Enhanced Magneto-Optic Properties in Sputtered Bi- Containing Ferrite Garnet Thin Films Fabricated Using Oxygen Plasma Treatment and Metal Oxide Protective Layers

Abstract

1. Introduction

2. Background and Transitional Layer Properties

3. Garnet Layers Sputter-Deposition and Annealing Process and Parameters

4. Results

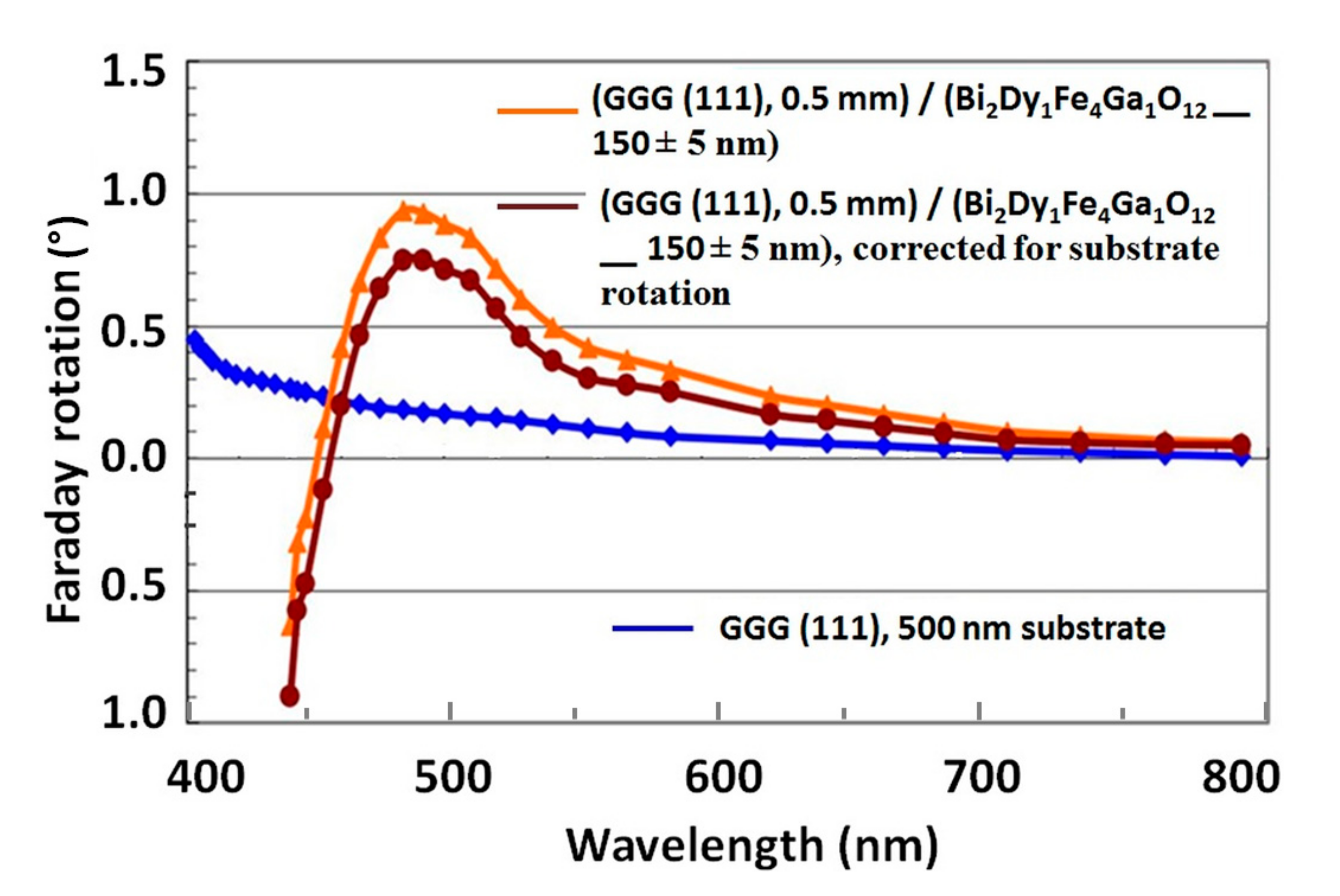

4.1. Spectral Dependencies of Faraday Rotation Measured for Nanocrystalline Films of Composition Bi2Dy1Fe4Ga1O12

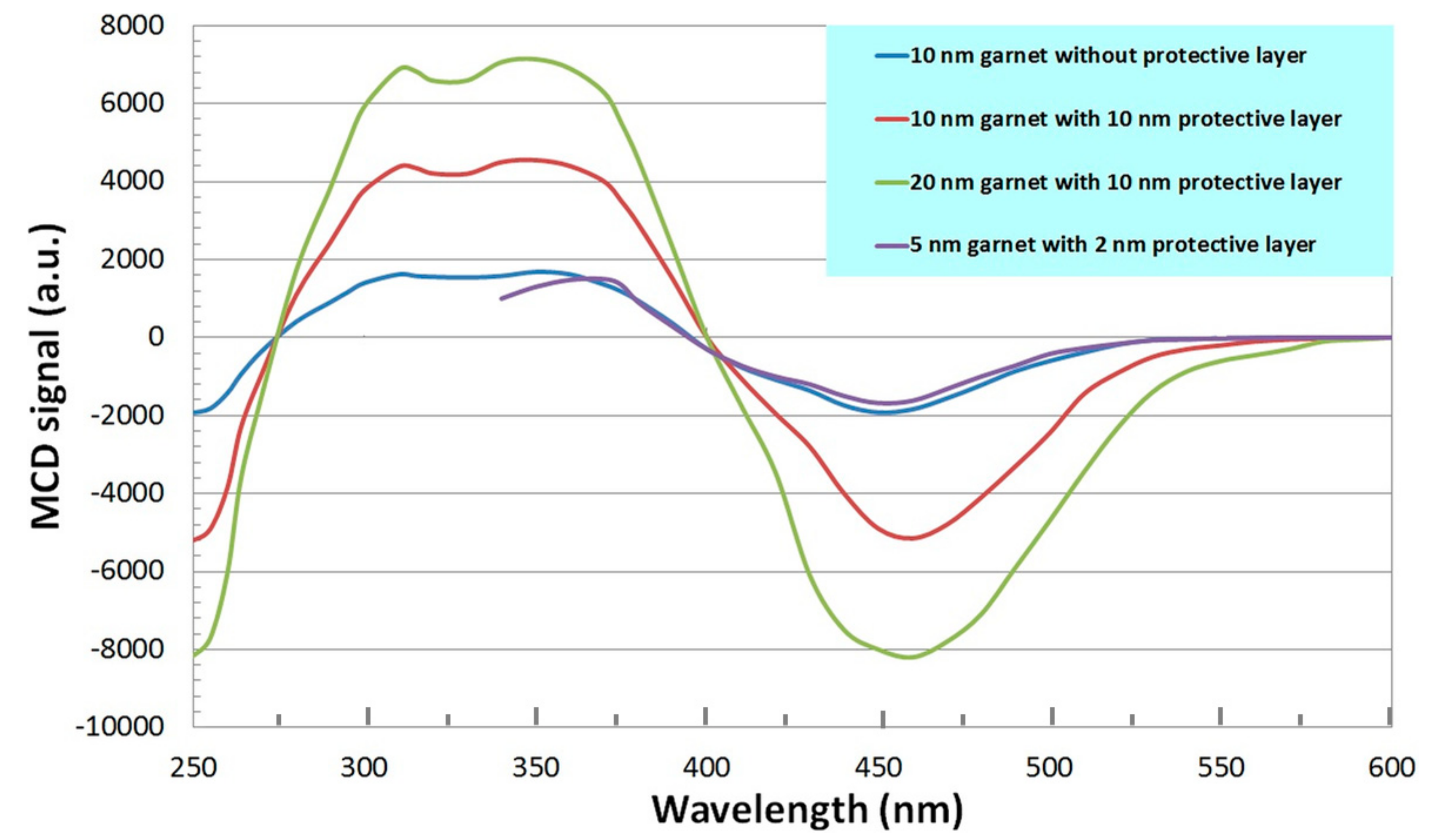

4.2. Scpectral Dependencies of Magnetic Circular Dichroism for Standard Nanocomposite-Type Samples of Bi2Dy1Fe4Ga1O12 + Bi2O3

