Biogenic Composite Filaments Based on Polylactide and Diatomaceous Earth for 3D Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analyses

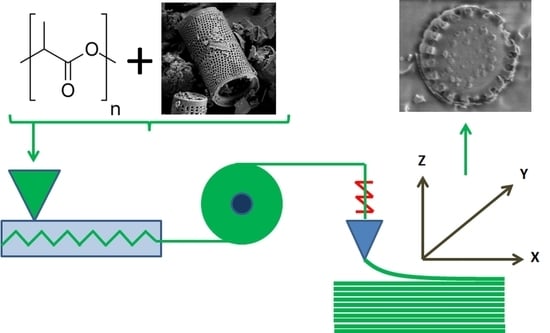

2.3. Fabrication of Filaments

- (a)

- Preparation of diatom modifier

- (b)

- Preparation of granulates

- (c)

- Extrusion of Filaments

3D Printing (FDM)

3. Results and Discussion

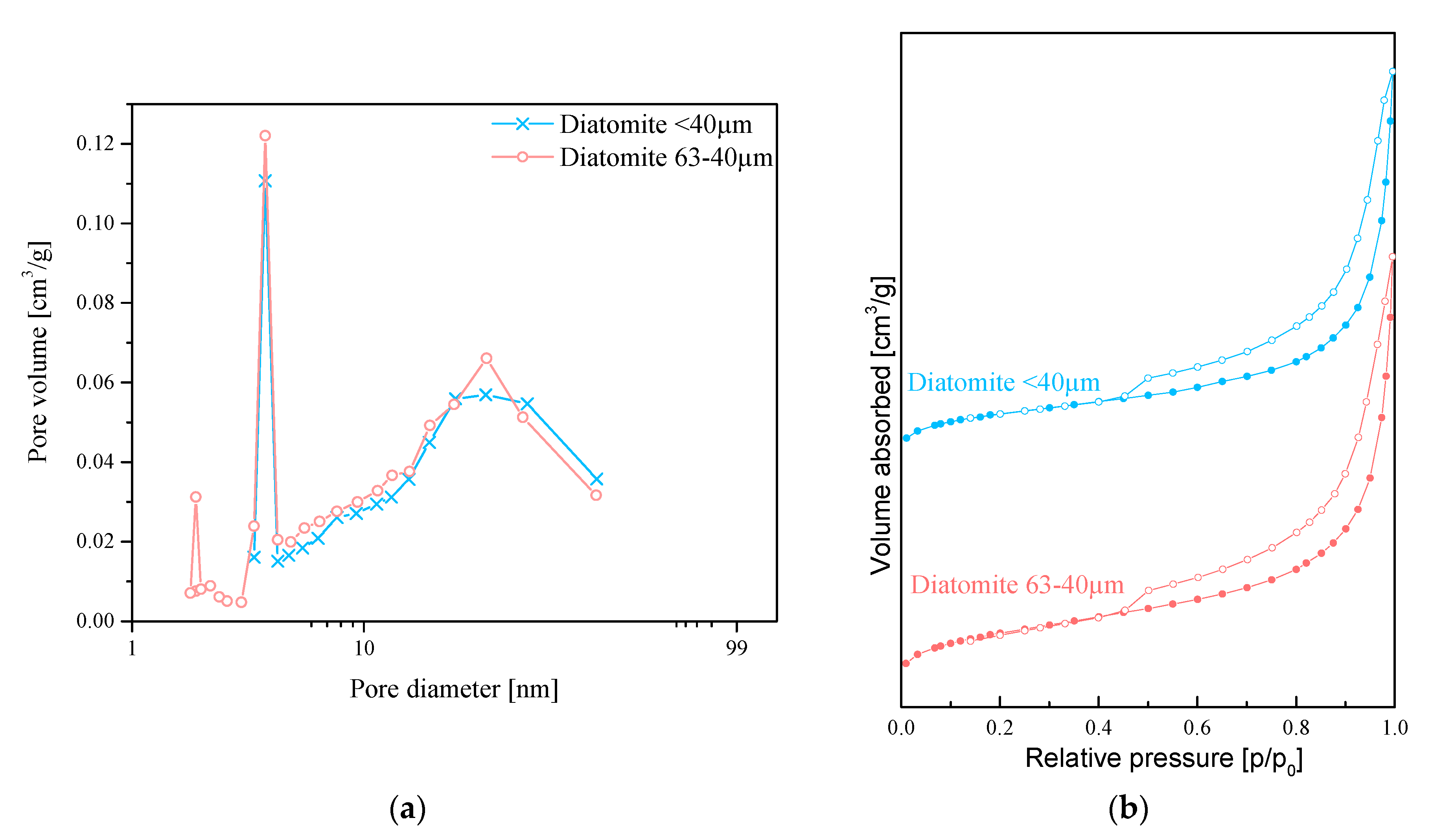

3.1. Low-Temperature Nitrogen Sorption

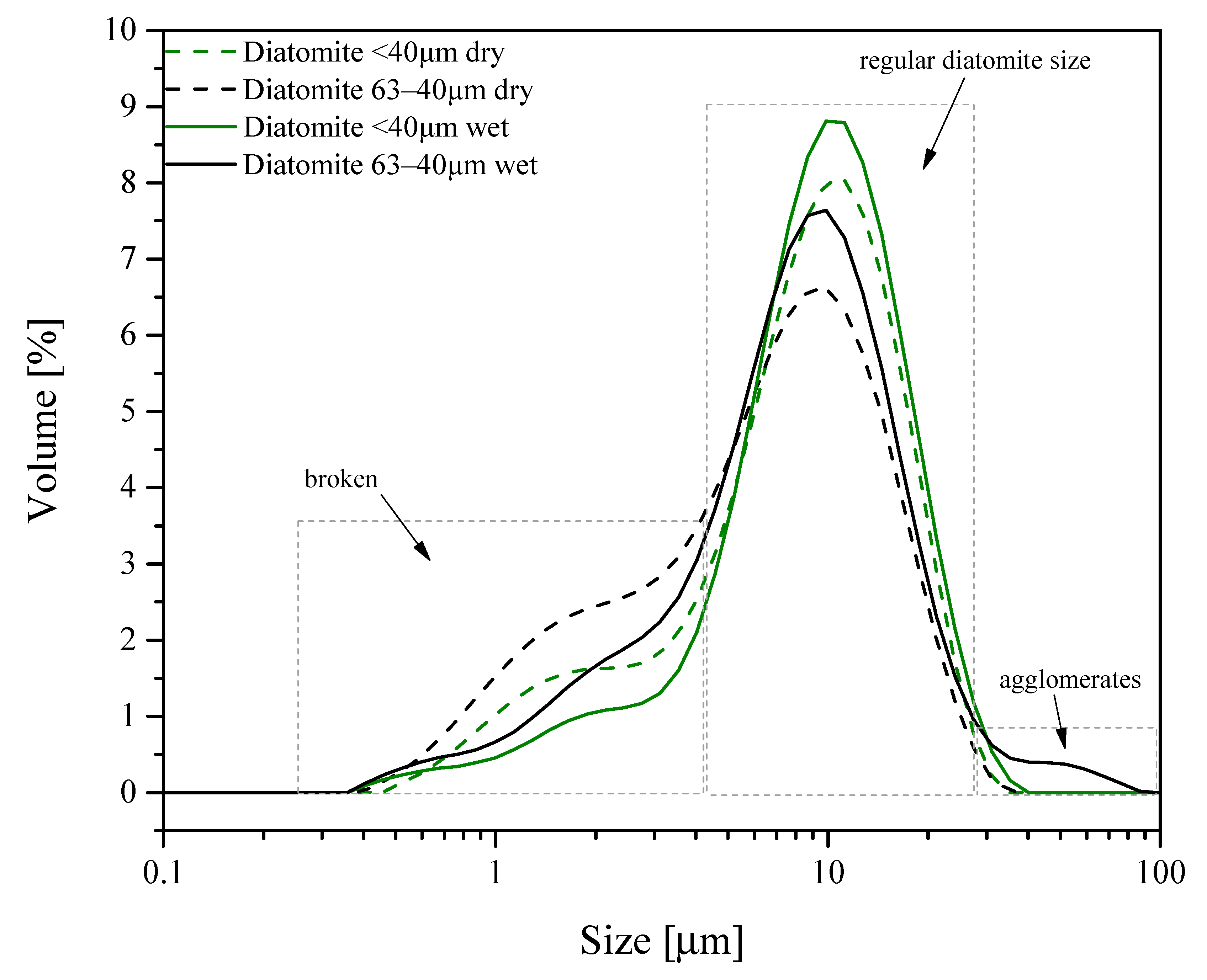

3.2. Particle Size Measurements by Dynamic Light Scattering (DLS)

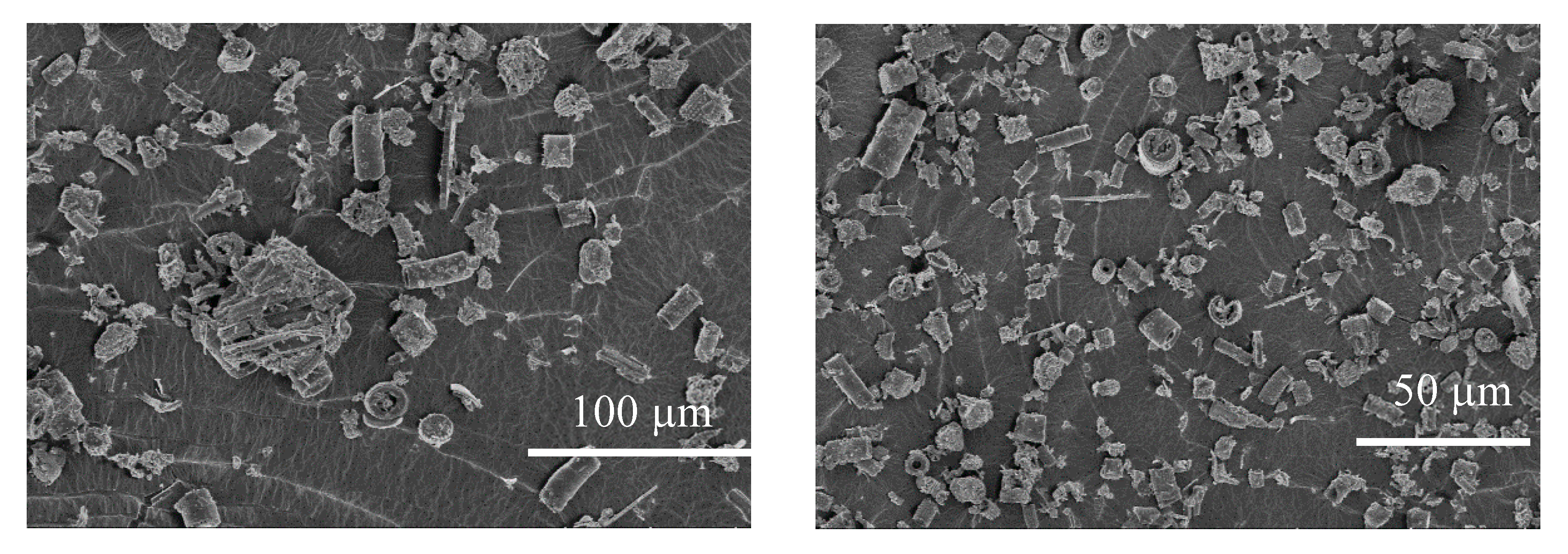

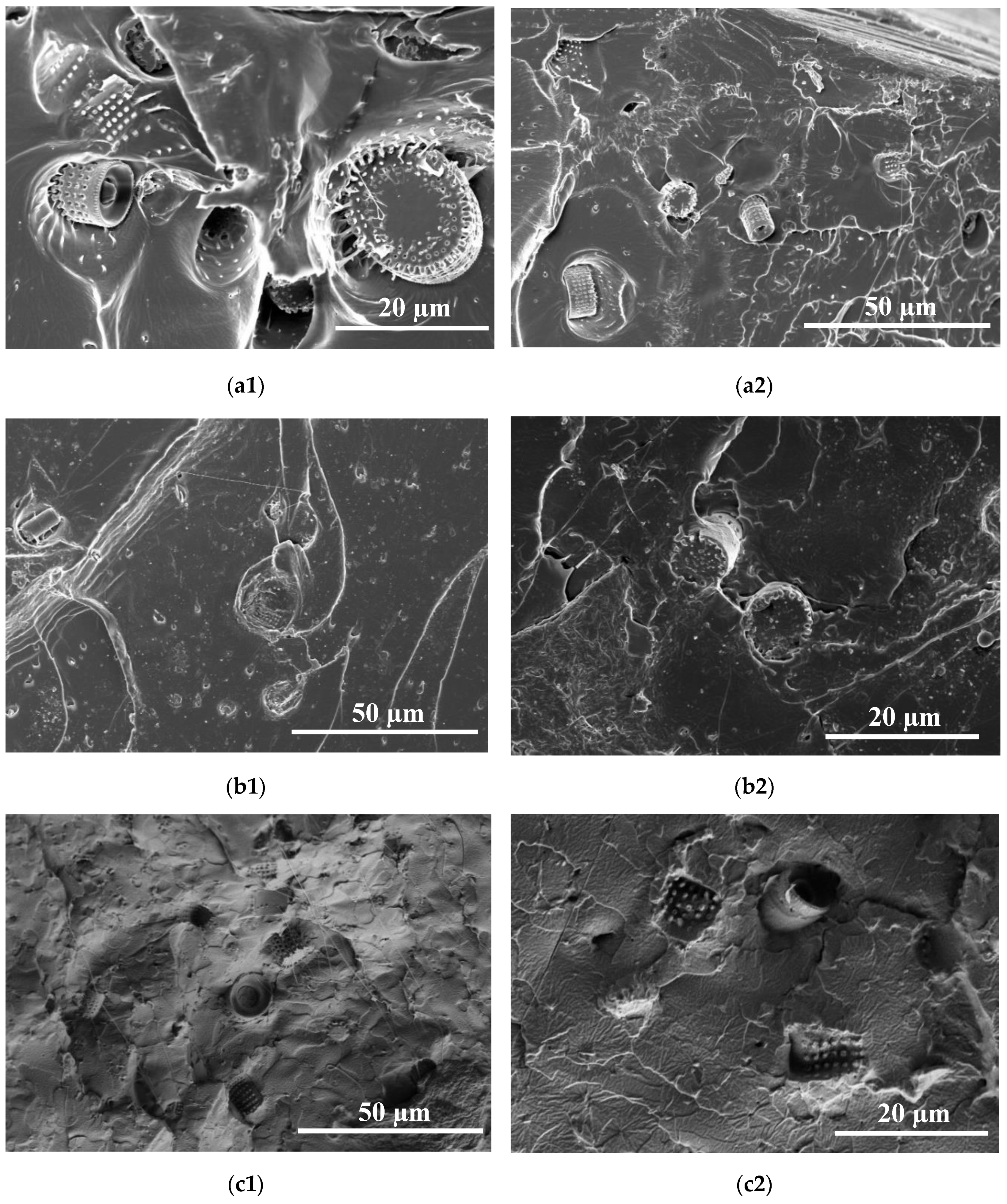

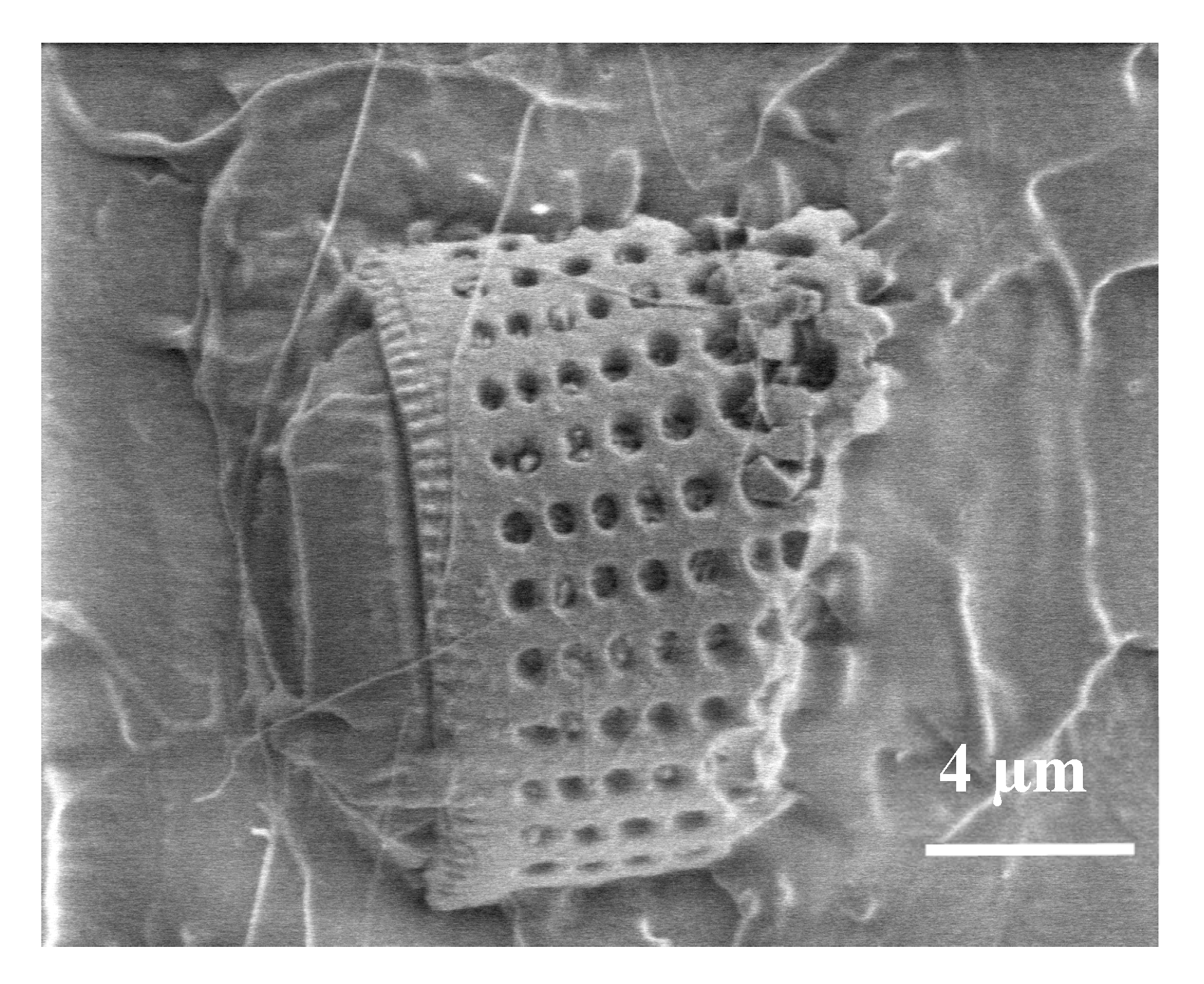

3.3. SEM

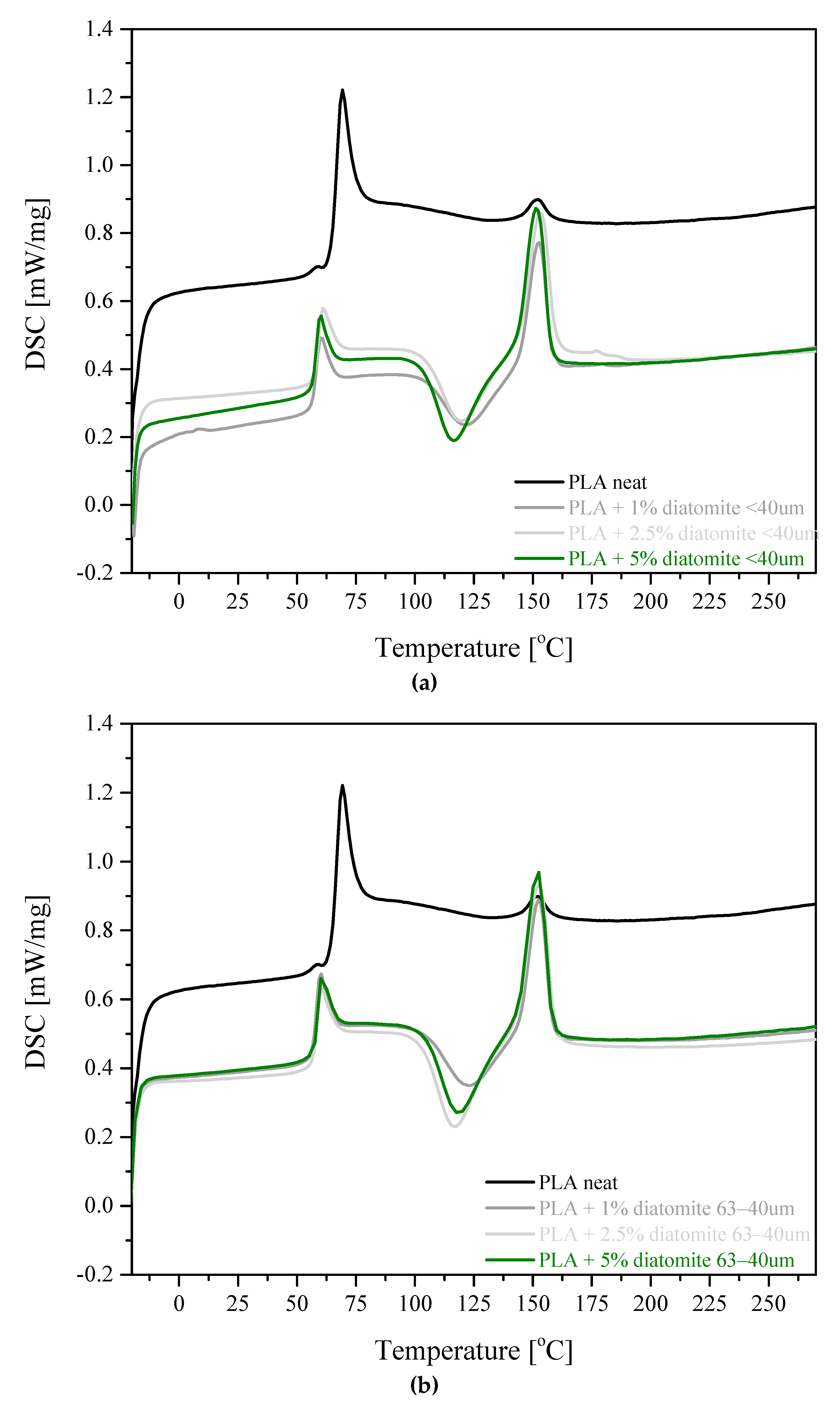

3.4. DSC and TGA Results

3.5. Contact Angle Measurements

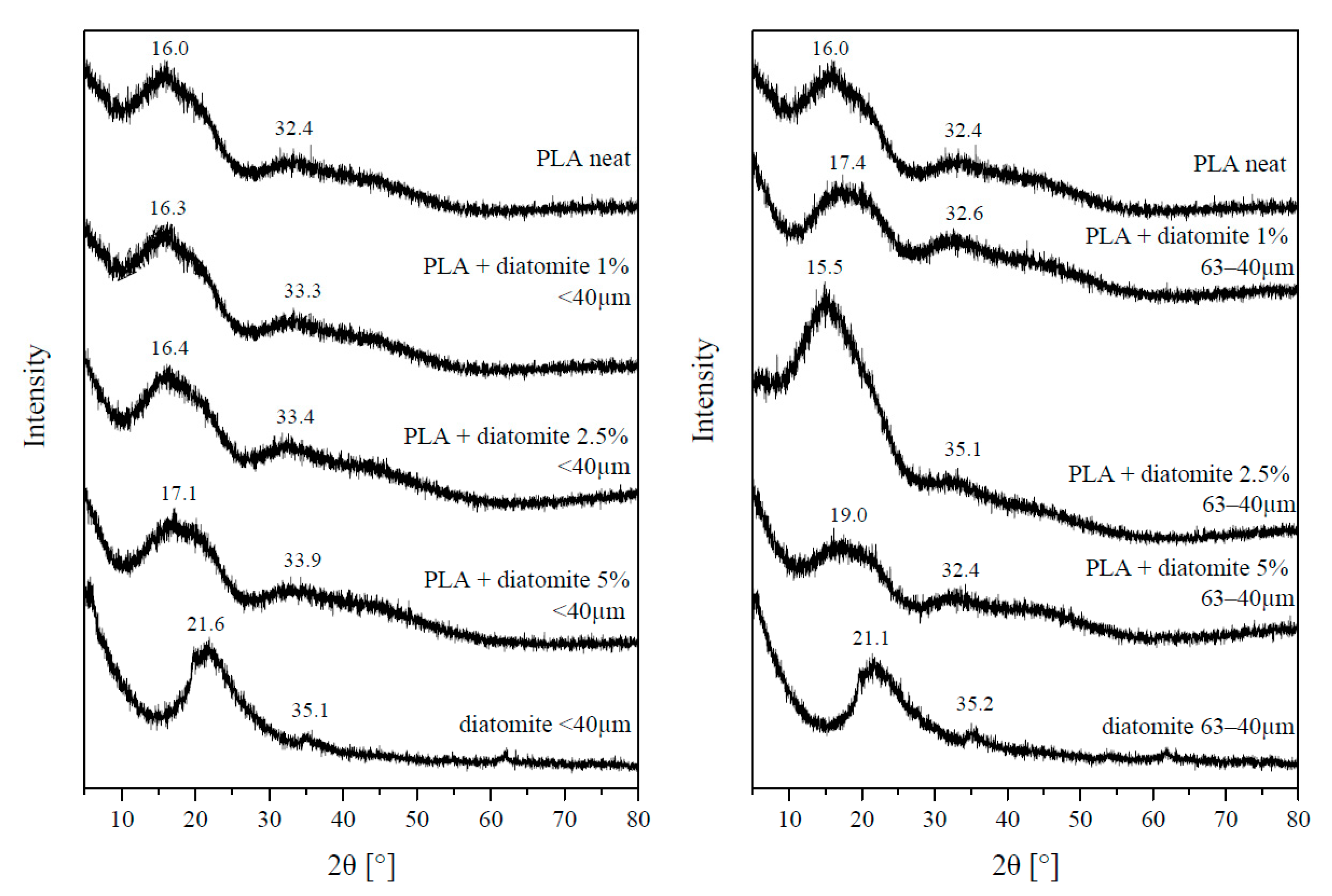

