The Effect of Laser Parameters on Cutting Metallic Materials

Abstract

1. Introduction

2. Experimental Setup and Materials

3. Results and Discussion

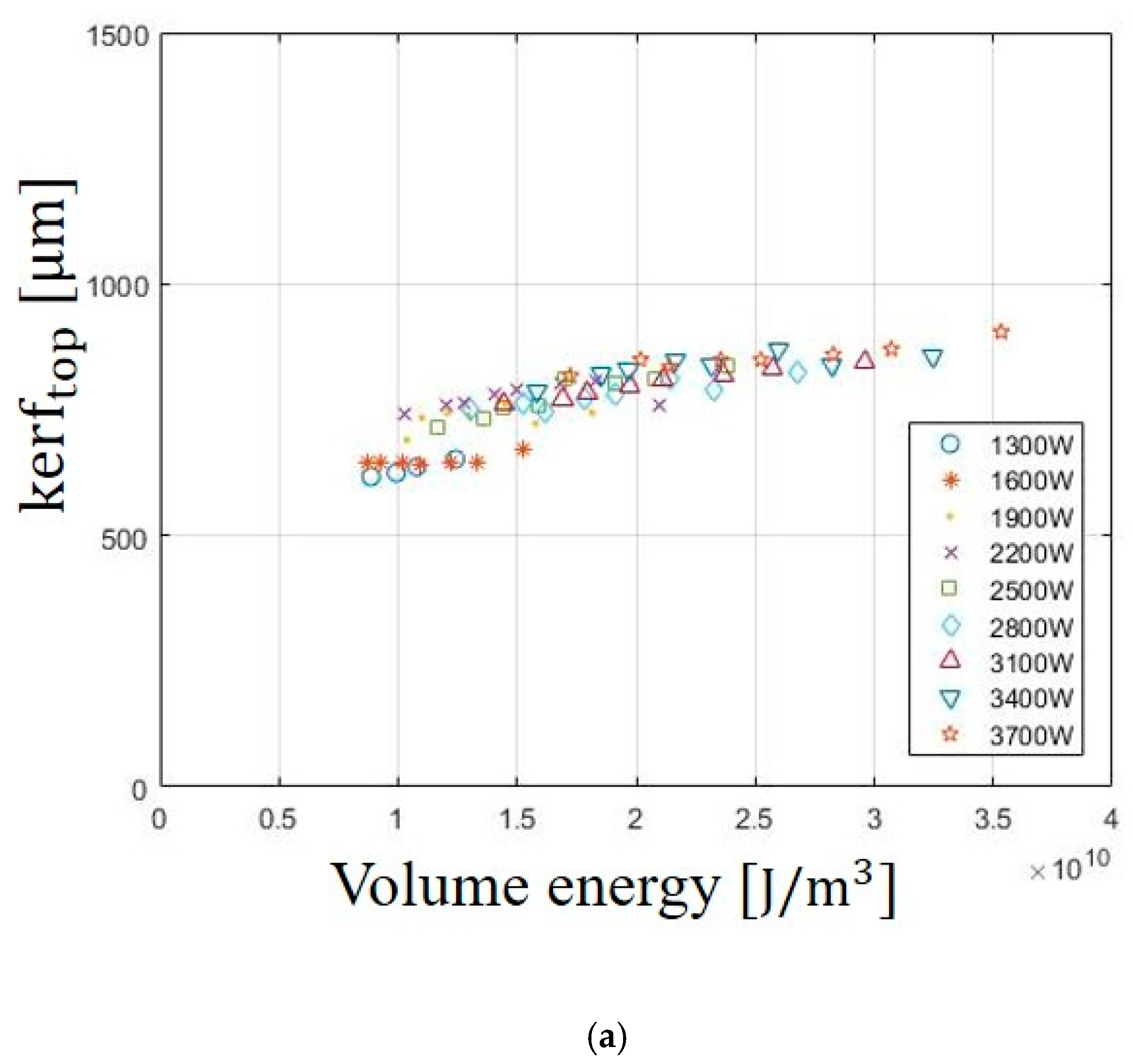

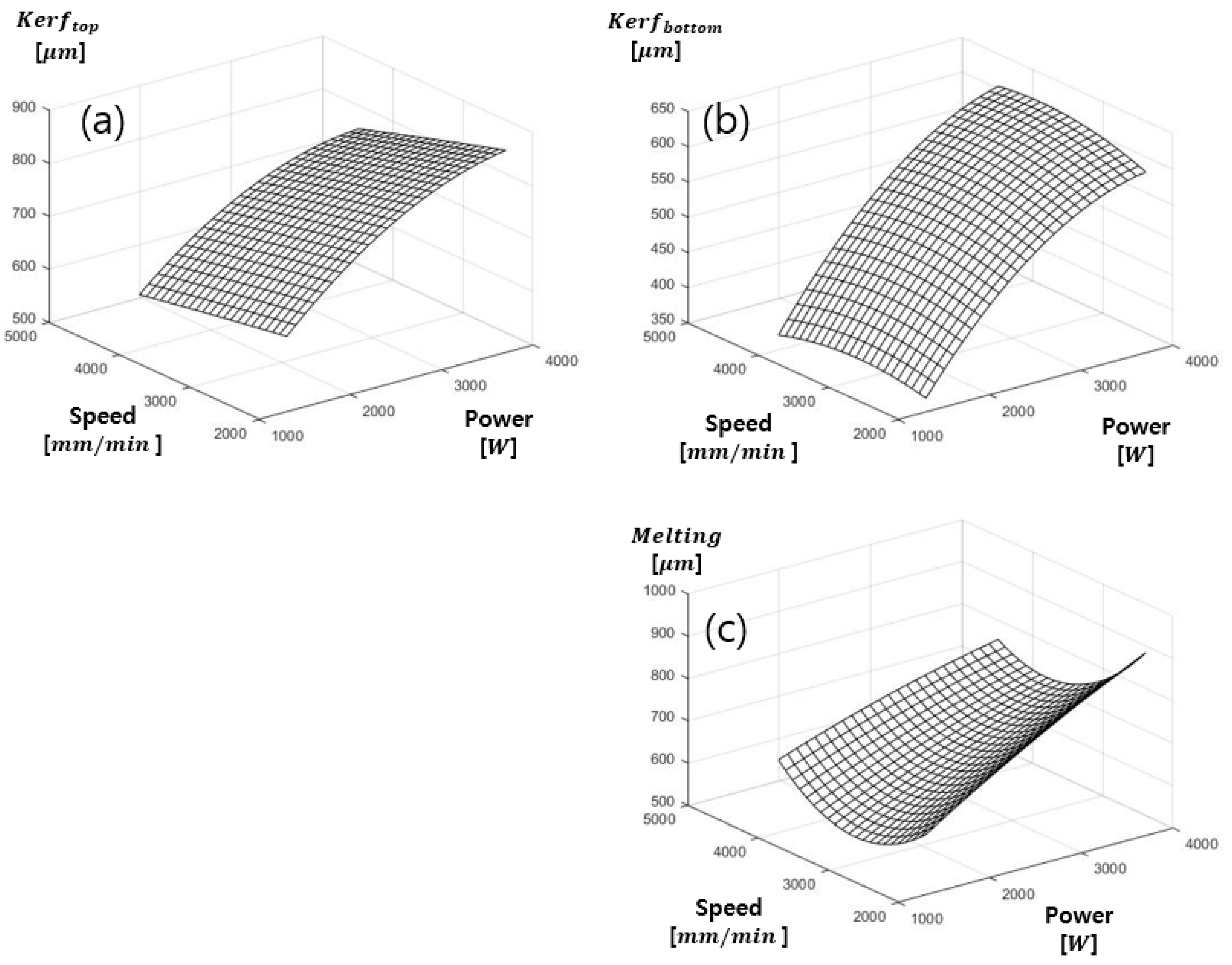

3.1. Analysis of Kerf Width in SS41 According to Volume Energy

3.2. Analysis of Melting Width in SS41 According to Volume Energy

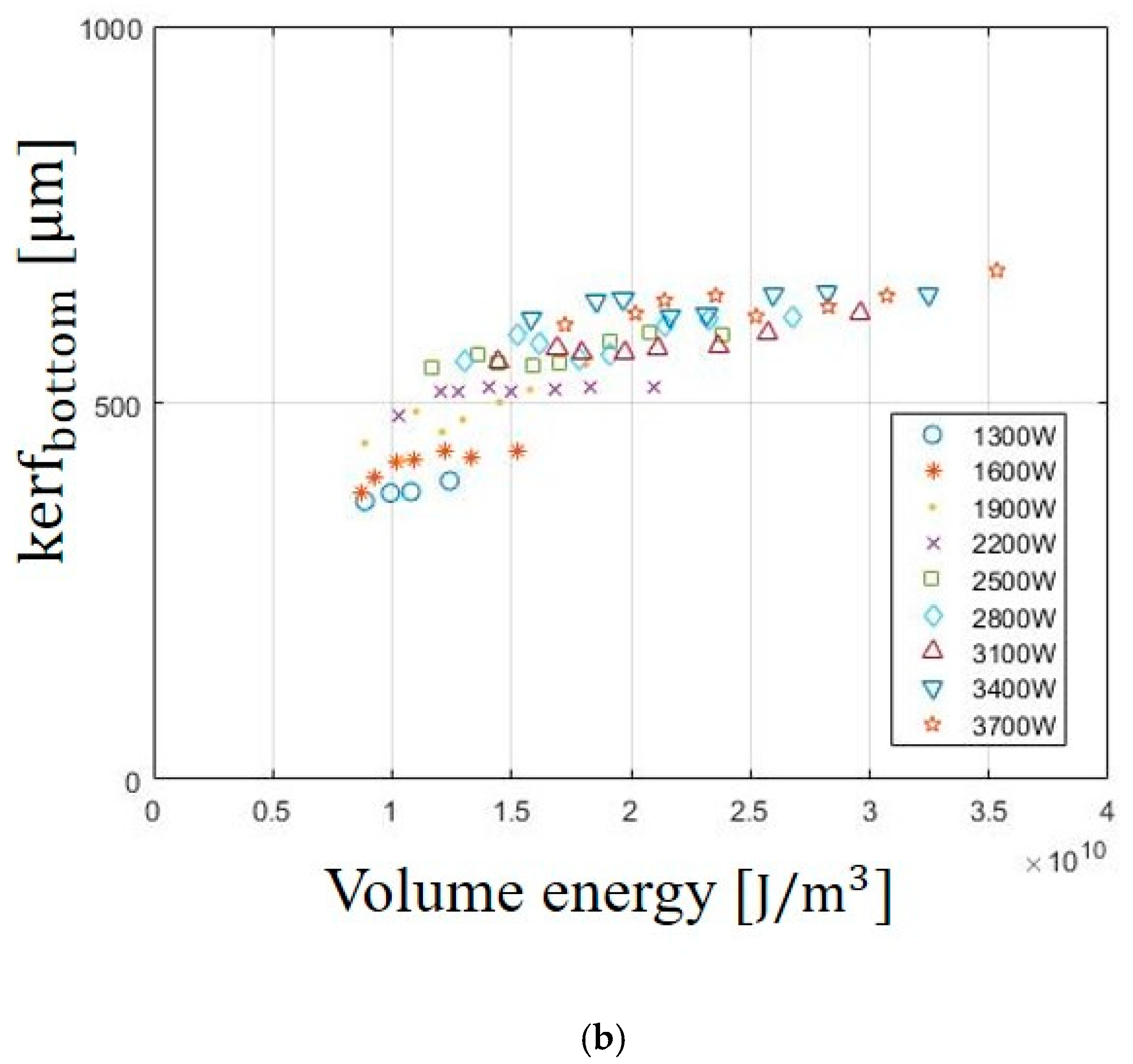

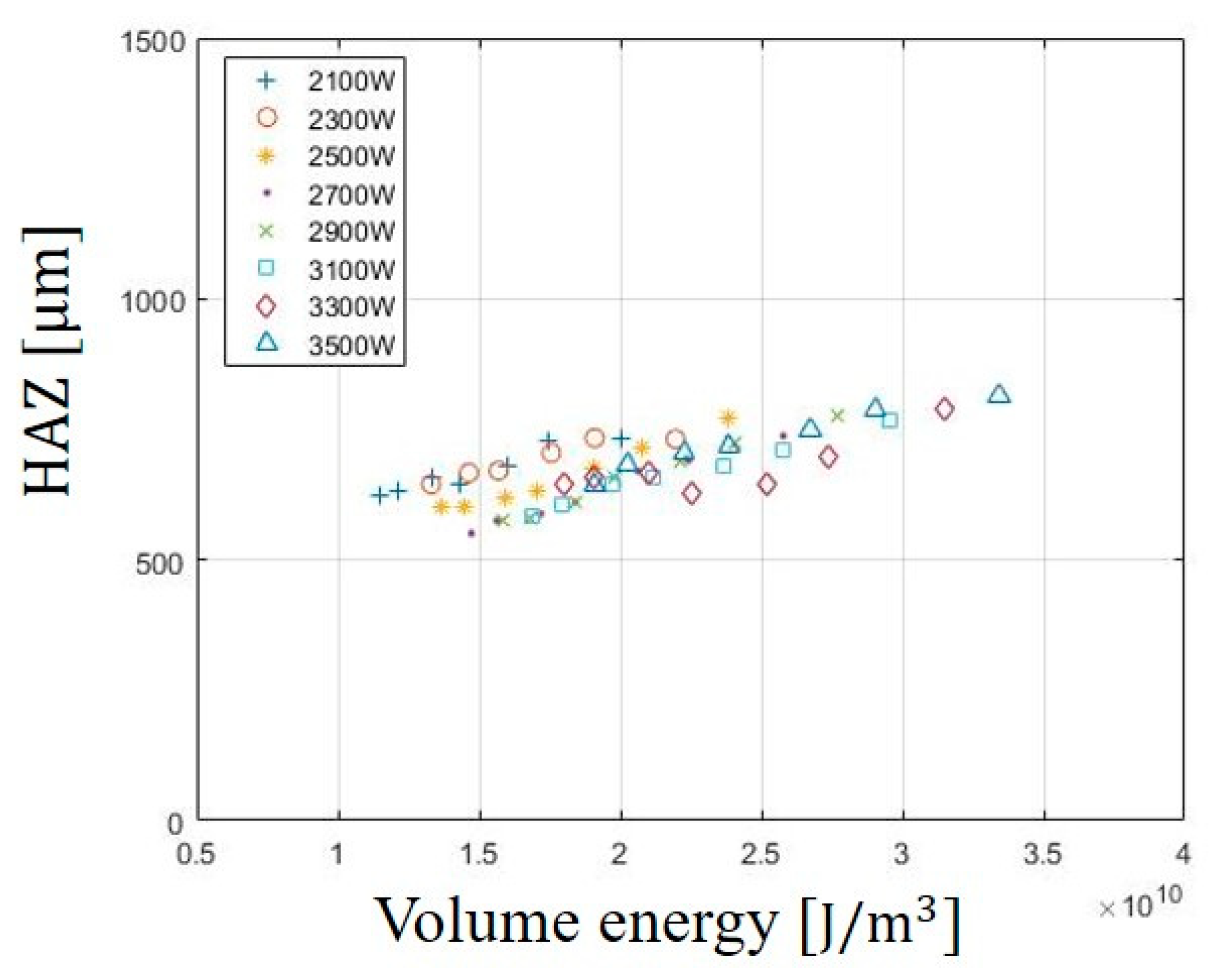

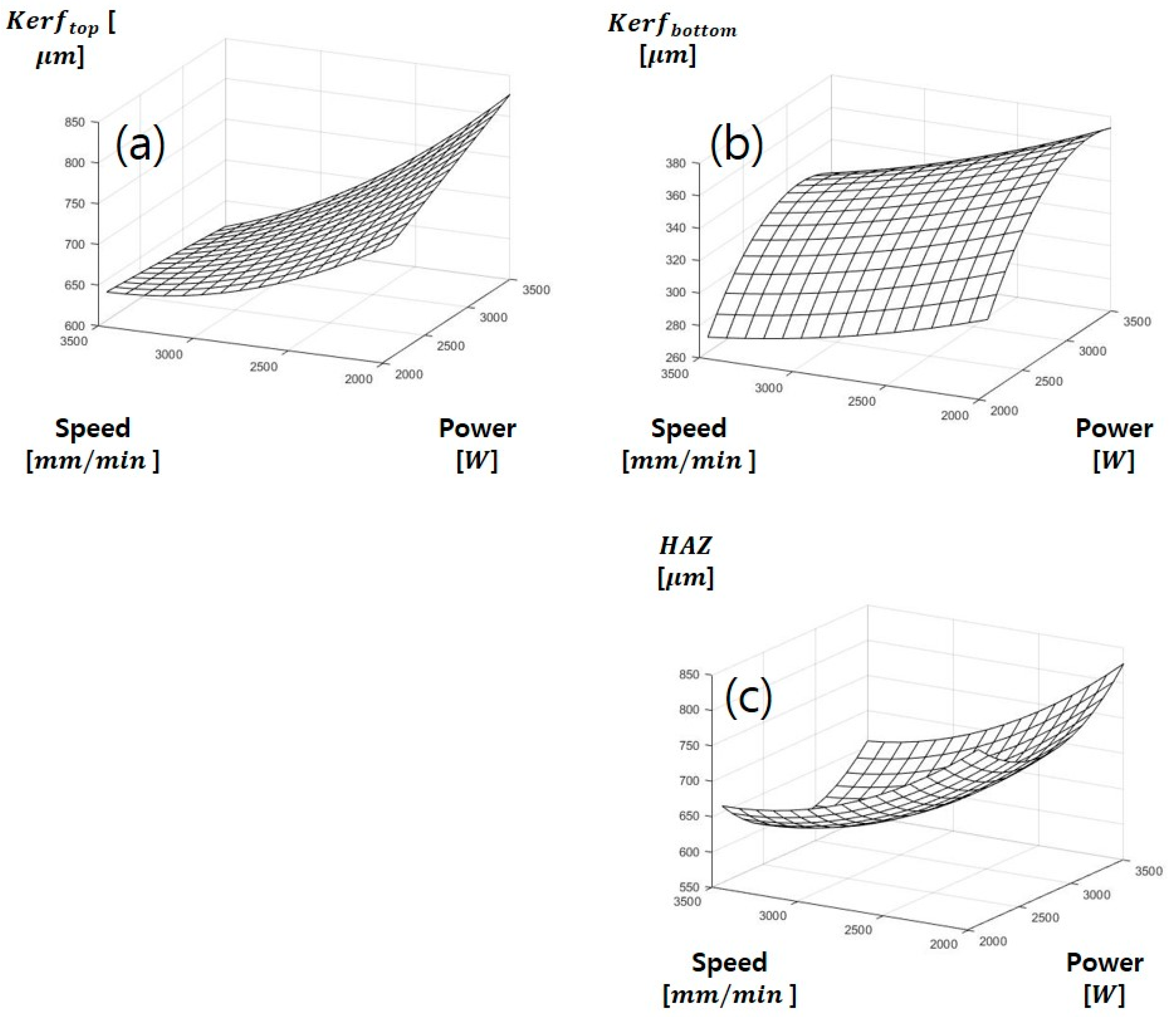

