Temperature Dependence of the Magnetic Properties of IrMn/CoFeB/Ru/CoFeB Exchange Biased Synthetic Antiferromagnets

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

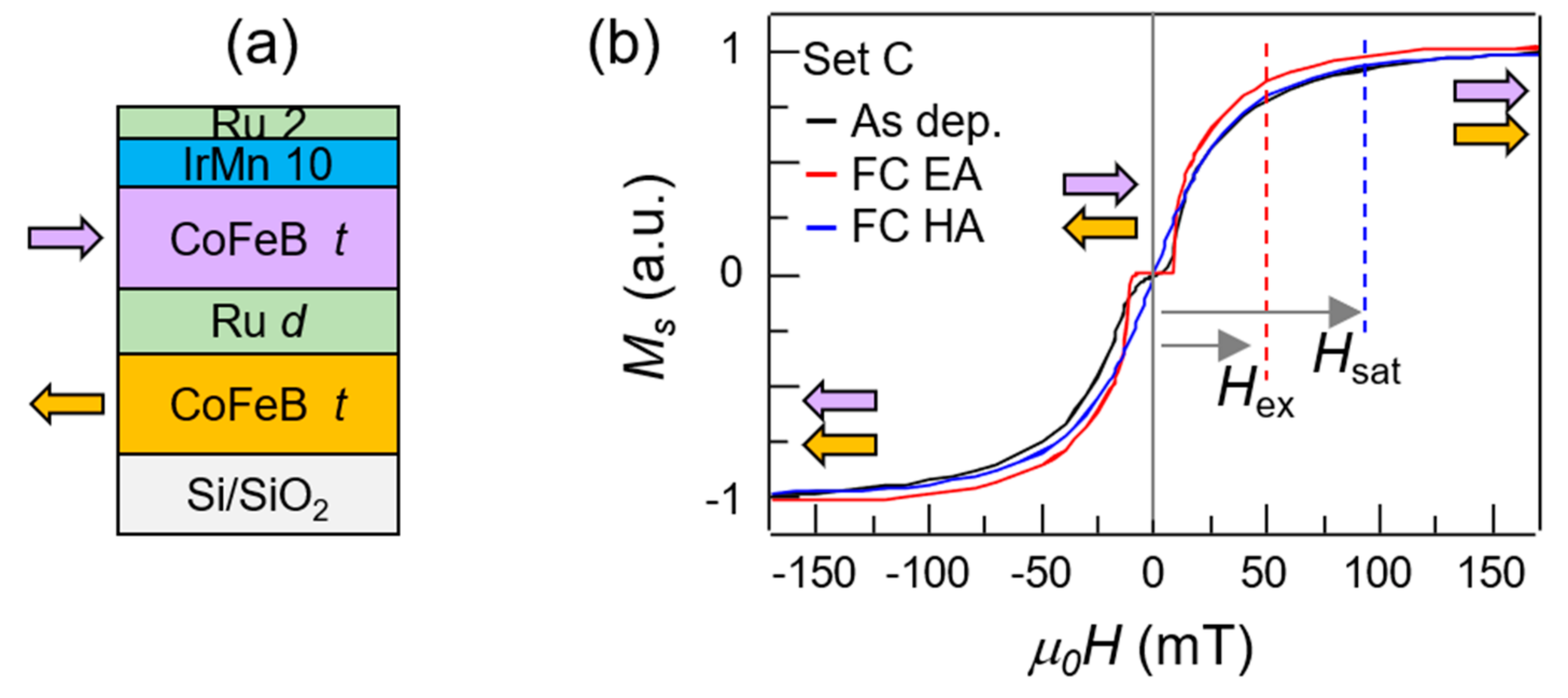

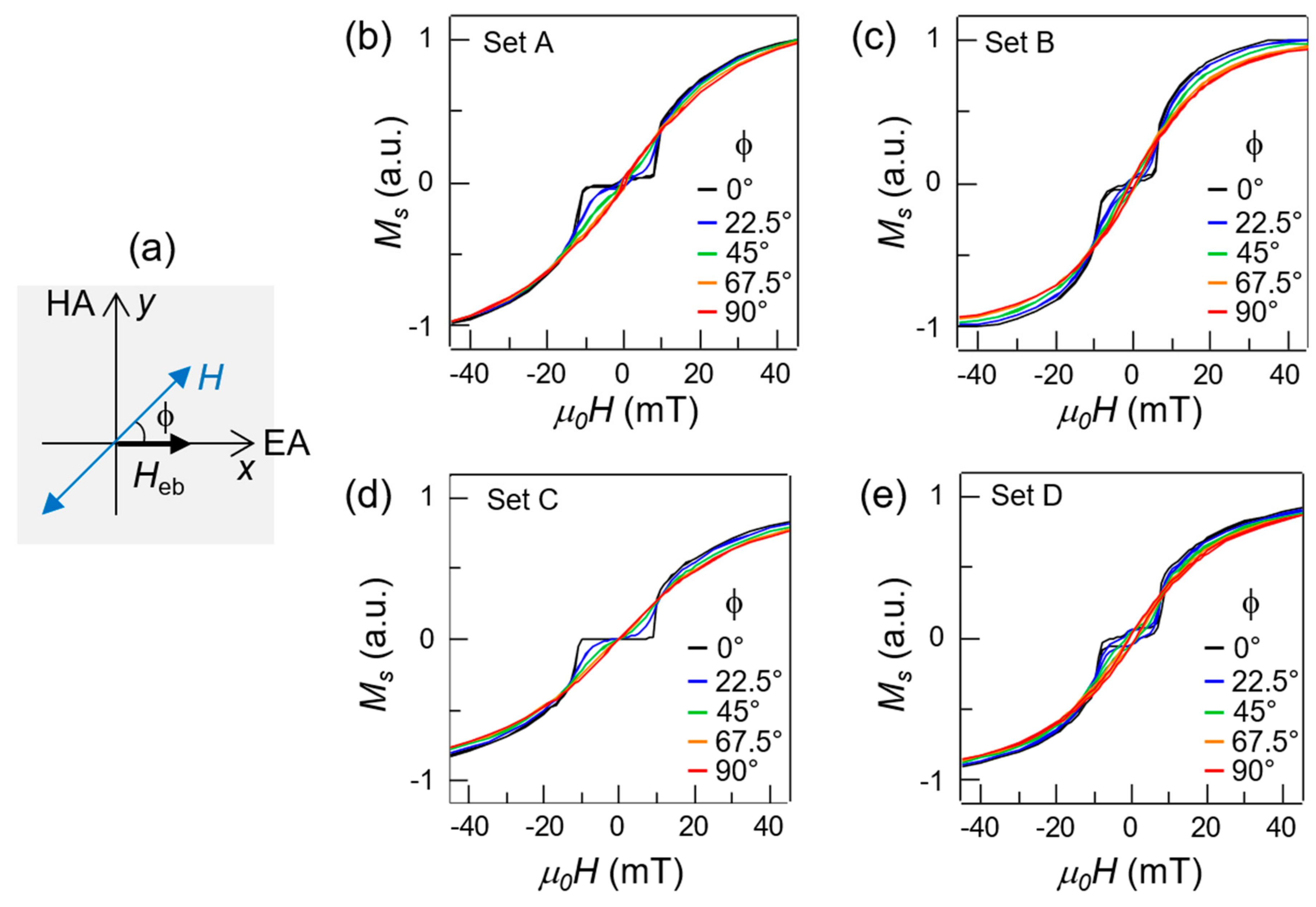

3.1. Room-Temperature Magnetic Characterization and Angular Hysteresis Loops

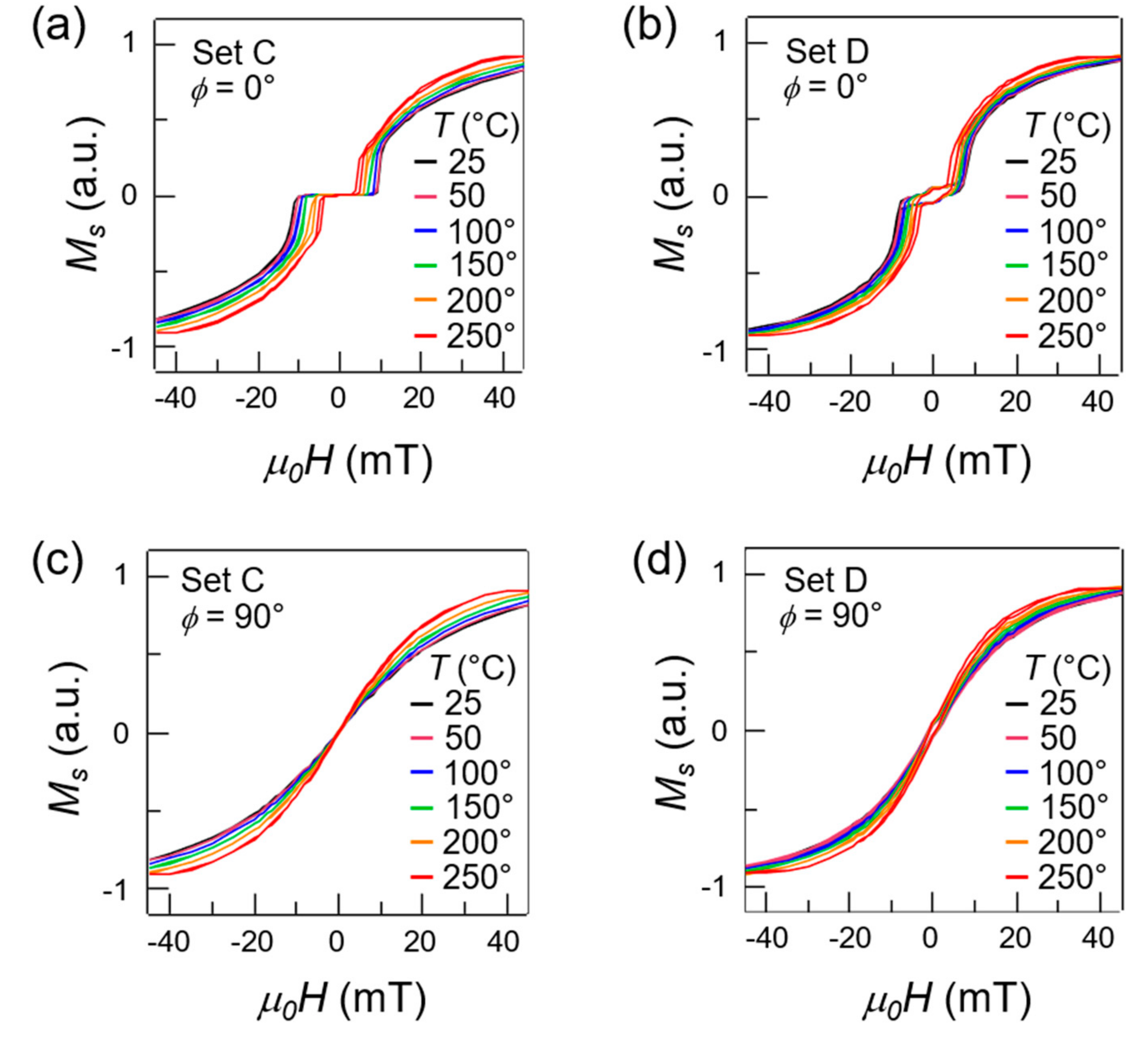

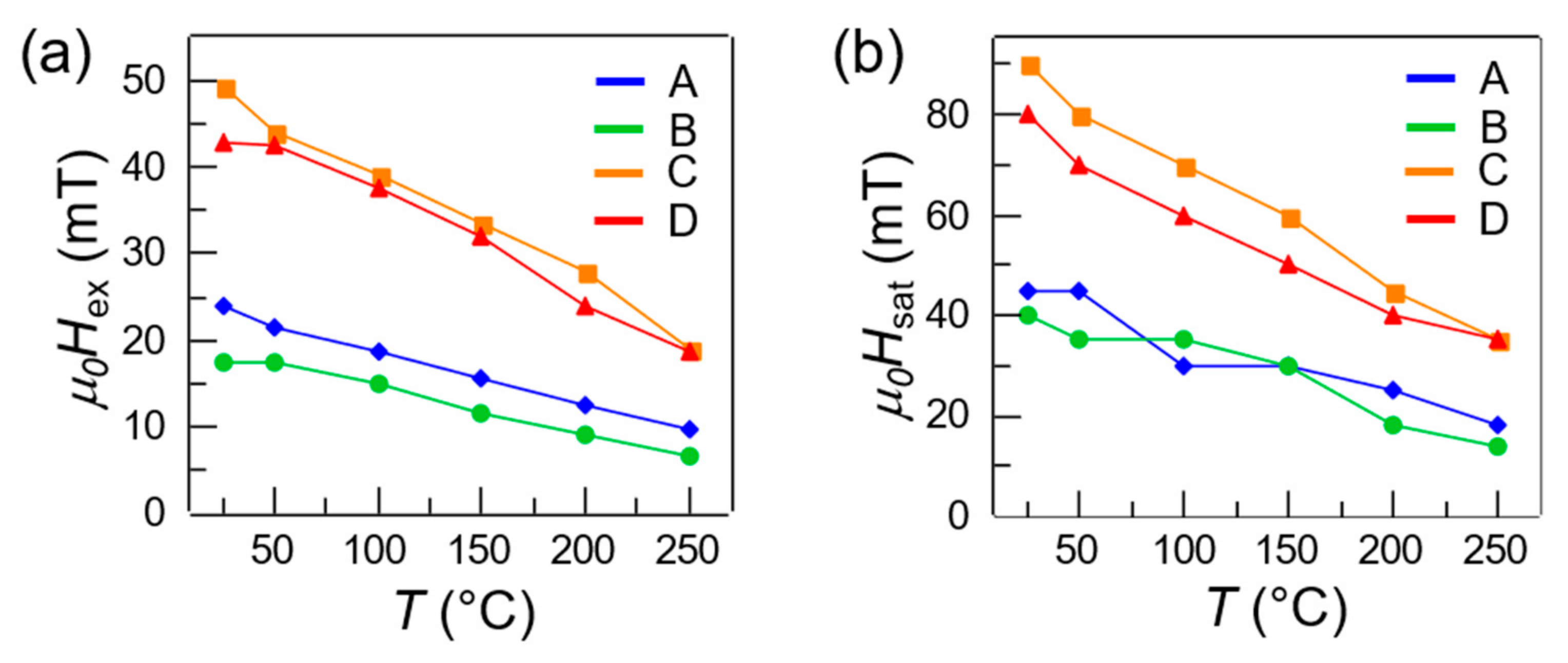

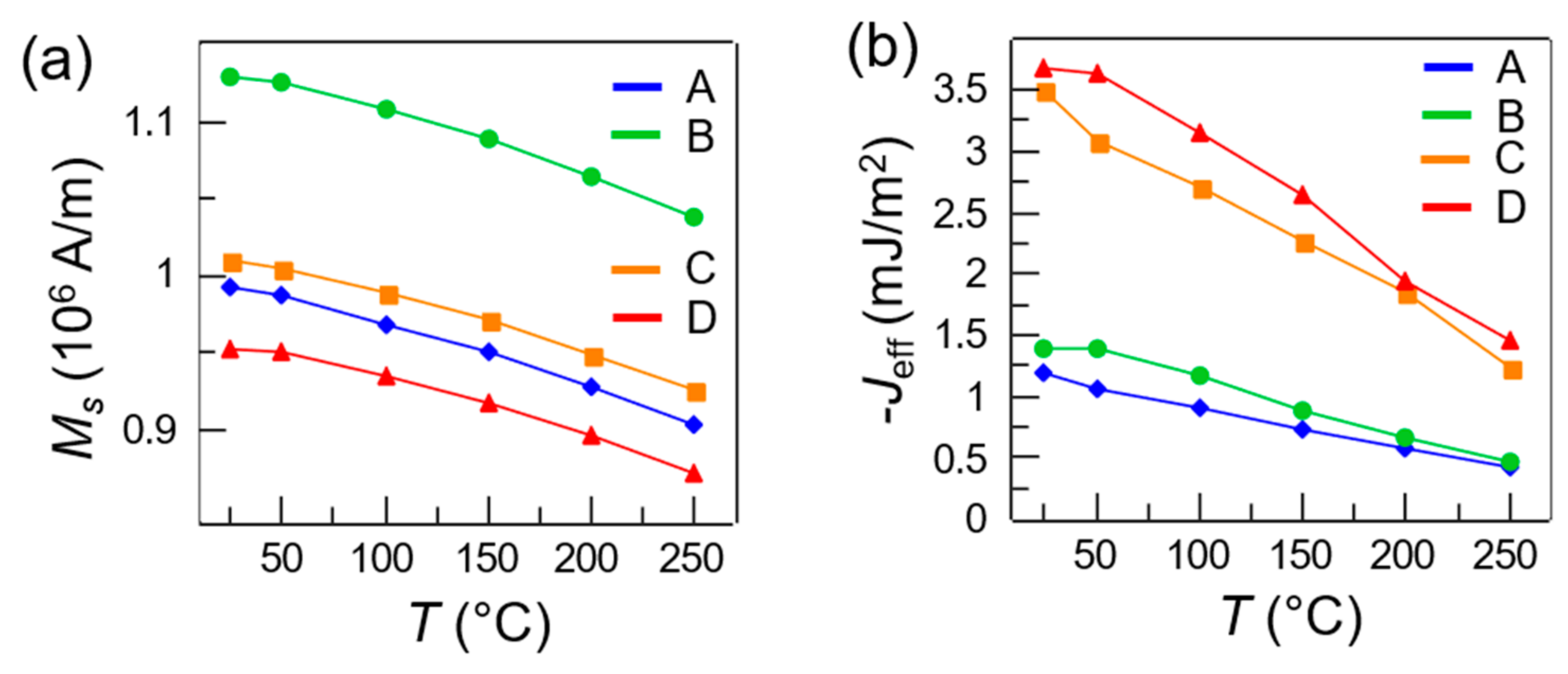

