Experimental Study on the Phase Transition Characteristics of Asphalt Mixture for Stress Absorbing Membrane Interlayer

Abstract

1. Introduction

2. Materials and Methods

2.1. Asphalt Binder

2.2. Asphalt Mixture

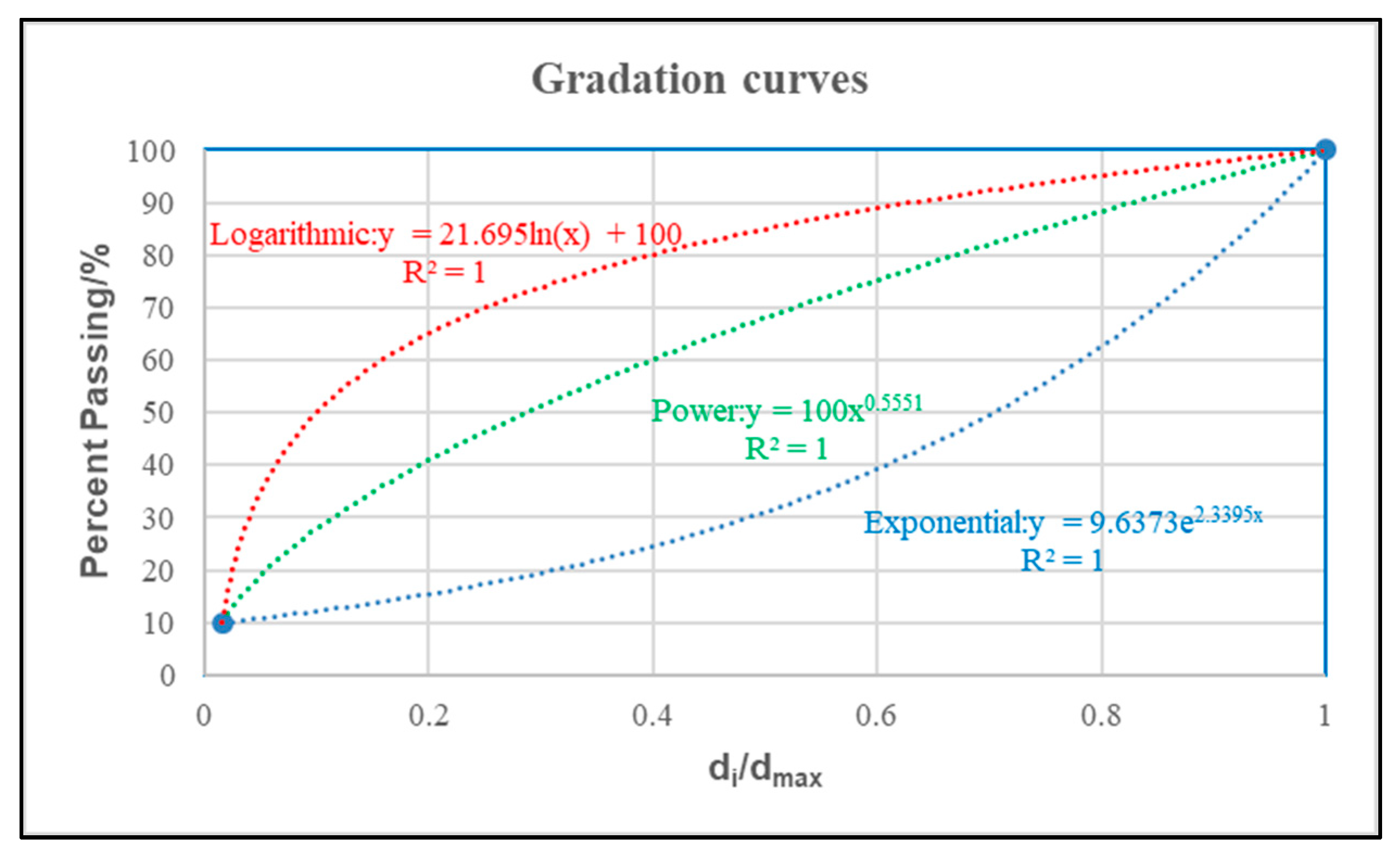

2.2.1. Gradation

2.2.2. Asphalt Content

2.3. Experimental Program

2.3.1. Specimen Preparation

2.3.2. Experimental Device

2.3.3. Test Method

