Determining the Damage and Failure Behaviour of Textile Reinforced Composites under Combined In-Plane and Out-of-Plane Loading

Abstract

1. Introduction

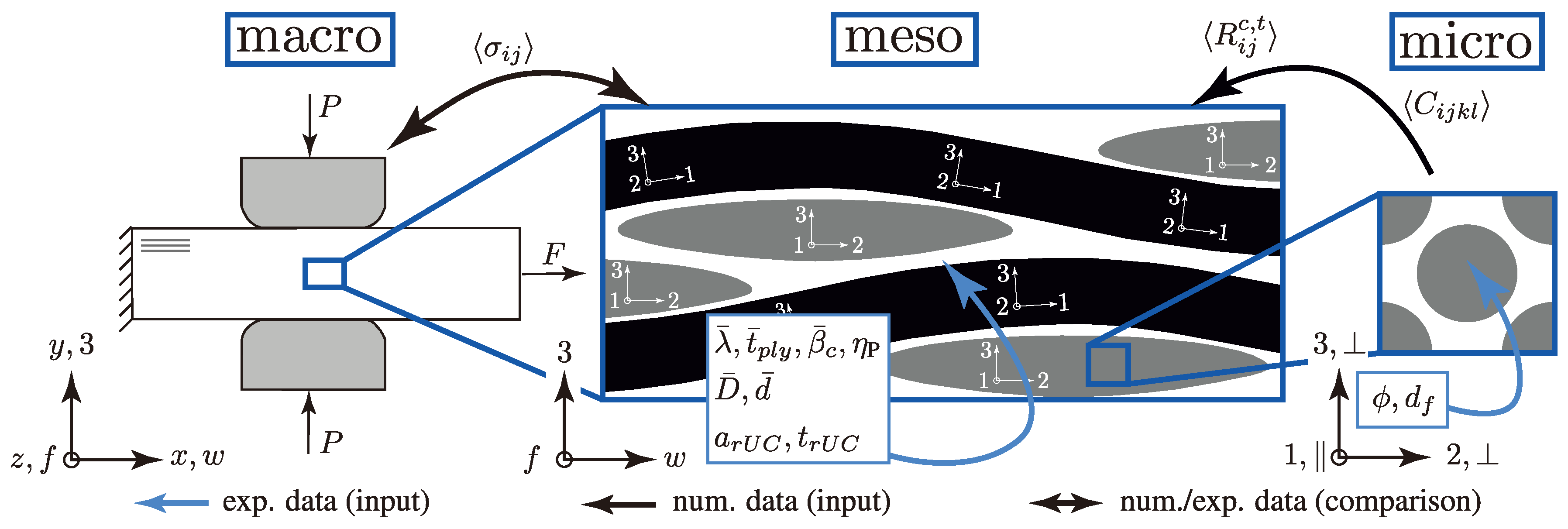

2. Experimental and Numerical Multi-Scale Approach

3. Experimental Methods

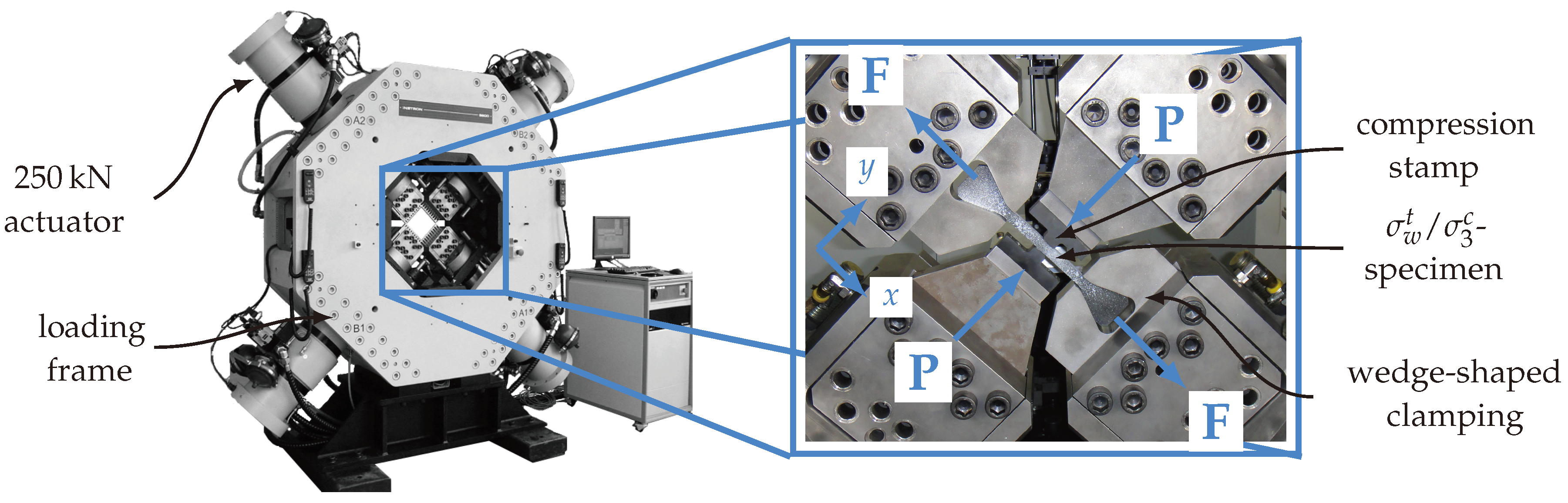

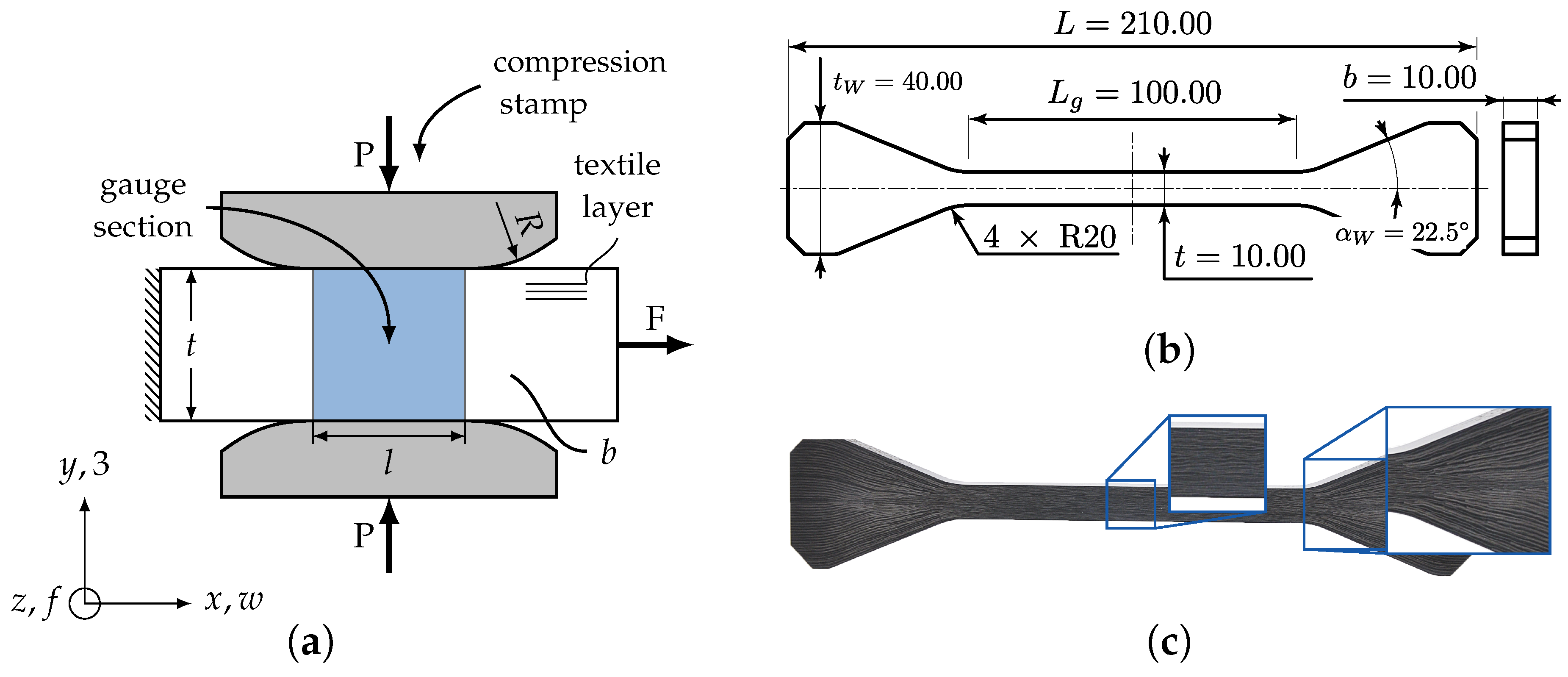

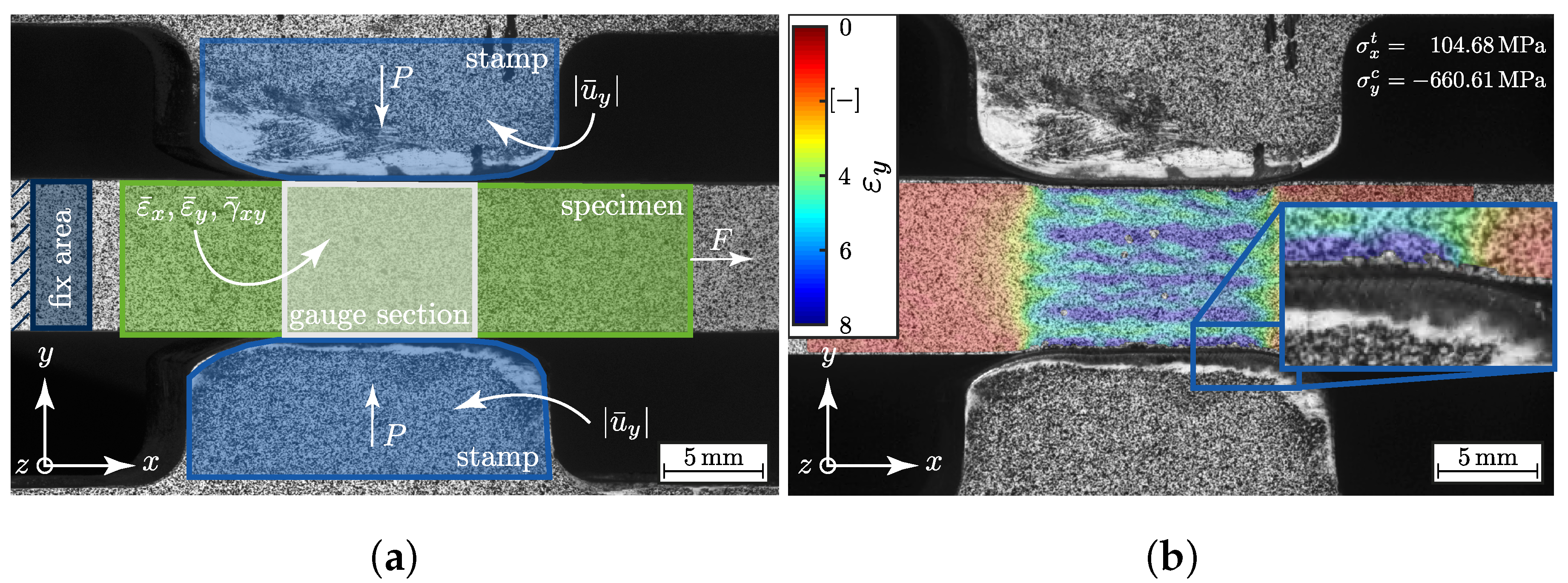

3.1. Biaxial Test Method for Textile Reinforced Composites: -Testing

