Modification of Ordinary Concrete Using Fly Ash from Combustion of Municipal Sewage Sludge

Abstract

:1. Introduction

2. Materials and Methods

2.1. Aim and Scope of the Experiment

2.2. Preparation of Concrete Specimens

- Concrete without admixtures—CON,

- Concrete mixed with fly ashes from combustion of municipal sewage sludge—FAMSS.

2.3. Test Methods for Fly Ash

2.4. Test Methods for Concrete Mixes and Concrete

3. Results and Discussion

3.1. Properties of Fly Ash and Concrete Mix

3.2. Physical Properties of Concrete Mix and Hardened Concrete

3.3. Mechanical Properties of Concrete

3.4. Leachability

4. Conclusions

- The addition of the analyzed fly ashes in amounts up to 25% by mass does not cause the deterioration of compressive strength of concrete in relation to reference concrete. The best strength parameters compared to the reference concrete were obtained for samples containing 10% to 20% FAMSS.

- The maturation time of the produced composites had a significant impact on the obtained results. The slow increase in the strength of concrete containing FAMSS could be caused by the presence of phosphorus delaying the cement hydration process.

- All concretes obtained the same class of C30/37 and higher C35/45 (FAMSS 20%) after 130 days of maturing, while the reference concrete (CON) and concretes with FAMSS in the amount of 10% (FAMSS 10%), 15% (FAMSS 15%) and 20% (FAMSS 20%) after 365 days of maturing achieved an even higher class of C35/45.

- The depth of water penetration under pressure for all samples was less than 30 mm, which met standard requirements.

- The pozzolanic activity of FAMSS did not meet the applicable requirements after 28 days (≥75%) and 90 days (≥85%) of curing. FAMSS reached the required values of pozzolanic activity (85%) after a longer period of curing, which allowed it to be classified as active mineral additives.

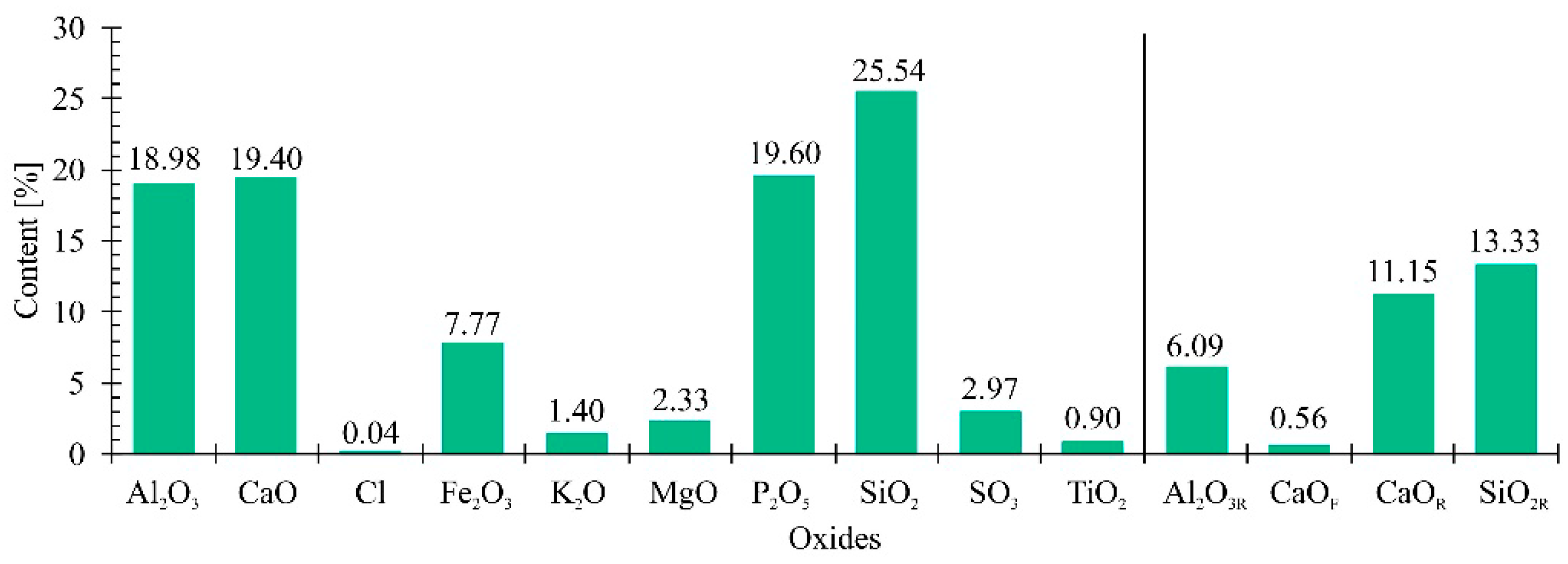

- Calcium, silica, phosphorus and aluminum oxide are the largest percentage of oxides in FAMSS samples. The sum of silica oxide, aluminum and iron oxides content does not meet the requirements contained in existing standards. However, there are no regulations regarding the physical and chemical properties of fly ashes from combustion of municipal sewage sludge.

