Preliminary Study on the Capability of the Novel Near Solidus Forming (NSF) Technology to Manufacture Complex Steel Components

Abstract

1. Introduction

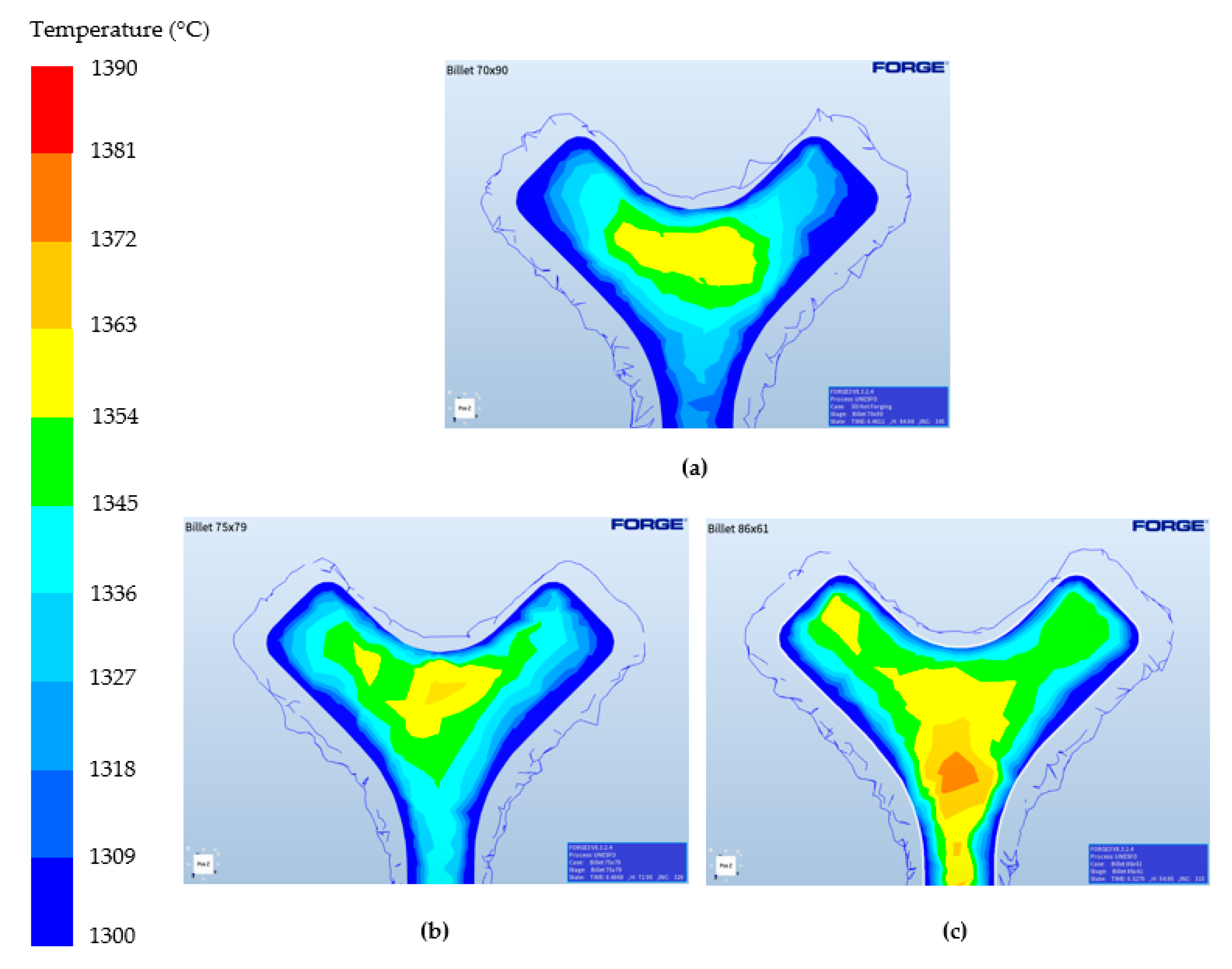

2. Materials and Methods

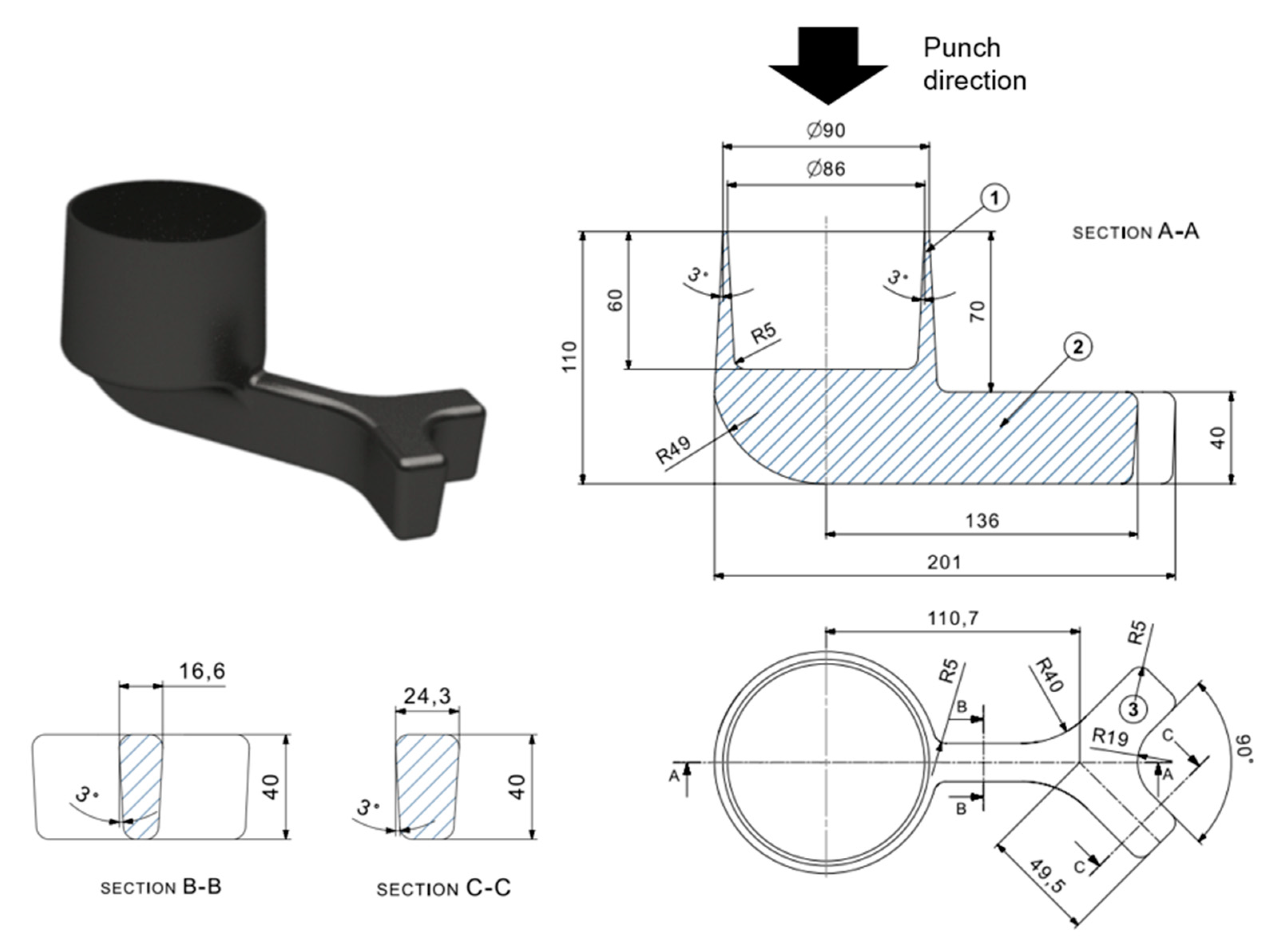

2.1. Geometry

2.2. Material