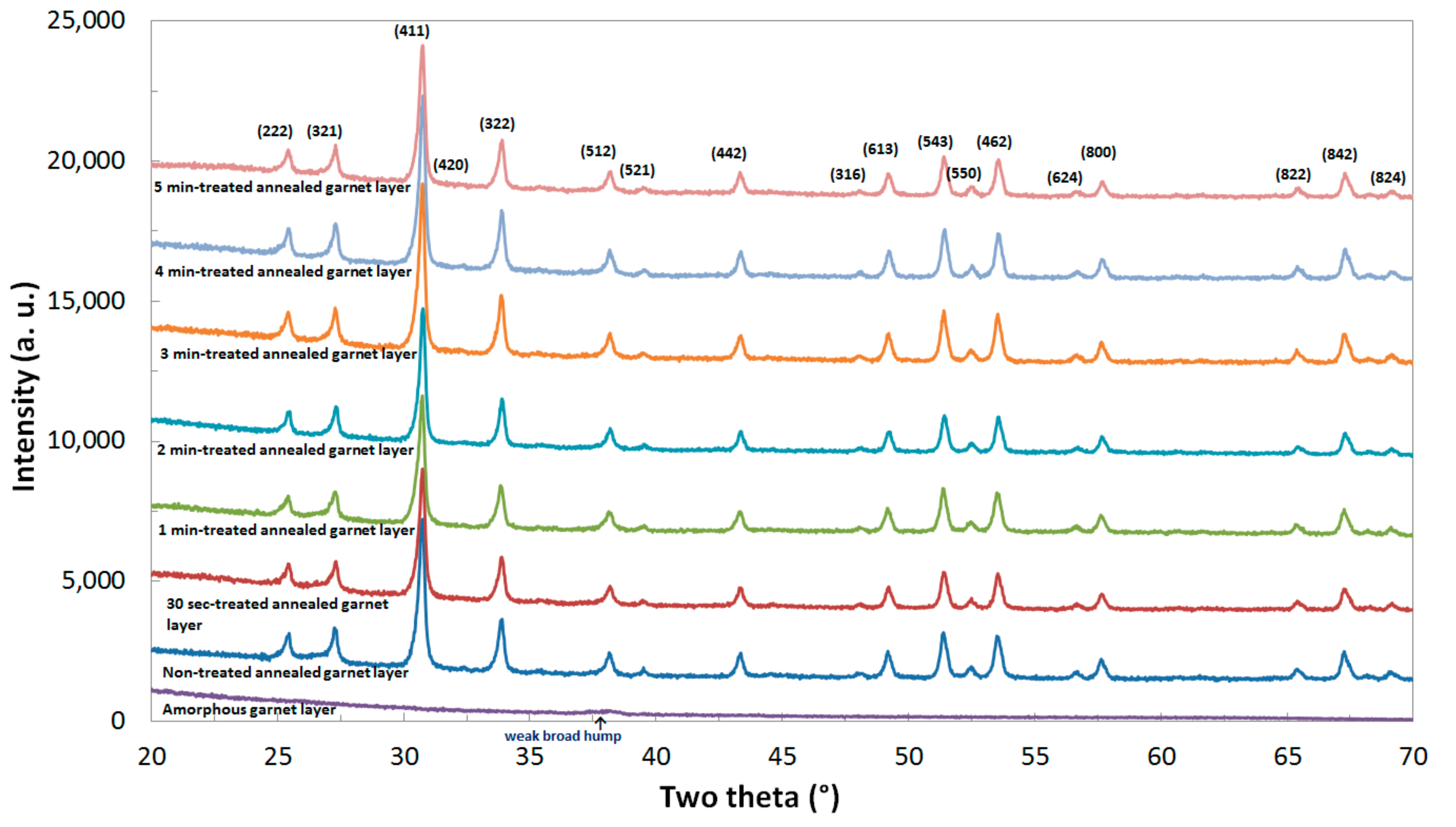

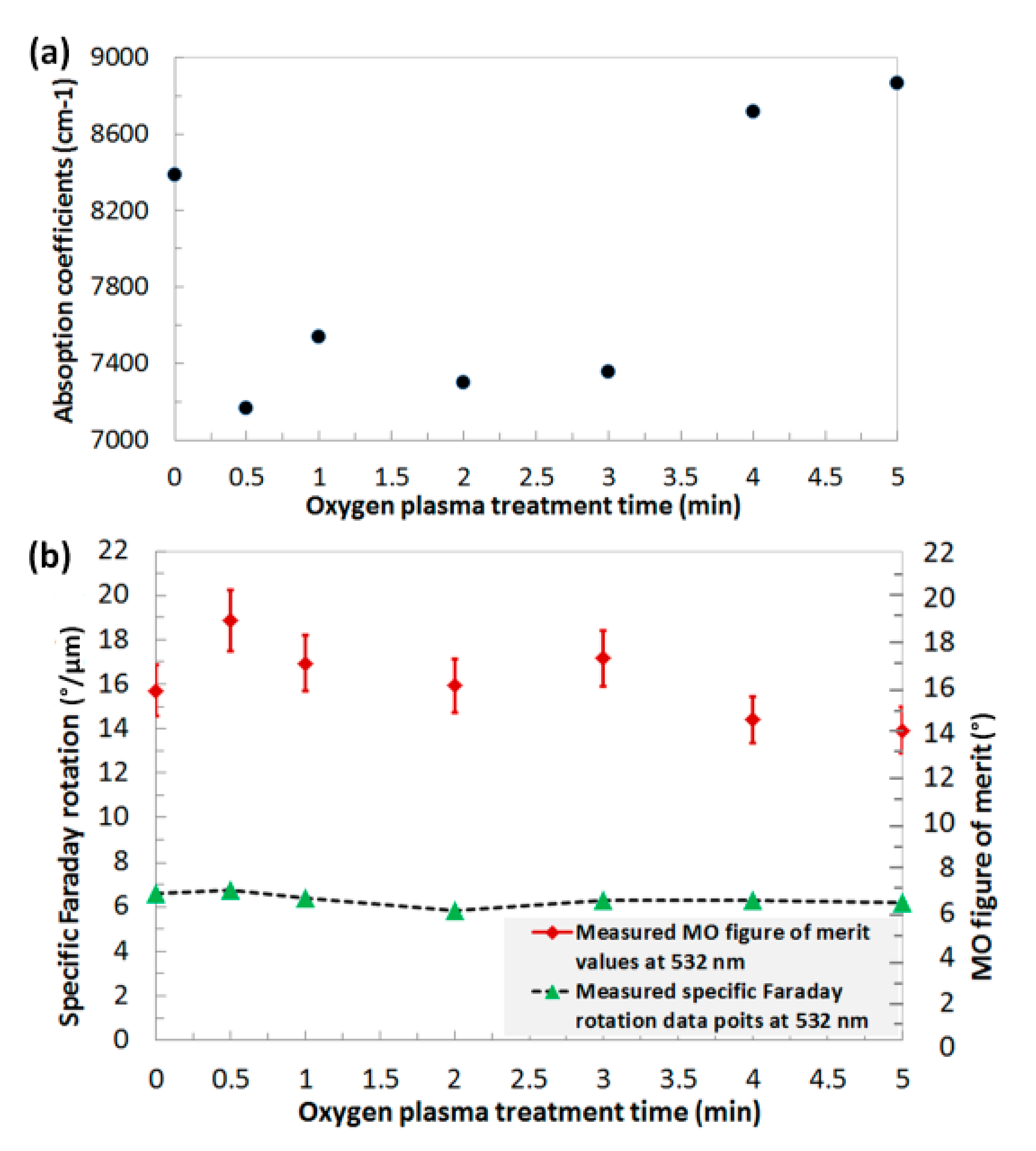

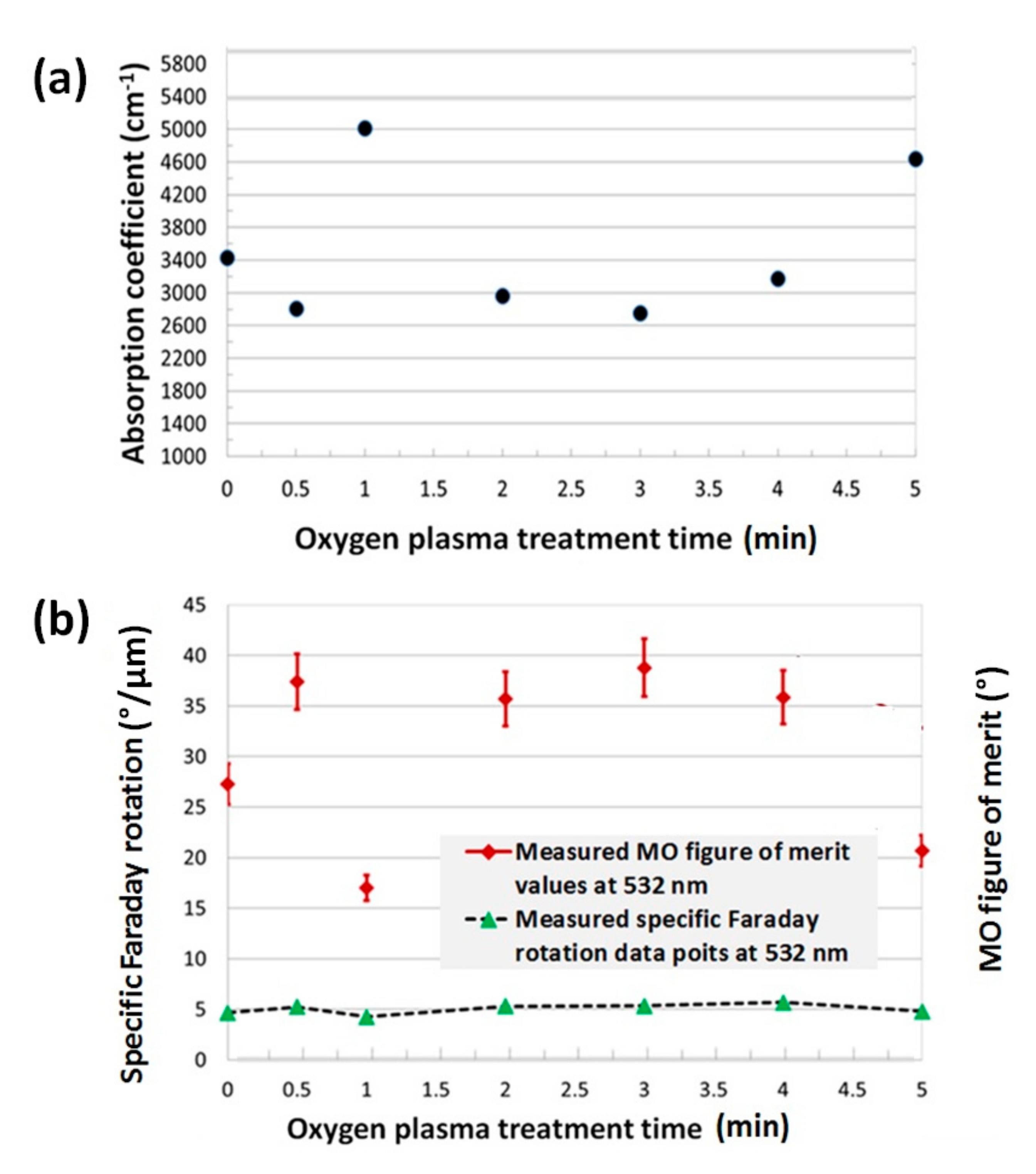

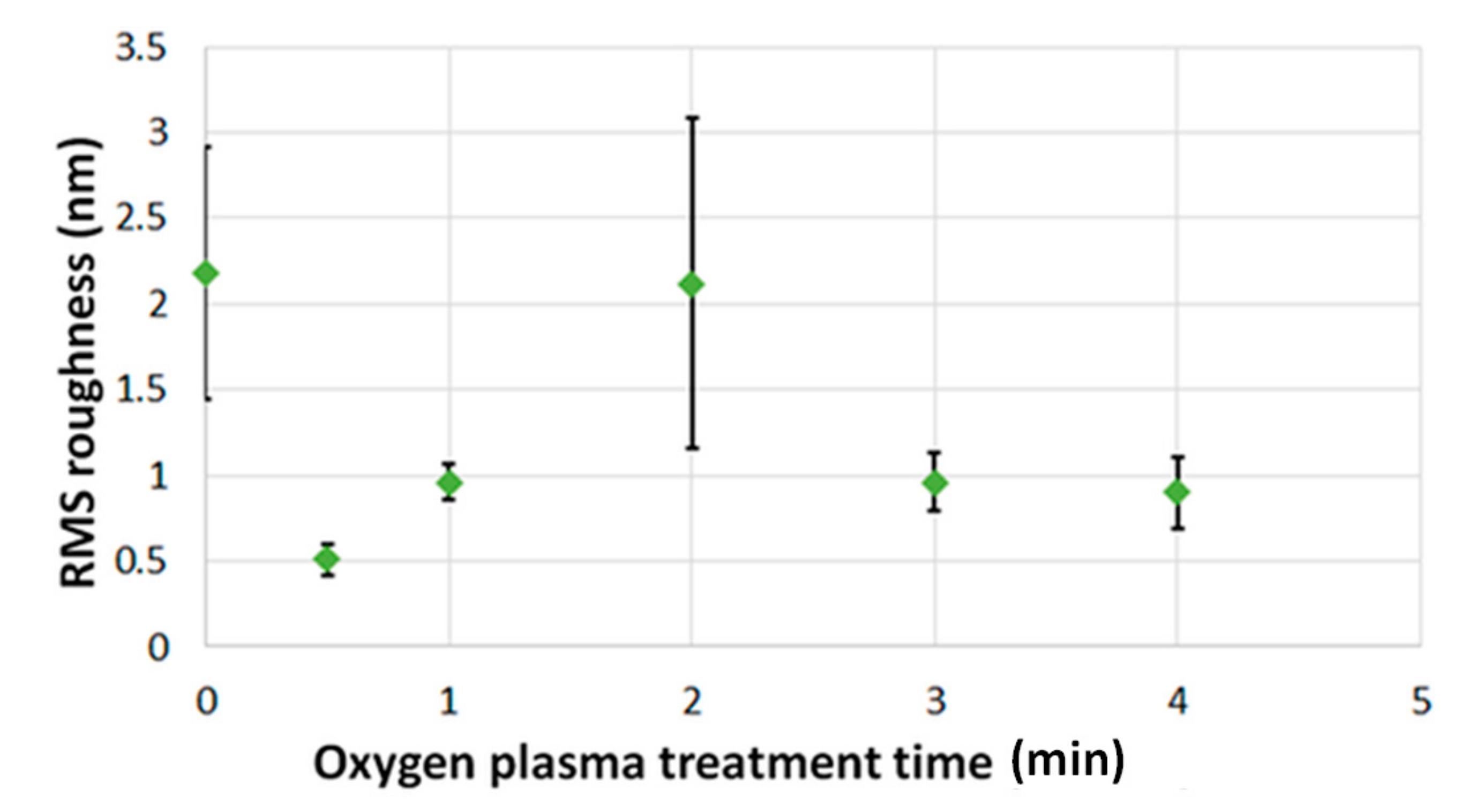

4.3. Bi2.1Dy0.9Fe3.9Ga1.1O12 and Bi1.8Lu1.2Fe3.6Al1.4O12 Garnet Layers Annealed Followed by Post-Deposition Oxygen Plasma Treatment

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zvezdin, A.K.; Kotov, V.A. Modern Magnetooptics and Magnetooptical Materials; Institute of Physics Publishing Bristol and Philadelphia: Boca Raton, FL, USA, 1997. [Google Scholar] [CrossRef]

- Kahl, S.; Grishin, S.I.; Kharstev, S.I.; Kawano, K.; Abell, J.S. Bi3Fe5O12 Thin film visualizer. IEEE. Trans. Mag. 2001, 3, 2457–2459. [Google Scholar] [CrossRef]

- Nur-E-Alam, M.; Vasiliev, M.; Alameh, K. High-performance RF-sputtered Bi-substituted iron garnet thin films with almost in-plane magnetization. Opt. Mater. Express 2017, 7, 676. [Google Scholar] [CrossRef]

