The Influence of HEMC on Cement and Cement-Lime Composites Setting Processes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Mortars and Pastes

2.3. Methods

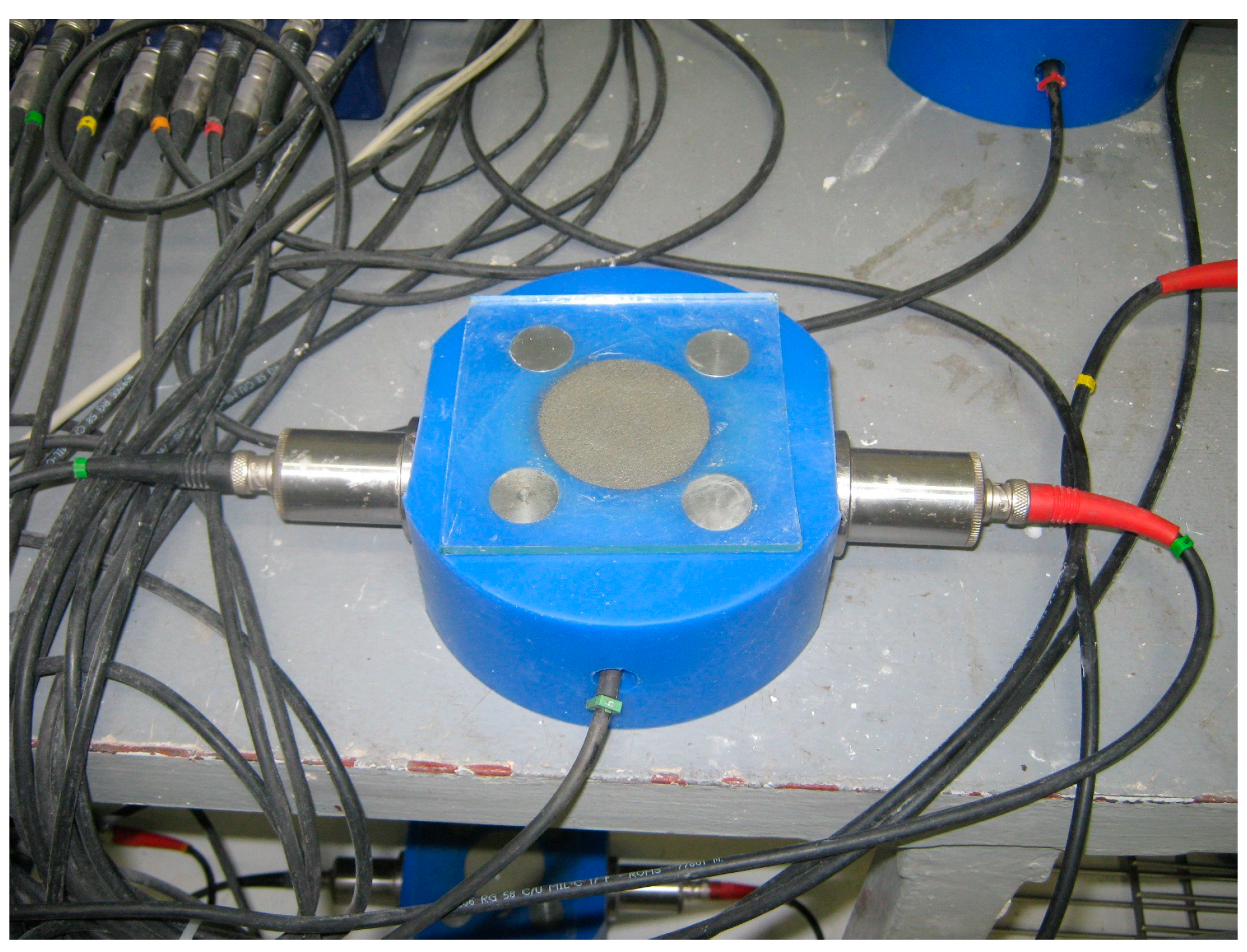

- Testing of setting processes by the ultrasonic method,

- Calorimetric measurements,

- Phases analysis by the XRD method.

