Equal Load-Carrying Design of Lapped Joints of Al–Cu Dissimilar Materials

Abstract

1. Introduction

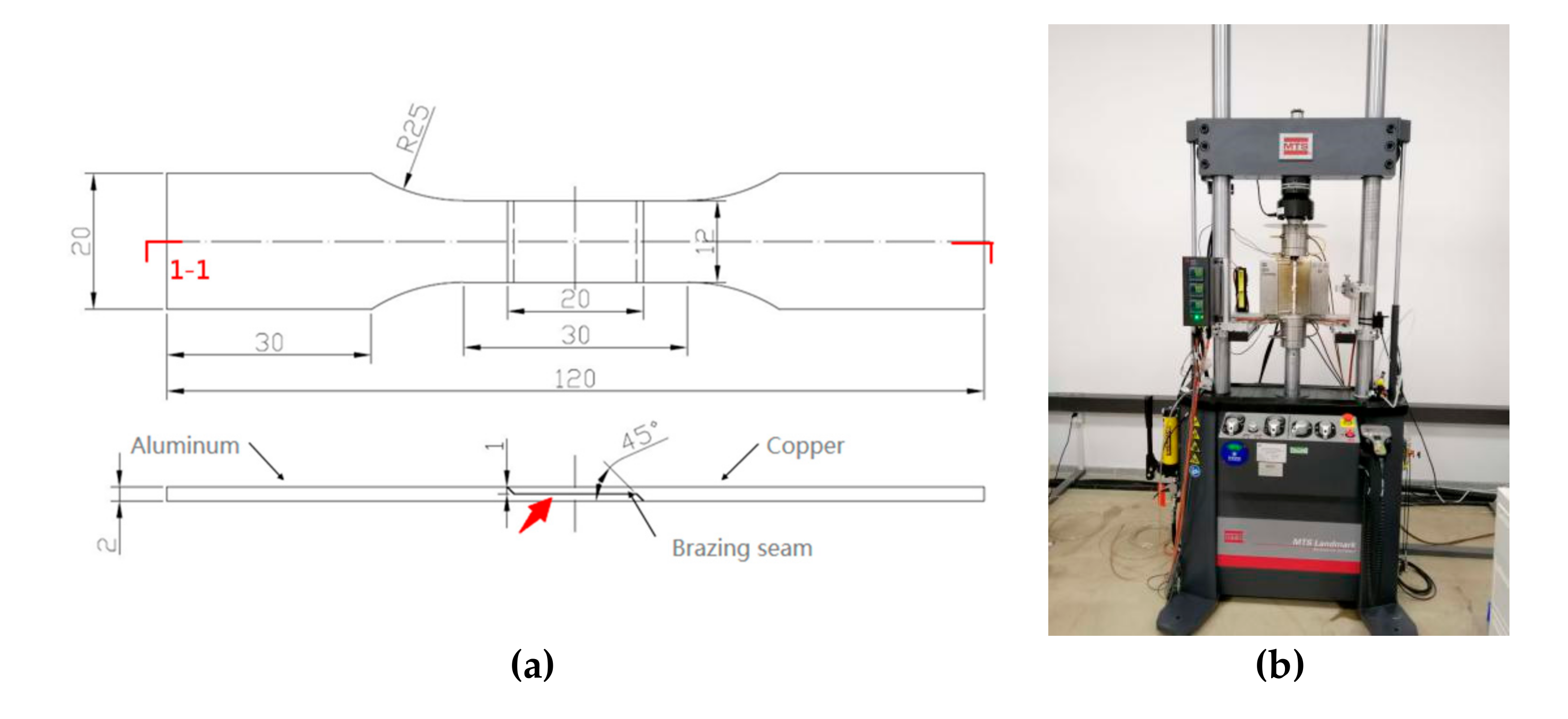

2. Materials and Methods about the Design of Lap Joint

