Aluminum Inserts for Enhancing Heat Transfer in PCM Accumulator

Abstract

1. Introduction

- no chemical reaction between the ceramic mold and the chosen casting alloy,

- sufficient gas permeability and strength of the ceramic mold, especially during the metal alloy pouring stage,

- precise cleaning of the casting surface from the remnants of ceramic plaster.

2. Materials and Methods

3. Results and Discussion

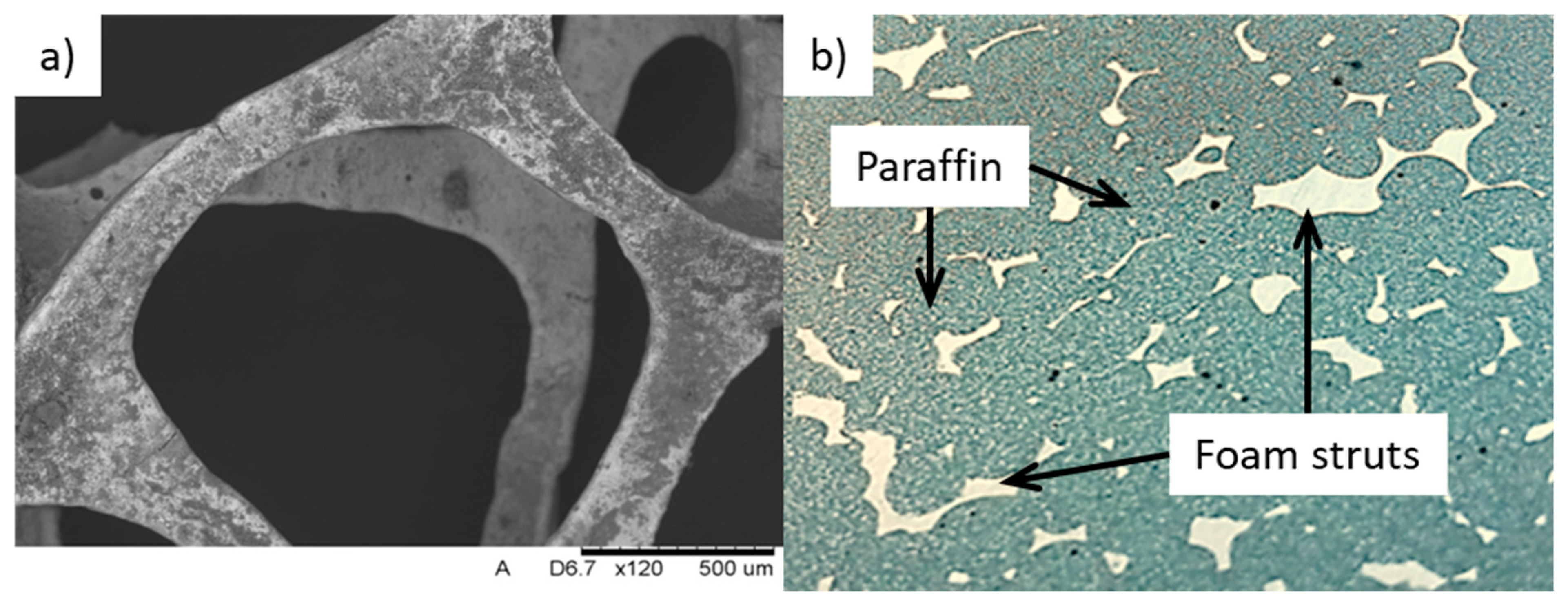

3.1. Investment Casting of Metallic Foams

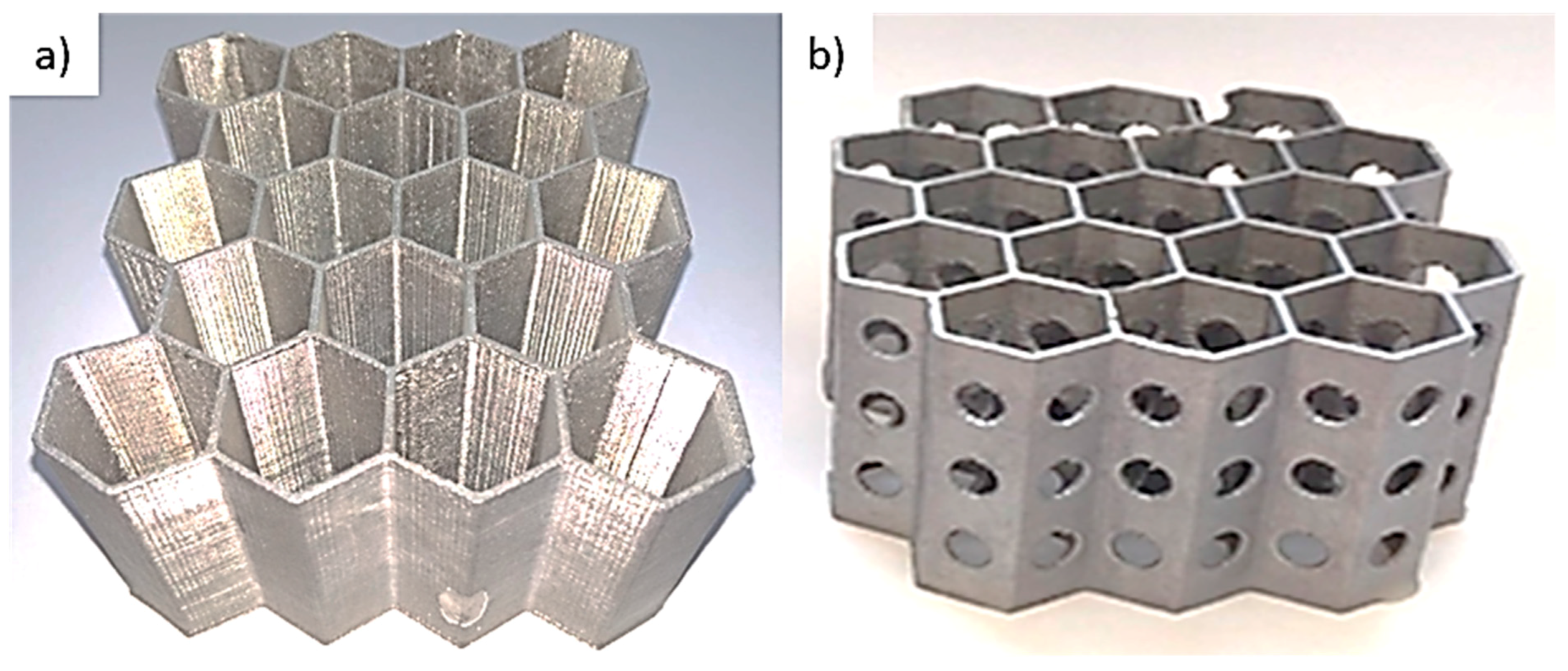