3.6. XRD

3.7. Mechanical Properties

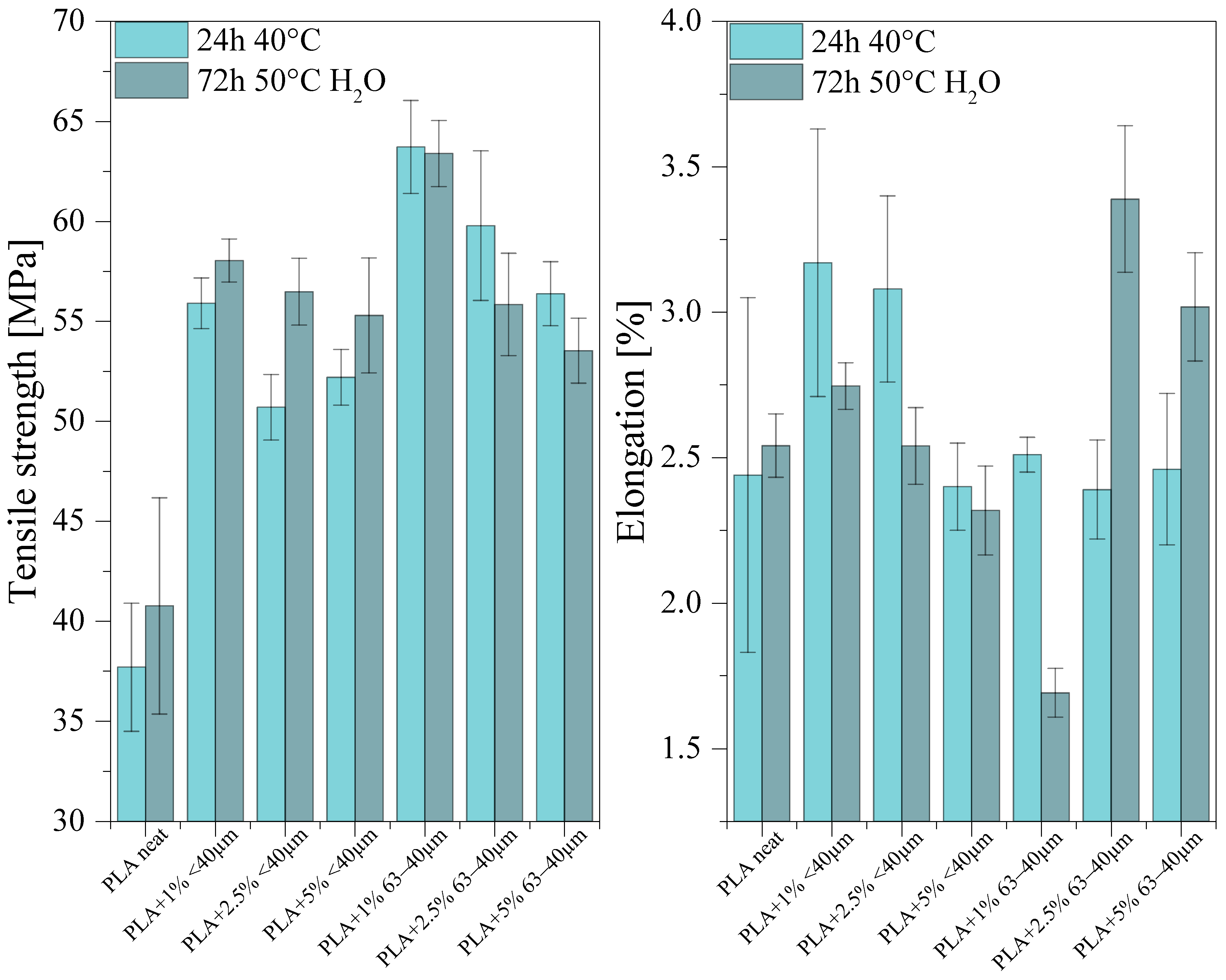

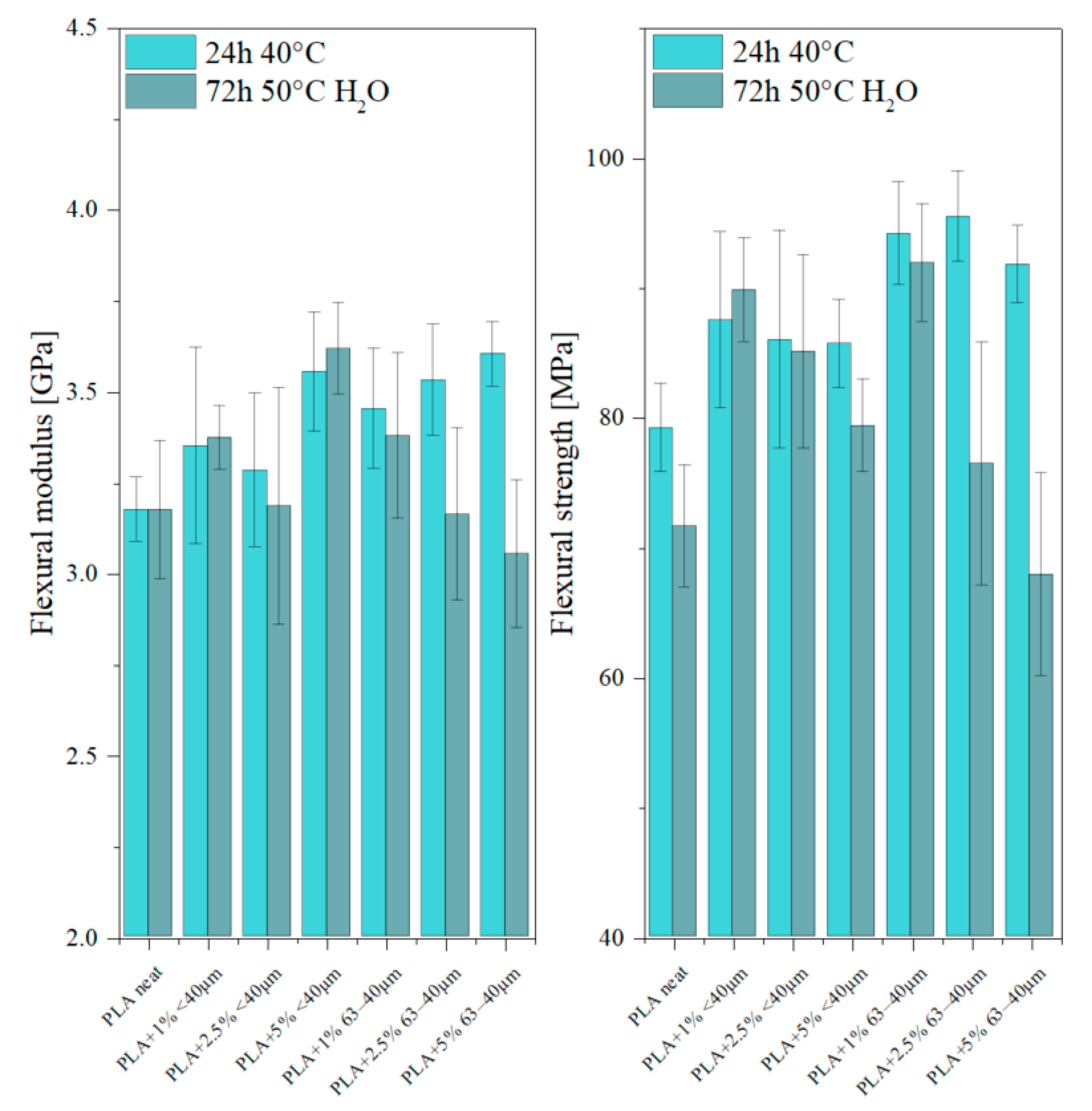

3.7.1. Tensile Strength and Flexural Strength

3.7.2. Impact Strength and Hardness

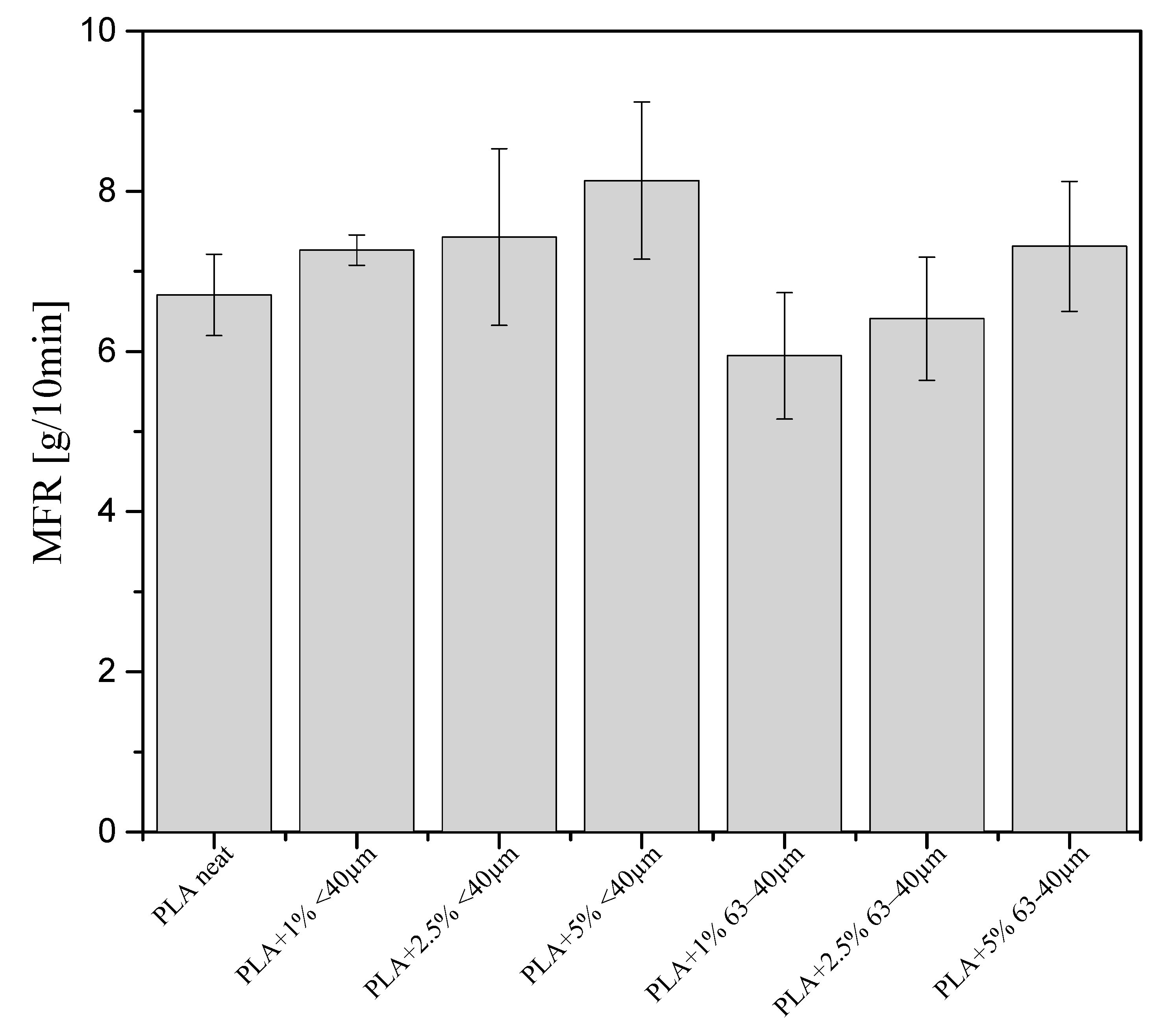

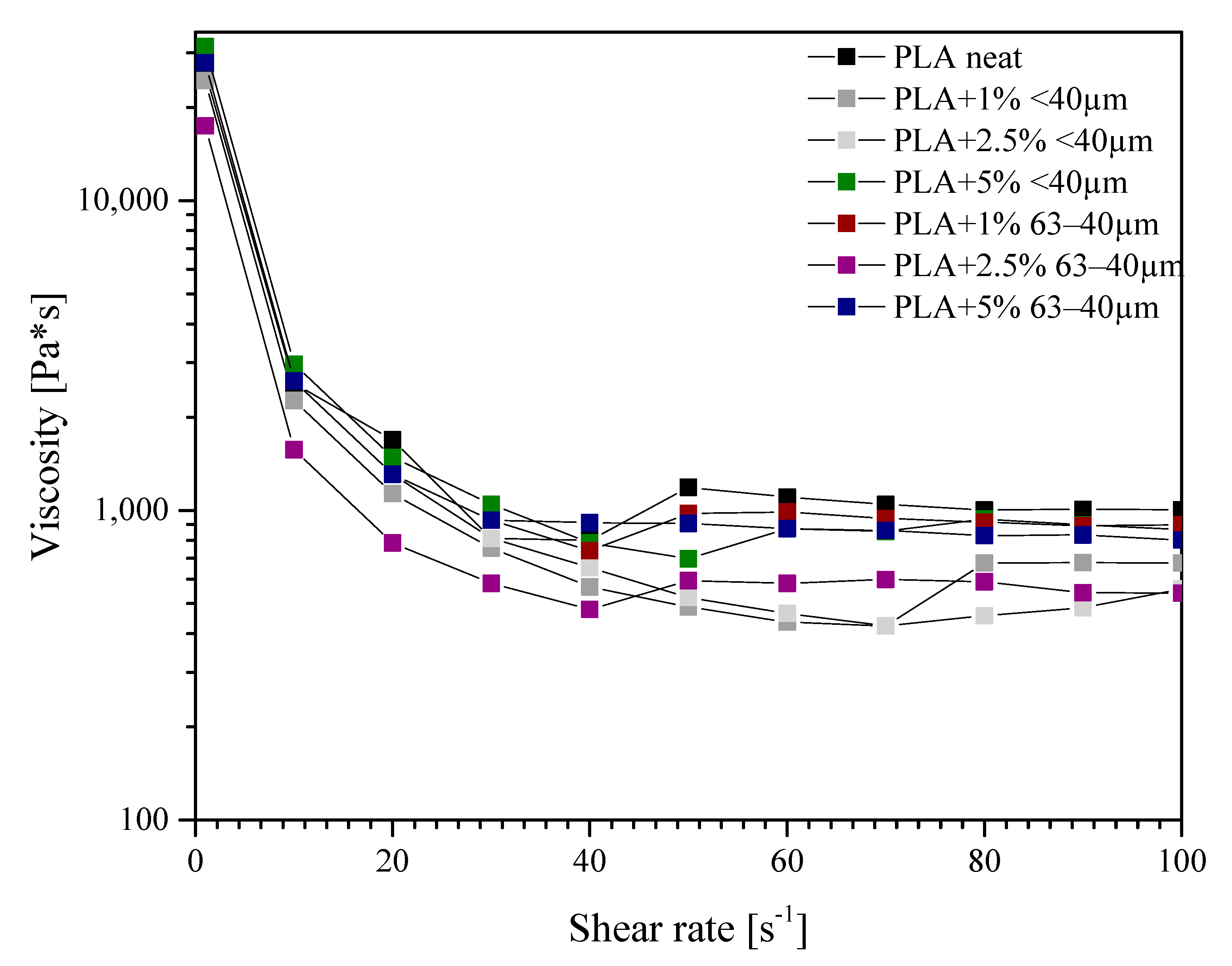

3.8. Rheology

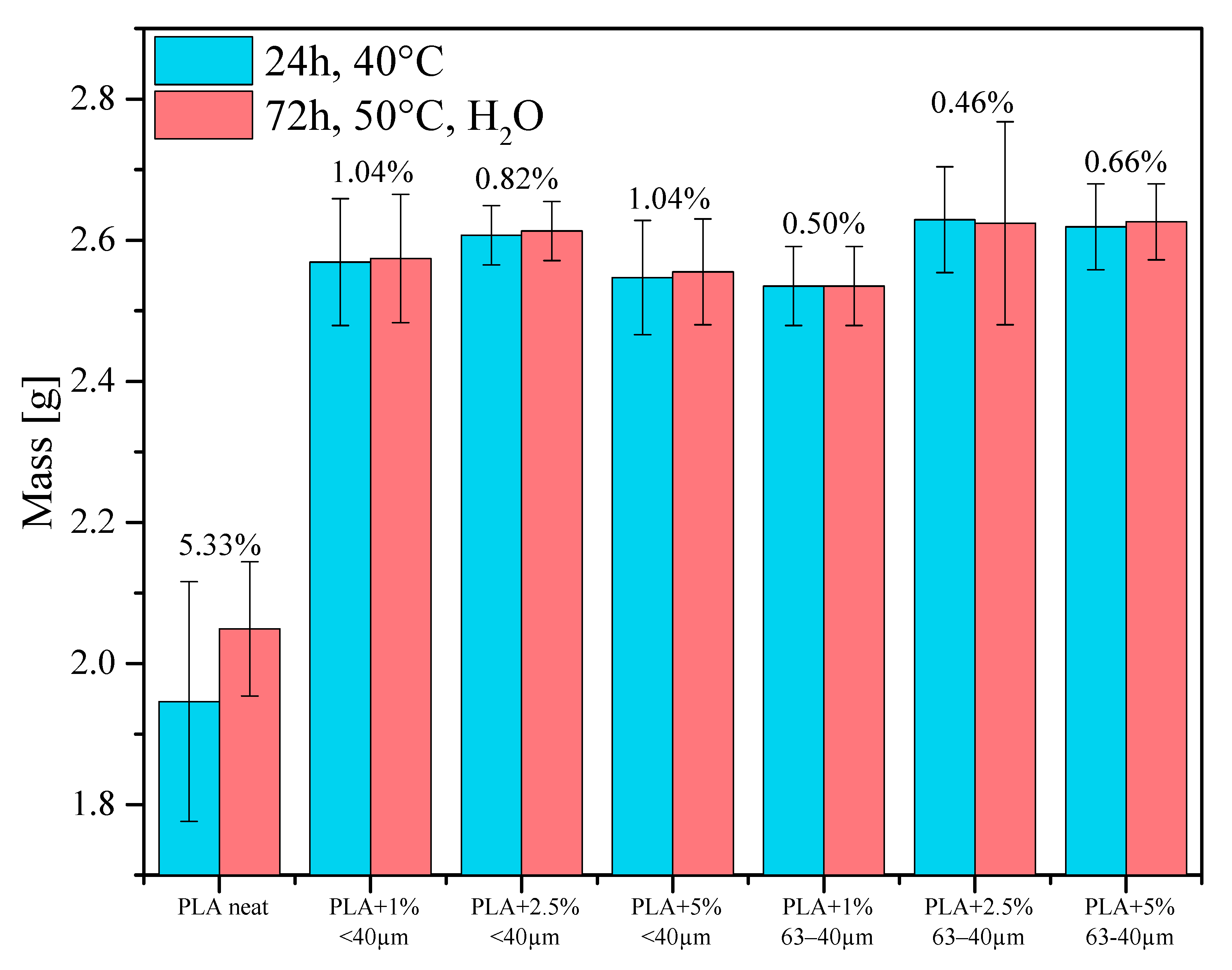

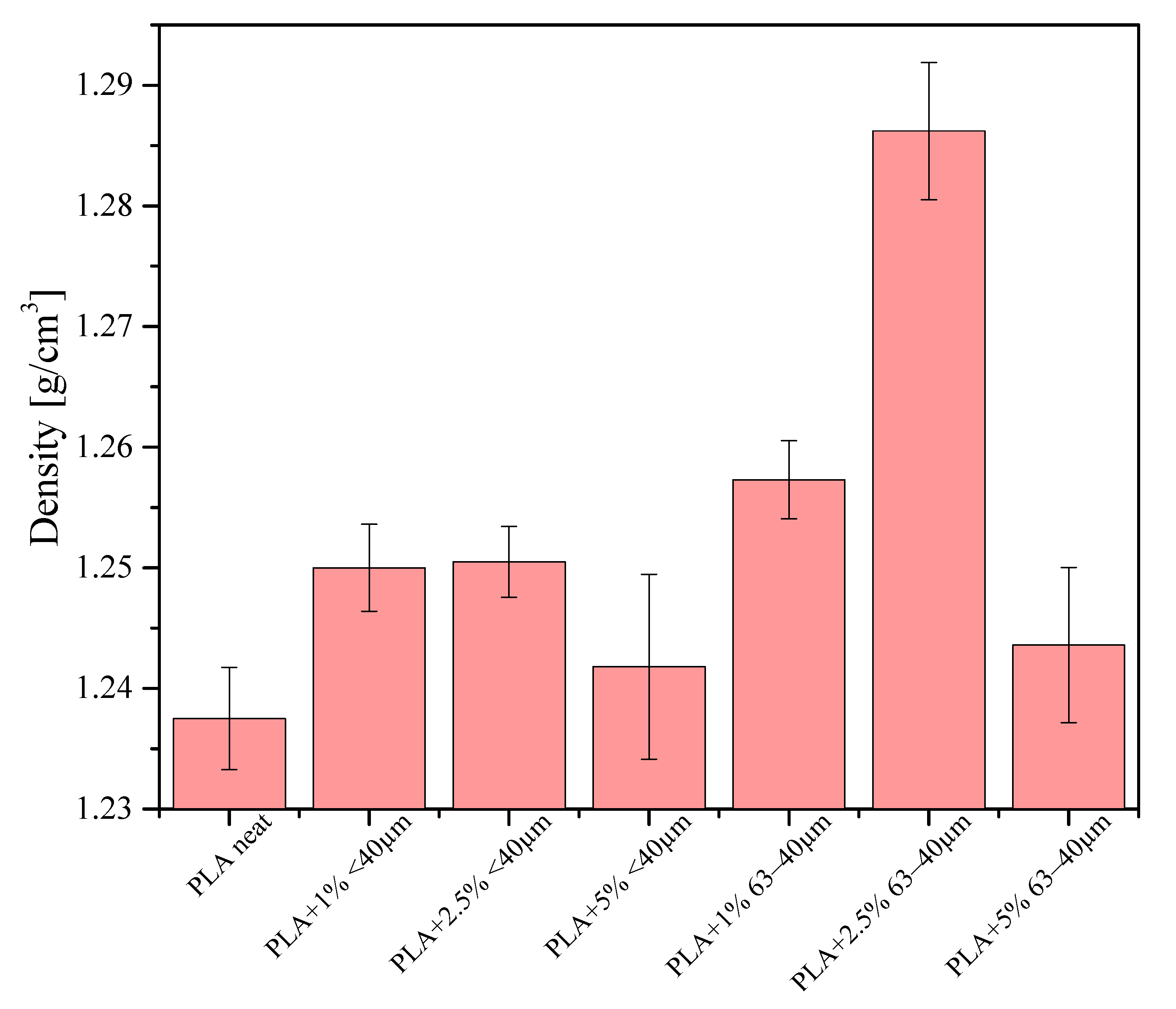

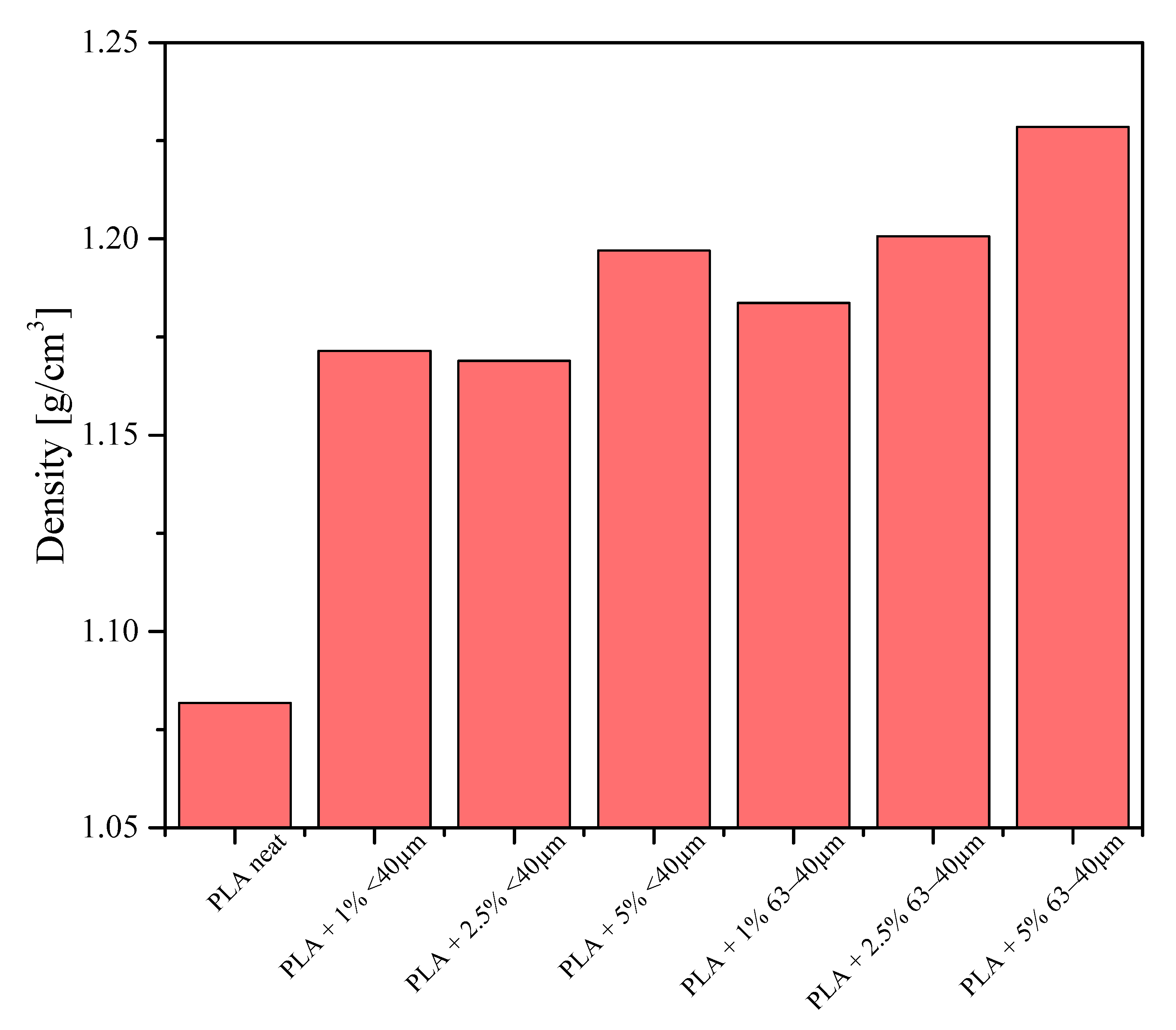

3.9. Density Measurements

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Upcraft, S.; Fletcher, R. The rapid prototyping technologies. Assem. Autom. 2003, 23, 318–330. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies Rapid Prototyping to Direct Digital Manufacturing; Springer: Boston, MA, USA, 2010. [Google Scholar]