3.2. Temperature Dependence of the Magnetic Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Grünberg, P.; Schreiber, R.; Pang, Y. Layered Magnetic Structures: Evidence for Antiferromagnetic Coupling of Fe Layers across Cr Interlayers. Phys. Rev. Lett. 1986, 57, 2442–2445. [Google Scholar] [CrossRef] [PubMed]

- Parkin, S.S.P.; More, N.; Roche, K.P. Oscillations in exchange coupling and magnetoresistance in metallic superlattice structures: Co/Ru, Co/Cr, and Fe/Cr. Phys. Rev. Lett. 1990, 64, 2304–2307. [Google Scholar] [CrossRef] [PubMed]

- Bruno, P.; Chappert, C. Oscillatory coupling between ferromagnetic layers separated by a nonmagnetic metal spacer. Phys. Rev. Lett. 1991, 67, 1602–1605. [Google Scholar] [CrossRef] [PubMed]

- Dieny, B.; Speriosu, V.S.; Gurney, B.A.; Parkin, S.S.P.; Wilhoit, D.R.; Roche, K.P.; Metin, S.; Peterson, D.T.; Nadimi, S. Spin-valve effect in soft ferromagnetic sandwiches. J. Magn. Magn. Mater. 1991, 93, 101–104. [Google Scholar] [CrossRef]