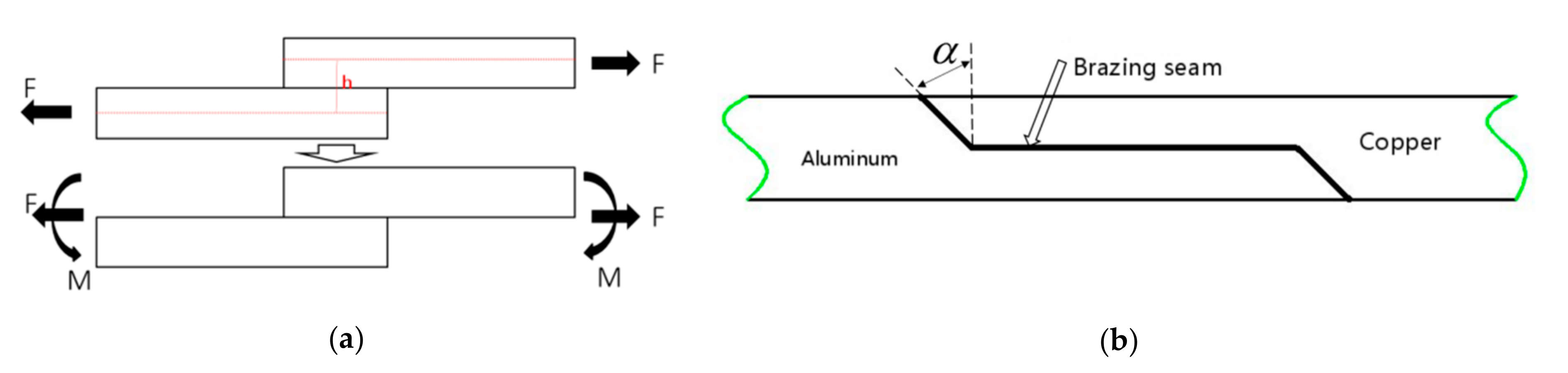

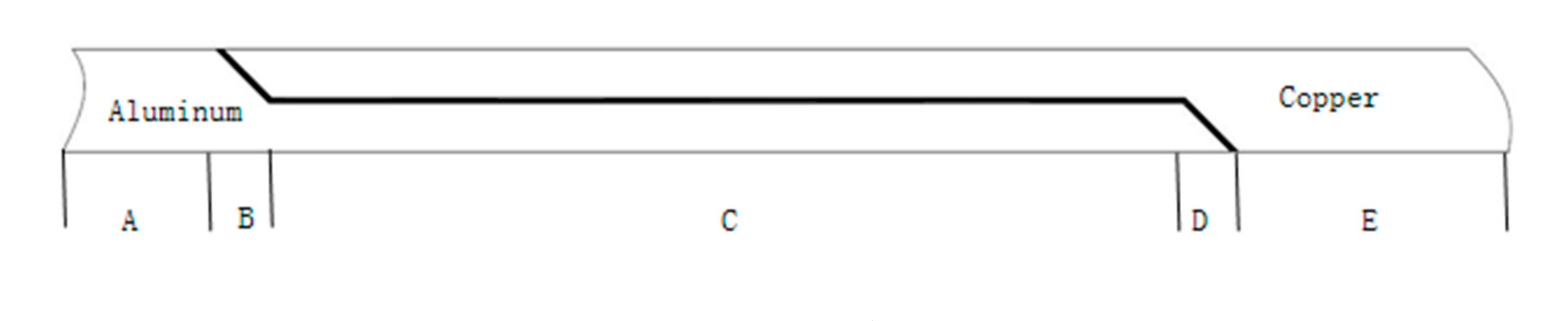

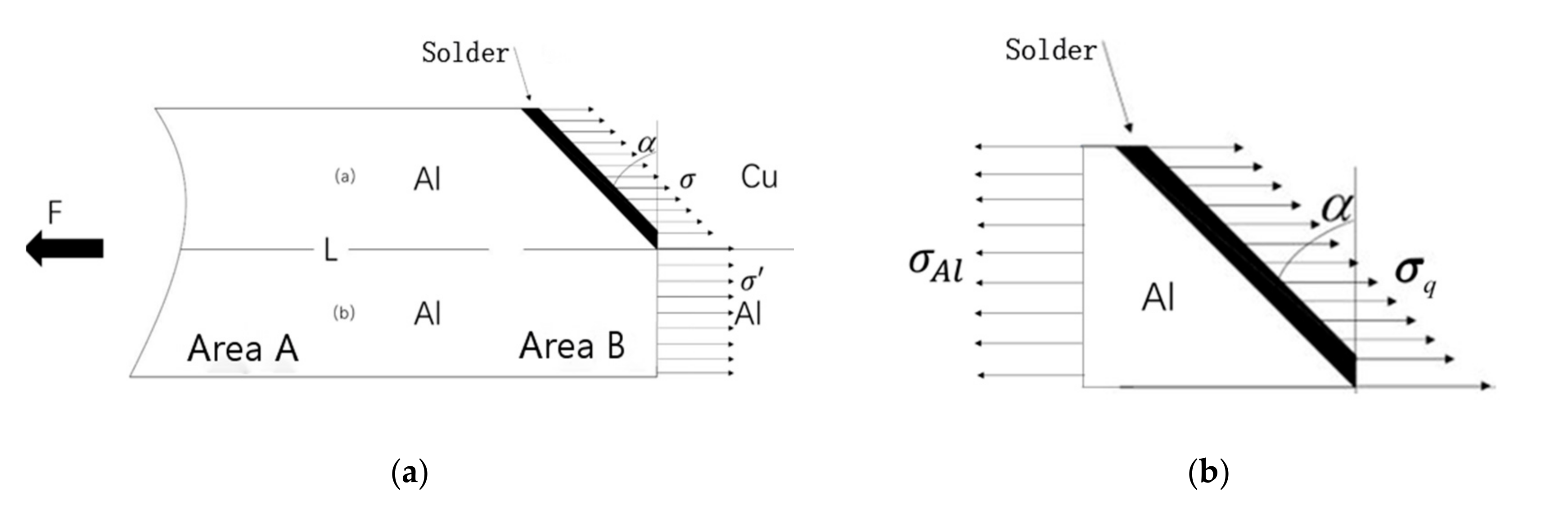

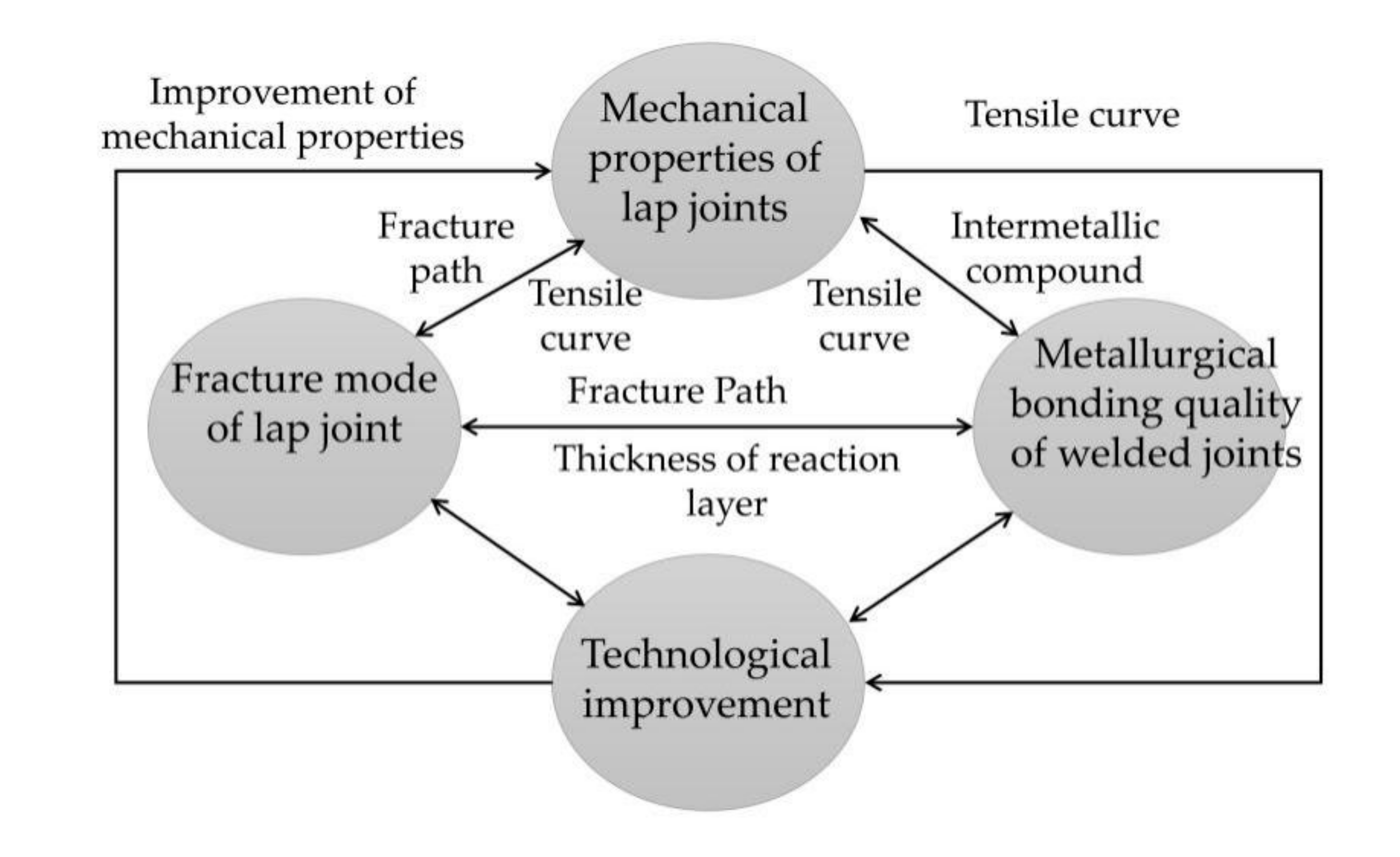

2.1. Equal Load-Carrying Lap Joint Form

