Effects of Reinforcement Ratios and Sintering Temperatures on the Mechanical Properties of Titanium Nitride/Nickel Composites

Abstract

1. Introduction

2. Material and Methods

2.1. Specimen Preparation

2.2. Microstructural Characteriszation

2.3. Mechanical Properties Tests

3. Results and Discussion

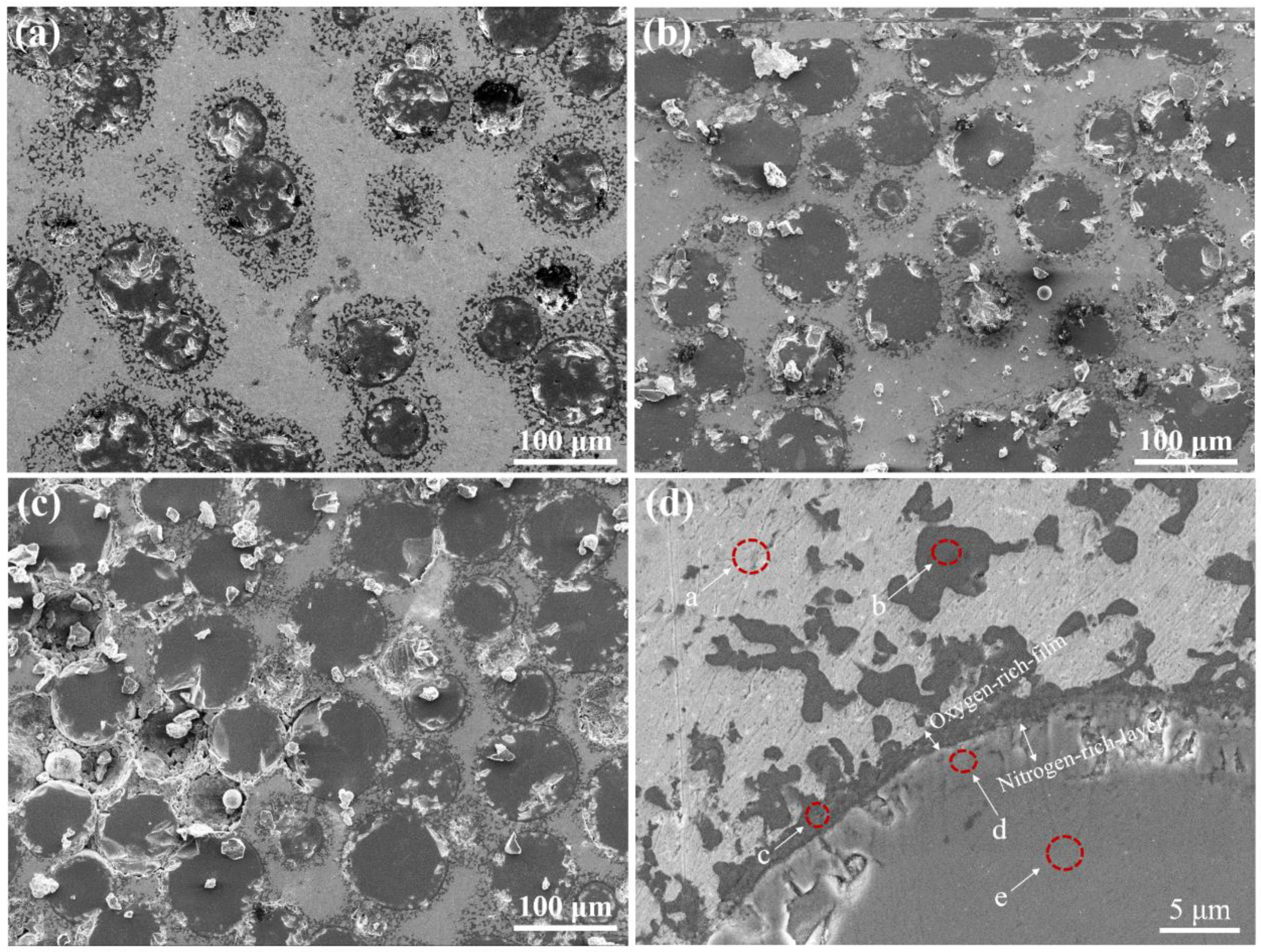

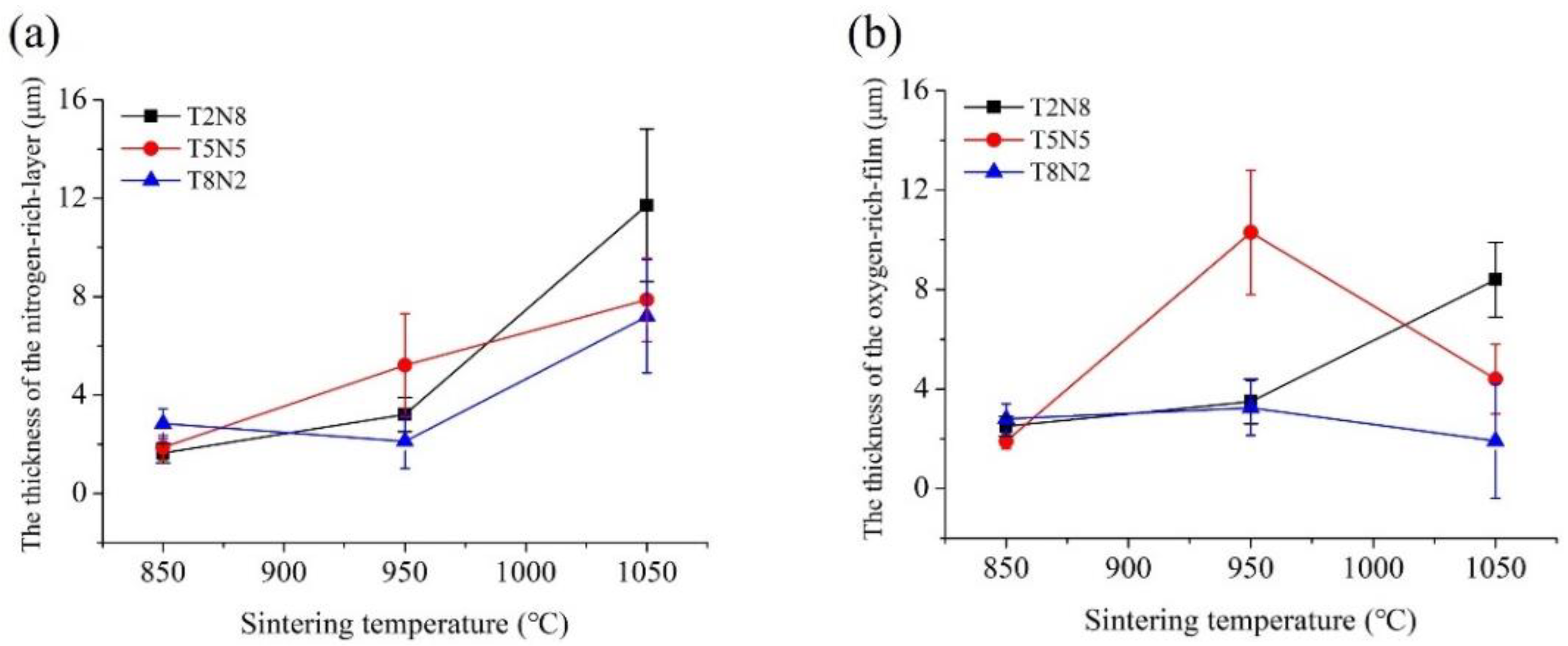

3.1. Microstructure

3.2. Composition

3.3. Porosity