3.2. Materials and Specimen Preparation

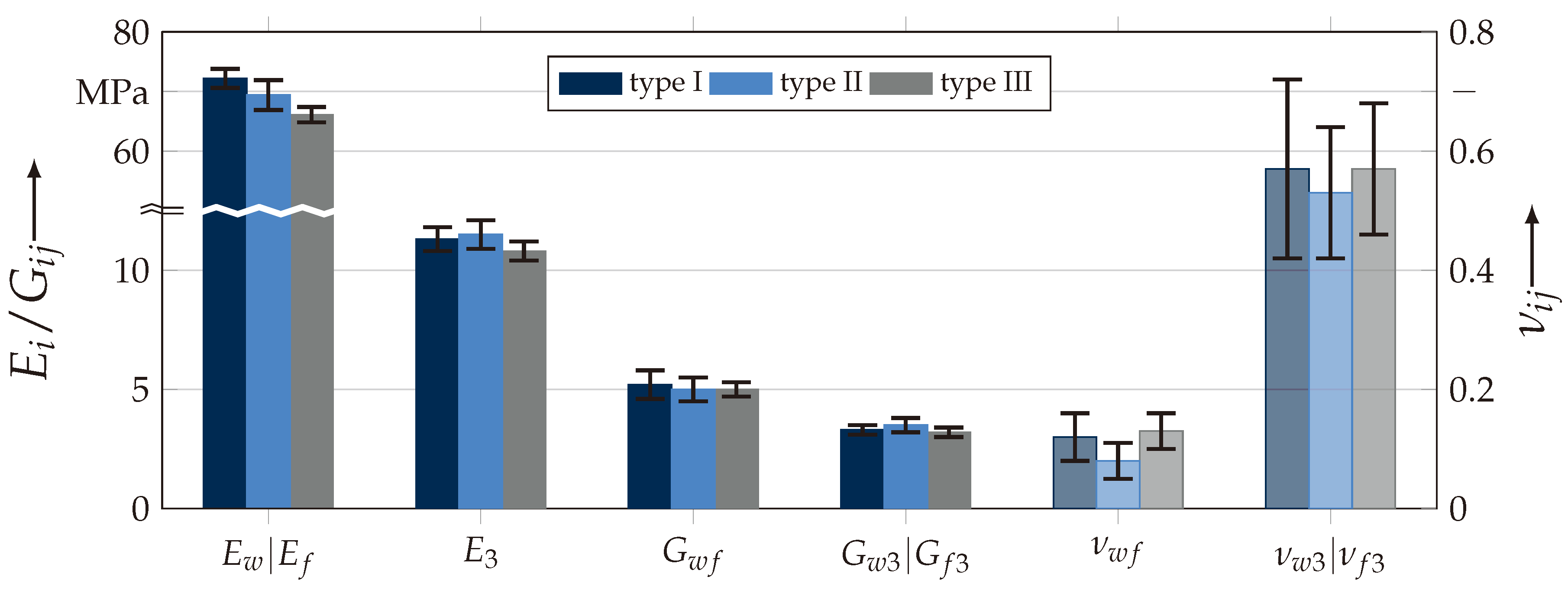

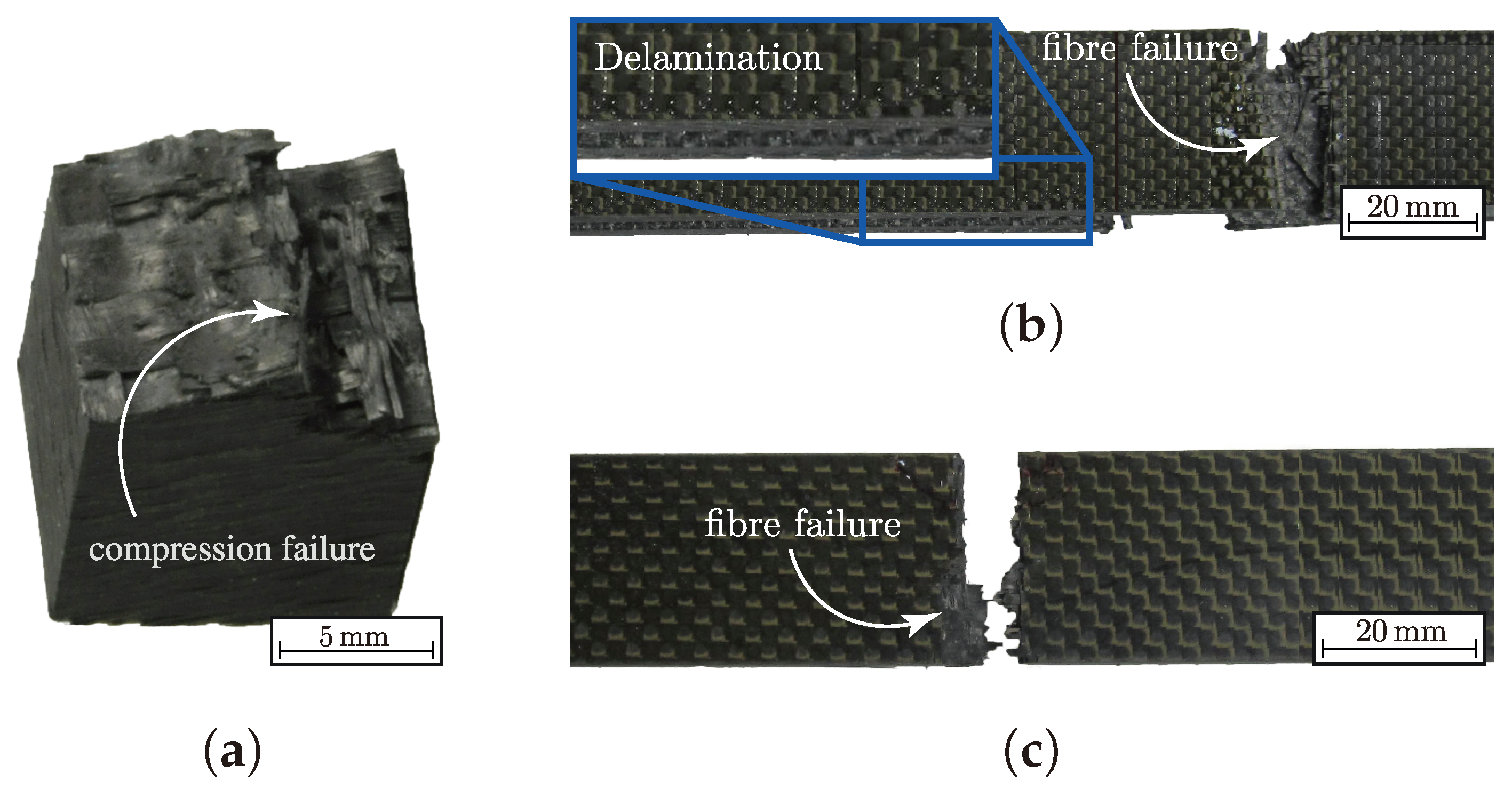

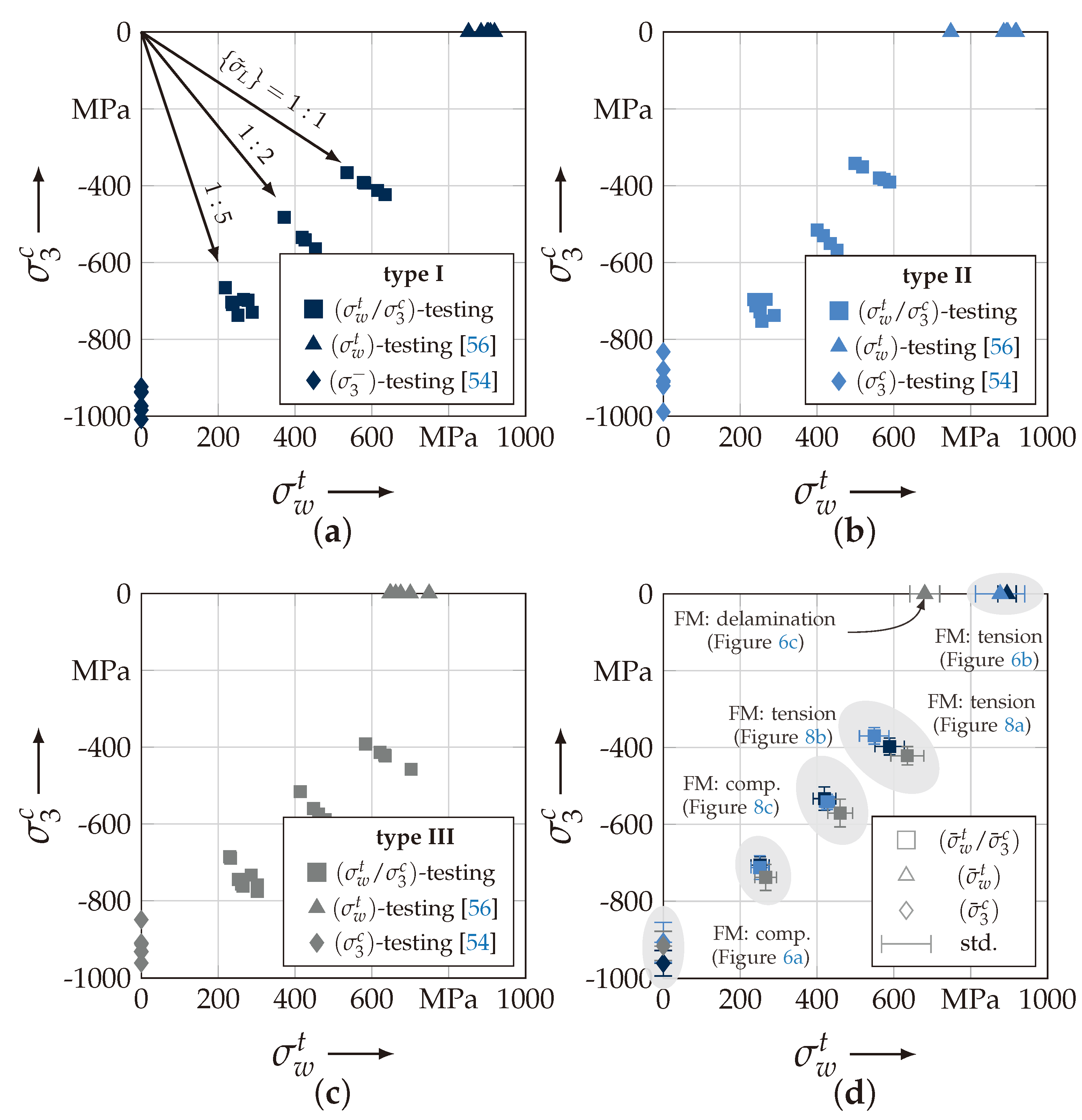

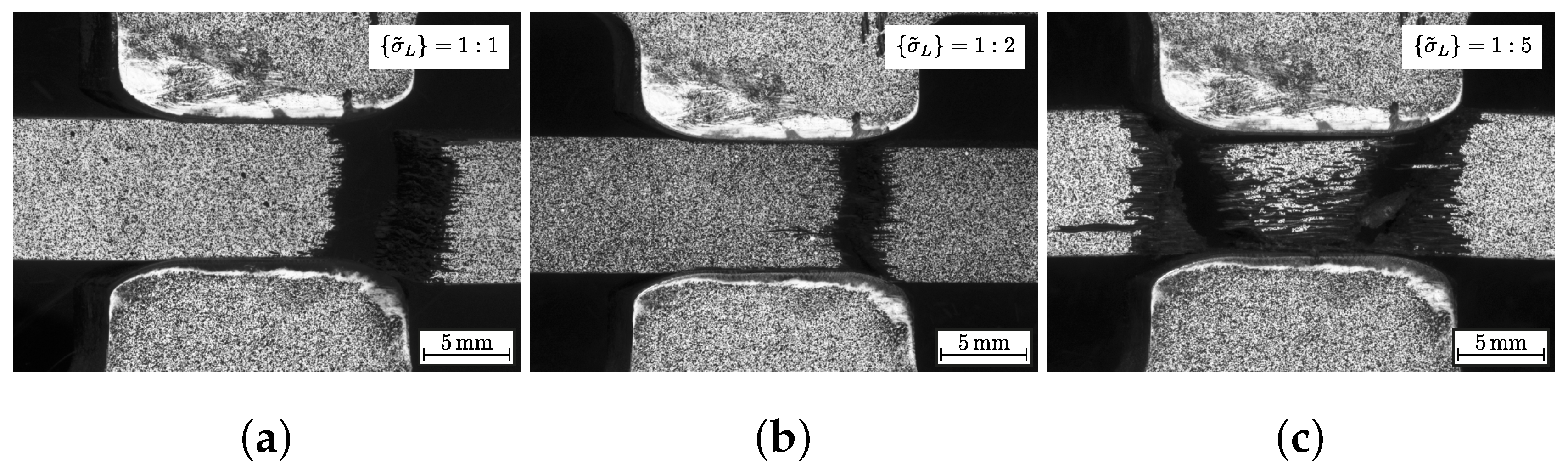

3.3. Experimental Results of Uniaxial and Biaxial Testing

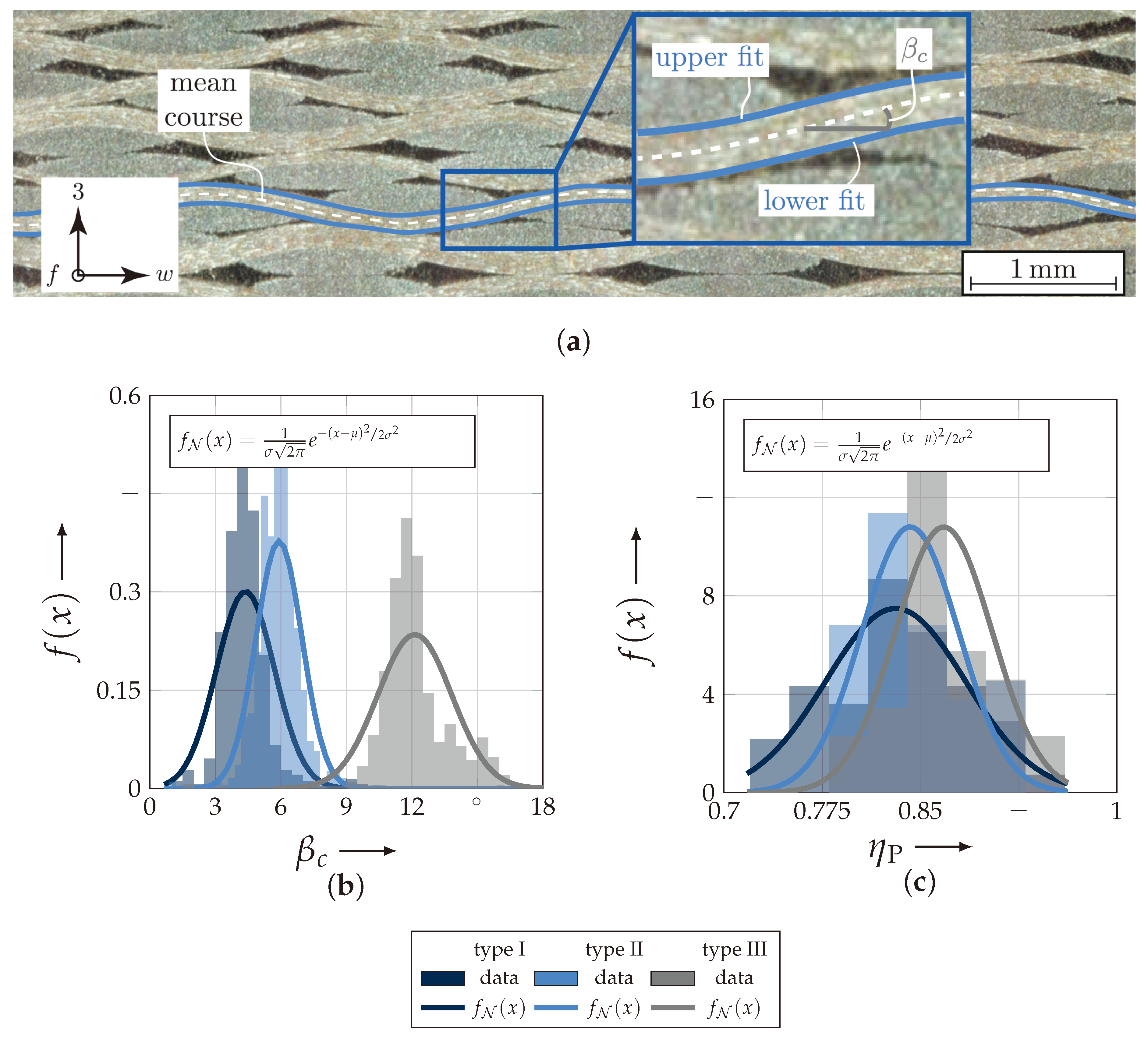

3.3.1. Meso-Scale Analysis of Textile Architecture

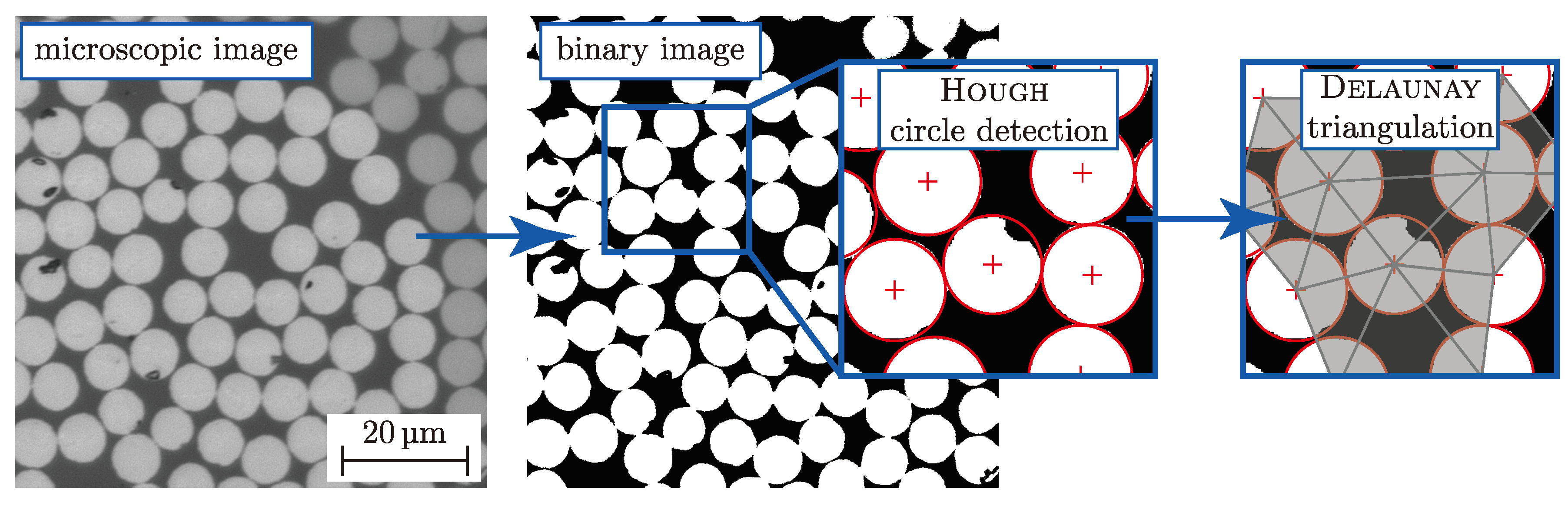

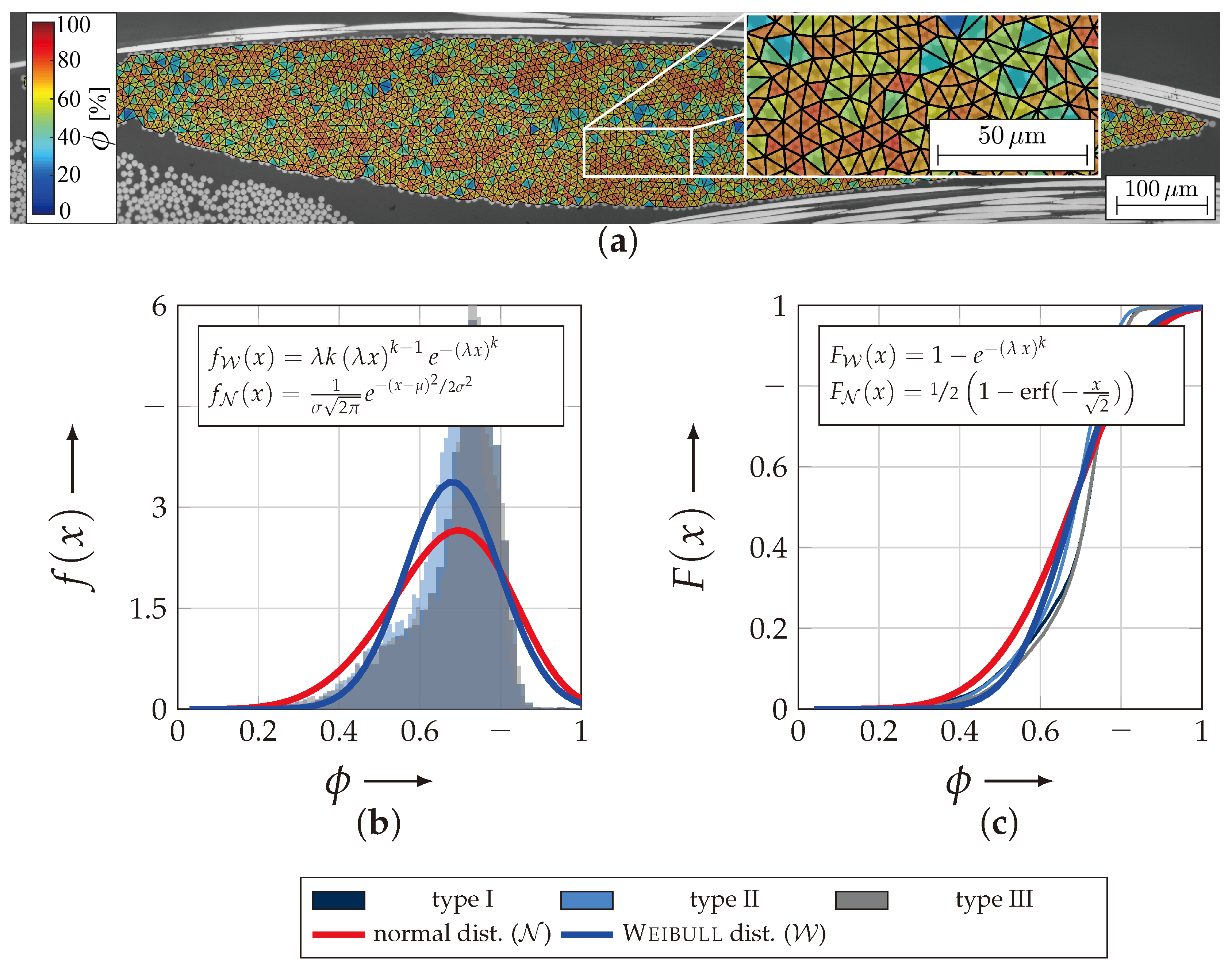

3.3.2. Microscopic Analysis of the Fibre Volume Content