- Molitch-Hou, M. The First 3 D Printed Polymer Implant to Receive FDA Approval. 2013. Available online: https://3dprintingindustry.com/news/the-first-3d-printed-polymer-implant-to-receive-fda-approval-5821/ (accessed on 12 August 2020).

- Kellner, T. Jet Engines with 3 D-Printed Parts Power Next-Gen Airbus Passenger Jet. 2015. Available online: https://lrrprojects.lanexus.com/reports/post/119370423770/jet-engines-with-3d-printed-parts-power-next-gen/ (accessed on 12 August 2020).

- Palumbo, J. Inside the Race to Perfect the 3 D-Printed Home. Available online: https://www.artsy.net/article/artsy-editorial-inside-race-perfect-3d-printed (accessed on 12 August 2020).

- Vuković-Kwiatkowska, I.; Kaczmarek, H. Innowacyjne kompozyty poli(kwasu mlekowego) do produkcji folii opakowaniowych. Chemik 2014, 68, 135–140. (In Polish) [Google Scholar]

- Vert, M.; Chen, J.; Hellwich, K.-H.; Hodge, P.; Nakano, T.; Scholz, C.; Slomkowski, S.; Vohlidal, J. Nomenclature and terminology for linear lactic acid-based polymers (IUPAC Recommendations 2019). Pure Appl. Chem. 2020, 92, 193–211. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Richert, J. Synteza, właściwości i zastosowania polilaktydu. Przetwórstwo Tworzyw 2009, 5, 192–199. (In Polish) [Google Scholar]

- Bates-Green, K.; Howie, T. Technical Education in Additive Manufacturing & Materials TEAMM. Available online: http://www.4teamm.org/ (accessed on 12 August 2020).

- Leuschel, M.; Llorens, M.; Oliver, J.; Silva, J.; Tamarit, S. SOC. In Proceedings of the 2009 ACM SIGPLAN Workshop on ML—ML ’09, Savannah, GA, USA, 19–20 January 2008; ACM: New York, NY, USA, 2018; Volume 76, pp. 92–98. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, J.; Jiang, Y.; Jiang, X.; Zhang, D. Preparation of biosilica structures from frustules of diatoms and their applications: Current state and perspectives. Appl. Microbiol. Biotechnol. 2012, 97, 453–460. [Google Scholar] [CrossRef] [PubMed]

- Ruggiero, I.; Terracciano, M.; Martucci, N.M.; De Stefano, L.; Migliaccio, N.; Tatè, R.; Rendina, I.; Arcari, P.; Lamberti, A.; Rea, I. Diatomite silica nanoparticles for drug delivery. Nanoscale Res. Lett. 2014, 9, 329. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, B.; Liu, L.; Li, L. Use of Diatoms in River Health Assessment. Annu. Res. Rev. Biol. 2014, 4, 4054–4074. [Google Scholar] [CrossRef]

- Kieu, K.; Li, C.; Fang, Y.; Cohoon, G.; Herrera, O.D.; Hildebrand, M.; Sandhage, K.H.; Norwood, R.A. Structure-based optical filtering by the silica microshell of the centric marine diatom Coscinodiscus wailesii. Opt. Express 2014, 22, 15992–15999. [Google Scholar] [CrossRef]

- Rakowska, B. Okrzemki—ogranizmy, które odniosły sukces. Kosmos Problemy Nauk Biologicznych 2003, 52, 307–314. [Google Scholar]

- Aggarwal, S.; Johnson, S.; Saloni, D.; Hakovirta, M. Novel 3D printing filament composite using diatomaceous earth and polylactic acid for materials properties and cost improvement. Compos. B. Eng. 2019, 177, 107310. [Google Scholar] [CrossRef]

- Seckbach, J.; Gordon, R. Diatoms: Fundamentals and Applications; Scrivener Publishing LLC: Beverly, MA, USA, 2019. [Google Scholar]

- Goldberg, S.; Lebron, I.; Suarez, D.L.; Hinedi, Z.R. Surface Characterization of Amorphous Aluminum Oxides. Soil Sci. Soc. Am. J. 2001, 65, 78–86. [Google Scholar] [CrossRef]

- Hans, E.; Johansson Bo, V. Larsson, Silica Sols Having High Surface Area. U.S. Patent 5368833 A, 29 November 1990. [Google Scholar]

- Dry, M.; Du Plessis, J.; Leuteritz, G. The influence of structural promoters on the surface properties of reduced magnetite catalysts. J. Catal. 1966, 6, 194–199. [Google Scholar] [CrossRef]

- Legodi, M.; DeWaal, D. The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste. Dye. Pigment. 2007, 74, 161–168. [Google Scholar] [CrossRef]

- Li, J.; Deng, H.; Michalatos, P. TransVision. ACM SIGGRAPH 2019 Art Gallery 2019, 2750, 2759. [Google Scholar] [CrossRef]

- Rothon, R.N. Mineral Fillers in Thermoplastics: Filler Manufacture and Characterisation. In Advances in Polymer Science; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2007; Volume 139, pp. 67–107. [Google Scholar]