- Based on the sum of heavy metals leached and the concentration of individual heavy metals concentration in the eluate it may be concluded that concrete containing FAMSS in the range of 5% to 25% is environmentally safe. However, studies of the physical and chemical properties of FAMSS have shown their variability in time. Therefore, further research on the impact of this variability on the technical parameters of concretes containing FAMSS seems necessary.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References and Notes

- Markiv, T.; Sobol, K.; Franus, M.; Franus, W. Mechanical and durability properties of concretes incorporating natural zeolite. Arch. Civ. Mech. Eng. 2016, 16, 554–562. [Google Scholar] [CrossRef]

- Topcu, I.B.; Saridemir, M. Prediction of compressive strength of concrete containing fly ash using artificial neural networks and fuzzy logic. Comput. Mater. Sci. 2008, 41, 305. [Google Scholar] [CrossRef]

- Uliasz-Bocheńczyk, A.; Deja, J. CCS technology for the cement industry. Sci. Works Inst. Ceram. Build. Mater. 2012, 11, 136–143. [Google Scholar]

- Statistics Poland. International Statistics Yearbook; GUS: Warsaw, Poland, 2015. [Google Scholar]

- IEA Greenhouse Gas R&D Programme (IEA GHG). CO2 Capture in the Cement Industry; Technical Report; IEA GHG: Cheltenham, UK, July 2008. [Google Scholar]

- The Statistics Portal for Market Data. Available online: https://www.statista.com (accessed on 23 September 2019).

- Statistics Poland. Statistical Yearbook of Industry 2018 —Poland; GUS: Warsaw, Poland, 2018. [Google Scholar]

- Statistics Poland. Statistical Yearbook of Industry 2002 —Poland; GUS: Warsaw, Poland, 2002. [Google Scholar]

- Cement Producers Association SPC. Available online: https://www.polskicement.pl/ (accessed on 5 July 2019).

- Deja, J.; Antosiak, B. Degree of progress of the fly ash reaction in alkali-activated fly-ash binders. Cem. Lime Concr. 2012, 2, 67–76. [Google Scholar]

- Dziuk, D.; Giergiczny, Z.; Garbacik, A. Calcareous fly ash as a main constituent of common cements. Roads Bridges 2013, 12, 57–69. [Google Scholar]

- Chen, Z.; Poon, C.S. Comparative studies on the effects of sewage sludge ash and fly ash on cement hydration and properties of cement mortars. Constr. Build. Mater. 2017, 154, 791–803. [Google Scholar] [CrossRef]

- Yadav, S.; Agnihotri, S.; Gupta, S.; Tripathi, R.K. Incorporation of STP Sludge and Fly ash in Brick Manufacturing: An attempt to save the Environment. Int. J. Adv. Res. Technol. 2014, 3, 138–144. [Google Scholar] [CrossRef]

- Wichowski, P.; Rutkowska, G.; Nowak, P. Elution of selected heavy metals from concretes containing ashes produced in thermal conversion of sludge. Acta Sci. Pol. Architectura 2017, 16, 43–51. [Google Scholar]

- Brunarski, L.; Dohojda, M. Approach of concrete compressive strength in situ. Bull. Pol. Acad. Technol. 2016, 64, 687–695. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Blanc, D.; Gautier, M.; Mehu, J.; Gourdon, R. Environmental and technical assessments of the potential utilization of sewage sludge ashes (SSAs) as secondary raw materials in construction. Waste Manag. 2013, 33, 1268–1275. [Google Scholar] [CrossRef]

- Fontes, C.M.A.; Barbosa, M.C.; Toledo Filho, R.D.; Goncalves, J.P. Potentiality of sewage sludge ash as mineral additive in cement mortar and high performance concrete. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona, Spain, 8–11 November 2004; pp. 797–806. [Google Scholar]

- Wang, L.S.G.; Hustad, J.E.; Gronil, M.G. Sintering characteristics of sewage sludge ashes at elevated temperatures. Fuel Process. Technol. 2012, 96, 88–97. [Google Scholar] [CrossRef]