2.2. Selection Principle of Solder

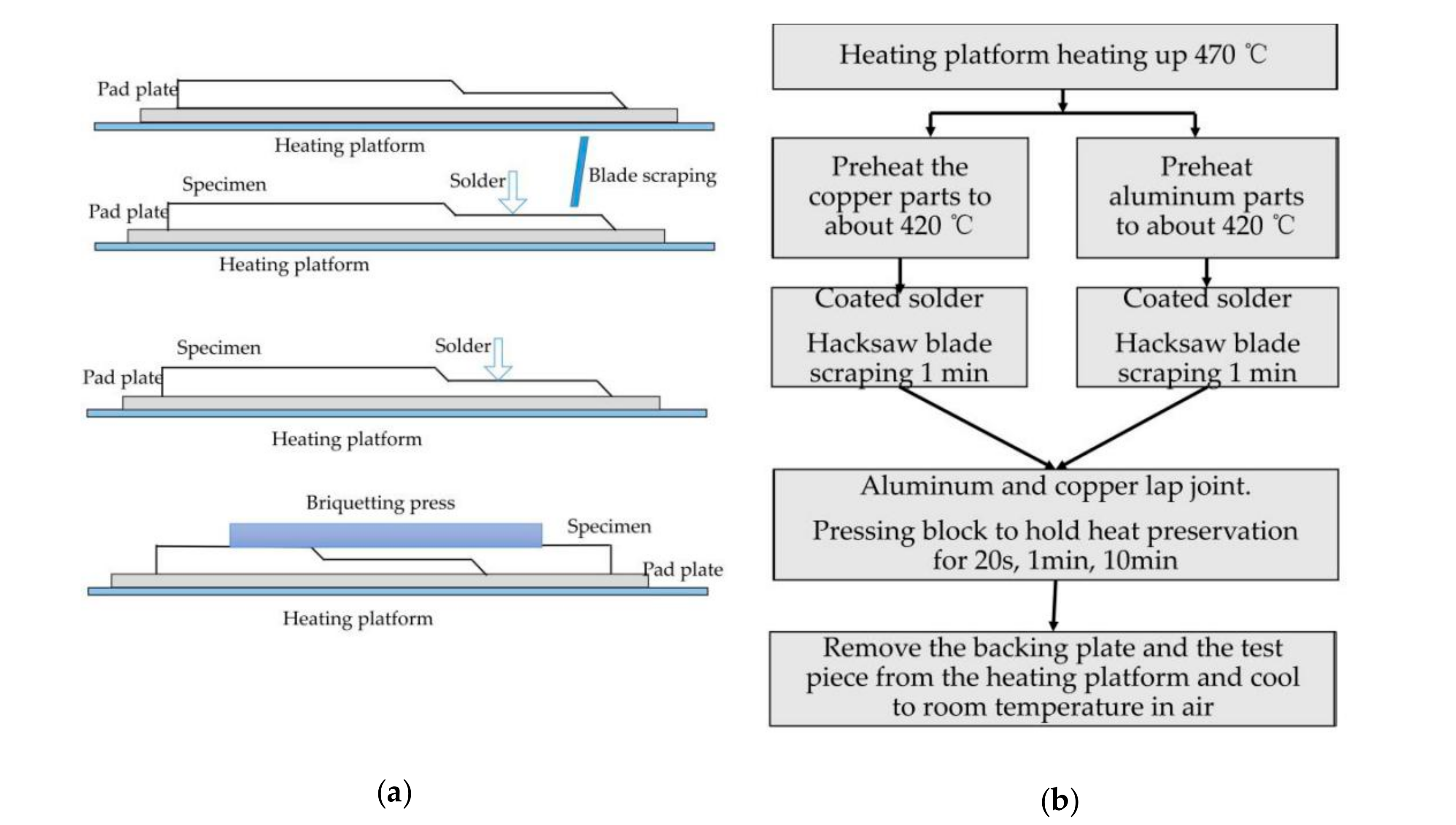

3. Scratch Brazing of Specimen

4. Result Analysis and Discussion

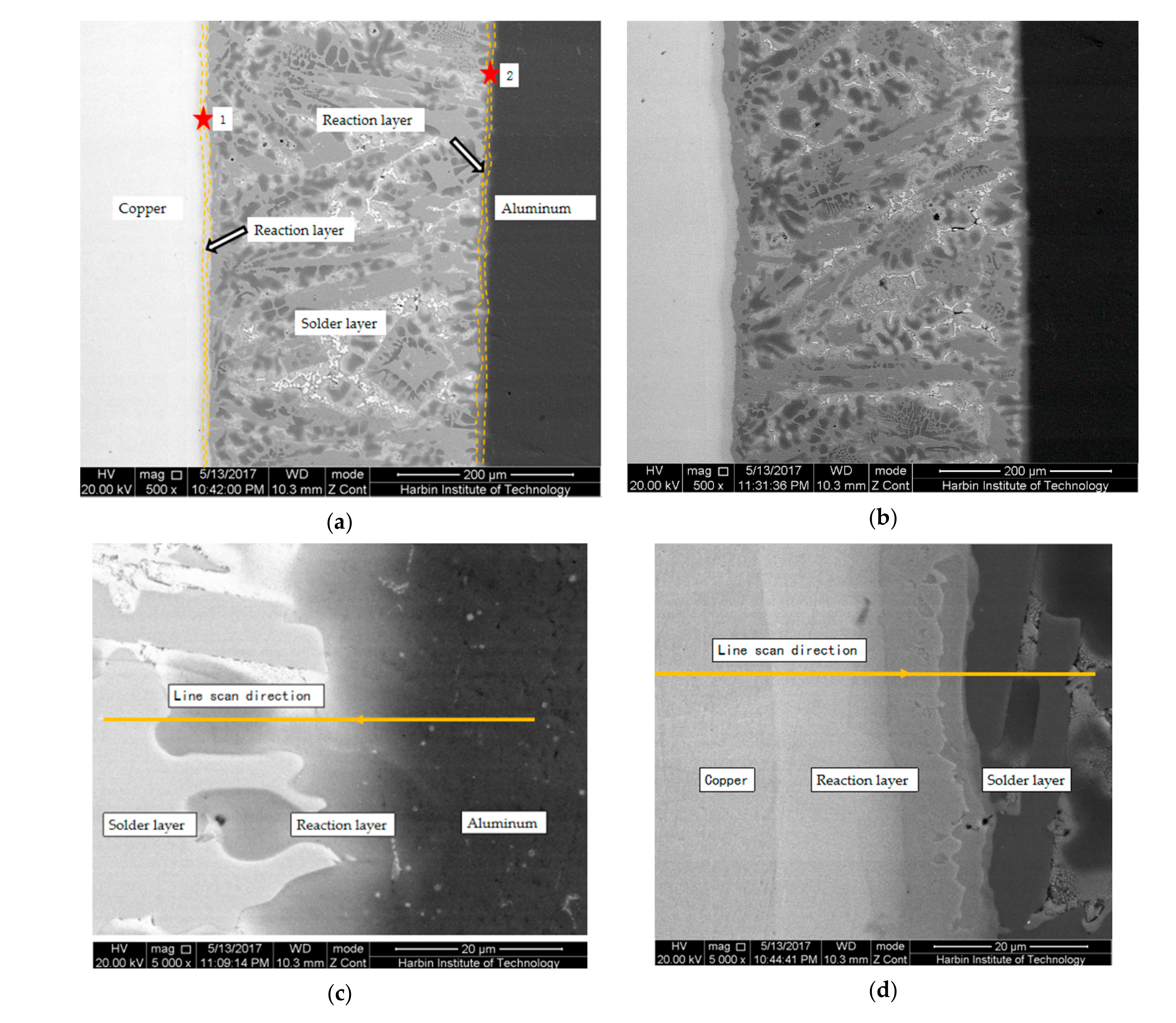

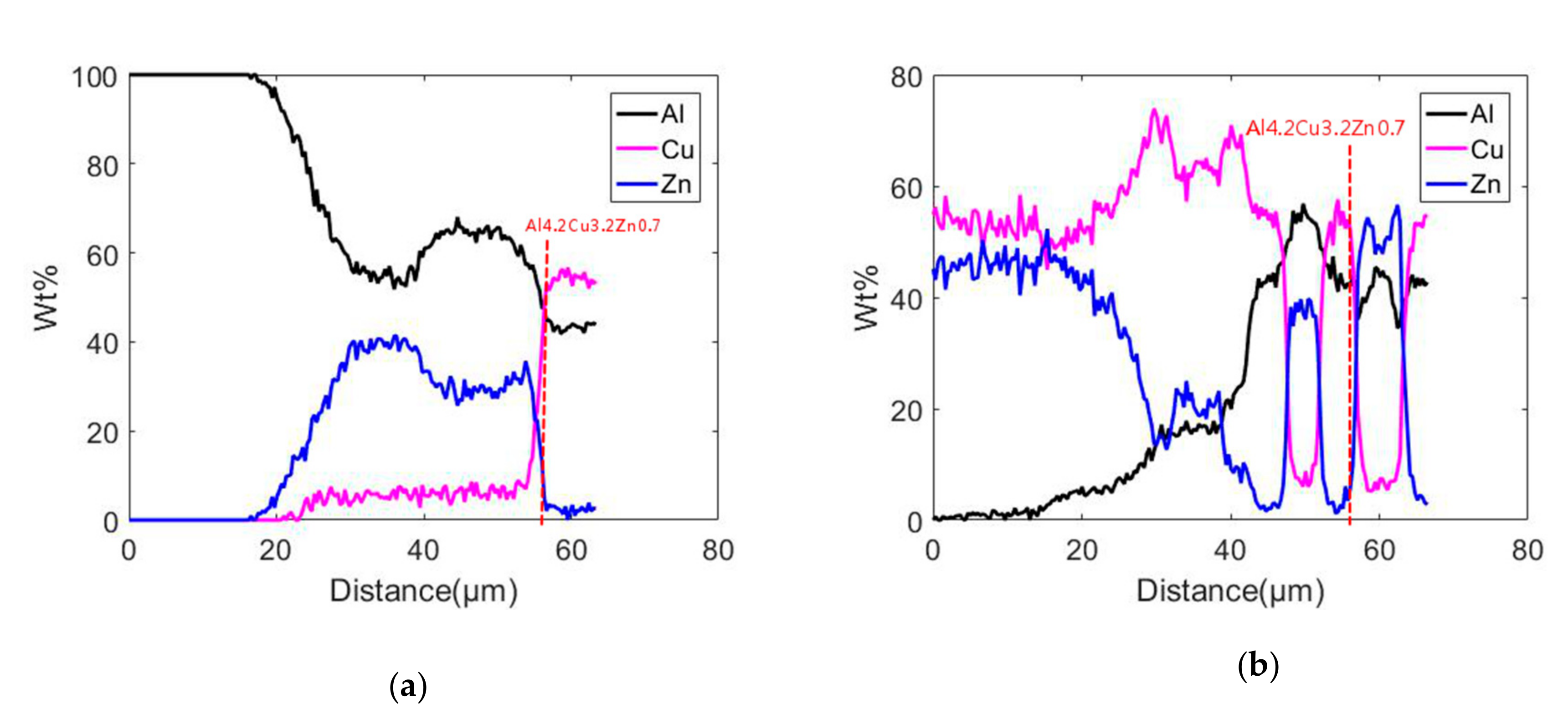

