Laser Surface Modification of Aluminium Alloy AlMg9 with B4C Powder

Abstract

1. Introduction

2. Experimental Procedure

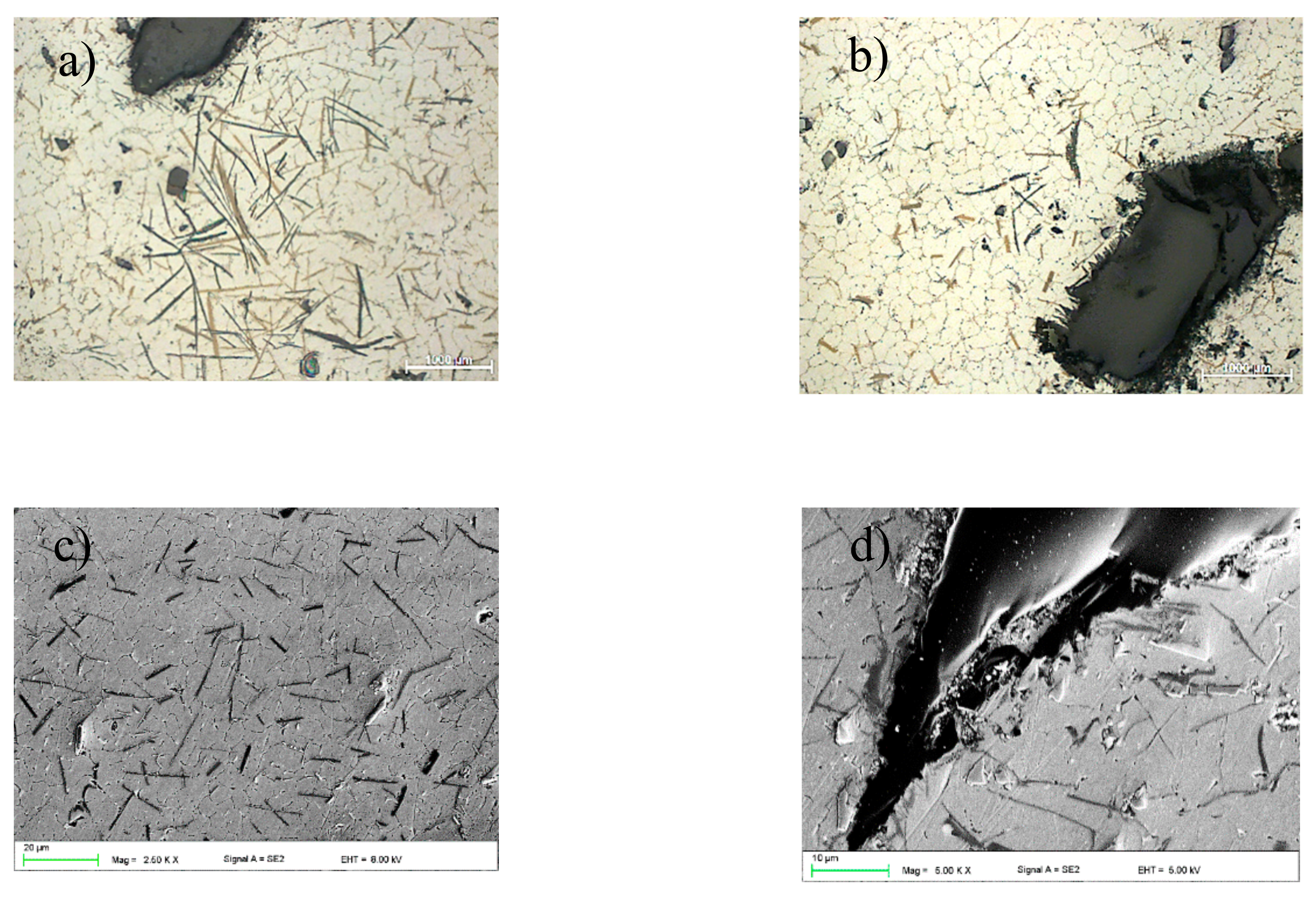

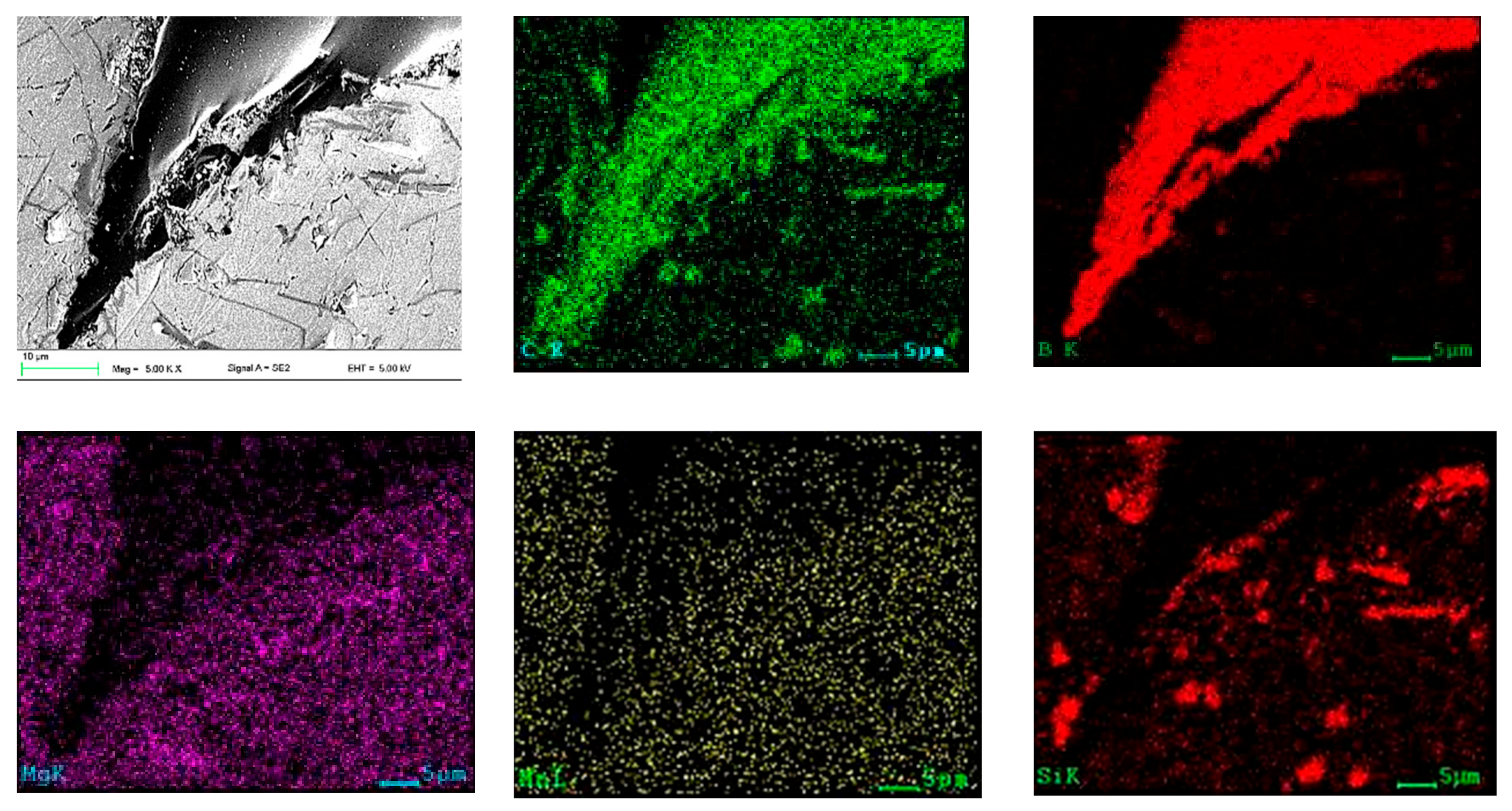

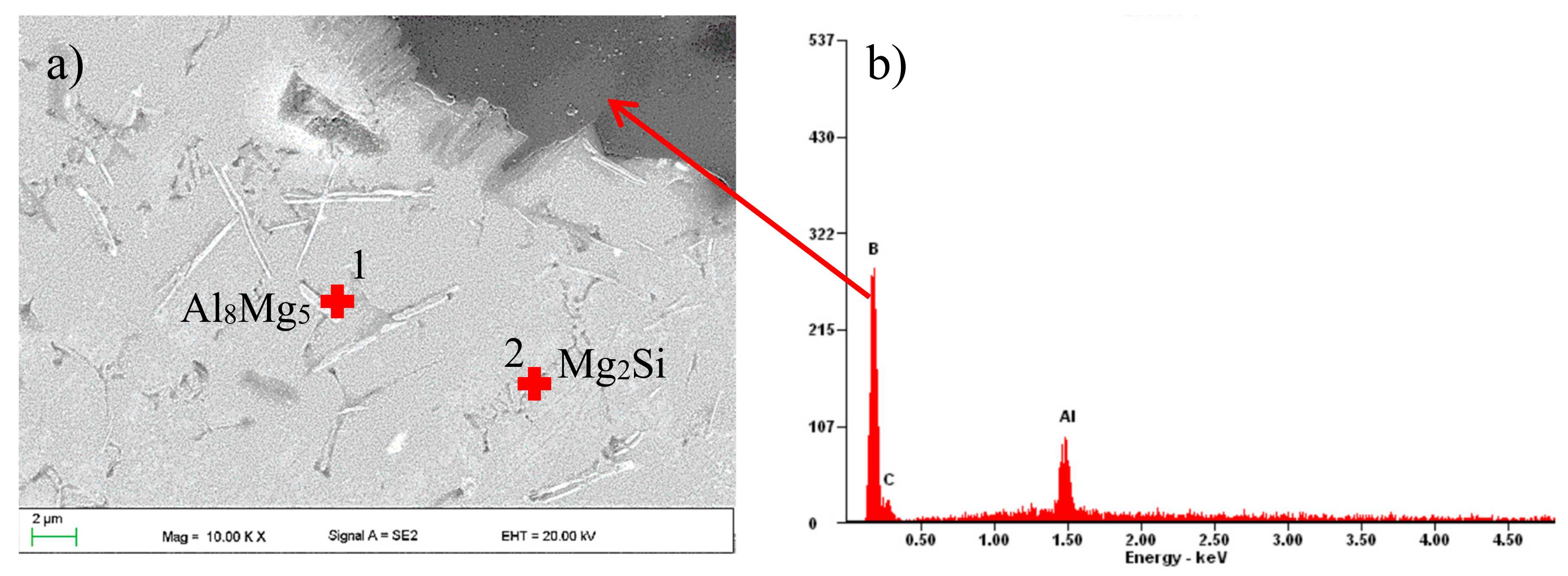

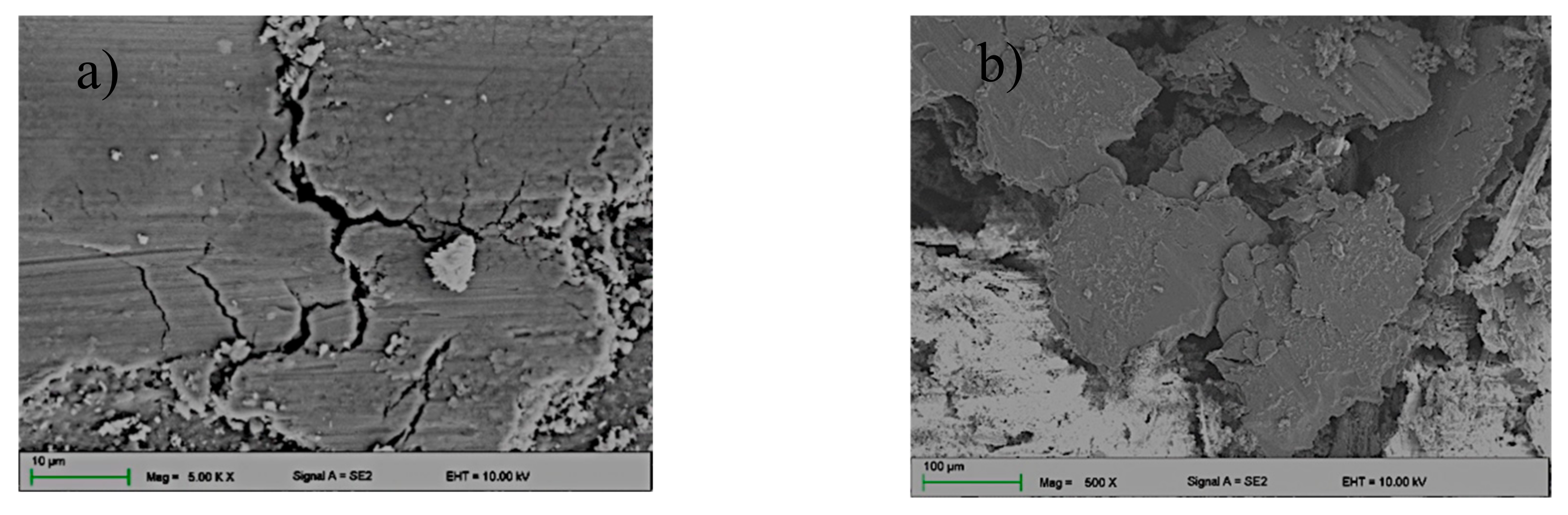

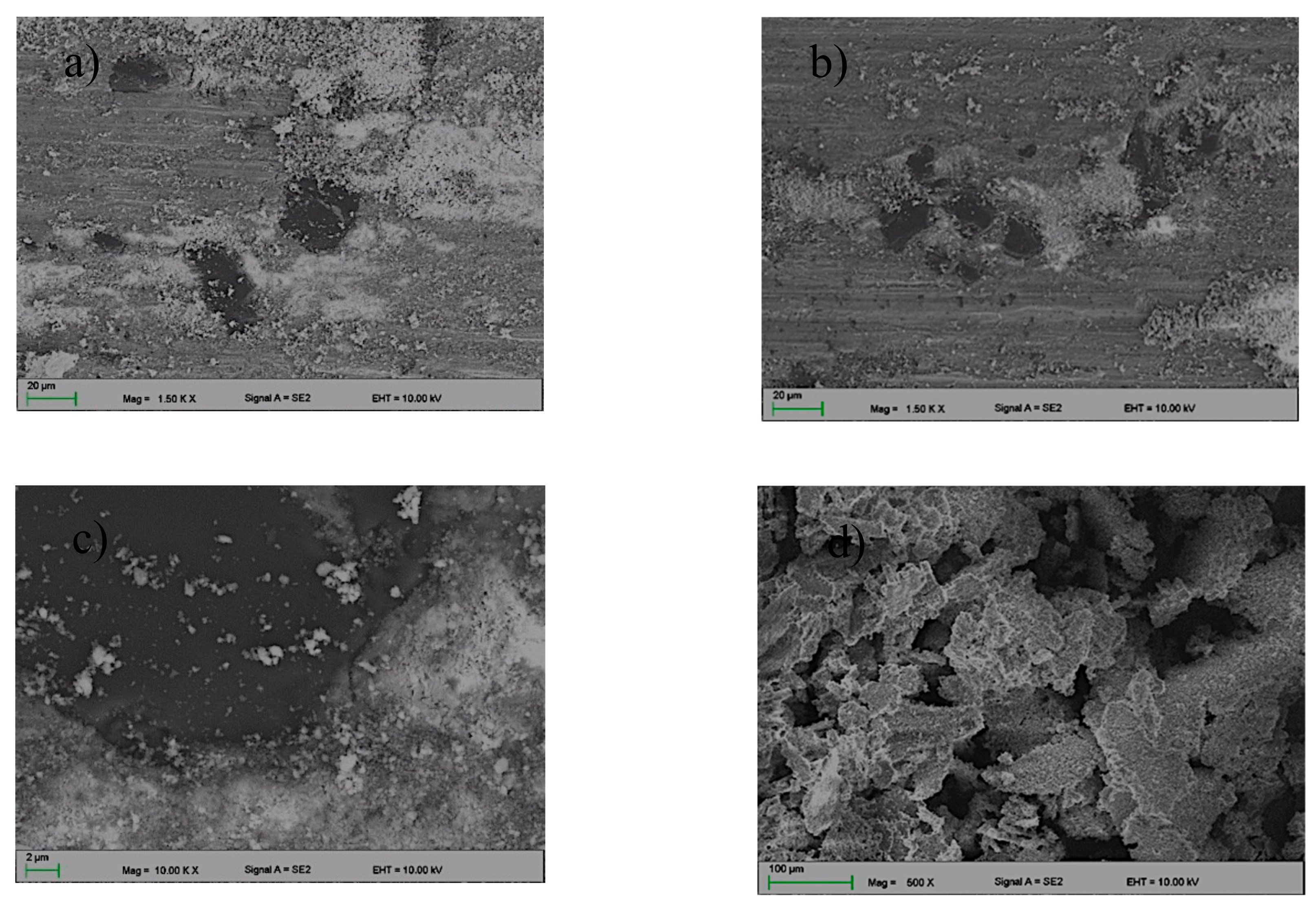

3. Results and Discussion

4. Conclusions

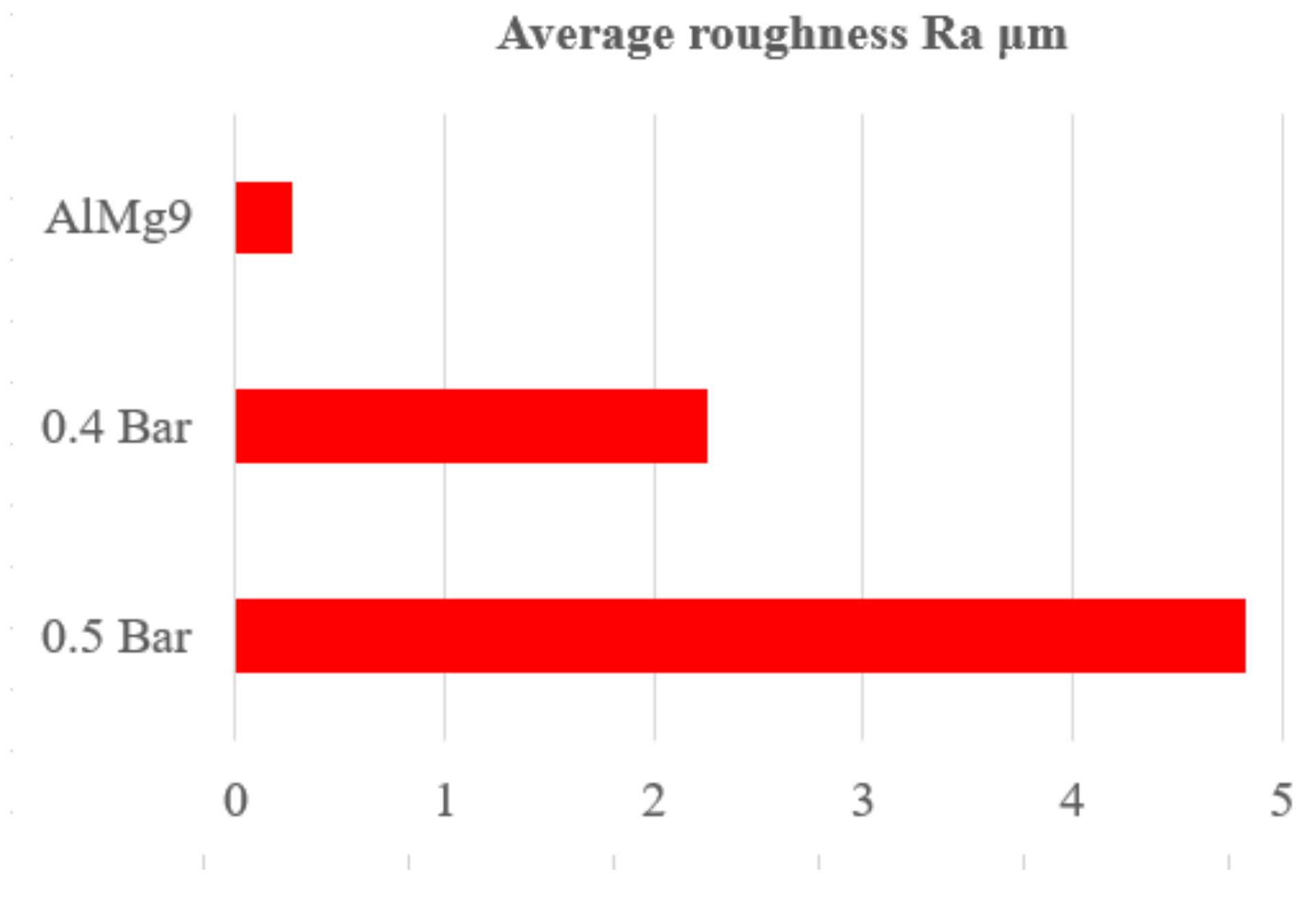

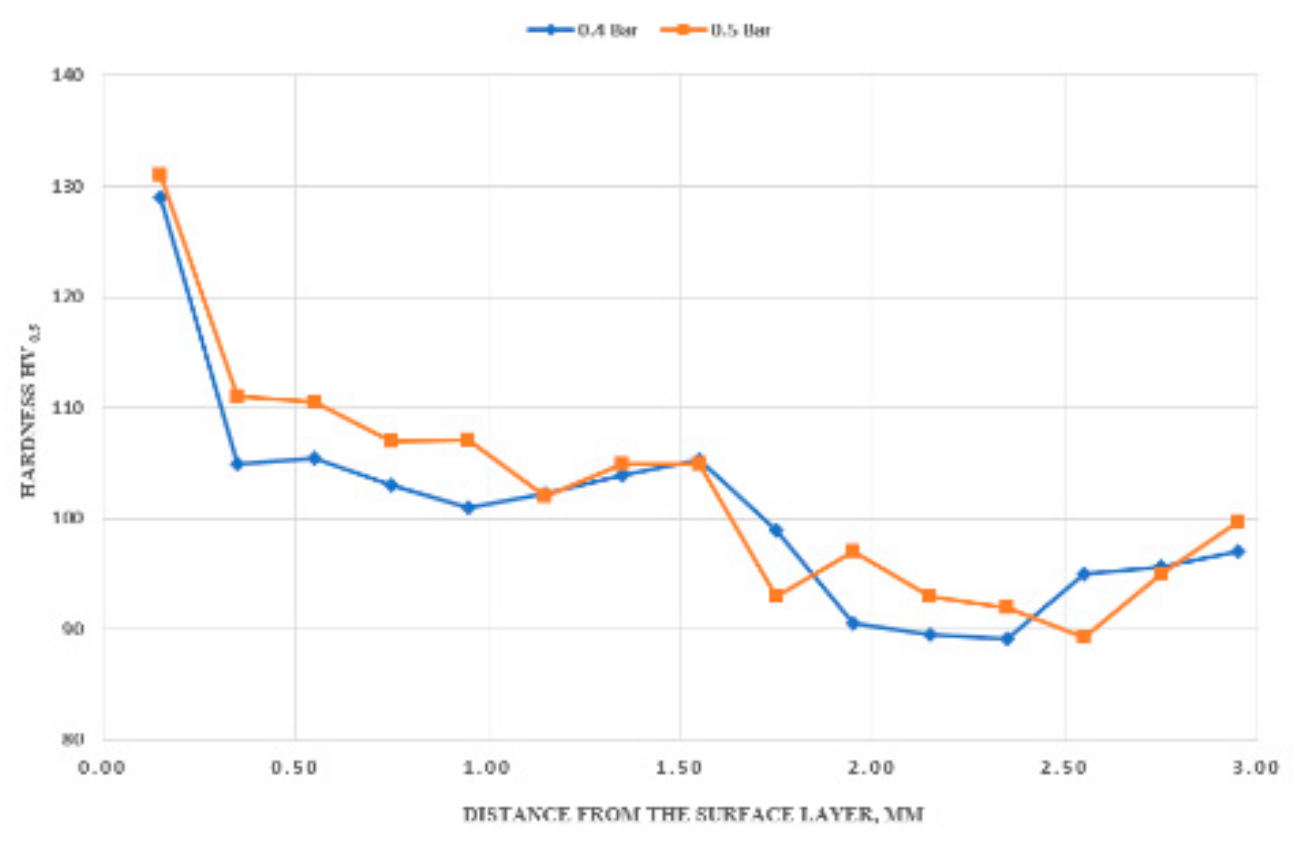

- The surface layer rich in alloying elements had a higher hardness than the substrate (128 HV0.5 for 0.4 Bar protective gas) and 131 HV0.5 (for 0.5 Bar protective gas).