- Weng, C.H.; Lind, F.; Chiang, P.C. Utilization of sludge as brick materials. Adv. Environ. Res. 2003, 7, 679–685. [Google Scholar] [CrossRef]

- Yenc, L.; Tseng, D.H.; Lin, T.T. Characterization of eco-cement paste produced from waste sludges. Chemosphere 2011, 84, 220–226. [Google Scholar]

- Gupta, S.M. Support vector machines based modelling of concrete strength. Eng. Technol. Word Acad. Sci. 2007, 36, 305–311. [Google Scholar]

- Kim, J.I.; Kim, D.K. Application of neural networks for estimation of concrete strength. KSCE J. Civ. Eng. 2002, 6, 429–438. [Google Scholar] [CrossRef] [Green Version]

- Lai, S.; Serra, M. Concrete strength prediction by means of neural network. Constr. Build. Mater. 1997, 11, 93–98. [Google Scholar] [CrossRef]

- Saridemir, M. Prediction of compressive strength of concretes containing metakaolin and silica fume by artificial neural networks. Adv. Eng. Softw. 2009, 40, 350–355. [Google Scholar] [CrossRef]

- EU/2014/955 Commission Decision of 18 December 2014 amending Decision 2000/532/EC on the list of waste pursuant to Directive 2008/98/EC of the European Parliament and of the Council. Off. J. 2014, L370, 44–86.

- Chen, Z.; Li, J.S.; Poon, C.S. Combined use of sewage sludge ash and recycled glass cullet for the production of concrete blocks. J. Clean. Prod. 2018, 171, 1447–1459. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S.; West, R.P. Sewage sludge ash characteristics and potential for use in concrete. Constr. Build. Mater. 2015, 98, 767–779. [Google Scholar] [CrossRef] [Green Version]

- Rutkowska, G.; Wichowski, P.; Fronczyk, J.; Franus, M.; Chalecki, M. Use of fly ashes from municipal sewage sludge combustion in production of ash concretes. Constr. Build. Mater. 2018, 188, 874–883. [Google Scholar] [CrossRef]

- Franus, M.; Józefaciuk, G.; Bandura, L.; Lamorski, K.; Hajnos, M.; Franus, W. Modification of Lightweight Aggregates’ Microstructure by Used Motor Oil Addition. Materials 2016, 9, 845. [Google Scholar] [CrossRef] [Green Version]

- Monzó, J.; Paya, J.; Borrachero, M.V.; Girbes, I. Reuse of sewage sludge ashes (SSA) in cement mixtures: The effect of SSA on the workability of cement mortars. Waste Manag. 2003, 23, 373–381. [Google Scholar] [CrossRef]

- Merino, J.; Arevalo, L.F.; Romero, F. Characterization and possible uses of ashes from wastewater treatment plants. Waste Manag. 2005, 25, 1046–1054. [Google Scholar] [CrossRef]

- Lopes, M.H.; Abelha, P.; Lapa, N.; Oliveira, J.S.; Cabrita, I.; Gulyurtlu, I. The behaviour of ashes and heavy metals during co-combustion of sewage sludges in a fluidized bed. Waste Manag. 2013, 23, 859–870. [Google Scholar] [CrossRef]

- Vouk, D.; Nakic, D.; Stirmer, N.; Malus, D. Possibilities for recycling of sewage sludge. In Proceedings of the 14th International Symposium Water Management and Hydraulic Engineering, Brno, Czech Republic, 8–10 September 2015; pp. 219–228. [Google Scholar]

- Perez-Carrion, M.; Baeza-Brotons, F.; Paya, J.; Saval, J.M.; Zornoza, E.; Borrachero, M.V.; Garces, P. Potential use of sewage sludge ash (SSA) as a cement replacement in precast concrete blocks. Mater. Construcc. 2014, 64, 313. [Google Scholar] [CrossRef] [Green Version]

- Baeza-Brotons, F.; Garces, P.; Paya, J.; Saval, J.M. Portland cement systems with addition of sewage sludge ash. Application in concretes for the manufacture of blocks. J. Clean. Prod. 2014, 82, 112–124. [Google Scholar] [CrossRef] [Green Version]

- Monzo, J.; Paya, J.; Borrachero, M.V.; Bellver, A.; Peris-Mora, E. Study of cement-based mortars containing spanish ground sewage sludge ash. Stud. Environ. Sci. 1997, 71, 349–354. [Google Scholar]

- Pan, S.C.; Tseng, D.H.; Lee, C.C.; Lee, C. Influence of the fineness of sewage sludge ash on the mortar properties. Waste Manag. 2003, 33, 1749–1754. [Google Scholar] [CrossRef]