3. Results and Discussion

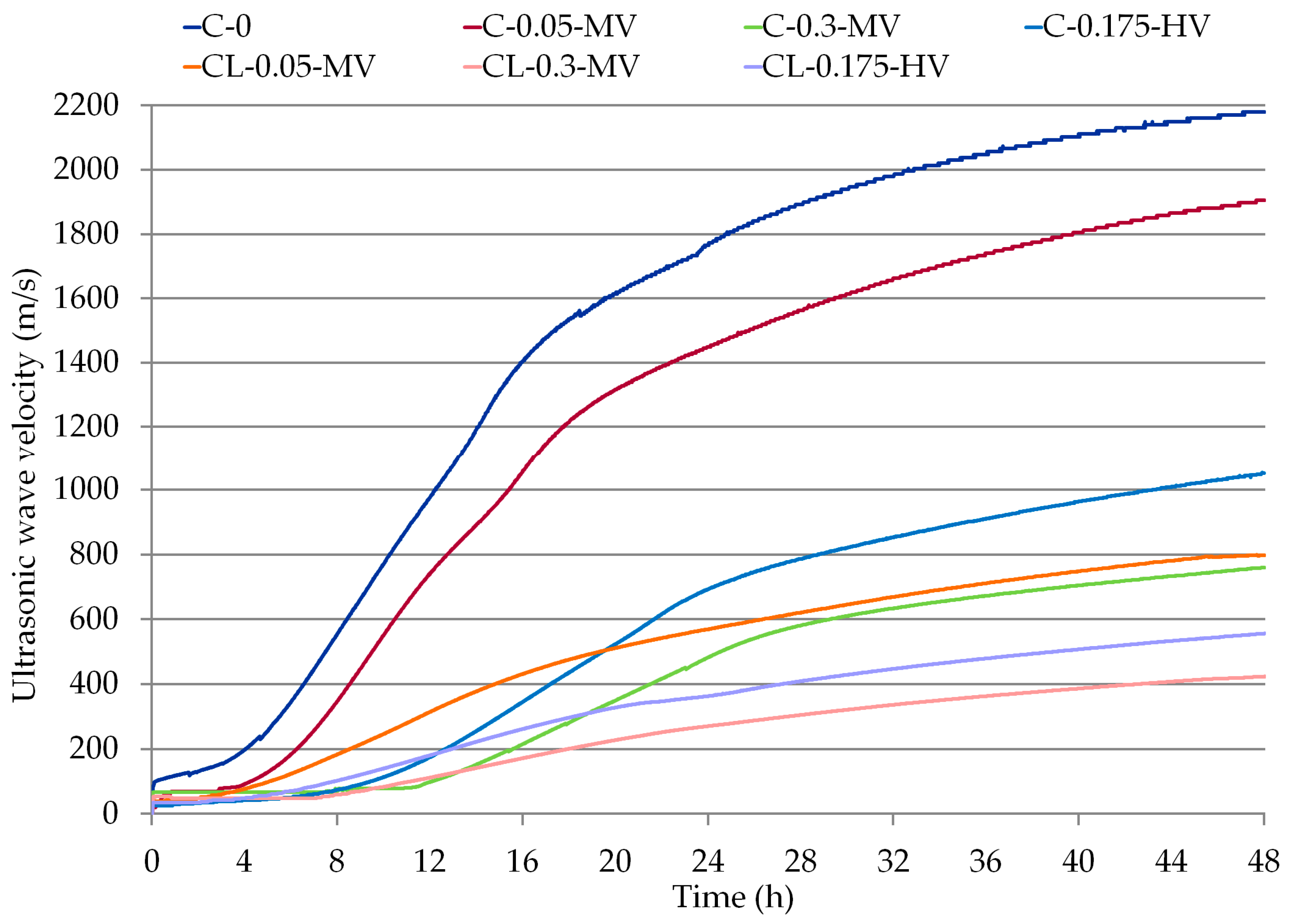

3.1. Effect of Setting Processes by the Ultrasonic Method of Mortars

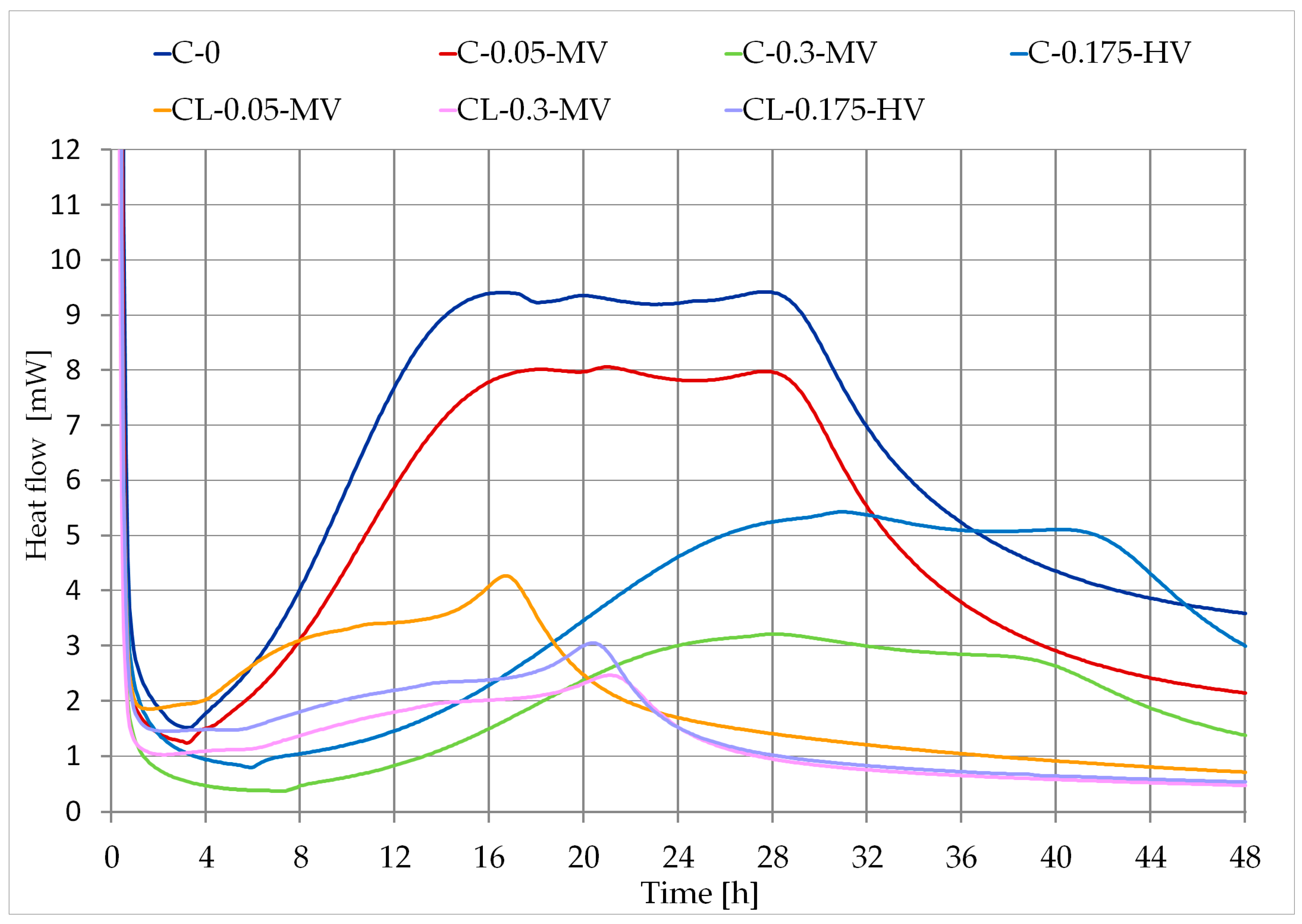

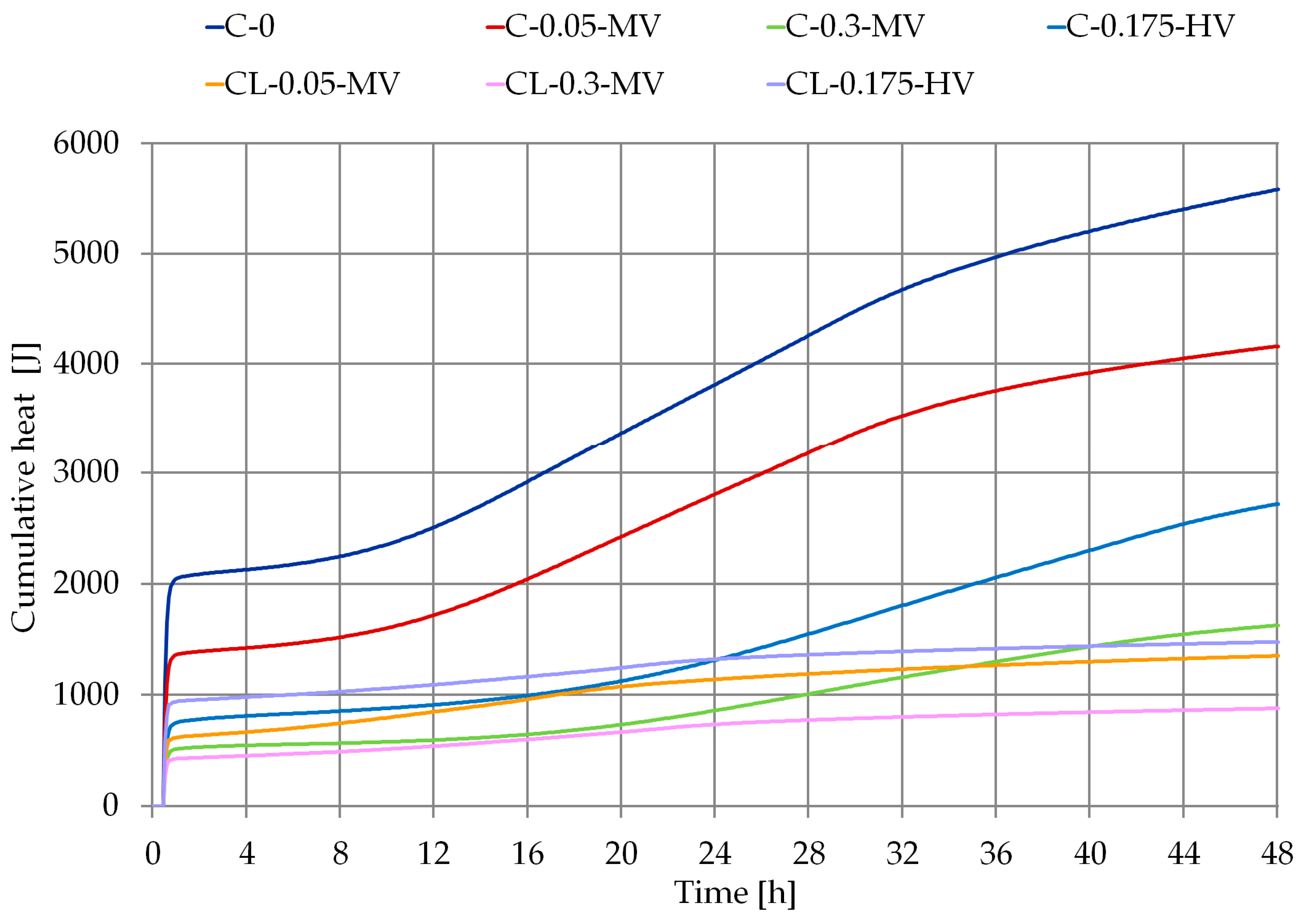

3.2. Effect of Hydration by the Calorimetry Method of Pastes

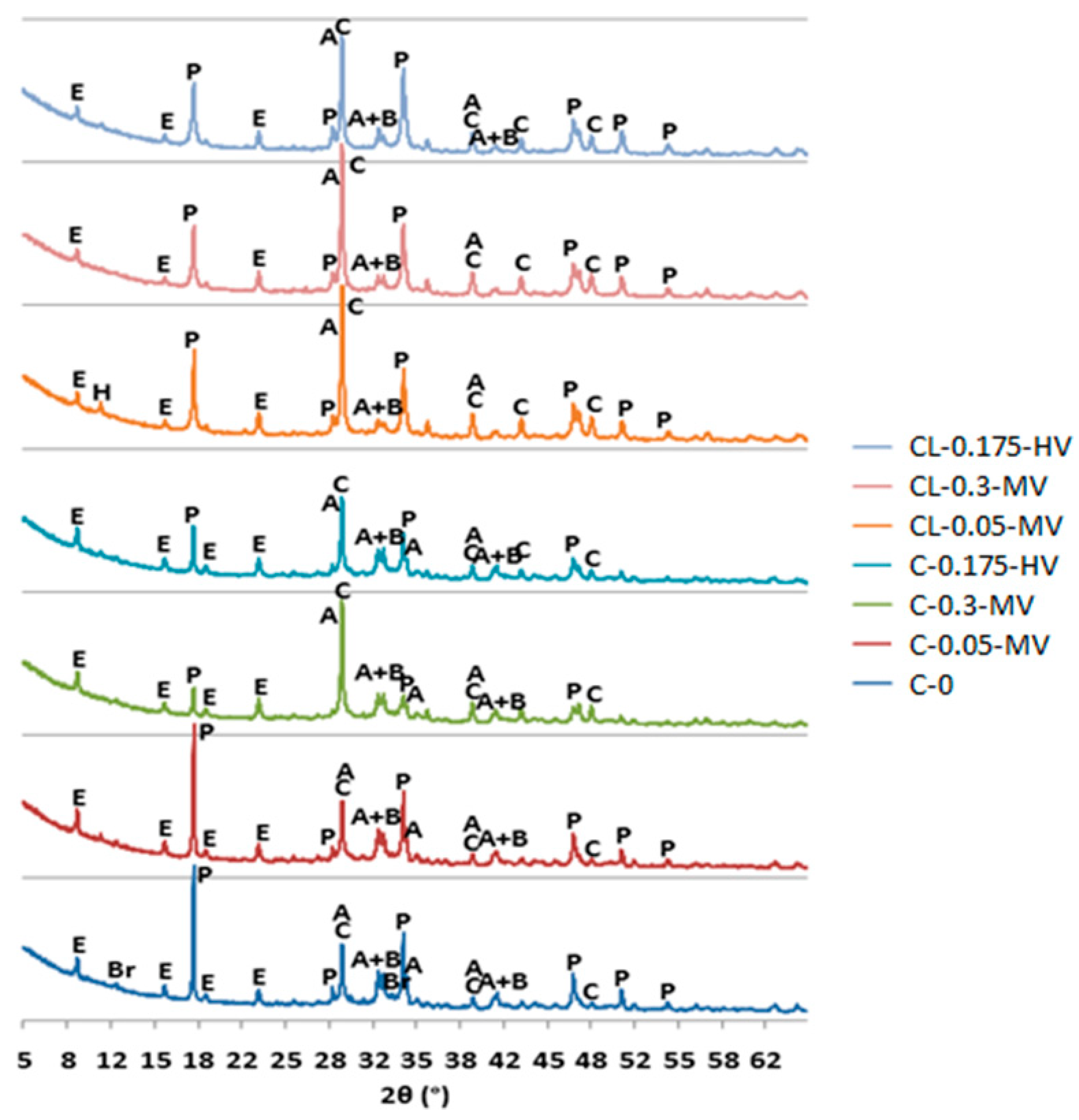

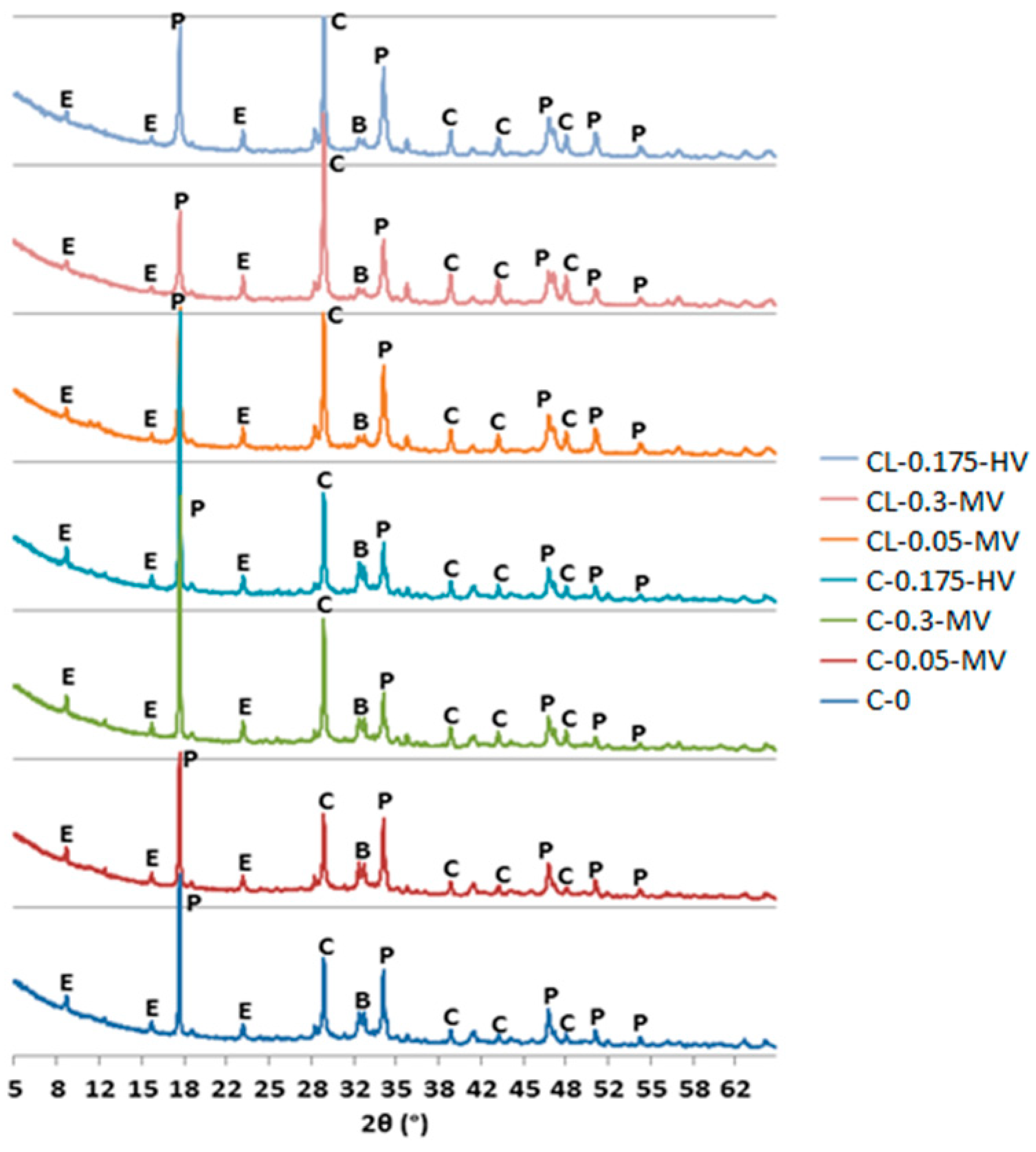

3.3. Effect of Hydration by the X-ray Diffraction of Pastes

4. Conclusions

- The addition of hydroxyethyl methyl cellulose influences the setting processes of cement and cement-lime mortars. The addition of HEMC with a viscosity