- Nur-E-Alam, M.; Vasiliev, M.; Kotov, V.A.; Alameh, K. Highly bismuth-substituted, record-performance magneto-optic garnet materials with low coercivity for applications in integrated optics, photonic crystals, imaging and sensing. Opt. Mater. Express 2011, 1, 413. [Google Scholar] [CrossRef]

- Vasiliev, M.; Alam, M.N.-E.; Kotov, V.A.; Alameh, K.; Belotelov, V.I.; Burkov, V.I.; Zvezdin, A.K. RF magnetron sputtered (BiDy)3(FeGa)5O12:Bi2O3 composite garnet-oxide materials possessing record magneto-optic quality in the visible spectral region. Opt. Express 2009, 17, 19519. [Google Scholar] [CrossRef] [PubMed]

- Syvorotka, I.M.; Ubizskii, S.B.; Kucera, M.; Kuhn, M.; Vertesy, Z. Growth and characterization of Bi, Pr-and Bi, Sc-substituted lutetium iron garnet films with planar magnetization for magneto-optic visualization. J. Phys. D Appl. Phys. 2001, 34, 117–1187. [Google Scholar] [CrossRef]

- Zamani, M.; Ghanaatshoar, M. Adjustable magneto-optical isolators with flat-top responses. Opt. Express 2012, 20, 24522–24535. [Google Scholar] [CrossRef] [PubMed]

- Hibiya, T.; Morishige, Y.; Nakashima, J. Growth and Characterization of Liquid-Phase Epitaxial Bi-Substituted Iron Garnet Films for Magneto-Optic Application. Jpn. J. Appl. Phys. 1985, 24, 1316–1319. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, S. A New Bi-substituted Rare-earth Iron Garnet for a Wideband and Temperature-stabilized Optical Isolator. J. Mater. Res. 2000, 15, 1665–1668. [Google Scholar] [CrossRef]

- Zeazjev, M. Magneto-optic iron-garnet thin films for integrated optical applications. SPIE Newsroom 2007. [Google Scholar] [CrossRef]

- Anoikin, E.V.; Sides, P.J. Plasma-activated chemical vapor deposition of bismuth-substituted iron garnets for magneto-optical data storage. IEEE Trans. Magn. 1995, 31, 3239–3241. [Google Scholar] [CrossRef]

- Kang, S.; Yin, S.; Adyam, V.; Li, Q.; Zhu, Y. Bi3Fe4Ga1O12 Garnet Properties and Its Application to Ultrafast Switching in the Visible Spectrum. IEEE Trans. Magn. 2007, 43, 3656–3660. [Google Scholar] [CrossRef]

- Aichele, T.; Lorenz, A.; Hergt, R.; Görnert, P. Garnet layers prepared by liquid phase epitaxy for microwave and magneto-optical applications—A review. Cryst. Res. Technol. 2003, 38, 575–587. [Google Scholar] [CrossRef]

- Gomi, M.; Tanida, T.; Abe, M. RF sputtering of highly Bi-substituted garnet films on glass substrates for magneto-optic memory. J. Appl. Phys. 1985, 57, 3888–3890. [Google Scholar] [CrossRef]

- Goossens, V.; Wielant, J.; Van Gils, S.; Finsy, R.; Terryn, H. Optical properties of thin iron oxide films on steel. Surf. Interface Anal. 2006, 38, 489–493. [Google Scholar] [CrossRef]

- Van der Zaag, P.J.; Fontijn, W.F.J.; Gaspard, P.; Wolf, R.M.; Brabers, V.A.M.; van de Veerdonk, R.J.M.; van der Heijden, P.A.A. A study of the magneto-optical Kerr spectra of bulk and ultrathin Fe3O4. J. Appl. Phys. 1996, 79, 5936. [Google Scholar] [CrossRef]

- Eschenfelder, A. Magnetic Bubble Technology; Springer: New York, NY, USA, 1980. [Google Scholar]

- Ivanov, V.E.; Kandaurova, G.S.; Svalov, A.V. Amorphous gadolinium-cobalt films as sensitive media for the topographic mapping nonuniform temperature fields. Tech. Phys. 1997, 42, 823–827. [Google Scholar] [CrossRef]

- Kandaurova, G.S.; Sviderskiy, A.; Klin, V.P.; Chany, V.I. Ferrite-garnet films, domain dynamic structure and anger state. J. Mag. Mag. Magn. 1995, 140, 2135–2136. [Google Scholar] [CrossRef]

- Hanna, S.M.; Friedlaender, F.J.; Gunshor, R.L.; Sato, H. Propagation of surface acoustic-waves in magnetic-bubble garnet-films. IEEE. Trans. Mag. 1983, 19, 1802–1804. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kim, J.S.; Kim, S.I.; Levy, M. Epitaxial Growth and Properties of Bi-Substituted Yttrium-Iron-Garnet Films Grown on (111) Gadolinium-Gallium-Garnet Substrates by Using rf Magnetron Sputtering. J. Korean Phys. Soc. 2003, 43, 400–405. [Google Scholar]