3.3. Analysis of Kerf Width in SUS304 According to Volume Energy

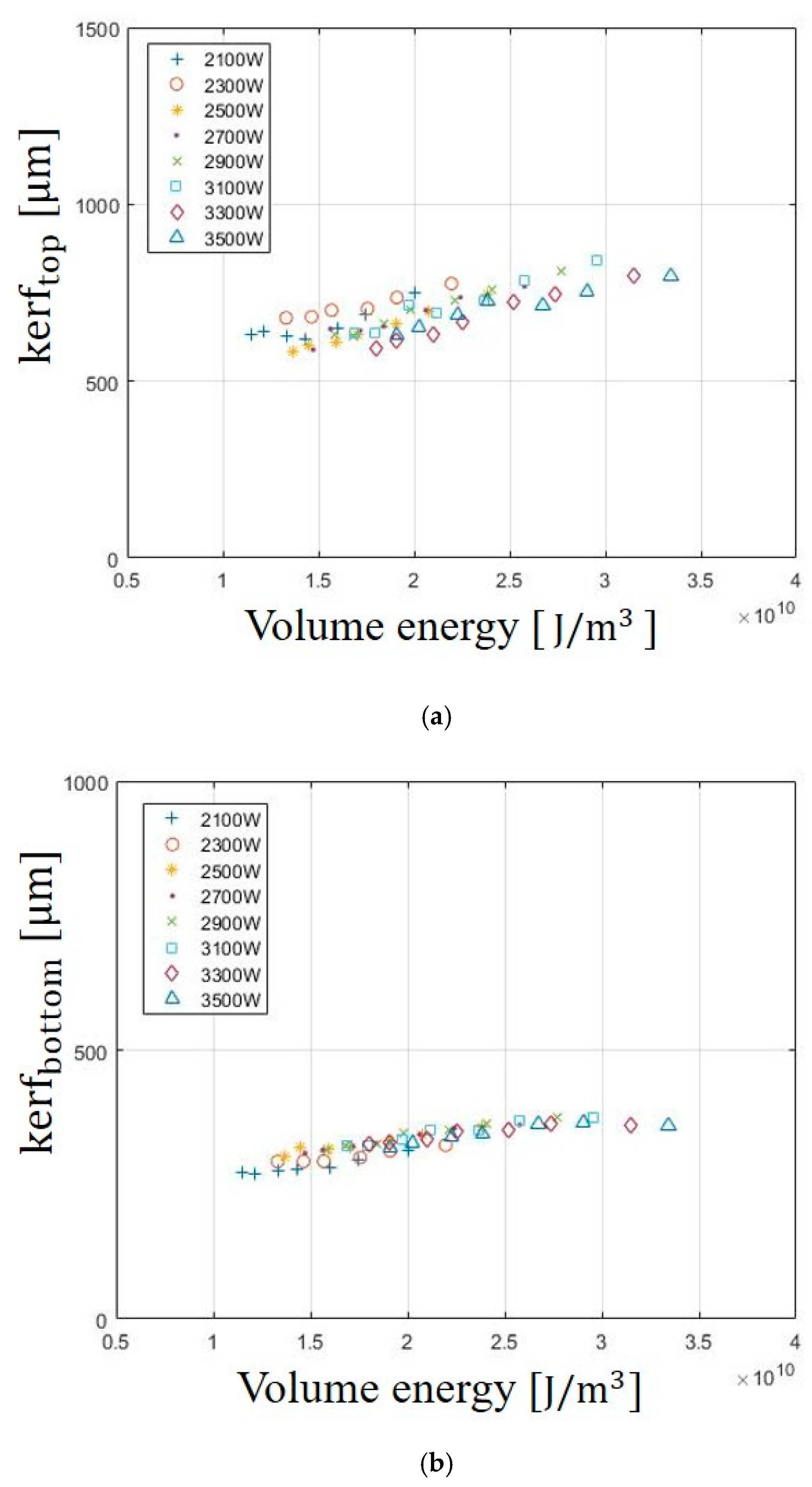

3.4. Analysis of Heat Affected Zone in SUS304 According to Volume Energy

3.5. Multiple Regression

3.6. Analysis of Variance (ANOVA)

4. Conclusions

- We confirmed that the experimental results depend on the laser parameters. For the experimental results on , as increases, the materials are heated until they evaporate rapidly and remove material easily. Furthermore, the laser power increases, the heat entering materials increases and the spread of heat damage also increases, so the melting and HAZ width also increase.

- In the case of multiple regression on the SSand SUS it is founded that the experimental results in kerf widths, melting, and HAZ are affected by laser parameters. The effect of laser power and cutting speed is analyzed through the multiple regression model. The regression equation can appropriately predict output variables from independent variables. Besides, the coefficient of determination () for , , and melting width for SSare and respectively. For the SUS the for , , and HAZ are and respectively. Each of is suitable for experimental data and the regression model makes it possible to predict the effect of laser parameters on the material.

- The results of the ANOVA on the SSand SUSanalyze the effect of each independent variable on the dependent variable during laser cutting. The most effective variable in , , and melting width on SSis laser power. In the case of on the SUS the most effective variables are laser power × cutting speed. On the other hand, for the and HAZ, the interaction effects of the laser power × cutting speed have been found most effective variables. The most effective variables are determined differently on SS41 and SUS 304. This may be caused by different chemical properties of metallic materials. Especially, we assumed that the influence of Ni and Cr components in SUS304 plays a critical role in the laser cutting. Therefore, the effect of laser cutting parameters on the chemical properties of SUS304 needs further study.

