3.1. Selection and Characterisation of the WW-Based Filler

Whereas the selection of the WW-based filler is for the further preparation of loose-fill PUR biocomposite foams which are processed without any additional loading, the average values of thermal conductivity for each filler are presented based on their measured bulk density (

Figure 1).

Taking into consideration the scattering of the results, it can be seen from

Figure 1 that the thermal conductivity values of most of the WW-based fillers are in the range of 0.046–0.061 W/m·K, while the WB filler is characterised by the highest thermal conductivity value. Additionally, an almost ~10% difference between HS-LT and HS-FR can be observed. This might be attributed to the size of the hemp particles and the bulk density. Compared to HS-FR, the HS-LT filler has 30% more 2.5–5 mm-sized particles, and a previous study in Reference [

27] confirms that the optimal thermal insulating properties of HS fillers are obtained when the HS particles are further shredded, or their size ranges from 2.5 to 5 mm. This is explained by the fact that, compared to larger particles, smaller voids and air gaps are formed between smaller HS particles through which a lower heat exchange occurs due to heat transfer through gas. Additionally, it is clearly seen from

Table 1 that HS-FR has 19% greater bulk density than that for HS-LT. The increase in thermal conductivity value based on bulk density is in good agreement with a study conducted in Reference [

28].

It can be clearly seen that the lowest thermal conductivity was determined for the WS filler. Compared to uWS, WB, HS-LT and HS-FR, the thermal conductivity of WS is lower by 3.0%, 16%, 2.2% and 6.0%, respectively. The differences in these values may be explained by the filler’s structure. Therefore,

Figure 2 presents the microstructures of the WW-based fillers.

It can be seen from

Figure 2a,b that uWS and WS particles show the traditional structure of wood with hollow lumen spaces which are visible in the cross-section, and numerous pits across longitudinal areas.

The pore sizes of uWS and WS are of 10–20 μm with approximately ~2 μm-sized pits located in the tracheid’s walls. Additionally, the surfaces of the uWS filler particles are covered with fine particles, of which 24.3% are of < 0.315 mm. Accordingly, this increases the average thermal conductivity by 2.2% compared to the WS filler (the content of < 0.315 mm particles is 0.89%) due to the increased heat transfer via solid components. However, the highest thermal conductivity value is observed for the WB filler. As can be seen from

Figure 2c, WB contains mainly two types of pores whose size varies from 20 to 100 μm, which is confirmed by the research in Reference [

29]. Taking into consideration the amount of < 0.315 mm-sized particles in the WB filler, i.e., ~8%, this might be the reason for the increased heat transfer through the solid parts and a higher thermal conductivity value compared to the other WW-based fillers.

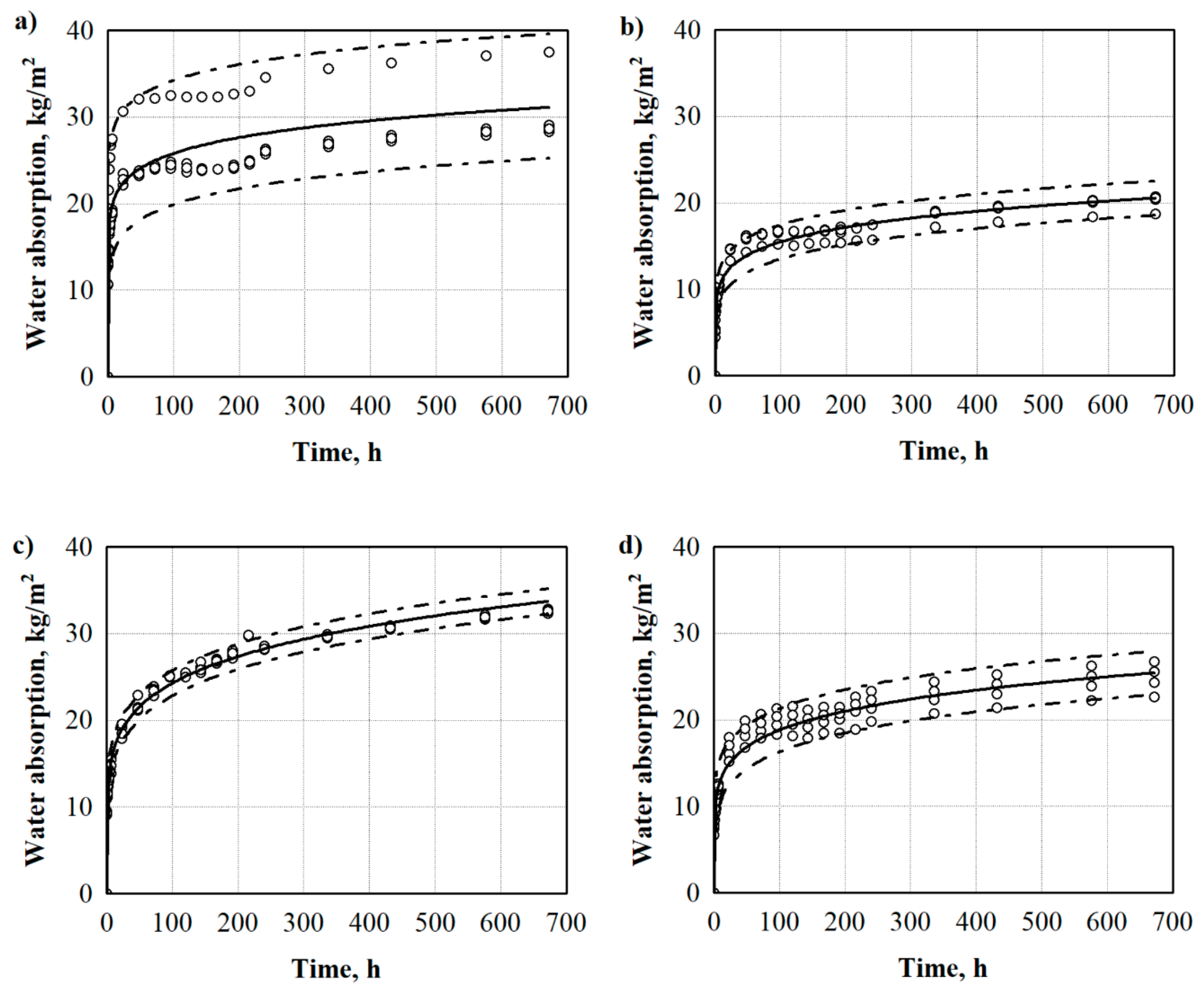

It is known that the WW-based fillers have many pores in their structure, and they include a large number of hydrophilic groups. Therefore, hygroscopicity of the WW-based fillers occurs in wet environmental conditions and this can lead to deformation, cracking and other defects of products made from them [