- Donatello, S.; Tyrer, M.; Cheeseman, C.R. EU landfill acceptance criteria and EU Hazardous Waste Directive compliance testing of incinerated sewage sludge ash. Waste Manag. 2010, 30, 63–71. [Google Scholar] [CrossRef]

- Cyr, M.; Coutand, M.; Clastres, P. Technological and environmental behaviour of sewage sludge ash (SSA) in cement-based materials. Cem. Concr. Res. 2007, 37, 1278–1289. [Google Scholar] [CrossRef]

- Monzó, J.; Paya, J.; Borrachero, M.V.; Peris-Mora, E. Mechanical behaviour of mortars containing sewage sludge ash (SSA) and Portland cements with different tricalcium aluminate content. Cem. Concr. Res. 1999, 29, 87–94. [Google Scholar] [CrossRef]

- Vouk, D.; Nakic, D.; Stirmer, N. Reuse of sewage sludge—Problems and possibilities. In Proceedings of the International Conference IWWATV 2015, Athens, Greece, 21–23 May 2015; Available online: http://iwwatv.uest.gr/proceedings/pdf/Vouk_et_al.pd (accessed on 28 August 2019).

- Donatello, S.; Cheeseman, C.R. Recycling and recovery routes for incinerated sewage sludge ash (SSA): A review. Waste Manag. 2013, 33, 2328–2340. [Google Scholar] [CrossRef] [PubMed]

- EN 206+A1:2016–12 Concrete. Part 1. Requirements, Properties, Manufacturing and Conformity.

- Jamroży, Z. Concrete and Its Technologirs, 3rd ed.; PWN: Warsaw, Poland, 2015. (In Polish) [Google Scholar]

- A CRH Company, Karsy 77, 27-530 Ożarów, Poland. Unpublished data from the cement producer.

- EN 450-1: 2012 Fly-ashes for concrete. Part1: Definitions, specifications and conformity criteria.

- ASTM C379-65T—Specification for fly ash for use as a pozzolanic material with lime.

- Hubbard, F.H.; Dhir, R.K. A compositional index of the pozzolanic potential of pulverized-fuel ash. J. Mater. Sci. 1984, 3, 958–960. [Google Scholar] [CrossRef]

- EN 12350-2: 2011 Testing of fresh concrete. Part 2: Slump test.

- EN 12350-6: 2011 Testing of fresh concrete. Part 6: Density.

- EN 12350-7: 2011 Testing of fresh concrete. Part 7: Air content - pressure method.

- EN 12390-3: 2011 Testing of hardened concrete. Part 3. Compressive strength of test specimens.

- EN ISO/IEC 17025:20018-02. General requirements for the competence of testing and calibration laboratories.

- EN 12390-8: 2019-08 Testing concrete. Part 8: Depth of water penetration under pressure.

- EN 12457-2: 2006. Characterization of waste. Leaching—Compliance test for leaching of granular waste materials and sludges. Part 2: One stage batch test at a liquid to solid ratio of 10 l/kg for materials with particle size below 4 mm (without or with size reduction).

- Tarko, B.; Gorazda, K.; Wzorek, Z.; Nowak, A.K.; Kowalski, Z.; Kulczycka, J.; Henclik, A. Recovery of phosphorus from industrial sewage sludge ashes. Chem. Ind. 2014, 93, 1041–1044. [Google Scholar]

- Rutkowska, G.; Świgoń, K. How are parameters of an ordinary concrete affected by ashes generated in thermal treatment of wastewater sediments and used as a substitute of a part of the cement. Acta Sci. Pol. Architectura 2019, 18, 47–57. (In Polish) [Google Scholar]

- Rutkowska, G. Concrete Modified by Fly-Ashes from Thermal Conversion of Sewage Sludge; SGGW: Warsaw, Poland, 2019. (In Polish) [Google Scholar]

- Ferreira, C.; Ribeiro, A.; Ottosen, L. Possible applications for municipal solid waste fly ash. J. Hazard. Mater. 2003, 96, 201–216. [Google Scholar] [CrossRef]

- Tkaczewska, E.; Małolepszy, J. Hydration of coal-biomass fly ash cement. Constr. Build. Mater. 2009, 3, 2694–2700. [Google Scholar] [CrossRef]

- Rutkowska, G.; Wichowski, P.; Świgoń, K.; Sobieski, P. Properties of concrete with fly ash addition from sewage sludge thermal treatment. Cem. Lime Concr. 2017, 2, 113–119. (In Polish) [Google Scholar]

- Yusuf, R.O.; Noor, Z.Z.; Din, M.D.F.M.D.; Abba, A.H. Use of sewage sludge ash (SSA) in the production of cement and concrete-a review. Int. J. Glob. Environ. Issues 2012, 12, 214–228. [Google Scholar] [CrossRef]