4. Numerical Methods

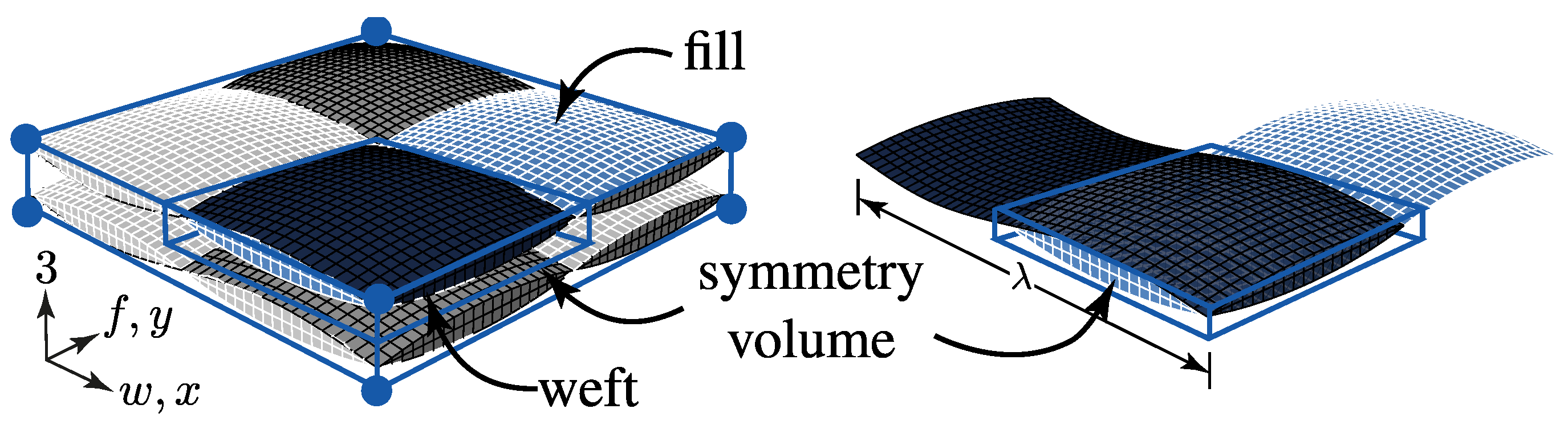

4.1. Numerical Modelling

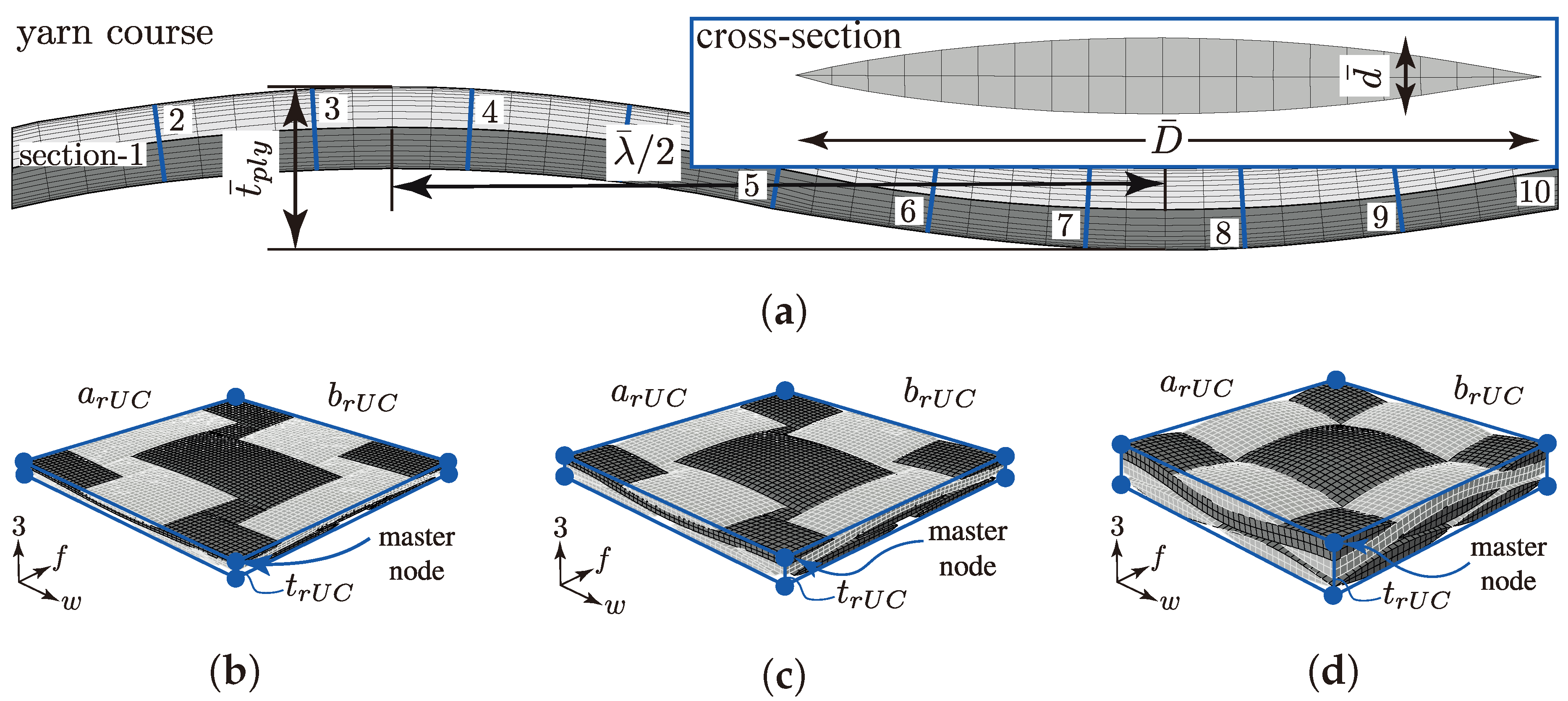

4.1.1. Geometry

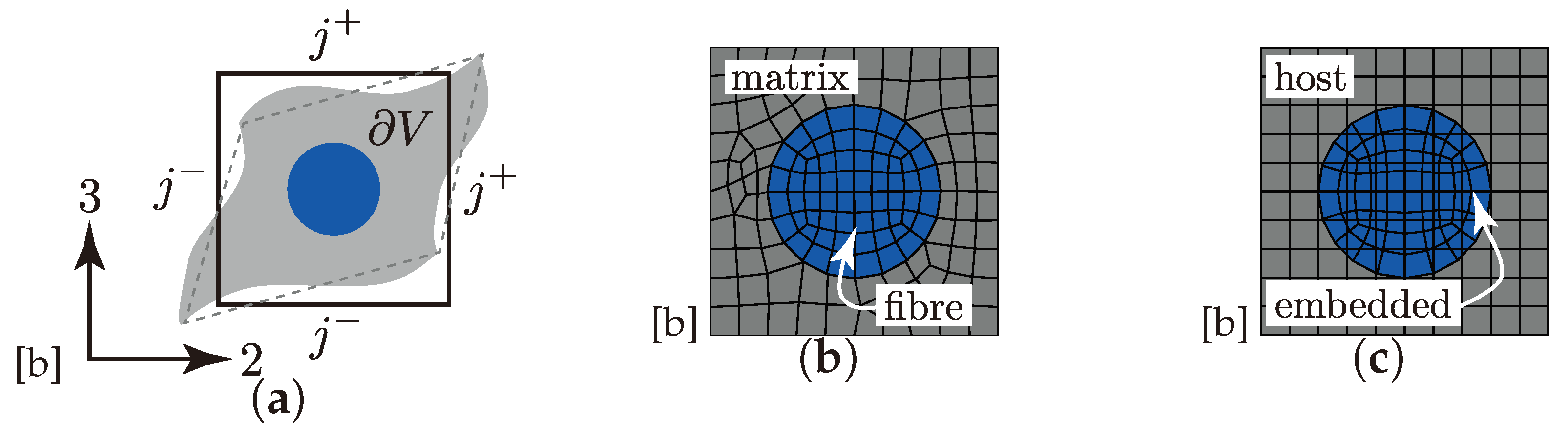

4.1.2. Mesh and Boundary Conditions

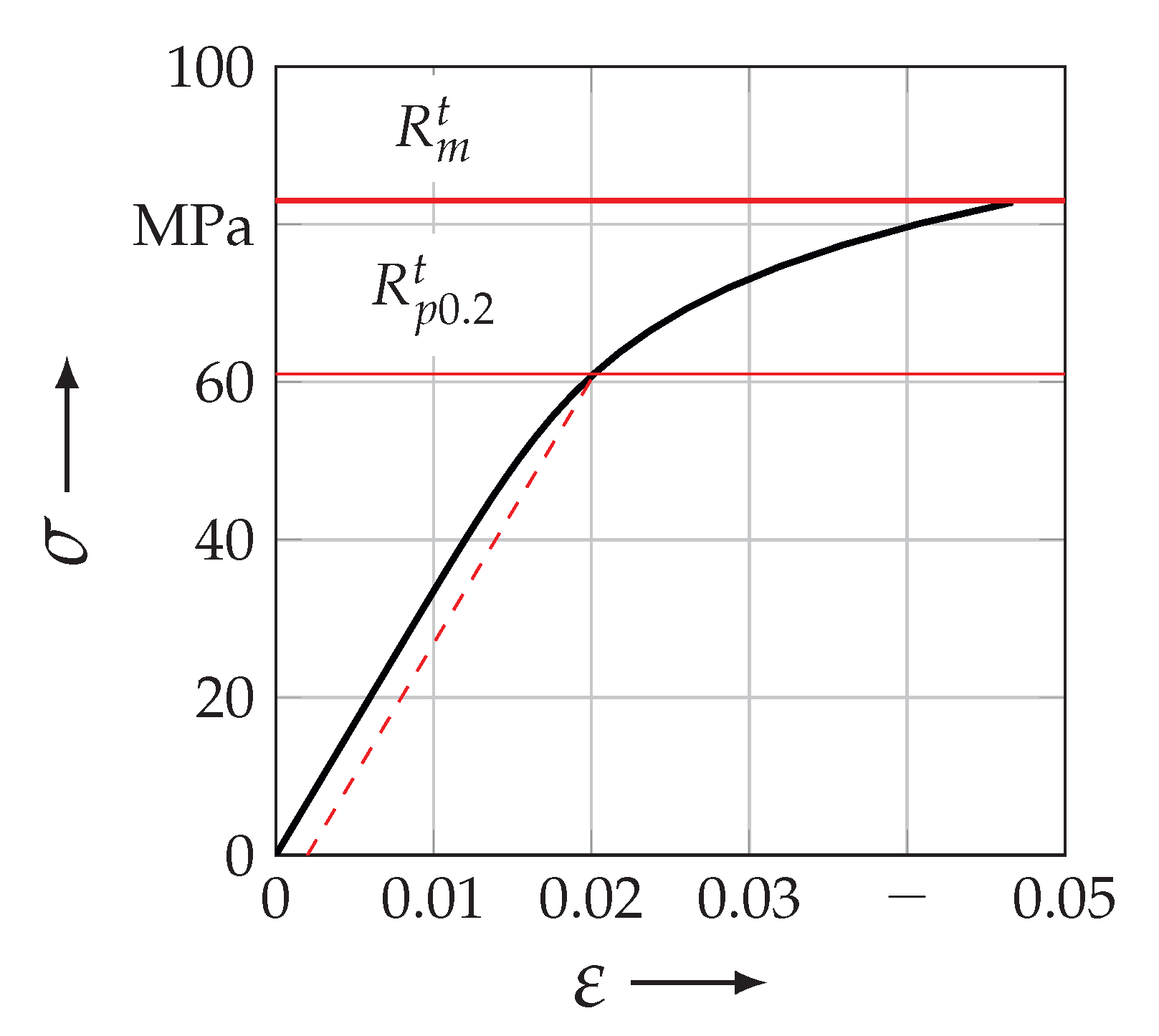

4.1.3. Elasticity

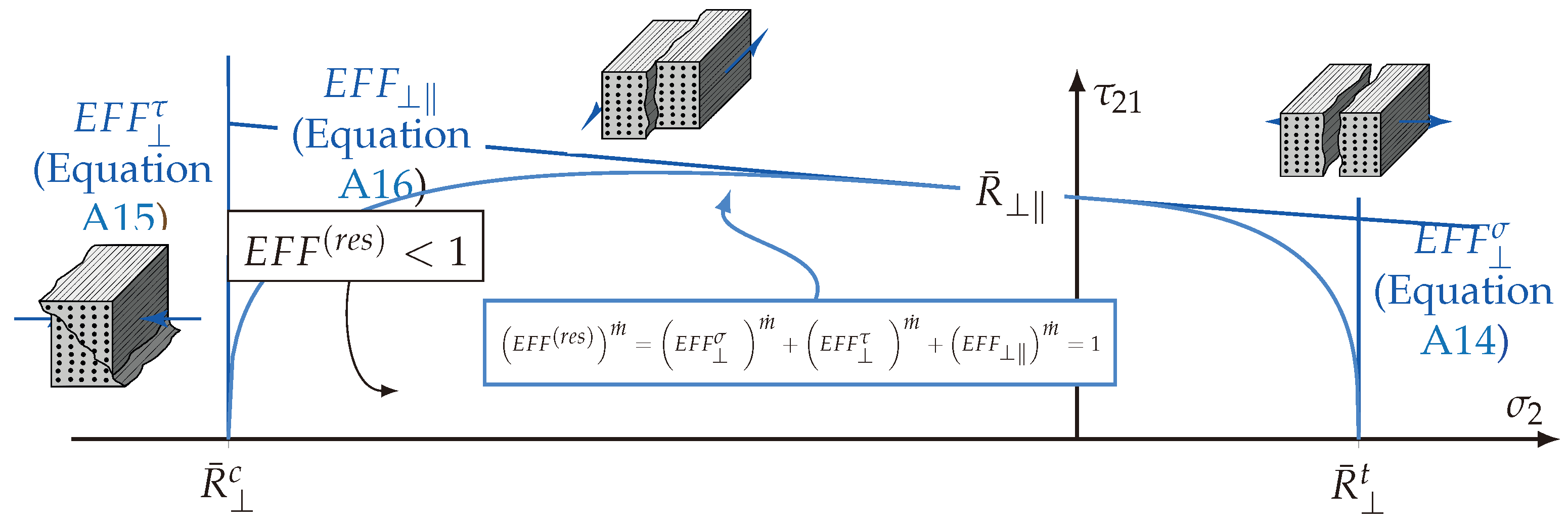

4.2. Implementation of Cuntze’s Failure Mode Concept

4.3. Numerical Analysis and Results

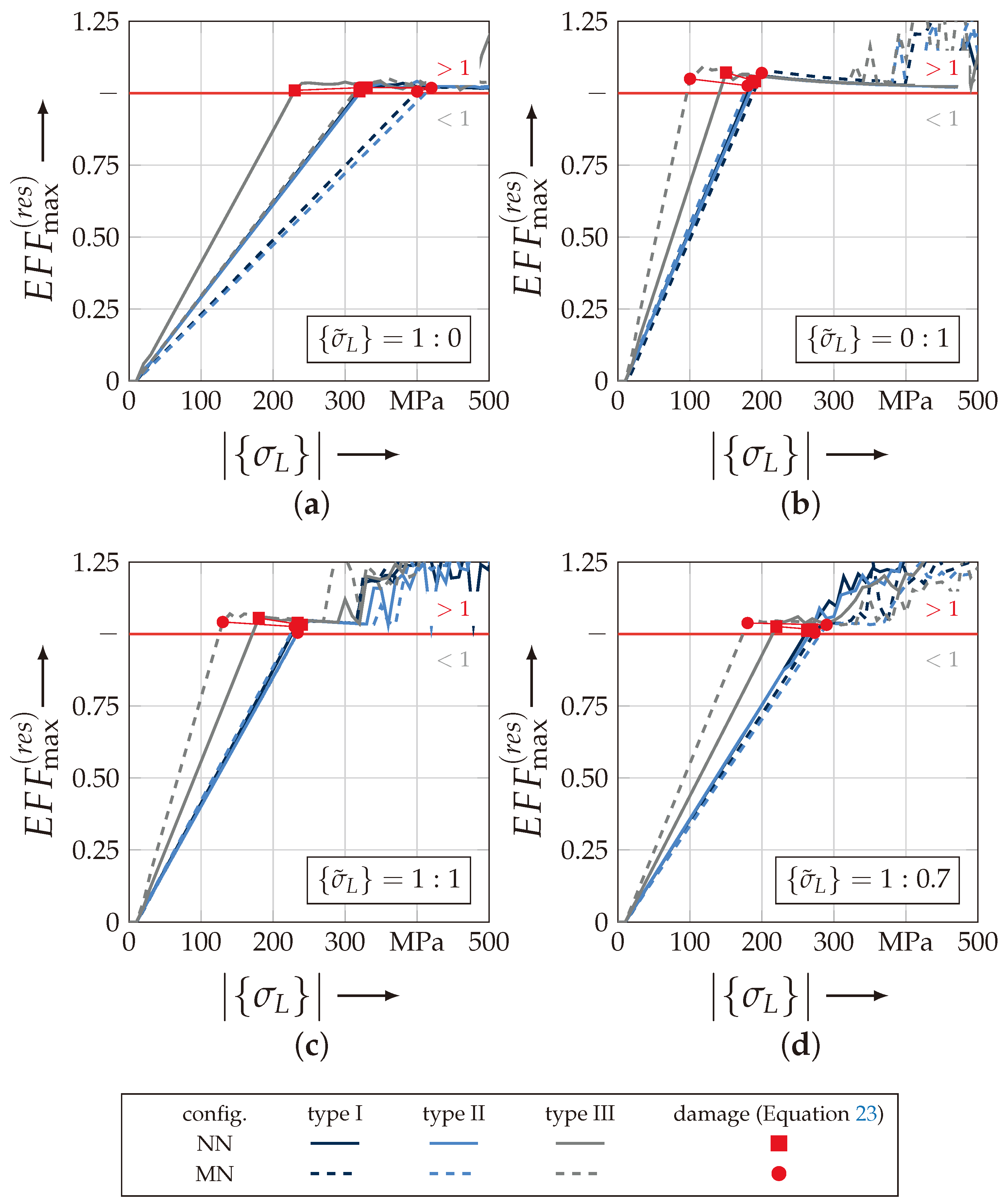

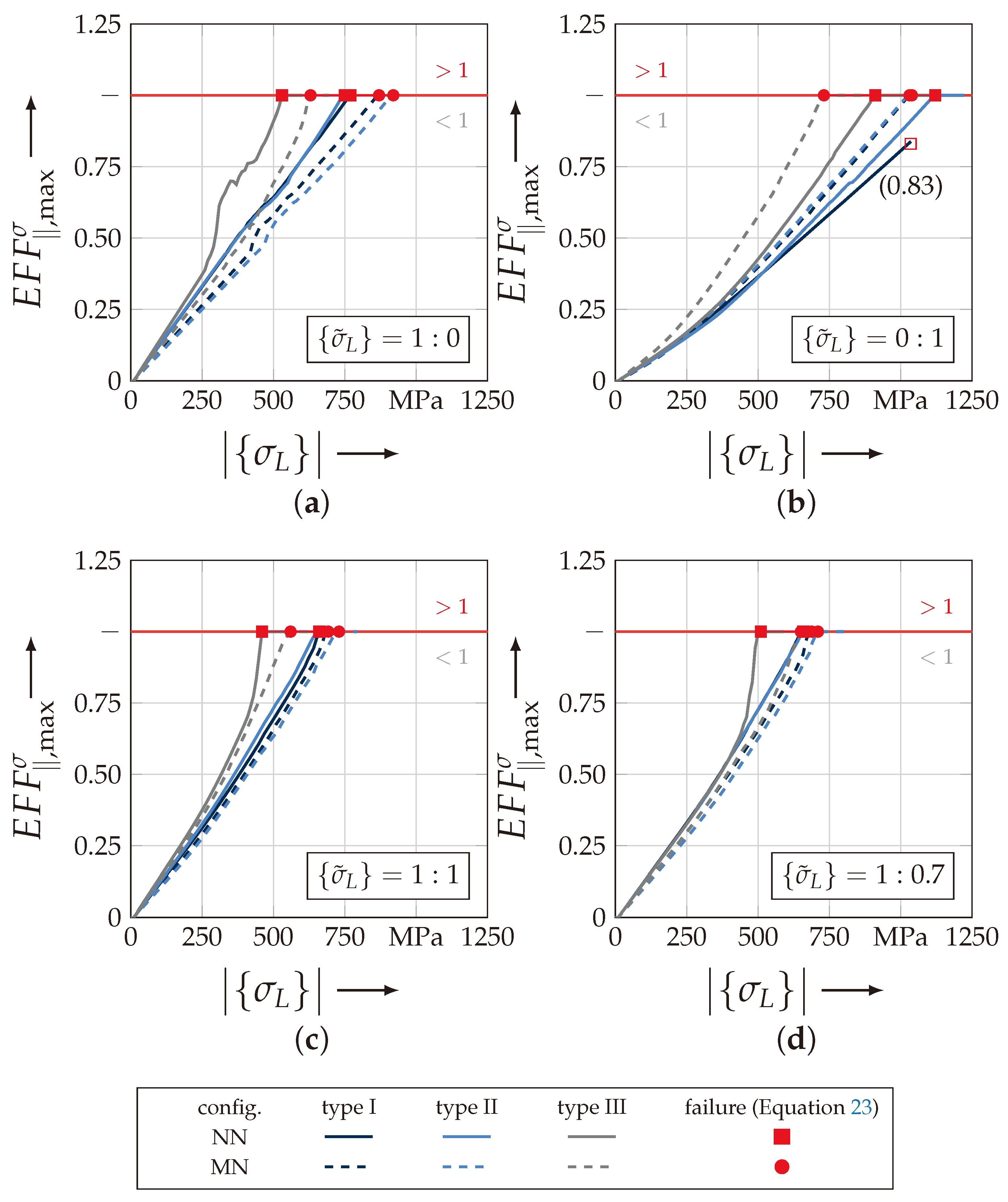