- Kerr, E.; van Dijken, S.; Coey, J.M.D. Influence of the annealing field strength on exchange bias and magnetoresistance of spin valves with IrMn. J. Appl. Phys. 2005, 97, 093910. [Google Scholar] [CrossRef]

- Yuasa, S.; Djayaprawira, D.D. Giant tunnel magnetoresistance in magnetic tunnel junctions with a crystalline MgO(0 0 1) barrier. J. Phys. D. Appl. Phys. 2007, 40, R337–R354. [Google Scholar] [CrossRef]

- Zaleski, A.; Skowronski, W.; Czapkiewicz, M.; Kanak, J.; Stobiecki, T.; Macedo, R.; Cardoso, S.; Freitas, P.P. Reduction of critical current in magnetic tunnel junctions with CoFeB/Ru/CoFeB synthetic free layer. J. Phys. Conf. Ser. 2010, 200, 052035. [Google Scholar] [CrossRef]

- Cuchet, L.; Rodmacq, B.; Auffret, S.; Sousa, R.C.; Prejbeanu, I.L.; Dieny, B. Perpendicular magnetic tunnel junctions with a synthetic storage or reference layer: A new route towards Pt- and Pd-free junctions. Sci. Rep. 2016, 6, 21246. [Google Scholar] [CrossRef]

