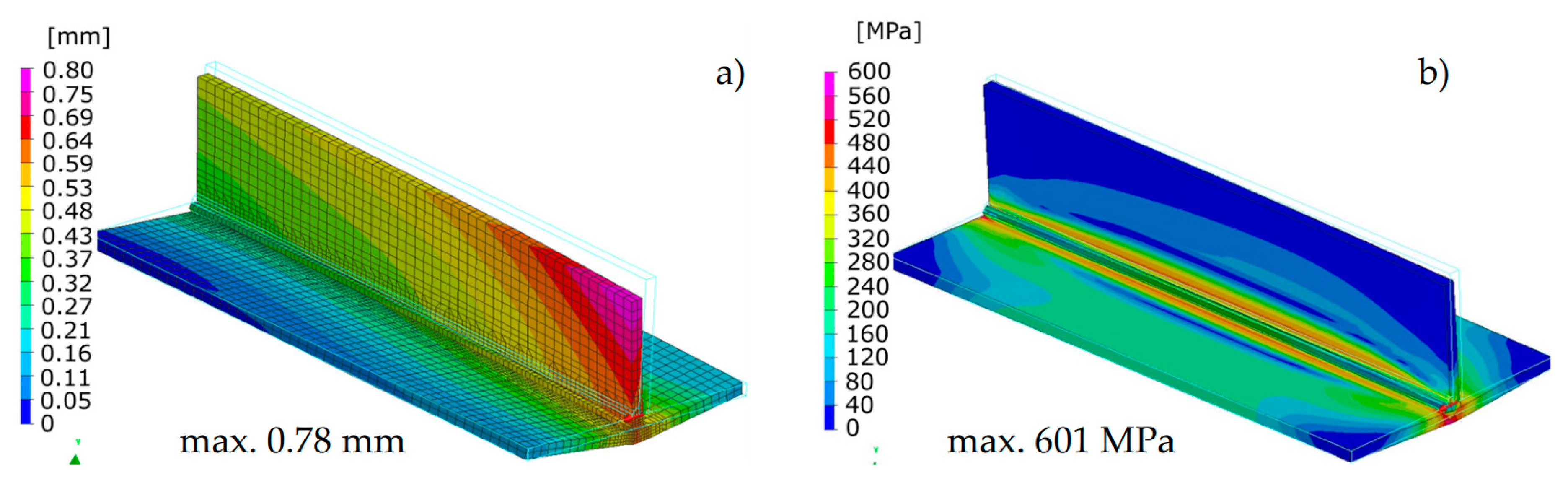

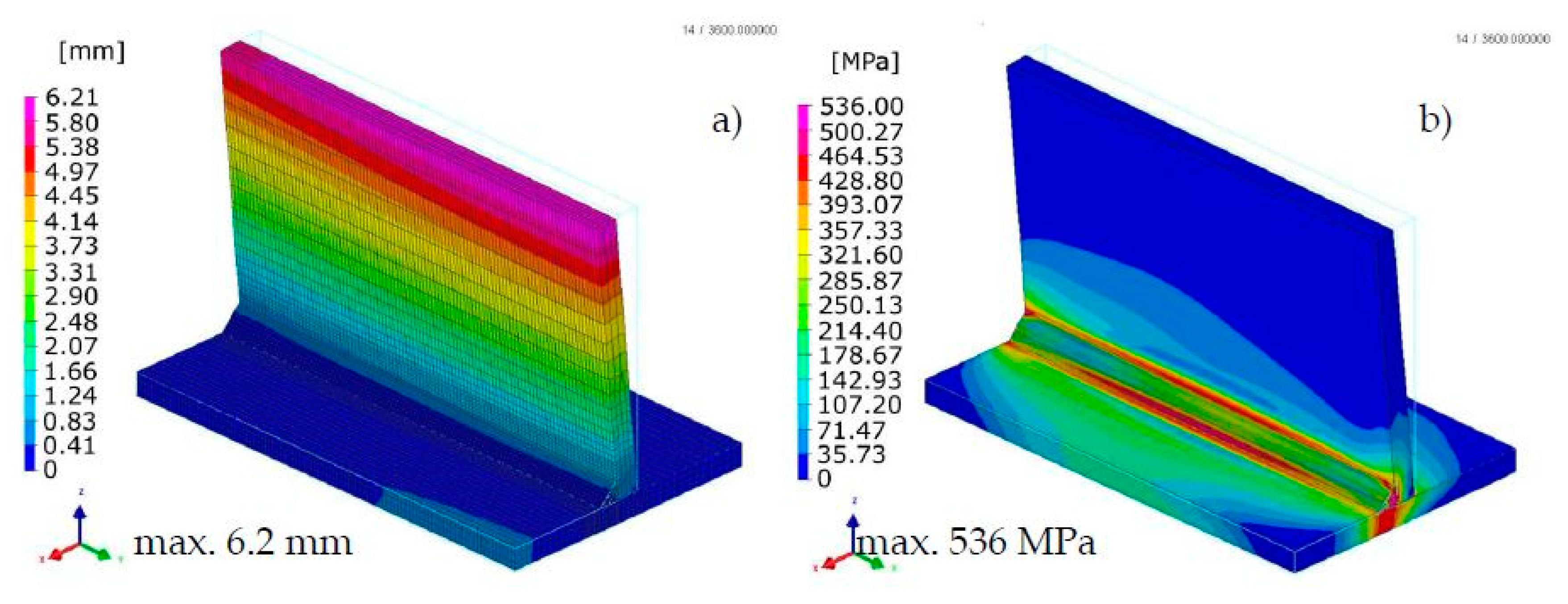

The analysis carried out using the “transient” technique is divided into three parts: preparation of the material base, calculation of thermal phenomena and related metallurgical changes as well as mechanical phenomena (i.e., stresses and displacement distributions, etc.) [

1,

2,

3,

4]. Taking into account the fact of performing calculations at each subsequent time, the user after completing the analysis receives a powerful set of thermo-metallurgical and mechanical data related to the simulated process. The price of such a complex solution is the extended duration of calculations. This is the main reason why the calculation of large welded structures with many welds uses other calculation techniques. However, such a large amount of data, including distribution of temperature fields, hardness, metallurgical phases, stresses and deformations makes it an ideal method by which the already mentioned local effects of the welding process can be determined. Based on the results of these analyses, it is also possible to conduct further simulations regarding the impact of external loads, i.e., forces, moments and pressures, as well as e.g., assessment of fatigue life of a structure based on the Dang Van criterion [

1,

2,

3,

4,

16,

18].

2.2. Macro-Bead Technique: Imposed Thermal Cycle

As it was already mentioned, calculations using the “transient” technique are practically impossible to use, from the point of view of the amount of data generated during them, in the case of numerical analyses of large or complex welded structures. In such cases, the “macro-bead” (MBD) technique is used [

1,

3,

4,

23,

24], which is in a way an extension of the “transient” technique and involves the use of a properly prepared thermal cycle immediately on one or several areas (elements) of the model simultaneously (