- Jongwannasiri, C.; Watanabe, S. Effects of RF Power and Treatment Time on Wettability of Oxygen Plasma-Treated Diamond-like Carbon Thin Films. Int. J. Chem. Eng. Appl. 2014, 5, 13–16. [Google Scholar] [CrossRef]

- Song, B.J.; Hong, K.; Kim, W.-K.; Kim, K.; Kim, S.; Lee, J.-L. Effect of Oxygen Plasma Treatment on Crystal Growth Mode at Pentacene/Ni Interface in Organic Thin-Film Transistors. J. Phys. Chem. B 2010, 114, 14854–14859. [Google Scholar] [CrossRef] [PubMed]

- Faber, H.; Hirschmann, J.; Klaumünzer, M.; Braunschweig, B.; Peukert, W.; Halik, M. Impact of Oxygen Plasma Treatment on the Device Performance of Zinc Oxide Nanoparticle-Based Thin-Film Transistors. ACS Appl. Mater. Interfaces 2012, 4, 1693–1696. [Google Scholar] [CrossRef] [PubMed]

- Vesel, A.; Mozetic, M. Surface functionalization of organic materials by weakly ionized highly dissociated oxygen plasma. J. Phys. Conf. Ser. 2009, 162, 012015. [Google Scholar] [CrossRef]

- Roh, J.W.; Yang, J.S.; Ok, S.H.; Woo, D.H.; Byun, Y.T.; Jhon, Y.M.; Mizumoto, T.; Lee, W.Y.; Lee, S. Low Temperature O2 Plasma-Assisted Wafer Bonding of InP and a Garnet Crystal for an Optical Waveguide Isolator. Solid State Phenom. 2007, 124–126, 475–478. [Google Scholar] [CrossRef]

- Mehmood, T.; Kaynak, A.; Dai, X.J.; Kouzani, A.; Magniez, K.; Rubin de Celis, D.; Hurren, C.J.; du Plessis, J. Study of oxygen plasma pre-treatment of polyester fabric for improved polypyrrole adhesion. Mater. Chem. Phys. 2014, 143, 668–675. [Google Scholar] [CrossRef]

- Bhoi, B.; Mahender, C.; Venkataramani, N.; Aiyar, R.P.R.C.; Prasad, S. Effect of Oxygen Pressure on the Magnetic Properties of Yttrium-Iron-Garnet Thin Films Made by Pulsed Laser Deposition. IEEE Magn. Lett. 2016, 7, 1–4. [Google Scholar] [CrossRef]

- Yu, D.; Lu, Y.F.; Xu, N.; Sun, J.; Ying, Z.F.; Wu, J.D. Preparation of α-Al2O3 thin films by electron cyclotron resonance plasma-assisted pulsed laser deposition and heat annealing. J. Vac. Sci. Technol. A Vac. Surf. Film. 2008, 26, 380–384. [Google Scholar] [CrossRef]

- Nachimuthu, R.K.; Jeffery, R.D.; Martyniuk, M.; Woodward, R.C.; Metaxas, P.J.; Dell, J.M.; Faraone, L. Investigation of Cerium-Substituted Europium Iron Garnets Deposited by Biased Target Ion Beam Deposition. IEEE Trans. Magn. 2014, 50, 1–7. [Google Scholar] [CrossRef]

- Loho, C.; Djenadic, R.; Bruns, M.; Clemens, O.; Hahn, H. Garnet-Type Li7La3Zr2O12 Solid Electrolyte Thin Films Grown by CO2-Laser Assisted CVD for All-Solid-State Batteries. J. Electrochem. Soc. 2017, 164, A6131–A6139. [Google Scholar] [CrossRef]

- Ma, Q.; Ogino, A.; Matsuda, T.; Nagatsu, M. Defect Control of ZnO Nano-particles Fabricated by Pulsed Nd:YAG Laser Ablation. Trans. Mater. Res. Soc. Jpn. 2010, 35, 611–615. [Google Scholar] [CrossRef]

- Kaynak, A.; Mehmood, T.; Dai, X.; Magniez, K.; Kouzani, A. Study of Radio Frequency Plasma Treatment of PVDF Film Using Ar, O2 and (Ar + O2) Gases for Improved Polypyrrole Adhesion. Materials 2013, 6, 3482–3493. [Google Scholar] [CrossRef] [PubMed]

- Leitenmeier, S.; Heinrich, A.; Lindner, J.K.N.; Stritzker, B. Growth of epitaxial bismuth and gallium substituted lutetium iron garnet films by pulsed laser deposition. J. Appl. Phys. 2006, 99, 08M704. [Google Scholar] [CrossRef]

- Pandiyaraj, K.N.; Kumar, A.A.; Ramkumar, M.C.; Sachdev, A.; Gopinath, P.; Cools, P.; De Geyter, N.; Morent, R.; Deshmukh, R.R.; Hegde, P.; et al. Influence of non-thermal TiCl4/Ar + O2 plasma-assisted TiOx based coatings on the surface of polypropylene (PP) films for the tailoring of surface properties and cytocompatibility. Mater. Sci. Eng. C 2016, 62, 908–918. [Google Scholar] [CrossRef] [PubMed]