- Lin, K.L.; Lin, C.Y. Hydration characteristics of waste sludge ash utilized as raw cement material. Cem. Concr. Res. 2005, 35, 1999–2007. [Google Scholar] [CrossRef]

- Chang, F.; Lin, J.; Tsail, C.; Wang, K. Study on cement mortar and concrete made with sewage sludge ash. Water Sci. Technol. 2010, 62, 1689–1693. [Google Scholar] [CrossRef] [PubMed]

- Jiao, F.; Zhang, L.; Dong, Z.; Namioka, T.; Yamada, N.; Ninomiya, Y. Study on the species of heavy metals in MSW incineration fly ash and their leaching behavior. Fuel Process. Technol. 2016, 152, 108–115. [Google Scholar] [CrossRef]

| Fraction | Fraction Mixing Percentage Ratio (for Sand and Gravel) | Grain Composition | |||

|---|---|---|---|---|---|

| I stage | II stage | III stage | Sand | Gravel | |

| 0.0–0.125 | - | 39 | 1.44 | 0.56 | |

| 0.0125–0.25 | 16.23 | 6.33 | |||

| 0.025–0.50 | 30.46 | 11.88 | |||

| 0.50–1.0 | 28.54 | 11.13 | |||

| 1.0–2.0 | 23.33 | 9.10 | |||

| 2.0–4.0 | - | 34 | 61 | - | 20.74 |

| 4.0–8.0 | 46 | 66 | - | 18.52 | |

| 8.0–16.0 | 54 | - | 21.74 | ||

| Specification | Mass of Concrete Ingredients (kg/m3) | |||

|---|---|---|---|---|

| Water | Aggregate | Cement | Fly Ash | |

| CON | 167.23 | 1885.18 | 376.27 | 0 |

| FAMSS 5% | 167.23 | 1885.18 | 357.46 | 18.81 |

| FAMSS 10% | 167.23 | 1885.18 | 338.64 | 37.63 |

| FAMSS 15% | 167.23 | 1885.18 | 319.83 | 56.44 |

| FAMSS 20% | 167.23 | 1885.18 | 301.02 | 75.25 |

| FAMSS 25% | 167.23 | 1885.18 | 282.20 | 94.07 |

| Component (unit) | Content | Content of CEM I Mineral Phases (mass%) |

|---|---|---|

| Loss in ignition (%) | 3.18 | C3S—61.8 |

| Sulphate content SO3 (%) | 3.20 | C2S—12.3 |

| Chloride content Cl (%) | 0.05 | C3A—7.5 |

| Alkali content as Na2Oeq (%) | 0.71 | C4AF—4.0 |

| ||

| Physical Parameters of Cement | Unit | Average Values |

|---|---|---|

| Specific surface area according to Blaine | (cm2/g) | 3330 |

| Start of setting time | (min) | 218 |

| Compressive strength after 2 days | (MPa) | 21.0 |

| Compressive strength after 28 days | (MPa) | 49.8 |

| Type of Concrete | Consistency (mm) | Air content (%) | Density (kg/m3) |

|---|---|---|---|

| CON | 90 (S2) | 3.1 | 2387 |

| FAMSS 5% | 39 (S1) | 2.8 | 2362 |

| FAMSS 10% | 67(S2) | 3.3 | 2353 |

| FAMSS 15% | 58 (S2) | 3.8 | 2338 |

| FAMSS 20% | 34 (S1) | 4.1 | 2327 |

| FAMSS 25% | 27 (S1) | 4.6 | 2319 |

| Type of Concrete | Period of Curing (days) | fcm 1 (MPa) | fc min 2 (MPa) | fc max 3 (MPa) | S 4 (MPa) | V 5 (-) | Up 6 0.95 (MPa) | Concrete Class Obtained |