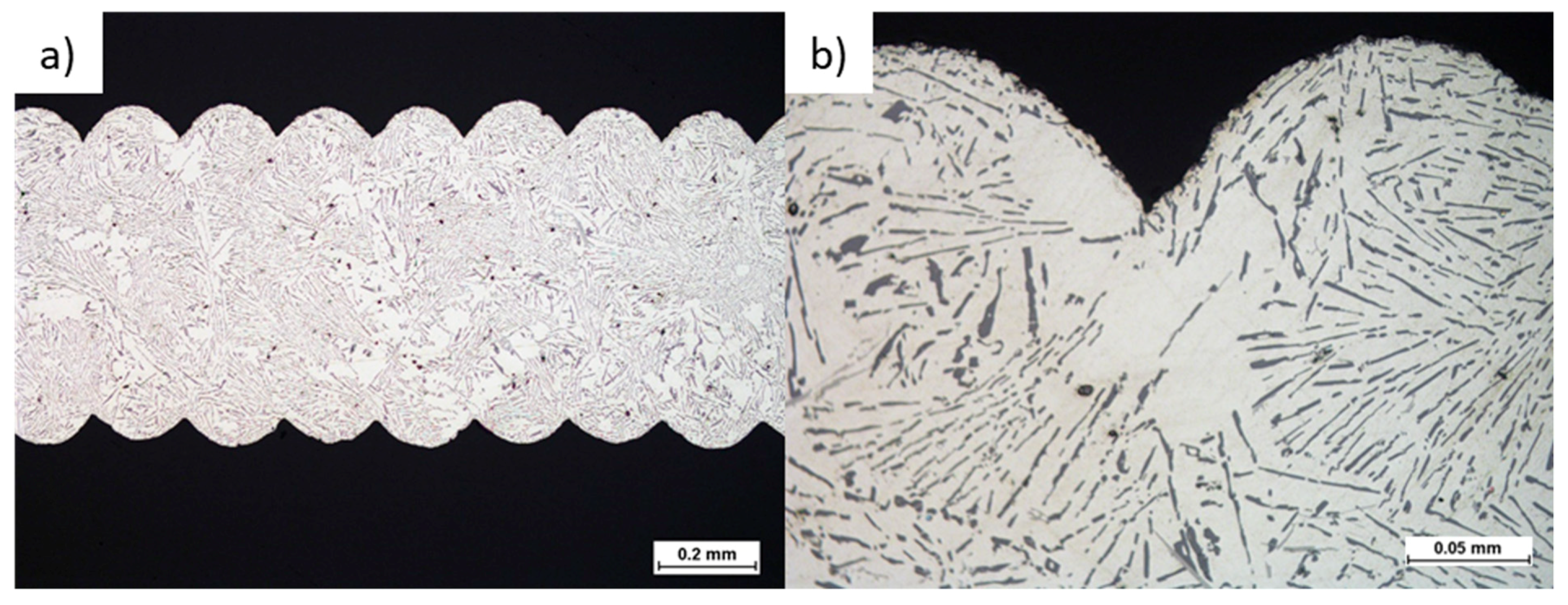

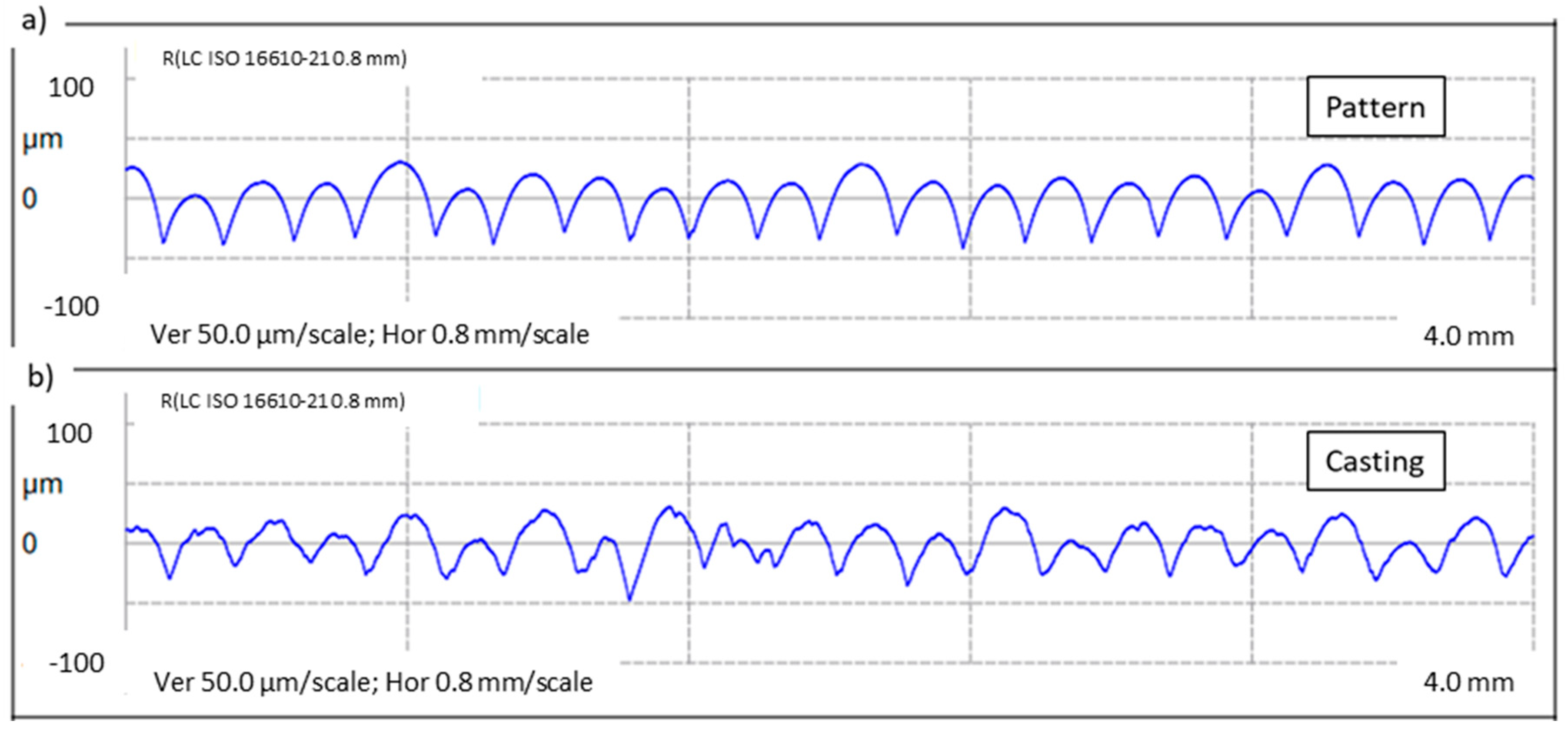

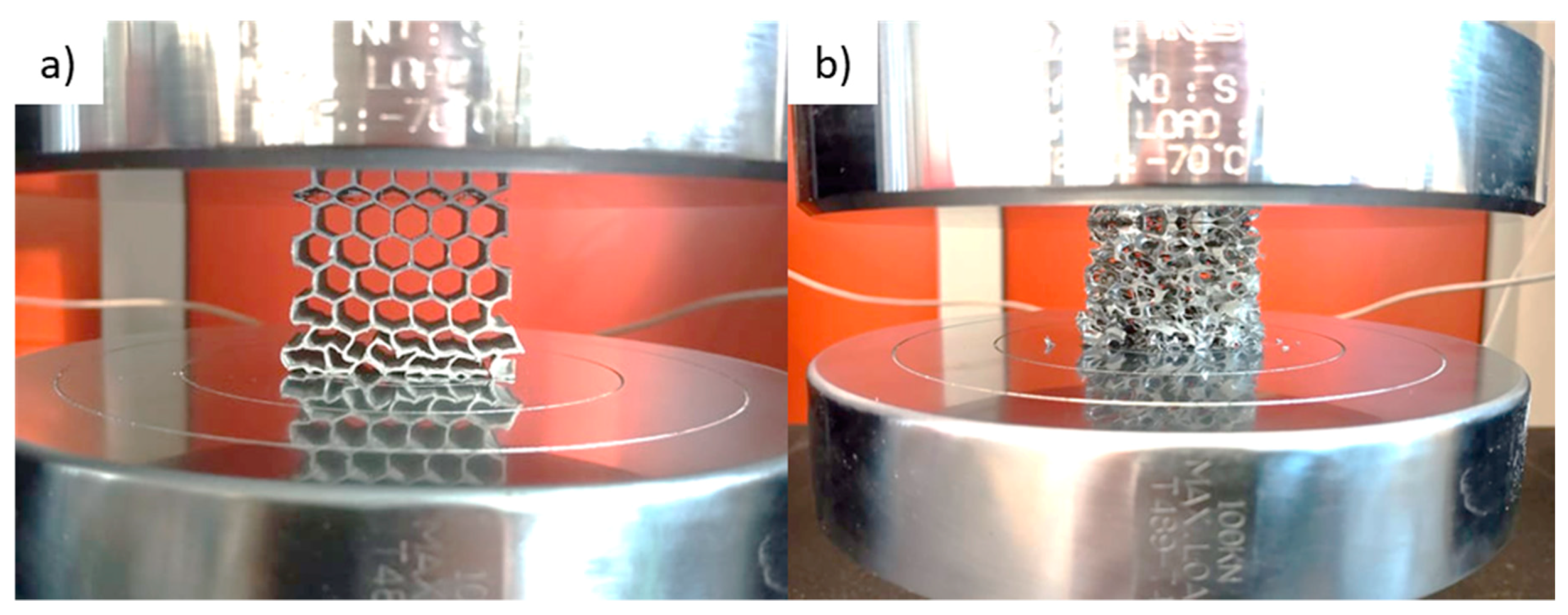

3.2. Investment Casting of Honeycomb Structures

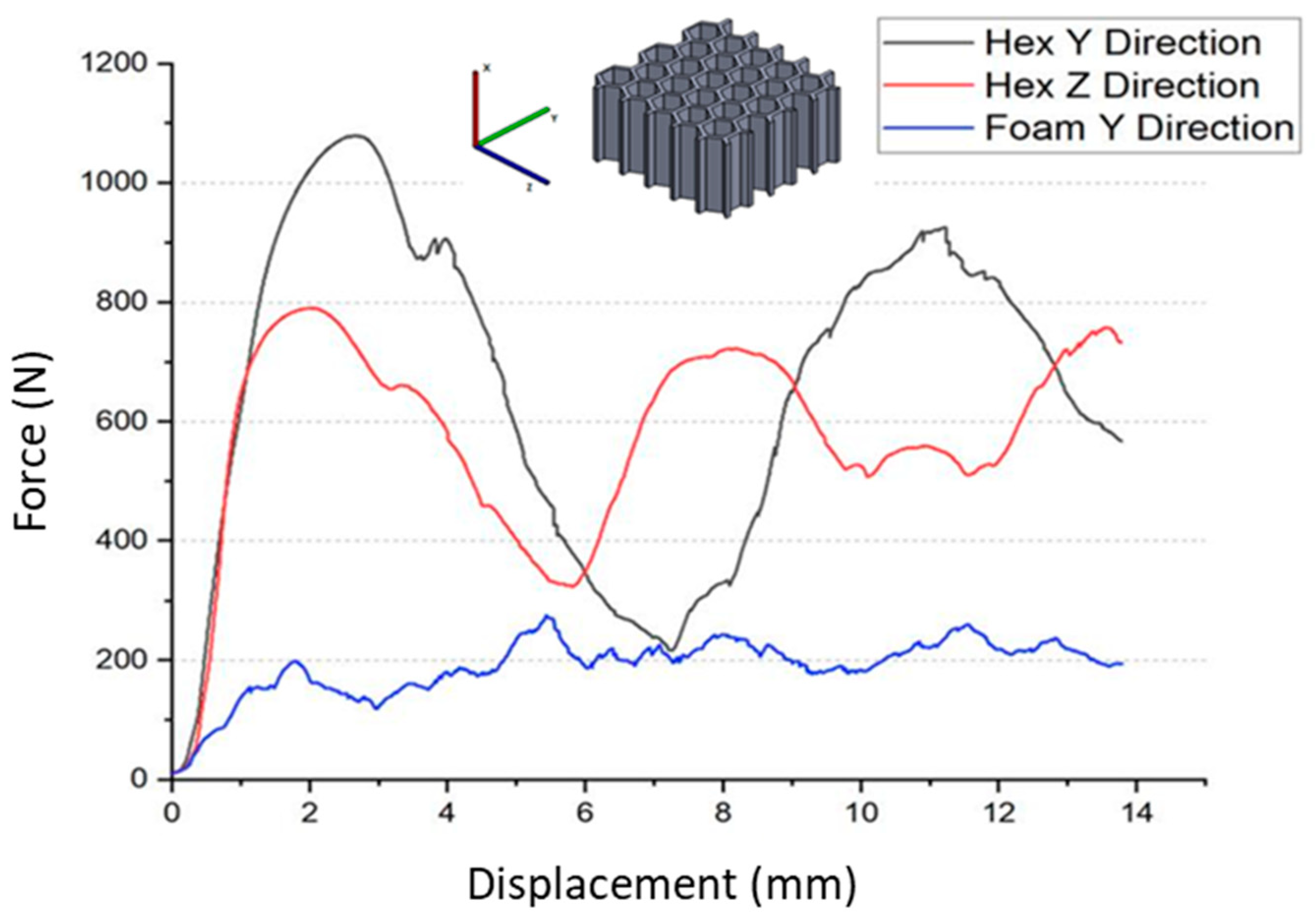

3.3. Compressive Strength of Metallic Foams and Honeycomb Structures

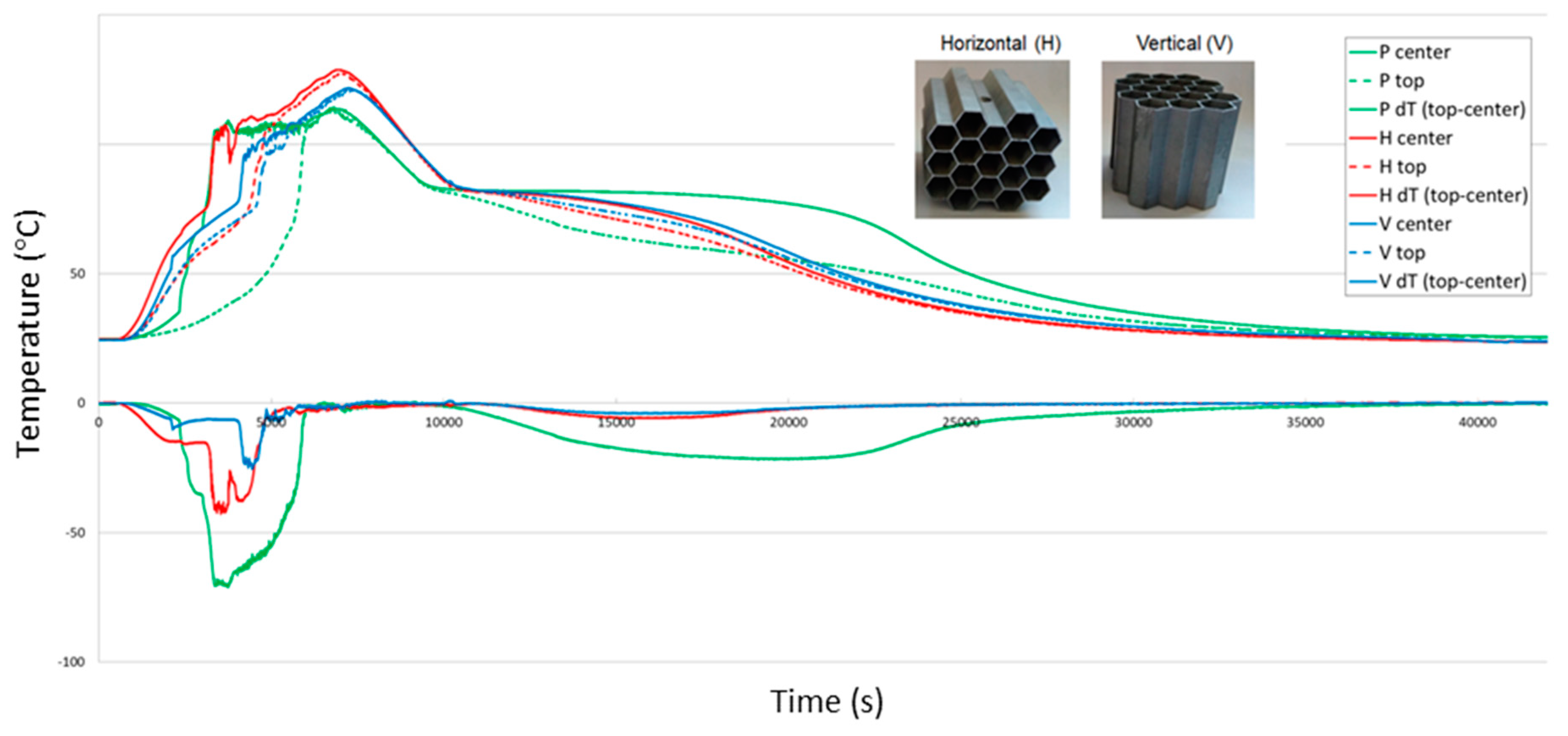

3.4. Heat Transfer Performance of Honeycomb Structures

4. Conclusions

- High fatigue resistance observed during the charging/discharging cycles and compressive strength of honeycomb structures in comparison to the ones of metallic foams cause them to be a