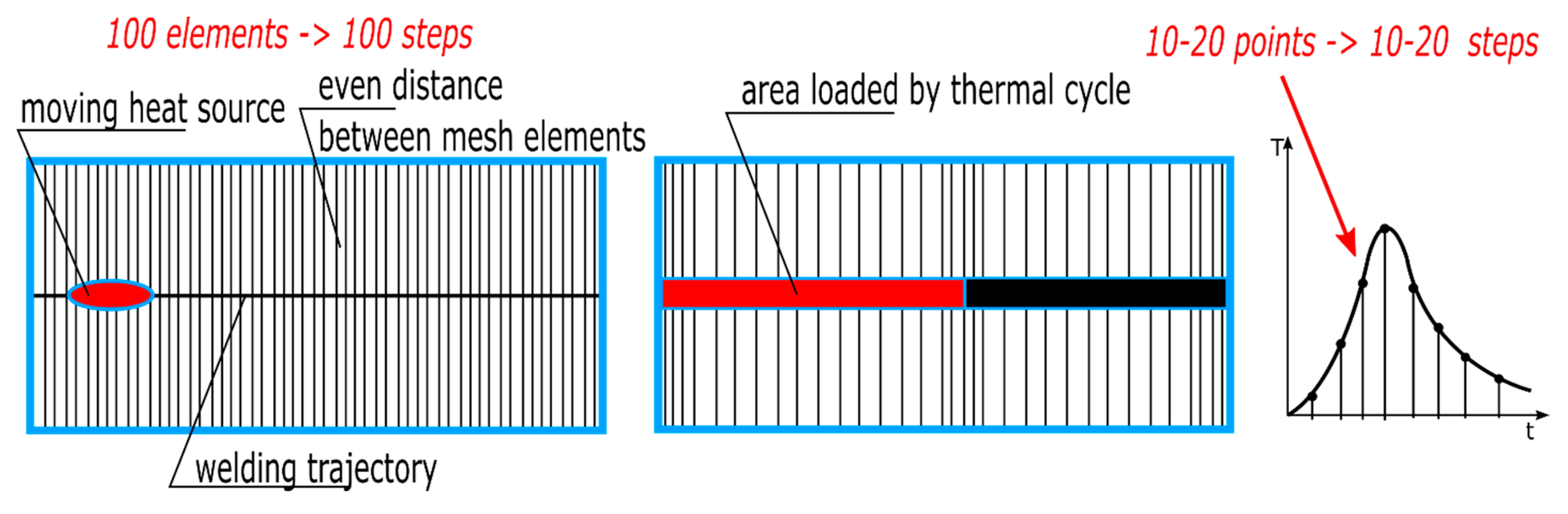

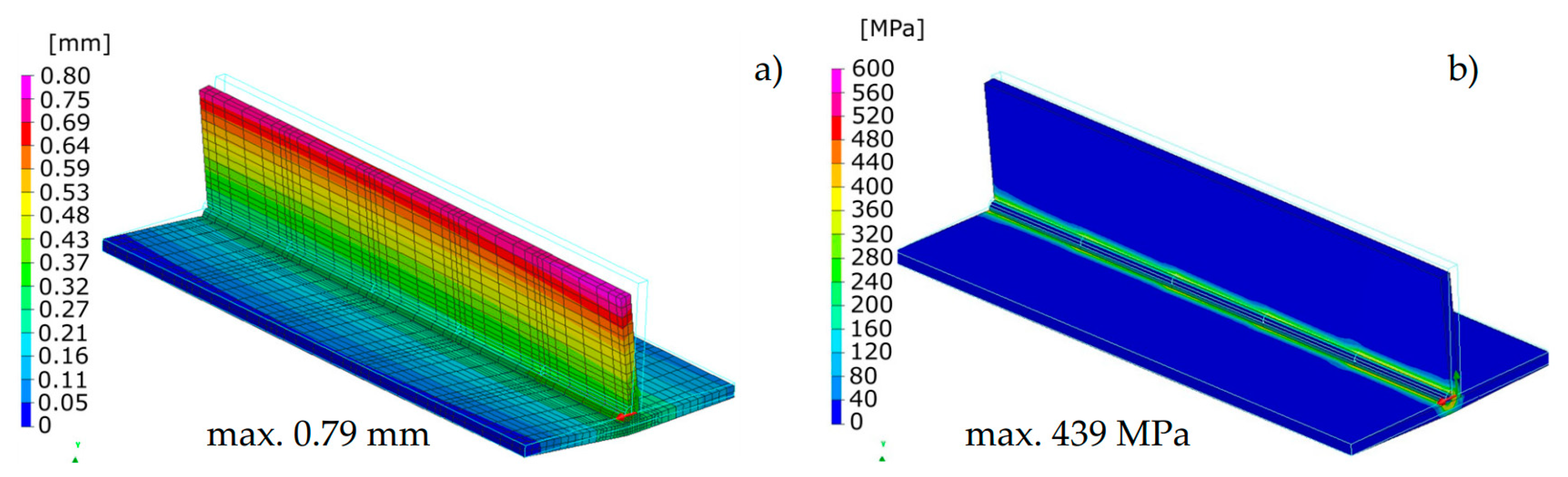

