Development and Application of Novel Sodium Silicate Microcapsule-Based Self-Healing Oil Well Cement

Abstract

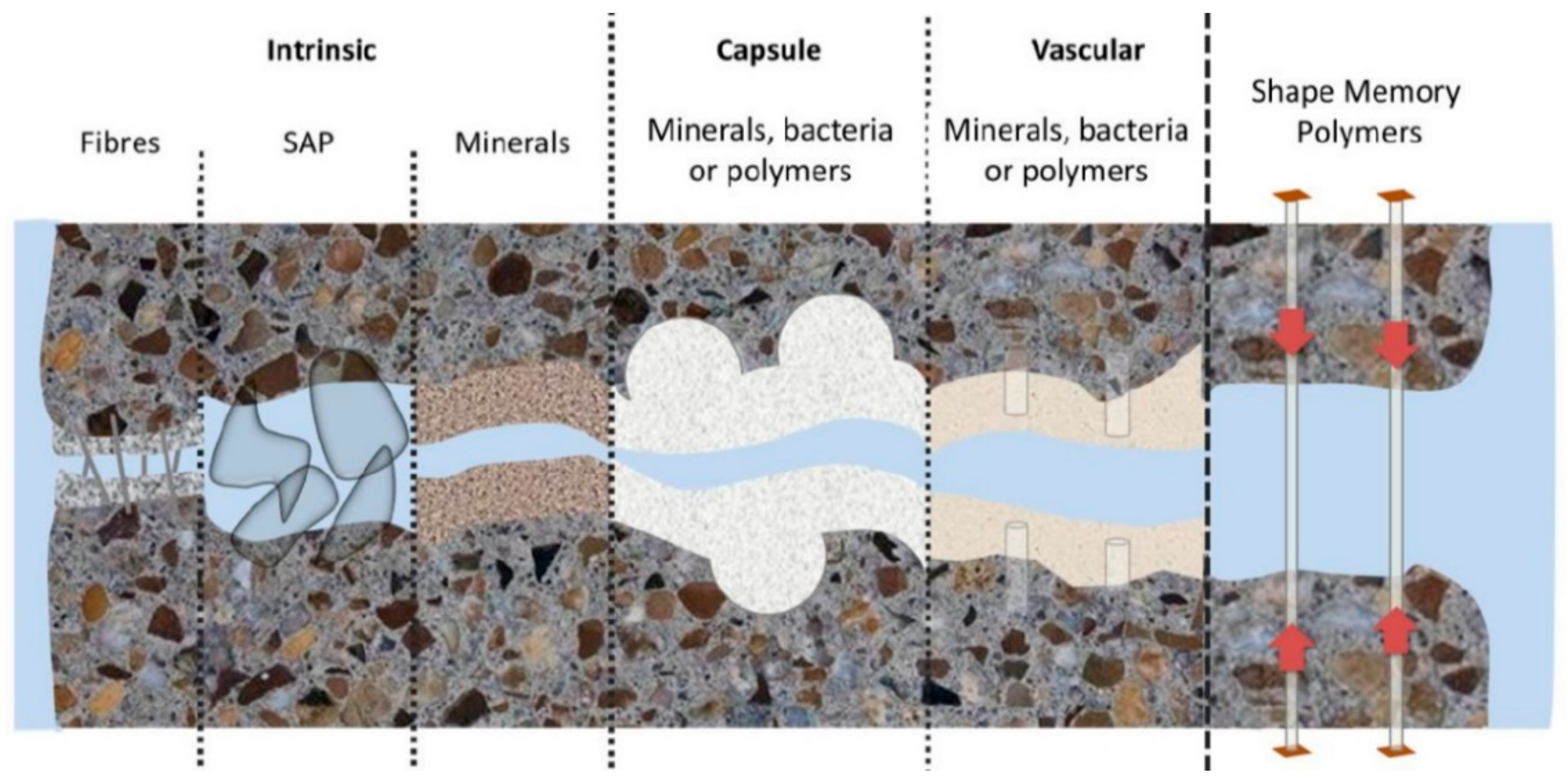

:1. Introduction

2. Experimental Program

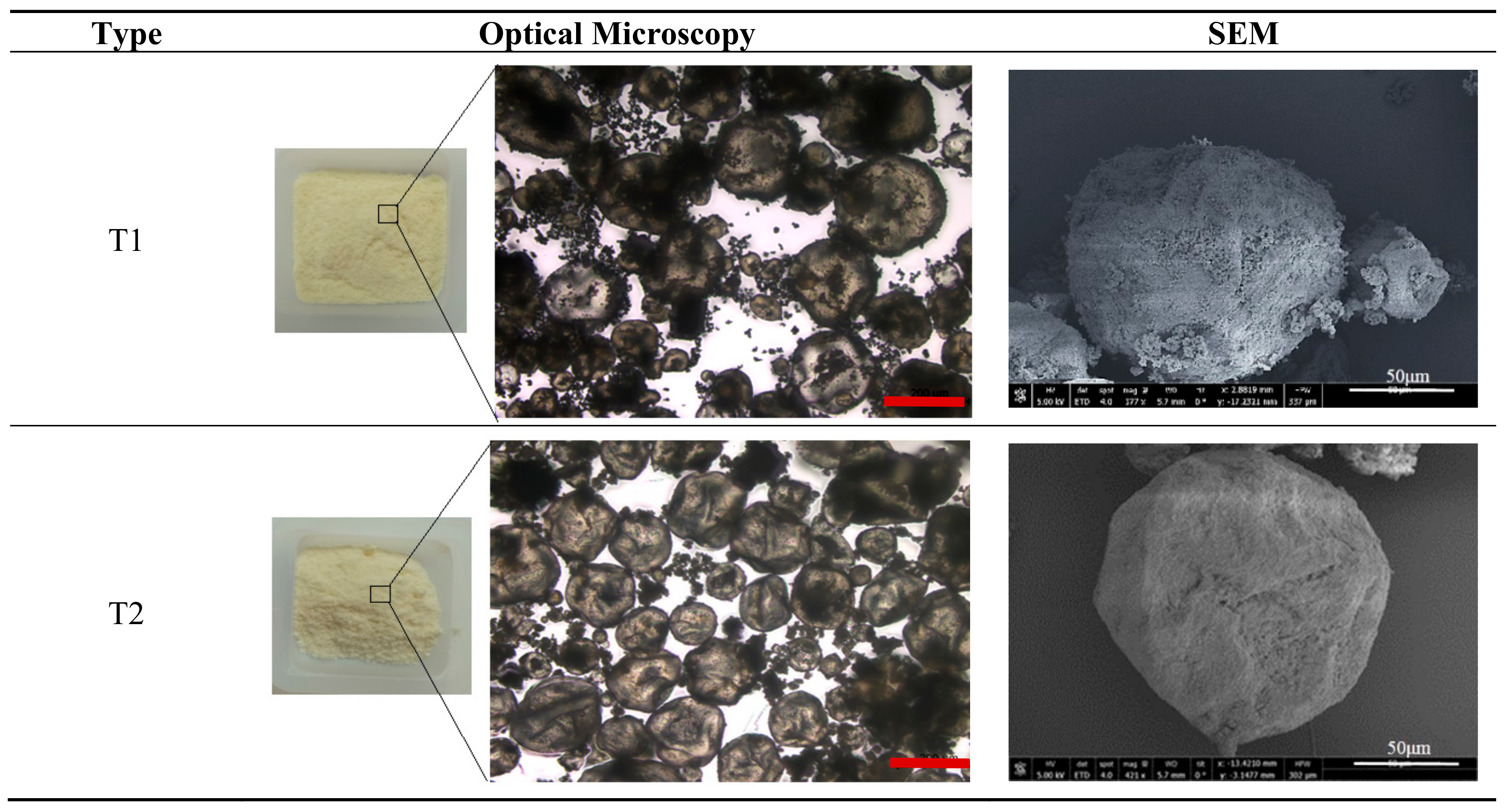

2.1. Materials

2.2. Thermal Stability and Chemical Resistance Analyses of the Microcapsules

2.3. Preparation of Oil Well Cement Pastes and Samples

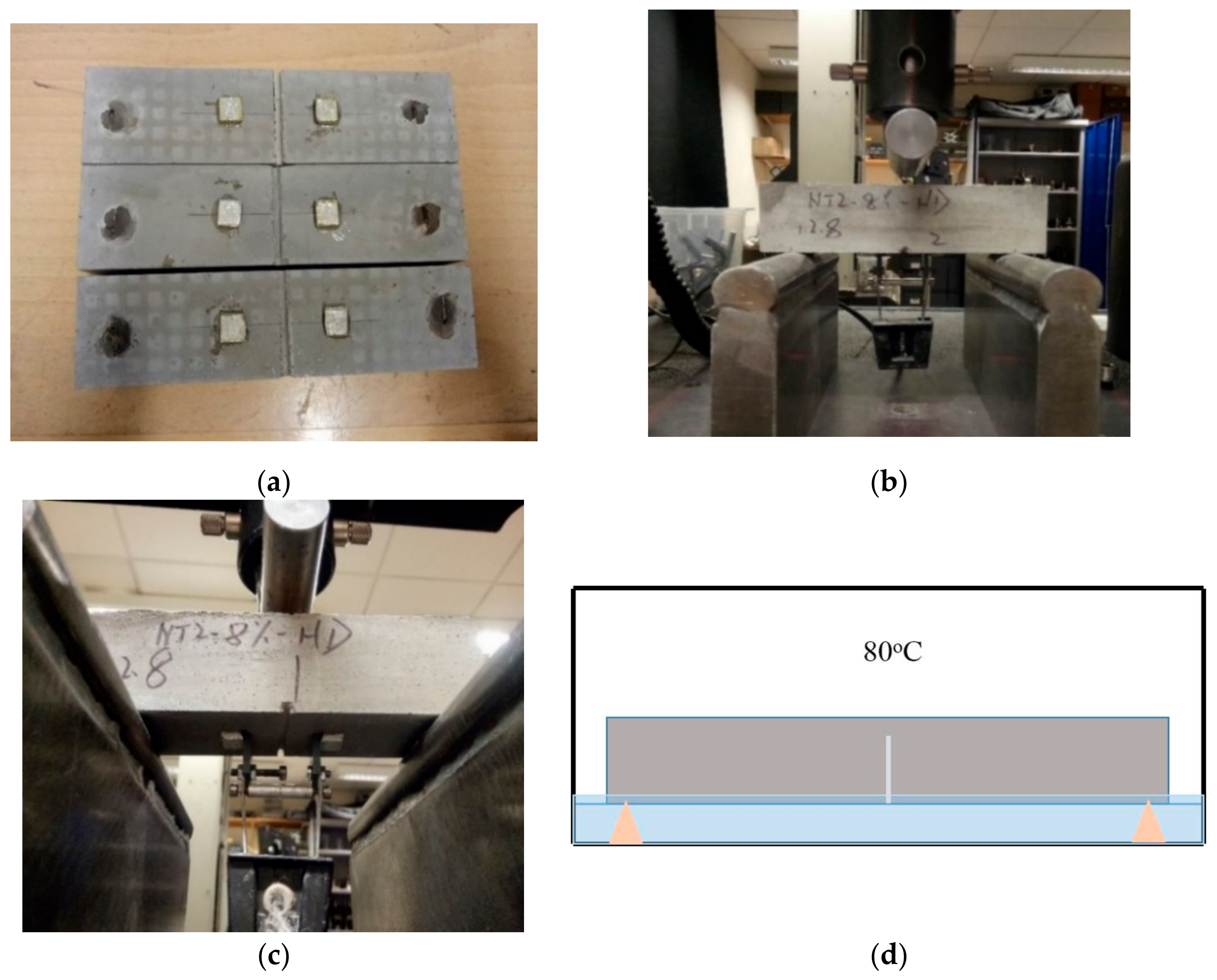

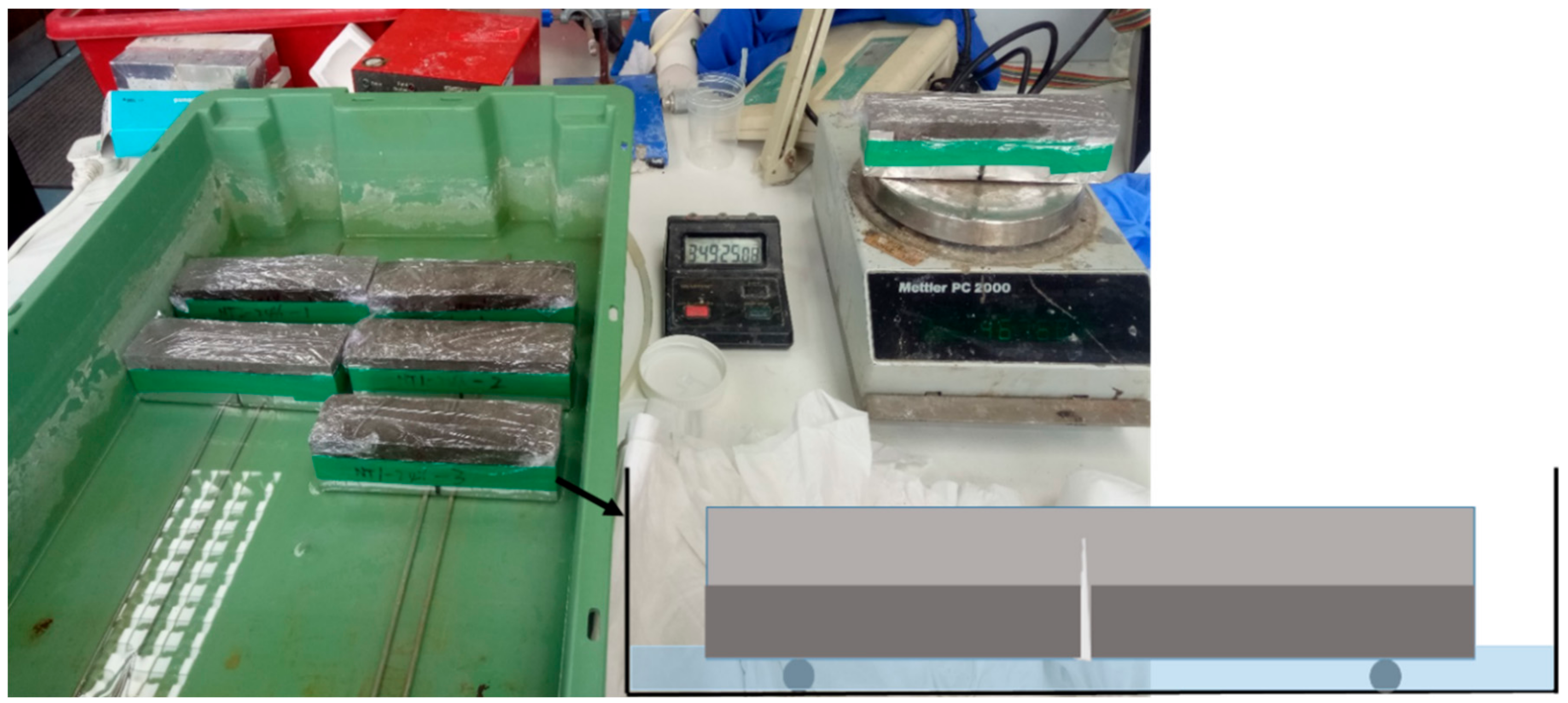

2.4. Rheology, Compressive Strength and Water Sorptivity Tests

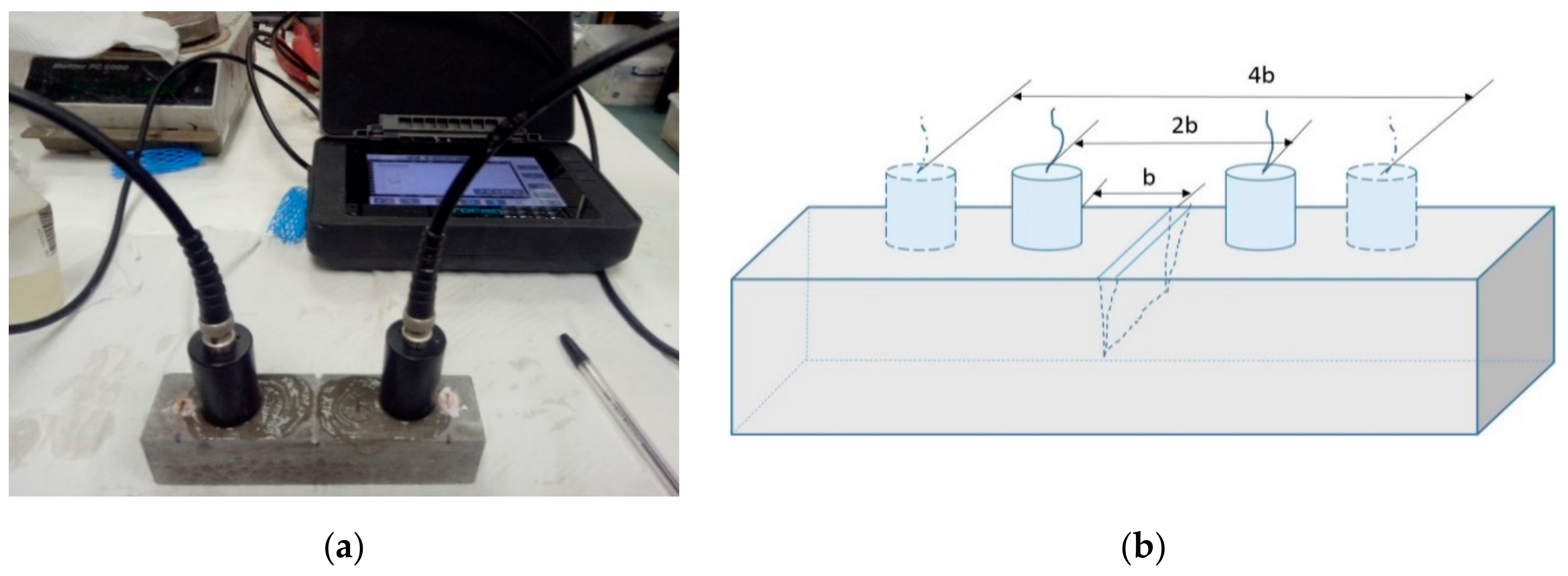

2.5. Ultrasonic Pulse Velocity Test on Crack Depth

2.6. Microstructural Analysis

3. Results and Discussion

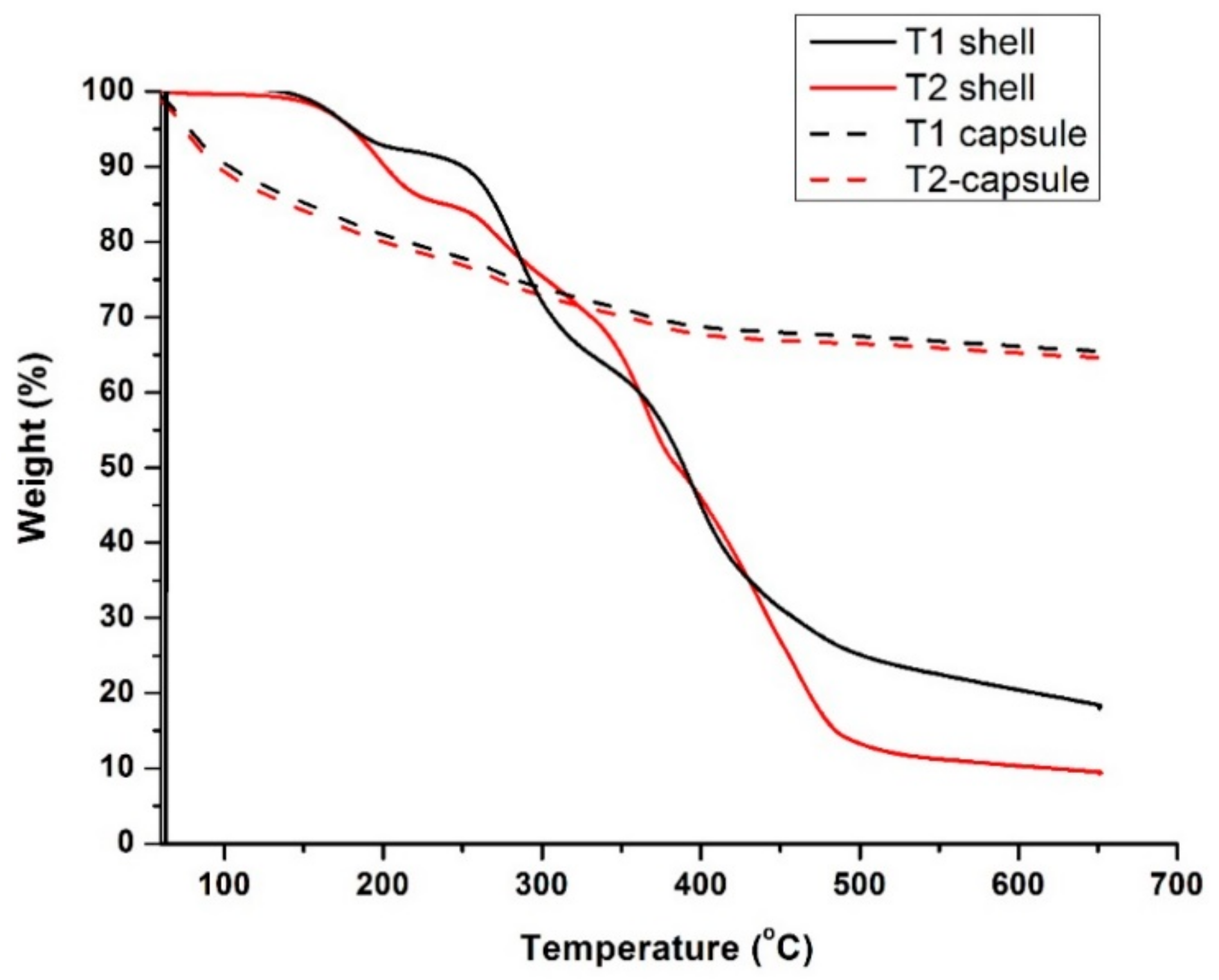

3.1. Thermal Stability and Chemical Resistance of the Microcapsules