- Lee, Y.M.; Hayakawa, J.; Ikeda, S.; Matsukura, F.; Ohno, H. Giant tunnel magnetoresistance and high annealing stability in CoFeB/MgO/CoFeB magnetic tunnel junctions with synthetic pinned layer. Appl. Phys. Lett. 2006, 89, 87–90. [Google Scholar] [CrossRef]

- Baibich, M.N.; Broto, J.M.; Fert, A.; Van Dau, F.N.; Petroff, F.; Etienne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant Magnetoresistance of (001)Fe/(001)Cr Magnetic Superlattices. Phys. Rev. Lett. 1988, 61, 2472–2475. [Google Scholar] [CrossRef]

- Binasch, G.; Grünberg, P.; Saurenbach, F.; Zinn, W. Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange. Phys. Rev. B 1989, 39, 4828–4830. [Google Scholar] [CrossRef] [PubMed]

- Childress, J.R.; Carey, M.J.; Wilson, R.J.; Smith, N.; Tsang, C.; Ho, M.K.; Carey, K.; Macdonald, S.A.; Ingall, L.M.; Gurney, B.A. IrMn Spin-Valves for High Density Recording. IEEE Trans. Magn. 2001, 37, 1745–1748. [Google Scholar] [CrossRef]

- Parkin, S.; Jiang, X.; Kaiser, C.; Panchula, A.; Roche, K.; Samant, M. Magnetically engineered spintronic sensors and memory. Proc. IEEE 2003, 91, 661–680. [Google Scholar] [CrossRef]

- Bhatti, S.; Sbiaa, R.; Hirohata, A.; Ohno, H.; Fukami, S.; Piramanayagam, S.N. Spintronics based random access memory: A review. Mater. Today 2017, 20, 530–548. [Google Scholar] [CrossRef]

- Smith, N.; Maat, S.; Carey, M.J.; Childress, J.R. Coresonant Enhancement of Spin-Torque Critical Currents in Spin Valves with a Synthetic-Ferrimagnet Free Layer. Phys. Rev. Lett. 2008, 101, 247205. [Google Scholar] [CrossRef]

- Hrkac, G.; Keatley, P.S.; Bryan, M.T.; Butler, K. Magnetic vortex oscillators. J. Phys. D. Appl. Phys. 2015, 48, 453001. [Google Scholar] [CrossRef]

- Search, H.; Journals, C.; Contact, A.; Iopscience, M.; Address, I.P.; Freitas, P.P.; Ferreira, R.; Cardoso, S.; Cardoso, F. Magnetoresistive sensors. J. Phys. Condens. Matter 2007, 19, 165221. [Google Scholar]

- Gaster, R.S.; Xu, L.; Han, S.-J.; Wilson, R.J.; Hall, D.A.; Osterfeld, S.J.; Yu, H.; Wang, S.X. Quantification of protein interactions and solution transport using high-density GMR sensor arrays. Nat. Nanotechnol. 2011, 6, 314–320. [Google Scholar] [CrossRef]

- Donolato, M.; Sogne, E.; Dalslet, B.T.; Cantoni, M.; Petti, D.; Cao, J.; Cardoso, F.; Cardoso, S.; Freitas, P.P.; Hansen, M.F.; et al. On-chip measurement of the Brownian relaxation frequency of magnetic beads using magnetic tunneling junctions. Appl. Phys. Lett. 2011, 98, 073702. [Google Scholar] [CrossRef]

- Sharma, P.; Albisetti, E.; Monticelli, M.; Bertacco, R.; Petti, D. Exchange Bias Tuning for Magnetoresistive Sensors by Inclusion of Non-Magnetic Impurities. Sensors 2016, 16, 1030. [Google Scholar] [CrossRef]

- Sharma, P.P.; Albisetti, E.; Massetti, M.; Scolari, M.; La Torre, C.; Monticelli, M.; Leone, M.; Damin, F.; Gervasoni, G.; Ferrari, G.; et al. Integrated platform for detecting pathogenic DNA via magnetic tunneling junction-based biosensors. Sens. Actuators B Chem. 2017, 242, 280–287. [Google Scholar] [CrossRef]

- Albisetti, E.; Petti, D.; Damin, F.; Cretich, M.; Torti, A.; Chiari, M.; Bertacco, R. Photolithographic bio-patterning of magnetic sensors for biomolecular recognition. Sens. Actuators B Chem. 2014, 200, 39–46. [Google Scholar] [CrossRef]

