Influence of Nanoparticles from Waste Materials on Mechanical Properties, Durability and Microstructure of UHPC

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

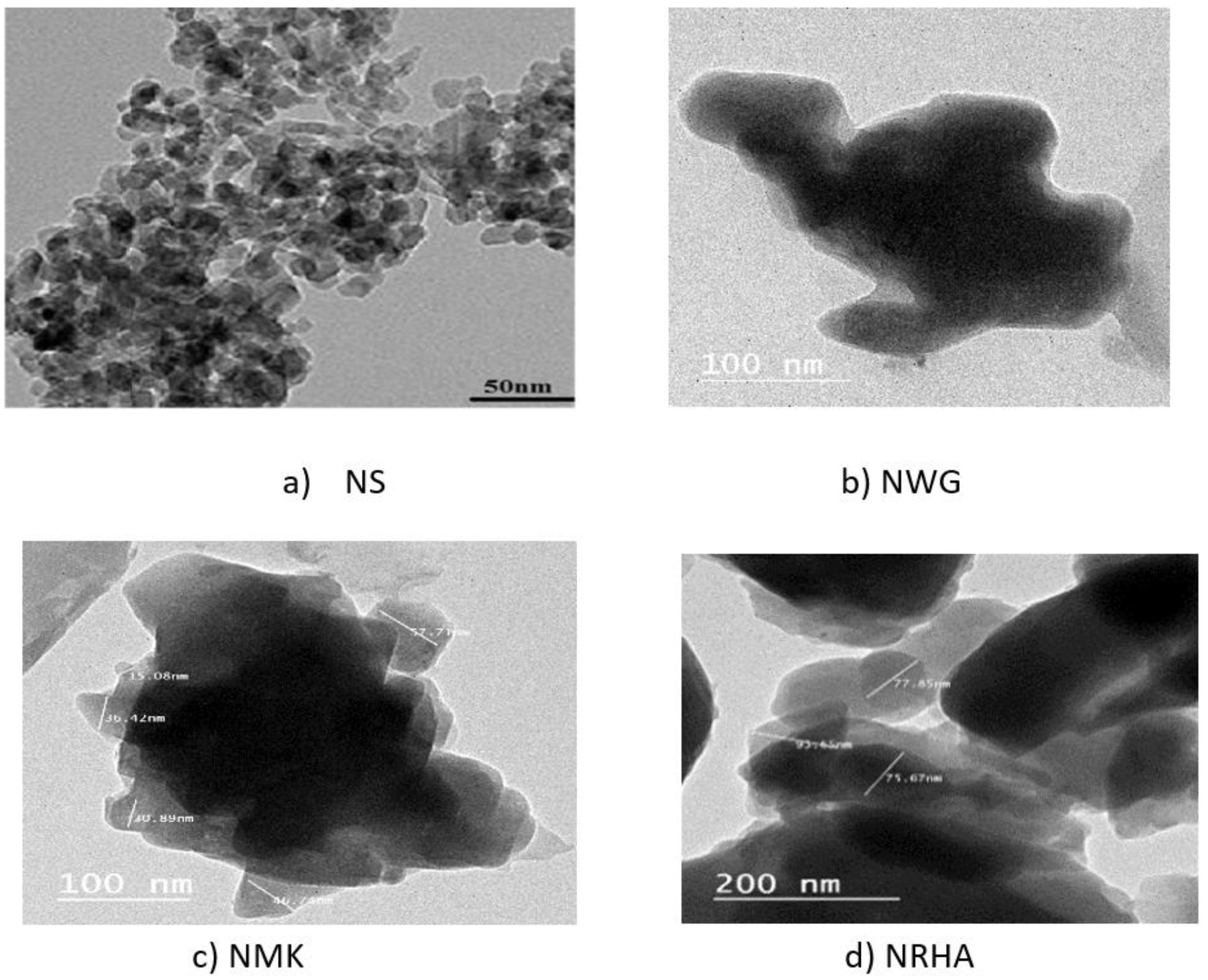

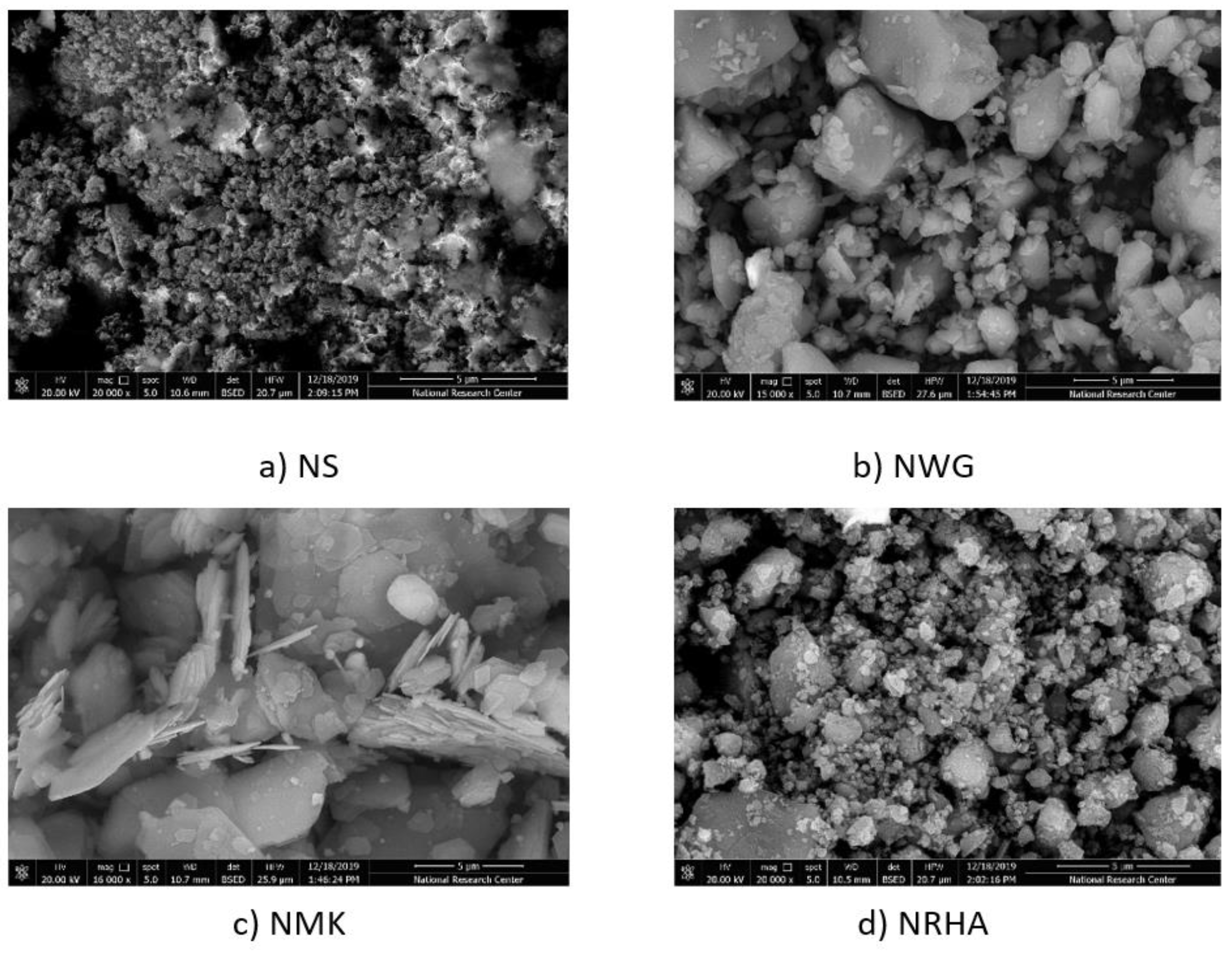

2.2. Nanomaterials

2.2.1. Nano Silica

- The gel produced remained for 24 h sedimentation of silica at room temperature.