3.2. Effect of the Microcapsules on the Rheological Properties of the Oil Well Cement Slurries

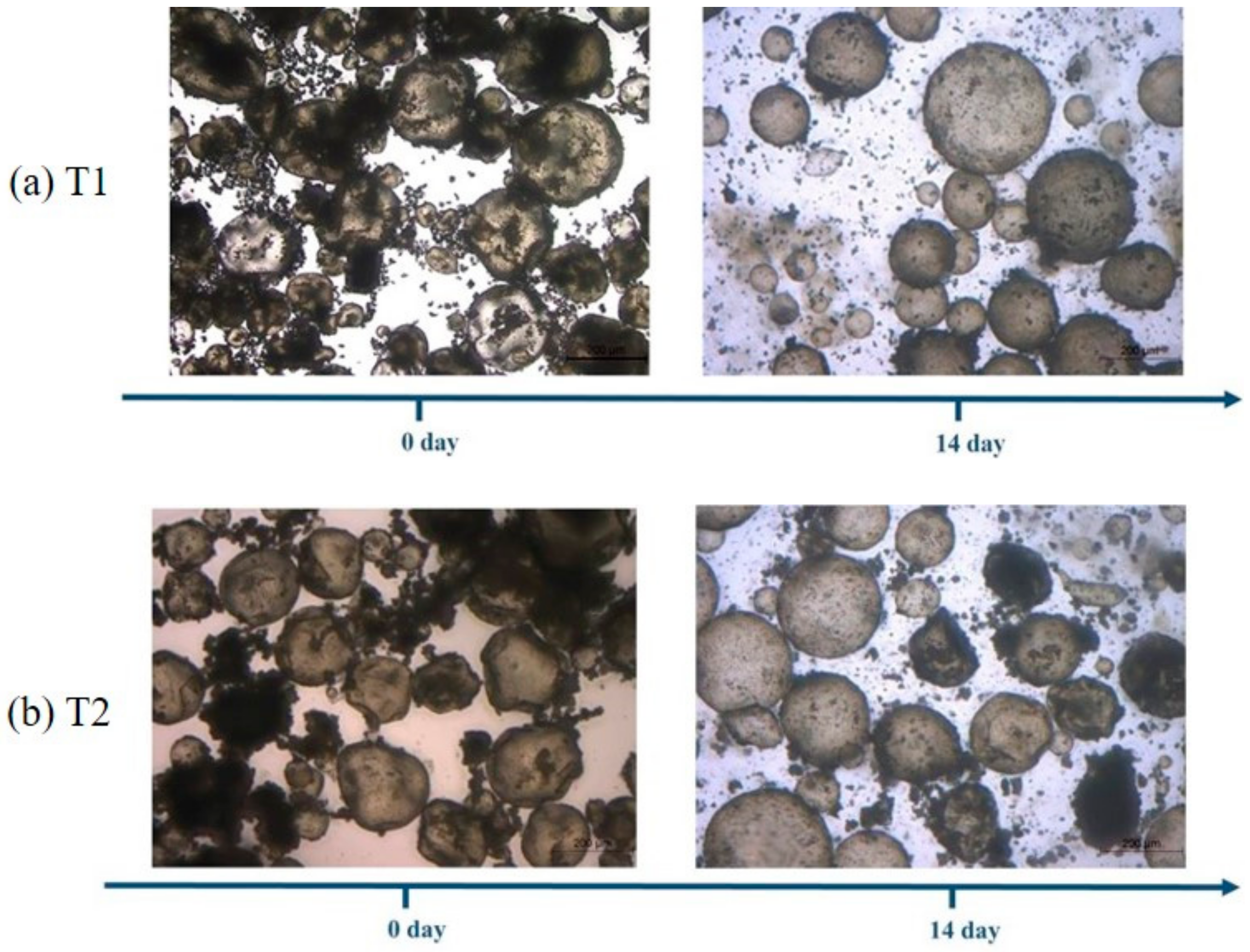

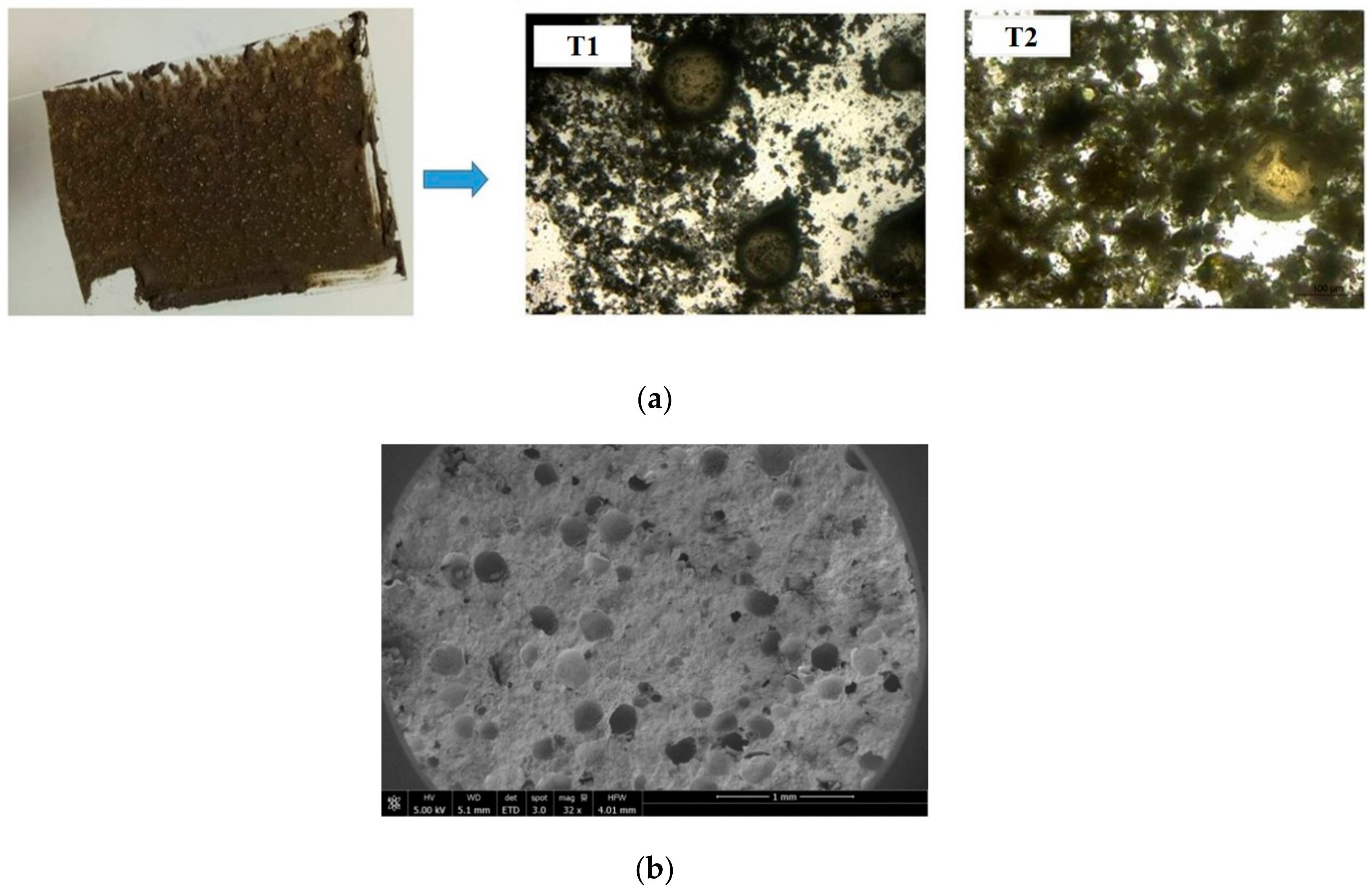

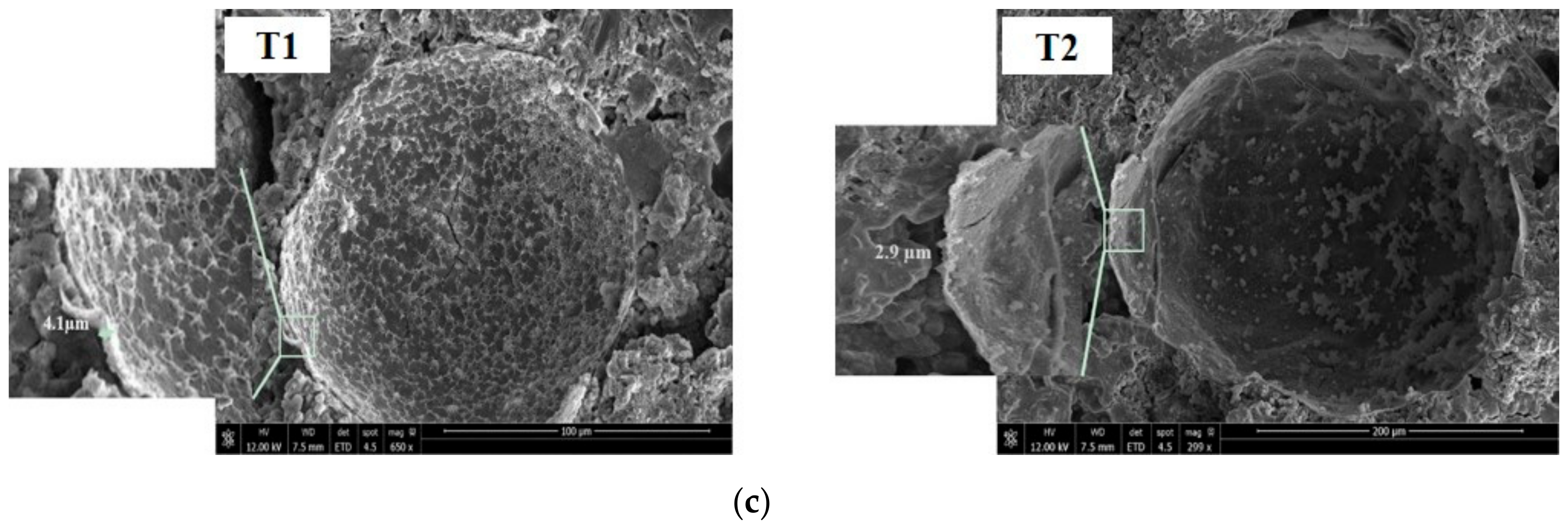

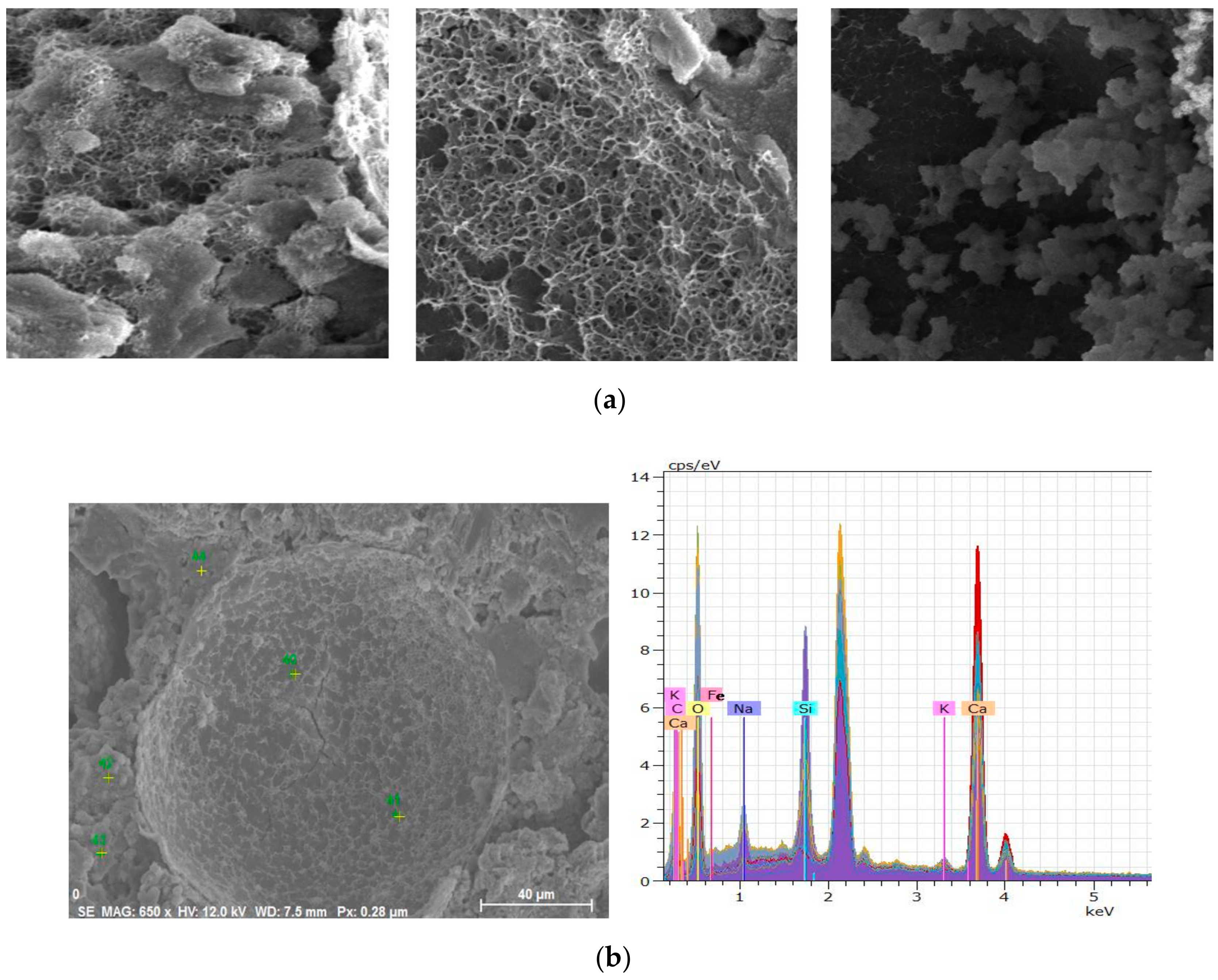

3.3. Survivability of the Microcapsules in the Cement Pastes

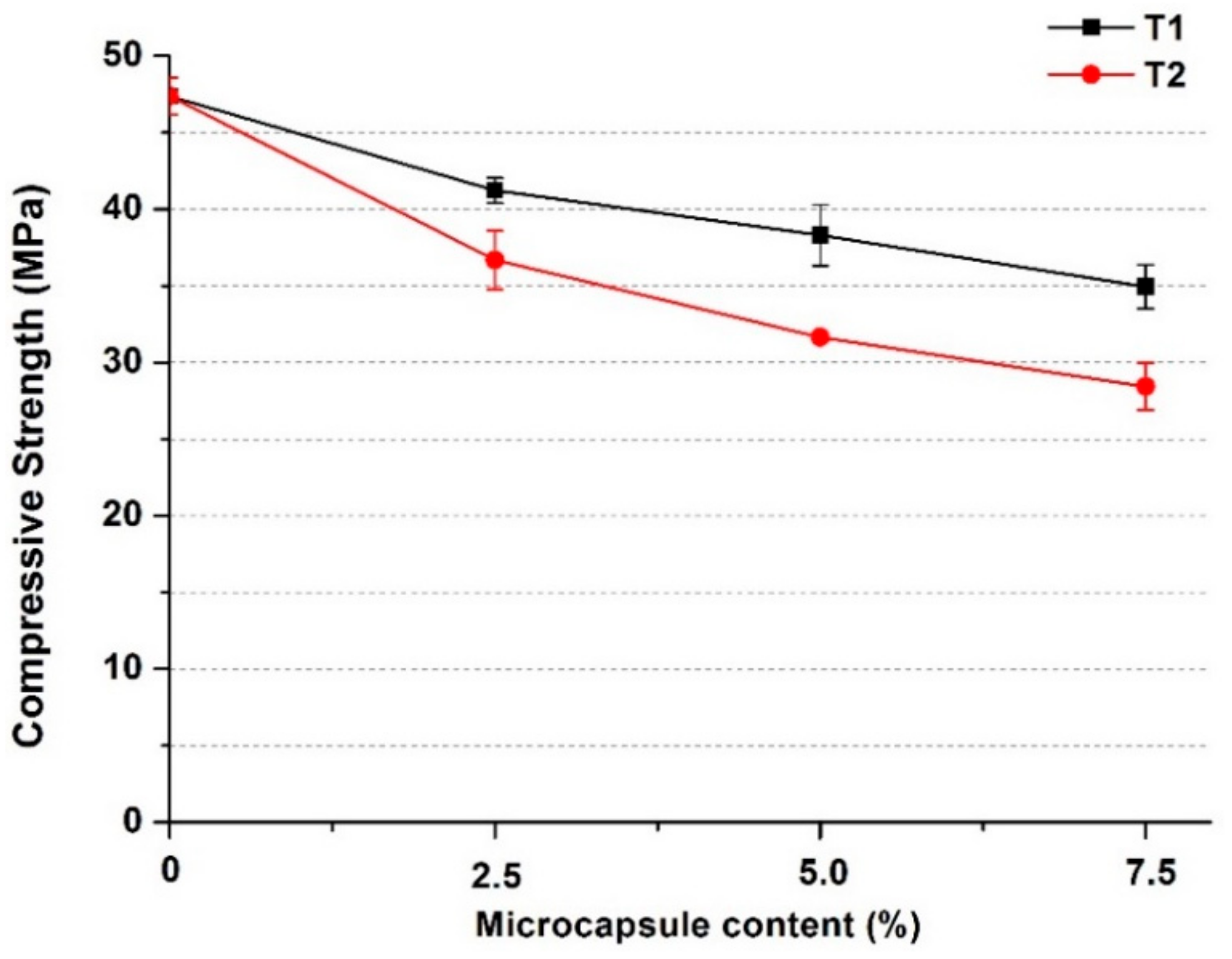

3.4. Effect of Microcapsules on Compressive Strength of the Oil Well Cement

3.5. Self-Healing Efficiency of Microcapsules in the Oil Well Cement System

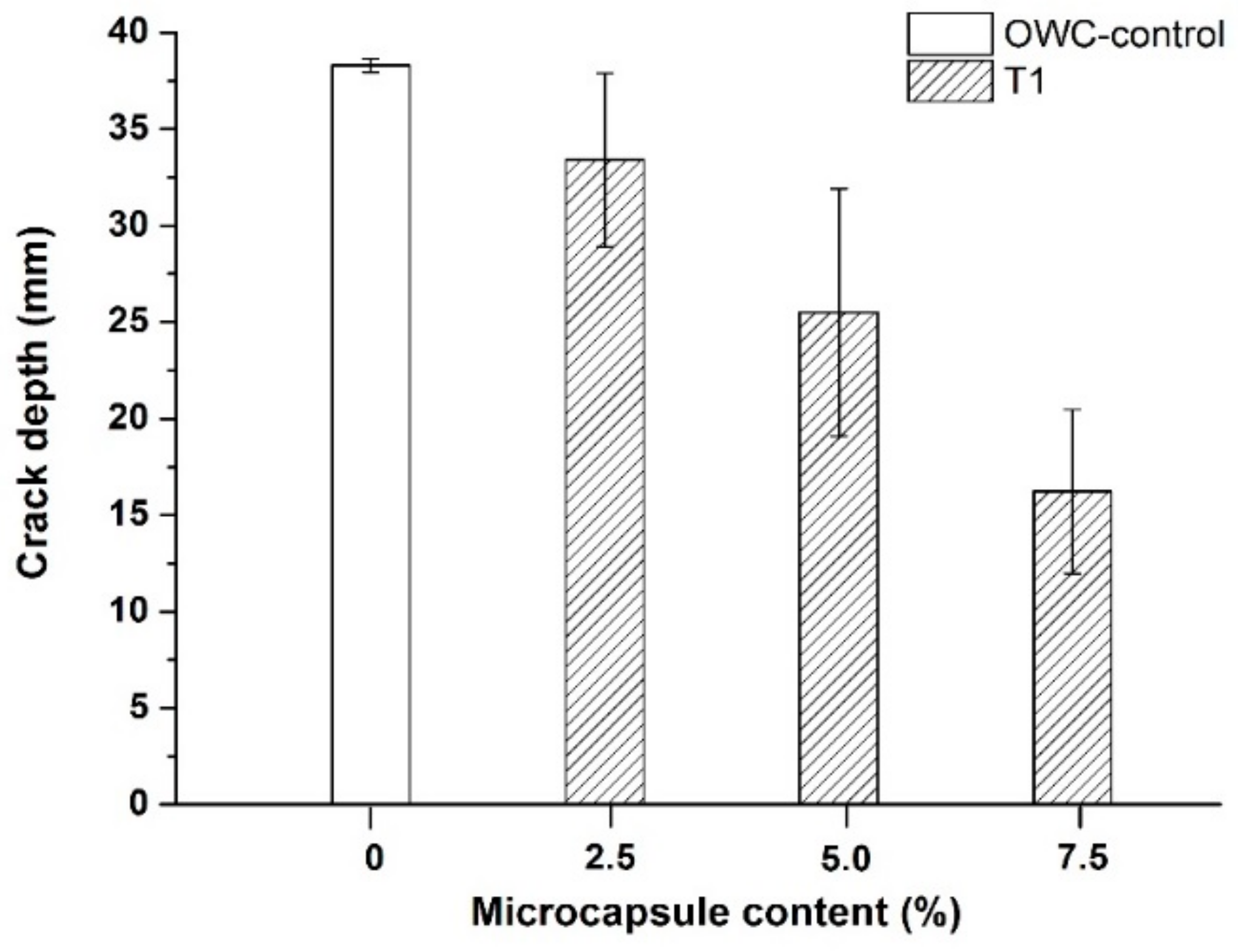

3.5.1. Crack Depth Measurements

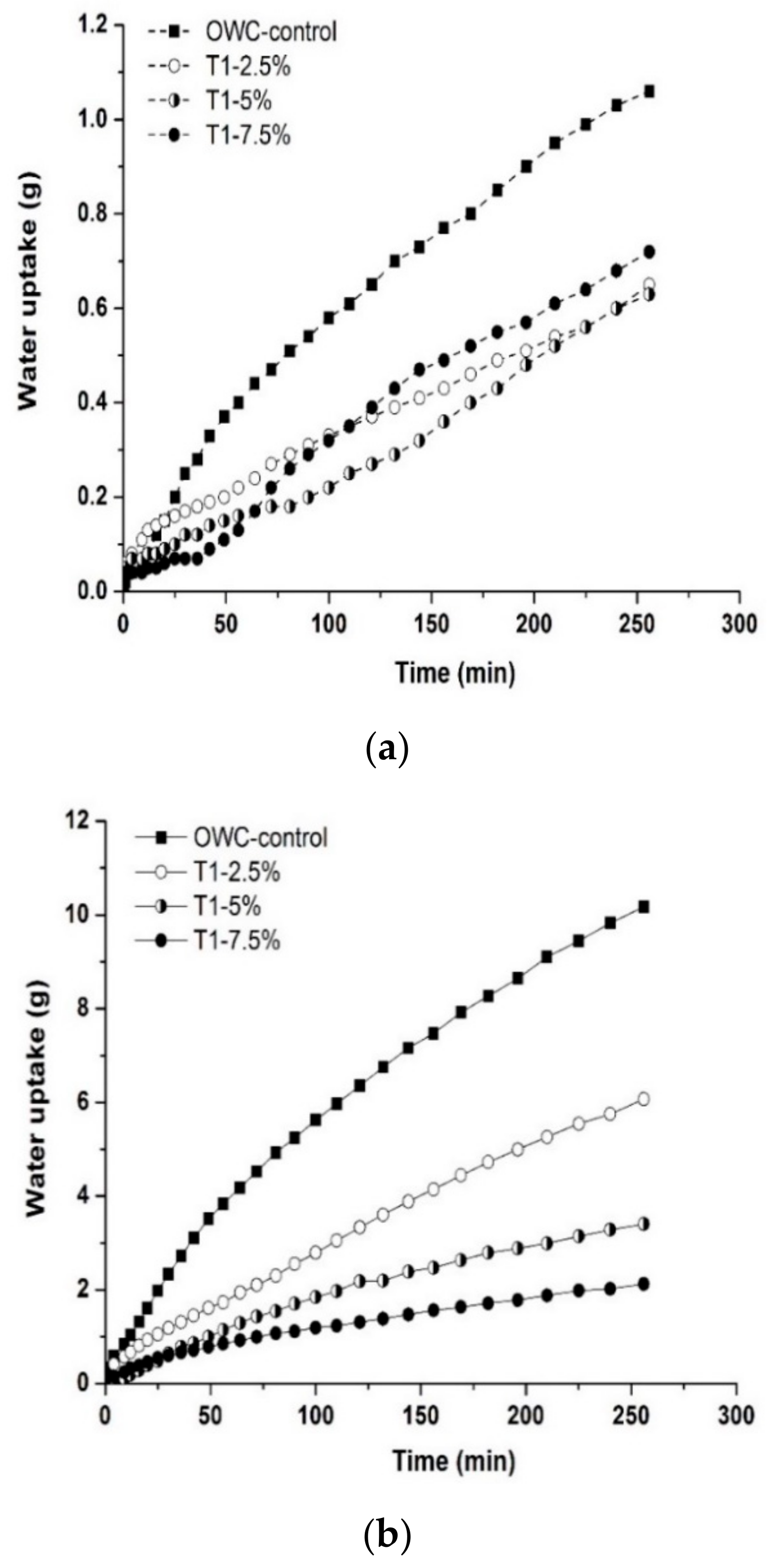

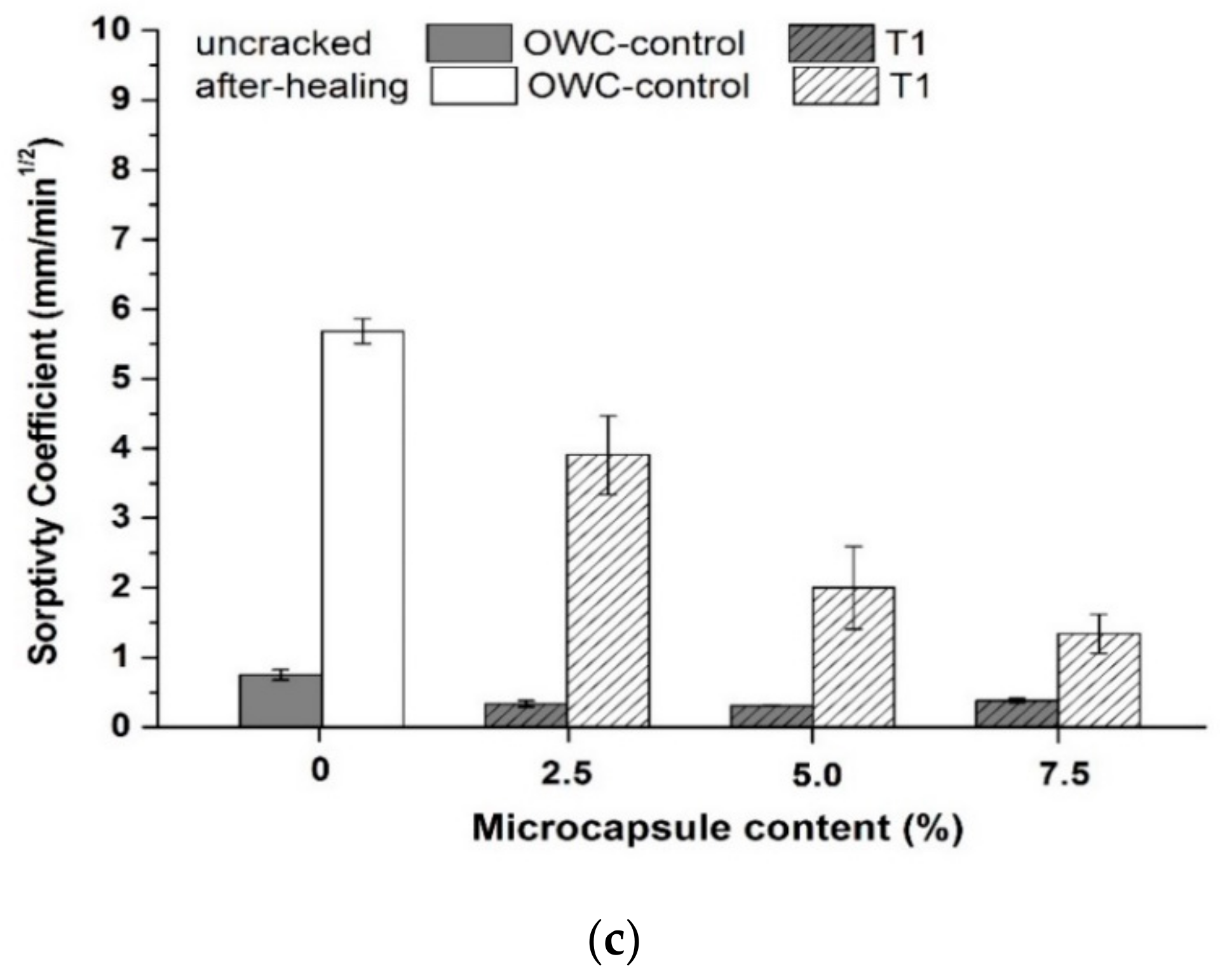

3.5.2. Recovery in Water Tightness

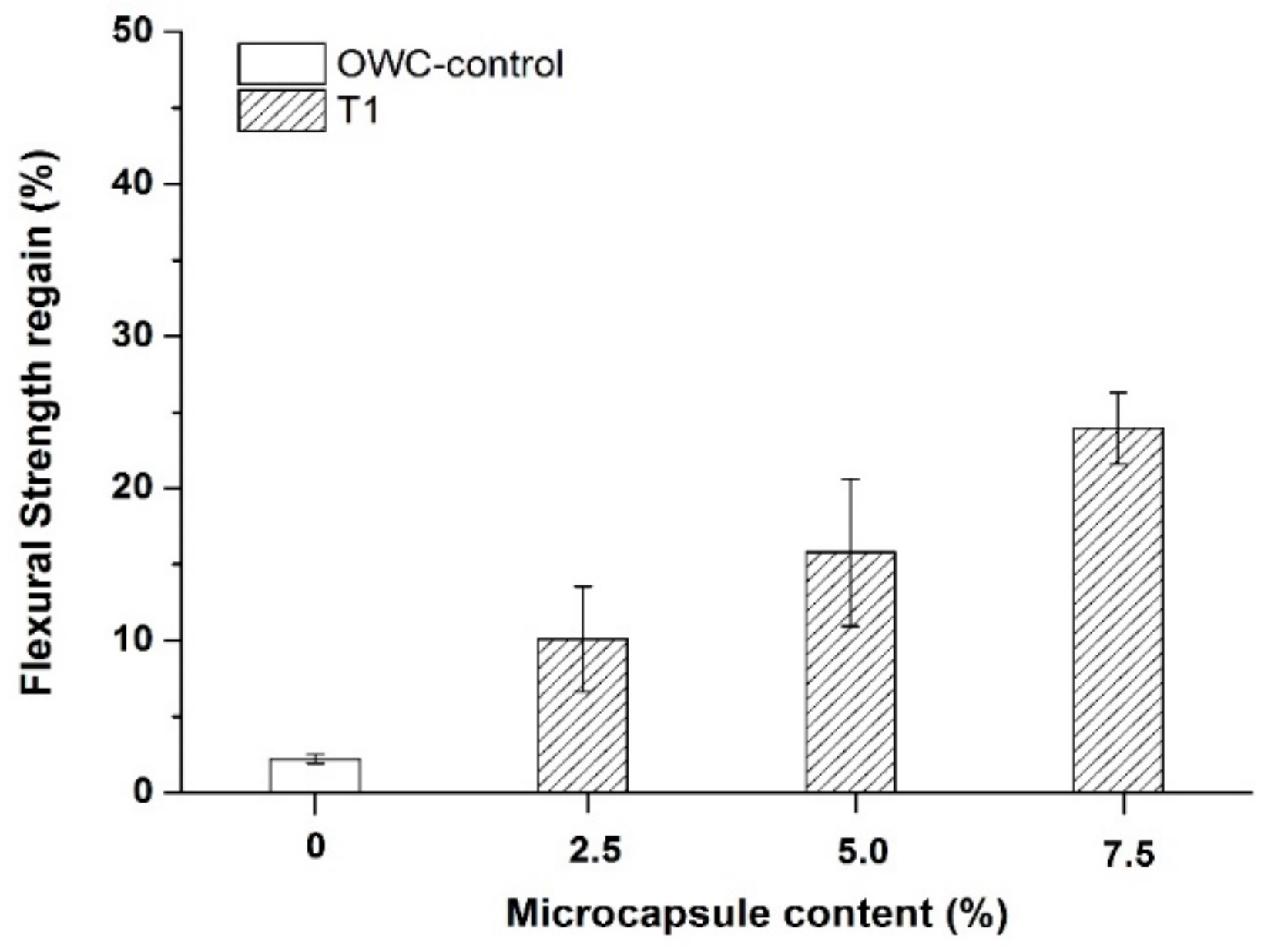

3.6. Recovery in Flexural Strength

3.7. Microstructural Analysis

4. Conclusions

