Aluminum Parts Fabricated by Laser-Foil-Printing Additive Manufacturing: Processing, Microstructure, and Mechanical Properties

Abstract

1. Introduction

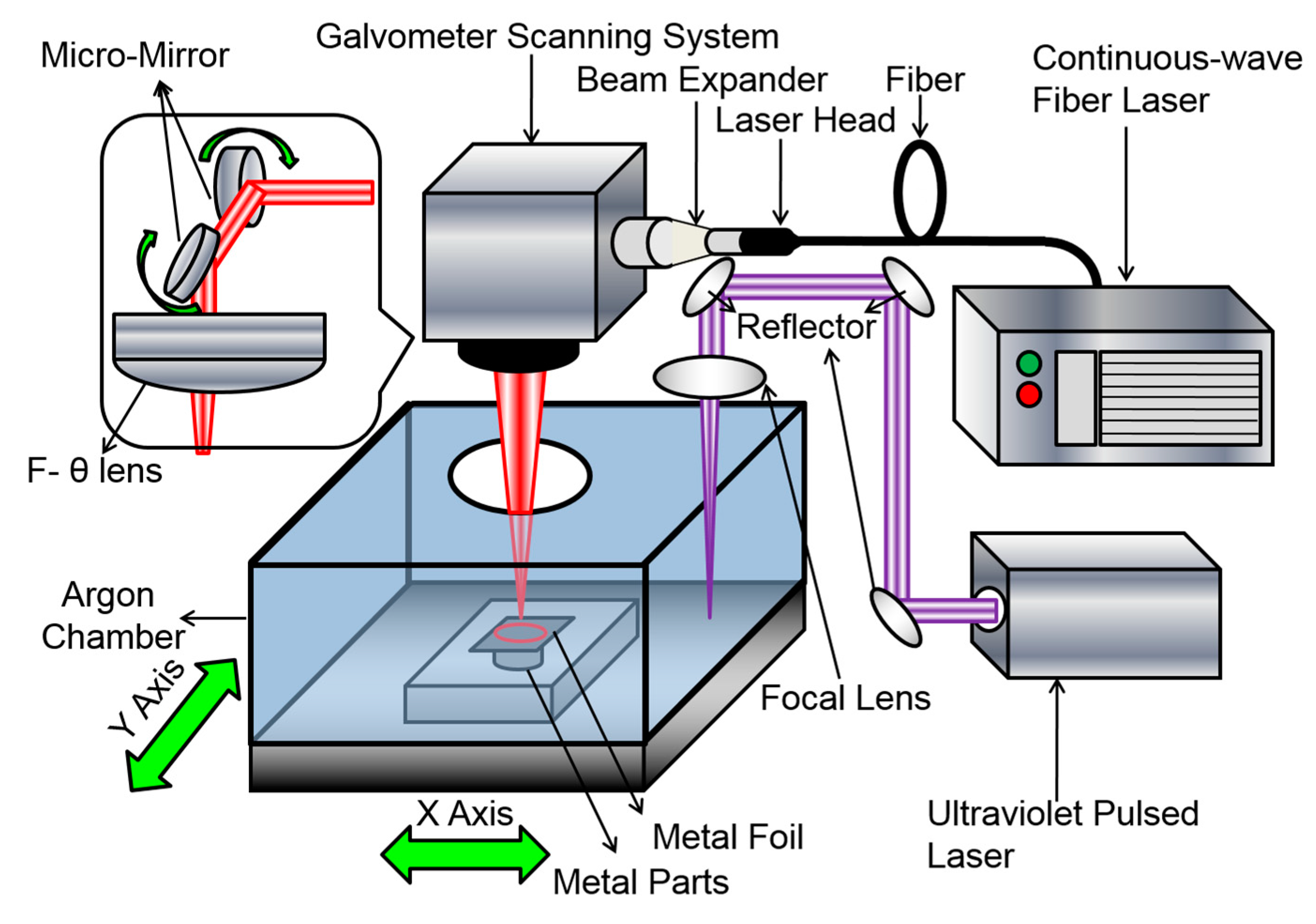

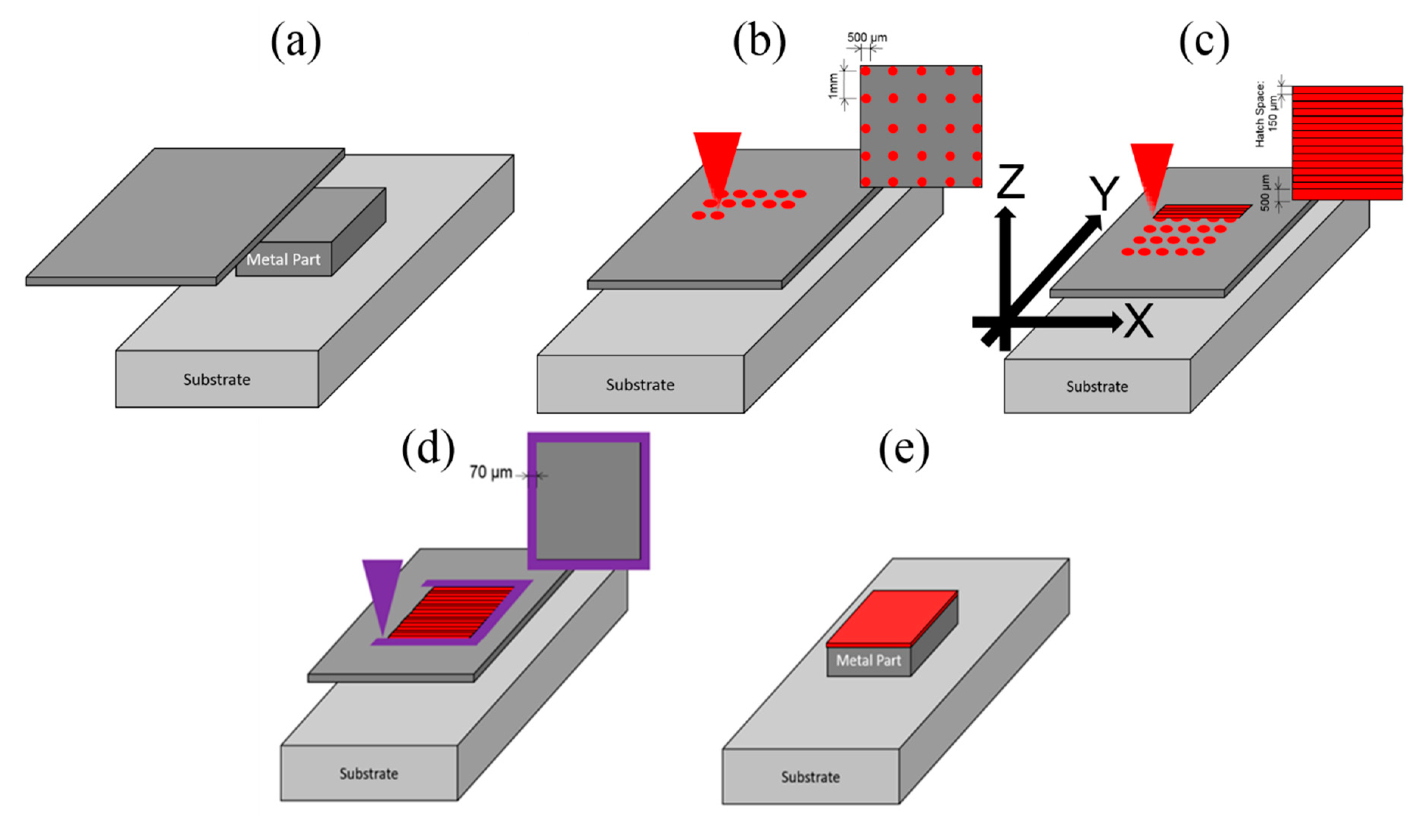

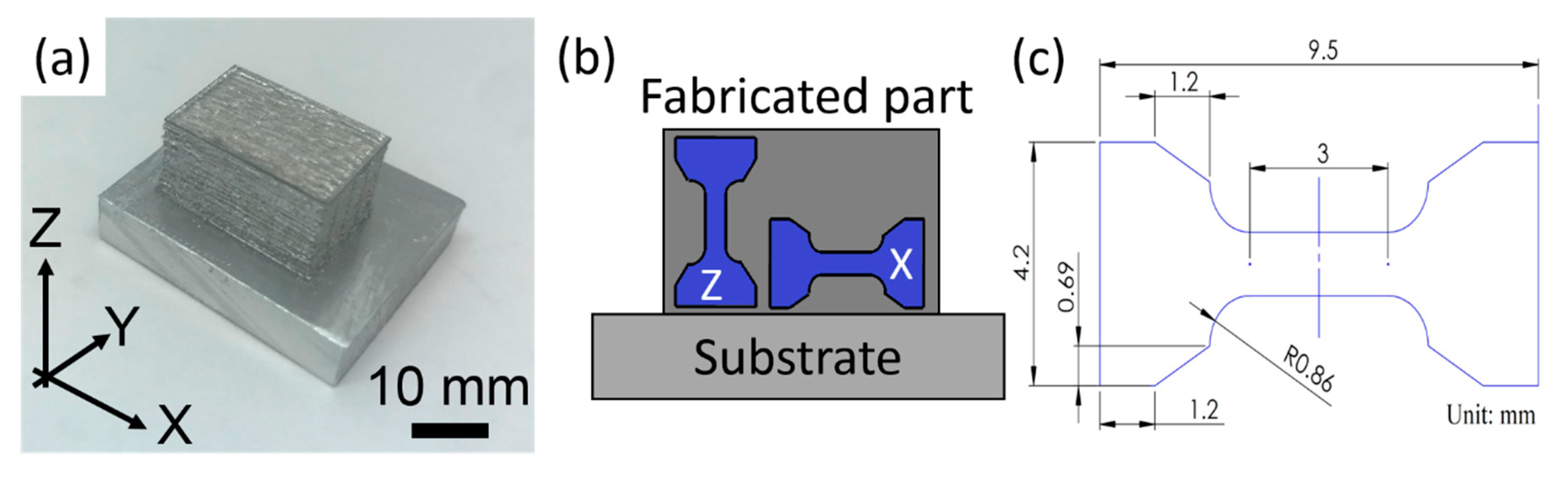

2. Process Overview and Experimental Setup

2.1. Laser Foil Printing (LFP)

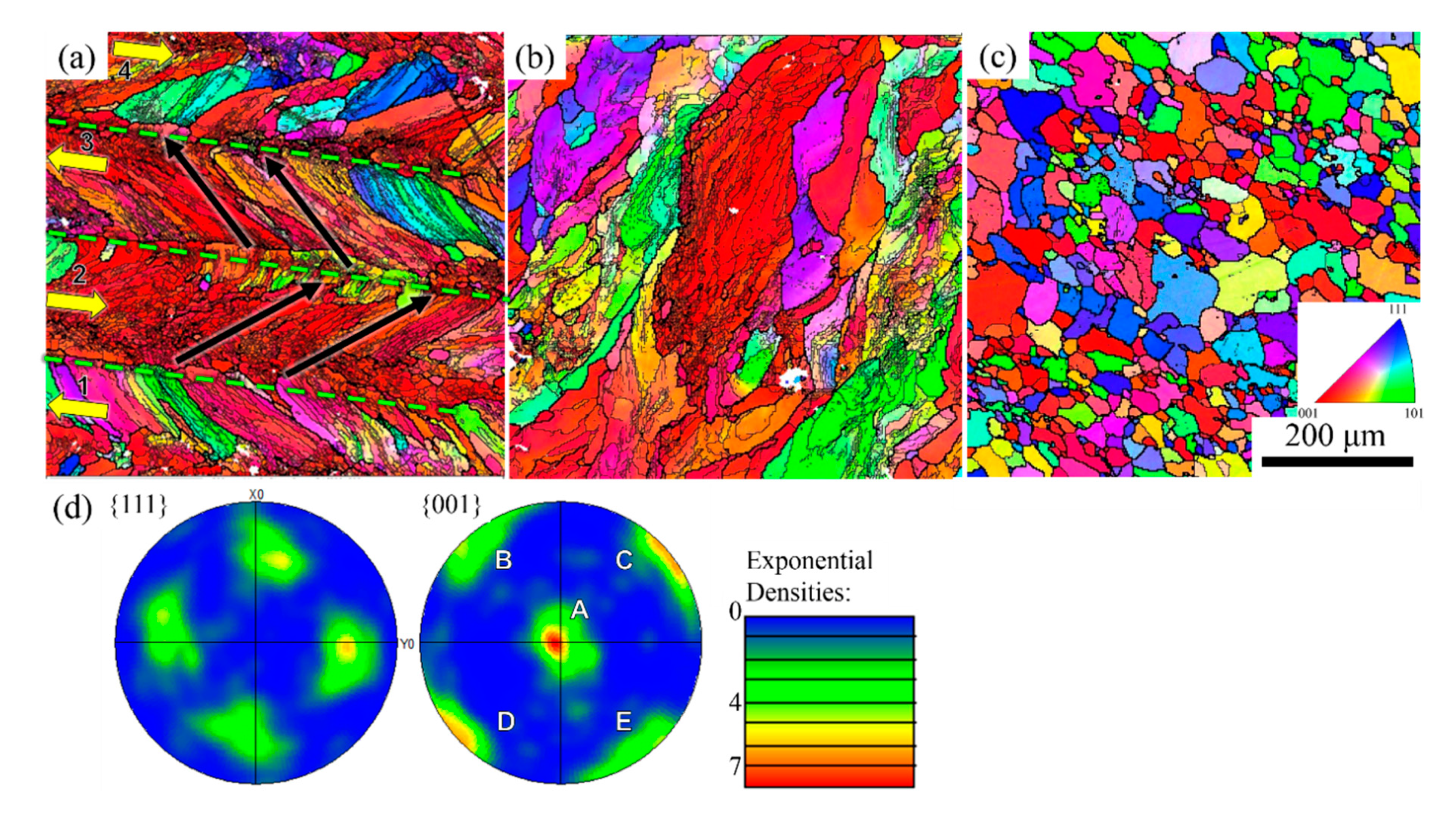

2.2. Characterization

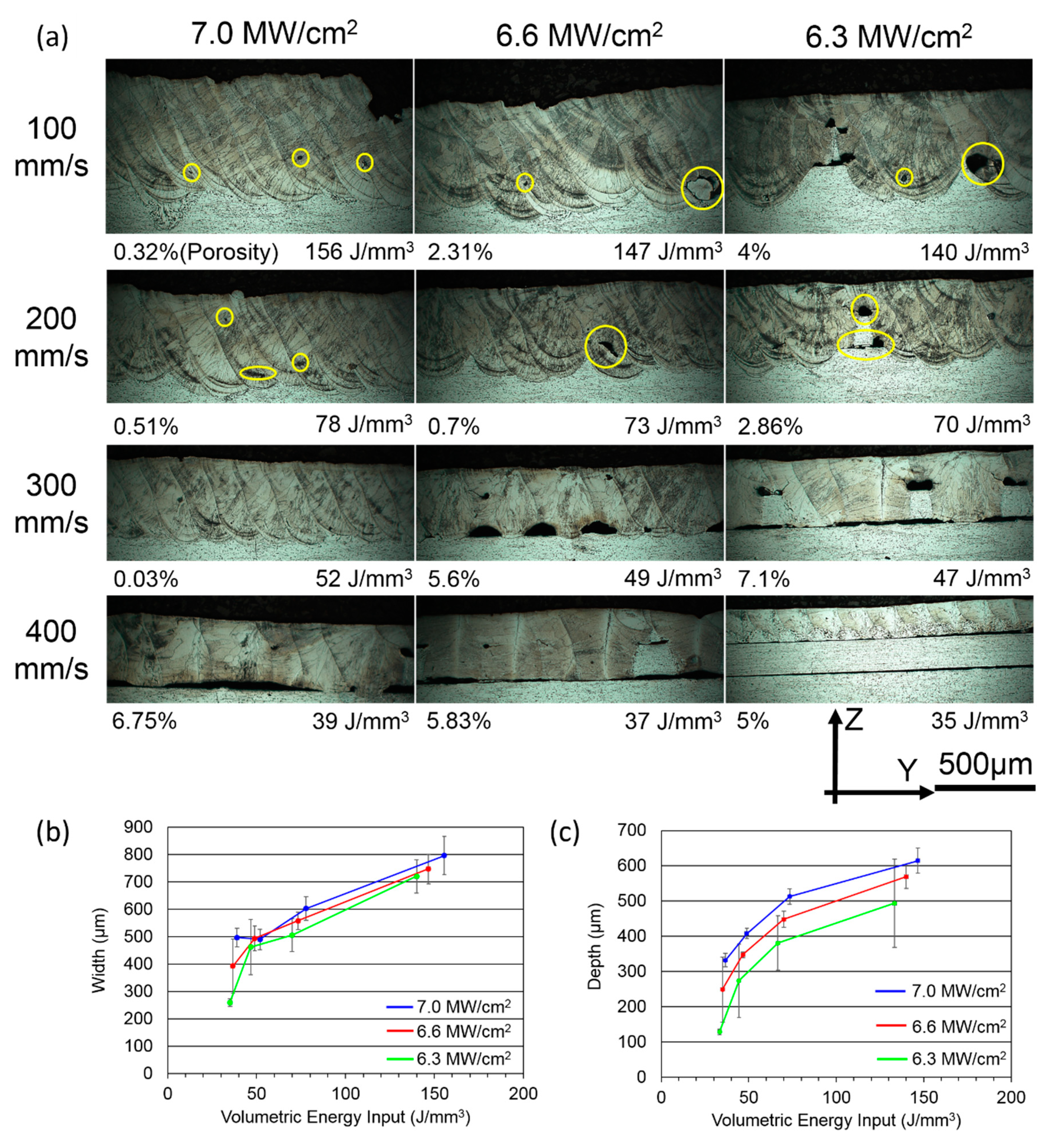

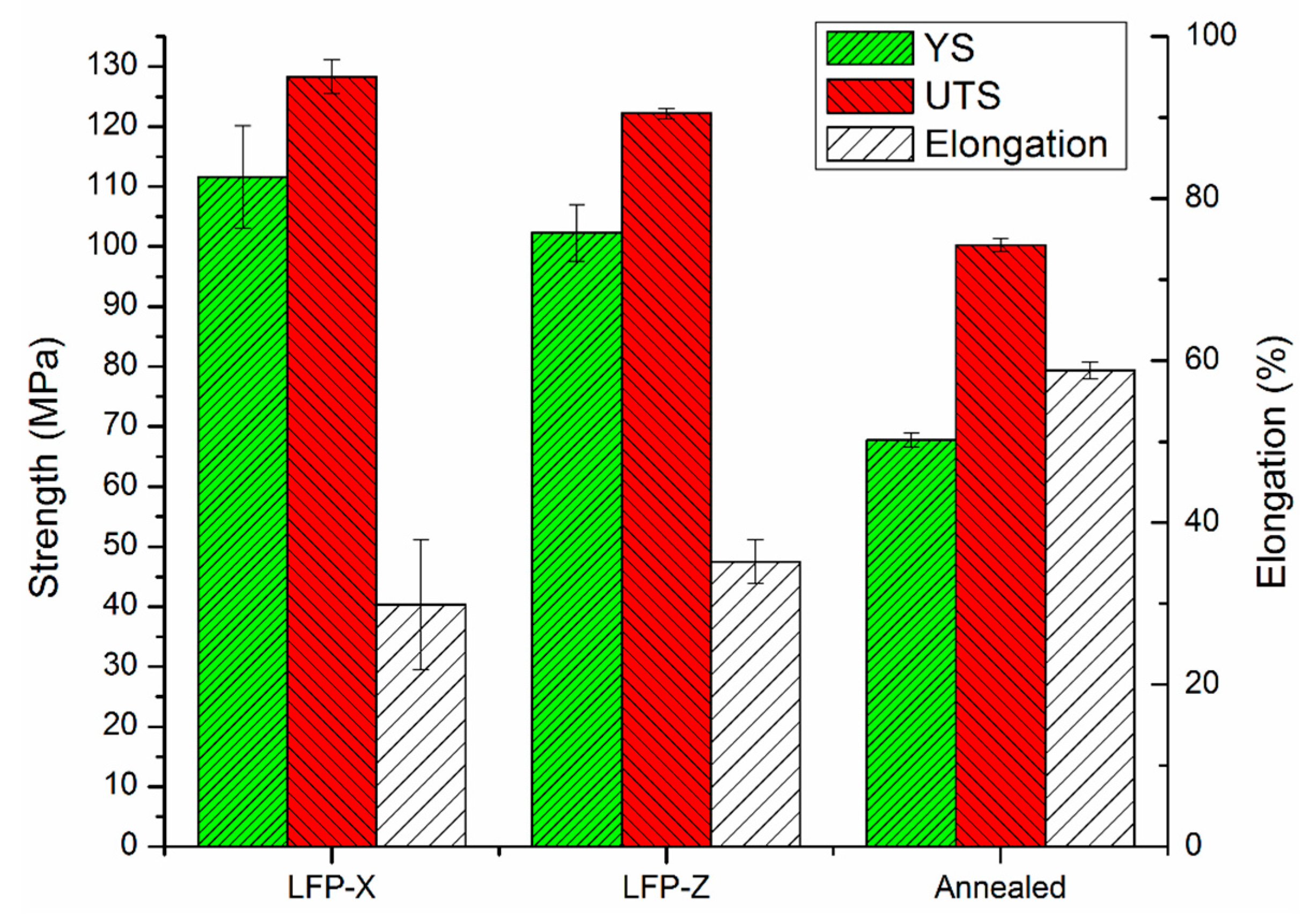

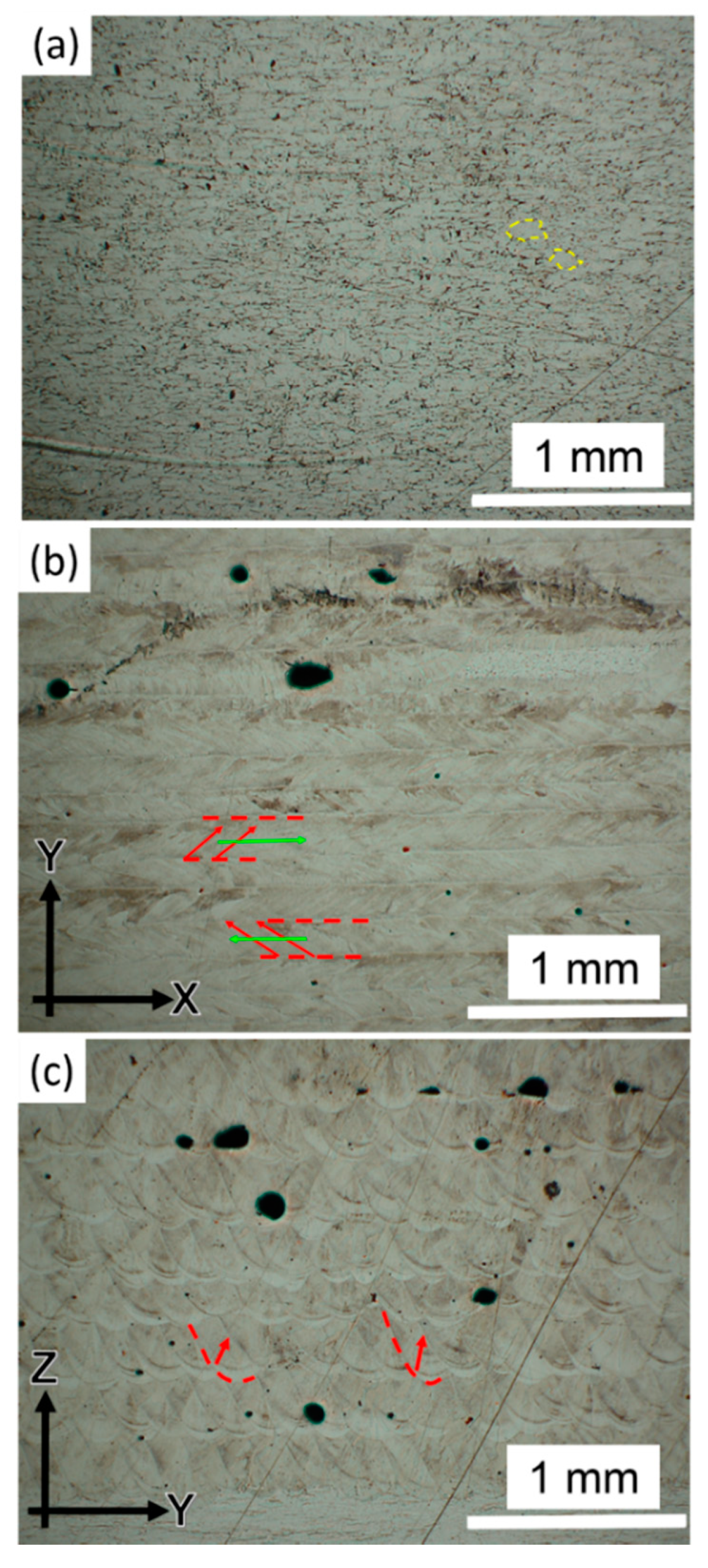

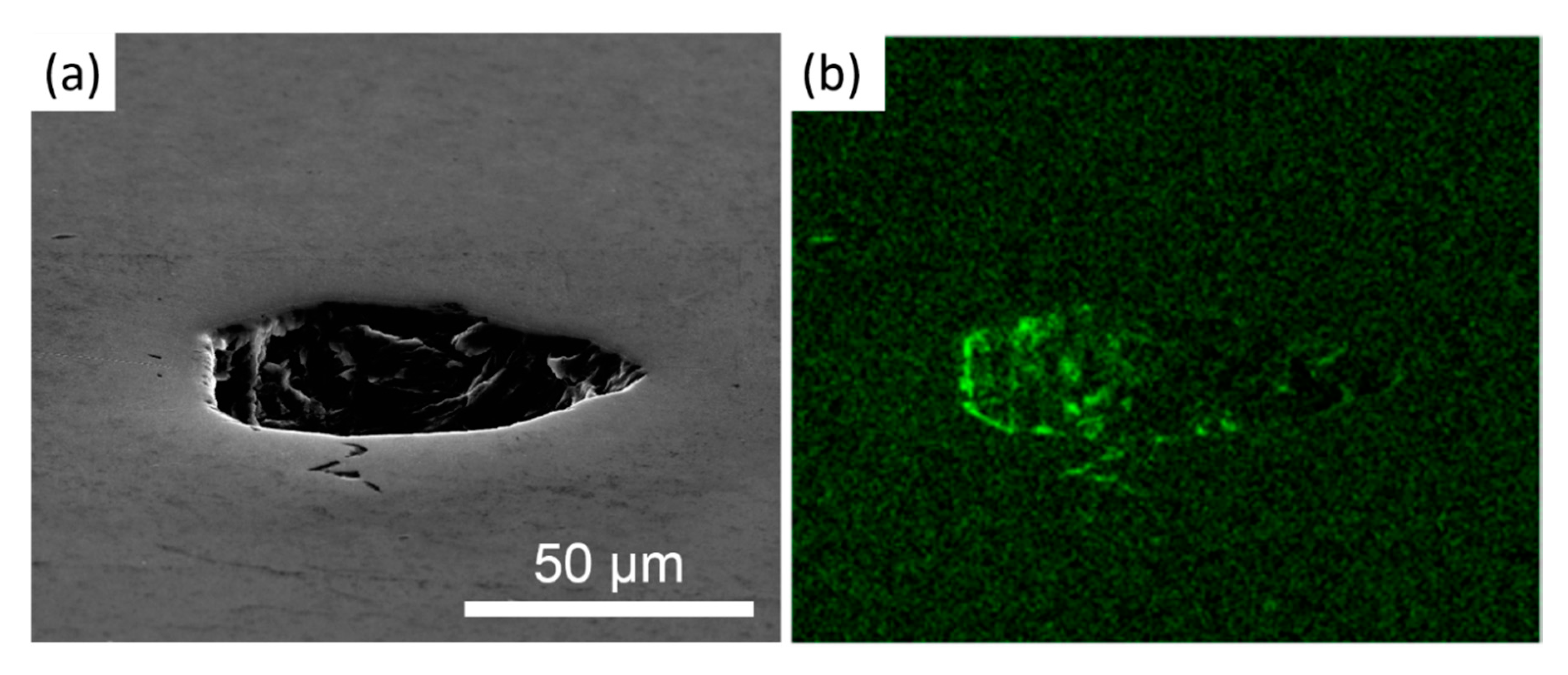

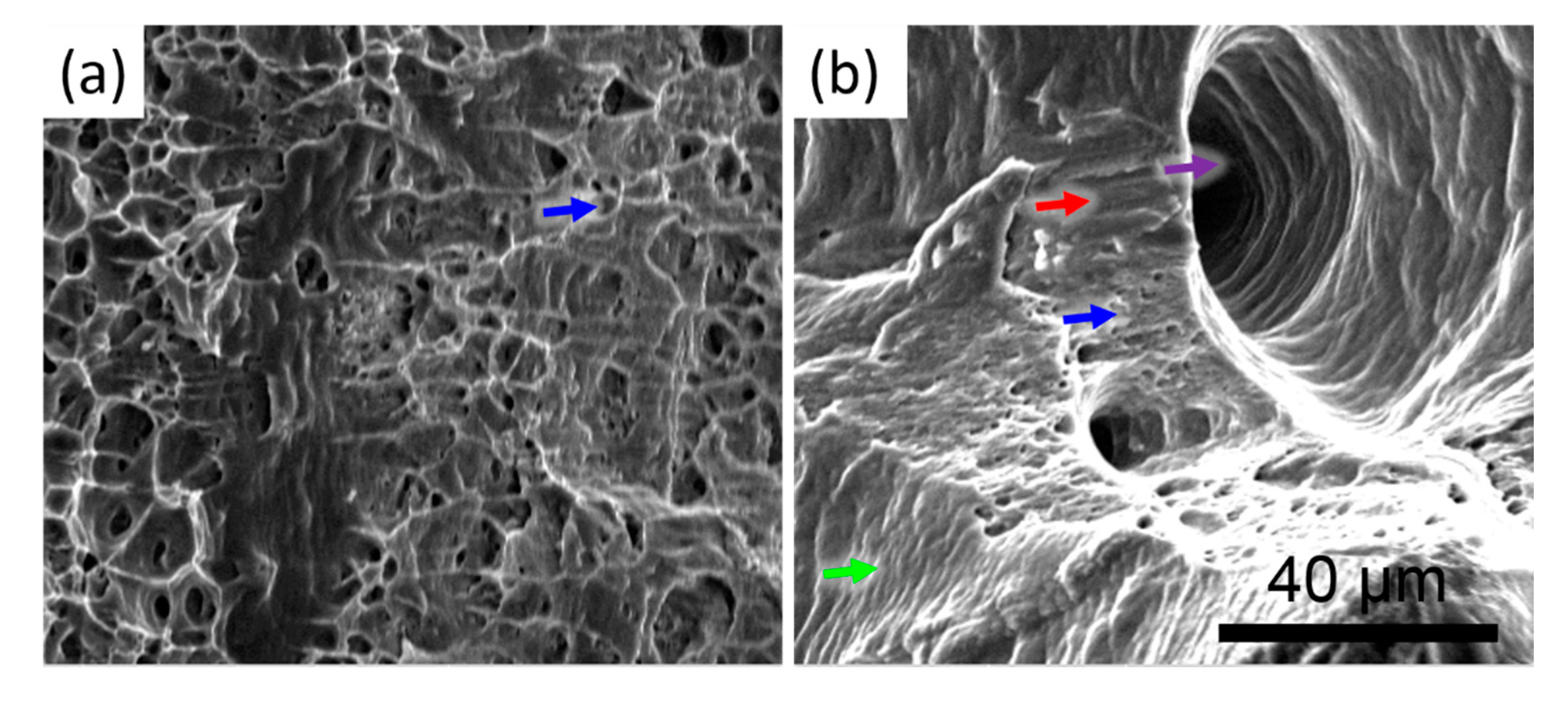