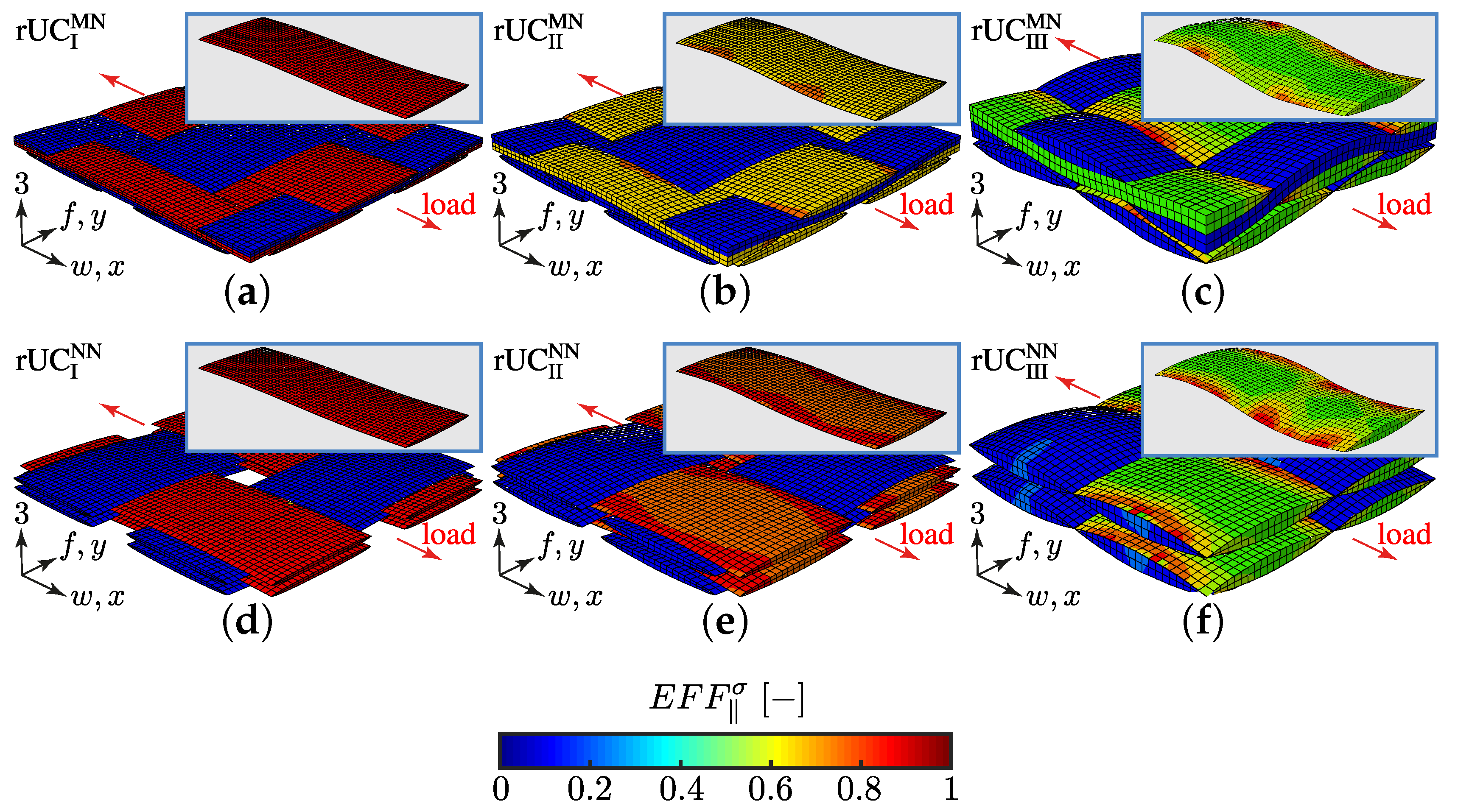

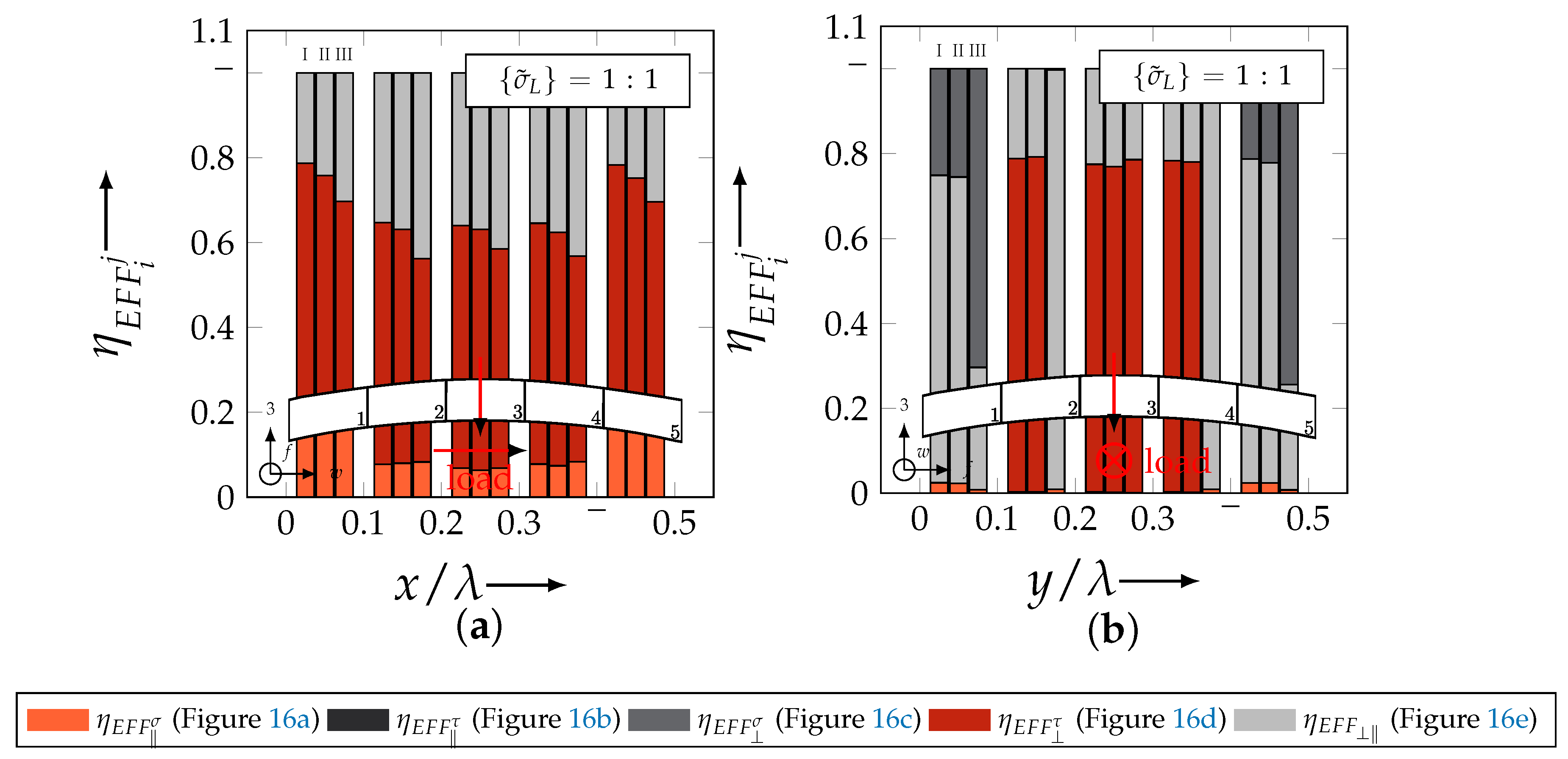

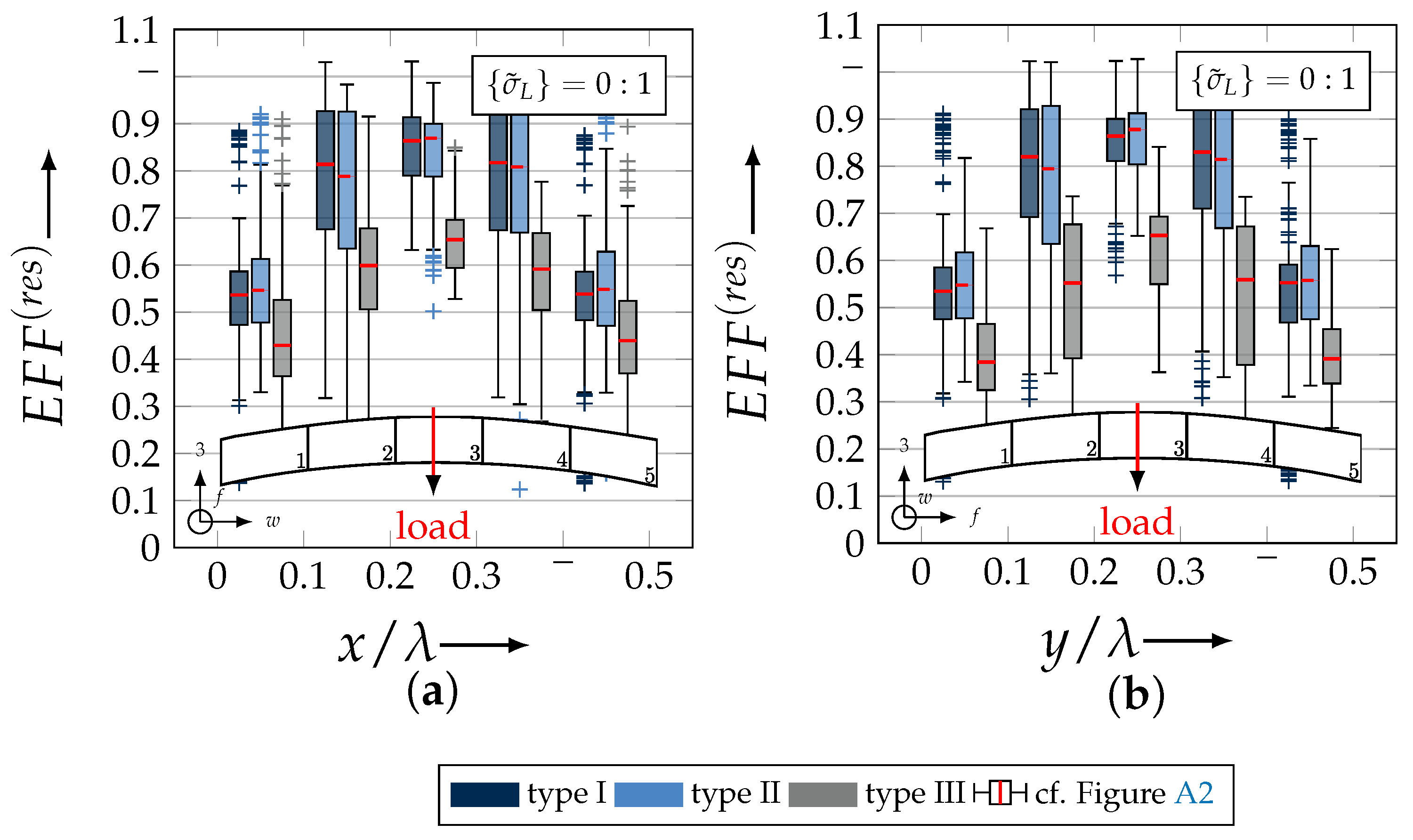

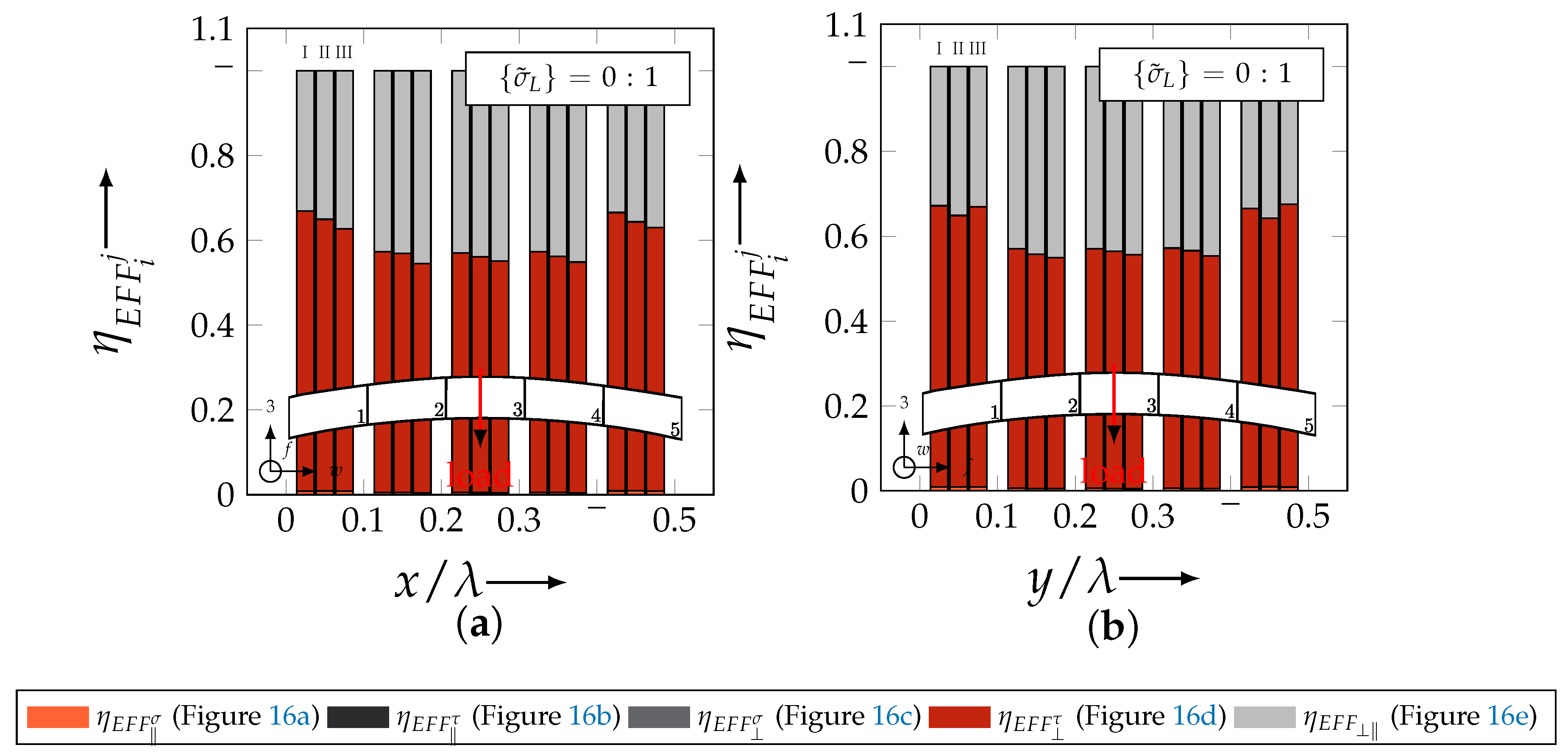

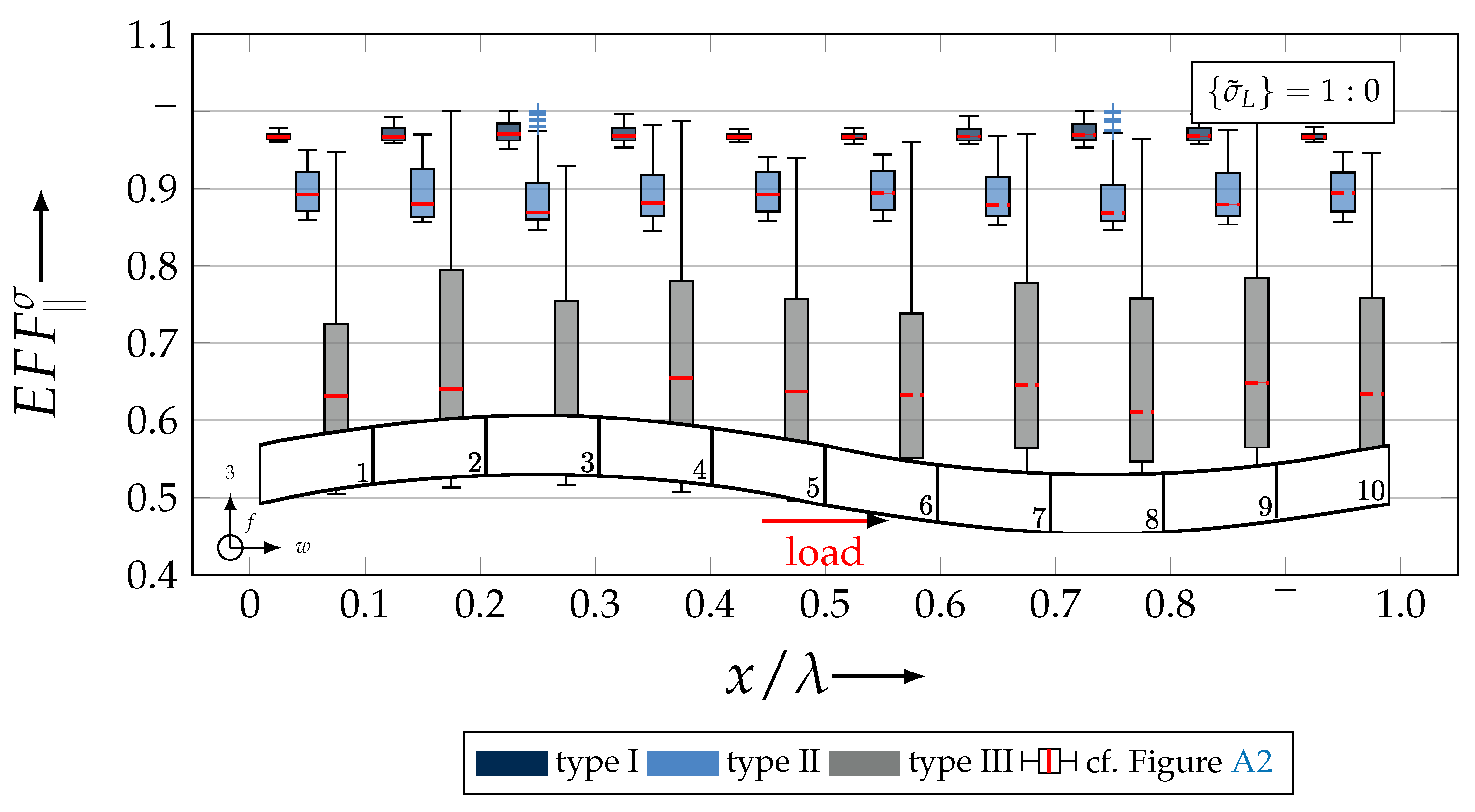

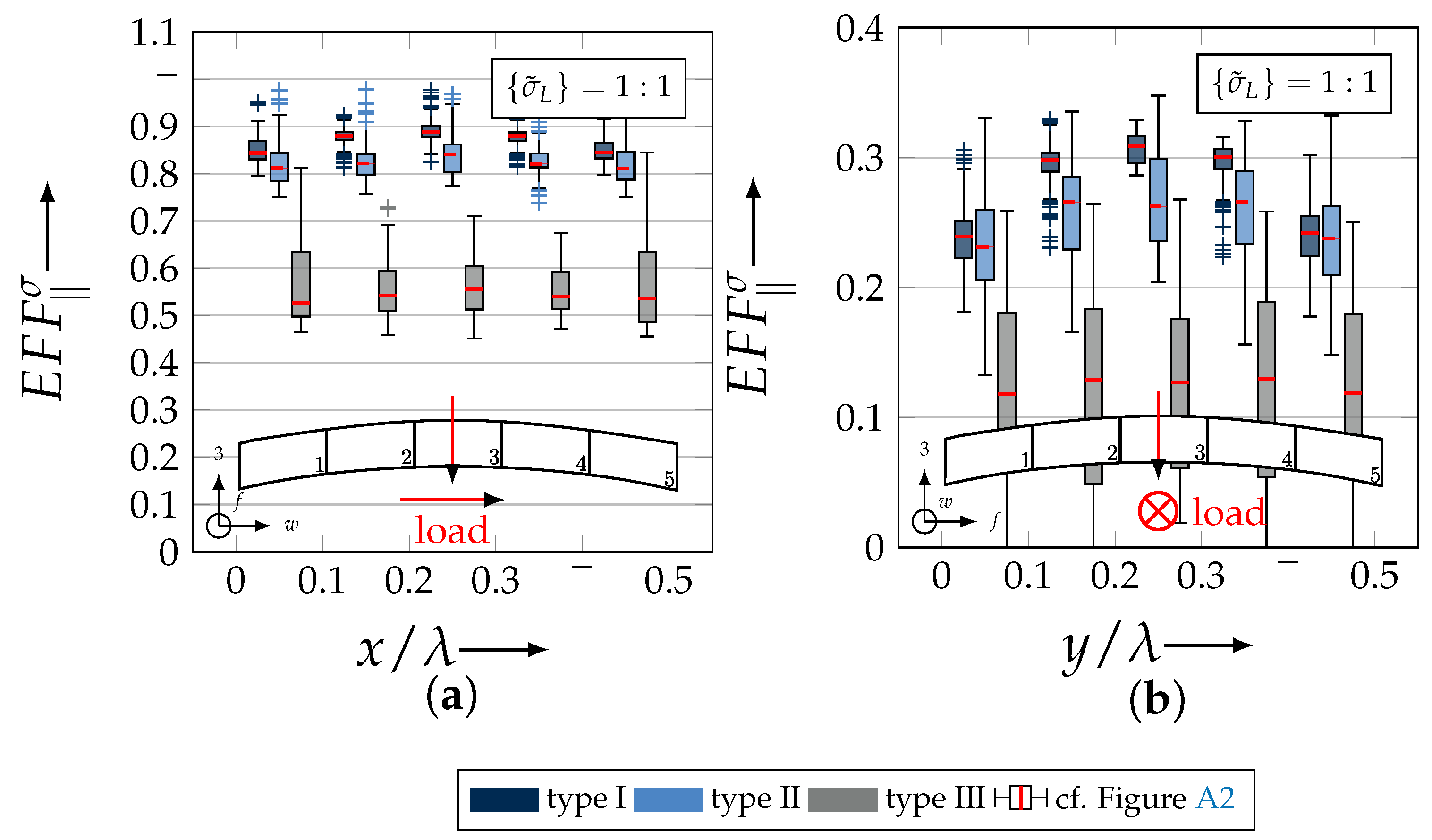

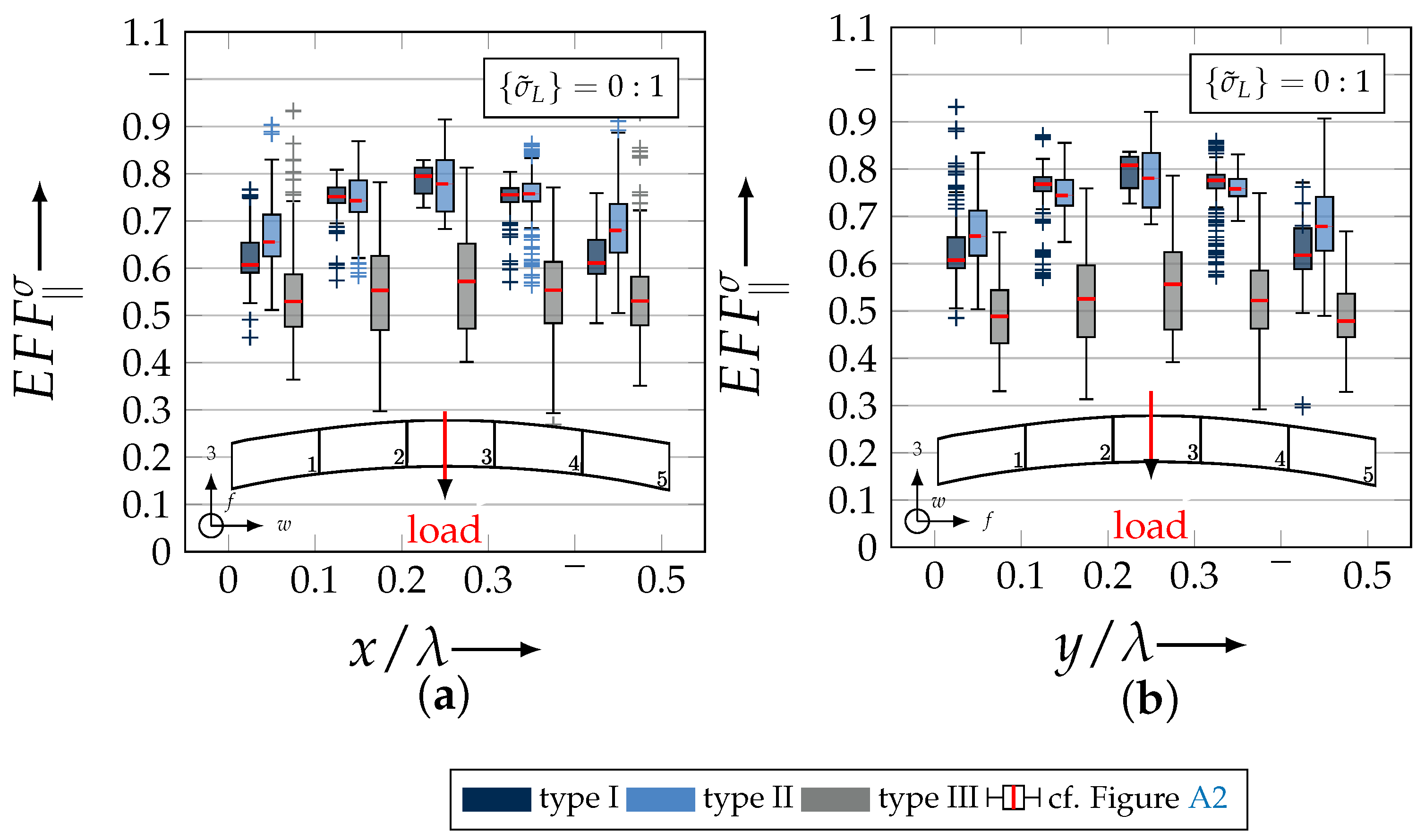

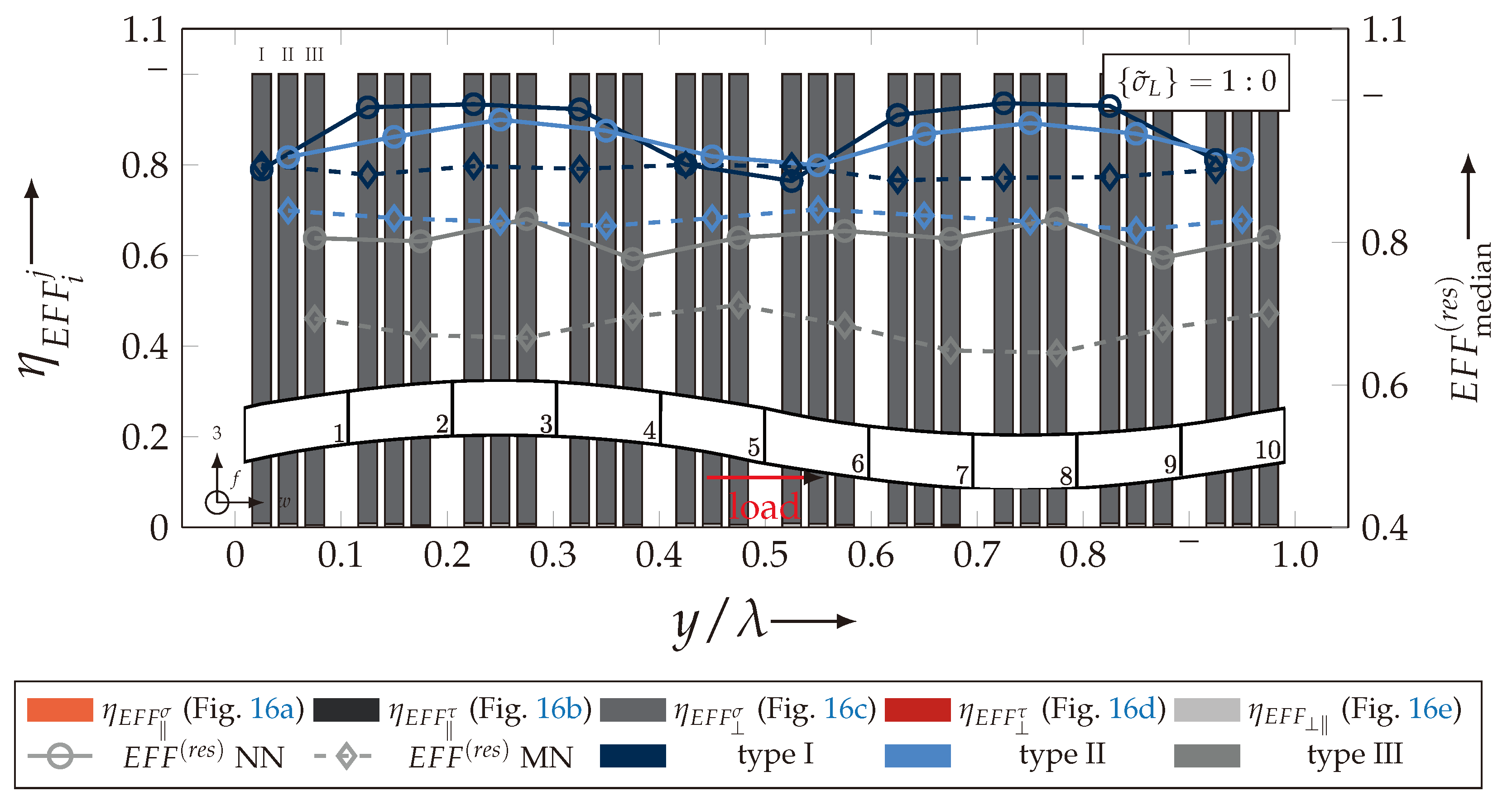

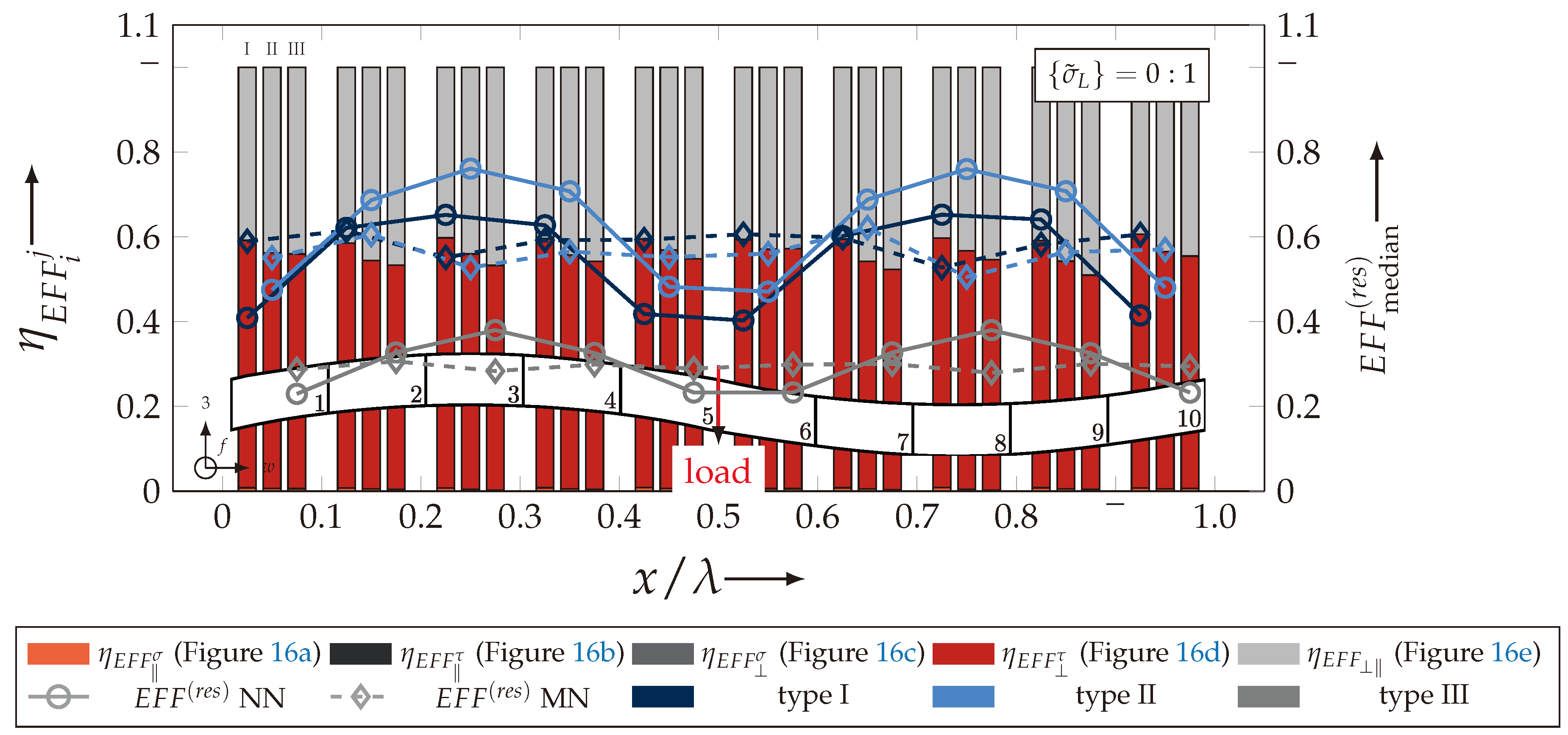

4.3.1. Analysis of Damage Initiation and Failure

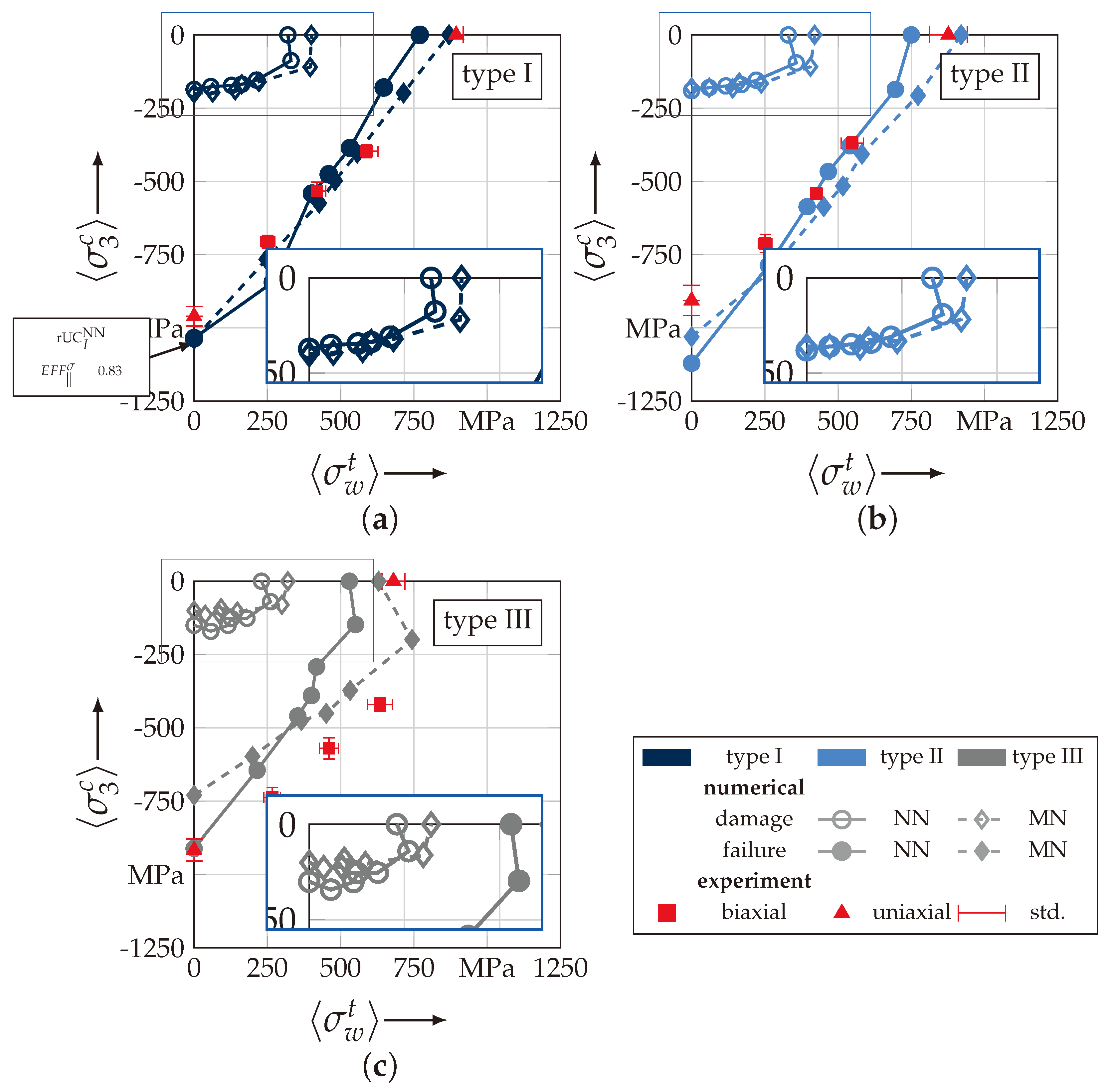