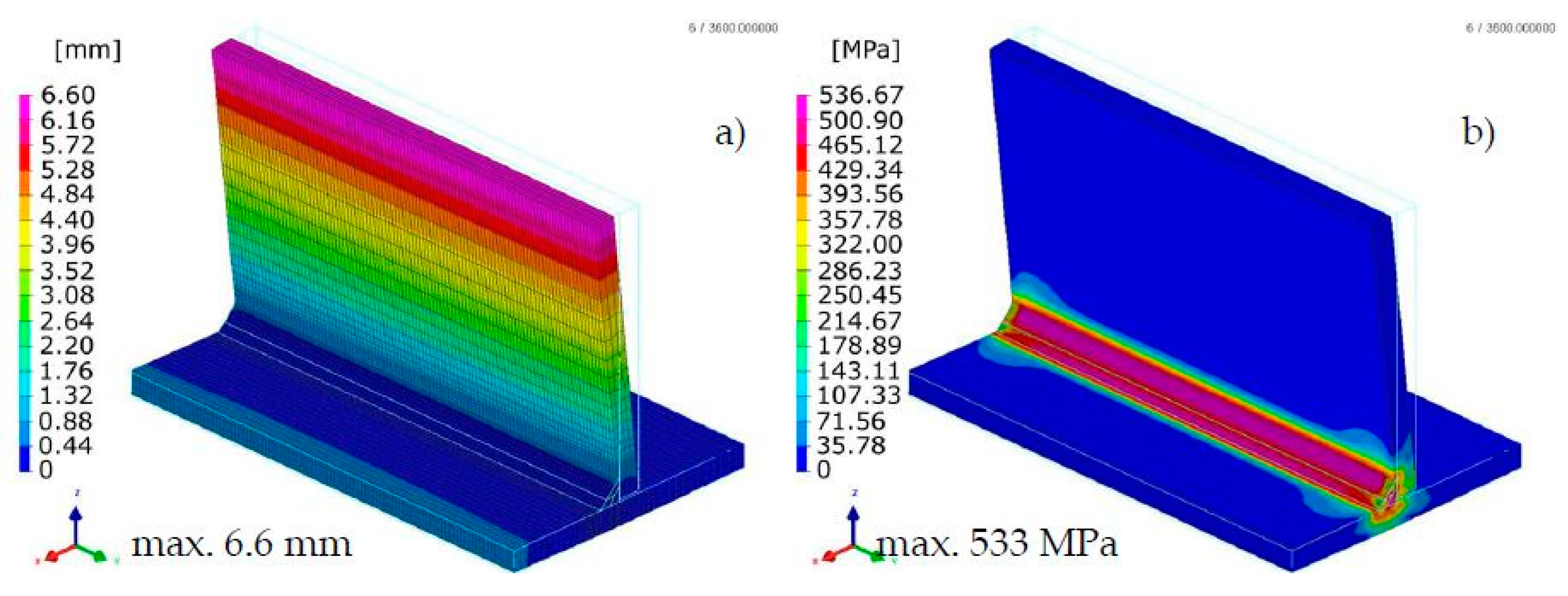

Figure 3).