|---|---|---|---|---|---|---|---|---|

| CON | 2 | 21.92 | 20.59 | 23.44 | 1.37 | 0.06 | 2.16 | C12/15 |

| 7 | 37.82 | 36.42 | 39.12 | 1.51 | 0.04 | 2.57 | C25/30 | |

| 28 | 41.36 | 40.62 | 42.16 | 0.42 | 0.01 | 1.52 | C25/30 | |

| 56 | 43.06 | 41.68 | 43.94 | 0.93 | 0.02 | 1.99 | C30/37 | |

| 90 | 44.88 | 43.40 | 45.97 | 1.27 | 0.03 | 2.40 | C30/37 | |

| 130 | 46.60 | 45.75 | 47.82 | 0.83 | 0.02 | 1.99 | C30/37 | |

| 365 | 52.72 | 51.52 | 53.94 | 1.01 | 0.02 | 2.31 | C35/45 | |

| FAMSS 5% | 2 | 19.01 | 17.36 | 20.46 | 1.97 | 0.10 | 2.99 | C12/15 |

| 7 | 26.52 | 25.01 | 27.98 | 1.49 | 0.06 | 2.39 | C16/20 | |

| 28 | 35.61 | 33.47 | 37.45 | 2.67 | 0.08 | 4.14 | C25/30 | |

| 56 | 37.74 | 36.12 | 40.37 | 1.45 | 0.04 | 3.73 | C25/30 | |

| 90 | 39.62 | 38.10 | 41.73 | 2.35 | 0.06 | 3.73 | C25/30 | |

| 130 | 41.24 | 40.12 | 42.67 | 1.49 | 0.04 | 2.61 | C30/37 | |

| 365 | 44.58 | 42.77 | 46.12 | 2.43 | 0.05 | 3.89 | C30/37 | |

| FAMSS 10% | 2 | 20.21 | 18.07 | 21.74 | 2.43 | 0.12 | 3.66 | C12/15 |

| 7 | 34.52 | 33.10 | 35.49 | 1.02 | 0.02 | 1.90 | C25/30 | |

| 28 | 37.84 | 36.54 | 39.12 | 1.28 | 0.03 | 2.29 | C25/30 | |

| 56 | 44.62 | 43.62 | 45.63 | 0.75 | 0.02 | 1.86 | C30/37 | |

| 90 | 46.46 | 45.10 | 47.94 | 1.36 | 0.03 | 2.55 | C30/37 | |

| 130 | 47.56 | 46.36 | 48.74 | 1.04 | 0.02 | 2.21 | C30/37 | |

| 365 | 51.12 | 49.86 | 52.33 | 1.12 | 0.02 | 2.38 | C35/45 | |

| FAMSS 15% | 2 | 21.66 | 20.86 | 22.98 | 0.84 | 0.04 | 1.44 | C12/15 |

| 7 | 30.66 | 29.79 | 31.24 | 1.30 | 0.04 | 2.19 | C20/25 | |

| 28 | 41.11 | 40.06 | 42.18 | 0.78 | 0.02 | 1.72 | C30/37 | |

| 56 | 45.96 | 43.93 | 47.85 | 2.89 | 0.06 | 4.55 | C30/37 | |

| 90 | 47.48 | 46.10 | 49.54 | 2.10 | 0.04 | 3.50 | C30/37 | |

| 130 | 48.85 | 46.46 | 50.62 | 3.10 | 0.06 | 4.88 | C30/37 | |

| 365 | 52.61 | 50.98 | 53.42 | 1.24 | 0.02 | 2.54 | C35/45 | |

| FAMSS 20% | 2 | 23.22 | 21.80 | 24.50 | 1.62 | 0.07 | 2.52 | C12/15 |

| 7 | 32.16 | 31.05 | 33.40 | 1.38 | 0.04 | 2.32 | C20/25 | |

| 28 | 42.58 | 41.47 | 44.70 | 2.15 | 0.05 | 3.49 | C30/37 | |

| 56 | 46.73 | 45.42 | 48.36 | 1.48 | 0.03 | 2.69 | C30/37 | |

| 90 | 48.43 | 47.00 | 49.90 | 1.54 | 0.03 | 2.79 | C30/37 | |

| 130 | 49.94 | 48.82 | 51.74 | 1.59 | 0.03 | 2.88 | C35/45 | |

| 365 | 53.64 | 52.33 | 54.85 | 1.55 | 0.03 | 2.91 | C35/45 | |

| FAMSS 25% | 2 | 20.65 | 19.10 | 21.79 | 1.22 | 0.06 | 1.93 | C12/15 |

| 7 | 29.40 | 28.15 | 31.22 | 1.88 | 0.06 | 2.95 | C20/25 | |

| 28 | 39.16 | 37.85 | 41.45 | 2.53 | 0.06 | 3.98 | C25/30 | |

| 56 | 42.83 | 41.23 | 44.00 | 1.42 | 0.03 | 2.54 | C30/37 | |

| 90 | 43.21 | 42.00 | 44.65 | 1.17 | 0.03 | 2.26 | C30/37 | |

| 130 | 44.70 | 43.46 | 45.98 | 1.09 | 0.02 | 2.10 | C30/37 | |

| 365 | 46.40 | 45.25 | 47.95 | 1.53 | 0.03 | 2.74 | C30/37 |

| Type of Concrete | Mass of Concrete Ingredients (kg/m3) | CO2 Emission (kg/m3) | Reduction in CO2 Emission (kg/m3) | |