30], thus making it important to know their behaviour under the impact of moisture. The water absorption ratio of different WW-based fillers is shown in

Figure 3. As can be seen, the water absorption rate was so fast that it almost reached its maximum value in 24 h, the values being 22.4 kg/m

2 for uWS, 12.5 kg/m

2 for WS, 19.0 kg/m

2 for WB, 15.0 kg/m

2 for HS-LT and 15.4 kg/m

2 for HS-FR. Between 14 and 672 h, the water absorption rate increased slowly, and thereafter it remained nearly constant for all the WW-based fillers. A similar pattern for water absorption increase was observed in Reference [

31] for pine wood under no, and various, heat treatments. Strangely, even though uWS and WS fillers are almost the same, the average values of long-term water absorption by partial immersion after 24 h of soaking in water differ by almost 2 times. It is noticed from a study conducted in Reference [

32] that in the comparison of coarse and fine fillers, fine WW-based particles attract and absorb more water than coarse ones. Therefore, the greater water absorption of uWS, which has the highest content of fine < 0.315 mm-sized particles (

Table 1), can be seen. This is primarily because of increased surface area and greater effective absorption capacity of the fine particles as compared to coarse particles. In principle, uWS has more fine particles (>20%) than any other filler involved in this study. The same can be attributed to the WB filler which has the second highest amount of fine particles, i.e., >8%, therefore, its water absorption value after 24 h is ~15% lower compared to uWS. Moreover, it was found out by the authors of Reference [

33] that a higher amount of lignin reduces the water retention ability of WW-based fillers as WB particles have ~37–40% lignin, while, e.g., WS has ~25% [

34]. The third type of WW-based fillers analysed are HS which, depending on their country of origin, show quite similar tendencies over the test time and an almost identical average water absorption value. However, water absorption results of the HS-FR filler are characterised by a wide scattering. This can be explained by the fact that HS-FR filler consists of hemp shives and accumulated fibres, which determined the uneven test results.

In order to evaluate the scattering of the results for all WW-based fillers, mathematical-statistical calculations and interpretations of the results were implemented. Statistical data of long-term water absorption by partial immersion results are presented in

Table 3.

Research shows that the obtained results of water absorption can be approximated by the regression equation.

Table 3 presents the constant coefficients

b0 and

b1 the average standard deviation

Sr, and the determination coefficient

. The obtained data show that the determination coefficients for WW-based fillers are 0.779, 0.962, 0.993, 0.961 and 0.751, for uWS, WS, WB, HS-LT and HS-FR, respectively. They show that the suggested regression model is suitable to describe the water absorption values of WW-based fillers. Additionally, determination of the coefficients for uWS and HS-FR water absorption shows that a high amount of fine particles and fibres in the fillers causes a higher scattering of the obtained results.

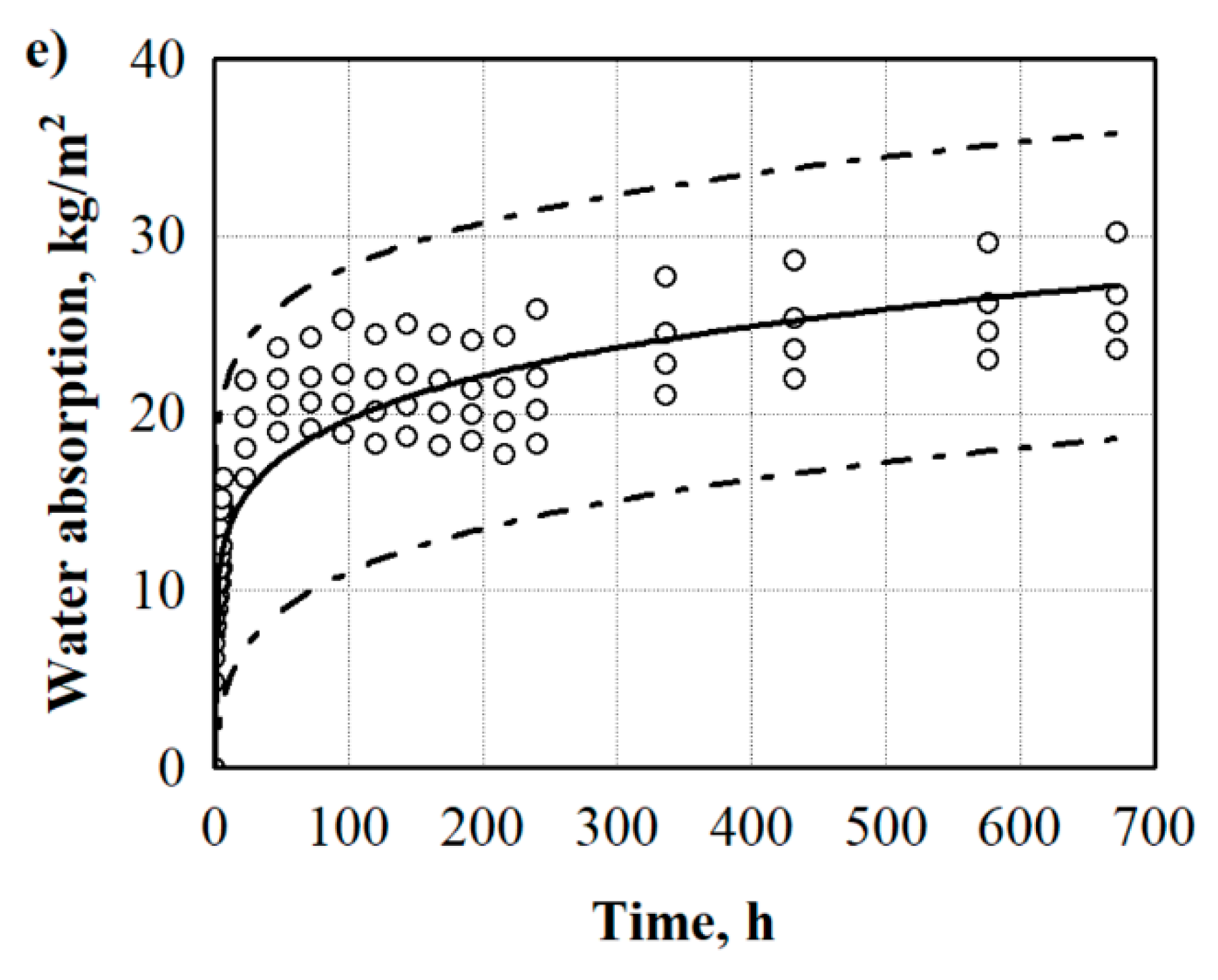

As the authors of Reference [

35] stated, bark is less hygroscopic than wood, and the water and humidity sorption/desorption behaviour of WW-based fillers plays an essential role in the heating energy consumption of buildings. Therefore, water vapour permeability tests were conducted, and the results of the water vapour resistance and water vapour diffusion resistance factor are presented in