more preferable and beneficial solution for improvement of the performance of PCM-based heat accumulators,

- Metallic inserts positively affect the performance of the entire energy storage system, facilitating heat transfer within the PCM material in thermal energy accumulators. Their use results in reduced charging time, a longer heat release time, increased maximum temperature, and a significant reduction in the temperature gradient in the heat storage unit. The most promising results, due to the enhanced thermal conduction and convection, still sustaining the possibly low volume content of metal in paraffin, resulting in the honeycombs with cells positioned vertically.

- Manufacturing of polymer patterns via the FDM printing method may be considered beneficial for enhancing the heat transfer due to the increased surface area and developed micro-finned structure.

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, C.Y.; Zhou, D.; Wu, Z.G. Heat transfer of phase change materials (PCMs) in porous materials. Front. Energy 2011, 5, 174–180. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Lu, W.; Tian, Y. Heat transfer enhancement for thermal energy storage using metal foams embedded within phase change materials (PCMs). Sol. Energy 2010, 84, 1402–1412. [Google Scholar] [CrossRef]

- Zhao, C.Y. Review on thermal transport in high porosity cellular metal foams with open cells. Int. J. Heat Mass Transf. 2012, 55, 3618–3632. [Google Scholar] [CrossRef]

- Munoz-Sanchez, B.; Iparraguirre-Torres, I.; Madina-Arrese, V.; Izagirre-Etxeberria, U.; Unzurrunzaga-Iturbe, A.; Garcia-Romero, A. Encapsulated high temperature PCM as active filler material in a thermocline-based thermal storage system. Energy Procedia 2015, 69, 937–946. [Google Scholar] [CrossRef]

- Caceres, G.; Fullenkamp, K.; Montane, M.; Naplocha, K.; Dmitruk, A. Encapsulated nitrates phase change material selection for use as thermal storage and heat transfer materials at high temperature in concentrated solar power plants. Energies 2017, 10, 1318. [Google Scholar] [CrossRef]

- Nomura, T.; Okinaka, N.; Akiyama, T. Impregnation of porous material with phase change material for thermal energy storage. Mater. Chem. Phys. 2009, 115, 846–850. [Google Scholar] [CrossRef]