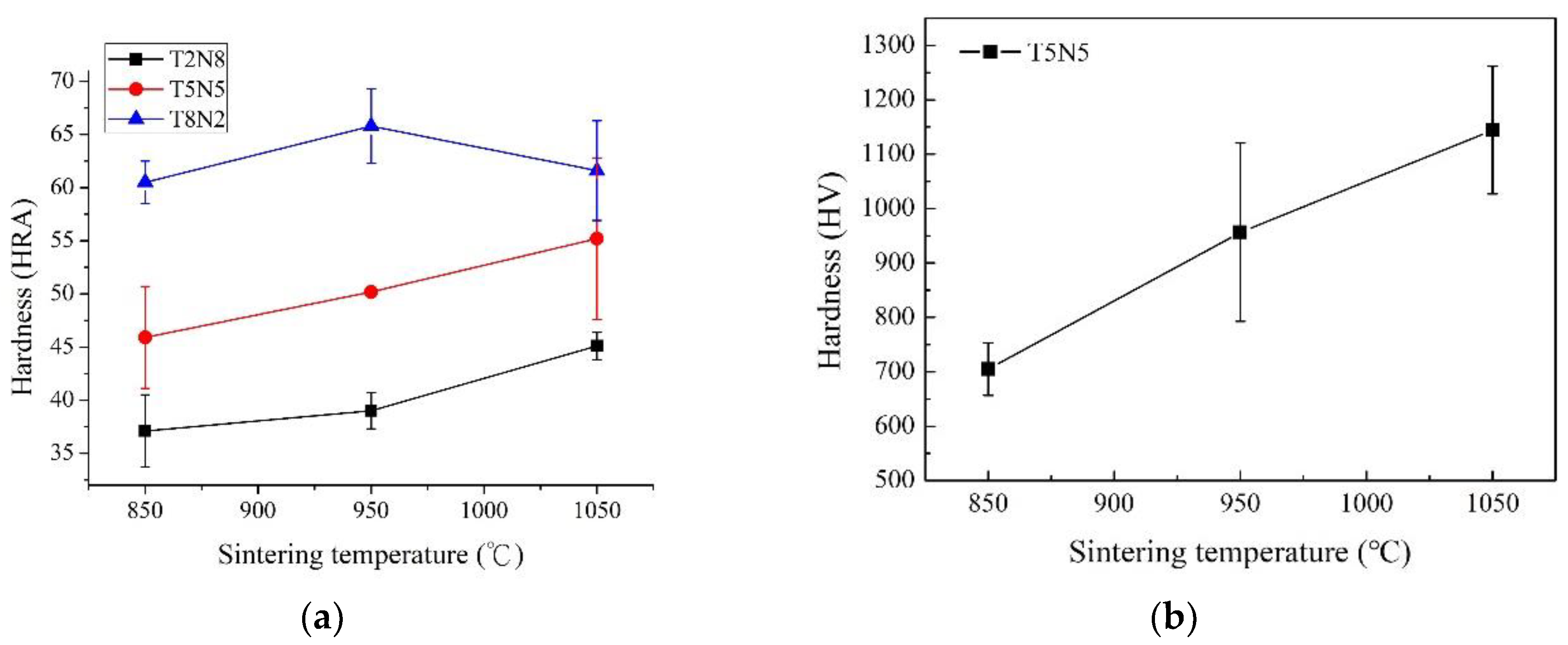

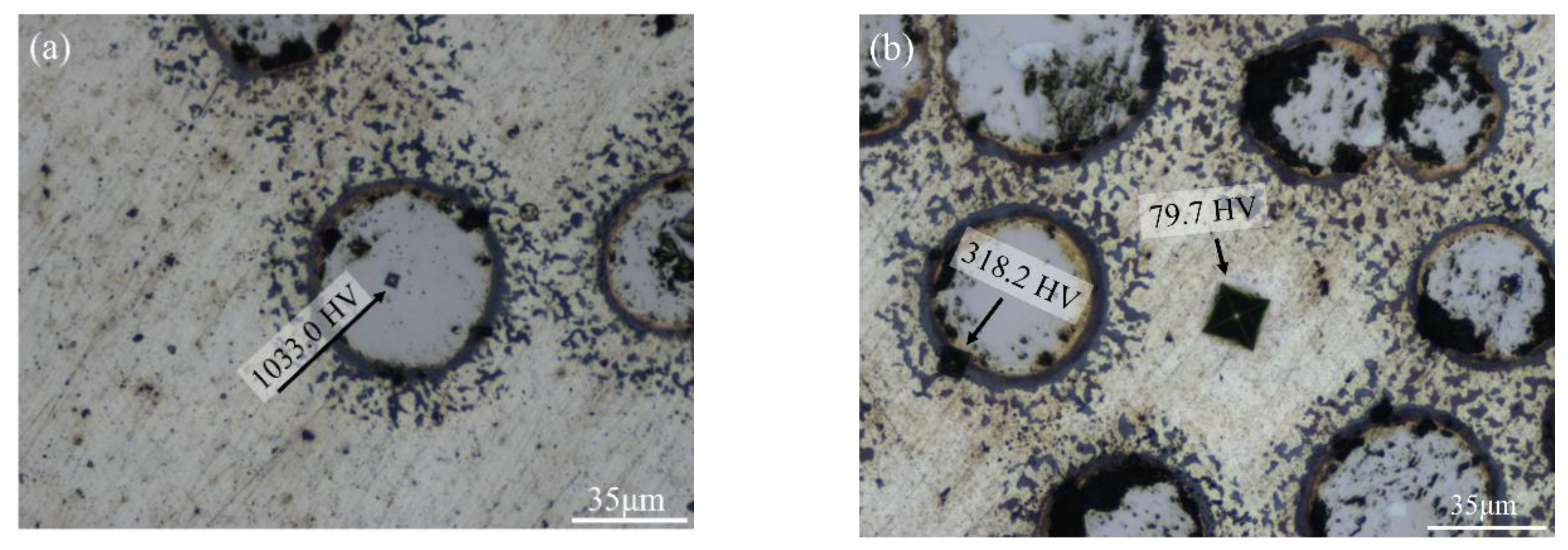

3.4. Hardness

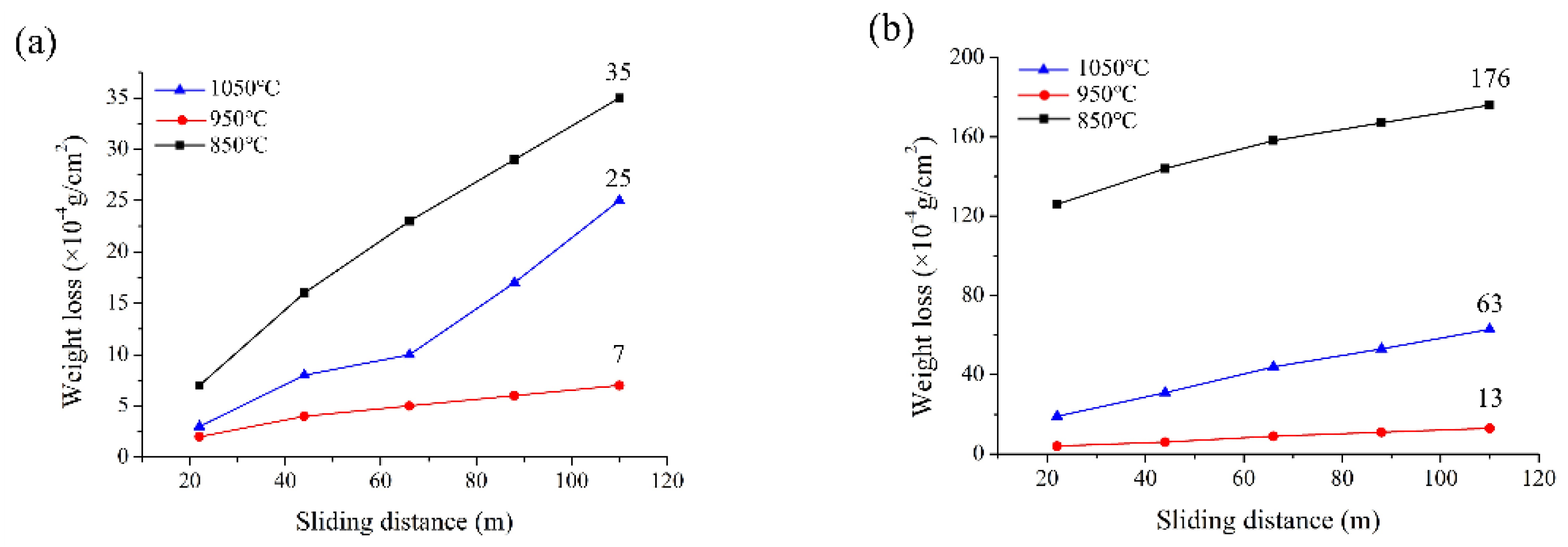

3.5. Wear Resistance

3.6. Compressive Strength

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Singla, M.; Dwivedi, D.D.; Singh, L.; Chawla, V. Development of aluminium based silicon carbide particulate metal matrix composite. J. Miner. Mater. Charact. Eng. 2009, 8, 455–467. [Google Scholar] [CrossRef]