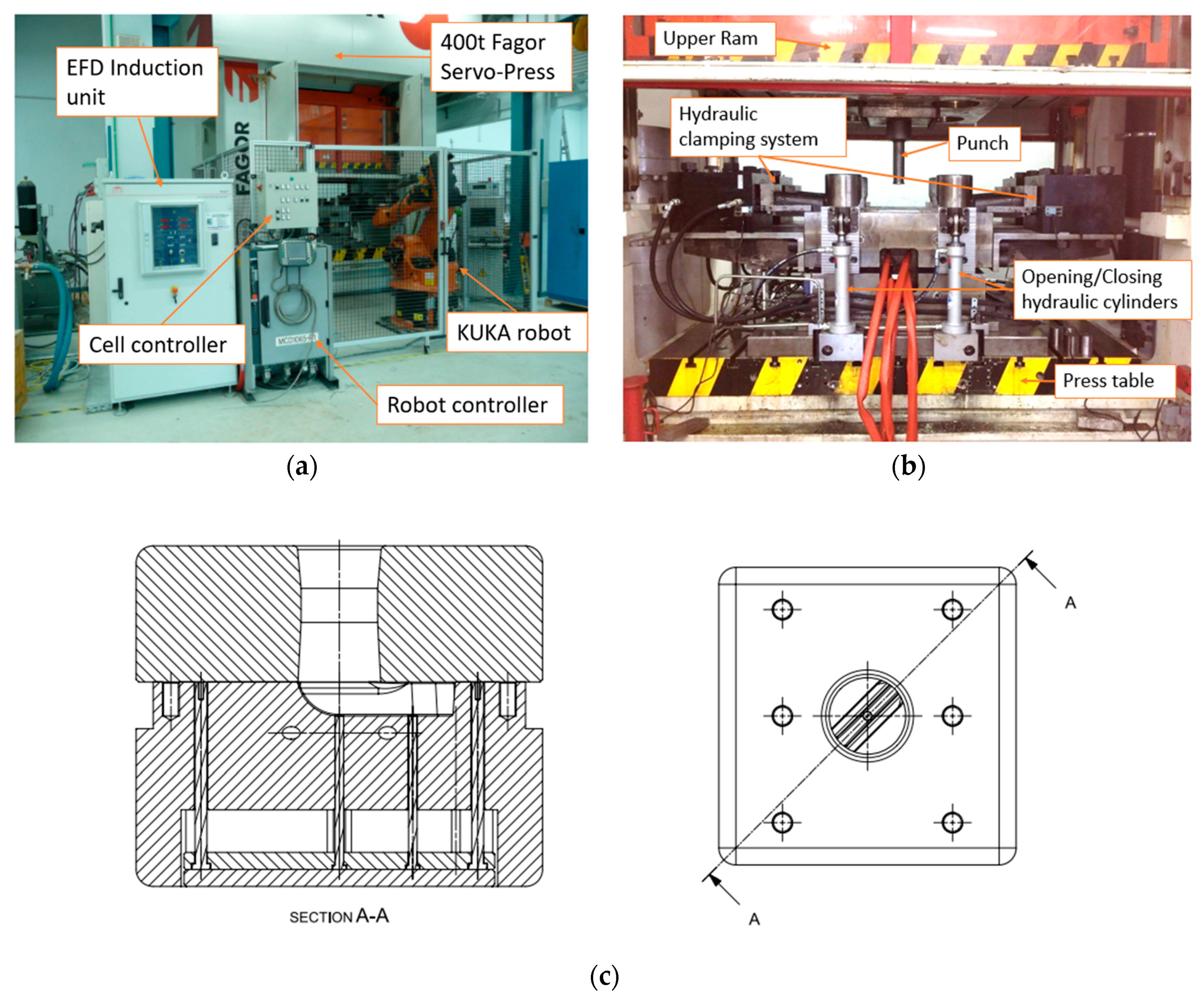

2.3. NSF Cell

2.4. NSF Process

2.4.1. Initial Preparations

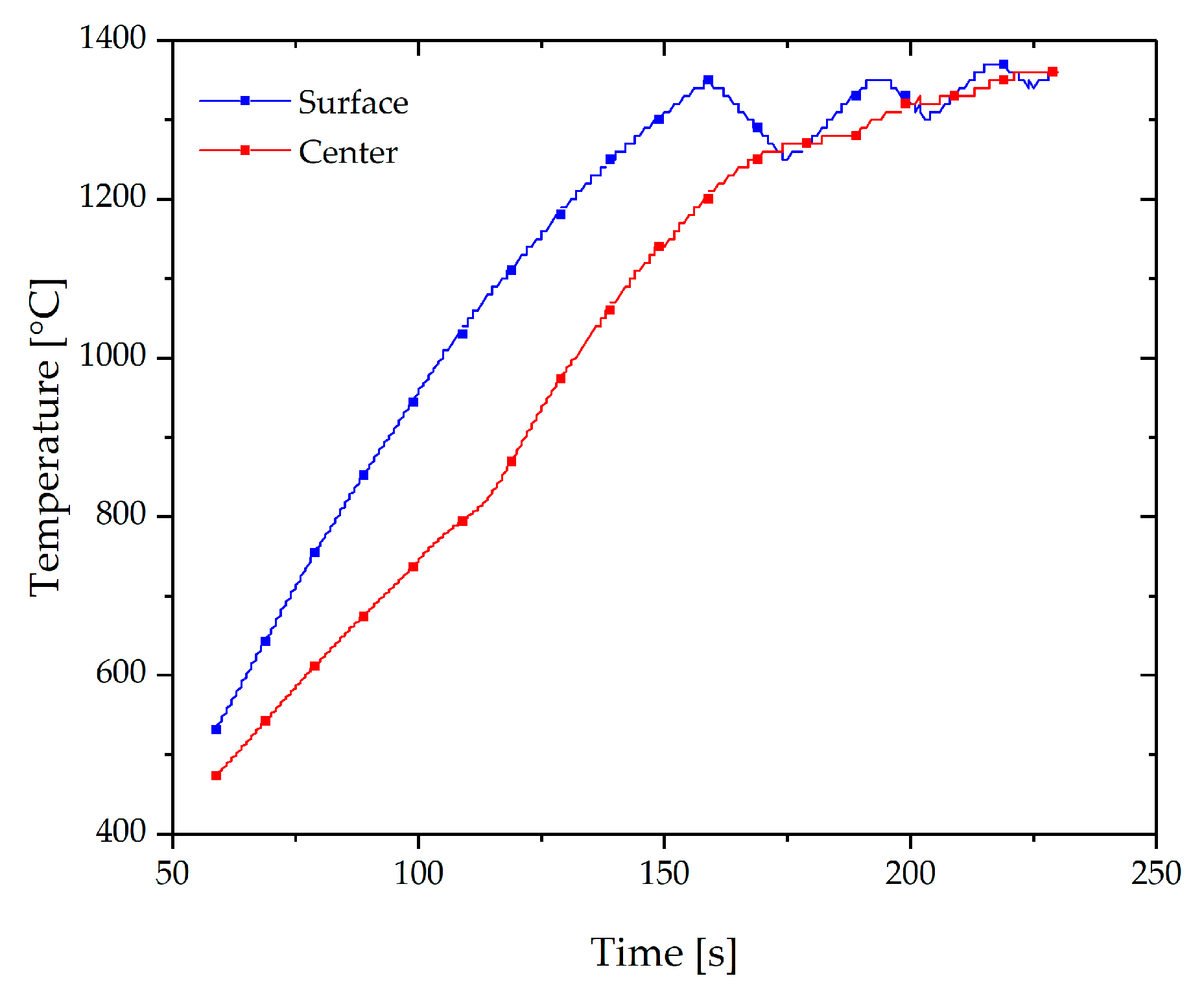

2.4.2. Heating of the Billet

2.4.3. Transfer Stage

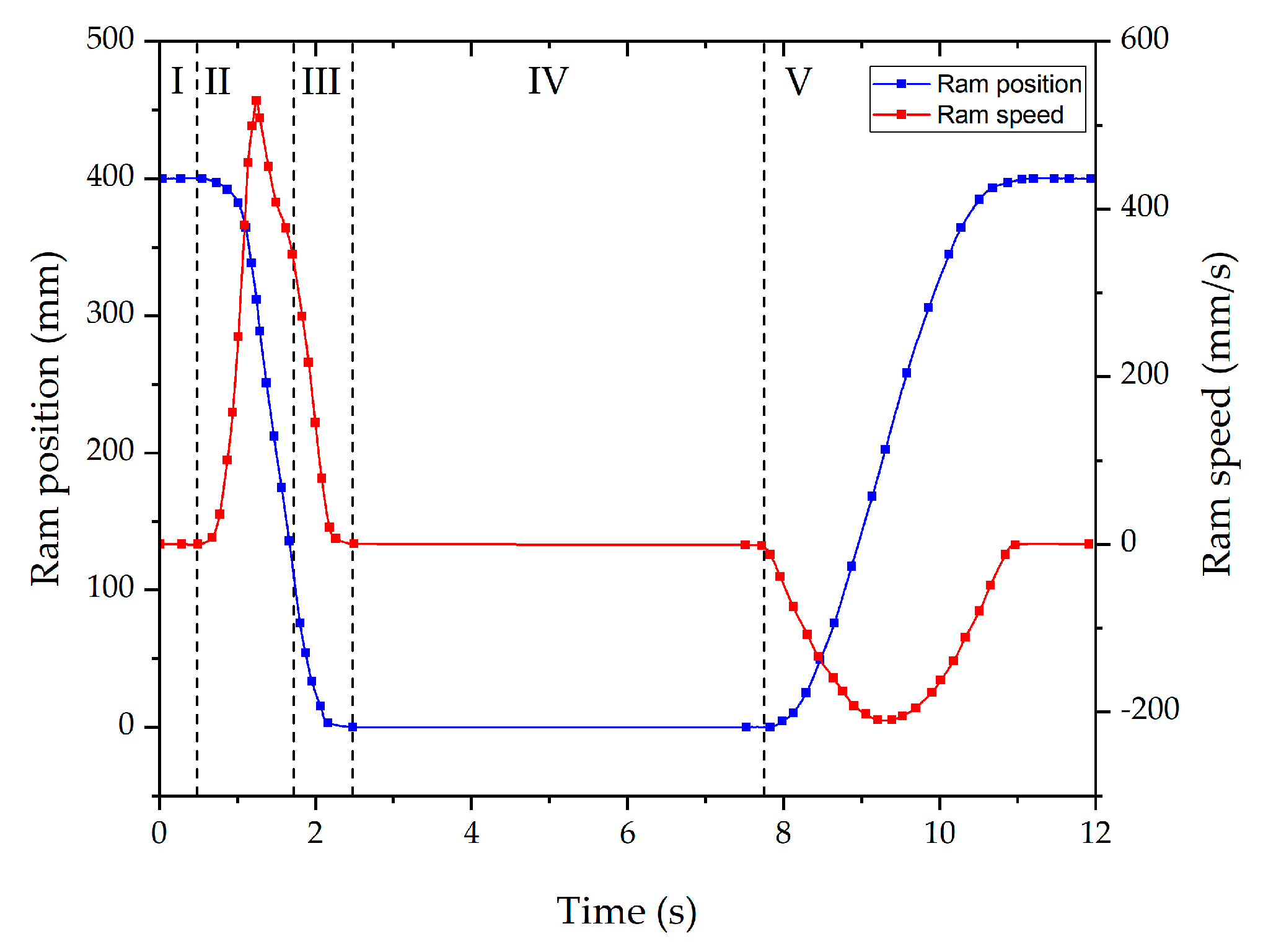

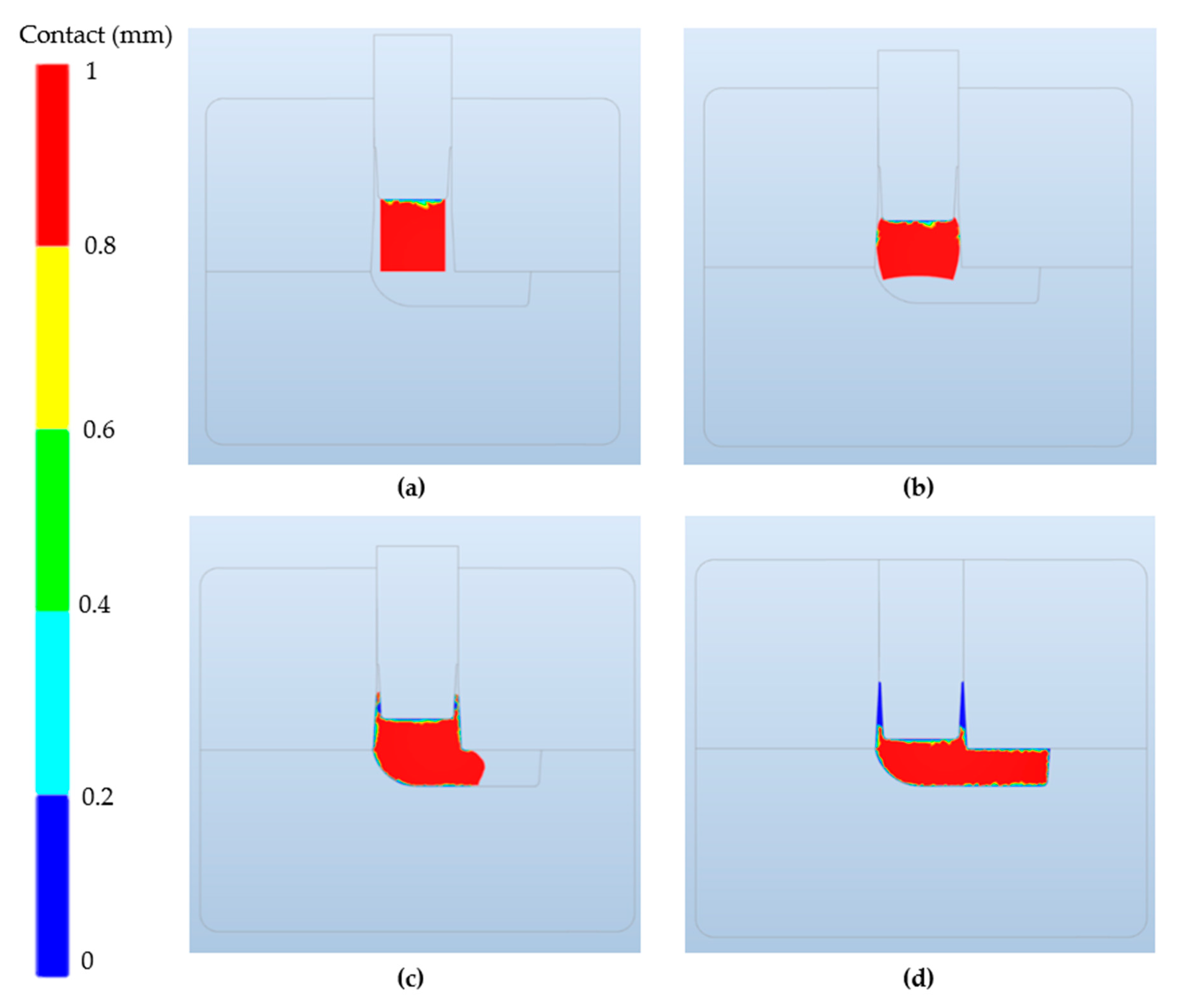