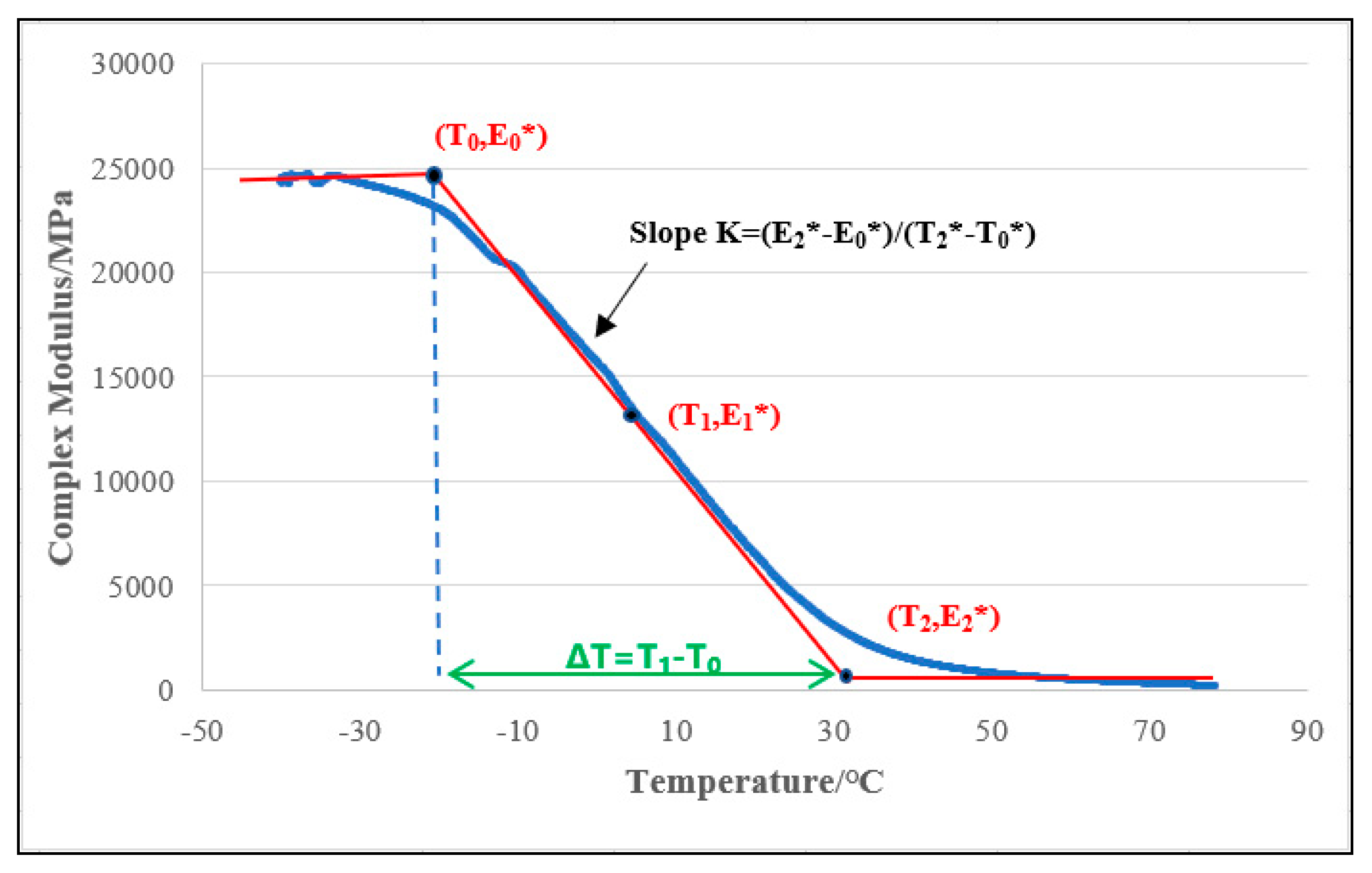

2.3.4. Parameter Acquisition

3. Results

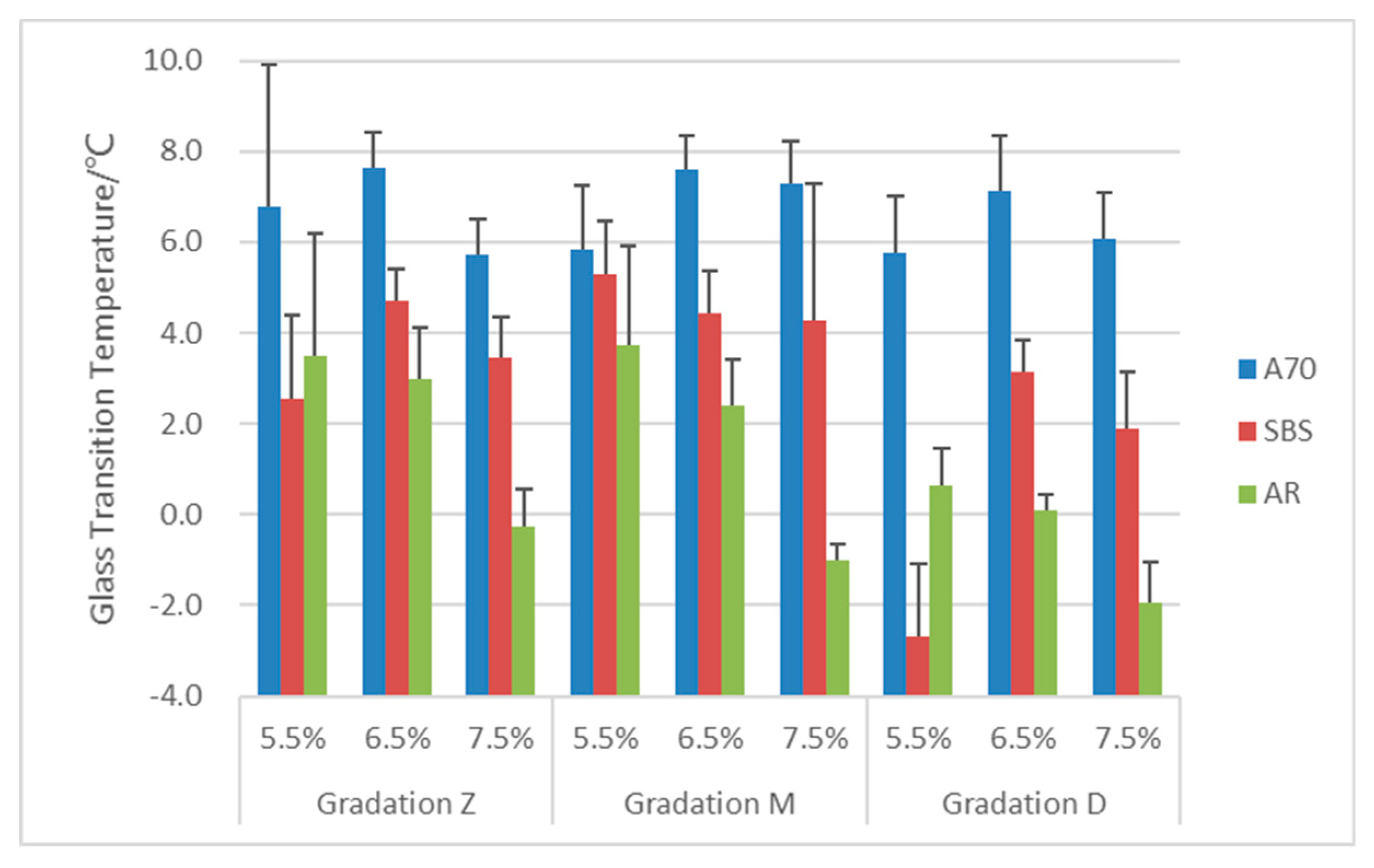

3.1. Glass Transition Temperature Tg

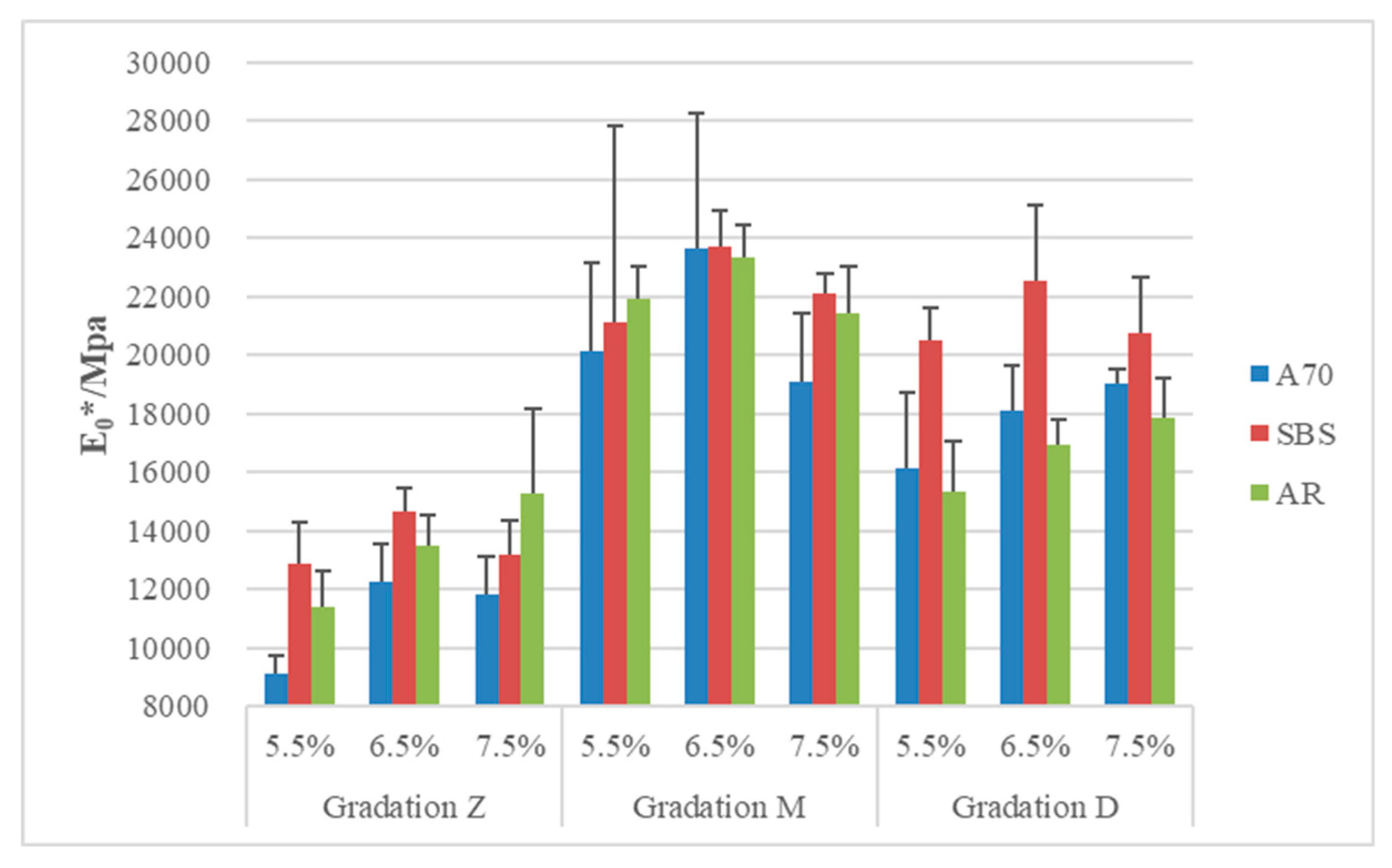

3.2. Stiffness at Extreme Low Temperature E0*

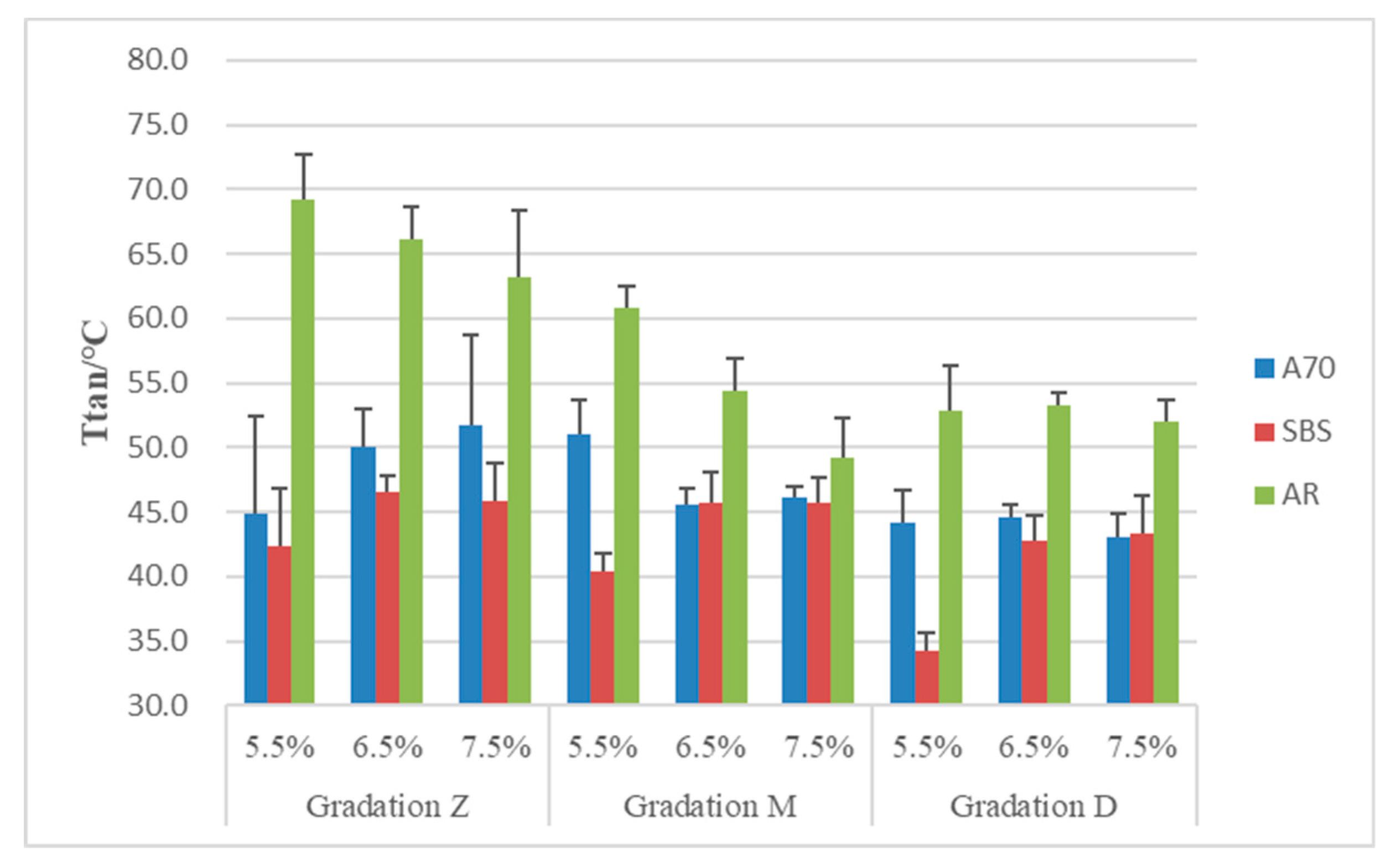

3.3. High-Temperature Properties Ttan

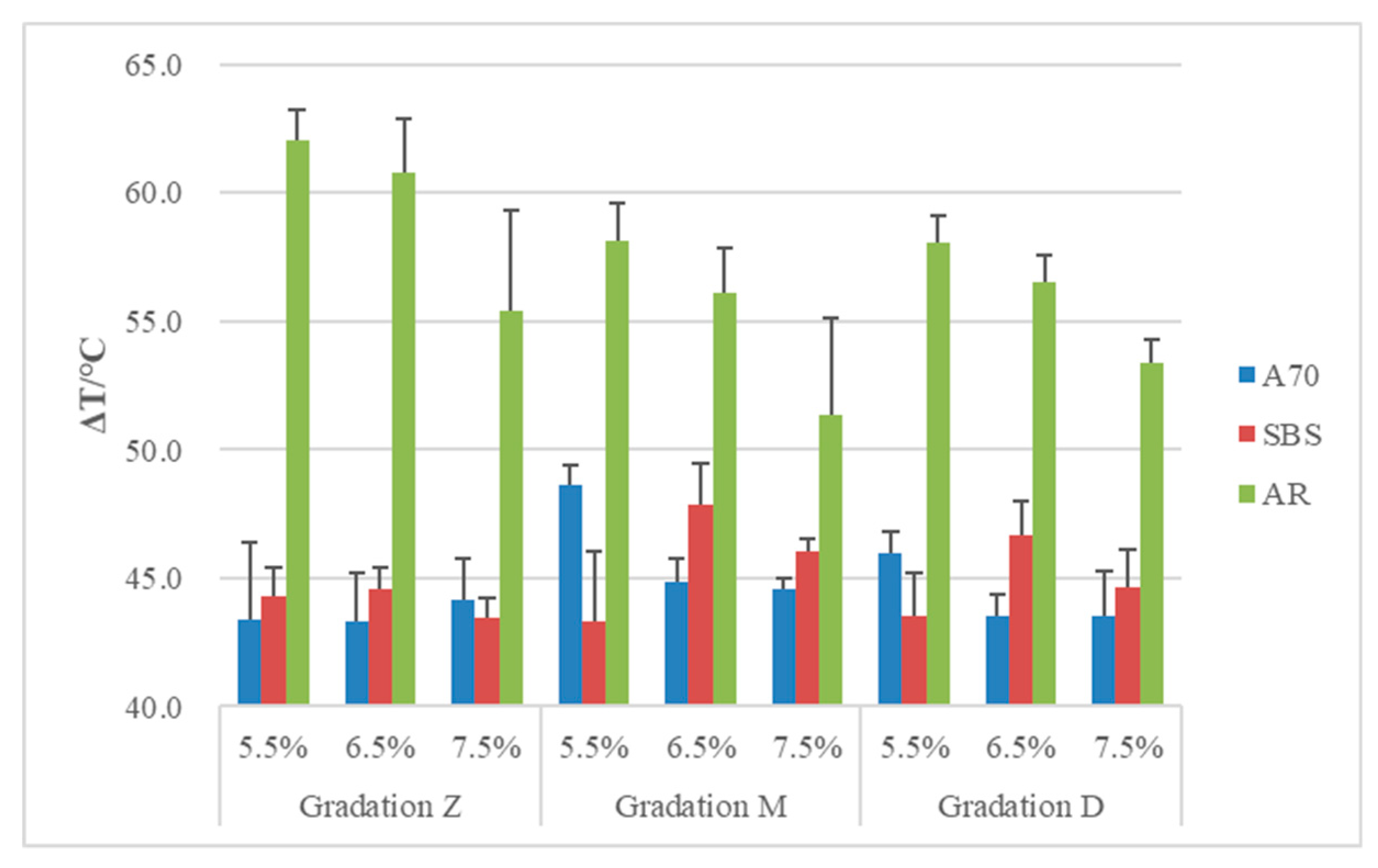

3.4. Range of Effective Function Temperature ΔT