- Behera, R.; Chatterjee, D.; Sutradhar, G. Effect of reinforcement particles on the fluidity and solidification behavior of the stir cast aluminum alloy metal matrix composites. Am. J. Mater. Sci. 2012, 2, 53–61. [Google Scholar] [CrossRef]

- Godfrey, T.M.T.; Goodwin, P.S.; Ward-Close, C.M. Titanium particulate metal matrix composites reinforcement, production methods, and mechanical properties. Adv. Eng. Mater. 2000, 2, 85–92. [Google Scholar] [CrossRef]

- Kainer, K.U.; Geesthacht, H.Z. Basics of Metal. Matrix Composites; Wiley-VCH Verlag GmbH & Co KGaA: Weinheim, Germany, 2006. [Google Scholar]

- Chen, J.; Wu, G.; Sun, D.; Jiang, L. Strengthening mechanism of metal matrix composites. J. Aeronaut. Mater. 2002, 22, 49–53. [Google Scholar]

- Wang, S.Y.; Tang, Q.; Li, D.J.; Zou, J.X.; Zeng, X.Q.; Ouyang, Q.B.; Ding, W.J. The hot workability of SiCp/2024 Al composite by stir casting. Mater. Manuf. Process. 2015, 30, 624–630. [Google Scholar] [CrossRef]

- Syahrial, A.Z.; Pancasakti, A. Effect of aging on characterization of sr-modified stir cast A356/Al2O3 composite. Key Eng. Mater. 2017, 753, 33–38. [Google Scholar] [CrossRef]

- Viswanatha, B.M.; Prasanna, K.M.; Basavarajappa, S.; Kiran, T.K. Study the formation of mechanically mixed layer and subsurface behavior of worn out surfaces of aged hybrid metal matrix composites. Ind. Lubr. Tribol. 2018, 70, 818–827. [Google Scholar]

- Singh, B.; Kumar, J.; Kumar, S. Investigation of the tool wear rate in tungsten powder-mixed electric discharge machining of AA6061/10%SiCp composite. Mater. Manuf. Process. 2016, 31, 456–466. [Google Scholar] [CrossRef]

- Bajakke, P.A.; Malik, V.R.; Deshpande, A.S. Particulate metal matrix composites and their fabrication via friction stir processing—A review. Mater. Manuf. Process. 2019, 34, 1–49. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M.; Dellasega, D.; Bassani, P.; Tuissi, A. Consolidated Al/Al2O3 nanocomposites by equal channel angular pressing and hot extrusion. Mater. Manuf. Process. 2015, 30, 1218–1222. [Google Scholar] [CrossRef]

- Soltani, N.; Sadrnezhaad, S.K.; Bahrami, A. Manufacturing wear-resistant 10Ce-TZP/Al2O3 nanoparticle aluminum composite by powder metallurgy processing. Mater. Manuf. Process. 2014, 29, 1237–1244. [Google Scholar] [CrossRef]

- Lakshmipathy, J.; Rajesh, K.S.; Manisekar, K.; Vinoth, K.S. Effect of reinforcement and tribological behaviour of AA7068 hybrid composites manufactured through powder metallurgy techniques. Appl. Mech. Mater. 2017, 867, 19–28. [Google Scholar] [CrossRef]

- Khosla, P.; Singh, H.K.; Katoch, V.; Dubey, A.; Singh, N.; Kumar, D.; Gupta, P. Synthesis, Mechanical and corrosion behaviour of iron–silicon carbide metal matrix nanocomposites. J. Compos. Mater. 2018, 52, 91–107. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Ibrahim, I.A.; Mohamed, F.A.; Lavernia, E.J. Processing techniques for particulate-reinforced metal aluminium matrix composites. J. Mater. Sci. 1991, 26, 5965–5978. [Google Scholar] [CrossRef]

- Buelens, C.; Fransaer, J.; Celis, J.P.; Roos, J.R. The mechanism of electrolytic codeposition of particles with metals. A review. Bull. Electrochem. 1992, 8, 371–375. [Google Scholar]

- Williams, R.V.; Martin, P.W. Electrodeposited Composite Coatings. Trans. Inst. Met. Finish. 1964, 42, 182–188. [Google Scholar] [CrossRef]

