4.1. Calculation Formula Based on Long-Term Deformation Theory of Concrete

The total deflection of a concrete beam under long-term loading can be divided into three parts: the initial deflection caused by loading, the deflection increment caused by concrete creep, and concrete shrinkage.

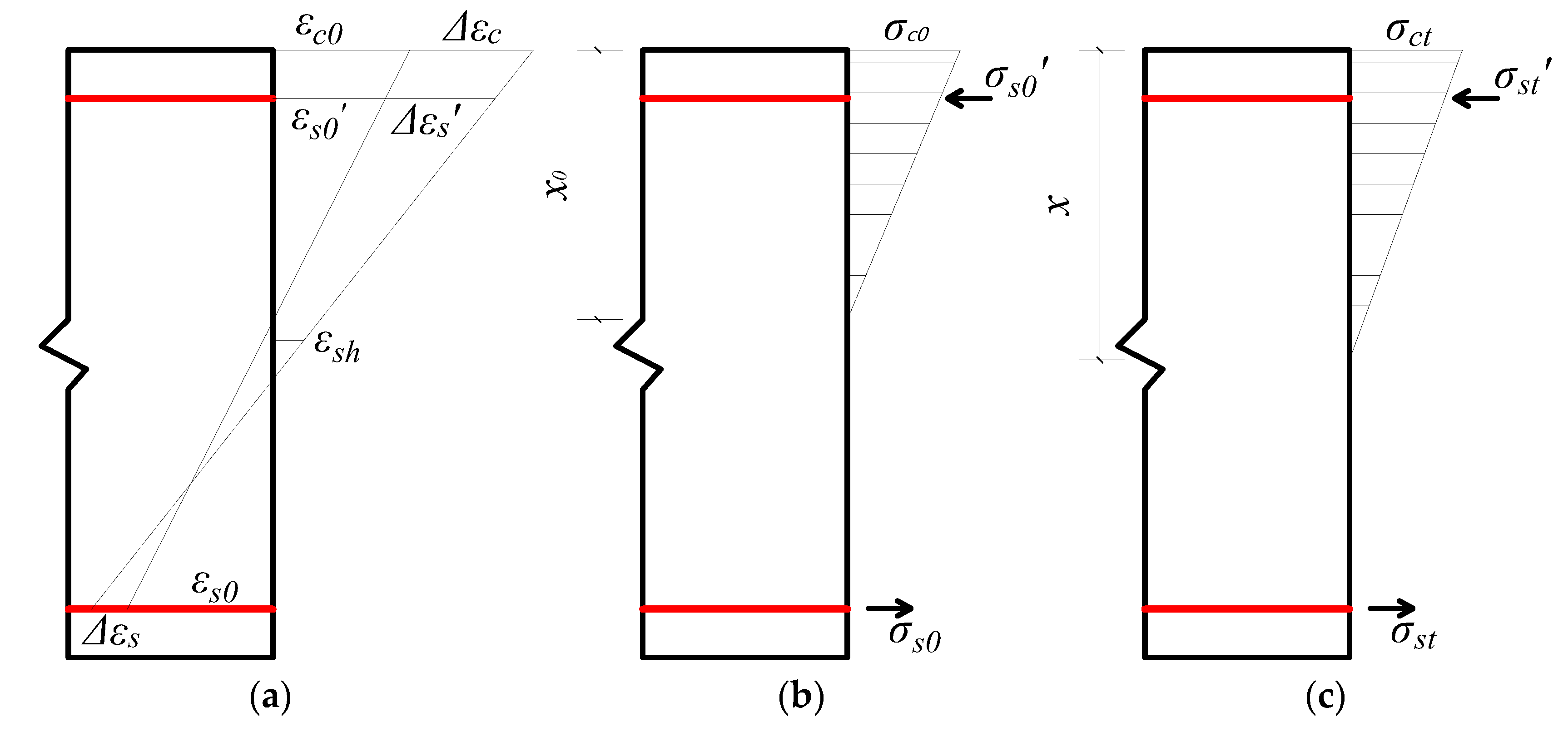

Under the effect of long-term loading, the stress–strain distribution of the concrete beam section is shown in

Figure 15.

t0 is defined as the initial moment when the beam is loaded to a stable long-term load, and t is any time point in the long-term loading process. In the process of loading, the tensile and compression bars endure a fixed bending moment. Due to the effect of shrinkage and creep, the concrete strain in the compression zone increases with time, but the reinforcement will not shrink or creep. Therefore, the deformation of the concrete in the compression zone will be confined by the compression reinforcement. The compressive stress in the concrete will continue to transfer to the reinforcement with time, and the internal force will continue to redistribute. Due to the fixed bending moment, to maintain the stress balance of the section, the height of the compression area of the concrete will continue to increase. Therefore, the shrinkage and creep of the concrete are the main cause of the increase in the deformation of the concrete beam with time.

In the long-term deflection calculation of concrete beams, the following basic assumptions are adopted [

54,

55]:

- (1)

Under the effect of short-term loading, the concrete in the tension area cracks, and the stress of the concrete in the compression area is not considered.

- (2)

Under the effect of long-term loading, the plane section assumption is still valid.

- (3)

Under long-term loading, the reinforcement and concrete work together without relative slip.

- (4)

Under long-term loading, the stress of the tensile steel bars changes only slightly and can be ignored.

- (5)

The calculation is performed by the age-adjusted effective modulus method.

In the time period from

t0 to

t, as the increment of the internal force and moment is 0, Equations (2) and (3) can be obtained.

where

,

, and

are the increment of the resultant force of the concrete compressive stress, the compression reinforcement, and the tensile reinforcement from

t0 to

t, respectively;

and

are the resultant compressive stresses of the concrete at

t and

t0, respectively;

h0 is the effective height of the beam section;

x and

x0 are the heights of the compression zone of the beam section at

t and

t0, respectively; and

is the distance from the resultant point of the compression reinforcement to the edge of the compression zone of the concrete.

Equations (4) and (5) can be obtained due to the plane section assumption and the age-adjusted effective modulus method.

where

,

, and

are the strain adjustment values of the concrete at the edge of the compression zone, the tensile reinforcement, and the compression reinforcement of the beam from

t0 to

t, respectively;

is the effective elastic modulus of the concrete adjusted by age at

t;

is the modulus of elasticity of the concrete at

t0;

is the age adjusted coefficient, which can be simplified as

; and

is the creep coefficient of the concrete from

t0 to

t, where the creep coefficient is the ratio of the creep strain

to the initial elastic strain under loading

, which can be simplified as

.

From

t0 to

t, the adjustment of the concrete compressive strain at the edge of the compression zone of the beam section

can be expressed by Equation (6).

where

is the adjustment of the compressive stress of the concrete from

t0 to

t, and

is the shrinkage strain of the concrete from

t0 to

t, which can be simplified to

.

The increment of the sectional curvature can be expressed by Equation (7).