|---|---|---|---|---|

| Cement | Fly Ash | |||

| CON | 376.27 | 0 | 303.65 | |

| FAMSS 5% | 357.46 | 18.81 | 288.47 | 15.18 |

| FAMSS 10% | 338.64 | 37.63 | 273.28 | 30.37 |

| FAMSS 15% | 319.83 | 56.44 | 258.10 | 45.55 |

| FAMSS 20% | 301.02 | 75.25 | 242.92 | 60.73 |

| FAMSS 25% | 282.20 | 94.07 | 227.74 | 75.91 |

| Compressive Strength After | SS Effect | df Effect | MS Effect | SS Error | df Error | MS Error | F | p |

|---|---|---|---|---|---|---|---|---|

| 2 days | 65.69 | 5 | 13.14 | 39.13 | 30 | 1.30 | 10.07 | 0.000 |

| 7 days | 471.92 | 5 | 94.38 | 34.84 | 30 | 1.16 | 81.27 | 0.000 |

| 28 days | 200.81 | 5 | 40.16 | 39.13 | 30 | 1.30 | 30.79 | 0.000 |

| 56 days | 309.35 | 5 | 61.87 | 43.40 | 30 | 1.45 | 42.77 | 0.000 |

| 90 days | 313.25 | 5 | 62.65 | 38.88 | 30 | 1.30 | 48.34 | 0.000 |

| 130 days | 296.37 | 5 | 59.27 | 38.94 | 30 | 1.30 | 45.66 | 0.000 |

| 365 days | 417.74 | 5 | 83.55 | 39.52 | 30 | 1.32 | 63.43 | 0.000 |

| Parameter | Type of Concrete | |||||

|---|---|---|---|---|---|---|

| CON | FAMSS 5% | FAMSS 10% | FAMSS 15% | FAMSS 20% | FAMSS 25% | |

| Depth of water penetration (mm) | 25.2 | 20.7 | 19.6 | 15.8 | 13.8 | 12.6 |

| Standard deviation (mm) | 1.7 | 1.92 | 1.97 | 1.80 | 1.57 | 1.04 |

| Coefficient of variation (-) | 0.07 | 0.09 | 0.10 | 0.11 | 0.11 | 0.08 |

| Type of Concrete | Fraction (mm) | pH | EC (mS/cm) | Color (mgPt) | Turbidity (NTU) | PO4 (mg/L) | SO4 (mg/L) | Cl (mg/L) |

|---|---|---|---|---|---|---|---|---|

| CON | <0.63 | 12.30 ± 0.08 | 8.43 ± 0.23 | 24 ± 15.5 | 4.02 ± 0.42 | 0.10 ± 0.00 | nd | 17.7 ± 1.4 |

| 0.63–6.3 | 12.26 ± 0.11 | 7.55 ± 0.46 | 22 ± 11.3 | 3.55 ± 0.17 | 0.05 ± 0.07 | nd | 14.9 ± 1.2 | |

| FAMSS 5% | <0.63 | 12.28 ± 0.03 | 9.17 ± 0.11 | 23.5 ± 4.5 | 2.87 ± 0.96 | 0.10 ± 0.14 | nd | 34.0 ± 2.0 |

| 0.63–6.3 | 12.27 ± 0.04 | 7.13 ± 0.76 | 20.5 ± 0.7 | 2.05 ± 0.10 | 0.10 ± 0.14 | nd | 32.6 ± 1.7 | |

| FAMSS 10% | <0.63 | 12.32 ± 0.05 | 8.05 ± 0.39 | 32 ± 2.8 | 3.95 ± 2.34 | 0.30 ± 0.07 | nd | 32.6 ± 1.5 |

| 0.63–6.3 | 12.24 ± 0.03 | 7.63 ± 0.55 | 24.5 ± 2.1 | 6.68 ± 5.69 | 0.20 ± 0.00 | nd | 29.8 ± 1.7 | |

| FAMSS 15% | <0.63 | 12.22 ± 0.04 | 8.82 ± 0.16 | 25.5 ± 13.4 | 3.99 ± 3.13 | 0.30 ± 0.07 | nd | 26.9 ± 1.3 |

| 0.63–6.3 | 12.13 ± 0.04 | 7.56 ± 0.12 | 25.5 ± 16.2 | 3.98 ± 2.77 | 0.15 ± 0.07 | nd | 25.8 ± 1.5 | |