Figure 4. It can be clearly seen that the WB filler has the highest water vapour resistance and water vapour diffusion resistance factor values, which are approximately 1.5 times higher compared to the uWS filler. This can be attributed to the highest bulk density amongst all the fillers. Similar observations were reported by the authors of Reference [

36], who investigated the water vapour diffusion resistance factor values of several commercially available wood-based products, with different densities and thicknesses, and found that the water vapour diffusion resistance factor of the wood-based products increased with increasing density. Additionally, the WB filler has the lowest possible porosity (~60 vol.% [

37]) compared to WS (~78 vol.% [

38]) and HS (~77 vol.% [

39]) fillers, which might be another key factor influencing the increased water vapour resistance.

Furthermore, it is possible to observe that the water vapour resistance properties obtained for the WW-based fillers are in the range of 2.2–3.3, which are in a good agreement with the values of vegetable fibres, such as wood (3–10), hemp, flax and corn (1–3), as presented in Reference [

40].

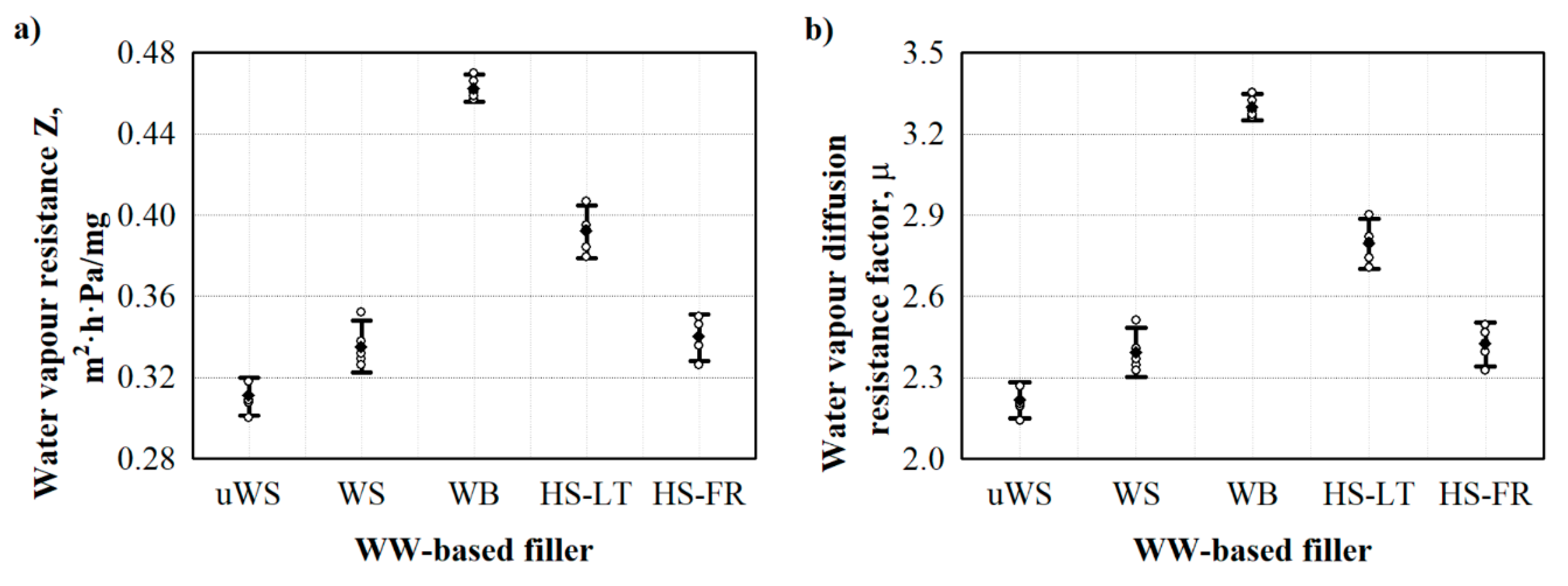

3.2. Apparent Density, Thermal Conductivity and Microstructure of WS-Filled PUR Biocomposite Foams

Application of the renewable raw materials, especially wood-based ones, in the synthesis of biocomposite polyurethane foams can significantly change their properties [

41,

42]. Regarding the application of a current PURb/WS biocomposite foam as a loose-fill thermal insulation for building envelopes, the determination of performance properties such as apparent density, thermal conductivity, compressive and tensile strengths, water absorption, water vapour permeability, dimensional stability and structural changes, are of great importance. Therefore, the changes in apparent density and mechanical behaviour of biocomposites with 0.40, 0.55, 0.70 and 0.85 of PURb/WS ratio are illustrated in

Figure 5.

It is seen that an increase in the PURb/WS ratio reduces the apparent density of PUR biocomposites. Compared to 0.40 PURb/WS, the apparent density of 0.85 PURb/WS is reduced by approximately 44%. The highest apparent density of PUR biocomposite foams at the lowest PURb/WS ratio is explained by the fact that no additional blowing agent was used for the preparation of the samples. Additionally, a lower ratio of PURb/WS indicates a lower amount of PURb, which hinders the foaming process of PUR biocomposite foams. The results of previous studies of PUR biocomposite foams modified with other fillers show that an incorporation of, e.g., industrial potato protein [

43], solid waste from leather industry [

44], or algal cellulose [

45], reduce the reactivity of the overall system, thus increasing the apparent density of the resultant PUR products. However, a further increase in PURb/WS ratio leads to a more effective blowing efficiency due to an increase in the PURb amount, which produces a higher reaction ability and CO

2 emission as the –OH groups from polyol and –NCO groups from isocyanate react with each other.

The thermal conductivity of biocomposites with different PURb/WS ratios is mainly affected by the apparent density, porosity, pore size distribution, moisture content and phase composition [

46]. However, the same raw materials and conditions were adopted in the tests, and therefore, the impact of moisture content and phase composition is not prominent. Moreover, in previous studies [

47,

48], pores were reported to be one of the main influencing factors on the value of thermal conductivity. Therefore, the average values of closed cell content for PUR biocomposite foams with different PURb/WS ratios are presented in

Table 4, and thermal conductivity values in

Figure 5b.