It can be seen that the parameters of the formula are relatively complex. To simplify the calculation, some parameters are simplified on the basis of meeting the following accuracy requirements [

56]:

- (1)

should be taken as 0.1, under the condition of meeting the structural requirements of beam section reinforcements.

- (2)

is usually taken as 0.8.

- (3)

can be regarded as ; the approximate values are 1.25 and 0.3, respectively.

The simplified expression of the additional curvature

can be expressed by Equation (8).

where

is the curvature caused by creep, and

is the curvature caused by shrinkage.

The deflection of the beam caused by creep can be related to the creep curvature through the virtual work principle, and the curvature caused by shrinkage is constant along the longitudinal direction of the beam. The calculation formula of the creep and shrinkage deflection can be expressed by Equations (9) and (10).

The midspan deflection of the concrete beam under long-term loading can be expressed by Equation (11).

The simplified formula parameters are relatively simple, and the midspan deflection of the beam under long-term loading can be calculated by determining the creep coefficient and shrinkage strain .

4.2. Calculation Method of the Initial Deflection

The deflection of the beams under loading is calculated by Equation (12).

where

is the short-term stiffness of the concrete beam,

is the distance from the support to the loading point, and

is the distance between the two supports.

The short-term stiffness of the beams can be calculated by the stiffness analysis method. The calculation formula of the stiffness based on the analytical method in GB50010-2010 [

39] is given in Equation (13).

where

is the elastic modulus of the reinforcement;

is the total section area of the tensile reinforcement;

is the nonuniformity coefficient of the longitudinal tensile reinforcement,

;

and

are the axial tensile strength and compressive strength of the concrete, respectively;

αc2 is the reduction coefficient considering the brittleness of the concrete, with values ranging from 0.87 to 1;

σs is the steel stress at the crack section,

;

is the internal force arm coefficient of the cracked section;

M is the bending moment in the middle span of the beam;

is the ratio of the elastic modulus of the reinforcement to that of the concrete;

ρ is the ratio of the reinforcement; and

is the reinforcement ratio of the longitudinal tensile steel bars calculated by the effective tensile concrete section area,

.

The comparison between the deflection calculated by the formula and the measured value is shown in

Table 6 and

Table 7.

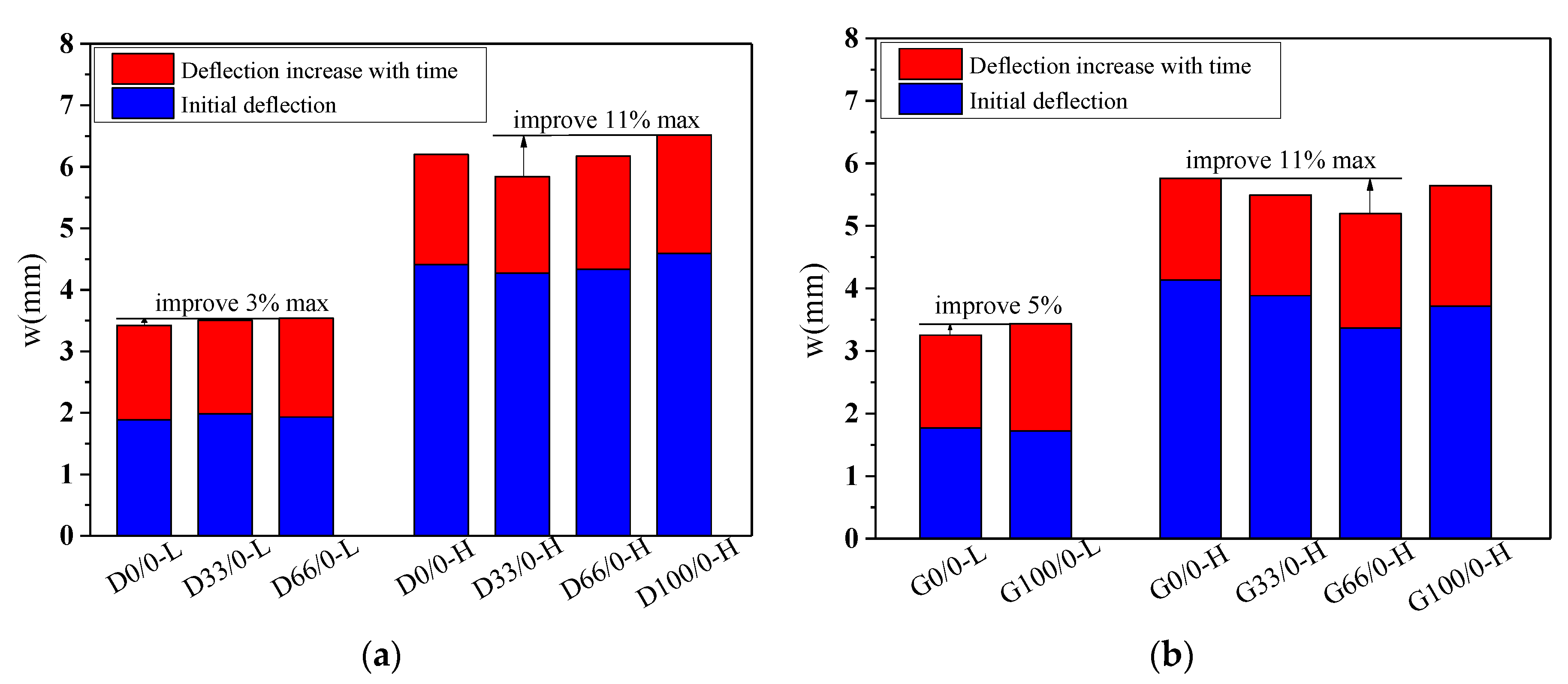

Table 6 shows that for the specimens without RFAs, the average ratio of the initial deflection calculated by the stiffness analysis method is 1.109, the standard deviation is 0.048, and the coefficient of variation is 0.043. This shows that the analytical method of calculating the stiffness can reasonably calculate the initial deflection of the beam and is conservative.

Table 7 shows that the initial deflection of the specimens with RFAs calculated by the stiffness analysis method is often smaller than the measured value. This shows that the analytical method of calculating the stiffness cannot effectively fit the initial deflection of beams with RFAs. Considering the influence of RFAs on the mechanical behavior of concrete, the nonuniformity coefficient

of the longitudinal tensile reinforcement is multiplied by the correction coefficient α. For specimens with RCAs, α is taken as 1.0; for specimens with RFAs or with both RCAs and RFAs, α is taken as 1.2. The results obtained by using the improved analytical method of calculating the stiffness are more conservative than the results calculated by other methods.

4.3. Calculation Method of the Deflection Increment

In the formula,

and

are generally calculated by the shrinkage and creep prediction model of concrete. The common concrete prediction models of shrinkage and creep are the CEB-FIP2010 model [

57] proposed by the European Concrete Association, the GL2000 model [

58], and the ACI209R-92 model [

59] proposed and recommended by the American Concrete Association. However, by analyzing the above models, the following observations can be made:

- (1)

The prediction models are for NAC, so the influence of recycled aggregates on the concrete shrinkage and creep is not considered.