- The abrasion resistance increased owing to an increase in the hardness of the surface layer. The obtained layers had friction coefficients of 0.52 (for 0.4 Bar protective gas) and 0.42 (for 0.5 Bar protective gas).

- An increase in tribological properties and a rougher surface (Ra = 4.82 µm) were found compared with the substrate before alloying (Ra = 0.27 µm).

- The hardness, roughness, and wear resistance measurements showed that the highest tribological properties of the obtained surface layer were achieved using 0.5 Bar protective gas (Ar) during alloying with B4C powder.

Author Contributions

Funding

Conflicts of Interest

References

- Labisz, K.; Tański, T.; Brytan, Z.; Pakieła, W.; Wiśniowski, M. Aluminium surface treatment with ceramic phases using diode laser. Appl. Phys. A Mater. 2016, 122, 1–10. [Google Scholar] [CrossRef]

- Tański, T.; Labisz, K.; Brytan, Z.; Jonda, E.; Sroka, M. Thermal fatigue influence of laser treated tool steel surface. Procedia Eng. 2014, 74, 429–442. [Google Scholar] [CrossRef]

- Tański, T.; Snopiński, P.; Prusik, K.; Sroka, M. The effects of room temperature ECAP and subsequent aging on the structure and properties of the Al-3%Mg aluminium alloy. Mater. Charact. 2017, 133, 185–195. [Google Scholar] [CrossRef]

- Pakieła, W.; Tański, T.; Pawlyta, M.; Pakieła, K.; Brytan, Z.; Sroka, M. The structure and mechanical properties of AlMg5Si2Mn alloy after surface alloying by the use of fiber laser. Appl. Phys. A Mater. 