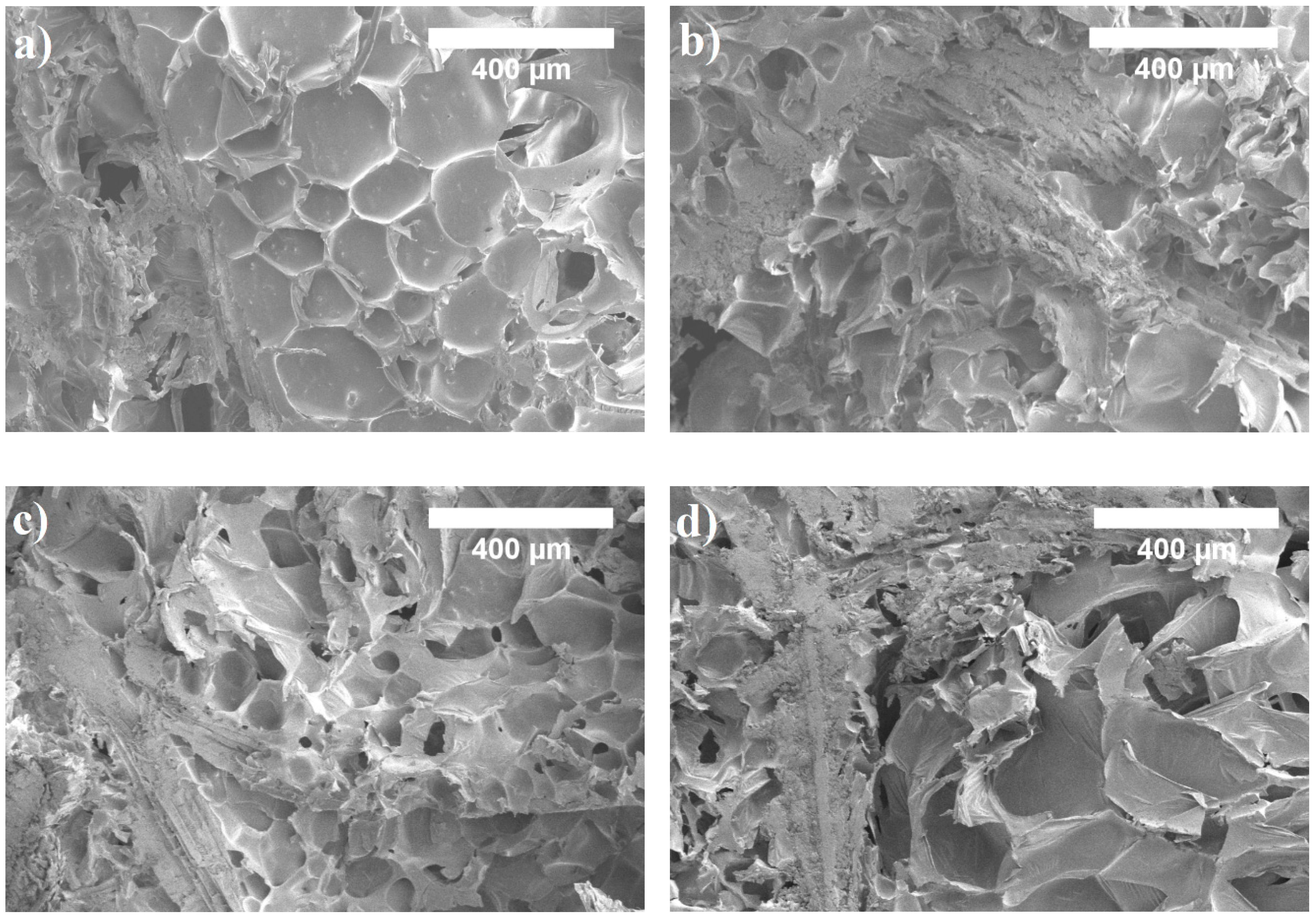

It shows that the lowest and the highest ratios of PURb/WS determined the PUR biocomposite foams with the lowest volumetric content of closed cells, i.e., approximately 50 vol.%, while 0.70 PURb/WS biocomposite foam reached almost 70 vol.%. It can be seen from

Figure 6a,d that the interface interaction between the porous polyurethane matrix and WS particles is not even, it is full of voids and flaws which increases the percentage of open pores and reduces the percentage of closed ones.

In the case of 0.40 PURb/WS, the excessive amount of WS particles, or the insufficient amount of PURb, disrupts the foaming process and results in the formation of a more defective microstructure, which determines a higher average value of thermal conductivity, which is 0.0523 W/m·K. The observations made are in good agreement with previous studies of polyurethane foams with various loadings of natural fillers [

10,

49,

50]. However, a 0.85 PURb/WS ratio allows a higher blowing efficiency of PUR biocomposite foams due to the increased capability of the PURb mixture to react with the moisture present in WS particles as the PURb amount increases. Consequently, some of the cell walls cannot withstand the pressure during excessive blowing, thus reducing the overall closed cell content and the thermal conductivity by approximately 19% and 13%, as compared to 0.70 PURb/WS. The observation made is also proven by the average cell size (