- (2)

The model generally aims at specimens with stress ratios of less than 0.4, and the effect of a high stress ratio is not considered.

Therefore, based on the test data, the shrinkage and creep prediction model of RAC can be obtained by modifying the RAC characteristics.

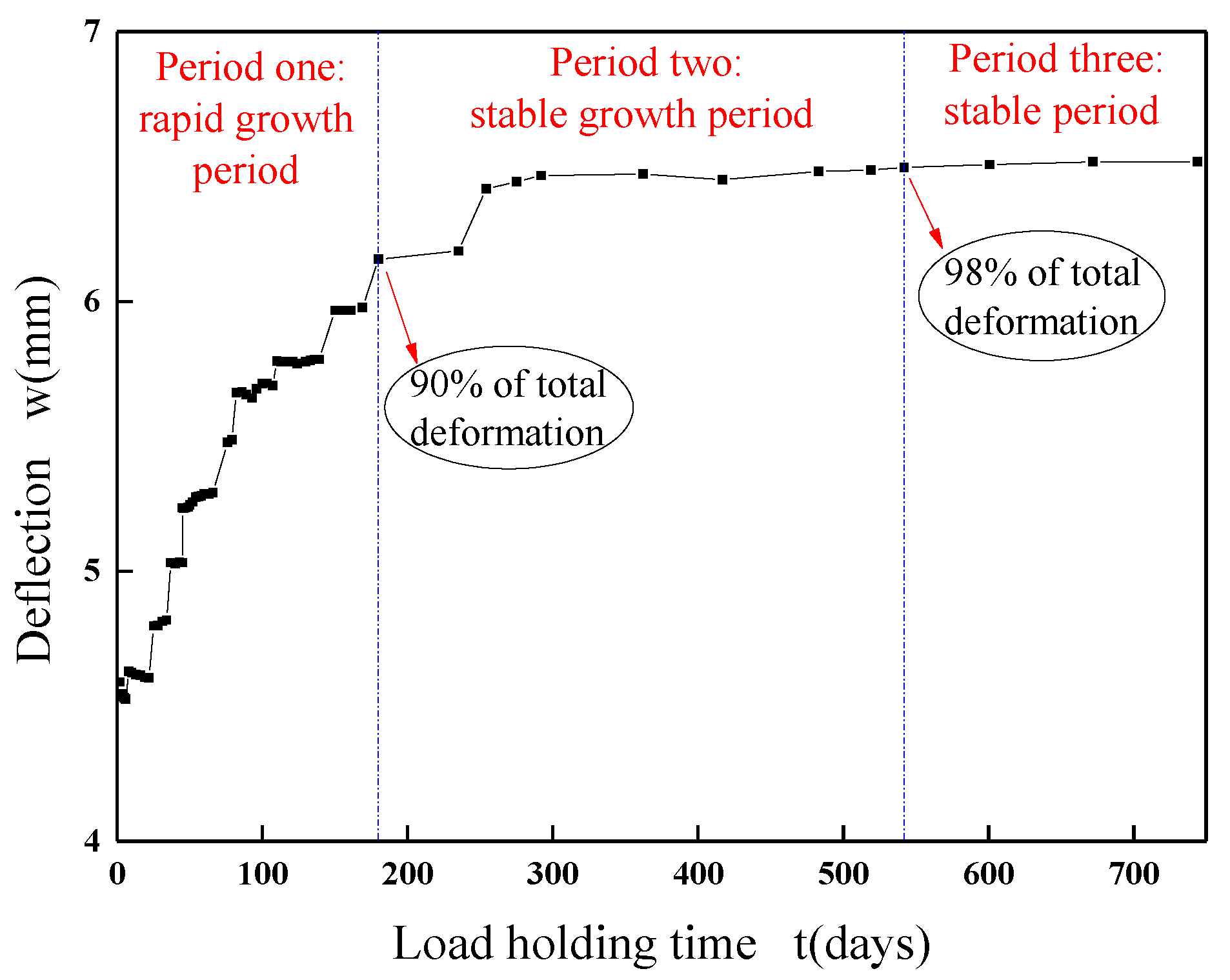

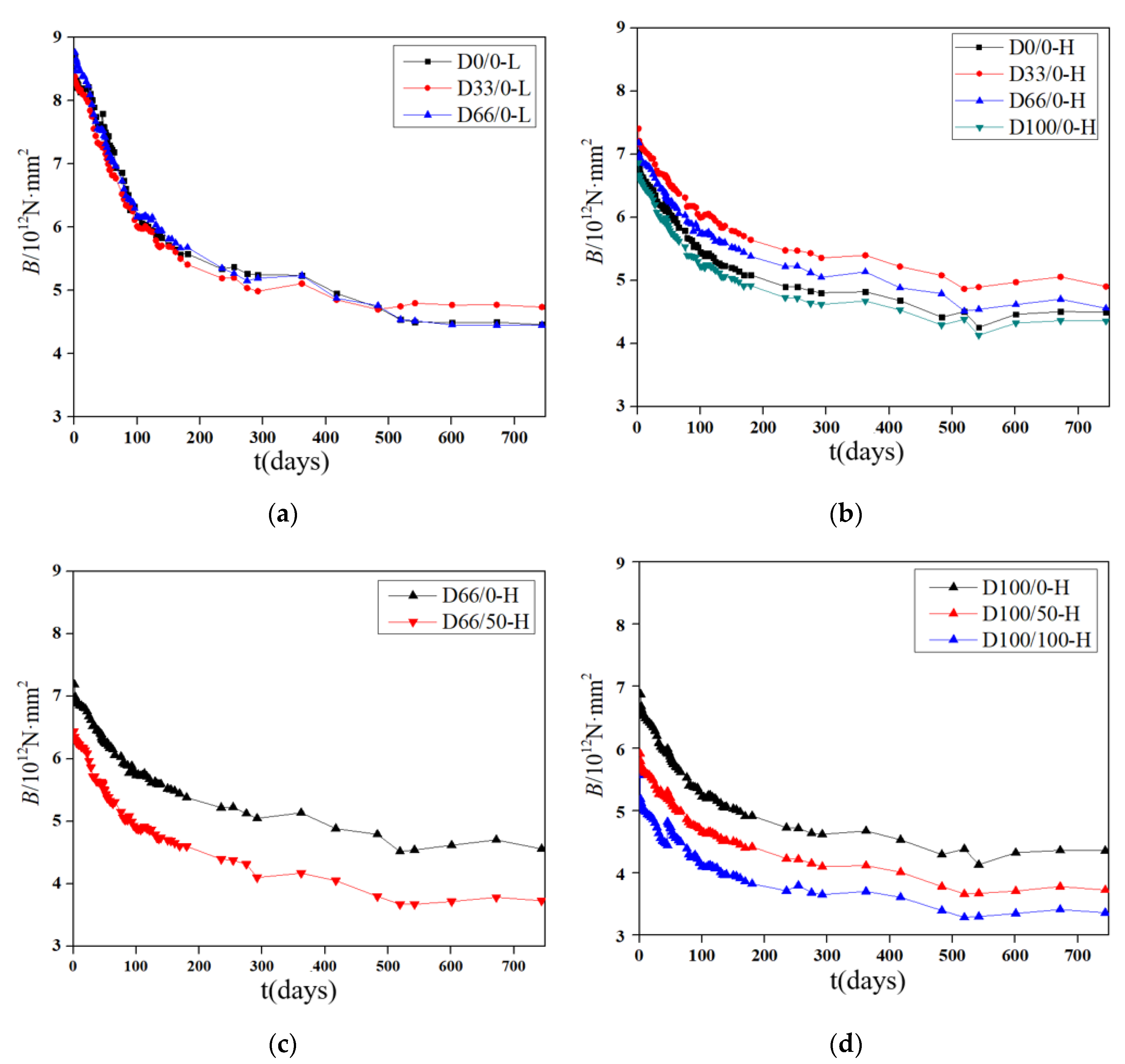

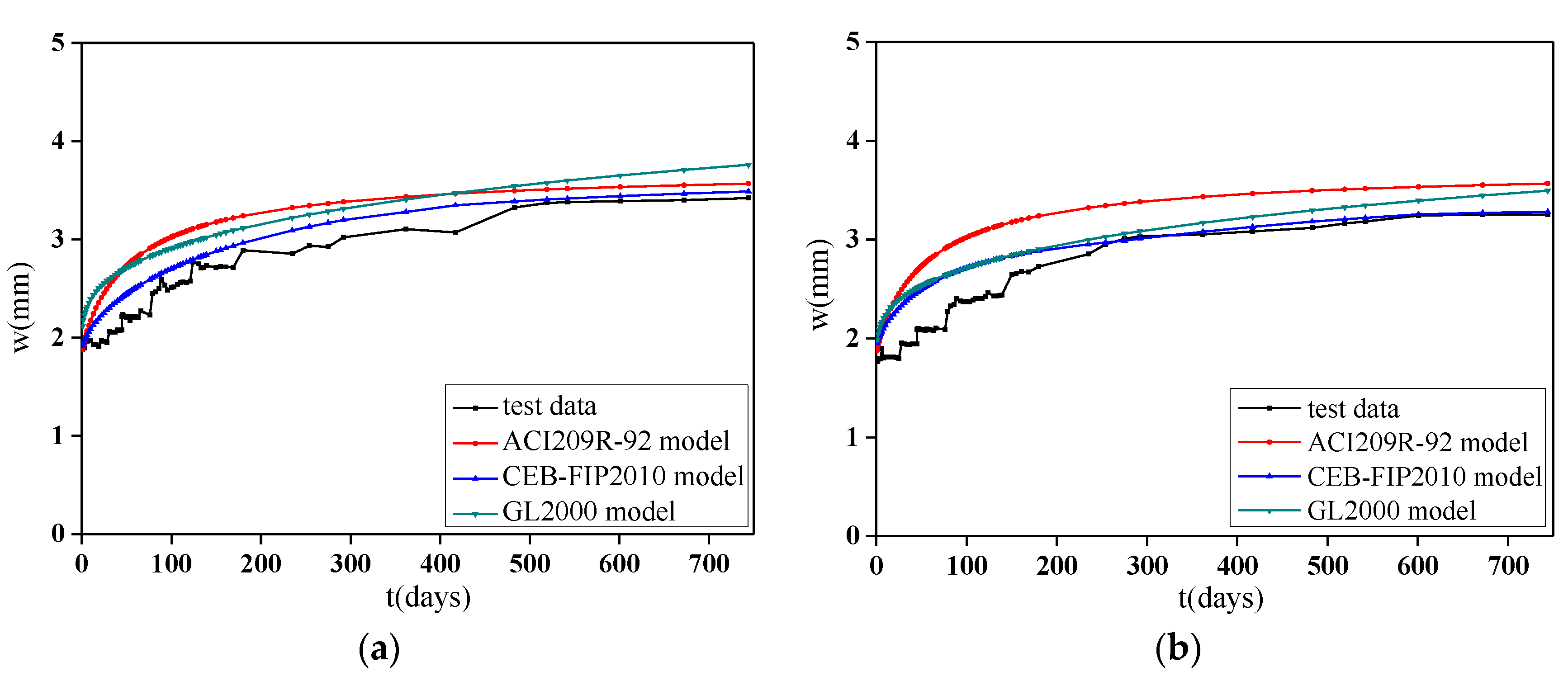

The deflection-load holding time curves of the NAC beams under low stress ratios obtained by the above three models are shown in

Figure 16. A comparison of the three curves reveals that the regular development pattern of the three models is similar to that of the experiment. The CEB-FIP2010 model is in good agreement with the test data and can reserve a certain amount of conservatism most of the time. Therefore, this model is selected as the basic model for the deflection increment calculation of RAC beams.

Compared with NAC beams, the larger self-shrinkage of the RAC is the main reason for the larger midspan deflection of the RAC beam. Based on this result, a correction coefficient is applied to the shrinkage strain of the prediction model. At a high stress ratio, the RCA and stress ratio will jointly affect the development of the deflection of the RAC beams. However, this study produced less data for high stress ratios, and the stress was more concentrated than that of other studies. Therefore, the influencing factors of the RCAs and RFAs on creep behavior are proposed, and the influencing factors of the RCAs on the creep are appropriately enlarged to ensure that the calculated deflection values of the beams under different stress ratios have a certain conservatism.

Based on the fitting results of the test data and considering the characteristics of RAC, new influence factors are proposed based on the shrinkage strain influence coefficient

:

, which is based on the influence of the RCAs and magnified appropriately, and

, which is based on the influence of the RFAs. The values are

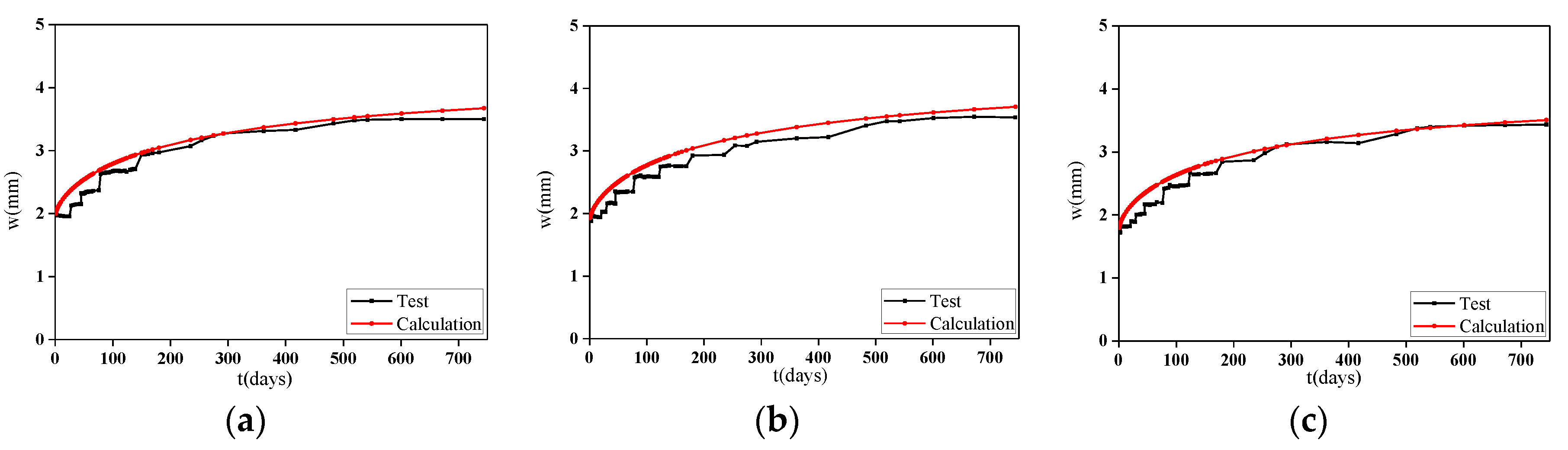

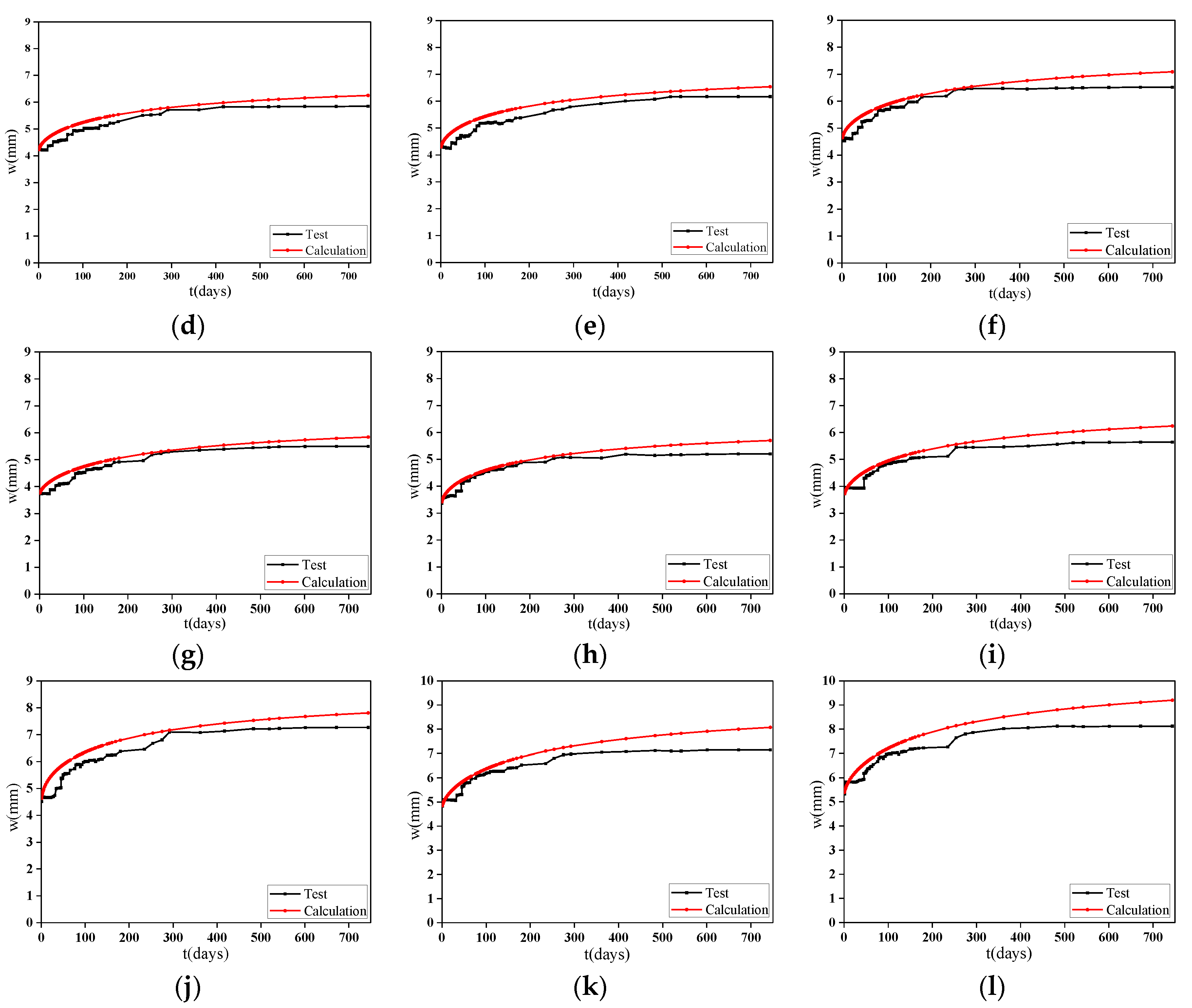

Based on the coefficient

and

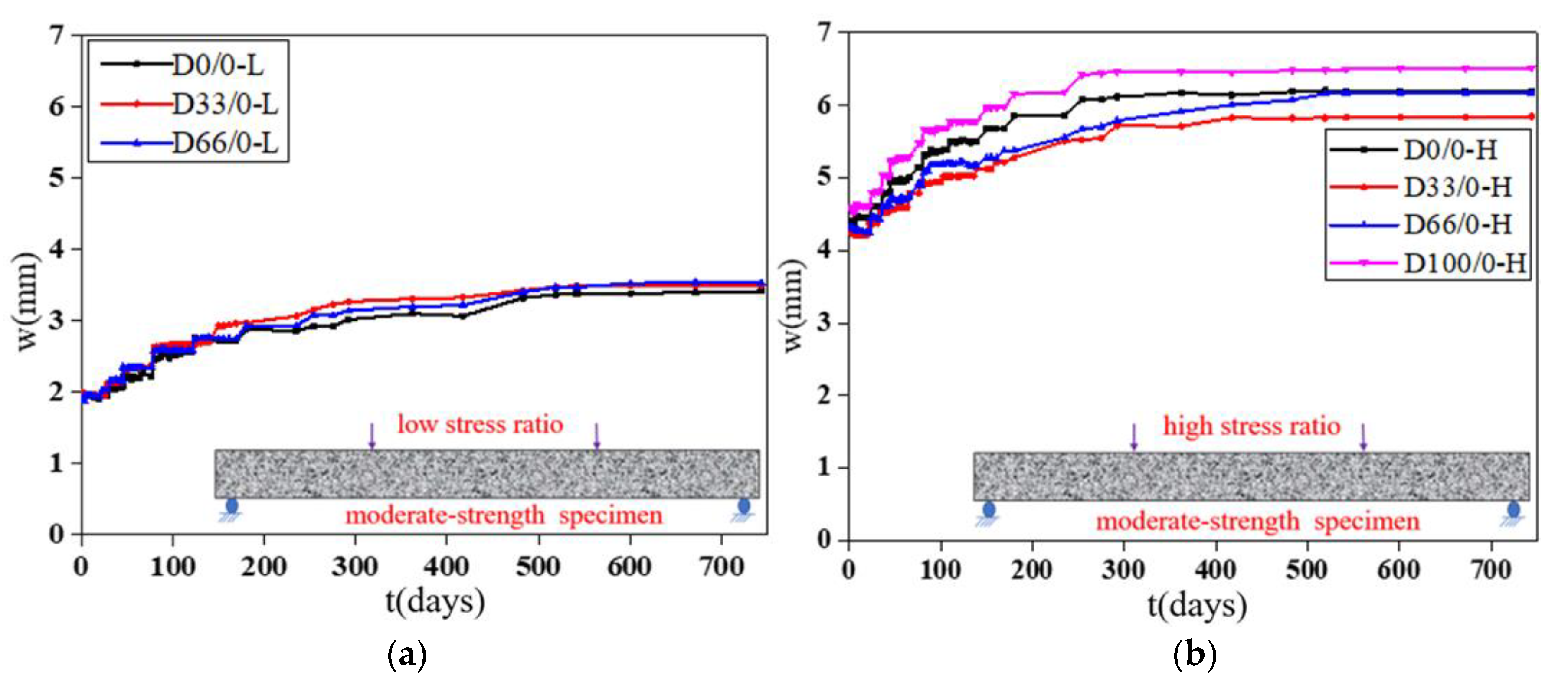

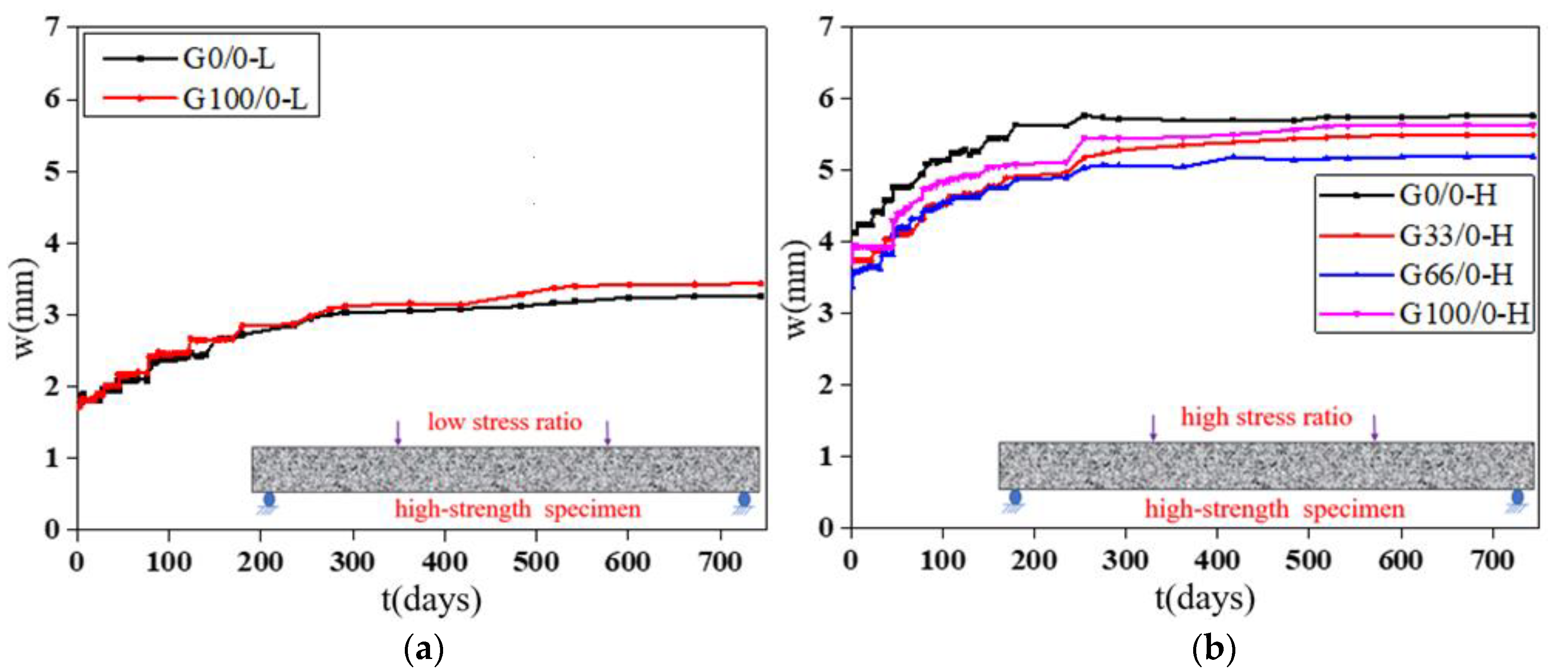

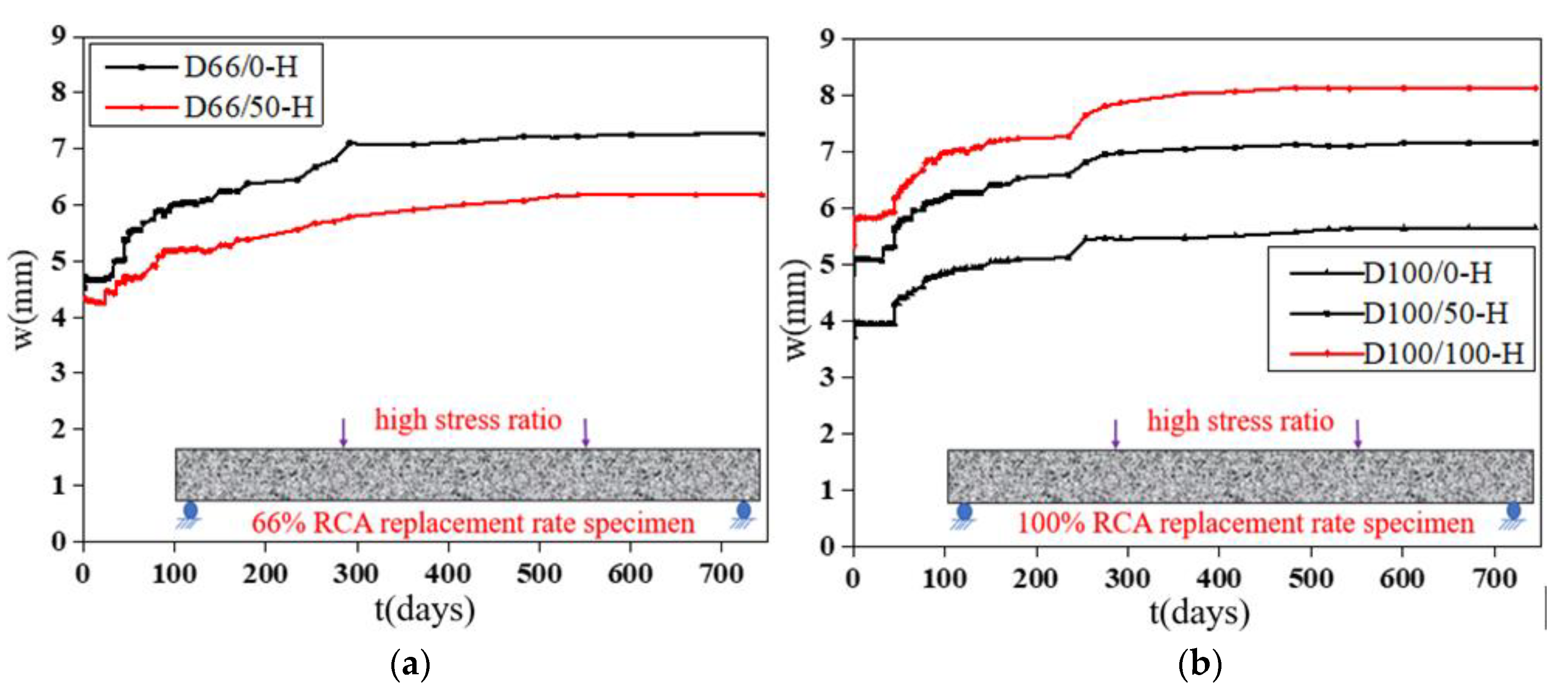

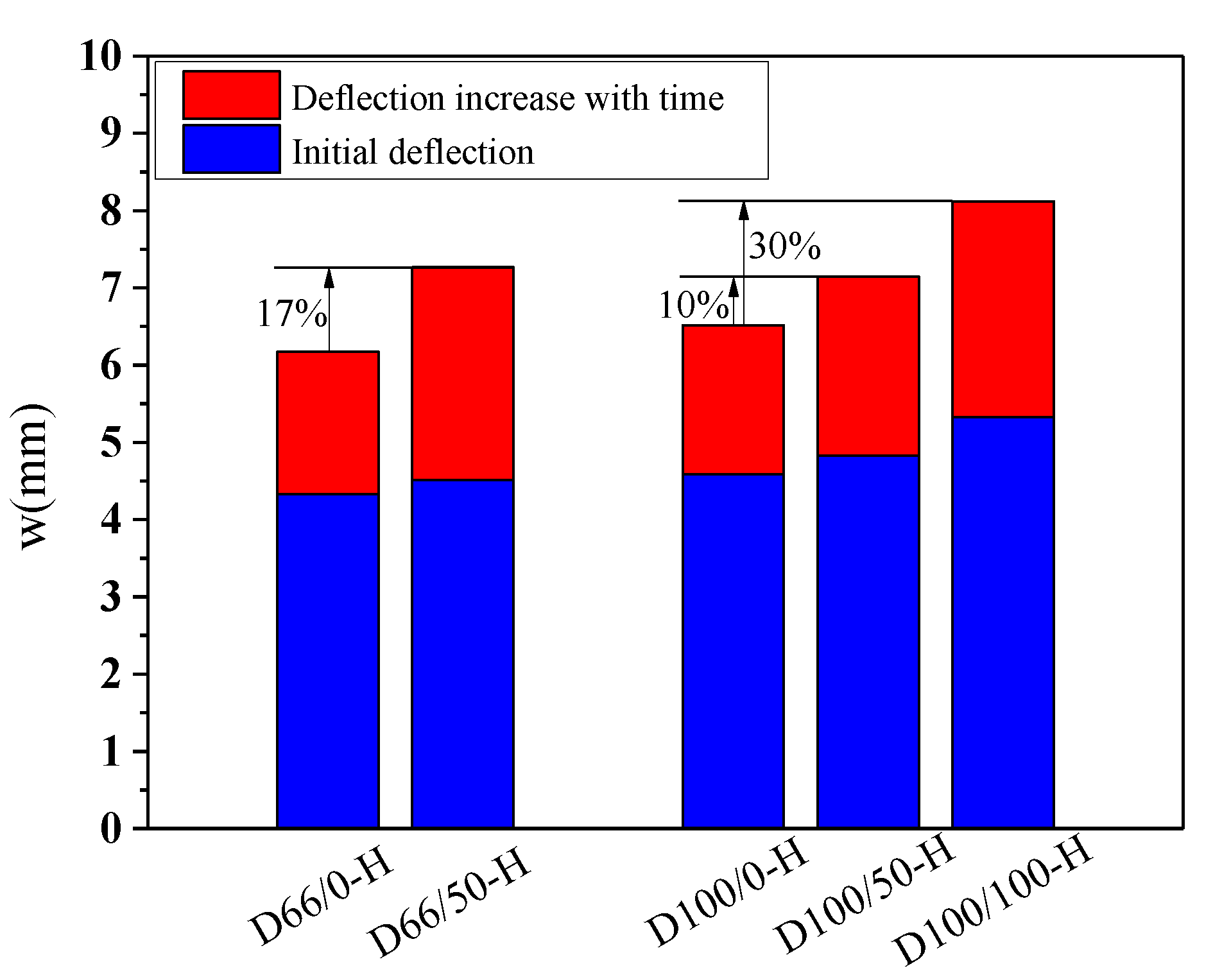

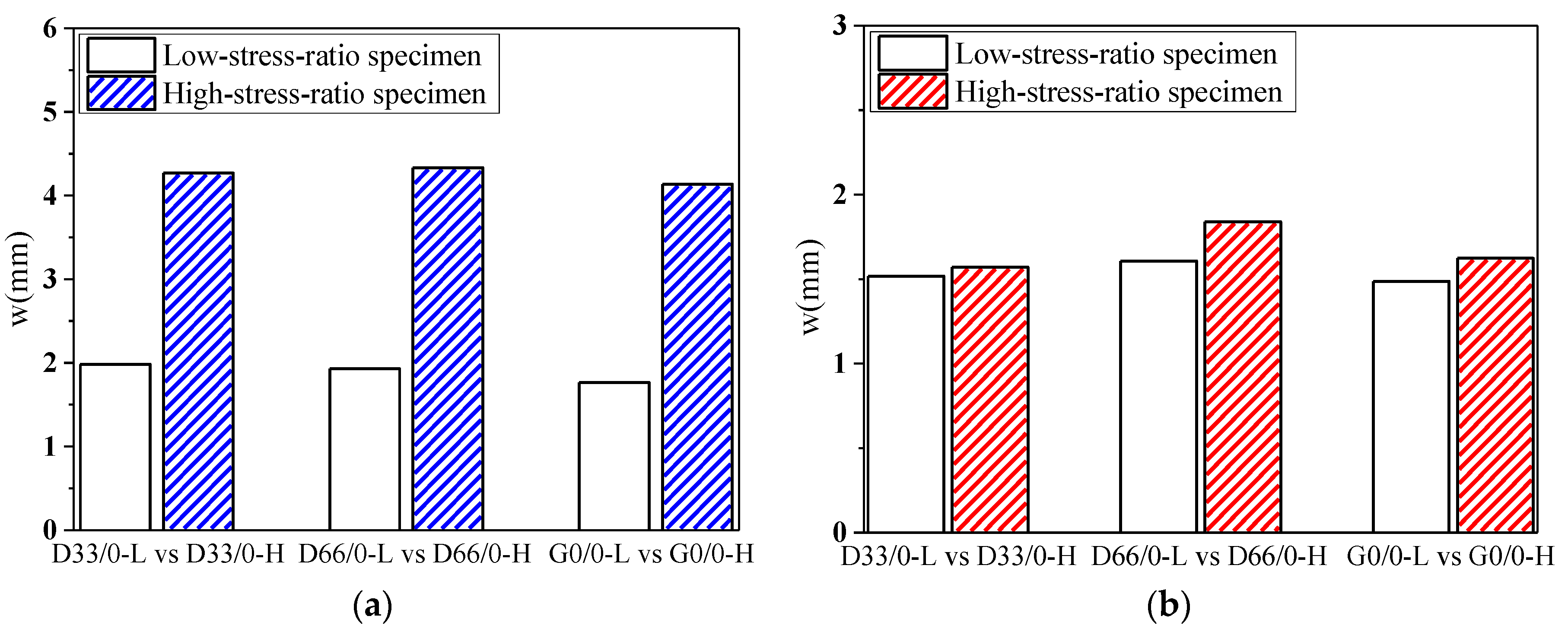