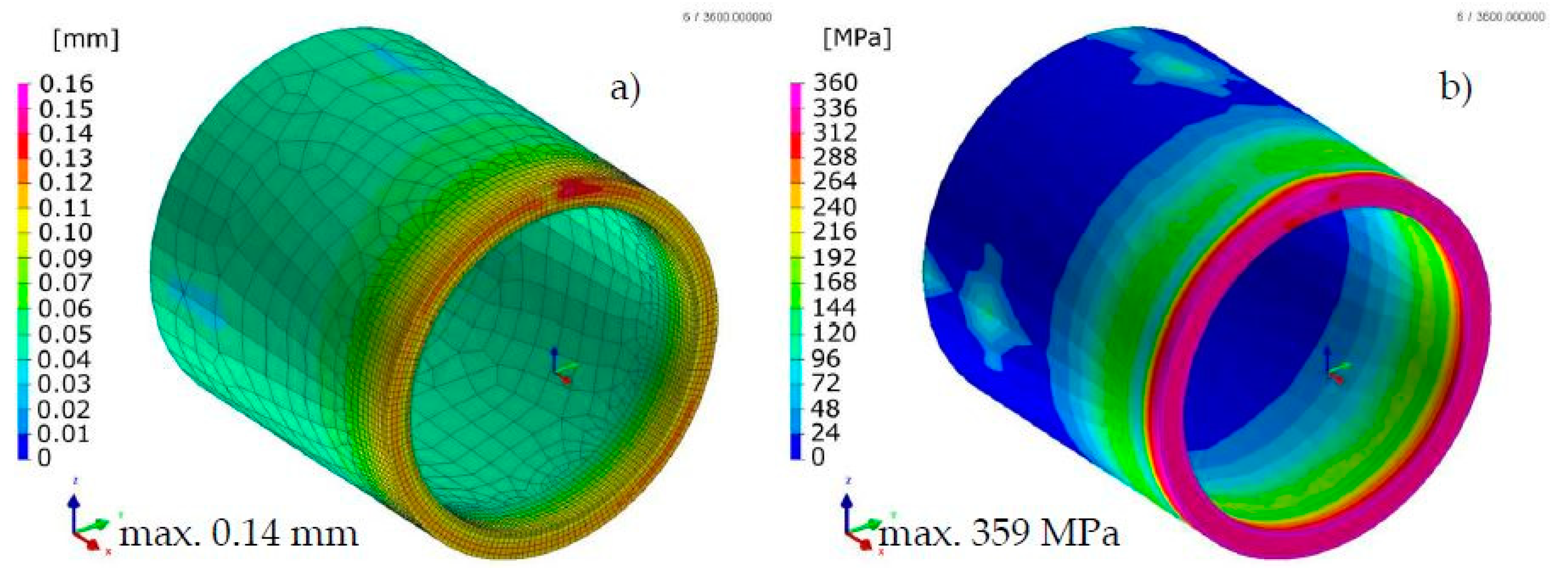

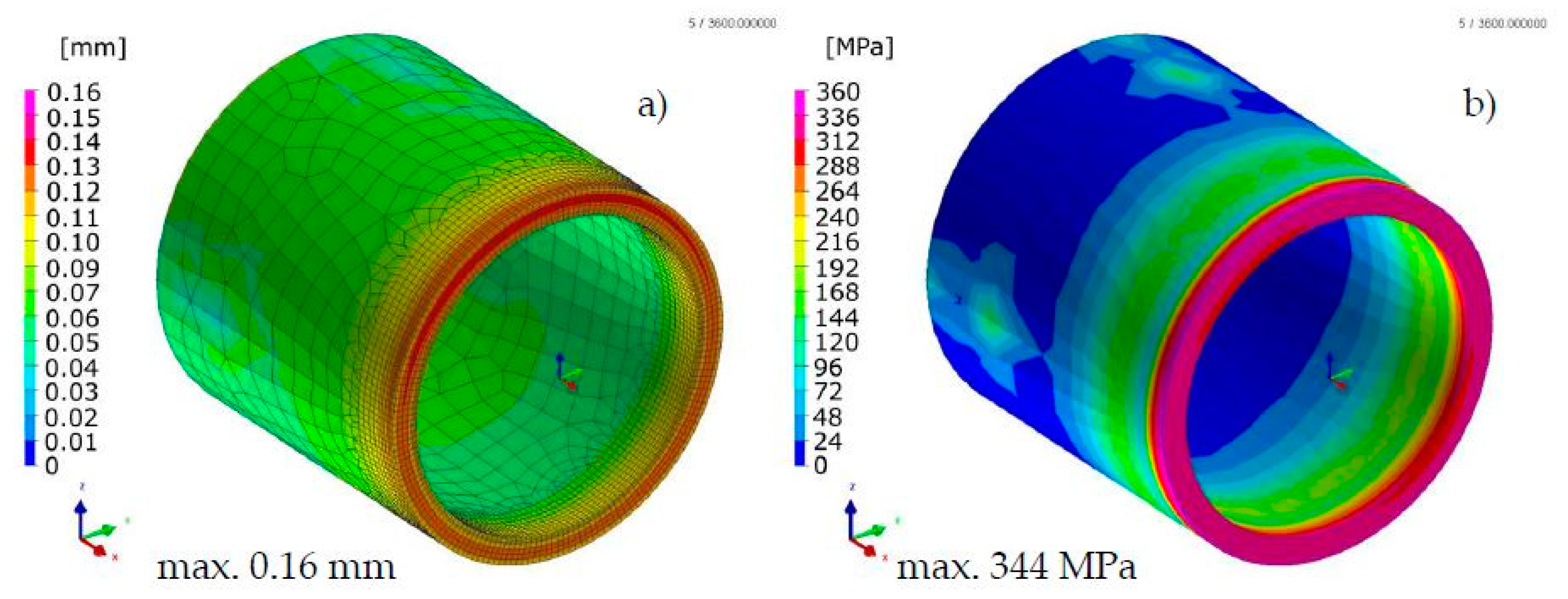

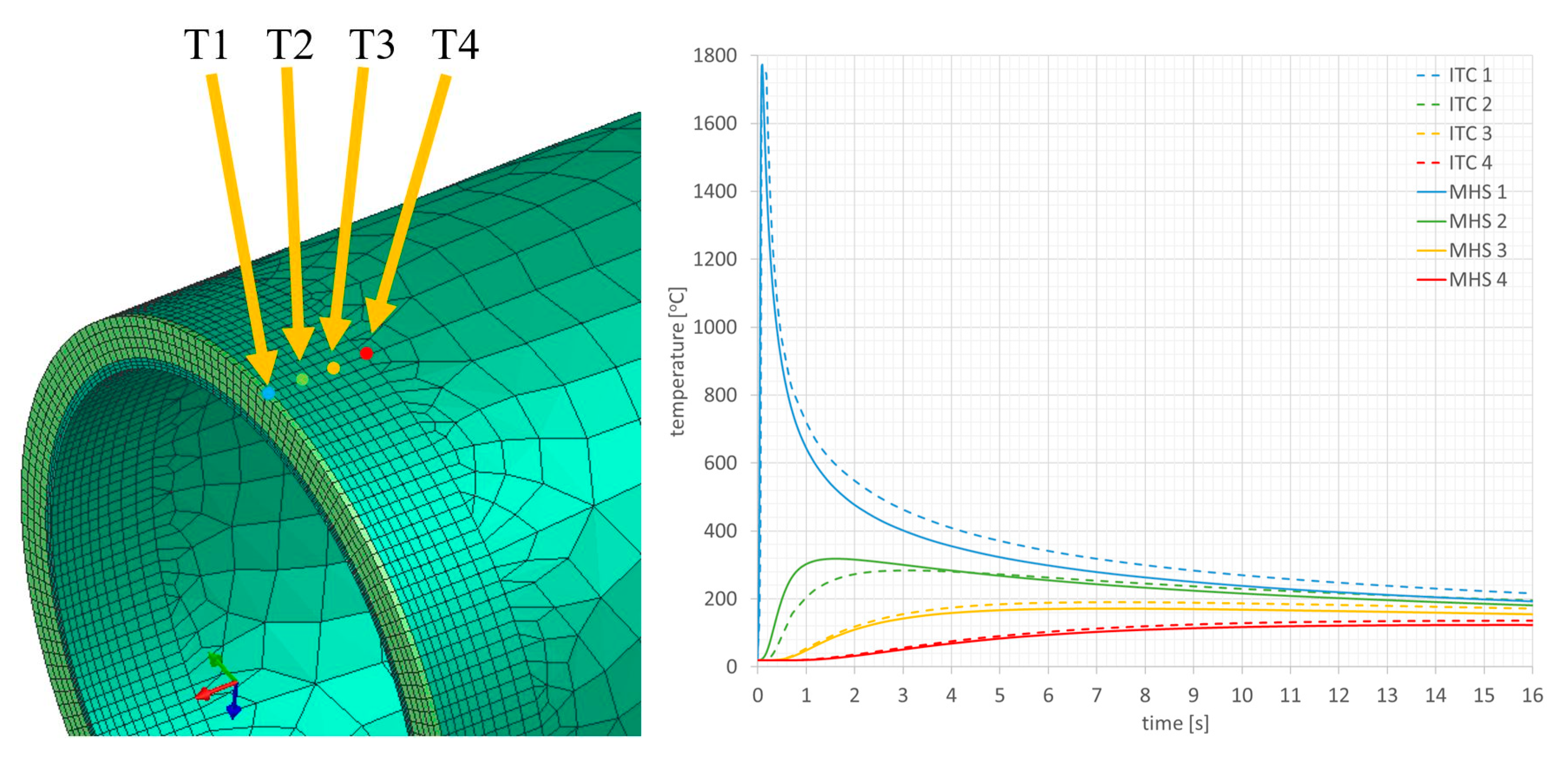

In this technique, the actual welding trajectory is divided into sub-areas so that the welding order and directions are maintained. The number of these sub-areas and the time step are defined on the basis of technological parameters of the welding process as well as the experience of the person working with this method [

1,

2,

3,

4]. The standard procedure is to prepare the thermal cycle based on a simple model “transient” analysis result (often using also 2D cross-section models) or as a