3.5. Temperature Sensitivity K Value

4. Conclusions

- (1)

- By measuring the glass transition temperature Tg, it can be concluded that crumb rubber modified asphalt mixtures AR with finer gradation D and higher asphalt content have a better low-temperature performance. Asphalt type has the largest impact on the Tg, which shows that asphalt plays a key role in low-temperature properties.

- (2)

- For stiffness at extreme low temperature, values of E0* among different asphalt types are similar. The gradation type plays a major role for E0* and mixtures with gradation M are larger than the others. Stiffness of mixtures with gradation Z is very low due to its higher air void and it is detrimental to waterproofness. AR asphalt mixtures with gradation D has a relative lower stiffness and it is beneficial to the low-temperature performance.

- (3)

- According to phase transition characterization, Ttan (temperature at peak of tanδ) can be used to evaluate the high-temperature performance of asphalt mixtures. Coarser gradation has a good effect on the high-temperature performance. Mixtures with AR asphalt have an obvious higher Ttan and they have a better high-temperature stability.

- (4)

- Range of effective function temperature ΔT can be used to describe the range of temperatures where asphalt mixtures can stay in a high-elastic state and work well. Slope K value can be used to evaluate the sensitivity of stiffness to temperature changes. Results show that AR asphalt mixtures have a wider ΔT and a lower K, which indicates that they are less sensitive to various temperatures. Besides, mixtures with more asphalt content and finer gradation are more sensitive to temperature changes.