Author Contributions

Funding

Conflicts of Interest

References

- Ezugwu, E.; Wang, Z. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Rajaram, N.; Sheikh-Ahmad, J.; Cheraghi, S. CO2 laser cut quality of 4130 steel. Int. J. Mach. Tools Manuf. 2003, 43, 351–358. [Google Scholar] [CrossRef]

- Lee, D.; Seo, Y.; Pyo, S. Effect of Laser Speed on Cutting Characteristics of Cement-Based Materials. Materials 2018, 11, 1055. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wong, W. CO2 laser cutting of metallic coated sheet steels. J. Mater. Process. Technol. 1999, 95, 164–168. [Google Scholar] [CrossRef]

- Seo, Y.; Lee, D.; Pyo, S. Microstructural Characteristics of Cement-Based Materials Fabricated Using Multi-Mode Fiber Laser. Materials 2020, 13, 546. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Mazumder, J. Effects of momentum transfer on sizing of current collectors for lithium-ion batteries during laser cutting. Opt. Laser Technol. 2018, 99, 315–325. [Google Scholar] [CrossRef]

- Son, S.; Lee, D. Study on the interaction characteristics of acrylonitrile butadiene styrene and UV laser. Arch. Civ. Mech. Eng. 2020, 20, 1–12. [Google Scholar] [CrossRef]

- Boutinguiza, M.; Comesaña, R.; Lusquiños, F.; Riveiro, A.; Del Val, J.; Pou, J. Production of silver nanoparticles by laser ablation in open air. Appl. Surf. Sci. 2015, 336, 108–111. [Google Scholar] [CrossRef]

- Hoffman, J.; Chrzanowska-Giżyńska, J.; Kucharski, S.; Mościcki, T.; Mihailescu, I.N.; Ristoscu, C.; Szymański, Z. The effect of laser wavelength on the ablation rate of carbon. Appl. Phys. A 2014, 117, 395–400. [Google Scholar] [CrossRef]

- Mustafa, H.; Mezera, M.; Matthews, D.; Römer, G. Effect of surface roughness on the ultrashort pulsed laser ablation fluence threshold of zinc and steel. Appl. Surf. Sci. 2019, 488, 10–21. [Google Scholar] [CrossRef]

- Lee, D. Understanding of BeCu Interaction Characteristics with a Variation of ns Laser-Pulse Duration. Materials 2018, 11, 1423. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Cho, J.; Kim, C.H.; Lee, S.H. Application of laser spot cutting on spring contact probe for semiconductor package inspection. Opt. Laser Technol. 2017, 97, 90–96. [Google Scholar] [CrossRef]

- Yalukova, O.; Sárady, I. Investigation of interaction mechanisms in laser drilling of thermoplastic and thermoset polymers using different wavelengths. Compos. Sci. Technol. 2006, 66, 1289–1296. [Google Scholar] [CrossRef]

- Bruneel, D.; Matras, G.; Le Harzic, R.; Huot, N.; König, K.; Audouard, E. Micromachining of metals with ultra-short Ti-Sapphire lasers: Prediction and optimization of the processing time. Opt. Lasers Eng. 2010, 48, 268–271. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast lasers—reliable tools for advanced materials processing. Light. Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Lamikiz, A.; De Lacalle, L.N.L.; Sánchez, J.A.; Del Pozo, D.; Etayo, J.; Lopez, J.; Lamikiz, A. CO2 laser cutting of advanced high strength steels (AHSS). Appl. Surf. Sci. 2005, 242, 362–368. [Google Scholar] [CrossRef]

- Kaebernick, H.; Jeromin, A.; Mathew, P. Adaptive Control for Laser Cutting Using Striation Frequency Analysis. CIRP Ann. 1998, 47, 137–140. [Google Scholar] [CrossRef]

- Rajaram, N.; Sheikh-Ahmad, J.; Hossein, C. Parametric Study of the Effect of Feed Speed and Power on Laser Cut Quality of 4130 Steel; Wichita State University: Wichita, KS, USA, 2002. [Google Scholar]

- Yilbas, B.S. Effect of process parameters on the kerf width during the laser cutting process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2001, 215, 1357–1365. [Google Scholar] [CrossRef]

- Anghel, C.; Gupta, K.; Jen, T. Analysis and optimization of surface quality of stainless steel miniature gears manufactured by CO2 laser cutting. Optik 2020, 203, 164049. [Google Scholar] [CrossRef]

- Golnabi, H.; Bahar, M. Investigation of optimum condition in oxygen gas-assisted laser cutting. Opt. Laser Technol. 2009, 41, 454–460. [Google Scholar] [CrossRef]

- Gabzdyl, J.T. Effects of gases on laser cutting of stainless steels. Int. Congr. Appl. Lasers Electro-Opt. 1996, 1996, C39. [Google Scholar] [CrossRef]

- Lee, D.; Suk, J. Laser Cutting Characteristics on Uncompressed Anode for Lithium-Ion Batteries. Energies 2020, 13, 2630. [Google Scholar] [CrossRef]

- Lee, D.; Oh, B.; Suk, J. The Effect of Compactness on Laser Cutting of Cathode for Lithium-Ion Batteries Using Continuous Fiber Laser. Appl. Sci. 2019, 9, 205. [Google Scholar] [CrossRef]

- Shrivastava, P.K.; Pandey, A.K. Parametric optimization of multiple quality characteristics in laser cutting of Inconel-718 by using hybrid approach of multiple regression analysis and genetic algorithm. Infrared Phys. Technol. 2018, 91, 220–232. [Google Scholar] [CrossRef]