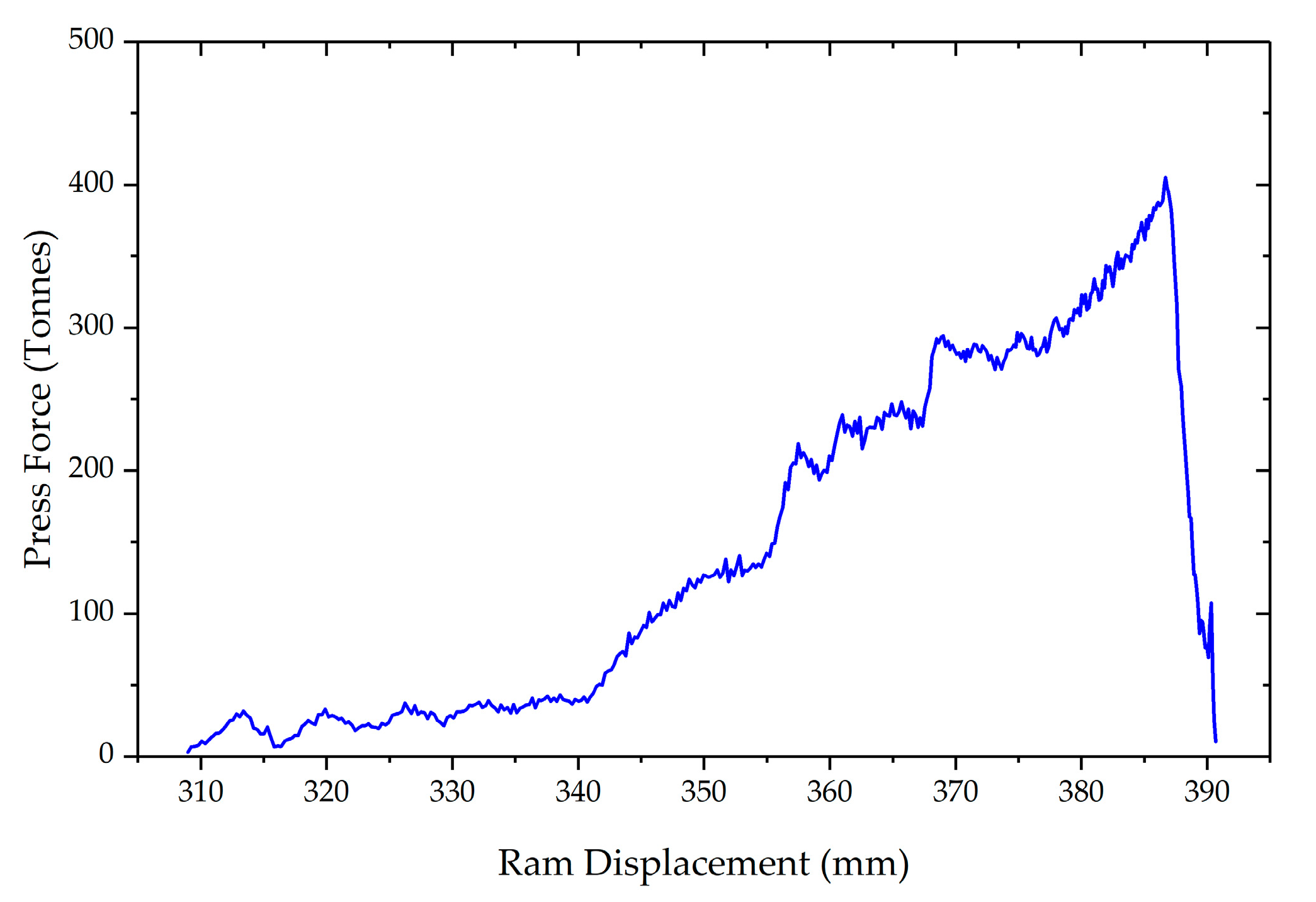

2.4.4. Deformation Stage

2.4.5. Component Ejection

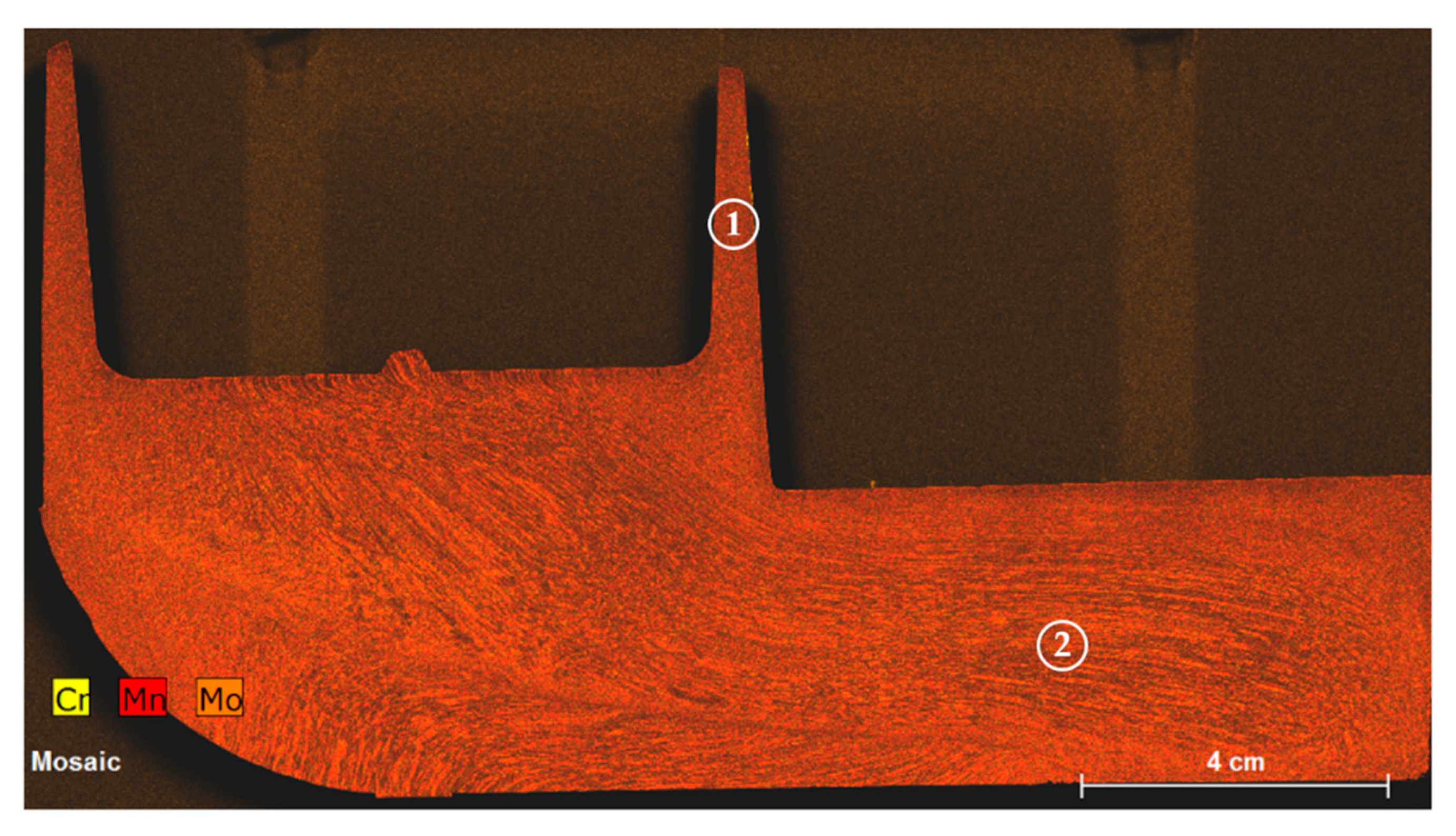

2.5. Microstructural Analysis

2.6. Experimental Sequence

3. Results and Discussion

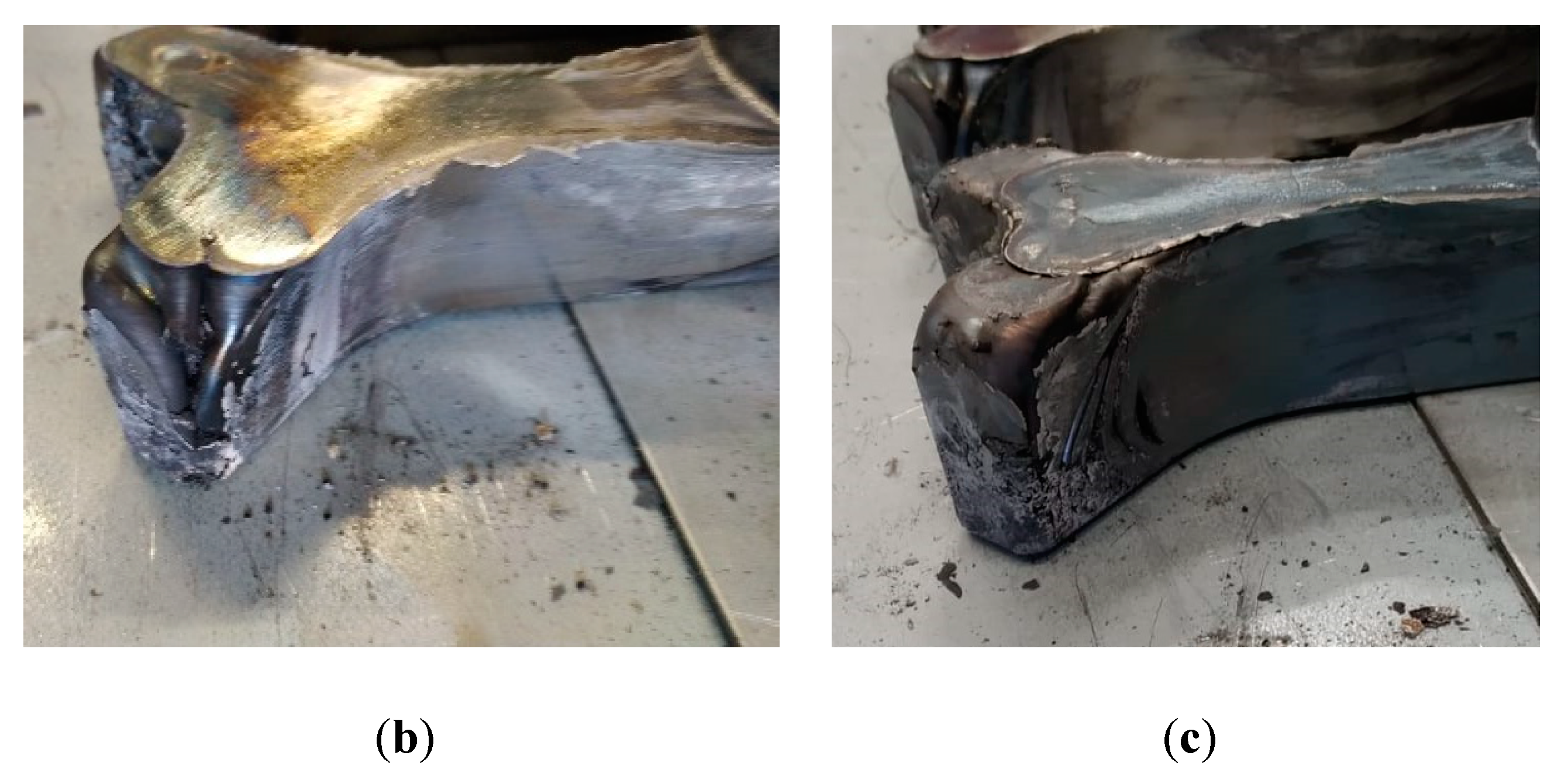

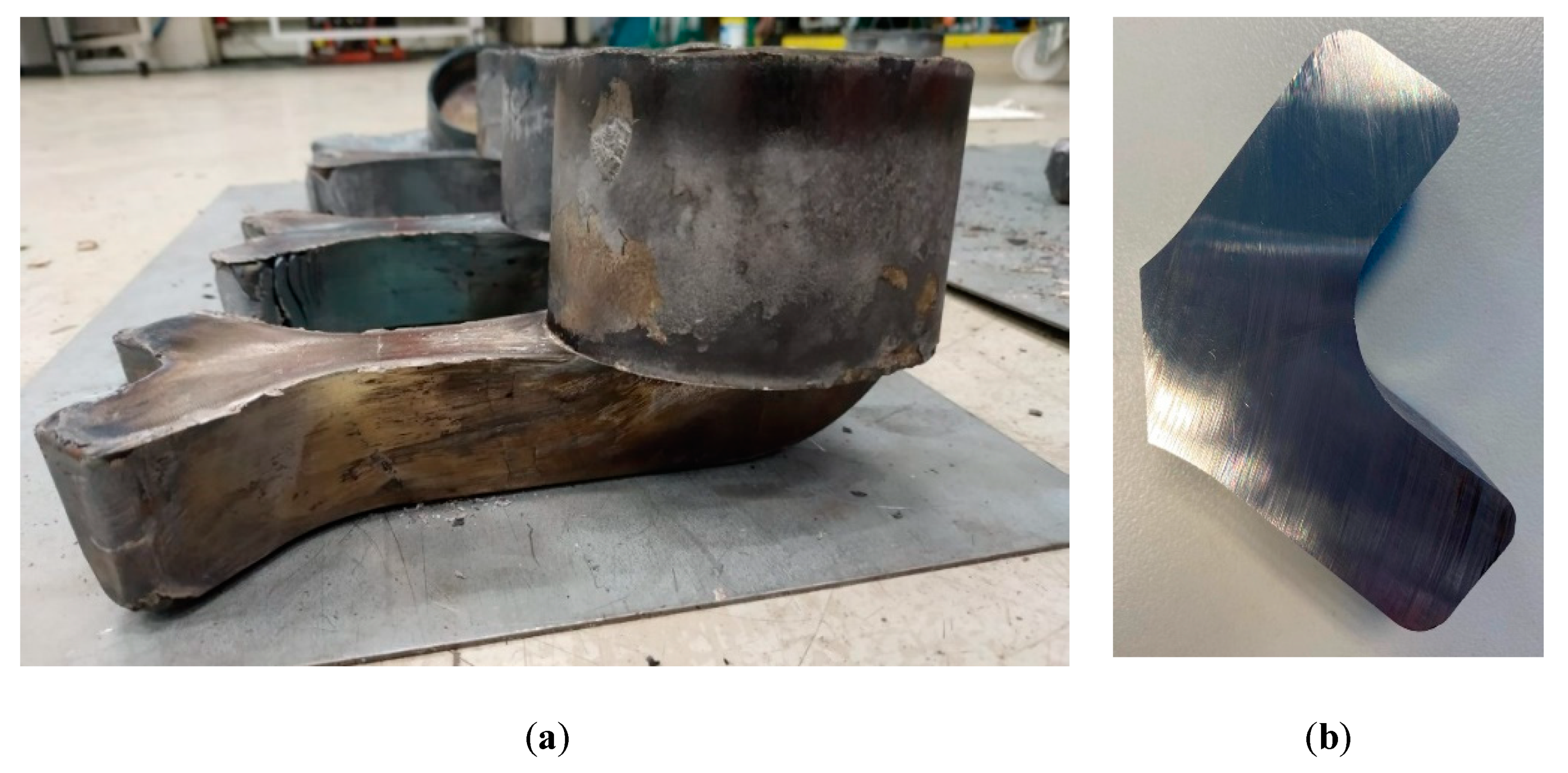

3.1. Component Manufacturing

3.2. Microstructural Evaluation

4. Conclusions

- Thicknesses below 3 mm can be achieved using the 42CrMo4 medium carbon alloy.

- Long distances perpendicular to the forming direction can be successfully filled.

- The material can fill negative cross-sections (from smaller to bigger cross-sections).

- The process enables the closure of defects such as folds and pores.

- The NSF process generates strain vectors in a single deformation that are otherwise difficult to attain via conventional forging routes.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Spencer, D.B.; Mehrabian, R.; Flemings, M.C. Rheological behavior of Sn-15 pct Pb in the crystallization range. Metall. Trans. 1972, 3, 1925–1932. [Google Scholar] [CrossRef]

- Flemings, M.C. Behavior of Metal Alloys in the Semisolid State. Metall. Mater. Trans. 1991, 22, 957–981. [Google Scholar] [CrossRef]

- Thanabumrungkul, S.; Janudom, S.; Burapa, R.; Dulyapraphant, P.; Wannasin, J. Industrial development of gas induced semi-solid process. Trans. Nonferrous Met. Soc. China 2010, 20, s1016–s1021. [Google Scholar] [CrossRef]