4.3.2. Comparison of Experimental and Numerical Results

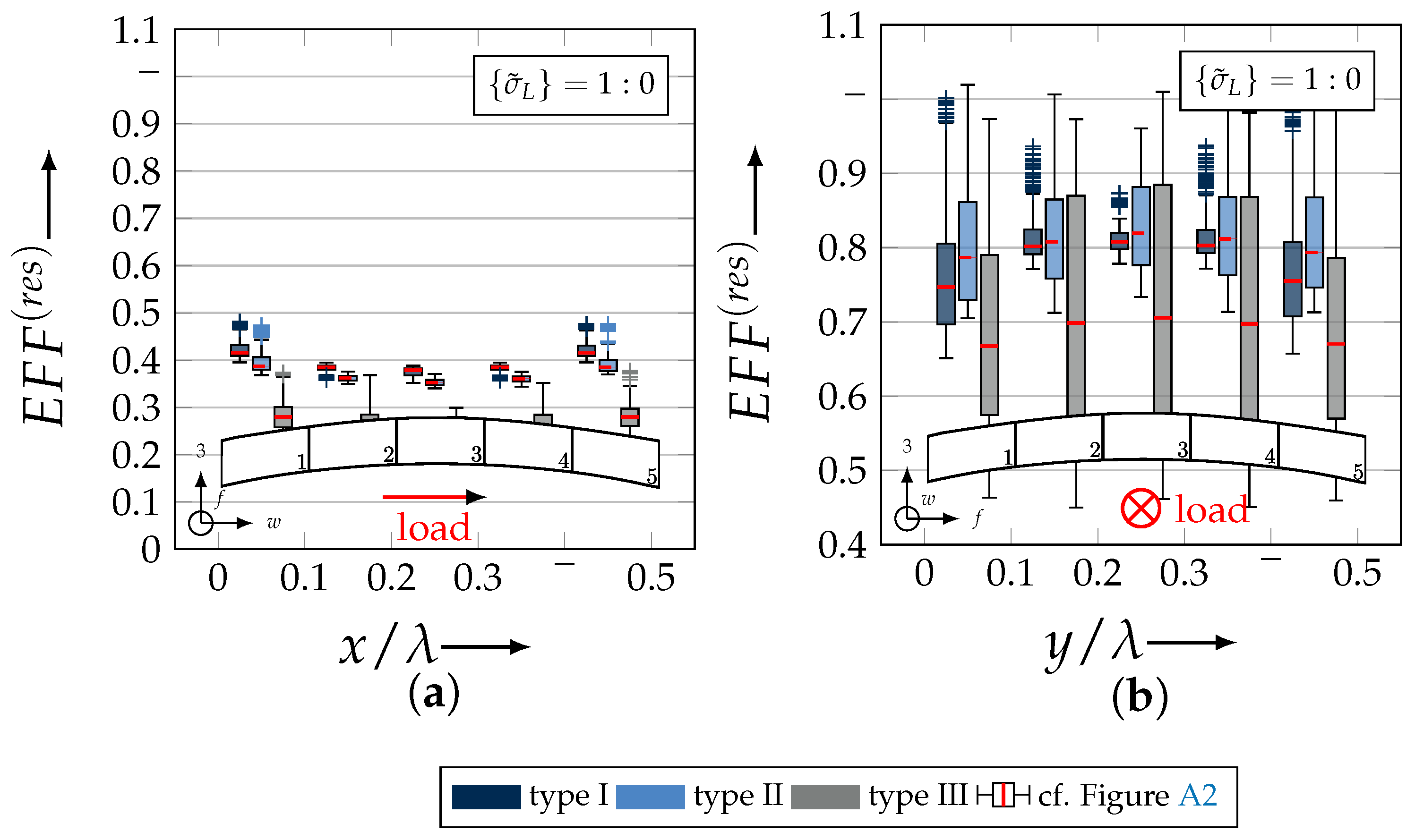

4.3.3. Identification of the Influence of the Textile Architecture (Ondulation)

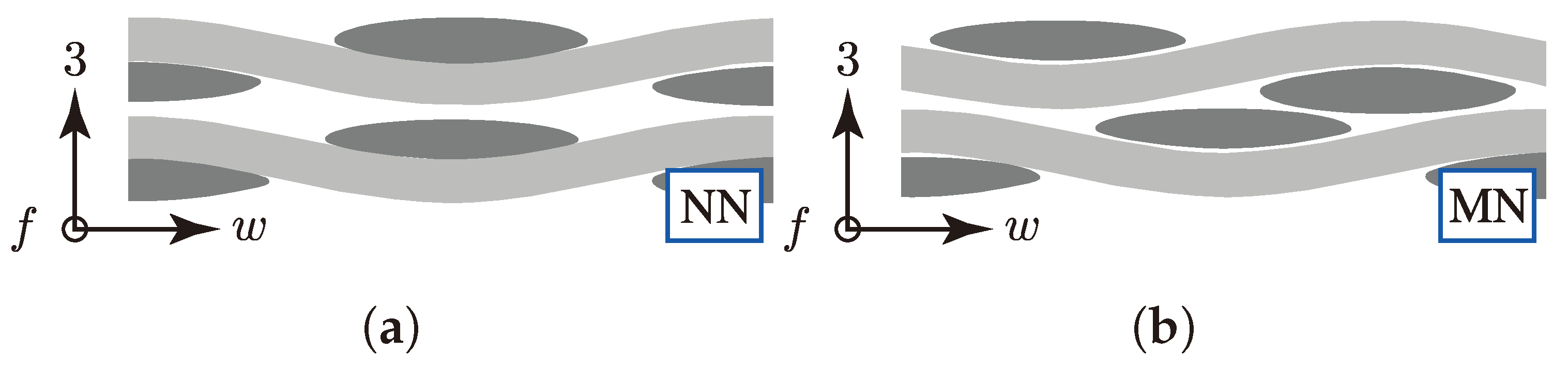

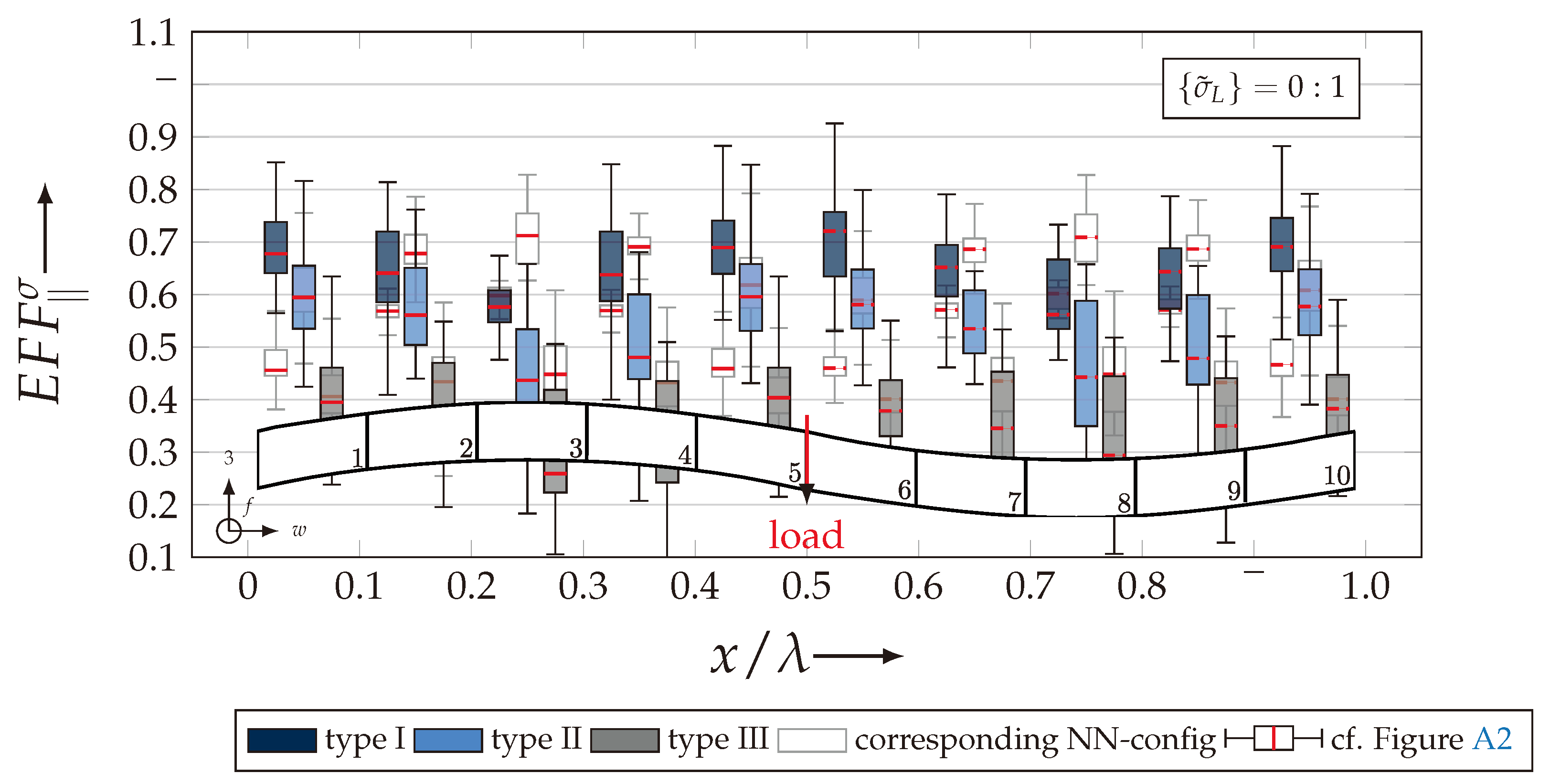

4.3.4. Identification of the Influence of the Textile Configuration (Nesting Effects)

5. Conclusions

- Textile reinforcements with minor areal weight;

- -

- Good agreement to experiment for prevailing in-plane tensile stress;

- -

- Higher deviation to the experiment for the out-of-plane compression load path;

- Higher deviation (underestimation) from the experiment of the reinforcement with the highest areal weight for considered load paths;

- Nesting results in a higher fracture resistance for load paths with dominating in-plane tensile stress and in a lower fracture resistance for load paths with dominating out-of-plane compression stress compared to an idealised no nesting configuration.