2018, 124, 263. [Google Scholar] [CrossRef]

- Jonda, E.; Brytan, Z.; Labisz, K.; Drygała, A. The influence of laser surface alloying on the thermal fatigue resistance of the hot work tool steels. Arch. Metall. Mater. 2016, 61, 963–968. [Google Scholar] [CrossRef][Green Version]

- Kulka, M.; Mikolajczak, D.; Makuch, N.; Dziarski, P.; Miklaszewski, A. Wear resistance improvement of austenitic 316L steel by laser alloying with boron. Surf. Coat. Technol. 2016, 291, 292–313. [Google Scholar] [CrossRef]

- Kwok, C.T.; Wong, P.K. Laser surface alloying of various engineering alloys for sliding wear and corrosion resistance. J. Laser Micro/Nanoeng. 2010, 5, 90–96. [Google Scholar] [CrossRef]

- Lisiecki, A. Titanium Matrix Composite Ti/TiN Produced by Diode Laser Gas Nitriding. Metals 2015, 5, 54–69. [Google Scholar] [CrossRef]

- Kulka, M.; Makuch, N.; Pertek, A.; Piasecki, A. Microstructure and properties of borocarburized and laser-modified 17CrNi6-6 steel. Opt. Laser Technol. 2012, 44, 872–881. [Google Scholar] [CrossRef]

- Rozmus-Gornikowska, M.; Kusinski, J.; Blicharski, M. The influence of the laser treatment on microstructure of the surface layer of an (X5CrNi18-10) austenitic stainless steel. Arch. Metall. Mater. 2011, 56, 717–721. [Google Scholar] [CrossRef]