- Filtration stage was important to separate the precipitate from salt water

- Hot distilled water was used for washing several times

- AgNO3 solution was used to ensure the efficiency of washing and it’s free from chlorides

- The solution was filtered and the nano silica was dried at 90 °C for about 48 h

- The dried white Nano particles were burnt in high temperature capacity muffle at 600 °C for 2 h; specimens were kept in muffle until cooling to ambient 20 °C.

- Finally, rapid mills for 30 s were done [24].

2.2.2. Nano Waste Materials

2.3. Raw Materials Characterization

2.4. Concrete Mix Design

2.5. Mixing Procedure

- Fine and coarse aggregate were mixed together for 1 min, thereafter, cement and silica fume were incorporated and dry mixed for 2 min

- 50% of estimated mixing water was added during mixing and continued for 6 min

- The nano materials’ solution with superplasticizer and water were added and mixed for 5 min

2.6. Experimental Tests

2.6.1. Mechanical Properties

2.6.2. Durability

2.6.3. Chemical and Microstructural Characteristics

3. Results and Discussion

3.1. Mechanical Properties

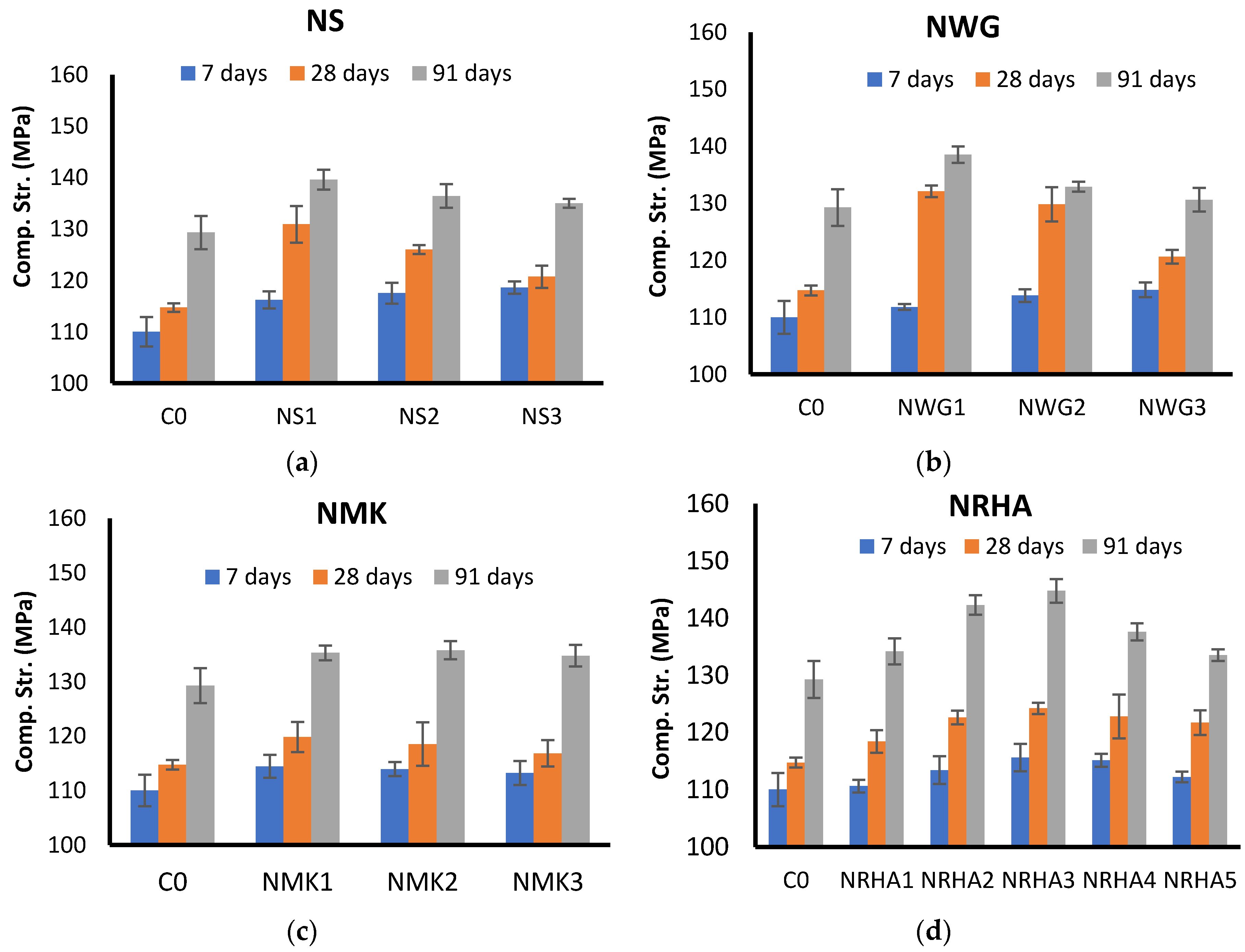

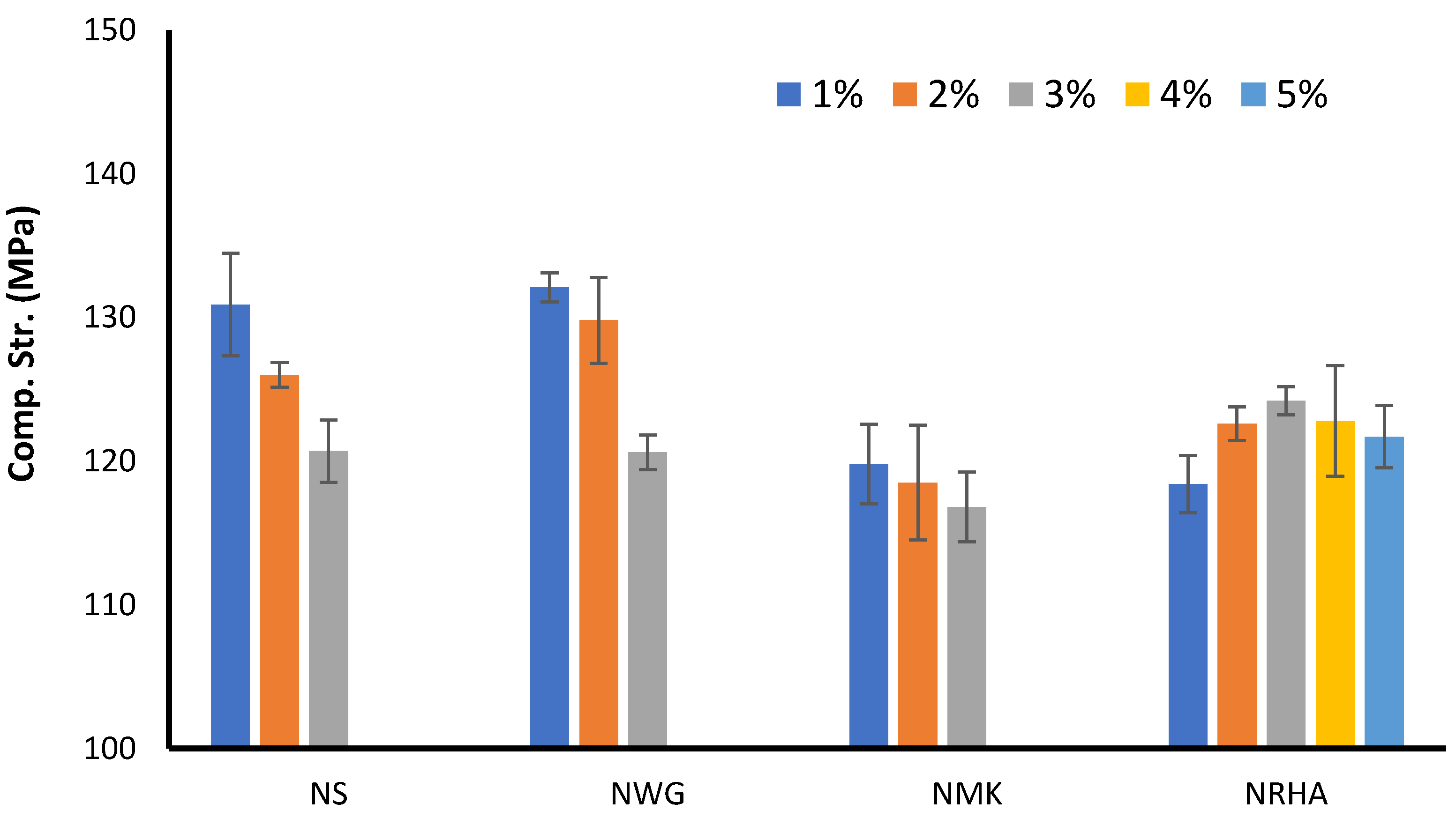

3.1.1. Compressive Strength

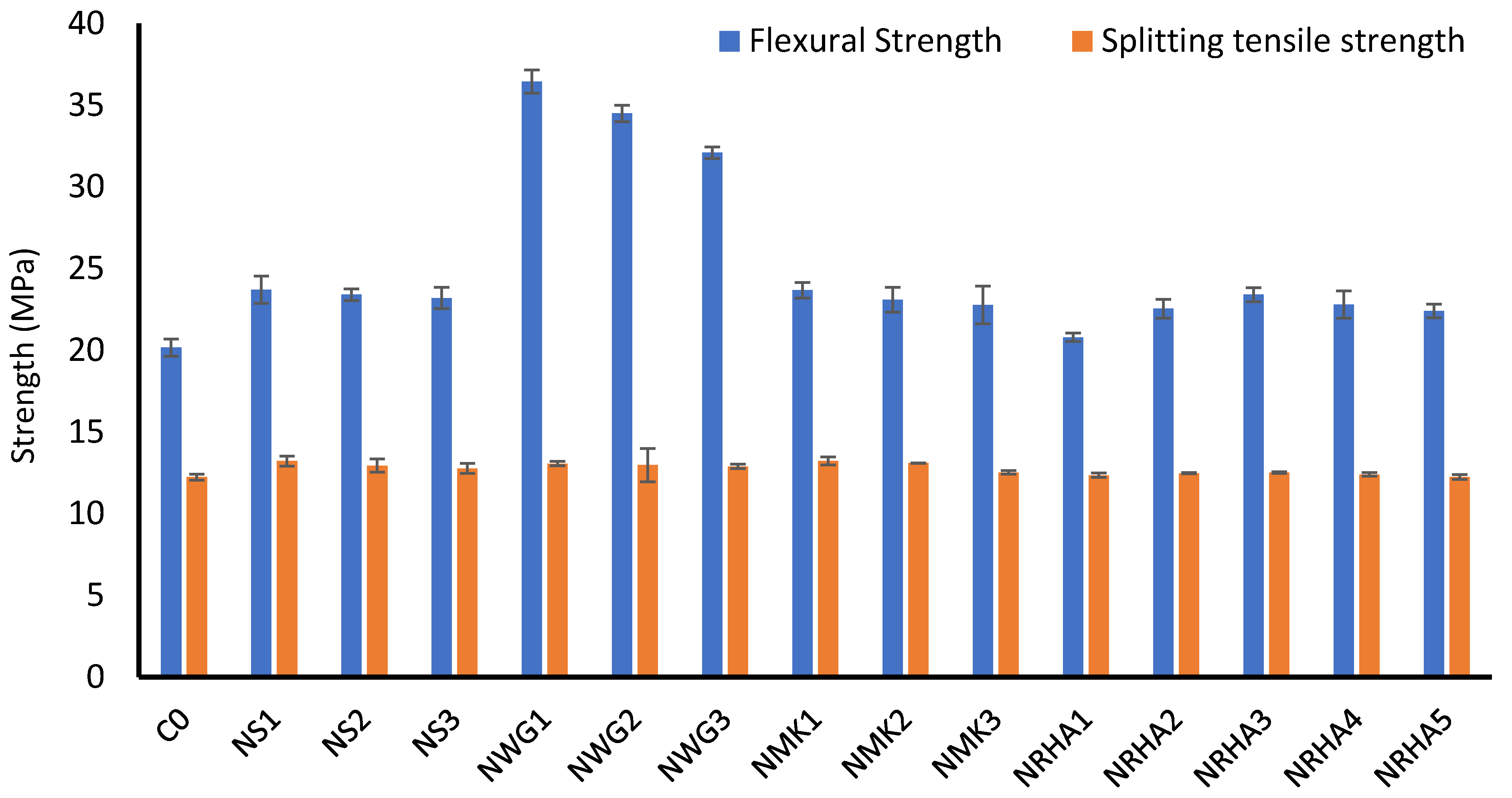

