Compressive Behavior of (Cu0.47Zr0.45Al0.08)98Dy2 Bulk Metallic Glass at Different Strain Rates

Abstract

1. Introduction

2. Materials and Experimental Program

3. Results and Discussion

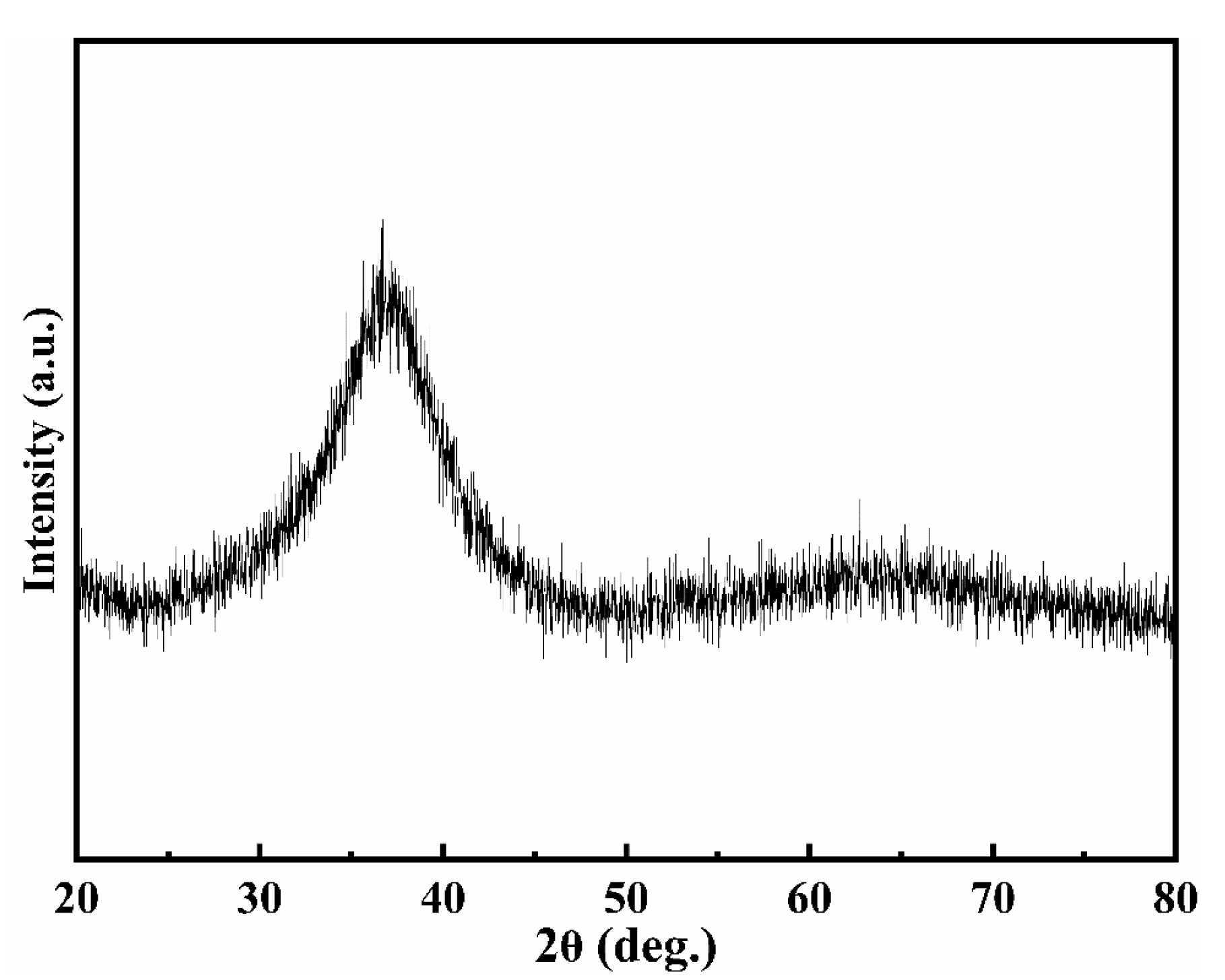

3.1. Structure Analysis of (Cu0.47Zr0.45Al0.08)98Dy2 BMG

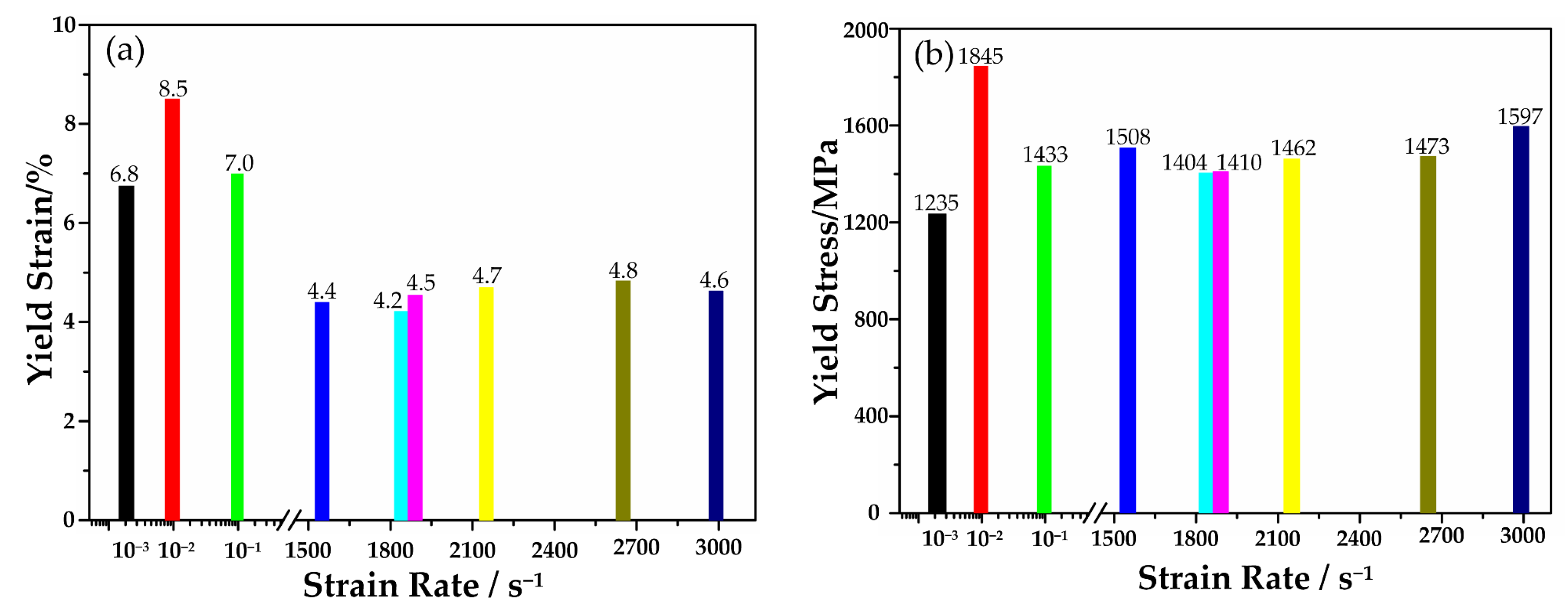

3.2. Mechanical Properties

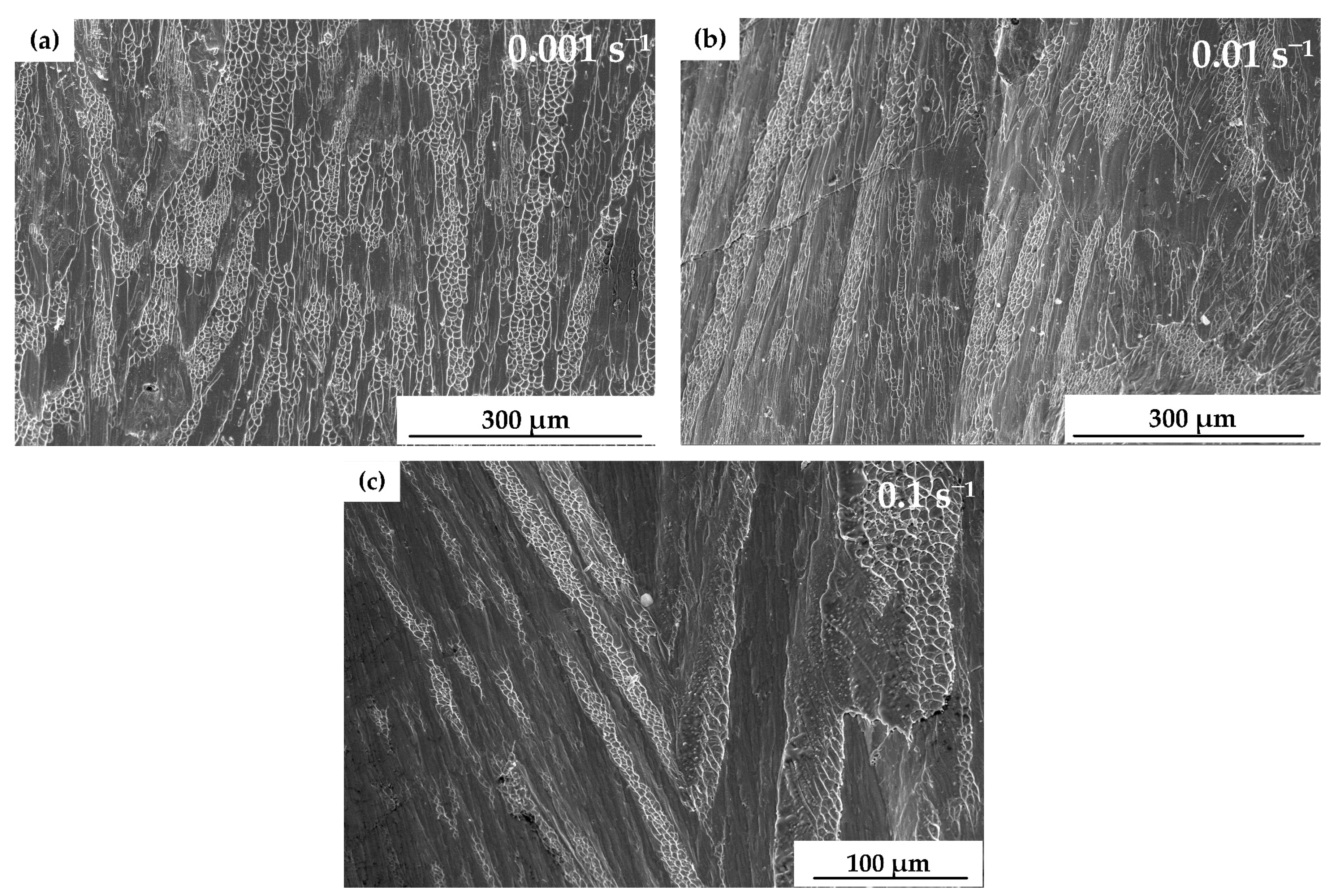

3.3. Fracture Behavior

4. Conclusions

- In the quasi-static compressive tests, the yield stress of (Cu0.47Zr0.45Al0.08)98Dy2 BMG increased from 1234 MPa to 1844 MPa when the strain rate increased from 0.001 s−1 to 0.01 s−1, and the yield stress decreased to 1430 MPa at the strain rate of 0.1 s−1.

- In the dynamic compressive tests, when the strain rate increased from 1550 s−1 to 2990 s−1, the yield stress of (Cu0.47Zr0.45Al0.08)98Dy2 BMG first decreased from 1508 MPa to 1404 MPa, and then increased to 1593 MPa.

- In the quasi-static compressive tests, the fracture exhibited a typical compressive shear fracture: a vein-like pattern, and vein-like patterns were distributed mainly along one direction, which indicated that the fracture occurred in the pure shear mode.