- Lisiecki, A. Study of Optical Properties of Surface Layers Produced by Laser Surface Melting and Laser Surface Nitriding of Titanium Alloy. Materials 2019, 12, 3112. [Google Scholar] [CrossRef] [PubMed]

- Janicki, D. Improvement of wear resistance of stainless steel AISI 304L by diode laser surface alloying with chromium carbide. Appl. Mech. Mater. 2015, 809–810, 363–368. [Google Scholar] [CrossRef]

- Tanski, T.; Snopinski, P.; Borek, W. Strength and structure of AlMg3 alloy after ECAP and post-ECAP processing. Mater. Manuf. Process. 2017, 32, 1368–1374. [Google Scholar] [CrossRef]

- Król, M.; Staszuk, M.; Mikuszewski, T.; Kuc, D. Refinement effect of RE in light weight Mg-Li-Al alloys. J. Therm. Anal. Calorim. 2018, 134, 333–341. [Google Scholar] [CrossRef]

- Shinn, M. Basics of Lasers and Laser Optics. In Laser Processing of Materials Fundamentals Applications and Developments, 1st ed.; Schaaf, P., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 139, pp. 5–20. [Google Scholar]

- Tański, T. Determining of laser surface treatment parameters used for light metal alloying with ceramic powders. Mater. Werkst. 2014, 45, 333–343. [Google Scholar] [CrossRef]

- Rao, S.; Padmanabhan, G. Fabrication and mechanical properties of aluminium–boron carbide composites. Int. J. Mater. Biomater. Appl. 2012, 2, 15–18. [Google Scholar]

- Ogunlana, M.O.; Akinlabi, E.T. Surface Effect of Laser Power on Microstructural Evolution and Hardness Behaviour of Titanium Matrix Composites. In Proceedings of the World Congress on Engineering, London, UK, 29 June–1 July 2016; Volume 2. [Google Scholar]

- Tian, Y.S.; Chen, C.Z.; Chen, L.B.; Liu, J.H. Wear properties of alloyed layers produced by laser surface alloying of pure titanium with B4C and Ti mixed powders. J. Mater. Sci. 2005, 10, 4387–4390. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Patel, F.; Karatas, C. Laser controlled melting of H12 hot-work tool steel with B4C particles at the surface. Opt. Laser Technol. 2015, 74, 36–42. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Matthews, A.; Leyland, A.; Karatas, C.; Akhtar, S.S.; Aleem, B.J. Laser surface modification treatment of aluminium bronze with B4C. Appl. Surf. Sci. 2012, 263, 804–809. [Google Scholar] [CrossRef]

- Hlawka, F.; Cornet, A. Laser surface alloying with a CO2 laser: Surface hardening of AISI 4135 H chromium–molybdenum steel. Adv. Eng. Mater. 2003, 5, 641–647. [Google Scholar] [CrossRef]

- Borowski, J. Obróbka laserowa warstw wierzchnich stopów aluminium. Projektowanie i Konstrukcje Inżynierskie 2013, 3, 1–4. (In Polish) [Google Scholar]

- Pakieła, W.; Dobrzański, L.A.; Labisz, K.; Tański, T.; Basa, K.; Roszak, M. The effect of laser Surface treatment on structure and mechanical properties aluminium alloy ENAC-AlMg9. Arch. Metall. Mater. 2016, 61, 1343–1350. [Google Scholar] [CrossRef]

- Jiru, W.G.; Sankar, M.R.; Dixit, U.S. Laser Surface Alloying of Copper, Manganese, and Magnesium with Pure Aluminium Substrate. J. Mater. Eng. Perform. 2016, 25, 1172–1181. [Google Scholar] [CrossRef]

- Irek, P. Laser surface alloying of AlSi7Cu4MgMn aluminium alloy with silicon carbide. Inst. Weld. Bull. 2014, 58, 42–48. [Google Scholar]