3.1.2. Flexural and Tensile Strength

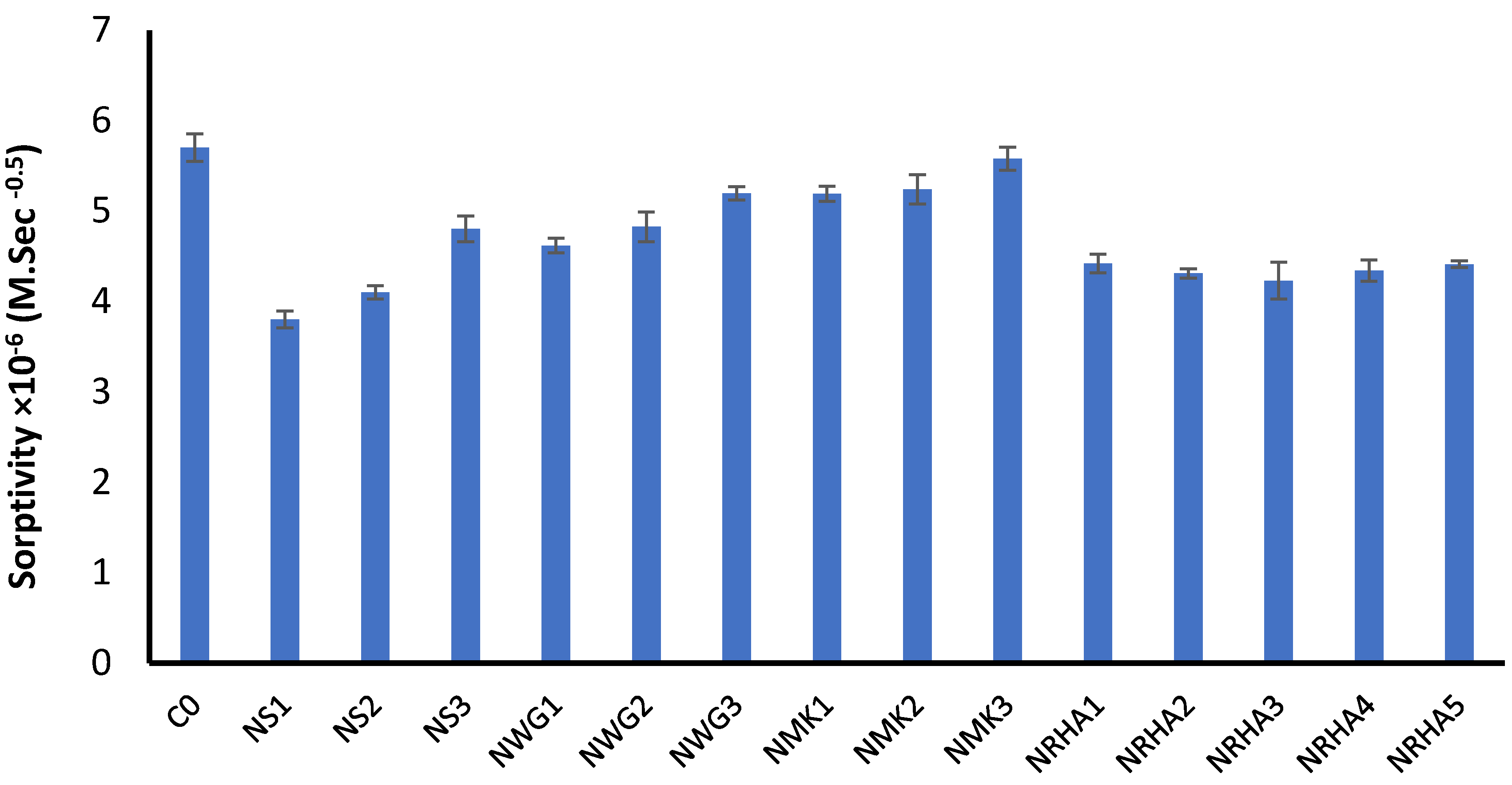

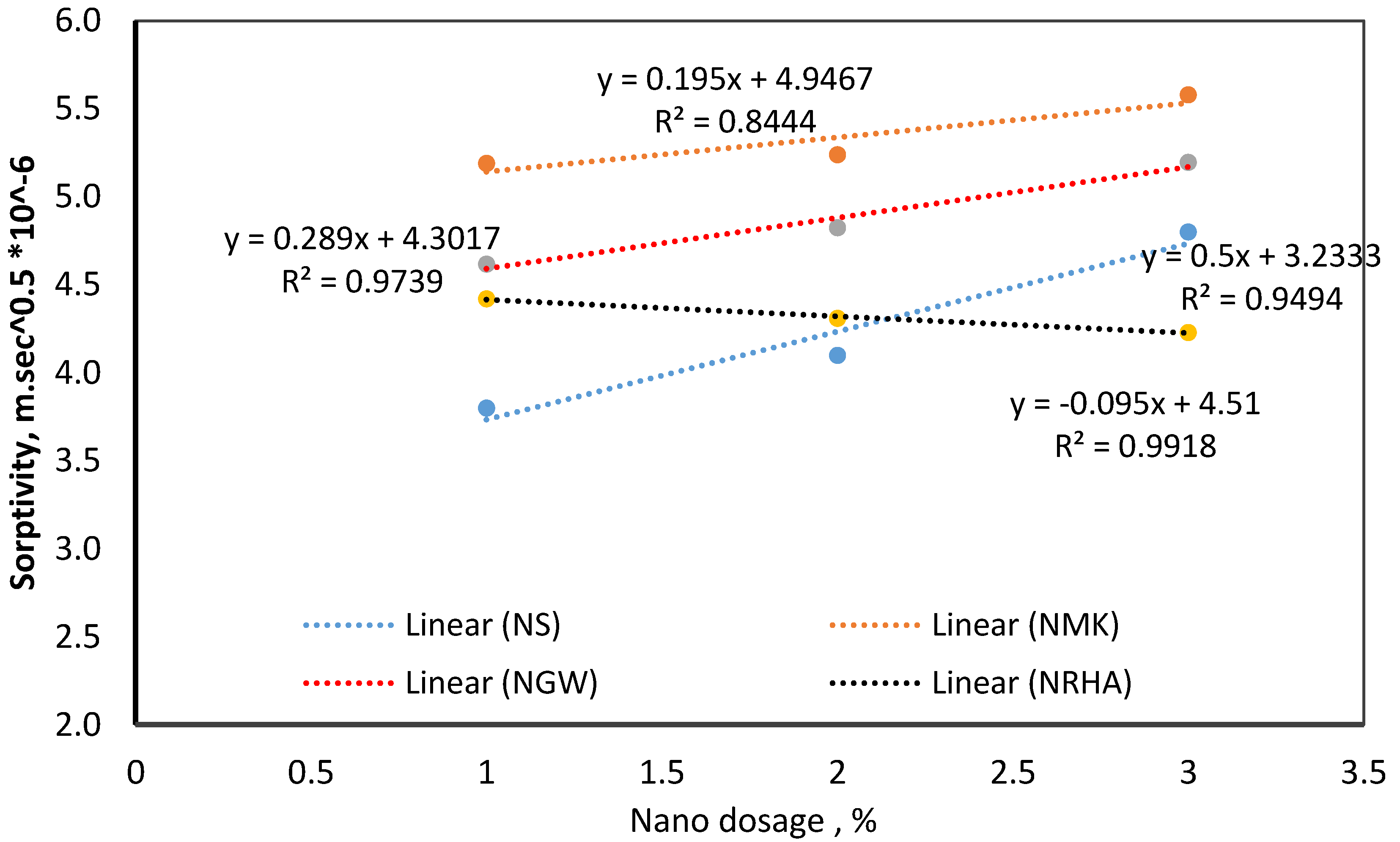

3.2. The Effect of Nano Materials Contents on Durability Properties of UHPC

3.3. Hydration and Microstructural Characteristics

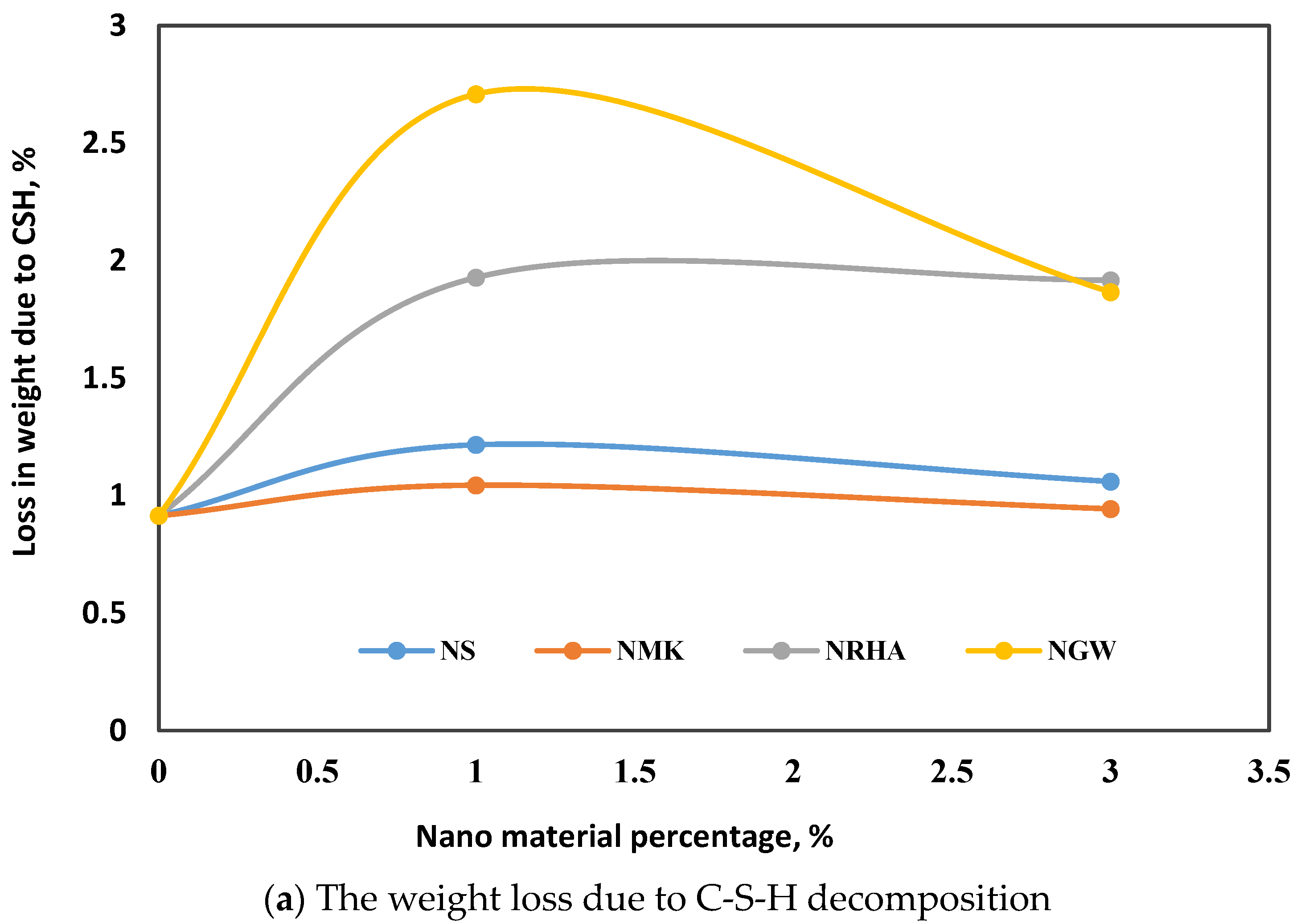

3.3.1. Thermogravimetric Analysis

3.3.2. X-ray Diffraction (XRD)

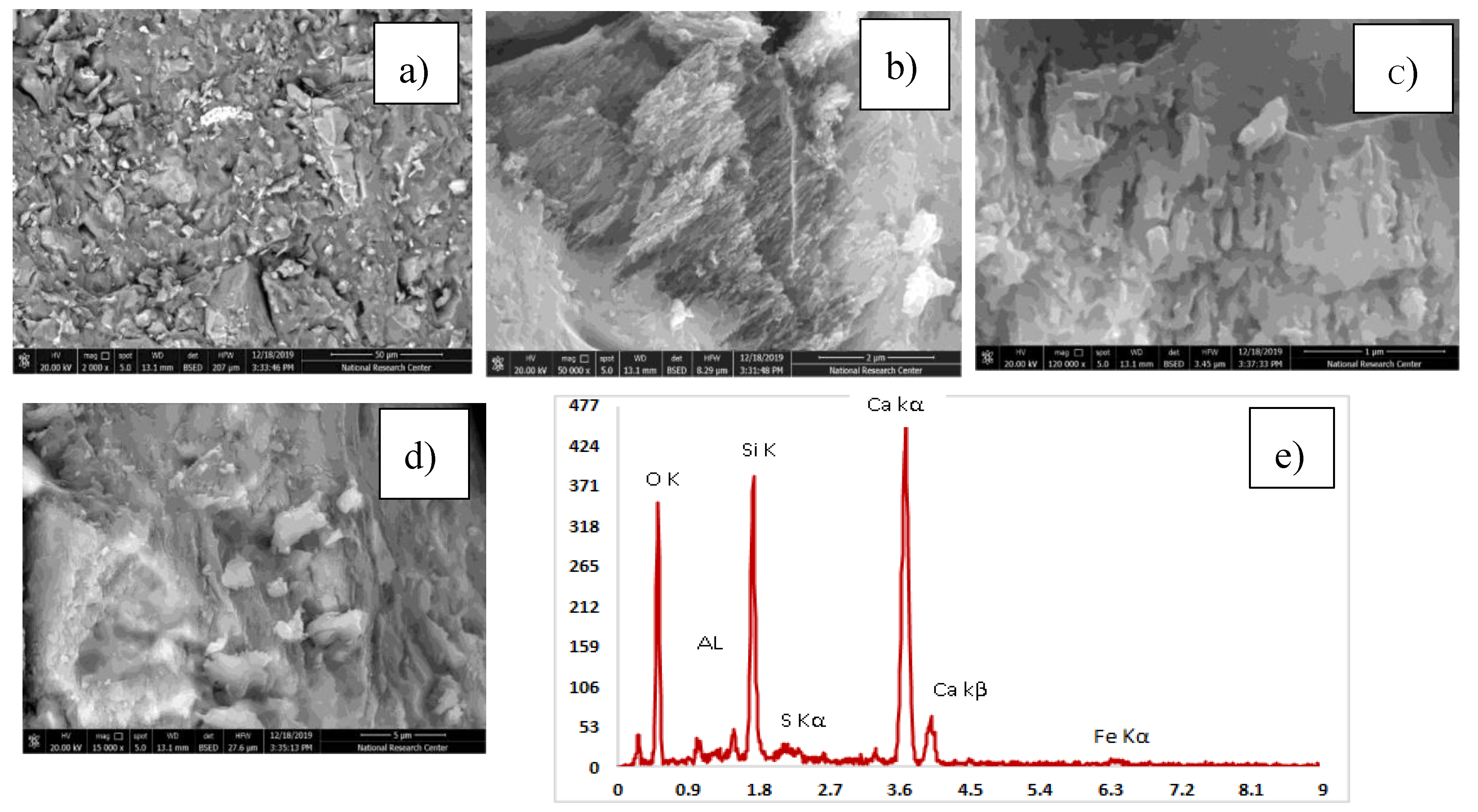

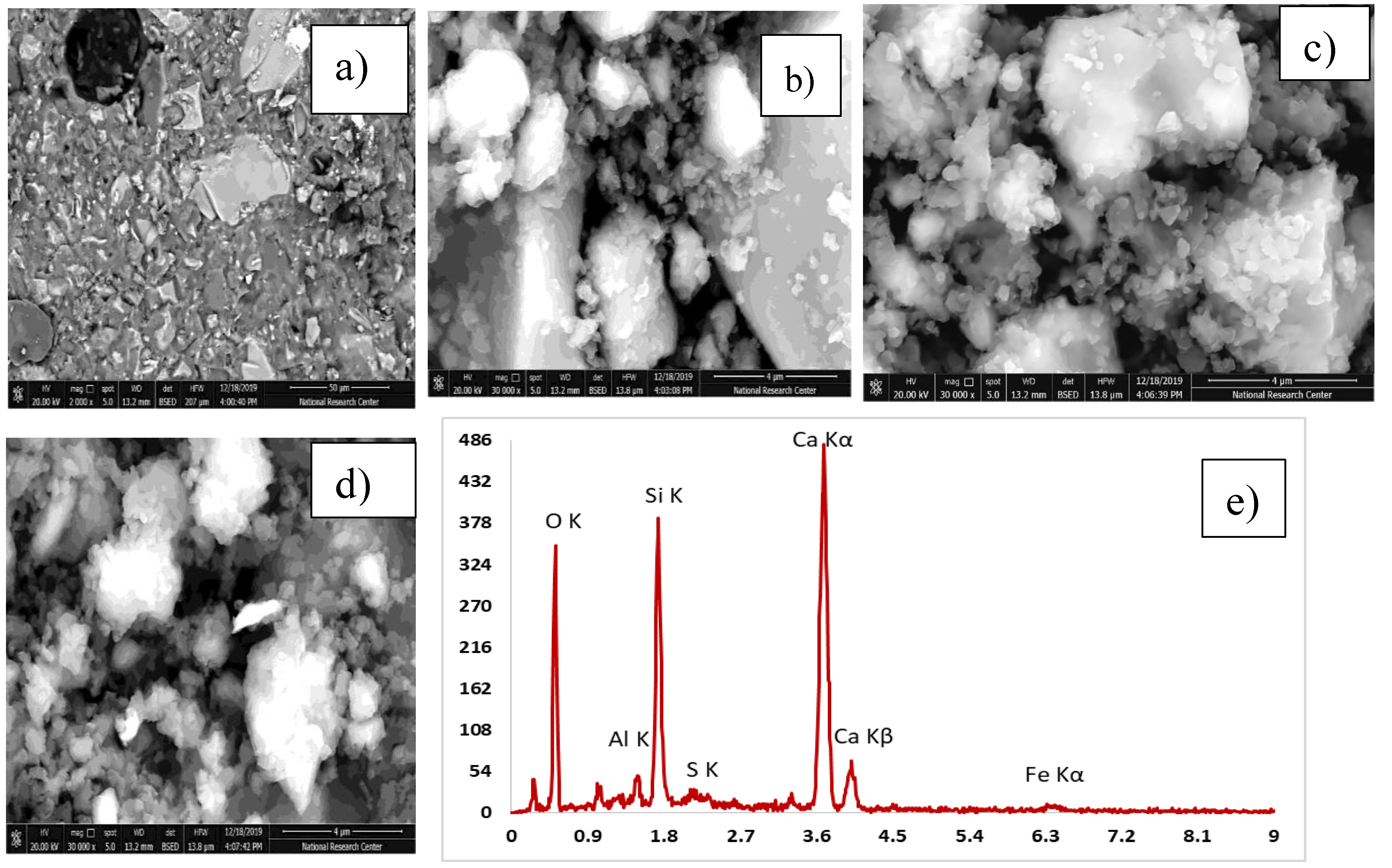

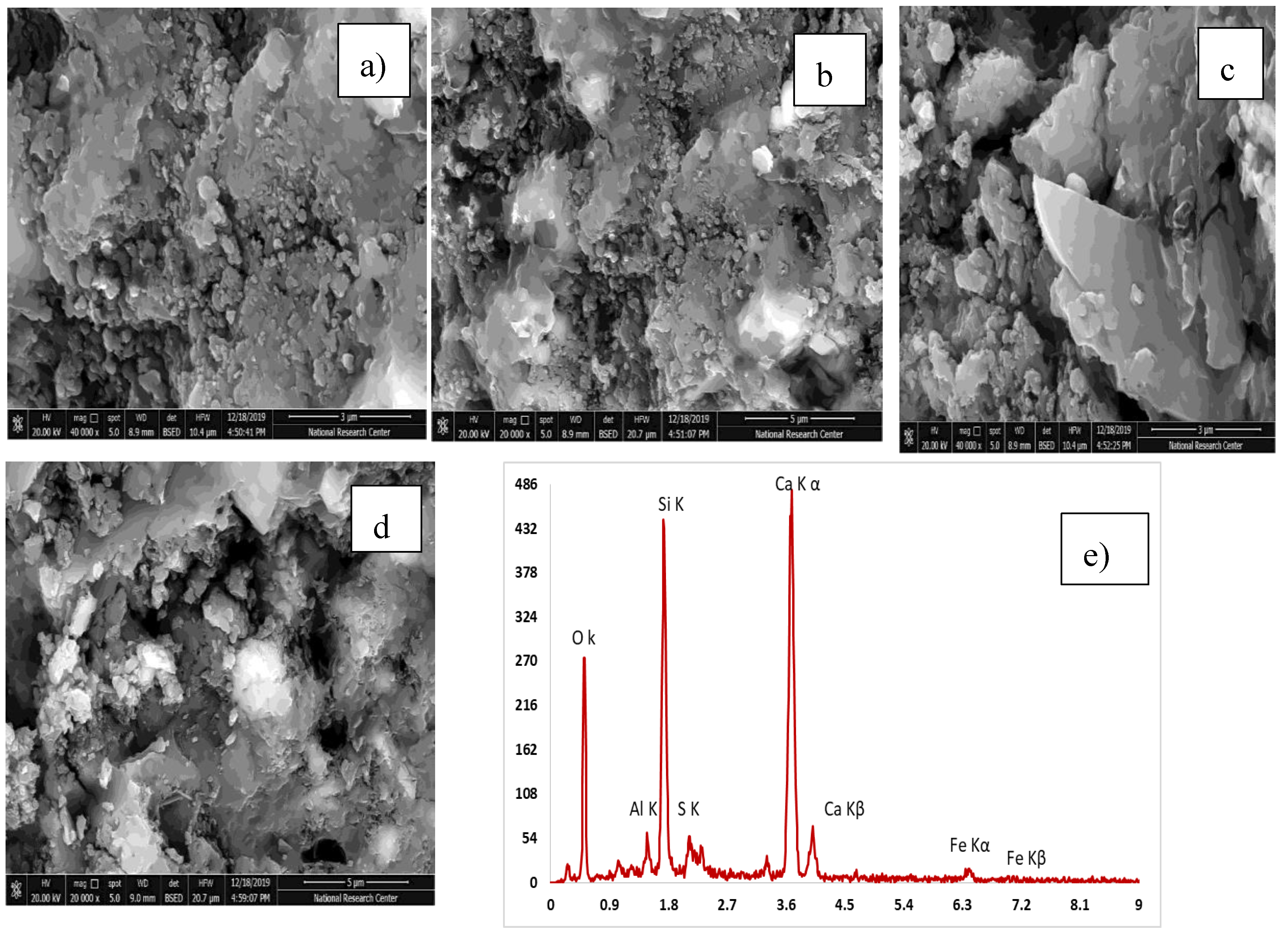

3.3.3. Scanning Electron Microscope

4. Conclusions

- The compressive strength is significantly improved by adding the nano-particles. Mixes incorporating nano-silica, nano-waste glass and nano-Metakaolin achieved the maximum strength at 1% NS, 1% NWG and 1% NMK due to their compactness, whereas, nano-rice husk ash increases the compressive strength, especially at later ages due to its characteristics of saving water at early ages and promoting them to share in the hydration process, with the optimum strength obtained at 3%. Meanwhile, the maximum compressive strength was achieved at 3% nano-rice husk ash.

- All four types of nano-materials used increased the splitting and flexure strength of concrete.

- The highest flexure strength was achieved at 1% of Nano Waste Glass of 80% comparing to 17%, 17%, 15% in case of NS1, NMK1 and NRHA3, while the highest splitting strength was achieved at 1% nano-silica and 1% nano-metakaolin of 9% whereas nano-waste glass and nano-rice husk ash achieved a 4% and 7% increase.

- Nano waste glass was found to be the most suitable admixture to be used in UHPC due to its lowest production costs as well as low dosage required to obtain the most superior properties among tested UHPCs

- Adding nano-particles reduced the value of absorption according to sorptivity test. The effect was more pronounced by adding 1%NS as it reduced the water absorbed ratio with 50%.