- The two types T1 and T2 of the polyurea microcapsules showed good thermal stability up to ~150 °C and good resistance to high alkalinity in combination. The characterisation results verified their suitability for use in oil well cements under high temperature wellbore conditions at 80 °C;

- The addition of the T1 and T2 microcapsules led to increase in the plastic viscosity and yield stress of the oil well cement slurries, particularly at dosages above 5% by weight of cement.

- The compressive strength decreased for increasing additions of both microcapsules. The main difference was in the extent of the decrease in the compressive strength of the oil well cement pastes. he addition of the T2 microcapsules with their rubbery shells led to greater strength reduction than the T1 microcapsules with their rigid shells. The T1 microcapsules were therefore considered more favorable for use;

- Based on the measurements of crack depth and water sorptivity, it was evident that the addition of the T1 microcapsules significantly improved the self-healing efficiency of oil well cement at 80 °C compared to the reference samples. The healing efficiency generally increased with microcapsule content as more healing agents were provided for healing. The addition of microcapsules at a content of 7.5% achieved crack depth reduction up to ~58%, and the reduction in sorptivity coefficient reached ~76%;

- The sodium silicate microcapsules also showed effectiveness in improving strength recovery. The C-S-H gels formed act as effective bindings within the cracking area, thus contributing to the strength recovery. The addition of microcapsules (T1 or T2) improved the strength recovery by ~27% at a content of 7.5%;