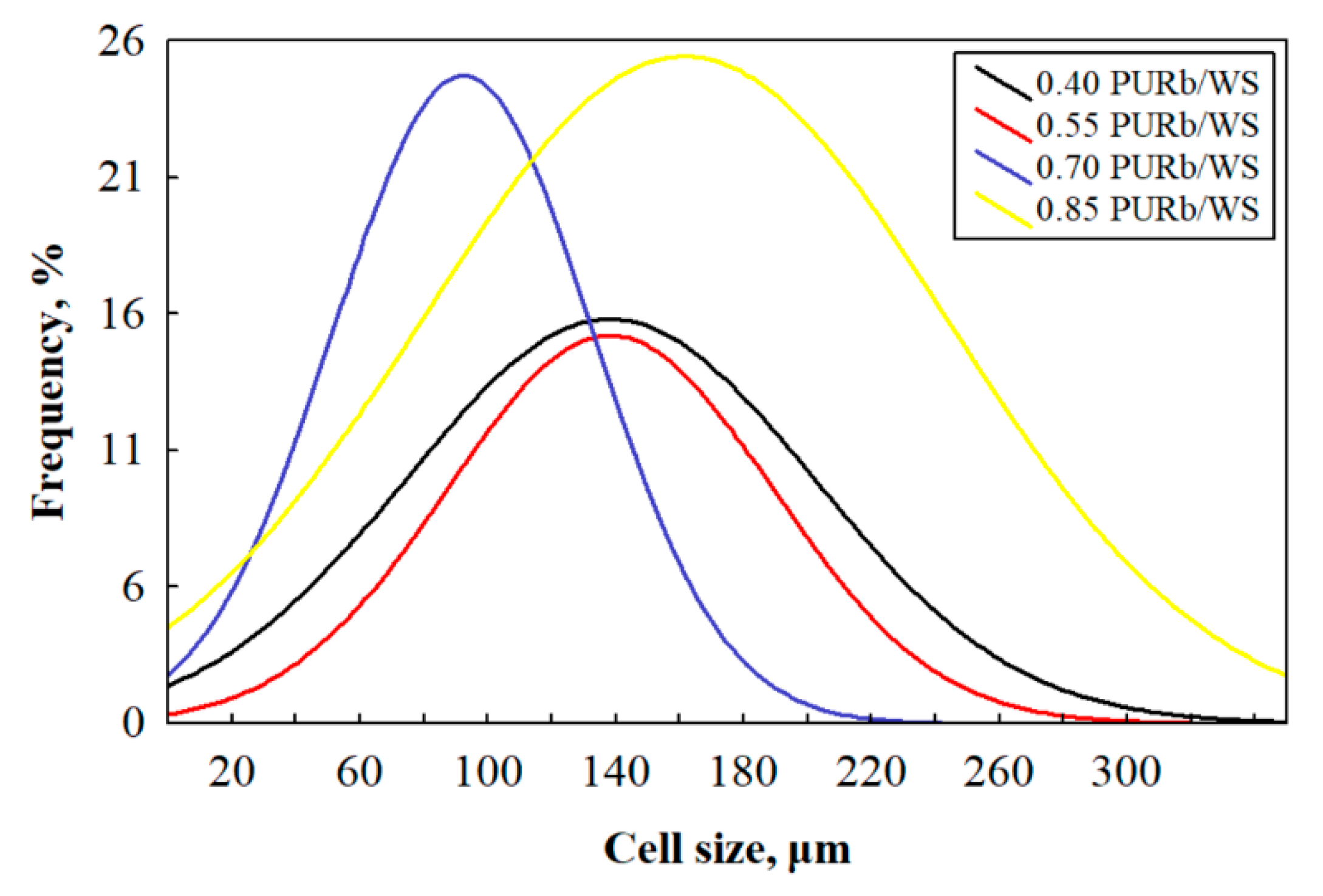

Table 4) and cell size distribution measurements in

Figure 7. It is calculated that the use of a 0.85 PURb/WS ratio determines by, on average, a 74% higher cell size compared to a 0.70 PURb/WS ratio and shifts cell size distribution curve towards higher sizes.

With the increasing ratio of PURb/WS, the overall cell structure becomes less uniform and the number of broken cells is increased. In the case of 0.40–0.70 PURb/WS ratios, the cellular structure is quite well preserved, and the reduction in cell size is visible (

Table 4 and

Figure 7). This indicates that the application of up to 0.70 PURb/WS enhances the formation of smaller cells due to the existence of small particles in the WS filler. It is known that the addition of filler may change the nucleation mode from homogeneous to heterogeneous, and reduce the nucleation energy, thus promoting the formation of a higher number of smaller cells [

51,

52]. This phenomenon can be observed for the PUR biocomposite foams with a 0.70 PURb/WS ratio (

Figure 6c). When the ratio of PURb/WS exceeds 0.70, damaged cells become visible (

Figure 6d).

In order to evaluate the impact of the PURb/WS ratio on the apparent density and thermal conductivity of the obtained PUR biocomposite foams, statistical-mathematical analysis was implemented and data for regression Equations (1) and (2) is presented in

Table 5.

where:

—the average apparent density of PUR biocomposite foams,

—the average thermal conductivity of PUR biocomposite foams,

—PURb/WS ratio in PUR biocomposite foams and

b0,

b1 and

b2—constant coefficients of regression equations (

Table 5).

The statistical analysis shows that the results of apparent density and thermal conductivity can be approximated by the regression equation.

Table 5 presents the constant coefficients

b0,

b1 and

b2, the average standard deviation

Sr, and the determination coefficient

. The obtained data show that the determination coefficients for apparent density and thermal conductivity are 0.959 and 0.966, respectively. They show that the suggested regression models are suitable for the description of PUR biocomposite foam’s apparent density and thermal conductivity.