of 25,000 mPa·s in the amount of 0.3% significantly delays the setting process regardless of the type of binder (cement, hydrated lime), which is not so visible in the case of the admixture in the amount of 0.05%.

- HEMC reduces the rate of the hydration reaction in cement and cement-lime pastes, which has been confirmed in calorimetric tests. The induction time on the heat evolution curve becomes significantly longer (by a maximum of 10 h 10 min). The changes are the most visible with an increasing dosage of the admixture.

- In the XRD analysis, significant effects of the presence of HEMC were found on the resulting Portlandite peaks. Limiting their intensity during the period of the first two days shows that the hydration process is lower.

- The differences in the hydration of pastes after 40 days of maturation are much smaller than the hydration of the same samples after two days of maturation. This shows that significant phase changes take place at a later stage of hydration (after 48 h). The addition of HEMC has a greater effect on the hydration of cement and cement-lime pastes in the initial hours of maturation. After a longer time, this effect practically disappears. Therefore, control of hydration kinetics of cement and cement-lime pastes on early stages is important.

- The effect of HEMC admixture on the inhibition of setting processes is more visible in pastes and mortars containing only cement binder, especially by analyzing the differences in the induction time from the ultrasonic technique and calorimetric measurements.

- The amount of the admixture used is the most important in the process of setting pastes and mortars. A much-reduced impact is visible when taking into account the viscosity of the admixture or the type of binder used.