- Compared to control mix, introducing nano materials in concrete mix led to increasing C-S-H and decreasing C-H.

- SEM analysis showed compact, thick sections with no porosity.

- EDX analysis pronounced that adding nano particles increased Ca/Si ratio, hence accelerating the internal reactions. The maximum percentage achieved at 1% nano-metakaolin and nano-waste glass of 34% and 26% compared to control mix, nano-silica, and nano-rice husk ash achieved an increase of 17% and 8.4%, respectively.

- As the outcome of this research, UHPC can be produced without the need for high cost techniques such special mixer or the special curing method. Moreover, it can be optimized using mechanically prepared nanoparticles from waste materials, which is less expensive than other types of nanomaterials available in the market.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, Z.; Khayat, K.H.; Shi, C. Effect of nano-SiO2 particles and curing time on development of fiber-matrix bond properties and microstructure of ultra-high strength concrete. Cem. Concr. Res. 2017, 95, 247–256. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Guo, J.-Y.; Wang, J.-Y.; Wu, K. Effects of self-healing on tensile behavior and air permeability of high strain hardening UHPC. Constr. Build. Mater. 2019, 204, 342–356. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Lee, M.; Wang, Y.-C.; Chiu, C.-T. A preliminary study of reactive powder concrete as a new repair material. Constr. Build. Mater. 2007, 21, 182–189. [Google Scholar] [CrossRef]

- Ahmad, S.; Mohaisen, K.O.; Adekunle, S.K.; Al-Dulaijan, S.U.; Maslehuddin, M. Influence of admixing natural pozzolan as partial replacement of cement and microsilica in UHPC mixtures. Constr. Build. Mater. 2019, 198, 437–444. [Google Scholar] [CrossRef]

- Lee, N.K.; Koh, K.T.; Kim, M.O.; Ryu, G.S. Uncovering the role of micro silica in hydration of ultra-high performance concrete (UHPC). Cem. Concr. Res. 2018, 104, 68–79. [Google Scholar] [CrossRef]

- Reda, M.; Shrive, N.; Gillott, J. Microstructural investigation of innovative UHPC. Cem. Concr. Res. 1999, 29, 323–329. [Google Scholar] [CrossRef]

- Chen, T.; Gao, X.; Ren, M. Effects of autoclave curing and fly ash on mechanical properties of ultra-high performance concrete. Constr. Build. Mater. 2018, 158, 864–872. [Google Scholar] [CrossRef]

- Su, Y.; Wu, C.; Li, J.; Li, Z.-X.; Li, W. Development of novel ultra-high performance concrete: From material to structure. Constr. Build. Mater. 2017, 135, 517–528. [Google Scholar] [CrossRef]

- Randl, N.; Steiner, T.; Ofner, S.; Baumgartner, E.; Mészöly, T. Development of UHPC mixtures from an ecological point of view. Constr. Build. Mater. 2014, 67, 373–378. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E. Critical review on eco-efficient ultra high performance concrete enhanced with nano-materials. Constr. Build. Mater. 2015, 101, 201–208. [Google Scholar] [CrossRef]

- Kütük-Sert, T. Stability analyses of submicron-boron mineral prepared by mechanical milling process in concrete roads. Constr. Build. Mater. 2016, 121, 255–264. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. The effect of nanosilica addition on flowability, strength and transport properties of ultra high performance concrete. Mater. Des. 2014, 59, 1–9. [Google Scholar] [CrossRef]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Norhasri, M.S.M.; Hamidah, M.S.; Fadzil, A.M.; Megawati, O. Inclusion of nano metakaolin as additive in ultra high performance concrete (UHPC). Constr. Build. Mater. 2016, 127, 167–175. [Google Scholar] [CrossRef]

- Heikal, M.; Ibrahim, N. Hydration, microstructure and phase composition of composite cements containing nano-clay. Constr. Build. Mater. 2016, 112, 19–27. [Google Scholar] [CrossRef]

- Morsy, M.; Shoukry, H.; Mokhtar, M.; Ali, A.M.; El-Khodary, S. Facile production of nano-scale metakaolin: An investigation into its effect on compressive strength, pore structure and microstructural characteristics of mortar. Constr. Build. Mater. 2018, 172, 243–250. [Google Scholar] [CrossRef]

- Balapour, M.; Ramezanianpour, A.; Hajibandeh, E. An investigation on mechanical and durability properties of mortars containing nano and micro RHA. Constr. Build. Mater. 2017, 132, 470–477. [Google Scholar] [CrossRef]

- Xiao, R.; Polaczyk, P.; Zhang, M.; Jiang, X.; Zhang, Y.; Huang, B.; Hu, W. Evaluation of glass powder-based geopolymer stabilized road bases containing recycled waste glass aggregate. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 22–32. [Google Scholar] [CrossRef]

- Norhasri, M.M.; Hamidah, M.; Fadzil, A.M. Applications of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Saleh, N.J.; Ibrahim, R.I.; Salman, A.D. Characterization of nano-silica prepared from local silica sand and its application in cement mortar using optimization technique. Adv. Powder Technol. 2015, 26, 1123–1133. [Google Scholar] [CrossRef]

- Al-Jabri, K.; Shoukry, H. Use of nano-structured waste materials for improving mechanical, physical and structural properties of cement mortar. Constr. Build. Mater. 2014, 73, 636–644. [Google Scholar] [CrossRef]

- Jal, P.; Sudarshan, M.; Saha, A.; Patel, S.; Mishra, B. Synthesis and characterization of nanosilica prepared by precipitation method. Colloids Surf. A Physicochem. Eng. Asp. 2004, 240, 173–178. [Google Scholar] [CrossRef]

- Castro, C.L.D.; Mitchell, B.S. Nanoparticles from Mechanical Attrition, Synthesis, Functionalization and Surface Treatment of Nanoparticles; Chapter 1; American Scientific Publishers: Valencia, CA, USA, 2002; pp. 1–15. [Google Scholar]

- Börner, L.; Eckert, J. Nanostructure formation and steady-state grain size of ball-milled iron powders. Mater. Sci. Eng. A 1997, 226, 541–545. [Google Scholar] [CrossRef]

- Tawfik, T.A.; El-Aziz, M.A.A.; El-Aleem, S.A.; Faried, A.S. Influence of nanoparticles on mechanical and nondestructive properties of high-performance concrete. J. Chin. Adv. Mater. Soc. 2018, 6, 409–433. [Google Scholar] [CrossRef]

- Vandenberg, A.; Wille, K. Evaluation of resonance acoustic mixing technology using ultra high performance concrete. Constr. Build. Mater. 2018, 164, 716–730. [Google Scholar] [CrossRef]

- Hiremath, P.N.; Yaragal, S.C. Influence of mixing method, speed and duration on the fresh and hardened properties of Reactive Powder Concrete. Constr. Build. Mater. 2017, 141, 271–288. [Google Scholar] [CrossRef]

- Abousnina, R.; Manalo, A.; Ferdous, W.; Lokuge, W.; Benabed, B.; Al-Jabri, K.S. Characteristics, strength development and microstructure of cement mortar containing oil-contaminated sand. Constr. Build. Mater. 2020, 252, 119155. [Google Scholar] [CrossRef]

- ASTM C39/C39M. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM C496/C496M-17. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C1609/C1609M. Standard Test Method for Flexural Performance of Fiber Reinforced Concrete (Using Beam with Third Point Loading); American Society for Testing and Materials: West Conshohocken, PA, USA, 2010; p. 9. [Google Scholar]