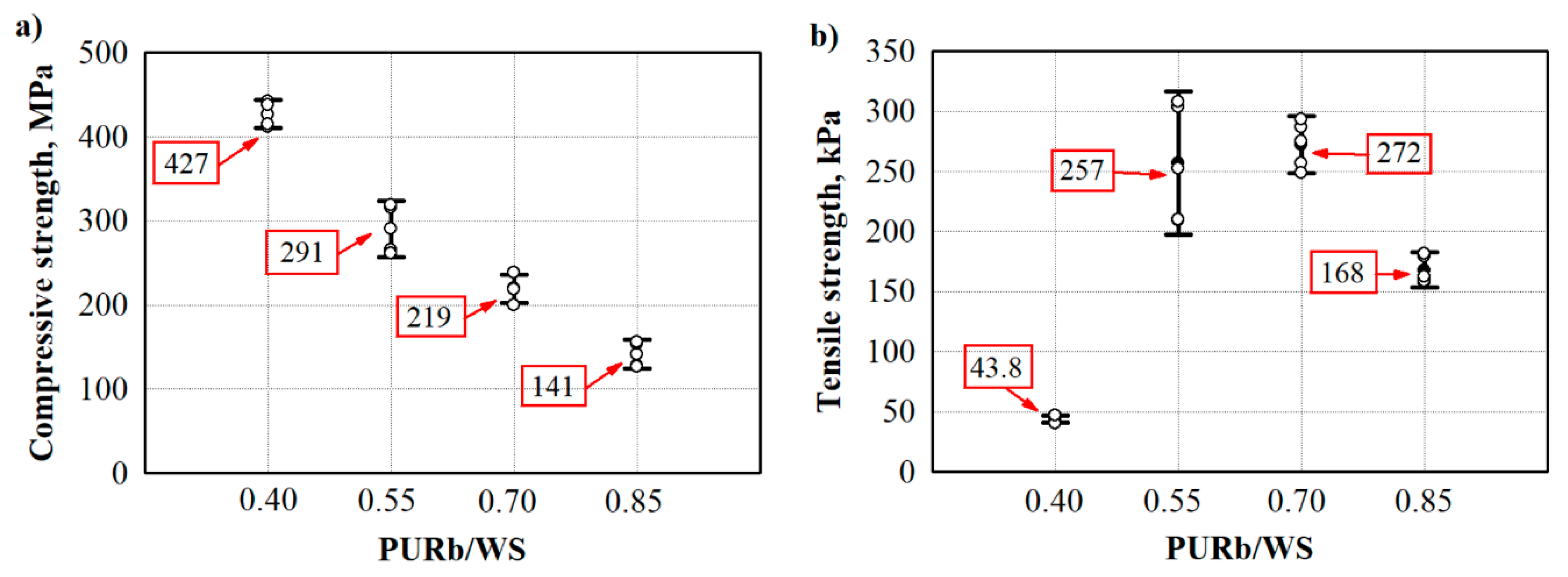

3.3. Strength Properties and Interfacial Adhesion of WS-Filled PUR Biocomposite Foams

The mechanical performance of cellular materials is closely dependent on their apparent density as well as their structural parameters, such as closed cell content and cells’ shape and sizes [

53]. Therefore, it is of great importance to know how the PURb/WS ratio alters the overall mechanical properties of PUR biocomposite foams. Hence, the average numerical values of compressive and tensile strengths are presented in

Figure 8. It can be seen that the compressive strength of PUR biocomposite foams with different PURb/WS ratios reduces with the reduction in apparent density. The highest value of compressive strength is reached for PUR biocomposite foams at a 0.40 PURb/WS ratio. The increase in PURb triggers a decrease in the compressive strength of the PUR biocomposite foams by ~32%, ~49% and ~70% respectively, for 0.55 PURb/WS, 0.70 PURb/WS and 0.85 PURb/WS. This happens due to the increased blowing efficiency under the reaction between moisture in the WS particles and isocyanate as one of the main components in the PURb mixture.

Although enhancement of the PUR biocomposite foams’ compressive strength was not observed, it is still important to address the required standard for insulation materials (≥120 kPa) [

9]. This shows that the PUR biocomposite foams may be comparable to commercially available ones only at 0.40–0.55 PURb/WS ratios (≥250 kPa) [

54].

Despite the reduction in compressive strength with the addition of PURb, the tensile strength (

Figure 8b) shows a quite different tendency. It can be seen that the lowest tensile strength is obtained at 0.40 PURb/WS while 0.70 PURb/WS gives the highest value of the parameter, i.e., with the addition of PURb, the tensile strength increased by 621% compared to 0.40 PURb/WS, giving an average value of 272 kPa, indicating an improved interfacial adhesion and improved stress transfer during the stretching process between WS particles and PURb. Similar observations were reported in Reference [

55], where microcellular polyurethane with sisal fibres were investigated, and in Reference [

56], where research was conducted on waterborne polyurethane with cellulose reinforcement.

However, further additions of PURb negatively affects the tensile strength of PUR biocomposite foams at 0.85 PURb/WS. This effect can be attributed to the reduced density and, presumably, the thickness of the cell walls, which determines the overall tensile behaviour of PUR biocomposite foams.

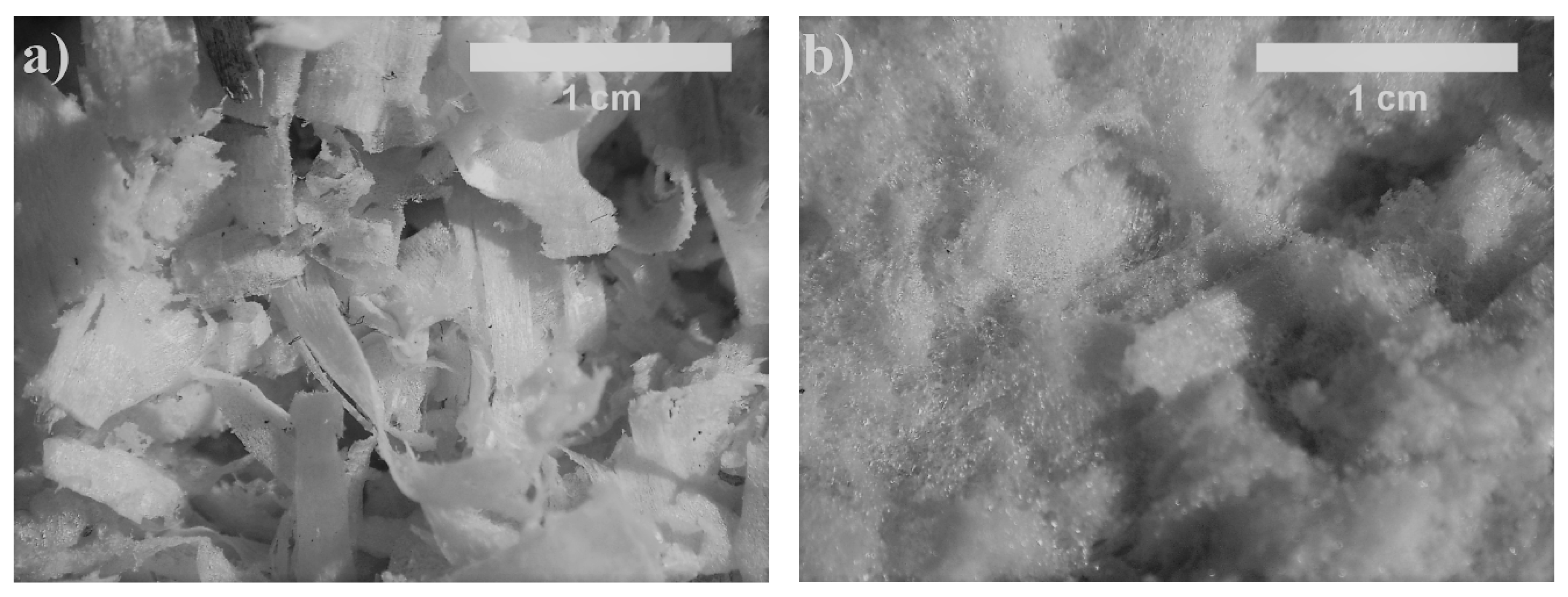

Moreover, as presented in

Figure 9, WS particles are not completely built in the PUR matrix, some of them are loose and pulled out from the matrix at a 0.40 PURb/WS ratio. This indicates poor interfacial adhesion and insufficient wetting between the WS surface and the PU matrix at a 0.40 PURb/WS ratio, which in turn leads to voids and the formation of open pores in the foam structure (

Table 4). This can be attributed to the lower amount of PURb used for the formation of PUR biocomposite foams. Furthermore, PUR biocomposite foams at a 0.70 PURb/WS ratio are characterised by a more regular structure with a lower content of open cells compared to PUR biocomposite foams at a 0.40 PURb/WS ratio. In this case, WS particles are sufficiently covered with the PU matrix, thus leading to a better interfacial interaction and greater tensile strength values.