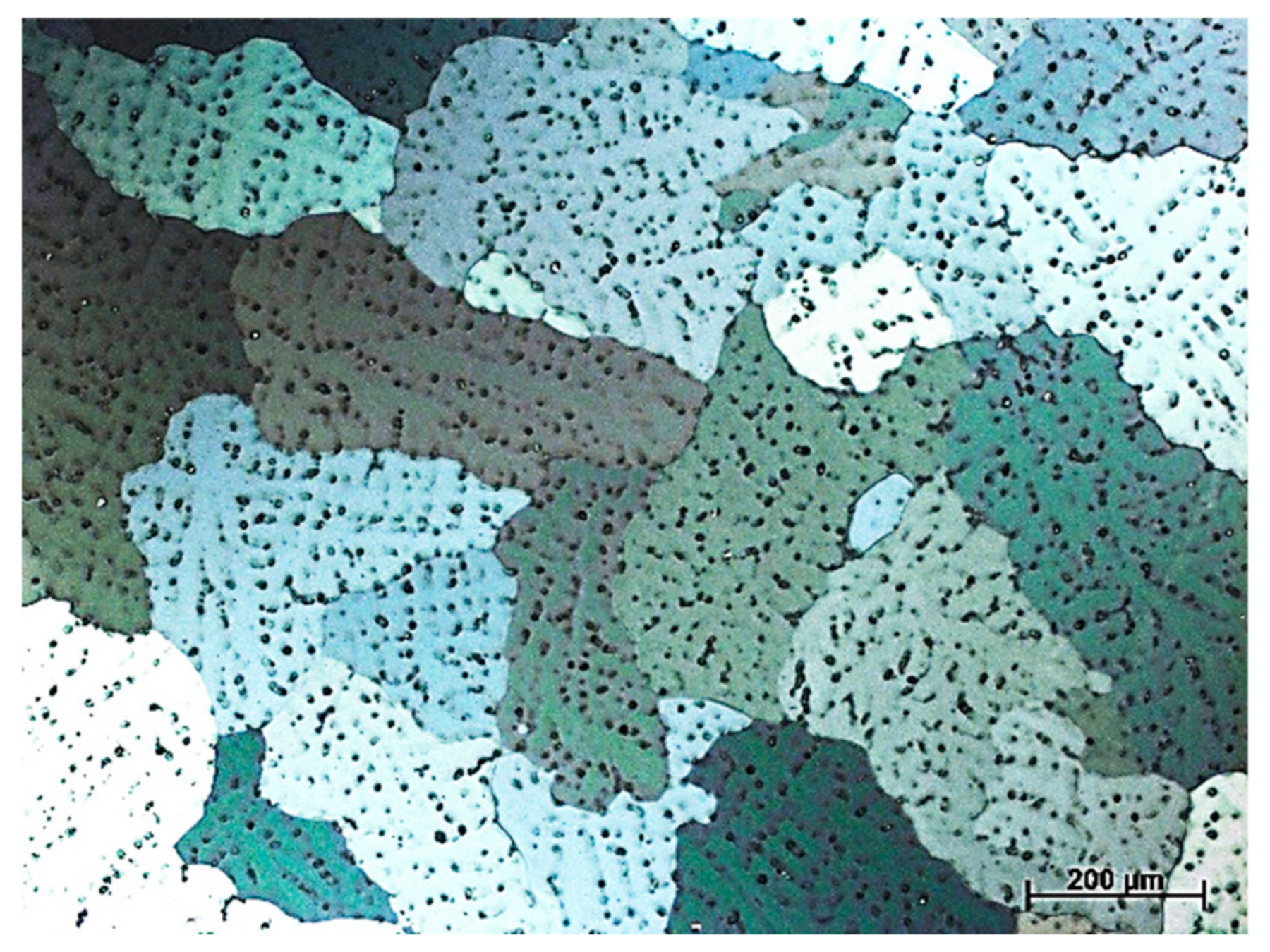

- Snopiński, P.; Król, M.; Tański, T.; Krupińska, B. Effect of cooling rate on microstructural development in alloy ALMG9. J. Therm. Anal. Calorim. 2018, 133, 379–390. [Google Scholar] [CrossRef]

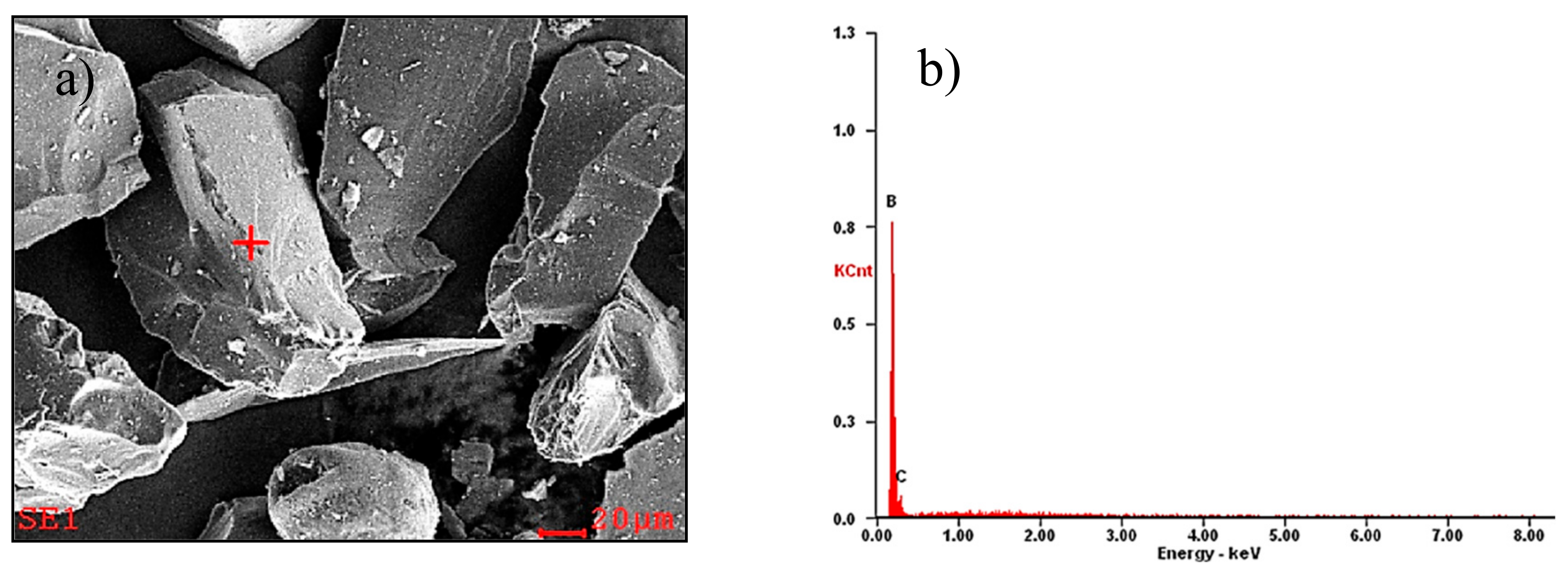

- Boron Carbide (B4C)—Properties and Information about Boron Carbide. Available online: https://www.azom.com/article.aspx?ArticleID=75 (accessed on 28 December 2019).