4.1. Microstructure of Brazing Seam and Interface Layer

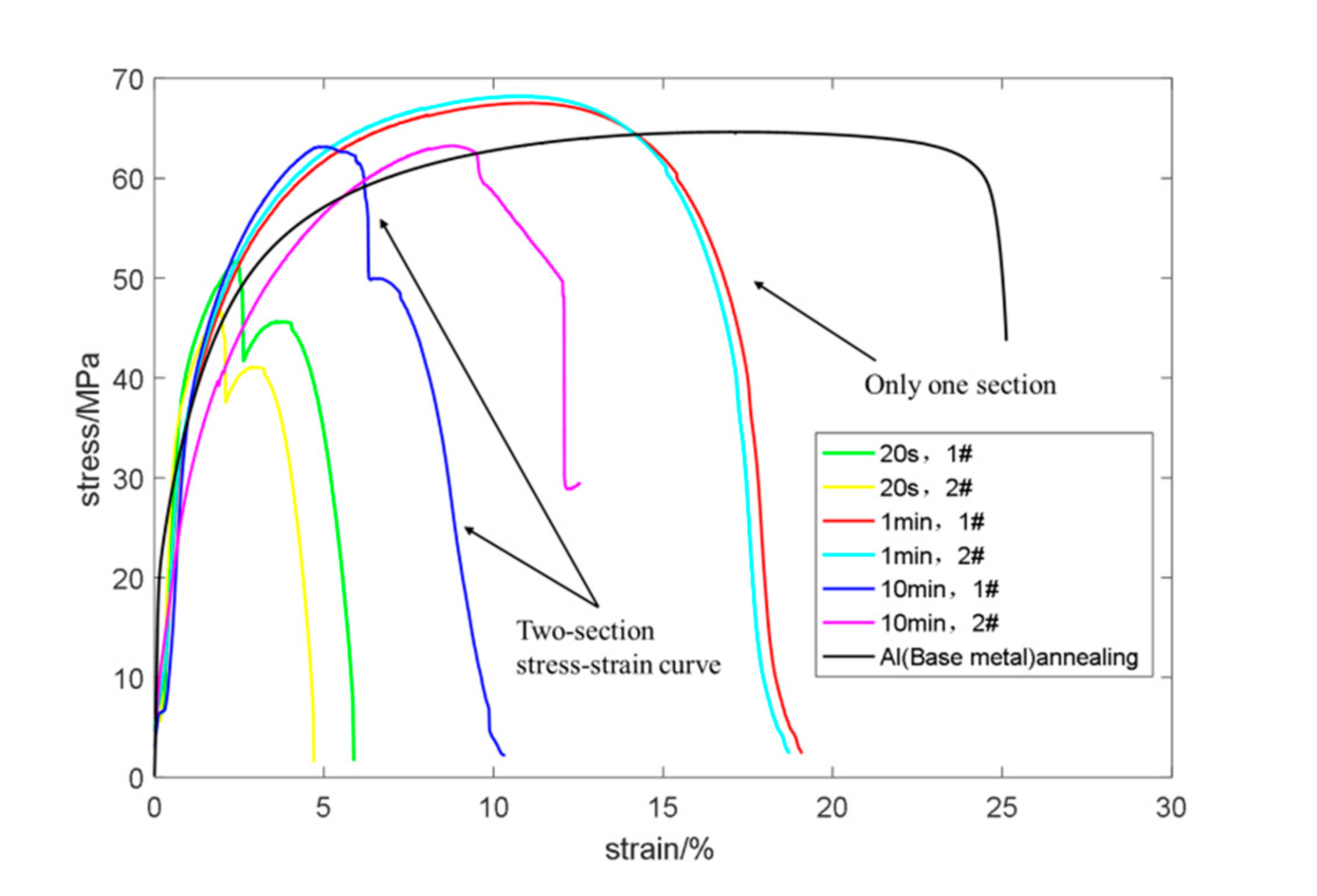

4.2. Fracture Mode and Mechanical Properties

5. Conclusions

- (1)

- On the basis of the form determination of a new lap joint, combined with the brazing of an Al–Cu dissimilar metal, according to the characteristics of static analysis and brazing, the design method of static tension and loads was given.

- (2)