- Parkin, S.S.P.; Hayashi, M.; Thomas, L. Magnetic Domain-Wall Racetrack Memory. Science 2008, 320, 190–194. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.H.; Ryu, K.S.; Parkin, S. Domain-wall velocities of up to 750 m s-1 driven by exchange-coupling torque in synthetic antiferromagnets. Nat. Nanotechnol. 2015, 10, 221–226. [Google Scholar] [CrossRef]

- Legrand, W.; Maccariello, D.; Ajejas, F.; Collin, S.; Vecchiola, A.; Bouzehouane, K.; Reyren, N.; Cros, V.; Fert, A. Room-temperature stabilization of antiferromagnetic skyrmions in synthetic antiferromagnets. Nat. Mater. 2019, 19, 34–42. [Google Scholar] [CrossRef]

- Chumak, A.V.; Vasyuchka, V.I.; Serga, A.A.; Hillebrands, B. Magnon spintronics. Nat. Phys. 2015, 11, 453–461. [Google Scholar] [CrossRef]

- Lenk, B.; Ulrichs, H.; Garbs, F.; Münzenberg, M. The building blocks of magnonics. Phys. Rep. 2011, 507, 107–136. [Google Scholar] [CrossRef]

- Sluka, V.; Schneider, T.; Gallardo, R.A.; Kákay, A.; Weigand, M.; Warnatz, T.; Mattheis, R.; Roldán-Molina, A.; Landeros, P.; Tiberkevich, V.; et al. Emission and propagation of 1D and 2D spin waves with nanoscale wavelengths in anisotropic spin textures. Nat. Nanotechnol. 2019, 14, 328–333. [Google Scholar] [CrossRef]

- Albisetti, E.; Tacchi, S.; Silvani, R.; Scaramuzzi, G.; Finizio, S.; Wintz, S.; Wintz Rinaldi, C.; Cantoni, M.S.; Raabe, J.; Carlotti, G.; et al. Optically-inspired nanomagnonics with nonreciprocal spin waves in synthetic antiferromagnets. Adv. Mater. 2020. [Google Scholar] [CrossRef]

- Albisetti, E.; Petti, D.; Pancaldi, M.; Madami, M.; Tacchi, S.; Curtis, J.; King, W.P.; Papp, A.; Csaba, G.; Porod, W.; et al. Nanopatterning reconfigurable magnetic landscapes via thermally assisted scanning probe lithography. Nat. Nanotechnol. 2016, 11, 545–551. [Google Scholar] [CrossRef]

- Albisetti, E.; Petti, D.; Sala, G.; Silvani, R.; Tacchi, S.; Finizio, S.; Wintz, S.; Calò, A.; Zheng, X.; Raabe, J.; et al. Nanoscale spin-wave circuits based on engineered reconfigurable spin-textures. Commun. Phys. 2018, 1, 56. [Google Scholar] [CrossRef]

- Albisetti, E.; Calò, A.; Spieser, M.; Knoll, A.W.; Riedo, E.; Petti, D. Stabilization and control of topological magnetic solitons via magnetic nanopatterning of exchange bias systems. Appl. Phys. Lett. 2018, 113, 162401. [Google Scholar] [CrossRef]

- Desai, M.; Misra, A.; Doyle, W.D. Effect of interface roughness on exchange coupling in synthetic antiferromagnetic multilayers. IEEE Trans. Magn. 2005, 41, 3151–3153. [Google Scholar] [CrossRef]

- Varvaro, G.; Laureti, S.; Peddis, D.; Hassan, M.; Barucca, G.; Mengucci, P.; Gerardino, A.; Giovine, E.; Lik, O.; Nissen, D.; et al. Co/Pd-Based synthetic antiferromagnetic thin films on Au/resist underlayers: Towards biomedical applications. Nanoscale 2019, 11, 21891–21899. [Google Scholar] [CrossRef] [PubMed]

- Wiese, N.; Dimopoulos, T.; Rührig, M.; Wecker, J.; Reiss, G.; Sort, J.; Nogués, J. Strong temperature dependence of antiferromagnetic coupling in CoFeB/Ru/CoFeB. Europhys. Lett. 2007, 78, 67002. [Google Scholar] [CrossRef][Green Version]