result of thermocouple measurements. This cycle is then applied successively to the mentioned sub-areas of welds.

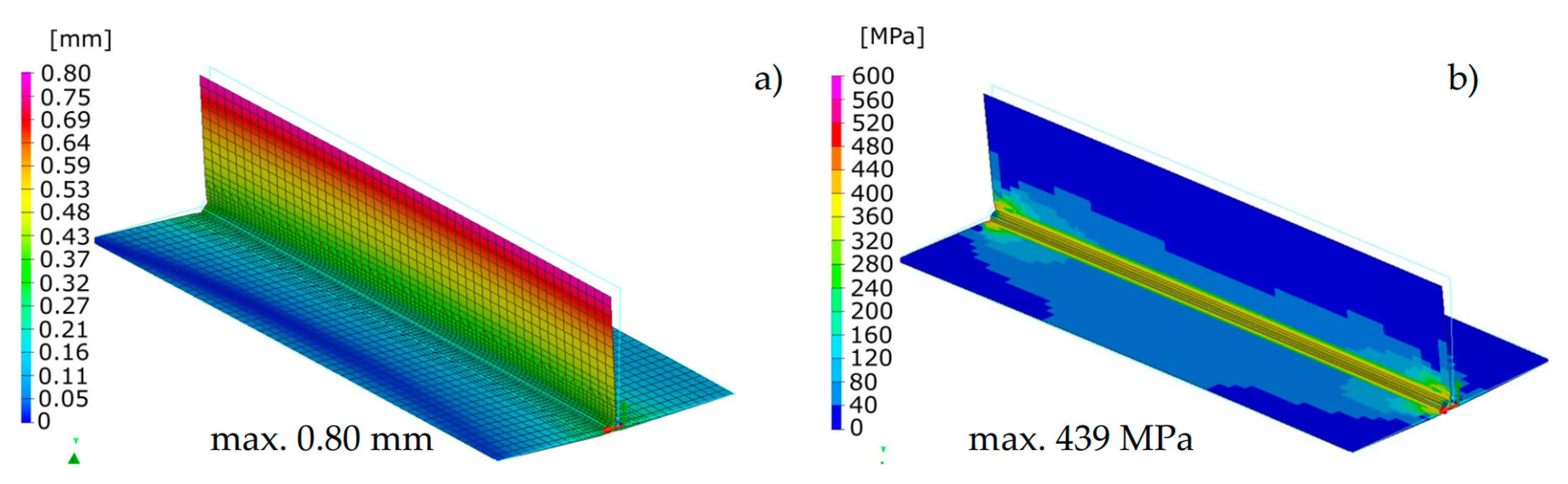

The difference is that in the case of the “transient” technique with a moving heat source, it is needed as many time steps (calculation cards) as there are elements in the grid on the welding trajectory. When applying the imposed thermal cycle, required are as many steps as the points describing the given thermal cycle in each of the sub-areas (

Figure 4). In addition, the mesh can be modified and divided into a significantly smaller number of finite elements because there are no temperature gradients in the middle of the weld section at the time of the applied thermal cycle. They only occur at the beginning and end of the bead (sub-section). Therefore, in the MBD technique, the mesh is only refined at the edges of the section of elements on which the thermal cycle is applied. In their center, due to the lack of thermal gradient, the mesh is much thinner. Thus, for example, 100-time steps in the calculation with the “transient” technique can be replaced with a maximum of 20–40 time steps in the MBD technique, which significantly reduces the calculation time (

Figure 4).