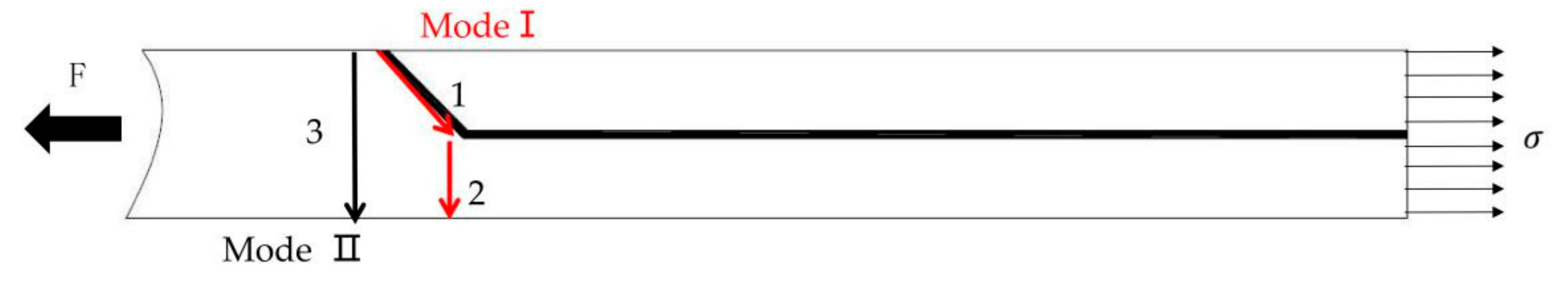

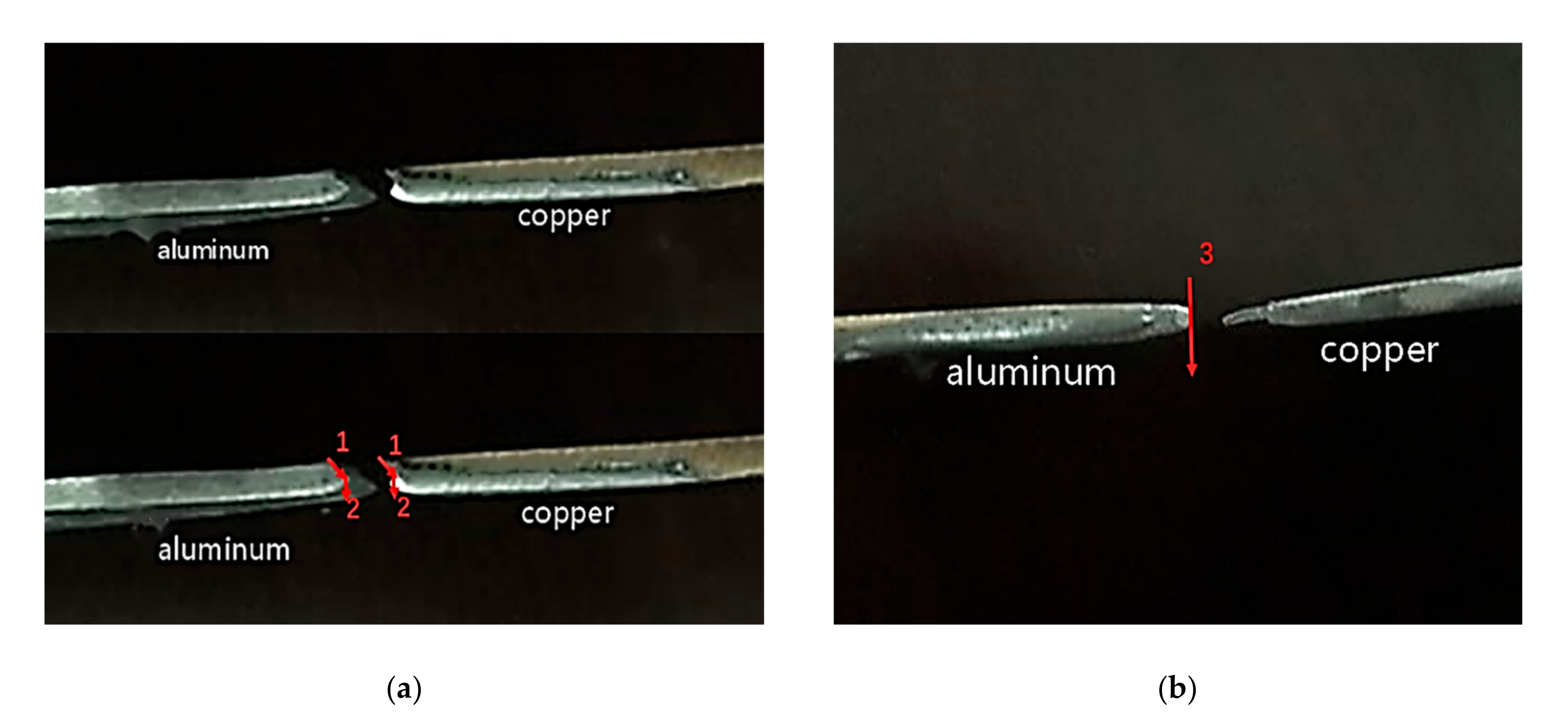

- Two fracture modes of lap joints were analyzed from which mode Ⅱ was the ultimate goal of equal load-carrying design, and mode Ⅰ might be due to the wrong selection of solder or unreasonable brazing process.

- (3)

- The relationship between fracture mode, static tensile curve and brazing quality was deduced. The results demonstrated that the static tensile curve of mode Ⅰ followed a two-stage rule, while mode Ⅱ presented a one-stage law. When the brazing holding time was too long or too short, the fracture mode of the joint was mode Ⅰ.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, P.; Wen, X.; Mi, Y.; Fang, H. Equal load-carrying design of welded joints. Weld. Join. 2019, 11, 1–7. [Google Scholar] [CrossRef]

- Niu, Z.W.; Ye, Z.; Huang, J.H. Interfacial structure and properties of Cu/Al joints brazed with Zn-Al filler metals. Mater. Charact. 2018, 138, 78–88. [Google Scholar] [CrossRef]

- Furuya, H.S.; Sato, Y.S.; Kokawa, H.; Huang, T.; Xiao, R.S. Improvement of Interfacial Strength with the Addition of Ni in Al/Cu Dissimilar Joints Produced via Laser Brazing. Met. Mater. Trans. A 2018, 49, 6215–6223. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, D.; Chu, B. Effect of the addition of Sb and rare-earth elements La and Nd on the properties of Cu/6061Al with Zn–10Al–5Cu filler metals. J. Mater. Sci. Mater. Electron. 2018, 29, 17137–17143. [Google Scholar] [CrossRef]