- Li, J.P.H.; Adesina, A.; Kennedy, E.; Stockenhuber, M. A mechanistic study of the Knoevenagel condensation reaction: New insights into the influence of acid and base properties of mixed metal oxide catalysts on the catalytic activity. Phys. Chem. Chem. Phys. 2017, 19, 26630–26644. [Google Scholar] [CrossRef]

- Ibrahim, S.S.; Selim, A.Q. Heat treatment of natural diatomite. Physicochem. Probl. Miner. Process. 2012, 48, 413–424. [Google Scholar]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.-S. Catalytic Pyrolysis of Plastic Waste: Moving Toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7. [Google Scholar] [CrossRef]

- Brząkalski, D.; Przekop, R.E.; Dobrosielska, M.; Sztorch, B.; Marciniak, P.; Marciniec, B. Highly bulky spherosilicates as functional additives for polyethylene processing—Influence on mechanical and thermal properties. Polym. Compos. 2020, 41, 3389–3402. [Google Scholar] [CrossRef]

- Hesami, M.; Jalali-Arani, A. Cold crystallization behavior of poly(lactic acid) in its blend with acrylic rubber; the effect of acrylic rubber content. Polym. Int. 2017, 66, 1564–1571. [Google Scholar] [CrossRef]

- Gonzalez, L.; Aguero, A.; Quiles-Carrillo, L.; Lascano Aimacana, D.S.; Montanes, N. Optimalization of the Loading of an Enviromentally Friendly Copatibilizer Derived from Linseed Oil in Pol(Lactic Acid)/Diatomaceous Earth Composites. Materials 2019, 12, 1627. [Google Scholar] [CrossRef]

- Puchalski, M.; Kwolek, S.; Szparaga, G.; Chrzanowski, M.; Krucińska, I. Investigation of the Influence of PLA Molecular Structure on the Crystalline Forms (α’ and α) and Mechanical Properties of Wet Spinning Fibres. Polymers 2017, 9, 18. [Google Scholar] [CrossRef] [PubMed]

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure Analysis and Mechanical Characterization of 3D Printed ABS with Respect to Layer Thickness and Orientation. J. Fail. Anal. Prev. 2016, 16, 467–481. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Tarrazó-Serrano, D.; Castiñeira-Ibáñez, S.; Sánchez-Aparisi, E.; Uris, A.; Rubio, C. MRI Compatible Planar Material Acoustic Lenses. Appl. Sci. 2018, 8, 2634. [Google Scholar] [CrossRef]

| Layer height | 0.18 mm |

| Top layer height | 0.27 mm |

| Shells | 2 |

| Top and bottom layers number | 3 |

| Bottom layers number | 3 |

| Infill density | 100% |

| Infill pattern | Hexagonal |

| Printing speed | 60 mm/s |

| Idle speed | 80 mm/s |

| Extruder temp. | 220 °C |

| 1% Mass Loss [°C] | Onset Temperature. [°C] | Temperature at the Maximum Rate of Mass Loss [°C] | Dry Mass Left after Pyrolysis [%] | |

|---|---|---|---|---|

| Neat PLA | 305.8 | 348.3 | 376.0 | 0.00 |

| PLA + 1% diatomite < 40 µm | 292.9 | 354.1 | 366.7 | 0.21 |

| PLA + 2.5% diatomite < 40 µm | 311.3 | 352.2 | 373.8 | 1.73 |

| PLA + 5% diatomite < 40 µm | 301.2 | 350.5 | 372.3 | 3.25 |

| PLA + 1% diatomite 63–40 µm | 312.1 | 353.2 | 373.5 | 0.60 |

| PLA + 2.5% diatomite 63–40 µm | 313.0 | 352.4 | 375.6 | 2.01 |

| PLA + 5% diatomite 63–40 µm | 311.4 | 351.4 | 372.5 | 3.74 |

| Diatomite < 40 µm powder | 66.9 | 194.5 | 234.8 | 86.09 |

| Diatomite 63–40 µm powder | 74.4 | 145.5 | 228.8 | 86.90 |

| Tg [°C] | Tcc [°C] | Tm [°C] | ||||

|---|---|---|---|---|---|---|

| Granulate | Granulate | Granulate | ||||

| PLA natural | 59.9 | 57.7 | 126.4 | 124.6 | 153.3 | 151.5 |

| PLA + 1% diatomite < 40 µm | 57.0 | 57.6 | 121.6 | 123.1 | 152.5 | 152.8 |

| PLA + 2.5% diatomite < 40 µm | 58.2 | 59.6 | 119.5 | 119.1 | 153.3 | 150.5 |

| PLA + 5% diatomite < 40 µm | 57.3 | 58.3 | 116.3 | 117.8 | 151.5 | 151.6 |

| PLA + 1% diatomite 63–40 µm | 57.2 | 59.4 | 122.9 | 124.1 | 152.5 | 153.9 |

| PLA + 2.5% diatomite 63–40µm | 57.5 | 55.0 | 117.0 | 120.9 | 152.6 | 153.1 |

| PLA + 5% diatomite 63–40 µm | 58.0 | 55.1 | 118.6 | 118.7 | 152.0 | 152.5 |

| Contact Angle [°] | |||||

|---|---|---|---|---|---|

| Storage Condition | Fraction | Neat PLA | PLA + 1% Diatomite | PLA + 2.5% Diatomite | PLA + 5% Diatomite |

| 24 h, 40 °C | <40 µm | 93.5 | 105.2 | 104.9 | 105.3 |

| 63−40 µm | 86.6 | 87.6 | 83.1 | ||

| 72 h, 50 °C, H2 O | <40 µm | 112.9 | 123.8 | 115.2 | 113.8 |

| 63−40 µm | 117.4 | 116.3 | 114.3 | ||

| Impact Strength [kJ/m2] (24 h, 40 °C) | Impact Strength [kJ/m2] (72 h, 50°C, H2O) | Hardness Shore D [°] (24 h, 40°C) | Hardness Shore D [°] (72 h, 50°C, H2O) | |

|---|---|---|---|---|

| Neat PLA | 13.35 ± 4.42 | 2.22 ± 0.52 | 82 ± 2 | 77 ± 3 |

| PLA + 1% diatomite < 40 µm | 20.90 ± 4.39 | 7.37 ± 2.14 | 81 ± 1 | 79 ± 1 |

| PLA + 2.5% diatomite < 40 µm | 20.52 ± 5.78 | 24.58 ± 4.14 | 80 ± 1 | 78 ± 2 |

| PLA + 5% diatomite < 40 µm | 18.51 ± 3.47 | 19.3 ± 6.97 | 83 ± 2 | 79 ± 1 |

| PLA + 1% diatomite 63–40 µm | 21.81 ± 4.42 | 27.19 ± 2.64 | 81 ± 3 | 75 ± 2 |

| PLA + 2.5% diatomite 63–40 µm | 20.24 ± 5.10 | 21.66 ± 4.60 | 80 ± 1 | 78 ± 1 |

| PLA + 5% diatomite 63–40 µm | 20.54 ± 3.14 | 25.11 ± 1.38 | 79 ± 1 | 77 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobrosielska, M.; Przekop, R.E.; Sztorch, B.; Brząkalski, D.; Zgłobicka, I.; Łępicka, M.; Dobosz, R.; Kurzydłowski, K.J. Biogenic Composite Filaments Based on Polylactide and Diatomaceous Earth for 3D Printing. Materials 2020, 13, 4632. https://doi.org/10.3390/ma13204632

Dobrosielska M, Przekop RE, Sztorch B, Brząkalski D, Zgłobicka I, Łępicka M, Dobosz R, Kurzydłowski KJ. Biogenic Composite Filaments Based on Polylactide and Diatomaceous Earth for 3D Printing. Materials. 2020; 13(20):4632. https://doi.org/10.3390/ma13204632

Chicago/Turabian StyleDobrosielska, Marta, Robert Edward Przekop, Bogna Sztorch, Dariusz Brząkalski, Izabela Zgłobicka, Magdalena Łępicka, Romuald Dobosz, and Krzysztof Jan Kurzydłowski. 2020. "Biogenic Composite Filaments Based on Polylactide and Diatomaceous Earth for 3D Printing" Materials 13, no. 20: 4632. https://doi.org/10.3390/ma13204632

APA StyleDobrosielska, M., Przekop, R. E., Sztorch, B., Brząkalski, D., Zgłobicka, I., Łępicka, M., Dobosz, R., & Kurzydłowski, K. J. (2020). Biogenic Composite Filaments Based on Polylactide and Diatomaceous Earth for 3D Printing. Materials, 13(20), 4632. https://doi.org/10.3390/ma13204632