- Christen, H.M.; Ohkubo, I.; Rouleau, C.M.; Jellison, G.E., Jr.; Puretzky, A.A.; Geohegan, D.B.; Lowndes, D.H. A laser-deposition approach to compositional-spread discovery of materials on conventional sample sizes. Meas. Sci. Technol. 2005, 16, 21–31. [Google Scholar] [CrossRef]

- Krumme, J.-P.; David, B.; Doormann, V.; Eckart, R.; Rab, G.; Dossεl, O. Growth, morphology and superconductivity of epitaxial (RΕ)1Ba2Cl13O7-δ films on SrTiO3 and NdGaO3. Substrates 1997, 1, 55–68. [Google Scholar]

- Kotov, V.A.; Balabanov, D.E.; Grigorovich, S.M.; Kozlov, V.I.; Nevolin, V.K. Magnetic and magnetooptical properties of the transition layer in epitaxial bismuth–gallium iron garnet structures. Sov. Phys. Tech. Phys. 1986, 31, 544–549. [Google Scholar]

- Sun, Y.; Song, Y.-Y.; Chang, H.; Kabatek, M.; Jantz, M.; Schneider, W.; Wu, M.; Schultheiss, H.; Hoffmann, A. Growth and ferromagnetic resonance properties of nanometer-thick yttrium iron garnet films. Appl. Phys. Lett. 2012, 101, 152405. [Google Scholar] [CrossRef]

- Nur-E-Alam, M.; Vasiliev, M.; Alameh, K.; Kotov, V.; Demidov, V.; Balabanov, D. YIG: Bi2O3 Nanocomposite Thin Films for Magnetooptic and Microwave Applications. J. Nanomater. 2015, 2015, 1–6. [Google Scholar] [CrossRef]

- Balabanov, D.E.; Kotov, V.A.; Shavrov, V.G.; Vasiliev, M.; Alameh, K. Magneto-optical methods for analysis of nanothick magnetodielectric films. J. Commun. Technol. Electron. 2017, 62, 78–82. [Google Scholar] [CrossRef]

- Vasiliev, M.; Alameh, K.; Nur-E-Alam, M. Analysis, Optimization and characterization of magnetic photonic crystal structures and thin-film material layers. Technologies 2019, 7, 49. [Google Scholar] [CrossRef]

| Sample Preparation Stage | Process Parameters | Values & Comments |

|---|---|---|

| Garnet layers deposition | Sputtering target stoichiometry oxide-mixed garnet targets | Bi2Dy1Fe4Ga1O12, Bi2.1Dy0.9Fe3.9Ga1.1O12, Bi1.8 Lu1.2Fe3.6Ga1.4O12 and Bi2O3 |

| Base pressure | 4–5 × 10-6 Torr | |

| Argon (Ar) pressure | ≈2 mTorr | |

| Substrate stage temperature | Room Temperature 21–23 °C | |

| Substrate stage rotation rate | 16–17 rpm | |

| Oxygen plasma treatment | Base pressure | 750 mTorr |

| Oxygen flow | 0.2 sccm/min | |

| RF power densities | 40 W | |

| Plasma exposure time | 30 s to 5 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotov, V.A.; Nur-E-Alam, M.; Vasiliev, M.; Alameh, K.; Balabanov, D.E.; Burkov, V.I. Enhanced Magneto-Optic Properties in Sputtered Bi- Containing Ferrite Garnet Thin Films Fabricated Using Oxygen Plasma Treatment and Metal Oxide Protective Layers. Materials 2020, 13, 5113. https://doi.org/10.3390/ma13225113

Kotov VA, Nur-E-Alam M, Vasiliev M, Alameh K, Balabanov DE, Burkov VI. Enhanced Magneto-Optic Properties in Sputtered Bi- Containing Ferrite Garnet Thin Films Fabricated Using Oxygen Plasma Treatment and Metal Oxide Protective Layers. Materials. 2020; 13(22):5113. https://doi.org/10.3390/ma13225113

Chicago/Turabian StyleKotov, V. A., M. Nur-E-Alam, M. Vasiliev, K. Alameh, D. E. Balabanov, and V. I. Burkov. 2020. "Enhanced Magneto-Optic Properties in Sputtered Bi- Containing Ferrite Garnet Thin Films Fabricated Using Oxygen Plasma Treatment and Metal Oxide Protective Layers" Materials 13, no. 22: 5113. https://doi.org/10.3390/ma13225113

APA StyleKotov, V. A., Nur-E-Alam, M., Vasiliev, M., Alameh, K., Balabanov, D. E., & Burkov, V. I. (2020). Enhanced Magneto-Optic Properties in Sputtered Bi- Containing Ferrite Garnet Thin Films Fabricated Using Oxygen Plasma Treatment and Metal Oxide Protective Layers. Materials, 13(22), 5113. https://doi.org/10.3390/ma13225113