- Chen, X.; Lei, Z.; Chen, Y.; Han, Y.; Jiang, M.; Tian, Z.; Bi, J.; Lin, S.; Jiang, N. Effect of Laser Beam Oscillation on Laser Welding–Brazing of Ti/Al Dissimilar Metals. Materials 2019, 12, 4165. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhang, G.; Shi, Y.; Zhu, M.; Yang, F. Microstructures and mechanical behavior of aluminum-copper lap joints. Mater. Sci. Eng. A 2017, 705, 105–113. [Google Scholar] [CrossRef]

- Li, F.; Xu, R.; Wang, P.; Sun, X.; Liu, X. Study on electron beam lap welding of Al-Cu dissimilar metals. Spec. Cast. Nonferrous Alloy. 2019, 39, 556–560. [Google Scholar]

- Qin, Y.; He, X.; Jiang, W. Influence of Preheating Temperature on Cold Metal Transfer (CMT) Welding–Brazing of Aluminium Alloy/Galvanized Steel. Appl. Sci. 2018, 8, 1659. [Google Scholar] [CrossRef]

- Tan, C.; Liu, F.; Sun, Y.; Chen, B.; Song, X.; Li, L.; Zhao, H.; Feng, J. Laser Brazing Characteristics of Al to Brass with Zn-Based Filler. J. Mater. Eng. Perform. 2018, 27, 3521–3531. [Google Scholar] [CrossRef]

- He, H.; Wu, C.; Lin, S.; Yang, C. Pulsed TIG Welding–Brazing of Aluminum–Stainless Steel with an Al-Cu Twin Hot Wire. J. Mater. Eng. Perform. 2019, 28, 1180–1189. [Google Scholar] [CrossRef]

- Singh, J.; Arora, K.S.; Shukla, D.K. Lap weld-brazing of aluminium to steel using novel cold metal transfer process. J. Mater. Process. Technol. 2020, 283, 116728. [Google Scholar] [CrossRef]