- The ultrasonic technique in combination with calorimetric measurements and XRD method gives the possibility of a more complete and broader assessment of the setting mortars. It also enables the assessment of the influence of a chemical admixture on the hydration and setting processes of pastes and mortars. It can be useful in monitoring and controlling for application plastering mortars.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Petit, J.-Y.; Wirquin, E. Evaluation of various cellulose ethers performance in ceramic tile adhesive mortars. Int. J. Adhes. Adhes. 2013, 40, 202–209. [Google Scholar] [CrossRef]

- Brachaczek, W. Influence of cellulose ethers on the consistency, water retention and adhesion of renovating plasters. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 471, p. 032020. [Google Scholar]

- Bülichen, D.; Kainz, J.; Plank, J. Working mechanism of methyl hydroxyethyl cellulose (MHEC) as water retention agent. Cem. Concr. Res. 2012, 42, 953–959. [Google Scholar] [CrossRef]

- Szczygielska, A.; Rudnik, E.; Polaczek, J. Cellulose ethers—Preparation, application and market situation. Przem. Chem. 2002, 81, 704–707. [Google Scholar]

- Paiva, H.; Esteves, L.; Cachim, P.; Ferreira, V. Rheology and hardened properties of single-coat render mortars with different types of water retaining agents. Constr. Build. Mater. 2009, 23, 1141–1146. [Google Scholar] [CrossRef]

- Brumaud, C.; Baumann, R.; Schmitz, M.; Radler, M.; Roussel, N. Cellulose ethers and yield stress of cement pastes. Cem. Concr. Res. 2014, 55, 14–21. [Google Scholar] [CrossRef]

- Vyšvařil, M.; Hegrová, M.; Žižlavský, T. Influence of cellulose ethers on fresh state properties of lime mortars. Solid State Phenom. 2018, 276, 69–74. [Google Scholar] [CrossRef]

- Vyšvařil, M.; Bayer, P. Cellulose ethers as water-retaining agents in natural hydraulic lime mortars. In Proceedings of the 13th International Conference “Modern Building Materials, Structures and Techniques” (MBMST 2019), Vilnius, Lithuania, 16–17 May 2019; pp. 194–200. [Google Scholar]

- Lachemi, M.; Hossain, K.; Lambros, V.; Nkinamubanzi, P.-C.; Bouzoubaâ, N. Performance of new viscosity modifying admixtures in enhancing the rheological properties of cement paste. Cem. Concr. Res. 2004, 34, 185–193. [Google Scholar] [CrossRef]

- Chen, N.; Wang, P.; Zhao, L.; Zhang, G. Water retention mechanism of HPMC in cement mortar. Materials 2020, 13, 2918. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Y.; Zhou, L.; Xu, L.; Diao, G.; Liu, G. Effects of hydroxyethyl methyl cellulose ether on the hydration and compressive strength of calcium aluminate cement. J. Therm. Anal. Calorim. 2019, 140, 545–553. [Google Scholar] [CrossRef]

- Sobala, M.; Nosal, K.; Pichniarczyk, P. Effect of methyl cellulose on the properties of adhesive cement mortars. Cem. Lime Concr. 2010, 6, 359–365. [Google Scholar]

- Seabra, M.; Labrincha, J.A.; Ferreira, V.M. Rheological behaviour of hydraulic lime-based mortars. J. Eur. Ceram. Soc. 2007, 27, 1735–1741. [Google Scholar] [CrossRef]

- Spychał, E. The effect of lime and cellulose ether on selected properties of plastering mortar. Procedia Eng. 2015, 108, 324–331. [Google Scholar] [CrossRef]

- Kotwa, A.; Spychał, E. The influence of cellulose ethers on the chosen properties of cement mortar in the plastic state. Struct. Environ. 2016, 8, 153–159. [Google Scholar]

- Gołaszewski, J.; Cygan, G. Wpływ domieszek zwiększających lepkość na skurcz wczesny zapraw. Civ. Envir. Eng. 2011, 2, 263–266. [Google Scholar]

- Messan, A.; Ienny, P.; Nectoux, D. Free and restrained early-age shrinkage of mortar: Influence of glass fiber, cellulose ether and EVA (ethylene-vinyl acetate). Cem. Concr. Compos. 2011, 33, 402–410. [Google Scholar] [CrossRef]

- Pourchez, J.; Govin, A.; Grosseau, P.; Guyonnet, R.; Guilhot, B.; Ruot, B. Alkaline stability of cellulose ethers and impact of their degradation products on cement hydration. Cem. Concr. Res. 2006, 36, 1252–1256. [Google Scholar] [CrossRef]

- Pourchez, J.; Grosseau, P.; Ruot, B. Current understanding of cellulose ethers impact on the hydration of C3A and C3A-sulphate systems. Cem. Concr. Res. 2009, 39, 664–669. [Google Scholar] [CrossRef]

- Pourchez, J.; Peschard, A.; Grosseau, P.; Guyonnet, R.; Guilhot, B.; Vallée, F. HPMC and HEMC influence on cement hydration. Cem. Concr. Res. 2006, 36, 288–294. [Google Scholar] [CrossRef]