- Ratnam, C.; Vikram, K.A.; Ben, B.; Murthy, B. Process monitoring and effects of process parameters on responses in turn-milling operations based on SN ratio and ANOVA. Measurment 2016, 94, 221–232. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Han, M.-S.; Kim, S.-J. Cavitation-erosion Resistance of Stabilized Stainless Steel with Niobium Addition in Sea Water Environment. J. Korean Inst. Surf. Eng. 2016, 49, 274–279. [Google Scholar] [CrossRef][Green Version]

- Ghany, K.A.; Newishy, M. Cutting of 1.2mm thick austenitic stainless steel sheet using pulsed and CW Nd:YAG laser. J. Mater. Process. Technol. 2005, 168, 438–447. [Google Scholar] [CrossRef]

| SS41 | SUS304 | |

|---|---|---|

| Laser Power [W] | 1000–3700 | 2100–3900 |

| Cutting Speed [mm/s] | 2000–4100 | 2000–3500 |

| Assistance Gas | O2 | N2 |

| Gas Pressure [bar] | 3 | 3 |

| Thickness [mm] | 2 | 2 |

| C | Si | Mn | P | S | Ni | Cr | |

|---|---|---|---|---|---|---|---|

| SS41 Properties [%] | 0.14~0.22 | 0.3 | 0.36~0.65 | 0.045 | 0.05 | ||

| SUS304 Properties [%] | 0.08 | 1.00 | 2.00 | 0.45 | 0.30 | 8.00~10.50 | 18.00~20.00 |