Based on the MBD technique, it is also possible to perform calculations using the “local–global” method [

1,

3,

4]. Its main idea is the assumption that the welding process leads to local changes in stresses distribution and plastic deformations, while the effect of this on a global scale is a specific state of deformations. The local effects of the welding process are determined in this case by means of precise calculation models of single welded joints using the “transient” or MBD techniques. When the joints are repetitive (welded with the same parameters), the calculations are significantly accelerated. The results of local analyses are then transferred to the global model to determine the total deformations of the structure. The limitation of this method, however, is that the results of the analyses carried out on the global model are only structural deformations as well as internal forces and moments under specific mounting conditions. The stresses level and distribution of individual metallurgical phases are determined by local models obtained as a result of analyses carried out using the “transient” or MBD technique [

1,

3,

4,

23,

24].

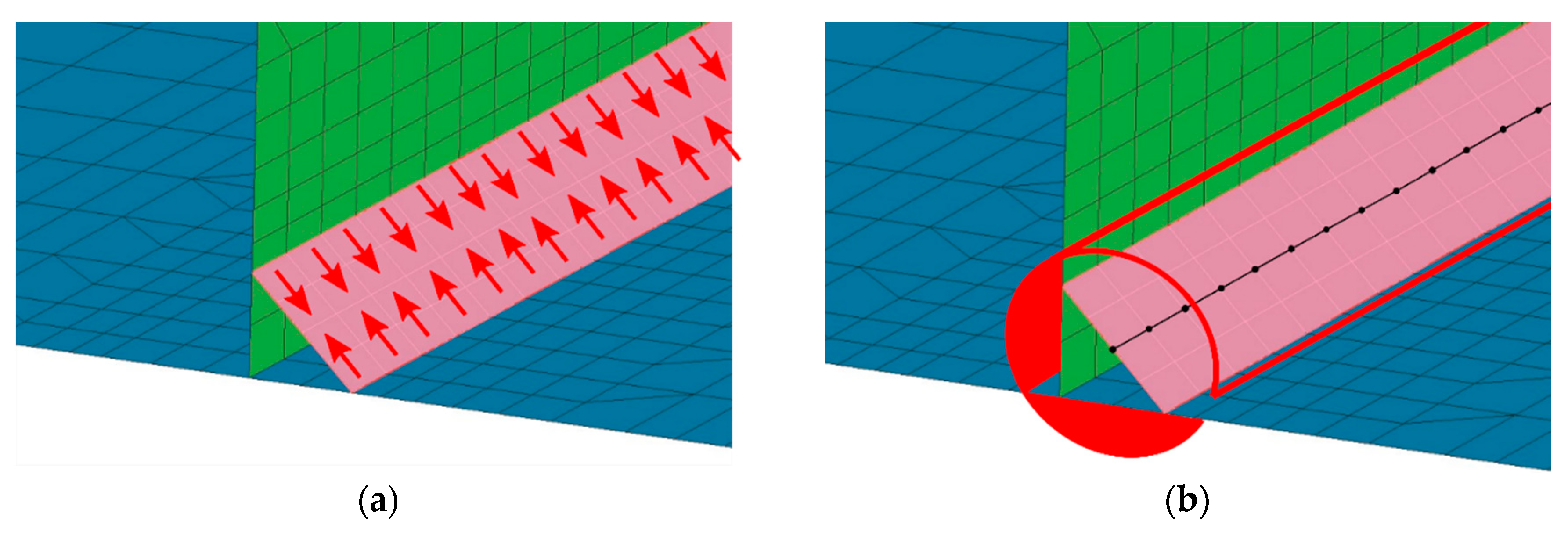

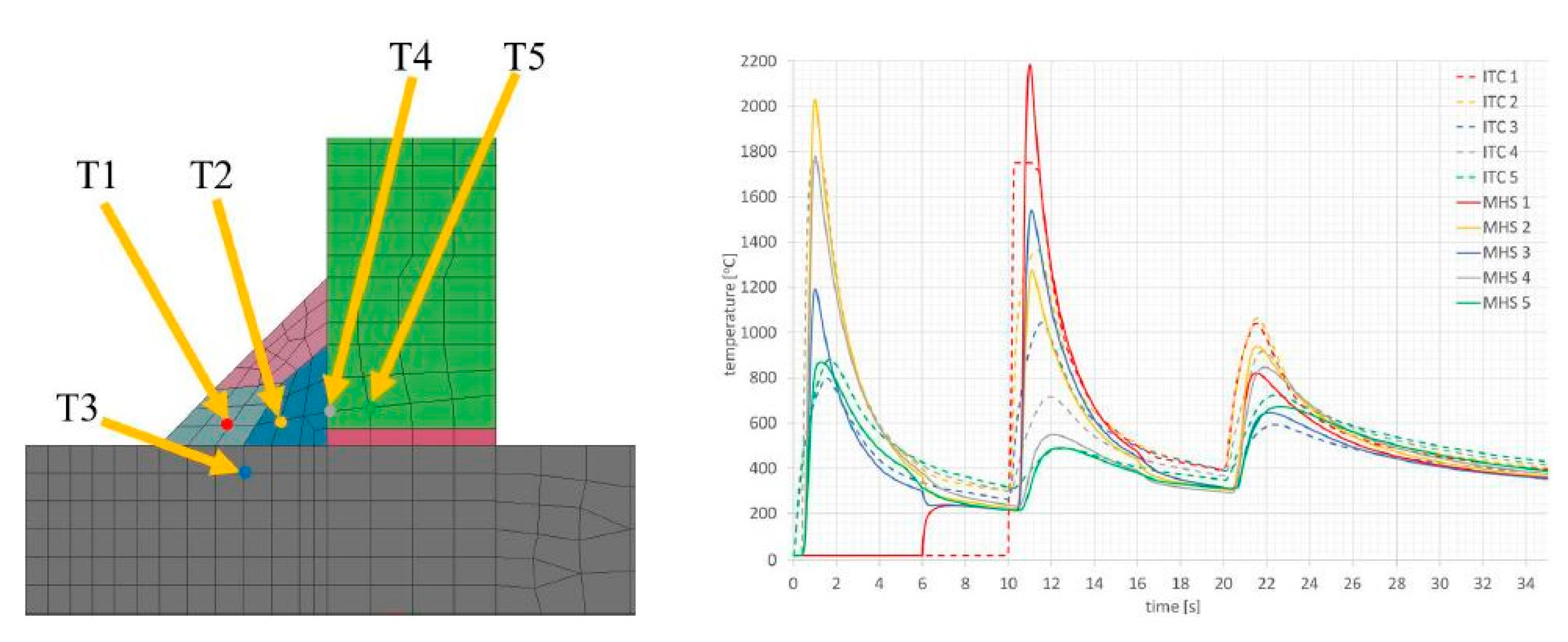

2.3. Shrinkage Technique: Distortion Engineering

The application of the “local–global” method in the case of very large and complicated welded constructions may have been problematic even despite the acceleration of calculations, which is provided by the use of the MBD technique [

1,

3,

4]. In this case, it is also possible to use the “shrinkage” technique, which, despite many simplifications, allows to determine the deformation of the structure in situations where the standard techniques and even MBD is not possible to carry out due to too long calculations time. In accordance with the assumptions of the “local–global” method, in the case of calculations carried out using the “shrinkage” technique, calculations of thermal phenomena and related metallurgical changes are not carried out. Only the results of the analysis of mechanical phenomena occurring during the welding process are used. In a simplified way, it can be described that the thermal cycle first causes an expansion of a certain area of the material as a result of its heating and then shrinkage, which is caused by specific cooling conditions and heat dissipation from this zone. If during