- Pourchez, J.; Grosseau, P.; Guyonnet, R.; Ruot, B. HEC influence on cement hydration measured by conductometry. Cem. Concr. Res. 2006, 36, 1777–1780. [Google Scholar] [CrossRef]

- Pichniarczyk, P. Influence of methylcellulose on the hydration of cement. Cem. Lime Concr. 2015, 3, 186–192. [Google Scholar]

- Knapen, E.; Van Gemert, D. Cement hydration and microstructure formation in the presence of water-soluble polymers. Cem. Concr. Res. 2009, 39, 6–13. [Google Scholar] [CrossRef]

- Betioli, A.M.; Gleize, P.J.P.; Silva, D.; John, V.M.; Pileggi, R.G. Effect of HMEC on the consolidation of cement pastes: Isothermal calorimetry versus oscillatory rheometry. Cem. Concr. Res. 2009, 39, 440–445. [Google Scholar] [CrossRef]

- Ou, Z.H.; Ma, B.G.; Jian, S.W. Influence of cellulose ethers molecular parameters on hydration kinetics of Portland cement at early ages. Constr. Build. Mater. 2012, 33, 78–83. [Google Scholar] [CrossRef]

- Qu, X.; Zhao, X. Influence of SBR latex and HPMC on the cement hydration at early age. Case Stud. Constr. Mater. 2017, 6, 213–218. [Google Scholar] [CrossRef]

- Izaguirre, A.; Lanas, J.; Alvarez, J.I. Characterization of aerial lime-based mortars modified by the addition of two different water-retaining agents. Cem. Concr. Compos. 2011, 33, 309–318. [Google Scholar] [CrossRef]

- Arizzi, A.; Cultrone, G. Aerial lime-based mortars blended with a pozzolanic additive and different admixtures: A mineralogical, textural and physical-mechanical study. Constr. Build. Mater. 2012, 31, 135–143. [Google Scholar] [CrossRef]

- Dima, C.; Badanoiu, A.; Cirstea, S.; Nicoara, A.I.; Stoleriu, S. Lightweight gypsum materials with potential use for thermal insulations. Materials 2020, 13, 5454. [Google Scholar] [CrossRef]

- Spychał, E. Ultrasonic method in research of plastering mortars’ setting and hardening process. In Współczesny stan wiedzy w inżynierii lądowej. Prace naukowe doktorantów; Bzówka, J., Ed.; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2015; pp. 491–500. [Google Scholar]

- Spychał, E. Evaluation of Selected Properties of Plastering Mortar Modified with Hydrated Lime and Cellulose Ether. Ph.D. Thesis, Kielce University of Technology, Kielce, Poland, 2016. [Google Scholar]

- PN-EN 1015-3:2000+A2:2007 Test Methods of Mortars for Walls. Determining the Consistency of Fresh Mortar (Using a Flow Table); Comite Europeen de Normalisation: Warsaw, Poland, 2007.

- Zych, J. Application of ultrasonic technique in examination of the setting and hardening process of cement-bonded materials. Cem. Lime. Concr. 2006, 1, 5–16. [Google Scholar]

- Trtnik, G.; Valič, M.I.; Kavčič, F.; Turk, G. Comparison between two ultrasonic methods in their ability to monitor the setting process of cement pastes. Cem. Concr. Res. 2009, 39, 876–882. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Grosse, C.U. Continuous monitoring of setting and hardening of mortar and concrete. Constr. Build. Mat. 2004, 18, 145–154. [Google Scholar] [CrossRef]

- Kulesza, M.; Dębski, D.; Fangrat, J. Effect of redispersible polymer powder on setting time of thin-bed mortars. In Proceedings of the MATEC Web of Conferences, MATBUD’2018 8th Scientific-Technical Conference on Material Problems in Civil Enginnering, Cracow, Poland, 25–27 June 2018; EDP Sciences: Les Ulis, France, 2018; Volume 163, p. 04005. [Google Scholar]

- Zhang, G.; Zhao, J.; Wang, P.; Xu, L. Effect of HEMC on the early hydration of Portland cement highlighted by isothermal calorimetry. J. Therm. Anal. Calorim. 2015, 119, 1833–1843. [Google Scholar] [CrossRef]

- Kurdowski, W. Cement and Concrete Chemistry; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Owsiak, Z. The hydration of Portland cement with fly ash. Cem. Lime Concr. 2000, 5, 29–31. [Google Scholar]

| Chemical Composition (wt. %) | Physical Properties | ||

|---|---|---|---|

| SiO2 | 20.22 | Water requirement of normal consistency/% | 28.8 |

| Al2O3 | 4.43 | Initial setting/min | 173 |

| Fe2O3 | 3.65 | Final setting/min | 237 |

| CaO | 64.06 | Specific surface area/(m2/kg) | 387.9 |

| Na2O | 0.29 | 2 d compressive strength/MPa | 28.9 |

| MgO | 1.24 | 28 d compressive strength/MPa | 59.5 |

| SO3 | 3.31 | 2 d flexural strength/MPa | 5.1 |

| Cl | 0.093 | 28 d flexural strength/MPa | 8.4 |

| K2O | 0.54 | Loss on ignition/% | 3.81 |

| free CaO | 1.83 | - | - |

| Chemical Composition (wt. %) | |

|---|---|

| CaO + MgO | 95.17 |

| MgO | 0.80 |

| CO2 | 1.86 |

| SO3 | 0.41 |

| Mortar/Paste | Binder (Cement + Lime) (g) | Fine Aggregate (g) | Cellulose Ether (wt.%) | Viscosity of Cellulose Ether | Water (g) | |