- Aydin, D.; Casey, S.P.; Riffat, S. The latest advancements on thermochemical heat storage systems. Renew. Sustain. Energy Rev. 2015, 41, 356–367. [Google Scholar] [CrossRef]

- Naplocha, K.; Dmitruk, A.; Lichota, J.; Kaczmar, J. Enhancement of heat transfer in PCM by cellular Zn-Al structure. Arch. Foundry Eng. 2016, 16, 91–94. [Google Scholar] [CrossRef][Green Version]

- Naplocha, K.; Dmitruk, A.; Kaczmar, J.; Lichota, J.; Smykowski, D. Effects of cellular metals on the performances and durability of composite heat storage systems. Int. J. Heat Mass Transf. 2017, 114, 1214–1219. [Google Scholar] [CrossRef]

- Sivasamy, P.; Devaraju, A.; Harikrishnan, S. Review on heat transfer enhancement of Phase Change Materials (PCMs). Mater. Today Proc. 2018, 5, 14423–14431. [Google Scholar] [CrossRef]

- Qu, Z. Heat transfer enhancement technique of PCMs and its lattice Boltzmann modelling. Thermal energy battery with nano-enhanced PCM. IntechOpen 2019. [Google Scholar] [CrossRef]

- Tao, Y.B.; You, Y.; He, Y.L. Lattice Boltzmann simulation of phase change heat transfer in metal foams/paraffin phase change material. Appl. Eng. 2016, 93, 476–485. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, P.; Li, M. Effective thermal conductivity of open-cell metal foams impregnated with pure paraffin for latent heat storage. Int. J. Sci. 2014, 81, 94–105. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, P. Morphologies and thermal characterization of paraffin/carbon foam composite phase change material. Sol. Energy Mater. Sol. Cells 2013, 117, 451–461. [Google Scholar] [CrossRef]

- Nadolski, M.; Konopka, Z.; Łągiewka, M.; Zyska, A. Mechanical properties of investment casting moulds reinforced with ceramic fibre. Arch. Foundry Eng. 2008, 8, 149–152. [Google Scholar]

- Cholewa, M.; Dziuba, M.; Kondracki, M.; Suchoń, J. Validation Studies of Temperature Distribution and Mould Filling Process for Composite Skeleton Castings. Arch. Foundry Eng. 2008, 8, 163–168. [Google Scholar]

- Tryteka, A.; Nawrocki, J.; Sarek, D. Lost wax process–mould properties. Arch. Foundry Eng. 2010, 10, 427–430. [Google Scholar]

- Nadolski, M.; Konopka, Z.; Łągiewka, M.; Zyska, A. Examining of slurries and production of moulds by spraying method in lost wax technology. Arch. Foundry Eng. 2008, 8, 107–110. [Google Scholar]

- Sahoo, S.K.; Das, M.K.; Rath, P. Application of TCE-PCM based heat sinks for cooling of electronic components: A review. Renew. Sustain. Energy Rev. 2016, 59, 550–582. [Google Scholar] [CrossRef]

- Fatoba, O.; Akid, R. Low cycle fatigue behaviour of API 5L X65 pipeline steel at room temperature. Proc. Eng. 2014, 74, 279–286. [Google Scholar] [CrossRef]

- Unigovski, Y.B.; Grinberg, A.; Gutman, E.M. Low-cycle fatigue of the light advanced materials. Proc. Eng. 2013, 66, 713–722. [Google Scholar] [CrossRef]

- Ingraham, M.D.; DeMaria, C.J.; Issen, K.A.; Morrison, D.J. Low cycle fatigue of aluminum foam. Mater. Sci. Eng. A 2009, 504, 150–156. [Google Scholar] [CrossRef]

- Puga, H.; Carneiro, V.H.; Correira, P.; Vieira, V.; Barbosa, J.; Meireles, J. Mechanical behavior of honeycomb lattices manufactured by investment casting for scaffolding applications. J. Mater. Des. Appl. 2017, 231, 73–81. [Google Scholar] [CrossRef]

- Hedges, P.J. Extended surface heat transfer in heat exchangers and performance measurements. Heat Transf. Enhanc. Heat Exch. 1999, 49–66. [Google Scholar] [CrossRef]

- Pioro, I.L.; Rohsenow, W.; Doerffer, S.S. Nucleate pool-boiling heat transfer – I. Review of parametric effects of boiling surface. Int. J. Heat Mass Transf. 2004, 47, 5033–5044. [Google Scholar] [CrossRef]