- When cured at high temperature of 80 °C, the healing process largely depended on the autonomic healing by the sodium silicate microcapsule reactions while the contributions from autogenous healing were very limited. The higher temperature curing may have also induced fast healing;

- The microstructure analysis through SEM observations confirmed the survivability of microcapsules in oil well cement system and the successful release of the sodium silicate healing agent. The formation of main healing products C-S-H was also verified by the EDX analysis.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nelson, E.B. Well Cementing, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Bonett, A.; Pafitis, D. Getting to the Root of Gas Migration. Oilfield Rev. 1996, 8, 36–49. [Google Scholar]

- Liu, J.; Vipulanandan, C. Failure Modes of Oil Well Cement During Service Life. In Proceedings of the Hurricanes-2012 Conference Proceedings, Houston, TX, USA, 30 July 2012; pp. 2–3. [Google Scholar]

- Shadravan, A.; Schubert, J.; Amani, M.; Teodoriu, C. HPHT cement sheath integrity evaluation method for unconventional wells. In Proceedings of the SPE International Conference on Health, Safety, and Environment, Long Beach, CA, USA, 17–19 March 2014; Volume 1, pp. 73–81. [Google Scholar]

- CBC News. Available online: www.cbc.ca/news/world/bp-oil-disaster-largely-blamed-on-cement-failure-1.1057694 (accessed on 14 September 2011).

- De Rooij, M.; Van Tittelboom, K.; De Belie, N.; Schlangen, E. (Eds.) Self-Healing Phenomena in Cement-Based Materials: State-of-the-Art Report of RILEM Technical Committee 221-SHC: Self-Healing Phenomena in Cement-Based Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 11. [Google Scholar]

- Al-Tabbaa, A.; Lark, B.; Paine, K.; Jefferson, T.; Litina, C.; Gardner, D.; Embley, T. Biomimetic cementitious construction materials for next-generation infrastructure. Proc. Inst. Civ. Eng. Smart Infrastruct. Constr. 2018, 171, 67–76. [Google Scholar] [CrossRef] [Green Version]

- Mao, W. Reactive MgO and Self-healing Microcapsules for Enhanced Well Cement System Performance. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2018. [Google Scholar]

- Schlumberger. Effective Zonal Isolation for the Life of a UGS Well; Schlumberger: Huston, TX, USA, 2010; Available online: https://www.slb.com/-/media/files/ce/case-study/futur-flexstone-germany (accessed on 14 September 2011).