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 0411011. [Google Scholar] [CrossRef]

- Campbell, F.C. Manufacturing Technology for Aerospace Structural Materials; Elsevier Science: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Hirsch, J. Recent development in aluminum for automotive applications. Trans. Nonferrous Met. Soc. China 2014, 24, 1995–2002. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective laser melting of high strength Al-Cu-Mg Alloys: Processing, microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Gu, T.; Chen, B.; Tan, C.; Feng, J. Microstructure evolution and mechanical properties of laser additive manufacturing of high strength Al-Cu-Mg alloy. Opt. Laser Technol. 2019, 112, 140–150. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Bhattacharya, S.; Natu, H.; Dutta, B.; Mazumder, J. Microstructural Characterization of Laser-Deposited Al 4047 alloy. Metall. Mater. Trans. A 2013, 44, 2233–2242. [Google Scholar] [CrossRef]

- Chen, B.; Moon, S.K.; Yao, X.; Bi, G.; Shen, J.; Umeda, J.; Kondoh, K. Comparison study on additive manufacturing and powder metallurgy AlSi10Mg alloys. JOM 2018, 70, 644–649. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Humbeeck, J.V.; Kruth, J.P. Processing AlSi10Mg by selective laser melting: Parameter optimization and material characterization. Mater. Sci. Technol. 2015, 31, 917–923. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.P.; Humbeeck, J.V. Fine-structured aluminum products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Rana, R.S.; Purohit, R.; Das, S. Reviews on the influence of alloying elements on the microstructure and mechanical properties of aluminum alloys and aluminum alloy composites. Int. J. Sci. Res. Publ. 2012, 2, 1–7. [Google Scholar]