- A non homogeneous distribution of the stress efforts for all considered load paths, in particular a higher scatter. Hence less accuracy of the considered failure stress state (underestimation);

- Lower scatter of median values of the stress efforts for damage initiation and failure along the weft or fill yarn direction;

- Less influence of the ondulation on the distribution for a out-of-plane compression loading. The peaks alternating with the ondulation are decreased.

- Less influence of the ondulation on the damage initiation;

- Altered load transmission that leads to shifted failure initiation for out-of-plane loading.

- Higher ondulation;

- Less nesting capability;

- More pronounced damage and failure behaviour;

- More damage tolerant behaviour and less spontaneous failure, which can be beneficial for impact or fatigue application;

- Less ultimate strengths for in-plane tensile load;

- Higher ultimate strengths for out-of-plane compression loading.

6. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CFRP | carbon fibre reinforced plastic |

| CS | coordinate system |

| DIC | digital image correlation |

| EEM | embedded element method |

| FVC | fibre volume content |

| FF | fibre failure |

| FF1 | fibre failure () |

| FF2 | fibre failure () |

| IFF | inter-fibre failure |

| IFF1 | inter-fibre failure () |

| IFF2 | inter-fibre failure () |

| IFF3 | inter-fibre failure () |

| FM | failure mode |

| FMC | failure mode concept |

| FRP | fibre-reinforced plastic |

| rUC | representative unit cell |

| NN | no nesting configuration |

| MN | maximum nesting configuration |

| UD | unidirectional |

Appendix A. Experimental Appendix

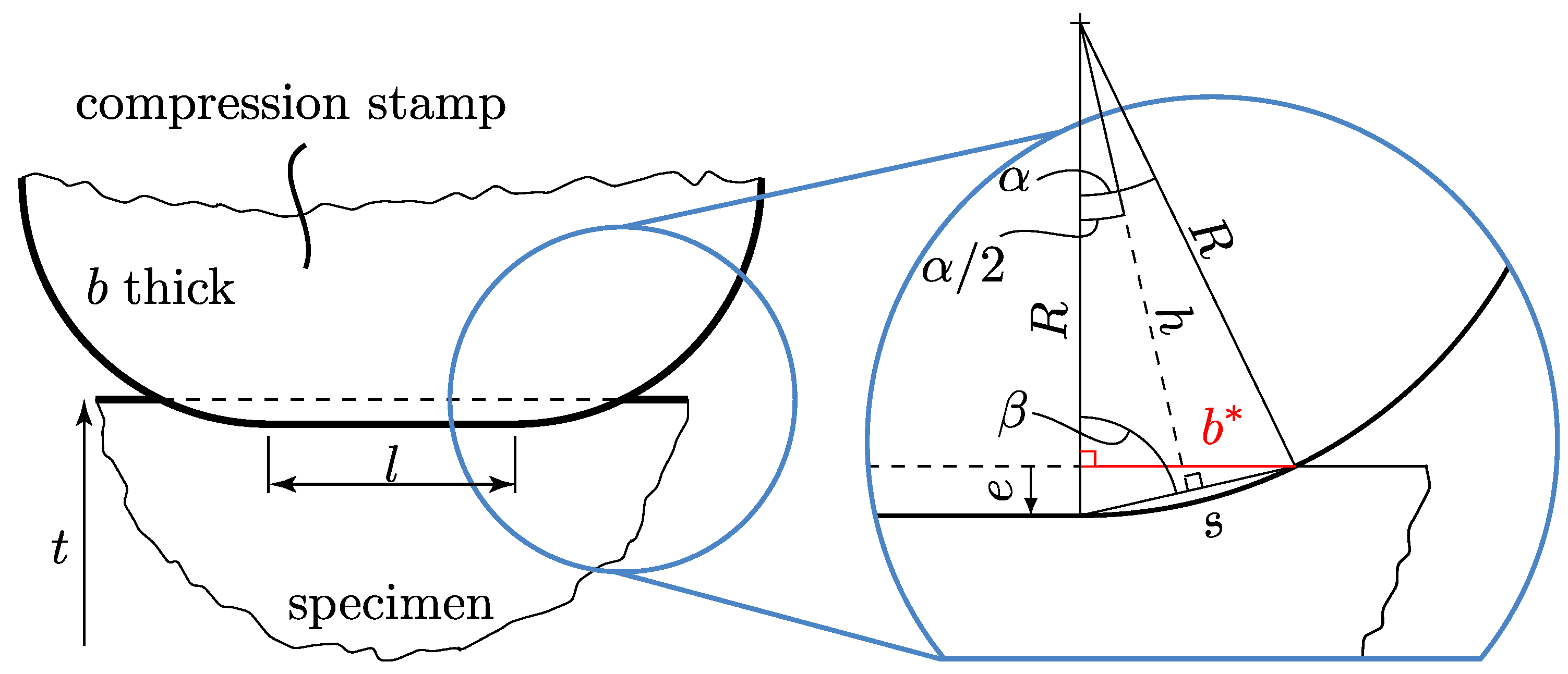

Appendix A.1. Determination of the True Stress State (-Testing)

Appendix A.2. Results of Uniaxial and Biaxial Testing

| Fabric Type | [GPa] | [GPa] | [GPa] | [GPa] | ||

|---|---|---|---|---|---|---|

| I | 72.2 ± 1.6 | 11.3 ± 0.5 | 5.2 ± 0.6 | 3.3 ± 0.2 | 0.12 ± 0.04 | 0.57 ± 0.15 |

| II | 69.4 ± 2.5 | 11.5 ± 0.6 | 5.0 ± 0.5 | 3.5 ± 0.3 | 0.08 ± 0.03 | 0.53 ± 0.08 |

| III | 66.1 ± 1.3 | 10.8 ± 0.4 | 5.0 ± 0.3 | 3.2 ± 0.2 | 0.13 ± 0.03 | 0.57 ± 0.11 |

| Type | [MPa] | [MPa] | |

|---|---|---|---|

| 1:0 | I | 894 ± 24 | − |

| II | 876 ± 64 | − | |

| III | 680 ± 39 | − | |

| 1:1 | I | 589 ± 8 | 397 ± 22 |

| II | 549 ± 38 | 370 ± 22 | |

| III | 635 ± 43 | 421 ± 24 | |

| 1:2 | I | 419 ± 30 | 533 ± 30 |

| II | 426 ± 19 | 541 ± 20 | |

| III | 460 ± 32 | 570 ± 36 | |

| 1:5 | I | 252 ± 24 | 706 ± 22 |

| II | 251 ± 23 | 712 ± 31 | |

| III | 266 ± 28 | 738 ± 34 | |

| 0:1 | I | − | 960 ± 33 |

| II | − | 907 ± 51 | |

| III | − | 915 ± 37 |

Appendix B. Numerical Appendix

Appendix B.1. Analytical Determination of Elastic Properties (UD-Layer)

Appendix B.2. Formulation of Cuntze Stress Efforts for Transversal Isotropic Material

Results of Damage Initiation and Failure

| Type | Config. | Damage | Failure | ||||

|---|---|---|---|---|---|---|---|

[MPa] | [MPa] | [MPa] | [MPa] | Rel. Error [%] | |||

| 1:0 | I | NN | 320 | 0 | 770 | 0 | −13.87 |

| MN | 400 | 0 | 870 | 0 | −2.68 | ||

| II | NN | 330 | 0 | 750 | 0 | −14.38 | |

| MN | 420 | 0 | 920 | 0 | −5.02 | ||

| III | NN | 230 | 0 | 530 | 0 | −22.06 | |

| MN | 320 | 0 | 630 | 0 | −7.35 | ||

| 0:1 | I | NN | 0 | −186 | 0 | −1035 | 7.81 |

| MN | 0 | −200 | 0 | −1039 | 8.23 | ||

| II | NN | 0 | −190 | 0 | 1121 | 23.59 | |

| MN | 0 | −180 | 0 | −1030 | 13.56 | ||

| III | NN | 0 | −150 | 0 | −911 | −0.55 | |

| MN | 0 | −100 | 0 | −730 | −20.22 | ||

| 1:1 | I | NN | 163 | −168 | 460 | −476 | − |

| MN | 163 | −168 | 480 | −498 | − | ||

| II | NN | 170 | −170 | 467 | −467 | − | |

| MN | 163 | −163 | 516 | −516 | − | ||

| III | NN | 127 | −127 | 325 | −325 | − | |

| MN | 91 | −92 | 396 | −396 | − | ||

| 1:0.7 | I | NN | 128 | −172 | 402 | −542 | 5 |

| MN | 163 | −168 | 480 | −498 | −2.62 | ||

| II | NN | 170 | −170 | 467 | −467 | −0.24 | |

| MN | 163 | −163 | 516 | −516 | 10.22 | ||

| III | NN | 127 | −127 | 325 | −325 | −39.67 | |

| MN | 91 | −92 | 396 | −396 | −26.49 | ||

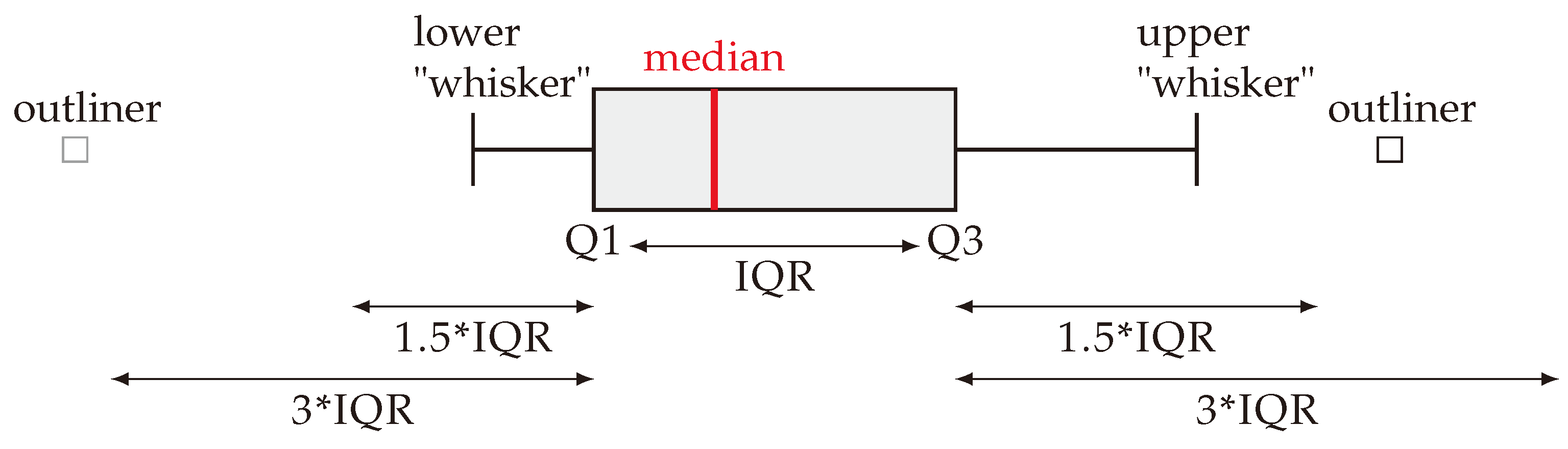

Appendix B.3. Graphical Notation of a Box Plot

References

- Koumoulos, E.P.; Trompeta, A.F.; Santos, R.M.; Martins, M.; Santos, C.M.D.; Iglesias, V.; Böhm, R.; Gong, G.; Chiminelli, A.; Verpoest, I.; et al. Research and Development in Carbon Fibers and Advanced High-Performance Composites Supply Chain in Europe: A Roadmap for Challenges and the Industrial Uptake. J. Compos. Sci. 2019, 3, 86. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Böhm, R.; Thieme, M.; Wohlfahrt, D.; Wolz, D.S.; Richter, B.; Jäger, H. Reinforcement Systems for Carbon Concrete Composites Based on Low-Cost Carbon Fibers. Fibers 2018, 6, 56. [Google Scholar] [CrossRef]

- Ricci, P.; Di Domenico, M.; Verderame, G.M. Experimental investigation of the influence of slenderness ratio and of the in-plane/out-of-plane interaction on the out-of-plane strength of URM infill walls. Constr. Build. Mater. 2018, 191, 507–522. [Google Scholar] [CrossRef]

- Kariou, F.A.; Triantafyllou, S.P.; Bournas, D.A. TRM strengthening of masonry arches: An experimental investigation on the effect of strengthening layout and textile fibre material. Compos. Part B Eng. 2018, 173, 13. [Google Scholar] [CrossRef]

- Würfel, V.; Grützner, R.; Hirsch, F.; Barfuß, D.; Gude, M.; Müller, R.; Kästner, M. Hybrid Fibre Reinfoced Thermoplastic Hollow Structures with a Multi-Scale Strucutred Metal Load Introduction Element. In Proceedings of the 4th International Conference on Hybrid -Materials and Structures, Karlsruhe, Germany, 18–22 April 2020. [Google Scholar]

- Hufenbach, W.; Böhm, R.; Thieme, M.; Winkler, A.; Mäder, E.; Rausch, J.; Schade, M. Polypropylene/glass fibre 3D-textile reinforced composites for automotive applications. Mater. Des. 2011, 32, 1468–1476. [Google Scholar] [CrossRef]

- Harris, B. Fatigue in Composites: Science and Technology of the Fatigue Response of Fibre-Reinforced Plastics; Woodhead Publishing Limited: Cambridge, UK, 2003. [Google Scholar]

- Böhm, H.; Schirner, R.; Gude, M.; Böhm, R. Experimental and numerical investigation of appropriate CFRP specimen designs for inducing in-plane tensile/through-thickness compressive and interlaminar shear/through-thickness compressive stress states. In Proceedings of the 8th International Conference on Composites Testing and Model Identification, Leuven, Belgium, 5–7 April 2017. [Google Scholar]

- Koch, I.; Just, G.; Brod, M.; Chen, J.; Doblies, A.; Dean, A.; Gude, M.; Rolfes, R.; Hopmann, C.; Fiedler, B. Evaluation and Modelling of the Fatigue Damage Behaviour of Polymer Composites at Reversed Cyclic Load. Materials 2019, 12, 1727. [Google Scholar] [CrossRef]

- Koch, I.; Zscheyge, M.; Tittmann, K.; Gude, M. Numerical fatigue analysis of CFRP components. Compos. Struct. 2017, 168, 392–401. [Google Scholar] [CrossRef]

- Böhm, R.; Gude, M.; Hufenbach, W. A phenomenologically based damage model for textile composites with crimped reinforcement. Compos. Sci. Technol. 2010, 70, 81–87. [Google Scholar] [CrossRef]

- Daniel, I.M.; Ishai, O. Engineering Mechanics of Composite Materials, 2nd ed.; Oxford Univ. Press: New York, NY, USA, 2006. [Google Scholar]

- Zscheyge, M.; Boehm, R.; Hornig, A.; Gerritzen, J.; Gude, M. Rate dependent non-linear mechanical behaviour of continuous fibre-reinforced thermoplastic composites—Experimental characterisation and viscoelastic-plastic damage modelling. Mater. Des. 2020, 193, 108827. [Google Scholar] [CrossRef]

- Daniel, I.M.; Luo, J.J.; Schubel, P.M.; Werner, B.T. Interfiber/interlaminar failure of composites under multi-axial states of stress. Compos. Sci. Technol. 2009, 69, 764–771. [Google Scholar] [CrossRef]

- Sun, C.; Tao, J. Prediction of Failure Envelopes and Stress/Strain Behaviour of Composite Laminates. Compos. Sci. Technol. 1998, 58, 1125–1136. [Google Scholar] [CrossRef]

- Varandas, L.F.; Catalanotti, G.; Melro, A.R.; Falzon, B.G. On the importance of nesting considerations for accurate computational damage modelling in 2D woven composite materials. Comput. Mater. Sci. 2020, 172, 109323. [Google Scholar] [CrossRef]