- Mangadlao, J.D.; Cao, P.; Advincula, R.C. Smart Cements and cement Additives for oil and gas Operations. J. Pet. Sci. Eng. 2015, 129, 63–76. [Google Scholar] [CrossRef]

- Lu, Z.; Kong, X.; Yang, R.; Zhang, Y.; Jiang, L.; Wang, Z.; Wang, Q.; Liu, W.; Zeng, M.; Zhou, S.; et al. Oil swellable polymer modified cement paste: Expansion and crack healing upon oil absorption. Constr. Build. Mater. 2016, 114, 98–108. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Schlangen, E.; Joseph, C. Self-Healing Processes in Concrete. In Self-Healing Materials: Fundamentals, Design Strategies, and Applications; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Pelletier, M.M.; Brown, R.; Shukla, A.; Bose, A. Self-Healing Concrete with a Microencapsulated Healing Agent; Technical Report; University of Rhode Island: Kingston, RI, USA, 2011. [Google Scholar]

- Huang, H.; Ye, G. Application of sodium silicate solution as self-healing agent in cementitious materials. In Proceedings of the International RILEM Conference on Advances in Construction Materials Through Science and Engineering, Hong Kong, China, 5–7 September 2011; RILEM Publications SARL: Hong Kong, China, 2011; pp. 530–536. [Google Scholar]

- Giannaros, P.; Kanellopoulos, A.; Al-Tabbaa, A. Sealing of cracks in cement using microencapsulated sodium silicate. Smart Mater. Struct. 2016, 25, 084005. [Google Scholar] [CrossRef]

- Giannaros, P.; Kanellopoulos, A.; Al-Tabbaa, A. Assessment of microencapsulated sodium silicate for self-healing of cementitious materials. In Proceedings of the 11th fib International Ph.D. Symposium in Civil Engineering, Tokyo, Japan, 29–31 August 2016; August Aimé Balkema: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Alghamri, R.; Kanellopoulos, A.; Al-Tabbaa, A. Impregnation of lightweight aggregates with sodium silicate for self-healing concrete. Constr. Build. Mater. 2016, 124, 910–921. [Google Scholar] [CrossRef]

- Mostavi, E.; Asadi, S.; Hassan, M.M.; Alansari, M. Evaluation of self-healing mechanisms in concrete with double-walled sodium silicate microcapsules. J. Mater. Civ. Eng. 2015, 27, 04015035. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Litina, C.; Giannaros, P.; Al-Tabbaa, A. Effect of different types of polymeric microcapsules on the self-healing efficiency of cement based composites. In Proceedings of the 9th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Berkeley, CA, USA, 29 May–1 June 2016. [Google Scholar]

- Kanellopoulos, A.; Giannaros, P.; Palmer, D.; Kerr, A.; Al-Tabbaa, A. Polymeric microcapsules with switchable mechanical properties for self-healing concrete: Synthesis, characterisation and proof of concept. Smart Mater. Struct. 2017, 26, 045025. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Giannaros, P.; Al-Tabbaa, A. The effect of varying volume fraction of microcapsules on fresh, mechanical and self-healing properties of mortars. Constr. Build. Mater. 2016, 122, 577–593. [Google Scholar] [CrossRef]

- Saihi, D.; Vroman, I.; Giraud, S.; Bourbigot, S. Microencapsulation of ammonium phosphate with a polyurethane shell. Part II. Interfacial polymerization technique. React. Funct. Polym. 2006, 66, 1118–1125. [Google Scholar] [CrossRef]

- Tan, N.P.B.; Keung, L.H.; Choi, W.H.; Lam, W.C.; Leung, H.N. Silica-based self-healing microcapsules for self-repair in concrete. J. Appl. Polym. Sci. 2016, 133, 43090. [Google Scholar]

- Giraud, S.; Salaün, F.; Bedek, G.; Vroman, I.; Bourbigot, S. Influence of chemical shell structure on the thermal properties of microcapsules containing a flame retardant agent. Polym. Degrad. Stab. 2010, 95, 315–319. [Google Scholar] [CrossRef]

- Beglarigale, A.; Seki, Y.; Demir, N.Y.; Yazıcı, H. Sodium silicate/polyurethane microcapsules used for self-healing in cementitious materials: Monomer optimization, characterization, and fracture behavior. Constr. Build. Mater. 2018, 162, 57–64. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Qureshi, T.S.; Al-Tabbaa, A. Glass encapsulated minerals for self-healing in cement based composites. Constr. Build. Mater. 2015, 98, 780–791. [Google Scholar] [CrossRef]

- Al-Tabbaa, A.; Litina, C.; Giannaros, P.; Kanellopoulos, A.; Souza, L. First UK field application and performance of microcapsule-based self-healing concrete. Constr. Build. Mater. 2019, 208, 669–685. [Google Scholar] [CrossRef]

- Scarfato, P.; Avallone, E.; Iannelli, P.; De Feo, V.; Acierno, D. Synthesis and characterization of polyurea microcapsules containing essential oils with antigerminative activity. J. Appl. Polym. Sci. 2007, 105, 3568–3577. [Google Scholar] [CrossRef]

- API Specification 10A. Specification for Cements and Materials for Well Cementing; American Petroleum Institute Publishing Services: Washington DC, USA, 2010. [Google Scholar]

- BS EN 196-1. British Standard BS EN 196-1:2016 Methods of Testing Cement; Part 1: Determination of Strength; British Standards Institution: London, UK, 2016. [Google Scholar]

- ASTM C1585-13. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes. ASTM Int. 2013, 41, 1–6. [Google Scholar]

- Hall, C.; Tse, T.K.M. Water movement in porous building materials-VII. The sorptivity of mortars. Build. Environ. 1986, 21, 113–118. [Google Scholar] [CrossRef]

- Hong, K.; Park, S. Preparation of polyurea microcapsules containing ovalbumin. Mater. Chem. Phys. 2000, 64, 20–24. [Google Scholar] [CrossRef]

- Schmid, R.L.; Felsche, J. Thermal studies on sodium silicate hydrates. I. Trisodium hydrogensilicate pentahydrate, Na3HSiO4·5H2O; Thermal stability and thermal decomposition reactions. Thermochim. Acta 1983, 71, 359–364. [Google Scholar] [CrossRef]

- Primeaux, D. Polyurea Elastomer Technology: History, Chemistry & Basic Formulating Techniques; White Paper; Primeaux Associates, LLC: Elgin, TX, USA, 2004. [Google Scholar]

- Mooney, M. The viscosity of a concentrated suspension of spherical particles. J. Colloid Sci. 1951, 6, 162–170. [Google Scholar] [CrossRef]

- Chong, J.S.; Christiansen, E.B.; Baer, A.D. Rheology of concentrated suspensions. J. Appl. Polym. Sci. 1971, 15, 2007–2021. [Google Scholar] [CrossRef]

- Guazzelli, E.; Pouliquen, O. Rheology of dense granular suspensions. J. Fluid Mech. 2018, 852. [Google Scholar] [CrossRef] [Green Version]

- Faroughi, S.A.; Huber, C. Crowding-based rheological model for suspensions of rigid bimodal-sized particles with interfering size ratios. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2014, 90, 1–5. [Google Scholar] [CrossRef]

- Mao, W.; Litina, C.; Al-Tabbaa, A. The use of self-healing sodium silicate microcapsules in oil well cement under high-temperature wellbore environment. In Proceedings of the LORCENIS Conference on Durable Concrete for Infrastructure under Severe Conditions, Ghent, Belgium, 10–11 September 2019. [Google Scholar]

- Wang, X.; Xing, F.; Zhang, M.; Han, N.; Qian, Z. Experimental study on cementitious composites embedded with organic microcapsules. Materials 2013, 6, 4064–4081. [Google Scholar] [CrossRef]

- Falzone, G.; Puerta Falla, G.; Wei, Z.; Zhao, M.; Kumar, A.; Bauchy, M.; Neithalath, N.; Pilon, L.; Sant, G. The influences of soft and stiff inclusions on the mechanical properties of cementitious composites. Cem. Concr. Compos. 2016, 71, 153–165. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, W.; Litina, C.; Al-Tabbaa, A. Development and Application of Novel Sodium Silicate Microcapsule-Based Self-Healing Oil Well Cement. Materials 2020, 13, 456. https://doi.org/10.3390/ma13020456

Mao W, Litina C, Al-Tabbaa A. Development and Application of Novel Sodium Silicate Microcapsule-Based Self-Healing Oil Well Cement. Materials. 2020; 13(2):456. https://doi.org/10.3390/ma13020456

Chicago/Turabian StyleMao, Wenting, Chrysoula Litina, and Abir Al-Tabbaa. 2020. "Development and Application of Novel Sodium Silicate Microcapsule-Based Self-Healing Oil Well Cement" Materials 13, no. 2: 456. https://doi.org/10.3390/ma13020456