the cooling process some areas of the joint are subject to shrinkage, it is the user’s task to find a representative value of the force that causes this shrinkage. In order to find this representative force causing the contraction, it is necessary to carry out the calibration process. For this reason, a special local model is created (for individual, selected joints from the whole structure), on which a classic “transient” analysis is performed and deformations are determined in specific places of the model. Then, the same model is calculated using the “shrinkage” technique. The deformations obtained as a result of the analysis are compared to the model from the classical analysis and the input data are calibrated to obtain similar values. The parameter that changes the value of the representative force for this calculation method is the radius of the pipe/sphere encompassing the model grid nodes at a certain distance from the assumed trajectory of the weld (weld axis) (

Figure 5). All mesh nodes inside the area enclosed by its radius will be subjected to contraction. By increasing the value of this radius, it is possible to set the conditions of the shrinkage impact in such a way that the results of the local model of this technique come close to the results obtained in the local analysis of the “transient” type. After the calibration, it can be transferred to the model of the entire structure. In the case where the structure has a large number of the same joints (joint type and lateral dimensions of the weld), due to its repeatability, the calculation process is significantly accelerated in time as it was the case with the “local–global” method using MBD techniques [

1,

2,

3,

4,

23,

24].

Analyses carried out using the “shrinkage” technique allows for quick analysis of structure deformations with a very large number of welded and welded joints, e.g., with a laser beam, as well as optimization of the order of their execution in terms of minimizing deformations. The method allows for an efficient search for a compromise between the clamping conditions (the degree of stiffening of the structure) and the level of stresses and deformations as well as determining the optimal welding sequence, which can additionally be a complicated, complex sequence of variable fastening of elements and increasing rigidity of the structure as the assembly progresses [

1,

3,

4,

23,

24].