| FAMSS 20% | <0.63 | 12.10 ± 0.03 | 3.16 ± 0.12 | 22 ± 5.7 | 3.05 ± 1.07 | 0.25 ± 0.07 | nd | 19.9 ± 1.3 |

| 0.63–6.3 | 12.01 ± 0.05 | 3.54 ± 0.02 | 24.5 ± 3.5 | 3.86 ± 1.78 | 0.20 ± 0.07 | 1 ± 0.97 | 15.6 ± 1.4 | |

| FAMSS 25% | <0.63 | 11.99 ± 0.04 | 3.69 ± 0.62 | 27 ± 8.5 | 6.35 ± 5.42 | 0.35 ± 0.21 | nd | 21.3 ± 1.1 |

| 0.63–6.3 | 11.91 ± 0.04 | 3.15 ± 0.84 | 40.5 ± 9.2 | 9.38 ± 1.26 | 0.5 ± 0.14 | 10 ± 1.2 | 18.4 ± 1.2 |

| Sample | Heavy Metals (m/L) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| As | Ba | Cd | Cr | Cu | Ni | Pb | Se | Zn | ΣHM | |

| CON | ||||||||||

| <0.63 | <0.010 | 0,447 | <0.002 | <0.010 | 0.043 | <0.005 | <0.003 | <0.010 | <0.030 | <0.086 |

| 0.63–6.3 | <0.010 | 0,371 | <0.002 | <0.010 | 0.040 | <0.005 | <0.003 | <0.010 | <0.030 | <0.083 |

| FAMSS 5% | ||||||||||

| <0.63 | <0.010 | 0,601 | <0.002 | 0.038 | 0.048 | <0.005 | <0.003 | <0.010 | <0.030 | <0.119 |

| 0.63–6.3 | <0.010 | 0,363 | <0.002 | 0.034 | 0.033 | <0.005 | <0.003 | <0.010 | <0.030 | <0.100 |

| FAMSS 10% | ||||||||||

| <0.63 | <0.010 | 0,659 | <0.002 | 0.038 | 0.046 | <0.005 | <0.003 | <0.010 | <0.030 | <0.117 |

| 0.63–6.3 | <0.010 | 0,421 | <0.002 | 0.036 | 0.032 | <0.005 | <0.003 | <0.010 | <0.030 | <0.101 |

| FAMSS 15% | ||||||||||

| <0.63 | <0.010 | 0,660 | <0.002 | 0.039 | 0.035 | <0.005 | <0.003 | <0.010 | <0.030 | <0.107 |

| 0.63–6.3 | <0.010 | 0,507 | <0.002 | 0.033 | 0.036 | <0.005 | <0.003 | <0.010 | <0.030 | <0.102 |

| FAMSS 20% | ||||||||||

| <0.63 | <0.010 | 1.37 | <0.002 | <0.010 | 0.027 | <0.005 | <0.003 | <0.010 | <0.030 | <1.440 |

| 0.63–6.3 | <0.010 | 0.421 | <0.002 | <0.010 | 0.019 | <0.005 | <0.003 | <0.010 | 0.044 | <0.524 |

| FAMSS 25% | ||||||||||

| <0.63 | <0.010 | 1.44 | <0.002 | <0.010 | 0.029 | <0.005 | <0.003 | <0.010 | <0.030 | <1.512 |

| 0.63–6.3 | <0.010 | 0.146 | <0.002 | <0.010 | 0.011 | <0.005 | <0.003 | <0.010 | <0.030 | <0.200 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rutkowska, G.; Wichowski, P.; Franus, M.; Mendryk, M.; Fronczyk, J. Modification of Ordinary Concrete Using Fly Ash from Combustion of Municipal Sewage Sludge. Materials 2020, 13, 487. https://doi.org/10.3390/ma13020487

Rutkowska G, Wichowski P, Franus M, Mendryk M, Fronczyk J. Modification of Ordinary Concrete Using Fly Ash from Combustion of Municipal Sewage Sludge. Materials. 2020; 13(2):487. https://doi.org/10.3390/ma13020487

Chicago/Turabian StyleRutkowska, Gabriela, Piotr Wichowski, Małgorzata Franus, Michał Mendryk, and Joanna Fronczyk. 2020. "Modification of Ordinary Concrete Using Fly Ash from Combustion of Municipal Sewage Sludge" Materials 13, no. 2: 487. https://doi.org/10.3390/ma13020487

APA StyleRutkowska, G., Wichowski, P., Franus, M., Mendryk, M., & Fronczyk, J. (2020). Modification of Ordinary Concrete Using Fly Ash from Combustion of Municipal Sewage Sludge. Materials, 13(2), 487. https://doi.org/10.3390/ma13020487