- (5)

- Considering the comprehensive evaluation of various indicators, AR asphalt mixtures are more suitable materials to be applied in SAMI. An optimum gradation type and asphalt content can be determined from the actual environmental condition and application requirement.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barksdale, R.D. Fabrics in asphalt overlay and pavement maintenance. In National Cooperative Highway Research Program Synthesis of Highway Practice 171; Transportation Research Board: Washington, DC, USA, 1991; pp. 7–9. [Google Scholar]

- Molenaar, A.A.A.; Heerkens, J.C.P.; Verhoeven, J.H.M. Effects of Stress Absorbing Membrane Interlayers; Association of Asphalt Paving Technologists: St. Paul, MN, USA, 1986; Volume 55, pp. 453–481. [Google Scholar]

- Ogundipe, O.; Thom, N.; Collop, A. Evaluation of performance of stress-absorbing membrane interlayer (SAMI) using accelerated pavement testing. Int. J. Pavement Eng. 2013, 14, 569–578. [Google Scholar] [CrossRef]

- Tang, W.; Sheng, X.; Sun, L. Research on Asphalt Mixture Performance of Stress Absorbing Membrane Interlayer (SAMI). J. Build. Mater. 2009, 12, 173–176. [Google Scholar]

- Wu, K. Study on Design and Performance of Stress Absorbing Membrane Interlayer (SAMI) Mixture. J. Highw. Transp. Res. Dev. 2006, 23, 18–20. [Google Scholar]

- Kim, H.; Wagoner, M.P.; Buttlar, W.G. Micromechanical fracture modeling of asphalt concrete using a single-edge notched beam test. Mater. Struct. 2008, 42, 677–689. [Google Scholar] [CrossRef]

- Bahia, H.U.; Hislop, W.P.; Zhai, H.; Rangel, A. Classification of asphalt binders into simple and complex binders. J. Assoc. Asphalt Paving Technol. 1998, 67, 1–41. [Google Scholar]

- Salas, M.Á.; Pérez-Acebo, H.; Calderó, V.; Gonzalo-Orden, H. Bitumen modified with recycled polyurethane foam for employment in hot mix asphalt. Ing. Investig. 2018, 38, 60–66. [Google Scholar] [CrossRef]

- García-Morales, M.; Partal, P.; Navarro, F.J.; Martínez-Boza, F.; Gallegos, C.; González, N.; González, O.; Munoz, M. Viscous properties and microstructure of recycled eva modified bitumen. Fuel 2004, 83, 31–38. [Google Scholar] [CrossRef]

- Wang, K.; Yuan, Y.; Han, S.; Yang, Y. Application of FTIR spectroscopy with solvent-cast film and PLS regression for the quantification of SBS content in modified asphalt. Int. J. Pavement Eng. 2019, 20, 1336–1341. [Google Scholar] [CrossRef]

- Bahia, H.U.; Hanson, D.I.; Zeng, M.; Zhai, H.; Khatri, M.A.; Anderson, R.M. Characterization of Modified Asphalt Binders in Superpave Mix Design; Transportation Research Board: Washington, DC, USA, 2001; pp. 32–37. [Google Scholar]

- Fu, Q.; Xie, Y.; Long, G.; Niu, D.; Song, H. Dynamic Mechanical Thermo-analysis of Cement and Asphalt Mortar. Powder Technol. 2017, 313, 36–43. [Google Scholar] [CrossRef]

- Yuan, Q.; Liu, W.; Pan, Y.; Deng, D.; Liu, Z. Characterization of Cement Asphalt Mortar for Slab Track by Dynamic Mechanical Thermoanalysis. J. Mater. Civ. Eng. 2016, 28, 04015154. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. Technical Specification for Construction of Highway Asphalt Pavement JTG F40-2004; China Communication Press: Beijing, China, 2004; pp. 12–14.