|---|---|---|---|---|---|---|

| 0.1–0.5 mm | 0.2–0.8 mm | (mPa·s) | ||||

| C-0 | 96 | 437 | 467 | 0.00 | - | 195 |

| C-0.05-MV | 96 | 437 | 467 | 0.05 | 25,000 | 148 |

| C-0.3-MV | 96 | 437 | 467 | 0.30 | 25,000 | 220 |

| C-0.175-HV | 96 | 437 | 467 | 0.175 | 45,000 | 185 |

| CL-0.05-MV | 48 + 48 | 437 | 467 | 0.05 | 25,000 | 176 |

| CL-0.3-MV | 48 + 48 | 437 | 467 | 0.30 | 25,000 | 225 |

| CL-0.175-HV | 48 + 48 | 437 | 467 | 0.175 | 45,000 | 195 |

| Mortar | Induction Time (h) | Ultrasonic Wave Velocity | |||

|---|---|---|---|---|---|

| after 12 h (m/s) | after 24 h (m/s) | after 36 h (m/s) | after 48 h (m/s) | ||

| C-0 | 0 h 00 | 980.6 | 1765.7 | 2047.5 | 2180.1 |

| C-0.05-MV | 0 h 00 | 822.1 | 1478.7 | 1740.4 | 1905.3 |

| C-0.3-MV | 10 h 54 | 98.9 | 484.0 | 673.2 | 760.0 |

| C-0.175-HV | 3 h 40 | 174.9 | 693.3 | 911.9 | 1050.4 |

| CL-0.05-MV | 0 h 00 | 315.6 | 570.0 | 712.3 | 797.3 |

| CL-0.3-MV | 7 h 18 | 112.0 | 270.4 | 363.2 | 423.3 |

| CL-0.175-HV | 2 h 04 | 181.0 | 363.2 | 479.3 | 556.4 |

| Pastes | Induction Time (h) | Time of Second Maximum (h) | Cumulative Heat | |||

|---|---|---|---|---|---|---|

| after 12 h (J) | after 24 h (J) | after 36 h (J) | after 48 h (J) | |||

| C-0 | 2 h 50 | 16 h 35 | 2555.49 | 3870.52 | 5004.47 | 5583.49 |

| C-0.05-MV | 3 h 10 | 18 h 15 | 1753.67 | 2855.17 | 3781.15 | 4160.72 |

| C-0.3-MV | 13 h 00 | 28 h 10 | 598.18 | 878.04 | 1316.79 | 1625.28 |

| C-0.175-HV | 4 h 45 | 31 h 00 | 919.00 | 1341.37 | 2088.41 | 2718.38 |

| CL-0.05-MV | 4 h 30 | 16 h 40 | 861.95 | 1146.33 | 1271.30 | 1351.04 |

| CL-0.3-MV | 5 h 15 | 21 h 05 | 545.89 | 740.88 | 826.38 | 878.06 |

| CL-0.175-HV | 4 h 50 | 20 h 20 | 1100.67 | 1327.26 | 1418.96 | 1476.46 |

| Pastes | Peak Intensity after 2 Days (%) | Peak Intensity after 40 Days | Changes in Peak Intensity |

|---|---|---|---|

| (%) | (%) | ||

| C-0 | 100.00 | 100.00 | +15.60 |

| C-0.05-MV | 98.58 | 83.43 | −2.17 |

| C-0.3-MV | 19.44 | 149.50 | +788.85 |

| C-0.175-HV | 33.77 | 172.03 | +488.81 |

| CL-0.05-MV | 58.96 | 83.26 | +63.25 |

| CL-0.3-MV | 44.87 | 50.65 | +30.48 |

| CL-0.175-HV | 44.58 | 73.40 | +90.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spychał, E.; Czapik, P. The Influence of HEMC on Cement and Cement-Lime Composites Setting Processes. Materials 2020, 13, 5814. https://doi.org/10.3390/ma13245814

Spychał E, Czapik P. The Influence of HEMC on Cement and Cement-Lime Composites Setting Processes. Materials. 2020; 13(24):5814. https://doi.org/10.3390/ma13245814

Chicago/Turabian StyleSpychał, Edyta, and Przemysław Czapik. 2020. "The Influence of HEMC on Cement and Cement-Lime Composites Setting Processes" Materials 13, no. 24: 5814. https://doi.org/10.3390/ma13245814

APA StyleSpychał, E., & Czapik, P. (2020). The Influence of HEMC on Cement and Cement-Lime Composites Setting Processes. Materials, 13(24), 5814. https://doi.org/10.3390/ma13245814