- Olakanmi, E.O. Selective laser sintering/melting (SLS/SLM) of pure Al, Al-Mg, and Al-Si powders: Effect of processing conditions and powder properties. J. Mater. Process. Technol. 2013, 213, 1387–1405. [Google Scholar] [CrossRef]

- Jerrard, P.G.E.; Hao, L.; Dadbakhsh, S.; Evans, K.E. Consolidation behavior and microstructure characteristics of pure aluminum and alloy powders following selective laser melting processing. In Proceedings of the 36th International MATADOR Conference, Manchester, UK, 14–16 July 2010; Springer: London, UK, 2010. [Google Scholar] [CrossRef]

- Shen, Y.; Li, Y.; Chen, C.; Tsai, H.L. 3D printing of large, complex metallic glass structures. Mater. Des. 2017, 117, 213–222. [Google Scholar] [CrossRef]

- Chen, C.; Shen, Y.; Tsai, H.L. A Foil-Based Additive Manufacturing Technology for Metal Parts. J. Manuf. Sci. Eng. 2016, 139, 024501. [Google Scholar] [CrossRef]

- Hung, C.H.; Sutton, A.; Li, Y.; Shen, Y.; Tsai, H.L.; Leu, M.C. Enhanced mechanical properties for 304L stainless steel parts fabricated by laser-foil-printing additive manufacturing. J. Manuf. Process. 2019, 45, 438–446. [Google Scholar] [CrossRef]

- Rombouts, M.; Froyen, L.; Gusarov, A.V.; Bentefour, E.H.; Glorieux, C. Photopyroelectric measurement of thermal conductivity of metallic powders. J. Appl. Phys. 2005, 97, 1–9. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- ASTM E2627-13. Standard Practice for Determining Average Grain Size Using Electron Backscatter Diffraction (EBSD) in Fully Recrystallized Polycrystalline Materials; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar] [CrossRef]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef]

- ASTM B209-14. Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar] [CrossRef]

- Zhou, J.; Tsai, H.L. Porosity formation and prevention in pulsed laser welding. J. Heat Transfer. 2007, 129, 1014–1024. [Google Scholar] [CrossRef]