- Longo, G.A.; Gasparella, A.; Sartori, R. Experimental heat transfer coefficients during refrigerant vaporisation and condensation inside herringbone-type plate heat exchangers with enhanced surfaces. Heat Mass Transf. 2004, 47, 4125–4136. [Google Scholar] [CrossRef]

- Copetti, J.B.; Macagnan, M.H.; de Souza, D.; Oliveski, R.D.C. Experiments with micro-fin tube in single phase. Int. J. Refrig. 2004, 27, 876–883. [Google Scholar] [CrossRef]

- Schlager, L.M.; Pate, M.B.; Bergles, A.E. Evaporation and Condensation Heat Transfer and Pressure Drop in Horizontal, 12.7-mm Microfin Tubes with Refrigerant 22. J. Heat Transf. 1990, 112, 1041–1047. [Google Scholar] [CrossRef]

- Bandarra Filho, E.P.; Barbieri, P.E.L. Flow boiling performance in horizontal microfinned copper tubes with the same geometric characteristics. Expel. Fluid Sci. 2011, 35, 832–840. [Google Scholar] [CrossRef]

- Pethkool, S.; Eiamsa-ard, S.; Kwankaomeng, S.; Promvonge, P. Turbulent heat transfer enhancement in a heat exchanger using helically corrugated tube. Int. Comm. Heat Mass Transf. 2011, 38, 34–347. [Google Scholar] [CrossRef]

- Yang, C.Y. Condensation of R-12 in small hydraulic diameter extruded aluminum tubes with and without micro-fins. Int. J. Heat Mass Transf. 1996, 39, 791–800. [Google Scholar] [CrossRef]

- Agyenim, F.; Hewitt, N.; Eames, P.; Smyth, M. A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew. Sustain. Energy Rev. 2010, 114, 615–628. [Google Scholar] [CrossRef]

- Choi, J.C.; Kim, S.D. Heat-transfer characteristics of a latent heat storage system using MgCl2 6H2O. Energy 1992, 17, 1153–1164. [Google Scholar] [CrossRef]

- Mahmoud, S.; Tang, A.; Toh, C.; AL-Dadah, R.; Soo, S.L. Experimental investigation of inserts configurations and PCM type on the thermal performance of PCM based heat sinks. Appl. Energy 2013, 112, 1349–1356. [Google Scholar] [CrossRef]

| Material | Latent Heat (kJ/kg) | Density (g/cm3) | Melting Point (°C) | Thermal Conductivity (W/m·K) | Thermal Diffusivity (mm2/s) |

|---|---|---|---|---|---|

| Al | 397 | 2.7 | 660 | 237 | 97 |

| AC 44200 Al alloy | 570 | 2.5 | 590 | 140–170 | 58 |

| Cu | 209 | 8.9 | 1085 | 401 | 111 |

| Graphite | - | 2.1 | - | 90 | 1220 |

| Paraffin | 147–184 | 0.8 | 54–64 | 0.2–0.25 | 0.1 |

| KNO3 | 116 | 2.1 | 337 | 0.4–0.5 | - |

| Paraffin/Cu foam | - | - | - | 3–10 | - |

| Paraffin/EG foam | - | - | - | 16–24 | - |

| NaNO3–KNO3–EG foam | - | - | - | 10–40 | - |

| Material | Ra | Rz | ||

|---|---|---|---|---|

| (µm) | σ | (µm) | σ | |

| 3D polymer pattern | 12.97 | 0.28 | 59.96 | 1.76 |

| Al–Si casting | 12.83 | 0.98 | 58.81 | 3.56 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dmitruk, A.; Naplocha, K.; Grzęda, J.; Kaczmar, J.W. Aluminum Inserts for Enhancing Heat Transfer in PCM Accumulator. Materials 2020, 13, 415. https://doi.org/10.3390/ma13020415

Dmitruk A, Naplocha K, Grzęda J, Kaczmar JW. Aluminum Inserts for Enhancing Heat Transfer in PCM Accumulator. Materials. 2020; 13(2):415. https://doi.org/10.3390/ma13020415

Chicago/Turabian StyleDmitruk, Anna, Krzysztof Naplocha, Jakub Grzęda, and Jacek W. Kaczmar. 2020. "Aluminum Inserts for Enhancing Heat Transfer in PCM Accumulator" Materials 13, no. 2: 415. https://doi.org/10.3390/ma13020415

APA StyleDmitruk, A., Naplocha, K., Grzęda, J., & Kaczmar, J. W. (2020). Aluminum Inserts for Enhancing Heat Transfer in PCM Accumulator. Materials, 13(2), 415. https://doi.org/10.3390/ma13020415