- In the dynamic compressive tests, vein-like patterns were also observed on the fracture surface, and vein-like patterns were distributed without clear direction, and within the strain rate range in this research, the higher the strain rate, the longer the vein-like pattern could be observed. Under strain rates of 2650 s−1 and 2990 s−1, rough regions were observed in the fracture surface. The fracture surfaces indicated that fracture occurred in the pure shear mode with strain rates below 2100 s−1, whereas shear fracture and normal fracture occurred simultaneously under strain rates of 2650 s−1 and 2990 s−1.

Author Contributions

Funding

Conflicts of Interest

References

- Löffler, J.F. Bulk metallic glasses. Intermetallics 2003, 11, 529–540. [Google Scholar] [CrossRef]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. R Rep. 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Lin, H.; Wu, J.K.; Wang, C.; Lee, P. The corrosion behavior of mechanically alloyed Cu–Zr–Ti bulk metallic glasses. Mater. Lett. 2008, 62, 2995–2998. [Google Scholar] [CrossRef]

- Lee, P.-Y.; Cheng, Y.-M.; Chen, J.-Y.; Hu, C.-J. Formation and Corrosion Behavior of Mechanically-Alloyed Cu–Zr–Ti Bulk Metallic Glasses. Metals 2017, 7, 148. [Google Scholar] [CrossRef]

- Yu, L.; Tang, J.; Wang, H.; Wang, Y.; Qiao, J.; Apreutesei, M.; Normand, B. Corrosion behavior of bulk (Zr58Nb3Cu16Ni13Al10)100-xYx (x = 0, 0.5, 2.5 at.%) metallic glasses in sulfuric acid. Corros. Sci. 2019, 150, 42–53. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Q.; Inoue, A. Fabrication of Cu–Zr–Ag–Al glassy alloy specimens with a diameter of 20 mm by water quenching. J. Mater. Res. 2008, 23, 1452–1456. [Google Scholar] [CrossRef]

- Inoue, A.; Zhang, W.; Zhang, T.; Kurosaka, K. High-strength Cu-based bulk glassy alloys in Cu–Zr–Ti and Cu–Hf–Ti ternary systems. Acta Mater. 2001, 49, 2645–2652. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.; Kato, H.; Inoue, A. High-strength Cu-based crystal-glassy composite with enhanced ductility. Appl. Phys. Lett. 2004, 84, 1088–1089. [Google Scholar] [CrossRef]

- Hajlaoui, K.; Doisneau, B.; Yavari, A.; Botta, W.J.; Zhang, W.; Vaughan, G.; Kvick, Å.; Inoue, A.; Greer, A. Unusual room temperature ductility of glassy copper–zirconium caused by nanoparticle dispersions that grow during shear. Mater. Sci. Eng. A 2007, 105–110. [Google Scholar] [CrossRef]

- Han, X.; Qin, Y.; Qin, K.; Li, X.; Wang, S.; Mi, J.; Song, K.; Wang, L. Glass-Forming Ability and Early Crystallization Kinetics of Novel Cu-Zr-Al-Co Bulk Metallic Glasses. Metals 2016, 6, 225. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.V.; Jiang, J. On Long-Term Stability of Metallic Glasses. Metals 2019, 9, 1076. [Google Scholar] [CrossRef]

- Fan, J.; Yang, L. Damage mechanisms of bulk metallic glasses under high-rate compression. Int. J. Impact Eng. 2017, 106, 217–222. [Google Scholar] [CrossRef]

- Chen, G.; Hao, Y.; Chen, X.-W.; Hao, H. Compressive behaviour of tungsten fibre reinforced Zr-based metallic glass at different strain rates and temperatures. Int. J. Impact Eng. 2017, 106, 110–119. [Google Scholar] [CrossRef]

- Bruck, H.A.; Rosakis, A.J.; Johnson, W.L. The dynamic compressive behavior of beryllium bearing bulk metallic glasses. J. Mater. Res. 1996, 11, 503–511. [Google Scholar] [CrossRef]