- ASTM C1585. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes; American Society for Testing and Materials: West Conshohocken, PA, USA, 2011; p. 6. [Google Scholar]

- Shaikh, F.U.; Supit, S.W. Mechanical and durability properties of high volume fly ash (HVFA) concrete containing calcium carbonate (CaCO3) nanoparticles. Constr. Build. Mater. 2014, 70, 309–321. [Google Scholar] [CrossRef]

- Jain, J.; Neithalath, N. Analysis of calcium leaching behavior of plain and modified cement pastes in pure water. Cem. Concr. Compos. 2009, 31, 176–185. [Google Scholar] [CrossRef]

- Sikora, P.; Lootens, D.; Liard, M.; Stephan, D. The effects of seawater and nanosilica on the performance of blended cements and composites. Appl. Nanosci. 2020, 1–18. [Google Scholar] [CrossRef]

- Shoukry, H.; Kotkata, M.; Abo-El-Enein, S.; Morsy, M. Flexural strength and physical properties of fiber reinforced nano metakaolin cementitious surface compound. Constr. Build. Mater. 2013, 43, 453–460. [Google Scholar] [CrossRef]

- Sikora, P.; Cendrowski, K.; Elrahman, M.A.; Chung, S.-Y.; Mijowska, E.; Stephan, D. The effects of seawater on the hydration, microstructure and strength development of Portland cement pastes incorporating colloidal silica. Appl. Nanosci. 2019, 10, 2627–2638. [Google Scholar] [CrossRef]

- Elrahman, M.A.; Chung, S.-Y.; Sikora, P.; Rucińska, T.; Stephan, D. Influence of Nanosilica on Mechanical Properties, Sorptivity, and Microstructure of Lightweight Concrete. Materials 2019, 12, 3078. [Google Scholar] [CrossRef]

- Sikora, P.; Rucinska, T.; Stephan, D.; Chung, S.-Y.; Elrahman, M.A. Evaluating the effects of nanosilica on the material properties of lightweight and ultra-lightweight concrete using image-based approaches. Constr. Build. Mater. 2020, 264, 120241. [Google Scholar] [CrossRef]

- Khotbehsara, M.M.; Manalo, A.C.; Aravinthan, T.; Reddy, K.R.; Ferdous, W.; Wong, H.; Nazari, A. Effect of elevated in-service temperature on the mechanical properties and microstructure of particulate-filled epoxy polymers. Polym. Degrad. Stab. 2019, 170, 108994. [Google Scholar] [CrossRef]

| Material | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | SO3 | LOI | Density (g/cm3) | Surface Area (cm2/g) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CEM I 52.5 N | 63.4 | 21.2 | 5.5 | 3.21 | 0.7 | 0.1 | 0.5 | 2.4 | 2.3 | 3.15 | 3500 |

| Silica fume | 0.2 | 97 | 0.1 | 1.0 | 0.15 | 0.10 | 0.2 | 0.1 | 2.2 | 2.15 |

| Physical Properties | Crushing (%) | Absorption (%) | Clay and Fine Materials% | Bulk Density (kg/m3) | Specific Gravity (g/m3) |

|---|---|---|---|---|---|

| Fine aggregate | - | 1 | 1 | 1700 | 2.5 |

| Coarse aggregate | 7 | 5.0 | 0.5 | 1720 | 2.65 |

| Items | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | Cl | TiO2 |

|---|---|---|---|---|---|---|---|---|---|---|

| NS | 95.39 | 0.15 | 1.11 | 0.43 | 0.09 | 0.05 | 0.030 | 1.790 | 0.71 | - |

| NWG | 72.58 | 0.17 | 1.11 | 12.12 | 2.09 | 0.19 | 0.030 | 11.700 | 0.01 | - |

| NMK | 89.6 | 0.9 | 2.0 | 0.43 | 2.0 | - | 4.55 | - | - | 0.7 |

| NRHA | 73.05 | 1.16 | 0.18 | 3.50 | 1.45 | 0.47 | 5.670 | 2.740 | 1.81 | - |

| No. | Cement | SF | Fine Aggregate | Coarse Aggregate | Water | SP | Fiber (V%) | NS % | NWG % | NMK % | NRHA % |

|---|---|---|---|---|---|---|---|---|---|---|---|

| kg/m3 | |||||||||||

| CO | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | - | - | - |

| NS1 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | 1 | - | - | - |

| NS2 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | 2 | - | - | - |

| NS3 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | 3 | - | - | - |

| NWG1 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | 1 | - | - |

| NWG2 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | 2 | - | - |

| NWG3 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | 3 | - | - |

| NMK1 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | - | 1 | - |

| NMK2 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | - | 2 | - |

| NMK2 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | - | 3 | - |

| NRHA1 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | - | - | 1 |

| NRHA2 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | - | - | 2 |

| NRHA3 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | - | - | 3 |

| NRHA4 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | - | - | 4 |

| NRHA5 | 900 | 135 | 349 | 776 | 186.3 | 22.5 | 1 | - | - | - | 5 |

| Element | Control (wt.%) | NWG (wt.%) | NS (wt.%) | NRHA (wt.%) | NMK (wt.%) |

|---|---|---|---|---|---|

| C K | 4.21 | 7.48 | 5.94 | 4.68 | 6.7 |

| O K | 53.2 | 50.64 | 51.46 | 45.89 | 49.29 |

| AlK | 1.93 | 0.95 | 1.69 | 1.34 | 2.45 |

| SiK | 11.44 | 10.23 | 10.86 | 12.65 | 8.29 |

| CaK | 24.42 | 27.85 | 27.56 | 29.26 | 29.04 |

| FeK | 1.29 | 0.87 | 2.49 | 2.12 | 4.23 |

| NaK | 2.59 | 1.98 | 100 | ||

| MgK | 0.93 | ||||

| S K | 3.27 | ||||

| K K | 0.79 |

| Mix ID | CO | NS1 | NWG1 | NMK | NRHA3 |

|---|---|---|---|---|---|

| Ca/Si | 2.13 | 2.53 | 2.72 | 3.5 | 2.31 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mostafa, S.A.; Faried, A.S.; Farghali, A.A.; EL-Deeb, M.M.; Tawfik, T.A.; Majer, S.; Abd Elrahman, M. Influence of Nanoparticles from Waste Materials on Mechanical Properties, Durability and Microstructure of UHPC. Materials 2020, 13, 4530. https://doi.org/10.3390/ma13204530

Mostafa SA, Faried AS, Farghali AA, EL-Deeb MM, Tawfik TA, Majer S, Abd Elrahman M. Influence of Nanoparticles from Waste Materials on Mechanical Properties, Durability and Microstructure of UHPC. Materials. 2020; 13(20):4530. https://doi.org/10.3390/ma13204530

Chicago/Turabian StyleMostafa, Sahar A., Ahmed S. Faried, Ahmed A. Farghali, Mohamed M. EL-Deeb, Taher A. Tawfik, Stanisław Majer, and Mohamed Abd Elrahman. 2020. "Influence of Nanoparticles from Waste Materials on Mechanical Properties, Durability and Microstructure of UHPC" Materials 13, no. 20: 4530. https://doi.org/10.3390/ma13204530

APA StyleMostafa, S. A., Faried, A. S., Farghali, A. A., EL-Deeb, M. M., Tawfik, T. A., Majer, S., & Abd Elrahman, M. (2020). Influence of Nanoparticles from Waste Materials on Mechanical Properties, Durability and Microstructure of UHPC. Materials, 13(20), 4530. https://doi.org/10.3390/ma13204530