- Callen, H.B.; Callen, E. The present status of the temperature dependence of magnetocrystalline anisotropy, and the power law. J. Phys. Chem. Solids 1966, 27, 1271–1285. [Google Scholar] [CrossRef]

- Sato, H.; Chureemart, P.; Matsukura, F.; Chantrell, R.W.; Ohno, H.; Evans, R.F.L. Temperature-dependent properties of CoFeB/MgO thin films: Experiments versus simulations. Phys. Rev. B 2018, 98, 214428. [Google Scholar] [CrossRef]

- Chen, Y.-T.; Xie, S.M. Magnetic and Electric Properties of Amorphous Co40Fe40B20 Thin Films. J. Nanomater. 2012, 2012, 29. [Google Scholar] [CrossRef]

- Conca, A.; Greser, J.; Sebastian, T.; Klingler, S.; Obry, B.; Leven, B.; Hillebrands, B. Low spin-wave damping in amorphous Co 40 Fe 40 B 20 thin films. J. Appl. Phys. 2013, 113, 213909. [Google Scholar] [CrossRef]

- Bloch, F. Zur Theorie des Ferromagnetismus. Z. Phys. A Hadron. Nucl. 1930, 61, 206–219. [Google Scholar] [CrossRef]

- Schwieger, S.; Nolting, W. Origin of the temperature dependence of interlayer exchange coupling in metallic trilayers. Phys. Rev. B 2004, 69, 224413. [Google Scholar] [CrossRef]

- Li, Y.; Jin, X.; Pan, P.; Tan, F.N.; Lew, W.S.; Ma, F. Temperature-dependent interlayer exchange coupling strength in synthetic antiferromagnetic [Pt/Co]2/Ru/[Co/Pt]4 multilayers. Chin. Phys. B 2018, 27, 127502. [Google Scholar] [CrossRef]

| Material | Power (W) | Ar Pressure (mTorr) |

|---|---|---|

| Ru | 50 | 3 |

| Ru SAF | 50 | 5 |

| Co40Fe40B20 | 58 | 4 |

| Ir22Mn78 | 50 | 3 |

| Set Name | Stack Compositions (Dimensions in nm) |

|---|---|

| A | Si/SiO2/CoFeB 25/Ru 0.7/CoFeB 25/IrMn 10/Ru 2 |

| B | Si/SiO2/CoFeB 35/Ru 0.7/CoFeB 35/IrMn 10/Ru 2 |

| C | Si/SiO2/CoFeB 35/Ru 0.6/CoFeB 35/IrMn 10/Ru 2 |

| D | Si/SiO2/CoFeB 45/Ru 0.6/CoFeB 45/IrMn 10/Ru 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albisetti, E.; Scaramuzzi, G.; Rinaldi, C.; Cantoni, M.; Bertacco, R.; Petti, D. Temperature Dependence of the Magnetic Properties of IrMn/CoFeB/Ru/CoFeB Exchange Biased Synthetic Antiferromagnets. Materials 2020, 13, 387. https://doi.org/10.3390/ma13020387

Albisetti E, Scaramuzzi G, Rinaldi C, Cantoni M, Bertacco R, Petti D. Temperature Dependence of the Magnetic Properties of IrMn/CoFeB/Ru/CoFeB Exchange Biased Synthetic Antiferromagnets. Materials. 2020; 13(2):387. https://doi.org/10.3390/ma13020387

Chicago/Turabian StyleAlbisetti, Edoardo, Giuseppe Scaramuzzi, Christian Rinaldi, Matteo Cantoni, Riccardo Bertacco, and Daniela Petti. 2020. "Temperature Dependence of the Magnetic Properties of IrMn/CoFeB/Ru/CoFeB Exchange Biased Synthetic Antiferromagnets" Materials 13, no. 2: 387. https://doi.org/10.3390/ma13020387

APA StyleAlbisetti, E., Scaramuzzi, G., Rinaldi, C., Cantoni, M., Bertacco, R., & Petti, D. (2020). Temperature Dependence of the Magnetic Properties of IrMn/CoFeB/Ru/CoFeB Exchange Biased Synthetic Antiferromagnets. Materials, 13(2), 387. https://doi.org/10.3390/ma13020387