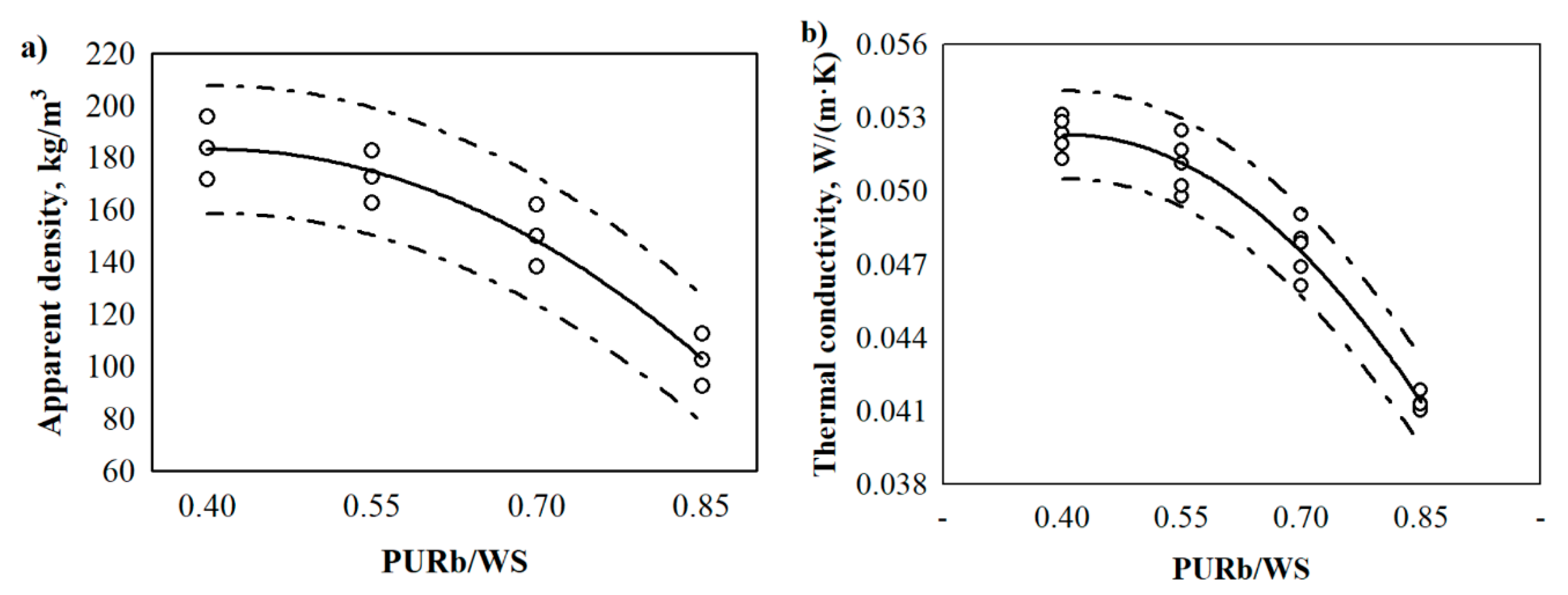

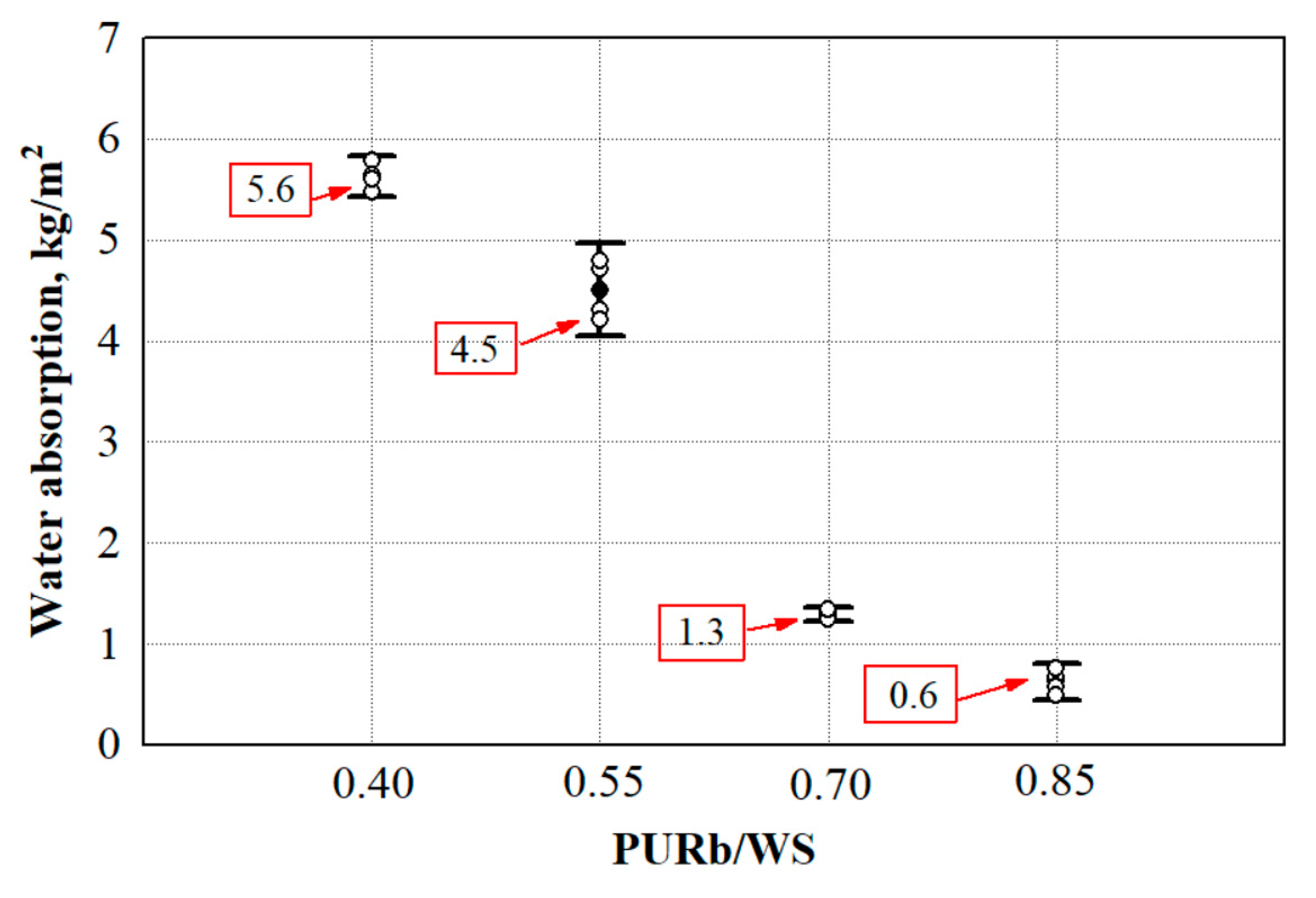

3.4. Water and Water Vapour Resistance of WS-Filled PUR Biocomposite Foams

Water absorption is another significant performance characteristic that has to be examined because it is highly important for the biodegradability of WW-based products [

57]. Pure synthetic matrices are inert to water absorption, which is the main reason for their long period of degradation, while WW-based products are more attractive to microorganisms which is due to their capability to absorb water [

58]. Therefore, the impact of water or water vapour on the obtained PUR biocomposite foams must be known, and the results are presented in

Figure 10 and

Table 6.

It is obvious that the increase in the amount of polymer matrix PURb reduces the total water absorption of PUR biocomposite foams. Compared to 0.40 PURb/WS, the parameter reduces by 20% for 0.55 PURb/WS, by 77% for 0.75 PURb/WS and by 90% for 0.85 PURb/WS ratios. The difference in water absorption and the change with the addition of PURb can be explained by the fact that at 0.85 PURb/WS, the WS particles are distributed in a higher volume, therefore, the hydrophobic matrix makes it harder for water to interact with WW-based filler, thus reducing the short-term water absorption by partial immersion values. This phenomenon has also been reported by other authors [

59,

60] who tested 24 h water immersion of pre-hydrolysed banana fibres-based polyurethane foam composites, and the contact angle of porous polyurethane filled with cellulose fibres from water hyacinth, respectively. Water vapour resistance is dependent on the thickness of the sample. Specimens with the edge size of 100 mm and thickness of 50 mm were used to determine the main parameters for the water vapour permeability test, water vapour resistance and water vapour diffusion resistance factor. It can be seen (

Table 6) that a higher PURb amount produces a lower water vapour resistance and water vapour diffusion resistance factor.

This means that despite the closed cell structure, the use of WS filler increases the amount of water vapour transmitted through the material. The higher resistance to water vapour transport at 0.55 PURb/WS and 0.70 PURb/WS is due to a greater amount of PURb and a higher content of closed cells. It is obvious from

Figure 4 that WS filler is sufficiently water vapour permeable, therefore, the obtained PUR biocomposite foams are characterised by a lower water vapour resistance and water vapour diffusion resistance factor compared to commercial ones. As a 0.40 PURb/WS ratio was considered insufficient for even wetting of the WS filler, it creates a path which can be easily accessed by water molecules penetrating through the specimens.

3.5. Dimensional Stability of WS-Filled PUR Biocomposite Foams

It known that the diffusion of gases accelerates with an increase in temperature. This is based on the basic polymer chemistry where gases in cells, influenced by a higher temperature, expand, thus exerting a pressure and changing the volume of the product. Moreover, the decrease in environmental temperature may impact the changes in linear dimensions. Therefore, it is of great importance to determine the influence of some standardised environmental conditions on PUR biocomposite foams with different PURb/WS ratios. The measured average percentage values of dimensional stability at 70 °C/90% and −20 °C are presented in