- Harlin, P.; Carlsson, P.; Bexell, U.; Olsson, M. Influence of surface roughness of PVD coatings on tribological performance in sliding contacts. Surf. Coat. Technol. 2006, 201, 4253–4259. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Meratian, M.; Emadi, R.; Najarian, A.R. Comparison of microstructural and mechanical properties of Al–TiC, Al–B4C and Al–TiC–B4C composites prepared by casting techniques. Mater. Sci. Eng. A Struct. 2013, 560, 278–287. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Elaya Peruma, A. Influence of B4C on the tribological and mechanical properties of Al 7075–B4C composites Composites. Engineering 2013, 54, 146–152. [Google Scholar] [CrossRef]

- Zhu, X.; Dong, H.; Lu, K. Coating different thickness nickel–boron nanolayers onto boron carbide particles. Surf. Coat. Technol. 2008, 202, 2927–2934. [Google Scholar] [CrossRef]

| Elements | Si | Mn | Zn | Mg | Al |

|---|---|---|---|---|---|

| AlMg9 | 1.32 | 0.50 | 0.20 | 9.24 | REST |

| Property | Value |

|---|---|

| Density, g/cm3 | 2.52 |

| Melting point, °C | 2445 |

| Knoop hardness (100g), kg/mm2 | 2900–3580 |

| Young’s modulus, GPa | 450–470 |

| Electrical conductivity (at 25 °C) | 1.40 |

| Parameter | Value |

|---|---|

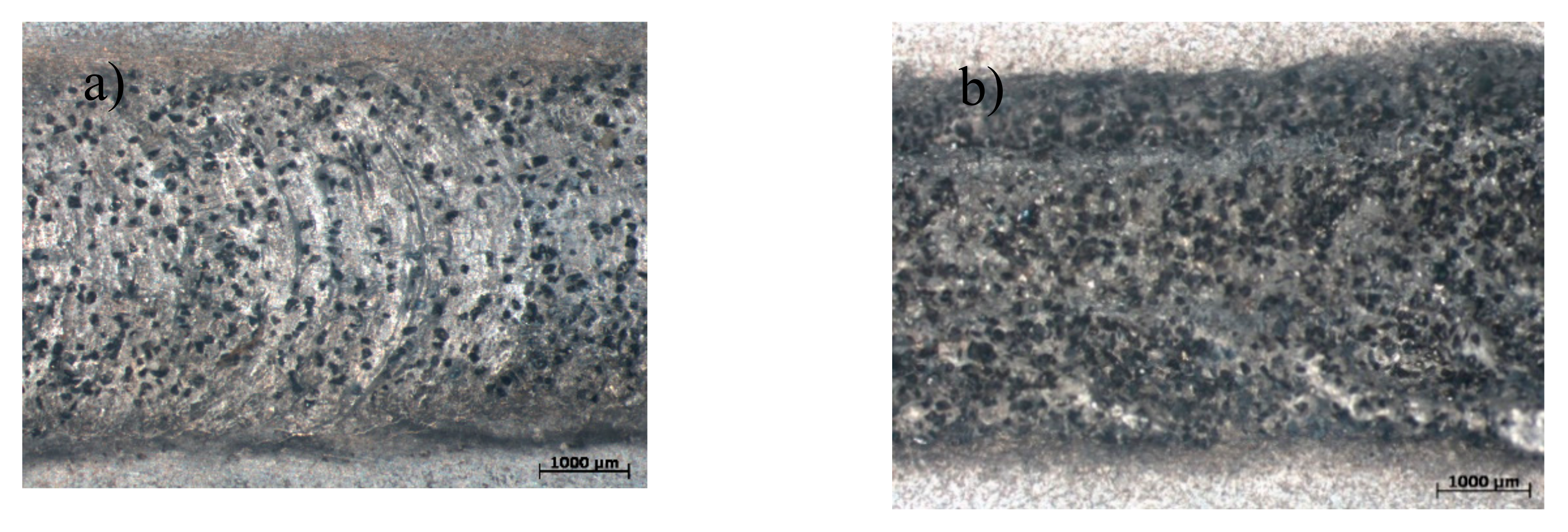

| Laser beam power, kW | 1.5 |

| Protective gas, Bar | 0.4 |

| 0.5 | |

| The share of supplied powder, g/min | 15 |

| Laser beam scanning speed, m/min | 0.2 |

| Circle spot, mm | 5 |

| Wavelength λ, nm | 1070 |

| Parameter | Value |

|---|---|

| Load, N | 15 |

| Linear speed, cm/s | 5 |

| Distance, m | 50 |

| Measuring distance, mm | 6 |

| Counter specimen | ball Al2O3 |

| Substrate | Dimensions of the Wear Track | ||||

|---|---|---|---|---|---|

| Volume, μm2 | Width, mm | Depth, µm | |||

| AlMg9 | 193,603 | 1.99 | 55.5 | ||

| AlMg9 +B4C | Protective gas, Bar | 0.4 | 38,619 | 1.15 | 48.7 |

| 0.5 | 26,313 | 1.2 | 43.2 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sroka, M.; Jonda, E.; Pakieła, W. Laser Surface Modification of Aluminium Alloy AlMg9 with B4C Powder. Materials 2020, 13, 402. https://doi.org/10.3390/ma13020402

Sroka M, Jonda E, Pakieła W. Laser Surface Modification of Aluminium Alloy AlMg9 with B4C Powder. Materials. 2020; 13(2):402. https://doi.org/10.3390/ma13020402

Chicago/Turabian StyleSroka, Marek, Ewa Jonda, and Wojciech Pakieła. 2020. "Laser Surface Modification of Aluminium Alloy AlMg9 with B4C Powder" Materials 13, no. 2: 402. https://doi.org/10.3390/ma13020402

APA StyleSroka, M., Jonda, E., & Pakieła, W. (2020). Laser Surface Modification of Aluminium Alloy AlMg9 with B4C Powder. Materials, 13(2), 402. https://doi.org/10.3390/ma13020402