, the deflection curve of the specimen is calculated by Equations (2)–(13). Comparisons between the calculated curves and the measured deflection-load holding time curves of the RAC beams obtained by adjusting the model are shown in

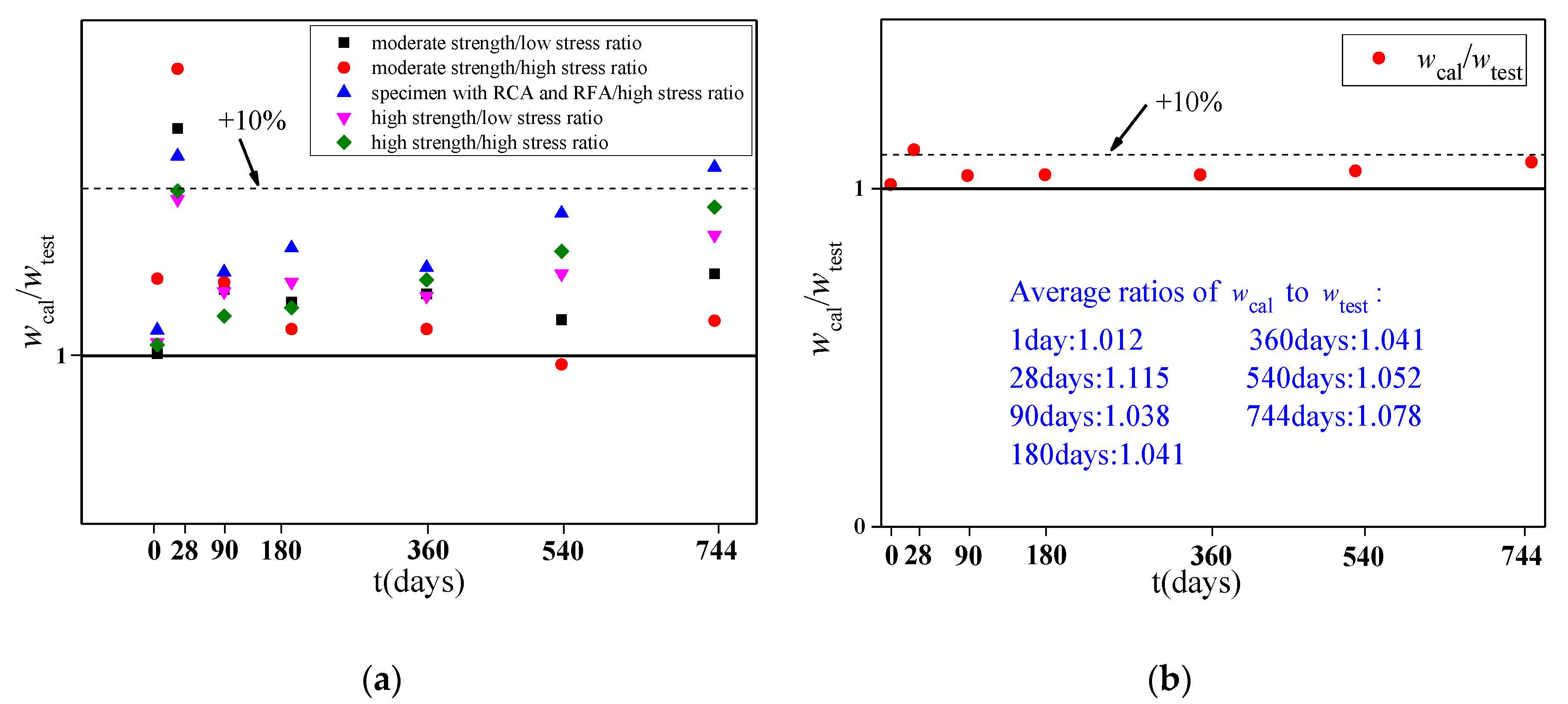

Figure 17. Some time periods are selected to compare the calculated results with the measured values to study their errors, including 1, 28, 90, 180, 360, 540, and 744 days. The ratio of the calculated deflection to the measured deflection of the specimens at different time periods is shown in

Table 8 and

Figure 18.

It can be seen from the results that the calculation values obtained by using the prediction model of RAC modified by the CEB-FIP2010 model are in good agreement with the test data. However, because the deformation of the specimen in the early period is easily affected by external factors and the development of deflection is prone to generate fluctuations, the formula is calculated under ideal conditions without considering the above factors, so the deflection calculated at a load holding time of 28 days is relatively large, with a large measured error. In the later period of loading, the convergence of the calculation model is worse than that of the measurement, especially for the specimens with RCAs and RFAs. Considering the small number of specimens, this method can meet the calculation accuracy, but it still needs to be verified with more test data.