- Chen, J.; Amirkhiz, B.S.; Zhang, R.; Rona, B. On the Joint Formation and Interfacial Microstructure of Cold Metal Transfer Cycle Step Braze Welding of Aluminum to Steel Butt Joint. Met. Mater. Trans. A 2020, 51, 5198–5212. [Google Scholar] [CrossRef]

- Rheingans, B.; Spies, I.; Schumacher, A.; Knappmann, S.; Furrer, R.; Jeurgens, L.P.H.; Janczak-Rusch, J. Joining with Reactive Nano-Multilayers: Influence of Thermal Properties of Components on Joint Microstructure and Mechanical Performance. Appl. Sci. 2019, 9, 262. [Google Scholar] [CrossRef]

- Wei, Y.; Sun, F.; Li, H.; Peng, X.; Zou, J. The Microstructure and Mechanical Properties of Multipass Friction Stir-Welded Al/Cu Lap Joints and Interface Transfer during Butt Joining of Thick Plates. Adv. Eng. Mater. 2020. [Google Scholar] [CrossRef]

- Shiliang, Z.; Zhongdian, Z.; Qiwei, L.; YuJun, X.; Xiubo, T. New technology for measuring resistance of electrical contact and estimating welding quality. Sci. Technol. Weld. Join. 2016, 21. [Google Scholar] [CrossRef]

- Lu, Z.; Gong, W.; Chen, S.; Yuan, T.; Kan, C.; Jiang, X. Interfacial microstructure and local bonding strength of magnetic pulse welding joint between commercially pure aluminum 1060 and AISI 304 stainless steel. J. Manuf. Process. 2019, 46, 59–66. [Google Scholar] [CrossRef]

- Chen, L.X.; Liu, Z.Q.; Song, W.G. Process-surface morphology-tribological property relationships for H62 brass employing various manufacturing approaches. Tribol. Int. 2020, 148, 106320. [Google Scholar] [CrossRef]

- Prach, M.; Kolenak, R. Soldering of copper with High-temperature Zn-based Solder. Procedia Eng. 2015, 100, 1370–1375. [Google Scholar] [CrossRef]

- Liu, G.; Hu, X.; Fu, Y.; Li, Y. Microstructure and Mechanical Properties of Ultrasonic Welded Joint of 1060 Aluminum Alloy and T2 Pure Copper. Metals 2017, 7, 361. [Google Scholar] [CrossRef]

- Xiao, Y.; Ji, H.J.; Li, J.M. Ultrasound-assisted brazing of Cu/Al dissimilar metals using a Zn-3Al filler metal. Mater. Des. 2013, 52, 740–747. [Google Scholar] [CrossRef]

- Reisgen, U.; Angerhausen, M.; Pipinikas, A.; Twiehaus, T.; Wesling, V.; Barthelmie, J. The effect of arc brazing process parameters on the microstructure and mechanical properties of high-strength steel HCT780XD using the copper-based filler metal CuAl8. J. Mater. Process. Technol. 2017, 249, 549–558. [Google Scholar] [CrossRef]

| Si | Cu | Mg | Zn | Mn | Cr | Fe | Al |

|---|---|---|---|---|---|---|---|

| 0.25 | 0.1 | 2.2–2.8 | 0.1 | 0.1 | 0.15–0.35 | 0.4 | Bal. |

| Cu | P | Bi | Sb | Pb | Fe | Zn |

|---|---|---|---|---|---|---|

| 60.5–63.5 | ≤0.01 | ≤0.002 | ≤0.005 | ≤0.08 | ≤0.15 | Bal. |

| Materials | Tensile Strength (MPa) |

|---|---|

| 1060 Pure aluminum (F state) | 112 |

| 1060 Pure aluminum (O state) | 64 |

| H62 Brass | 417 |

| Zn | Al | Cu | Mg | Si | Ag | Ni |

|---|---|---|---|---|---|---|

| 84.5 | 7.10 | 4.5 | 0.84 | 0.24 | 1.76 | 1.05 |

| Brazing Holding Time | 20 s | 1 min | 10 min |

|---|---|---|---|

| Thickness of reaction layer on aluminum side (μm) | <2 | 7 | 20 |

| h0 | <2 | >2.5 | 2.08 |

| Tensile strength (MPa) | 52 | 67 | 63 |

| Fracture path | 1→2 | 3 | 1→2 |

| Fracture mode | Mode Ⅰ | Mode Ⅱ | Mode Ⅰ |

| Elongation | 5–6% | 19% | 10–13% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Ma, J.; Fang, H.; Ni, Z.; Wang, P. Equal Load-Carrying Design of Lapped Joints of Al–Cu Dissimilar Materials. Materials 2020, 13, 4293. https://doi.org/10.3390/ma13194293

Chen Z, Ma J, Fang H, Ni Z, Wang P. Equal Load-Carrying Design of Lapped Joints of Al–Cu Dissimilar Materials. Materials. 2020; 13(19):4293. https://doi.org/10.3390/ma13194293

Chicago/Turabian StyleChen, Zhihao, Jianxiao Ma, Hongyuan Fang, Zhida Ni, and Ping Wang. 2020. "Equal Load-Carrying Design of Lapped Joints of Al–Cu Dissimilar Materials" Materials 13, no. 19: 4293. https://doi.org/10.3390/ma13194293

APA StyleChen, Z., Ma, J., Fang, H., Ni, Z., & Wang, P. (2020). Equal Load-Carrying Design of Lapped Joints of Al–Cu Dissimilar Materials. Materials, 13(19), 4293. https://doi.org/10.3390/ma13194293