- Lu, J.; Ravichandran, G.; Johnson, W.L. Deformation behavior of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass over a wide range of strain-rates and temperatures. Acta Mater. 2003, 51, 3429–3443. [Google Scholar] [CrossRef]

- Li, M.; Jiang, M.; Yang, S.; Jiang, F.; He, L.; Sun, J. Effect of strain rate on yielding strength of a Zr-based bulk metallic glass. Mater. Sci. Eng. A 2017, 680, 21–26. [Google Scholar] [CrossRef]

- Li, H.; Subhash, G.; Gao, X.-L.; Kecskes, L.J.; Dowding, R.J. Negative strain rate sensitivity and compositional dependence of fracture strength in Zr/Hf based bulk metallic glasses. Scr. Mater. 2003, 49, 1087–1092. [Google Scholar] [CrossRef]

- Mukai, T.; Nieh, T.; Kawamura, Y.; Inoue, A.; Higashi, K. Effect of strain rate on compressive behavior of a Pd40Ni40P20 bulk metallic glass. Intermettalics 2002, 10, 1071–1077. [Google Scholar] [CrossRef]

- Chen, T.-H.; Tsai, C.-K. The Microstructural Evolution and Mechanical Properties of Zr-Based Metallic Glass under Different Strain Rate Compressions. Materials 2015, 8, 1831–1840. [Google Scholar] [CrossRef]

- Zhang, J.; Park, J.M.; Kim, D.H.; Kim, H.S. Effect of strain rate on compressive behavior of Ti45Zr16Ni9Cu10Be20 bulk metallic glass. Mater. Sci. Eng. A 2007, 449, 290–294. [Google Scholar] [CrossRef]

- Liu, L.; Dai, L.-H.; Bai, Y.; Wei, B.; Yu, G. Strain rate-dependent compressive deformation behavior of Nd-based bulk metallic glass. Intermetallics 2005, 13, 827–832. [Google Scholar] [CrossRef]

- Hsu, K.C.; Chen, T.H.; Fang, T.H.; Hsu, Y.K. Mechanical Property and Fracture Characteristic of Ti–Cu–Ni–Alx Bulk Metallic Glasses under Different Strain Rates. Mater. Trans. 2020, 61, 1607–1612. [Google Scholar] [CrossRef]

- Tian, Y.B.; Lin, J.G.; Li, W.; Ma, M.; Luo, Z.C.; Jiang, W.J. Deformation behavior of a Cu-based amorphous alloy under different strain rates. J. Appl. Phys. 2011, 109, 083508. [Google Scholar] [CrossRef]

- Inoue, A.; Zhang, W.; Zhang, T.; Kurosaka, K. Cu-Based Bulk Glassy Alloys with Good Mechanical Properties in Cu-Zr-Hf-Ti System. Mater. Trans. 2001, 42, 1805–1812. [Google Scholar] [CrossRef][Green Version]

- Davies, E.; Hunter, S. The dynamic compression testing of solids by the method of the split Hopkinson pressure bar. J. Mech. Phys. Solids 1963, 11, 155–179. [Google Scholar] [CrossRef]

- Xue, Y.-F.; Cai, H.-N.; Wang, L.; Zhang, H.-F.; Cheng, H.-W. Testing of high-strength Zr-based bulk metallic glass with the Split Hopkinson Pressure Bar. J. Beijing Inst. Technol. 2008, 1, 24. [Google Scholar]

- Follansbee, P.S. Metals Handbook; ASM: Metals Park, OH, USA, 1985; pp. 198–203. [Google Scholar]

- Lewandowski, J.J.; Greer, A. Temperature rise at shear bands in metallic glasses. Nat. Mater. 2006, 5, 15–18. [Google Scholar] [CrossRef]

- Wu, F.-F.; Zhang, Z.; Shen, B.-L.; Mao, S.X.-Y.; Eckert, J. Size Effect on Shear Fracture and Fragmentation of a Fe57.6Co14.4B19.2Si4.8Nb4Bulk Metallic Glass. Adv. Eng. Mater. 2008, 10, 727–730. [Google Scholar] [CrossRef]