- Doutre, D.; Hay, G.; Wales, P.; Gabathuler, J.-P. Seed: A New Process for Semi-Solid Forming. Can. Metall. Q. 2014, 43, 265–272. [Google Scholar] [CrossRef]

- Jarfors, A.E.W.; Zheng, J.; Chen, L.; Yang, J. Recent Advances in Commercial Application of the Rheometal Process in China and Europe. Solid State Phenom. 2019, 285, 405–410. [Google Scholar] [CrossRef]

- Young, K.P.; Riek, R.G.; Flemings, M.C. Structure and properties of Thixocast steels. Met. Technol. 1979, 6, 130–137. [Google Scholar] [CrossRef]

- Modigell, M.; Volkmann, T.; Zang, C. A High-Precision Rotational Rheometer for Temperatures up to 1700 °C. Solid State Phenom. 2012, 192–193, 359–364. [Google Scholar] [CrossRef]

- Kapranos, P.; Kirkwood, D.H.; Sellars, C.M. Semi-solid processing of tool steel. J. Phys. 1993, 4, 835–840. [Google Scholar] [CrossRef]

- Cezard, P.; Sourmail, T. Thixoforming of Steel: A State of the Art from an Industrial Point of View. Solid State Phenom. 2008, 141–143, 25–35. [Google Scholar] [CrossRef]

- Hirt, G.; Bleck, W.; Bührig-Polaczek, A.; Shimahara, H.; Püttgen, W.; Afrath, C. Semi Solid Casting and Forging of Steel. Solid State Phenom. 2006, 116–117, 34–43. [Google Scholar] [CrossRef]

- Robelet, M.; Rassili, A.; Fischer, D. Steel Grades Adapted to the Thixoforging Process: Metallurgical Structures and Mechanical Properties. Solid State Phenom. 2006, 116–117, 712–716. [Google Scholar] [CrossRef]

- Rassili, A.; Lecomte-Beckers, J. Tooling Materials and Solutions for Thixoforming Steel: A Key to the Process Industrialization. Solid State Phenom. 2014, 217–218, 374–380. [Google Scholar] [CrossRef]

- Rassili, A. A Review on Thixoforming of High Melting Point Alloys. Solid State Phenom. 2016, 256, 228–236. [Google Scholar] [CrossRef]

- Lozares, J.; Plata, G.; Azpilgain, Z.; Álvarez, G. Semisolid forming of 42CrMo4E steel grade. In Proceedings of the 19th ESAFORM Conference, Nantes, France, 27–29 April 2016. [Google Scholar]

- Plata, G.; Lozares, J.; Hurtado, I.; Azpilgain, Z.; Idoyaga, Z. Semisolid Forming of 44MnSiV6 microalloyed steel. In Proceedings of the 21st ESAFORM Conference, Palermo, Italy, 23–25 April 2018. [Google Scholar]

- Plata, G.; Lozares, J.; Hurtado, I.; Azpilgain, Z. Semisolid forging of steels: Readiness from an industrial point of view. AIP Conf. Proc. 2019, 2113, 140001. [Google Scholar]

- Lozares, J.; Plata, G.; Hurtado, I.; Sánchez, A.; Loizaga, I. Near solidus forming (NSF): Semi-solid steel forming at high solid content to obtain as-forged properties. Metals 2020, 10, 198. [Google Scholar] [CrossRef]

- Balan, T.; Becker, E.; Langlois, L.; Bigot, R. A new route for semi-solid steel forging. CIRP Ann. Manuf. Technol. 2017, 66, 297–300. [Google Scholar] [CrossRef]

- Pierret, J.C.; Rassili, A.; Vaneetveld, G.; Bigot, R.; Lecomte-Beckers, J. Friction coefficients evaluation for steel thixoforging. Int. J. Mater. Form. 2010, 3, 763–766. [Google Scholar] [CrossRef]

- Lozares, J. Semisolid Forging of Steel Components for Automotive Industry. Ph.D. Thesis, Mondragon Unbertsitatea, Mondragón, Spain, 2014. [Google Scholar]

| C | Mn | Si | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| 0.42 | 0.80 | 0.25 | 0.011 | 0.024 | 1.08 | 0.10 | 0.21 |

| Billet T (°C) | Billet Size (mm) | Die T (°C) | Argon (dm3/min) | Heating Cycle (Pulses/Heating Time) | Lubricant | |

|---|---|---|---|---|---|---|

| Trial 1 | 1360 | ø70 × 90 | 270 | 14–20 | 4/230″ | CeraSpray® |

| Trial 2 | 1390 | 5/258″ | ||||

| Trial 3 | ø75 × 79 | |||||

| Trial 4 | ø85 × 61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plata, G.; Lozares, J.; Sánchez, A.; Hurtado, I.; Slater, C. Preliminary Study on the Capability of the Novel Near Solidus Forming (NSF) Technology to Manufacture Complex Steel Components. Materials 2020, 13, 4682. https://doi.org/10.3390/ma13204682

Plata G, Lozares J, Sánchez A, Hurtado I, Slater C. Preliminary Study on the Capability of the Novel Near Solidus Forming (NSF) Technology to Manufacture Complex Steel Components. Materials. 2020; 13(20):4682. https://doi.org/10.3390/ma13204682

Chicago/Turabian StylePlata, Gorka, Jokin Lozares, Andrea Sánchez, Iñaki Hurtado, and Carl Slater. 2020. "Preliminary Study on the Capability of the Novel Near Solidus Forming (NSF) Technology to Manufacture Complex Steel Components" Materials 13, no. 20: 4682. https://doi.org/10.3390/ma13204682

APA StylePlata, G., Lozares, J., Sánchez, A., Hurtado, I., & Slater, C. (2020). Preliminary Study on the Capability of the Novel Near Solidus Forming (NSF) Technology to Manufacture Complex Steel Components. Materials, 13(20), 4682. https://doi.org/10.3390/ma13204682