Table 7.

The percentage linear changes in length, width and thickness after exposure at 70 °C/90% and −20 °C for up to 2 days for PUR biocomposite foams with different PURb/WS ratios are presented in

Table 7. The dimensional stability of PUR biocomposite foams indicates that the increase in PURb/WS ratios (WS is constant and PURb increases according to the data presented in

Table 2) results in negligible changes of dimensional stability of the foams. The relative changes of PUR biocomposite foams with all PURb/WS ratios in the directions of length and width, range from 0.5% to 1.4%, and in thickness, from 1.1% to 2.3%, when tested at 70 °C /90% conditions. According to the factory-made polyurethane foam harmonised product standard [

61], the obtained biocomposite foams with 0.55–0.85 PURb/WS ratios fall into the fourth stability level and are characterised as extremely stable foams. However, the PUR biocomposite foams at a 0.40 PURb/WS ratio exceed the limits of the fourth level and fall into the third level. These slight changes might be attributed to the fact that WS particles in such PUR biocomposite foams are more exposed to a humid environment, which has a slightly negative effect on the final product. Additionally, according to the results presented in

Table 7, PUR biocomposite foams when tested at −20 °C can be described as extremely stable and fall into the highest level indicated by the product standard. In each case, the dimensional stability of PUR biocomposite foams exposed to various environmental conditions are still considered to be stable and within commercially acceptable limits. Even though the test duration was only 2 days, similar conclusions have been made after 14 days of exposure at different conditions of PUR foam with pigment filler [

62].

3.6. Comparison of the Obtained Results with the State-of-the-Art

After conducting a thorough literature review,

Table 8 was concluded. It shows the types of WW-based fillers used for various polymers-based biocomposites and foams. The numerical values presented in various references are quite different. This can be attributed to the WW-based fillers amounts used for the preparation of products as well as the type and application of the product.

Higher values of compressive and tensile strengths are mostly obtained for PUR biocomposites used, e.g., for structural, decorative, furniture, etc., applications, while lower strength results are attributed to thermal insulation and sound-absorbing foams. The performance of biocomposite foams independently on the foamed matrix used is determined by the interface between fibre/aggregate and polymer binder. Additionally, the size of fillers/aggregates and the production technology with its parameters are of great importance as well.

Comparing the results of the thermal conductivity and mechanical performance of the current study and

Table 8, it can be stated that the obtained WW-based PUR biocomposite foams are competitive to the ones already studied by other authors. However, there is a lack of information about short-term absorption by partial immersion of various polymers-based biocomposite foams. Therefore, it is hard to compare the obtained numerical values in

Table 8 with the percentage values obtained in a current study.