- Lankford, J.; Predebon, W.; Staehler, J.; Subhash, G.; Pletka, B.; Anderson, C. The role of plasticity as a limiting factor in the compressive failure of high strength ceramics. Mech. Mater. 1998, 29, 205–218. [Google Scholar] [CrossRef]

- Meyers, M.A. Dynamic Behavior of Materials; John Wiley & Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- Subhash, G.; Ravichandran, G.. Mechanical Testing and Evaluation; ASM Handbook; ASM International: Materials Park, OH, USA, 2000; pp. 497–504. [Google Scholar]

- Liu, L.; Dai, L.-H.; Bai, Y.; Wei, B. Initiation and propagation of shear bands in Zr-based bulk metallic glass under quasi-static and dynamic shear loadings. J. Non-Cryst. Solids 2005, 351, 3259–3270. [Google Scholar] [CrossRef]

- Li, M.; Jiang, M.; Li, G.; He, L.; Sun, J.; Jiang, F. Ductile to brittle transition of fracture of a Zr-based bulk metallic glass: Strain rate effect. Intermetallics 2016, 77, 34–40. [Google Scholar] [CrossRef]

- Freels, M.; Wang, G.; Zhang, W.; Liaw, P.; Inoue, A. Cyclic compression behavior of a Cu–Zr–Al–Ag bulk metallic glass. Intermetallics 2011, 19, 1174–1183. [Google Scholar] [CrossRef]

- Ojovan, M.I.; Louzguine-Luzgin, D. Revealing Structural Changes at Glass Transition via Radial Distribution Functions. J. Phys. Chem. B 2020, 124, 3186–3194. [Google Scholar] [CrossRef] [PubMed]

- Wright, W.J.; Saha, R.; Nix, W.D. Deformation Mechanisms of the Zr40Ti14Ni10Cu12Be24 Bulk Metallic Glass. Mater. Trans. 2001, 42, 642–649. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.; Cheng, H.W.; Xue, Y.-F.; Zhang, H.-F. Fracture behavior of Zr-based bulk amorphous alloy under high-speed impact. J. Trans. Beijing Inst. Technol. 2012, 32, 198–201. [Google Scholar]

- Addabedia, M. Brittle fracture dynamics with arbitrary paths III. The branching instability under general loading. J. Mech. Phys. Solids 2005, 53, 227–248. [Google Scholar] [CrossRef]

- Abraham, F.F. Unstable crack motion is predictable. J. Mech. Phys. Solids 2005, 53, 1071–1078. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-T.; Zu, X.-D.; Liu, X.-K.; Huang, Z.-X.; Jin, P.-G.; Kong, J. Compressive Behavior of (Cu0.47Zr0.45Al0.08)98Dy2 Bulk Metallic Glass at Different Strain Rates. Materials 2020, 13, 5828. https://doi.org/10.3390/ma13245828

Wang Y-T, Zu X-D, Liu X-K, Huang Z-X, Jin P-G, Kong J. Compressive Behavior of (Cu0.47Zr0.45Al0.08)98Dy2 Bulk Metallic Glass at Different Strain Rates. Materials. 2020; 13(24):5828. https://doi.org/10.3390/ma13245828

Chicago/Turabian StyleWang, Yu-Ting, Xu-Dong Zu, Xiang-Kui Liu, Zheng-Xiang Huang, Peng-Gang Jin, and Jian Kong. 2020. "Compressive Behavior of (Cu0.47Zr0.45Al0.08)98Dy2 Bulk Metallic Glass at Different Strain Rates" Materials 13, no. 24: 5828. https://doi.org/10.3390/ma13245828

APA StyleWang, Y.-T., Zu, X.-D., Liu, X.-K., Huang, Z.-X., Jin, P.-G., & Kong, J. (2020). Compressive Behavior of (Cu0.47Zr0.45Al0.08)98Dy2 Bulk Metallic Glass at Different Strain Rates. Materials, 13(24), 5828. https://doi.org/10.3390/ma13245828