| Coefficient | SE Coefficient | T Statistic | p-Value | |

| 388.6832 | 80.07202 | 4.85417 | 8.75 × 10−6 | |

| 0.2657 | 0.033199 | 8.00299 | 4.35 × 10−11 | |

| −0.00855 | 0.044628 | −0.1916 | 0.848694 | |

| −3 × 10−5 | 6.2 × 10−6 | −4.87501 | 8.11 × 10−6 | |

| −8.5 × 10−7 | 7.18 × 10−6 | −0.1179 | 0.906538 | |

| −7.6 × 10−6 | 7.02 × 10−6 | −1.08053 | 0.28416 | |

| = 0.90, (adj) = 0.89 | ||||

| Coefficient | SE Coefficient | T Statistic | p-Value | |

| −5.9335 | 89.49774223 | −0.066297523 | 0.947357769 | |

| 0.2503 | 0.037857046 | 6.611759502 | 1.0722 × 10−8 | |

| 0.0723 | 0.05112402 | 1.413235703 | 0.16266912 | |

| −3.289 × 10−5 | 7.25866 × 10−6 | −4.531773519 | 2.7836 × 10−5 | |

| −1.372 × 10−5 | 8.75522 × 10−6 | −1.566708952 | 0.122356105 | |

| 6.355 × 10−6 | 8.60318 × 10−6 | 0.738711082 | 0.462915371 | |

| = 0.89, (adj) = 0.88 | ||||

| Coefficient | SE Coefficient | T Statistic | p-Value | |

| 1030.875 | 112.6616 | 9.150191 | 4.76 × 10−13 | |

| 0.2174 | 0.046711 | 4.653414 | 1.81 × 10−5 | |

| −0.4547 | 0.062792 | −7.24157 | 8.9 × 10−10 | |

| −7.995 × 10−6 | 8.73 × 10−6 | −0.91606 | 0.363242 | |

| 8.1839 × 10−5 | 1.01 × 10−5 | 8.104238 | 2.91 × 10−11 | |

| −2.8654 × 10−5 | 9.88 × 10−6 | −2.8996 | 0.005187 | |

| = 0.86; (adj) = 0.85 | ||||

| Coefficient | SE Coefficient | T Statistic | p-Value | |

| 853.0468 | 251.3251 | 3.394196 | 0.001371 | |

| 0.167979 | 0.129446 | 1.297679 | 0.200474 | |

| −0.21867 | 0.11114 | −1.96752 | 0.054797 | |

| −1.1 × 10−6 | 2.14 × 10−5 | −0.05021 | 0.960161 | |

| 4.6 × 10−5 | 1.84 × 10−5 | 2.498231 | 0.015886 | |

| −5 × 10−5 | 1.76 × 10−5 | −2.82229 | 0.006871 | |

| = 0.80, (adj) = 0.78 | ||||

| Coefficient | SE Coefficient | T Statistic | p-Value | |

| −108.267 | 69.11328 | −1.56651 | 0.123665 | |

| 0.360518 | 0.035597 | 10.12777 | 1.32 × 10−13 | |

| −0.05506 | 0.030563 | −1.8015 | 0.077778 | |

| −5.3 × 10−5 | 5.9 × 10−6 | −8.97845 | 6.35 × 10−12 | |

| 8.64 × 10−6 | 5.06 × 10−6 | 1.707061 | 0.094141 | |

| −8.1 × 10−6 | 4.83 × 10−6 | −1.67321 | 0.100659 | |

| = 0.92, (adj) = 0.91 | ||||

| Coefficient | SE Coefficient | T Statistic | p-Value | |

| 2289.716 | 218.9419 | 10.4581 | 4.46 × 10−14 | |

| −0.68795 | 0.112767 | −6.10062 | 1.64 × 10−7 | |

| −0.40922 | 0.09682 | −4.22663 | 0.000103 | |

| 0.000132 | 1.87 × 10−5 | 7.041524 | 5.72 × 10−9 | |

| 6.28 × 10−5 | 1.6 × 10−5 | 3.913384 | 0.000281 | |

| −1.4 × 10−5 | 1.53 × 10−5 | −0.91761 | 0.363319 | |

| = 0.85, (adj) = 0.83 | ||||

| Source | SS | DF | MS | F Ratio | p-Value | PCR [%] |

|---|---|---|---|---|---|---|

| Laser Power | 5.6 × 106 | 8 | 7.0 × 105 | 4.2 × 103 | <0.05 | 59.28 |

| Cutting Speed | 1.2 × 106 | 7 | 1.7 × 105 | 1.0 × 103 | <0.05 | 12.48 |

| Laser power × Cutting speed | 2.7 × 106 | 56 | 4.7 × 104 | 2.8 × 102 | <0.05 | 27.99 |

| Error | 2.4 × 104 | 144 | 1.7 × 102 | 0.26 | ||

| Total | 9.5 × 106 | 215 | ||||

| Laser Power | 4.0 × 106 | 8 | 5.0 × 105 | 1.4 × 103 | <0.05 | 73.06 |

| Cutting Speed | 3.1 × 105 | 7 | 4.4 × 104 | 1.2 × 102 | <0.05 | 5.63 |

| Laser power × Cutting speed | 1.1 × 106 | 56 | 2.0 × 104 | 5.6 × 10 | <0.05 | 20.37 |

| Error | 5.1 × 104 | 144 | 3.6 × 102 | 0.94 | ||

| Total | 5.5 × 106 | 215 | ||||

| Laser Power | 5.3 × 106 | 8 | 6.6 × 105 | 1.2 × 103 | <0.05 | 59.65 |

| Cutting Speed | 1.1 × 106 | 7 | 1.5 × 105 | 2.7 × 102 | <0.05 | 12.08 |

| Laser power × Cutting speed | 2.4 × 106 | 56 | 4.3 × 104 | 7.6 × 10 | <0.05 | 27.35 |

| Error | 8.2 × 104 | 144 | 5.7 × 102 | 0.92 | ||

| Total | 8.9 × 106 | 215 | ||||

| Source | SS | DF | MS | F Ratio | p-Value | PCR [%] |

|---|---|---|---|---|---|---|

| Laser Power | 9.0 × 104 | 9 | 1.0 × 104 | 1.2 × 102 | <0.05 | 9.93 |

| Cutting Speed | 9.5 × 104 | 6 | 1.6 × 104 | 1.9 × 102 | <0.05 | 10.45 |

| Laser power × Cutting speed | 7.1 × 105 | 54 | 1.3 × 104 | 1.6 × 102 | <0.05 | 78.33 |

| Error | 1.2 × 104 | 140 | 8.4 × 10 | 1.29 | ||

| Total | 9.1 × 105 | 209 | ||||

| Laser Power | 1.9 × 105 | 9 | 2.1 × 104 | 3.9 × 102 | <0.05 | 38.03 |

| Cutting Speed | 9.9 × 104 | 6 | 1.6 × 104 | 3.1 × 102 | <0.05 | 20.22 |

| Laser power × Cutting speed | 2.0 × 105 | 54 | 3.6 × 103 | 6.9 × 10 | <0.05 | 40.25 |

| Error | 7.4 × 103 | 140 | 5.3 × 10 | 1.52 | ||

| Total | 4.9 × 105 | 209 | ||||

| Heat Affected Zone | ||||||

| Laser Power | 6.0 × 105 | 9 | 6.7 × 104 | 4.3 × 10 | <0.05 | 22.39 |

| Cutting Speed | 7.7 × 105 | 6 | 1.3 × 105 | 8.3 × 10 | <0.05 | 28.74 |

| Laser power × Cutting speed | 1.1 × 106 | 54 | 2.0 × 104 | 1.3 × 10 | <0.05 | 40.78 |

| Error | 2.2 × 105 | 140 | 1.6 × 103 | 8.09 | ||

| Total | 2.7 × 106 | 209 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, S.; Lee, D. The Effect of Laser Parameters on Cutting Metallic Materials. Materials 2020, 13, 4596. https://doi.org/10.3390/ma13204596

Son S, Lee D. The Effect of Laser Parameters on Cutting Metallic Materials. Materials. 2020; 13(20):4596. https://doi.org/10.3390/ma13204596

Chicago/Turabian StyleSon, Seungik, and Dongkyoung Lee. 2020. "The Effect of Laser Parameters on Cutting Metallic Materials" Materials 13, no. 20: 4596. https://doi.org/10.3390/ma13204596

APA StyleSon, S., & Lee, D. (2020). The Effect of Laser Parameters on Cutting Metallic Materials. Materials, 13(20), 4596. https://doi.org/10.3390/ma13204596