- Wang, X. Multi-Performance Design of Hot Mix Asphalt Based on Stone Interlock Structure Theory; China Communication Press: Beijing, China, 2014; pp. 338–353. [Google Scholar]

- Hevin, P.M. Dynamic Mechanical Analysis—A Practical Introduction, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008; pp. 1–4. [Google Scholar]

- Hesami, E.; Ghafar, A.N.; Birgisson, B.; Kringos, N. Multi-scale Characterization of Asphalt Mastic Rheology; Springer Science and Business Media LLC: Berlin, Geramny, 2013; pp. 45–61. [Google Scholar]

- Soliman, H.; Shalaby, A. Characterizing the Low-Temperature Performance of Hot-Pour Bituminous Sealants Using Glass Transition Temperature and Dynamic Stiffness Modulus. J. Mater. Civ. Eng. 2009, 21, 688–693. [Google Scholar] [CrossRef]

- Kang, Y.; Song, M.; Pu, L.; Liu, T. Rheological behaviors of epoxy asphalt binder in comparison of base asphalt binder and SBS modified asphalt binder. Constr. Build. Mater. 2015, 76, 343–350. [Google Scholar] [CrossRef]

- Fang, L.; Yuan, Q.; Deng, D.; Pan, Y.; Wang, Y. Effect of Mix Parameters on the Dynamic Mechanical Properties of Cement Asphalt Mortar. J. Mater. Civ. Eng. 2017, 29, 04017080. [Google Scholar] [CrossRef]

- Cercignani, C. The boltzmann equation. In The Boltzmann Equation and Its Applications; Springer: New York, NY, USA, 1988; pp. 40–103. [Google Scholar]

- Lei, Z.; Bahia, H.; Yi-Qiu, T. Effect of bio-based and refined waste oil modifiers on low temperature performance of asphalt binders. Constr. Build. Mater. 2015, 86, 95–100. [Google Scholar] [CrossRef]

- Guo, M.; Tan, Y.Q.; Zhang, L. Effect of Filler on Glass Transition of Asphalt Mastics. Adv. Eng. Forum 2012, 5, 376–381. [Google Scholar] [CrossRef]

- Lei, Z.; Yi-Qiu, T.; Bahia, H. Relationship between glass transition temperature and low temperature properties of oil modified binders. Constr. Build. Mater. 2016, 104, 92–98. [Google Scholar] [CrossRef]

| Technical Index | A70 | SBS | AR |

|---|---|---|---|

| Penetration/0.1 mm (25 °C) | 71.5 | 63.4 | 37.8 |

| Softening point/°C | 48.4 | 72.7 | 70.0 |

| Ductility/cm (5 cm/min, 5 °C) | - | 28.5 | 6.7 |

| Asphalt Type | Gradation | Asphalt Content |

|---|---|---|

| A70, SBS and AR | M, Z and D | 5.5%, 6.5% and 7.5% |

| Index | Binder Type | Gradation Type | Binder Content |

|---|---|---|---|

| Tg | * AR < SBS < A70 | D < M ≈ Z | 7.5 < 6.5 < 5.5 (AR) |

| E0* | Not clear | * Z < D < M | Not clear |

| Ttan | * AR > A70 ≈ SBS | Z > M > D | Not clear |

| ΔT | * AR > SBS ≈ A70 | Not clear | 5.5 > 6.5 > 7.5 (AR) |

| K value | AR > A70 > SBS | * Z > D > M | 5.5 > 6.5 > 7.5 (AR) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, G.; Wang, X.; Zhou, X.; Wang, Y. Experimental Study on the Phase Transition Characteristics of Asphalt Mixture for Stress Absorbing Membrane Interlayer. Materials 2020, 13, 474. https://doi.org/10.3390/ma13020474

Yang G, Wang X, Zhou X, Wang Y. Experimental Study on the Phase Transition Characteristics of Asphalt Mixture for Stress Absorbing Membrane Interlayer. Materials. 2020; 13(2):474. https://doi.org/10.3390/ma13020474

Chicago/Turabian StyleYang, Guang, Xudong Wang, Xingye Zhou, and Yanzhu Wang. 2020. "Experimental Study on the Phase Transition Characteristics of Asphalt Mixture for Stress Absorbing Membrane Interlayer" Materials 13, no. 2: 474. https://doi.org/10.3390/ma13020474

APA StyleYang, G., Wang, X., Zhou, X., & Wang, Y. (2020). Experimental Study on the Phase Transition Characteristics of Asphalt Mixture for Stress Absorbing Membrane Interlayer. Materials, 13(2), 474. https://doi.org/10.3390/ma13020474