- Antony, K.; Arivazhagan, N. Studies on energy penetration and Marangoni effect during laser melting process. J. Eng. Sci. Technol. 2015, 10, 509–525. [Google Scholar]

- Behler, K.; Berkanns, J.; Ehrhardt, A.; Frohn, W. Laser beam welding of low weight materials and structures. Mater. Des. 1998, 18, 261–267. [Google Scholar] [CrossRef]

- Cao, X.; Wallace, W.; Poon, C.; Immarigeon, J.P. Research and progress in laser welding of wrought aluminum alloys. I. laser welding processes. Mater. Manuf. Process. 2003, 18, 1–22. [Google Scholar] [CrossRef]

- Miyagi, M.; Wang, H.; Yoshida, R.; Kawahito, Y.; Kawakami, H.; Shubu, T. Effect of alloy element on weld pool dynamics in laser welding of aluminum alloys. Sci. Rep. 2018, 8, 1–10. [Google Scholar] [CrossRef]

- Alexander, M.R.; Thompson, G.E.; Zhou, X.; Beamson, G.; Fairley, N. Quantification of oxide film thickness at the surface of aluminum using XPS. Surf. Interface Anal. 2002, 34, 485–489. [Google Scholar] [CrossRef]

- Teng, X.; Mae, H.; Bai, Y.; Wierzbicki, T. Pore size and fracture ductility of aluminum low pressure die casting. Eng. Fract. Mech. 2009, 76, 983–996. [Google Scholar] [CrossRef]

- Conner, R.D.; Maire, R.E.; Johnson, W.L. Effect of oxygen concentration upon the ductility of amorphous Zr57Nb5Al10Cu15.4Ni12.6. Mater. Sci. Eng. A 2006, 419, 148–152. [Google Scholar] [CrossRef]

- Yin, H.B.; Koster, J.N. In-situ observed pore formation during solidification of aluminum. Iron Steel Inst. Jpn. 2000, 40, 364–372. [Google Scholar] [CrossRef]

- Yousefian, P. Pore Formation in Aluminum Castings: Theoretical Calculations and the Extrinsic Effect of Entrained Surface Oxide Films. Master’s Theses, College of Computing, Engineering & Construction, Jacksonville, FL, USA, 2017. [Google Scholar] [CrossRef]

- Fernandino, D.O.; Boeri, R.E. Fracture analysis. ASM Handb. 2017, 1, 399–410. [Google Scholar] [CrossRef]

- Nie, F.; Dong, H.; Chen, S.; Li, P.; Wang, L.; Zhao, Z.; Li, X.; Zhang, H. Microstructure and mechanical properties of pulse MIG welded 6061/A356 aluminum alloy dissimilar butt joints. J. Mater. Sci. Technol. 2016, 34, 551–560. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, X.; Tor, S.B.; Yeong, W.Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Mater. Des. 2016, 104, 197–204. [Google Scholar] [CrossRef]

| Mechanical Property | Source | DOF | Adj SS | F-Value | p-Value |

|---|---|---|---|---|---|

| YS | Process | 1 | 5114.8 | 112.16 | 0.000 |

| Error | 13 | 592.8 | |||

| UTS | Process | 1 | 2076.3 | 204.56 | 0.000 |

| Error | 13 | 132.0 | |||

| Strain | Process | 1 | 2304.7 | 82.89 | 0.000 |

| Error | 13 | 286.5 |

| Element | Fe | Mn | Cu | Si | Zn | Al |

|---|---|---|---|---|---|---|

| LFP | 0.4 | 0.0 | 0.0 | 0.2 | 0.0 | Bal. |

| Annealed | 0.5 | 0 | 0.2 | 0 | 0 | Bal. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, C.-H.; Li, Y.; Sutton, A.; Chen, W.-T.; Gong, X.; Pan, H.; Tsai, H.-L.; Leu, M.C. Aluminum Parts Fabricated by Laser-Foil-Printing Additive Manufacturing: Processing, Microstructure, and Mechanical Properties. Materials 2020, 13, 414. https://doi.org/10.3390/ma13020414

Hung C-H, Li Y, Sutton A, Chen W-T, Gong X, Pan H, Tsai H-L, Leu MC. Aluminum Parts Fabricated by Laser-Foil-Printing Additive Manufacturing: Processing, Microstructure, and Mechanical Properties. Materials. 2020; 13(2):414. https://doi.org/10.3390/ma13020414

Chicago/Turabian StyleHung, Chia-Hung, Yingqi Li, Austin Sutton, Wei-Ting Chen, Xiangtao Gong, Heng Pan, Hai-Lung Tsai, and Ming C. Leu. 2020. "Aluminum Parts Fabricated by Laser-Foil-Printing Additive Manufacturing: Processing, Microstructure, and Mechanical Properties" Materials 13, no. 2: 414. https://doi.org/10.3390/ma13020414

APA StyleHung, C.-H., Li, Y., Sutton, A., Chen, W.-T., Gong, X., Pan, H., Tsai, H.-L., & Leu, M. C. (2020). Aluminum Parts Fabricated by Laser-Foil-Printing Additive Manufacturing: Processing, Microstructure, and Mechanical Properties. Materials, 13(2), 414. https://doi.org/10.3390/ma13020414