- De Carvalho, N.; Pinho, S.; Robinson, P. An experimental study of failure initiation and propagation in 2D woven composites under compression. Compos. Sci. Technol. 2011, 71, 1316–1325. [Google Scholar] [CrossRef]

- Sevenois, R.; Garoz, D.; Gilabert, F.; Spronk, S.; Fonteyn, S.; Heyndrickx, M.; Pyl, L.; Hemelrijck, D.V.; Degrieck, J.; Paepegem, W.V. Avoiding interpenetrations and the importance of nesting in analytic geometry construction for Representative Unit Cell of woven composite laminates. Compos. Sci. Technol. 2016, 136, 119–132. [Google Scholar] [CrossRef]

- Adumitroaie, A.; Barbero, E.J. Stiffness and Strength Prediction for Plain Weave Textile Reinforced Composites. Mech. Adv. Mater. Struct. 2012, 19, 169–183. [Google Scholar] [CrossRef]

- Hufenbach, W.; Hornig, A.; Gude, M.; Böhm, R.; Zahneisen, F. Influence of interface waviness on delamination characteristics and correlation of through-thickness tensile failure with mode I energy release rates in carbon fibre textile composites. Mater. Des. 2013, 50, 839–845. [Google Scholar] [CrossRef]

- Düreth, C.; Thieme, M.; Böhm, H.; Gude, M. Experimental and numerical characterisation of the fracture behaviour of novel specimens for superimposed out-of-plane stresses. In Proceedings of the 10th European Solid Mechanics Conference, Bologna, Italy, 2–6 July 2018; p. 3. [Google Scholar]

- Olsson, R. A survey of test methods for multiaxial and out-of-plane strength of composite laminates. Compos. Sci. Technol. 2011, 71, 773–783. [Google Scholar] [CrossRef]

- Gan, K.W.; Wisnom, M.R.; Hallett, S.R. Effect of high through-thickness compressive stress on fibre direction tensile strength of carbon/epoxy composite laminates. Compos. Sci. Technol. 2014, 90, 1–8. [Google Scholar] [CrossRef]

- Yousaf, Z.; Potluri, P.; Withers, P.J. Influence of Tow Architecture on Compaction and Nesting in Textile Preforms. Appl. Compos. Mater. 2017, 24, 337–350. [Google Scholar] [CrossRef]

- Schirner, R.; Süß, M.; Gude, M. In-situ computed tomography of the compaction behaviour of single-ply and multi-ply carbon fibre woven fabrics. In Proceedings of the 10th Asian-Australasian Conference on Composite Materials (ACCM-10), Busan, Korea, 16–19 October 2016. [Google Scholar]

- Hufenbach, W.; Böhm, R.; Gude, M.; Berthel, M.; Hornig, A.; Ručevskis, S.; Andrich, M. A test device for damage characterisation of composites based on in situ computed tomography. Compos. Sci. Technol. 2012, 72, 1361–1367. [Google Scholar] [CrossRef]

- Böhm, R.; Stiller, J.; Behnisch, T.; Zscheyge, M.; Protz, R.; Radloff, S.; Gude, M.; Hufenbach, W. A quantitative comparison of the capabilities of in situ computed tomography and conventional computed tomography for damage analysis of composites. Compos. Sci. Technol. 2015, 110, 62–68. [Google Scholar] [CrossRef]

- Marques, O. Practical Image and Video Processing Using MATLAB®: Marques/Practical Image Processing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Galkin, S.; Kunze, E.; Kärger, L.; Böhm, R.; Gude, M. Experimental and Numerical Determination of the Local Fiber Volume Content of Unidirectional Non-Crimp Fabrics with Forming Effects. J. Compos. Sci. 2019, 3, 19. [Google Scholar] [CrossRef]

- Kunze, E.; Schwarz, B.; Weber, T.; Müller, M.; Böhm, R.; Gude, M. Forming Analysis of Internal Plies of Multi-Layer Unidirectional Textile Preforms using Projectional Radiography. Procedia Manuf. 2020, 47, 17–23. [Google Scholar] [CrossRef]

- Lomov, S. Modelling the geometry of textile reinforcements for composites: WiseTex. In Composite Reinforcements for Optimum Performance; Elsevier: Amsterdam, The Netherlands, 2011; pp. 200–238. [Google Scholar] [CrossRef]

- Long, A.; Brown, L. Modelling the geometry of textile reinforcements for composites: TexGen. In Composite Reinforcements for Optimum Performance; Elsevier: Amsterdam, The Netherlands, 2011; pp. 239–264. [Google Scholar] [CrossRef]

- Jacques, S.; De Baere, I.; Van Paepegem, W. Application of periodic boundary conditions on multiple part finite element meshes for the meso-scale homogenization of textile fabric composites. Compos. Sci. Technol. 2014, 92, 41–54. [Google Scholar] [CrossRef]

- Tabatabaei, S.A.; Lomov, S.V. Embeeded Element Method in meso finite element modelling of textile composite. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015; p. 12. [Google Scholar]

- De Carvalho, N.; Pinho, S.; Robinson, P. Numerical modelling of woven composites: Biaxial loading. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1326–1337. [Google Scholar] [CrossRef]

- Hivet, G.; Boisse, P. Consistent mesoscopic mechanical behaviour model for woven composite reinforcements in biaxial tension. Compos. Part B Eng. 2008, 39, 345–361. [Google Scholar] [CrossRef]

- Cuntze, R.; Freund, A. The predictive capability of failure mode concept-based strength criteria for multidirectional laminates. Compos. Sci. Technol. 2004, 64, 343–377. [Google Scholar] [CrossRef]

- Cuntze, R. The predictive capability of failure mode concept-based strength conditions for laminates composed of unidirectional laminae under static triaxial stress states. J. Compos. Mater. 2012, 46, 2563–2594. [Google Scholar] [CrossRef]

- Hinton, M.; Kaddour, A.; Soden, P. Failure Criteria in Fibre Reinforced Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Hinton, M.; Kaddour, A.; Soden, P. Evaluation of failure prediction in composite laminates: Background to ‘part C’ of the exercise. Compos. Sci. Technol. 2004, 64, 321–327. [Google Scholar] [CrossRef]

- Cuntze, R. Comparison between experimental and theoretical results using Cuntze’s “failure mode concept” model for composites under triaxial loadings—Part B of the second world-wide failure exercise. J. Compos. Mater. 2013, 47, 893–924. [Google Scholar] [CrossRef]

- Gan, K.W.; Wisnom, M.R.; Hallett, S.R. An approximate model of cylindrical and spherical contact on composite laminates of finite thickness. Compos. Struct. 2013, 103, 136–142. [Google Scholar] [CrossRef]

- Düreth, C.; Weck, D.; Böhm, R.; Thieme, M.; Gude, M.; Wolf, C.H.; Henkel, S.; Biermann, H. Interlaminar shear strength enhancement under out-of-plane compression of fabric reinforcements—A review on meso and macro scale. In Proceedings of the 18th European Conference on Composite Materials, Athen, Greece, 25–28 June 2018; p. 10. [Google Scholar]

- Andrich, M.; Hufenbach, W.; Kunze, K.; Scheibe, H.J. Characterisation of the friction and wear behaviour of textile reinforced polymer composites in contact with diamond-like carbon layers. Tribol. Int. 2013, 62, 29–36. [Google Scholar] [CrossRef]

- Andrich, M. Analyse des Schädigungs- und Versagensverhaltens dickwandiger textilverstärkter Kunststoffverbunde bei Druckbelastung in Dickenrichtung. Ph.D. Thesis, TU Dresden, Dresden, Geramny, 2013. [Google Scholar]

- Kim, J.S.; Kim, C.G.; Hong, C.S. Optimum design of composite structures with ply drop using genetic algorithm and expert system shell. Compos. Struct. 1999, 46, 171–187. [Google Scholar] [CrossRef]

- Mukherjee, A.; Varughese, B. Design guidelines for ply drop-off in laminated composite structures. Compos. Part B Eng. 2001, 32, 153–164. [Google Scholar] [CrossRef]

- Schreier, H.; Orteu, J.J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements; Springer: Boston, MA, USA, 2009. [Google Scholar] [CrossRef]

- Schürmann, H. Konstruieren mit Faser-Kunststoff-Verbunden; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Teijin Carbon Europe GmbH. Tenax® Filament Yarn—Product Data Sheet (EU); Version: 1.2; Teijin Carbon Europe GmbH: Heinsberg, Germany, 2020. [Google Scholar]

- Gude, M.; Schirner, R.; Müller, M.; Weckend, N.; Andrich, M.; Langkamp, A. Experimental-numerical test strategy for evaluation of curing simulation of complex-shaped composite structures: Experimentell-numerische Teststrategie zur Evaluierung der Aushärtungssimulation für komplex geformte Faserverbundstrukturen. Mater. Und Werkst. 2016, 47, 1072–1086. [Google Scholar] [CrossRef]

- Gude, M.; Hufenbach, W.; Andrich, M.; Mertel, A.; Schirner, R. Modified V-notched rail shear test fixture for shear characterisation of textile-reinforced composite materials. Polym. Test. 2015, 43, 147–153. [Google Scholar] [CrossRef]

- Gude, M.; Schirner, R.; Weck, D.; Dohmen, E.; Andrich, M. Through-thickness compression testing of fabric reinforced composite materials: Adapted design of novel compression stamps. Polym. Test. 2016, 56, 269–276. [Google Scholar] [CrossRef]

- Hsiao, H.; Daniel, I. Effect of fiber waviness on stiffness and strength reduction of unidirectional composites under compressive loading. Compos. Sci. Technol. 1996, 56, 581–593. [Google Scholar] [CrossRef]

- DIN EN ISO 527-4. Kunststoffe—Bestimmung der Zugeigenschaften—Teil 4: Prüfbedingungen für Isotrop und Anistrop Faserverstärkte Kunststoffverbunde; Beuth Verlag GmbH: Berlin, Germany, 1997. [Google Scholar]

- Puck, A. Festigkeitsanalyse von Faser-Matrix-Laminaten - Modelle für Die Praxis; Carl Hanser Verlag: München, Germany, 1996. [Google Scholar]

- Pan, N. Analysis of woven fabric strengths: Prediction of fabric strength under uniaxial and biaxial extensions. Compos. Sci. Technol. 1996, 56, 311–327. [Google Scholar] [CrossRef]

- Yurgartis, S.W.; Morey, K.; Jortner, J. Measurement of yarn-shape and nesting in plain-weave composites. Compos. Sci. Technol. 1993, 46, 39–50. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Endruweit, A.; Gommer, F.; Long, A. Stochastic analysis of fibre volume fraction and permeability in fibre bundles with random filament arrangement. Compos. Part A Appl. Sci. Manuf. 2013, 49, 109–118. [Google Scholar] [CrossRef]

- Brown, M.; Lowe, D.G. Automatic Panoramic Image Stitching using Invariant Features. Int. J. Comput. Vis. 2007, 74, 59–73. [Google Scholar] [CrossRef]

- Lomov, S.; Ivanov, D.; Verpoest, I.; Zako, M.; Kurashiki, T.; Nakai, H.; Hirosawa, S. Meso-FE modelling of textile composites: Road map, data flow and algorithms. Compos. Sci. Technol. 2007, 67, 1870–1891. [Google Scholar] [CrossRef]

- Thompson, A.J.; El Said, B.; Ivanov, D.; Belnoue, J.P.H.; Hallett, S.R. High fidelity modelling of the compression behaviour of 2D woven fabrics. Int. J. Solids Struct. 2018, 154, 104–113. [Google Scholar] [CrossRef]

- Middleton, C. Geometric and Mechanical Modelling of Textiles. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2007. [Google Scholar]

- Iarve, E.V.; Mollenhauer, D.H.; Zhou, E.G.; Breitzman, T.; Whitney, T.J. Independent mesh method-based prediction of local and volume average fields in textile composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1880–1890. [Google Scholar] [CrossRef]

- Xia, Z.; Zhang, Y.; Ellyin, F. A unified periodical boundary conditions for representative volume elements of composites and applications. Int. J. Solids Struct. 2003, 40, 1907–1921. [Google Scholar] [CrossRef]

- Tabatabaei, S.; Lomov, S.V. Eliminating the volume redundancy of embedded elements and yarn interpenetrations in meso-finite element modelling of textile composites. Comput. Struct. 2015, 152, 142–154. [Google Scholar] [CrossRef]

- Smith, M. ABAQUS/Standard User’s Manual; Version 2019; Dassault Systèmes Simulia Corp: Johnston, RI, USA, 2019. [Google Scholar]

- Kaddour, A.; Hinton, M.; Soden, P. Chapter 4.1—A comparative study of failure theories and predictions for fibre polymer composite laminates: Part (A). In Failure Criteria in Fibre-Reinforced-Polymer Composites; Hinton, M., Kaddour, A., Soden, P., Eds.; Elsevier: Oxford, UK, 2004; pp. 644–701. [Google Scholar] [CrossRef]

- Petersen, E.; Cuntze, R.; Hühne, C. Experimental determination of material parameters in Cuntze’s Failure-Mode-Concept-based UD strength failure conditions. Compos. Sci. Technol. 2016, 134, 12–25. [Google Scholar] [CrossRef]

| Type | ECC™-Style | Weight | Setting |

|---|---|---|---|

| I | 447 | 160 | 4 |

| II | 450 | 200 | 5 |

| III | 470 | 285 | 7 |

[GPa] | [GPa] | [GPa] | [MPa] | ||||

|---|---|---|---|---|---|---|---|

| 7.00 | 1.77 | 240 | 28 | 50 | 0.230 | 4100 | 1.700 × 10−2 |

| Type | ||||||

|---|---|---|---|---|---|---|

| I | 4.385 | 1.765 | 30.297 | 0.831 | 2.84 × 10−3 | 6.413 |

| II | 5.916 | 1.121 | 17.897 | 0.842 | 1.362 × 10−3 | 4.383 |

| III | 12.134 | 2.889 | 14.008 | 0.868 | 1.364 × 10−3 | 4.255 |

| Data | ||||||

|---|---|---|---|---|---|---|

| I | 0.692 | 0.014 | 17.098 | 0.679 | 0.023 | 22.369 |

| II | 0.665 | 0.013 | 17.145 | 0.653 | 0.020 | 21.660 |

| III | 0.684 | 0.015 | 17.906 | 0.672 | 0.023 | 22.607 |

| I + II + III | 0.681 | 0.014 | 17.375 | 0.726 | 0.022 | 20.522 |

| Type | Config. | Course | Cross Section | rUC | ||||

|---|---|---|---|---|---|---|---|---|

[mm] | ||||||||

| I | NN | 5.216 × 103 | 1.500 × 102 | 1.881 × 103 | 0.750 × 102 | 5.216 | 3.000 × 102 | (1) 0.852 |

| MN | 2.555 × 102 | |||||||

| II | NN | 3.746 × 103 | 1.900 × 102 | 1.577 × 103 | 0.950 × 102 | 3.746 | 3.800 × 102 | (1) 0.874 |

| MN | 3.321 × 102 | |||||||

| III | NN | 2.548 × 103 | 2.700 × 102 | 1.254 × 103 | 1.350 × 102 | 2.548 | 5.400 × 102 | (1) 0.870 |

| MN | 4.697 × 102 | |||||||

[MPa] | [MPa] | [MPa] | [MPa] | |

|---|---|---|---|---|

| 3354 | 0.380 | 1215 | 61 | 82 |

[GPa] | [GPa] | [GPa] | [GPa] | |||

|---|---|---|---|---|---|---|

| value | 172.299 | 18.548 | 9.280 | 6.941 | 0.272 | 0.336 |

| Equation | (A6) | (A6) | (A7) | (A8) | (A9) | (A10) |

[MPa] | [MPa] | [MPa] | [MPa] | [MPa] | |||

|---|---|---|---|---|---|---|---|

| 2602 | 1152 | 70 | 211 | 98 | 2.600 | 0.260 | 1.050 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Düreth, C.; Weck, D.; Böhm, R.; Thieme, M.; Gude, M.; Henkel, S.; Wolf, C.H.; Biermann, H. Determining the Damage and Failure Behaviour of Textile Reinforced Composites under Combined In-Plane and Out-of-Plane Loading. Materials 2020, 13, 4772. https://doi.org/10.3390/ma13214772

Düreth C, Weck D, Böhm R, Thieme M, Gude M, Henkel S, Wolf CH, Biermann H. Determining the Damage and Failure Behaviour of Textile Reinforced Composites under Combined In-Plane and Out-of-Plane Loading. Materials. 2020; 13(21):4772. https://doi.org/10.3390/ma13214772

Chicago/Turabian StyleDüreth, Christian, Daniel Weck, Robert Böhm, Mike Thieme, Maik Gude, Sebastian Henkel, Carl H. Wolf, and Horst Biermann. 2020. "Determining the Damage and Failure Behaviour of Textile Reinforced Composites under Combined In-Plane and Out-of-Plane Loading" Materials 13, no. 21: 4772. https://doi.org/10.3390/ma13214772

APA StyleDüreth, C., Weck, D., Böhm, R., Thieme, M., Gude, M., Henkel, S., Wolf, C. H., & Biermann, H. (2020). Determining the Damage and Failure Behaviour of Textile Reinforced Composites under Combined In-Plane and Out-of-Plane Loading. Materials, 13(21), 4772. https://doi.org/10.3390/ma13214772