- Itoh, H.; Kato, K.; Sugiyama, K. Chemical vapour deposition of corrosion-resistant TiN film to the inner walls of long steel tubes. J. Mater. Sci. 1986, 21, 751–756. [Google Scholar] [CrossRef]

- Zhang, S. Material Development of Titanium Carbonitride-Based Cermets for Machining Application. Key Eng. Mater. 1998, 138, 521–544. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, S.; Yan, J.; Hu, X. Cutting performance of titanium carbonitride cermet tools. Int. J. Refract. Met. Hard. Mater. 2007, 25, 440–444. [Google Scholar] [CrossRef]

- Ibrahim, M.A.M.; Kooli, F.; Alamri, S.N. Electrodeposition and Characterization of Nickel–TiN Microcomposite Coatings. Int. J. Electrochem. Sci. 2013, 8, 12308–12320. [Google Scholar]

- Ramesh Bapu, G.N.K.; Jayakrishnan, S. Development and characterization of electro deposited Nickel–Titanium CarboNitride (TiCN) metal matrix nanocomposite deposits. Surf. Coat. Technol. 2012, 206, 2330–2336. [Google Scholar] [CrossRef]

- Stefanescu, D.M. Issues in liquid processing of particulate metal matrix composites. Key Eng. 1993, 79, 75–90. [Google Scholar] [CrossRef]

- Mazurnder, M.K.; Mountain, J.R. Fluidity and flow properties of fine powders. Particul. Sci. Technol. 1997, 15, 106. [Google Scholar] [CrossRef]

- Wicks, C.E.; Block, F.E. Thermodynamic Properties of 65 Elements-Their Oxides, Halides, Carbides, and Nitrides; United States Government Printing Office: Washington, DC, USA, 1963.

- Ting, J.M.; Lin, R.Y. Effect of particle-size distribution on sintering Part l Modelling. J. Mater. Sci. 1994, 29, 1867–1872. [Google Scholar] [CrossRef]

- Hacisalihoglu, I.; Samancioglu, A.; Yildiz, F.; Purcek, G.; Alsaran, A. Tribocorrosion properties of different type titanium alloys in simulated body fluid. Wear 2015, 332, 679–686. [Google Scholar] [CrossRef]

- Anand, T.J.S. Nickel as an alternative automotive body materials. J. Mech. Eng. 2012, 2, 187–197. [Google Scholar]

- Bartłomiej, J.; Leszek, K. Nitriding of titanium and Ti6Al4V alloy in ammonia gas under low pressure. Mater. Sci. Technol. 2010, 26, 586–590. [Google Scholar]

- Tamura, Y.; Yokoyama, A.; Watari, F.; Uo, M.; Kawasaki, T. Mechanical Properties of Surface Nitrided Titanium for Abrasion Resistant Implant Materials. Mater. Trans. 2002, 4, 3043–3051. [Google Scholar] [CrossRef]

- van Hove, R.P.; Sierevelt, I.N.; van Royen, B.J.; Nolte, P.A. Titanium-Nitride Coating of Orthopaedic Implants: A Review of the Literature. Biomed. Res. Int. 2015, 2015, 485975. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Zhang, L.C.; Mai, Y.W. Wear of ceramic particle-reinforced metal-matrix composites. J. Mater. Sci. 1995, 30, 1967–1971. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.-C.; Ou, S.-F. Effects of Reinforcement Ratios and Sintering Temperatures on the Mechanical Properties of Titanium Nitride/Nickel Composites. Materials 2020, 13, 4473. https://doi.org/10.3390/ma13204473

Chen Y-C, Ou S-F. Effects of Reinforcement Ratios and Sintering Temperatures on the Mechanical Properties of Titanium Nitride/Nickel Composites. Materials. 2020; 13(20):4473. https://doi.org/10.3390/ma13204473

Chicago/Turabian StyleChen, Yi-Cheng, and Shih-Fu Ou. 2020. "Effects of Reinforcement Ratios and Sintering Temperatures on the Mechanical Properties of Titanium Nitride/Nickel Composites" Materials 13, no. 20: 4473. https://doi.org/10.3390/ma13204473

APA StyleChen, Y.-C., & Ou, S.-F. (2020). Effects of Reinforcement Ratios and Sintering Temperatures on the Mechanical Properties of Titanium Nitride/Nickel Composites. Materials, 13(20), 4473. https://doi.org/10.3390/ma13204473