Mechanical Characterization of Multiwalled Carbon Nanotubes: Numerical Simulation Study

Abstract

1. Introduction

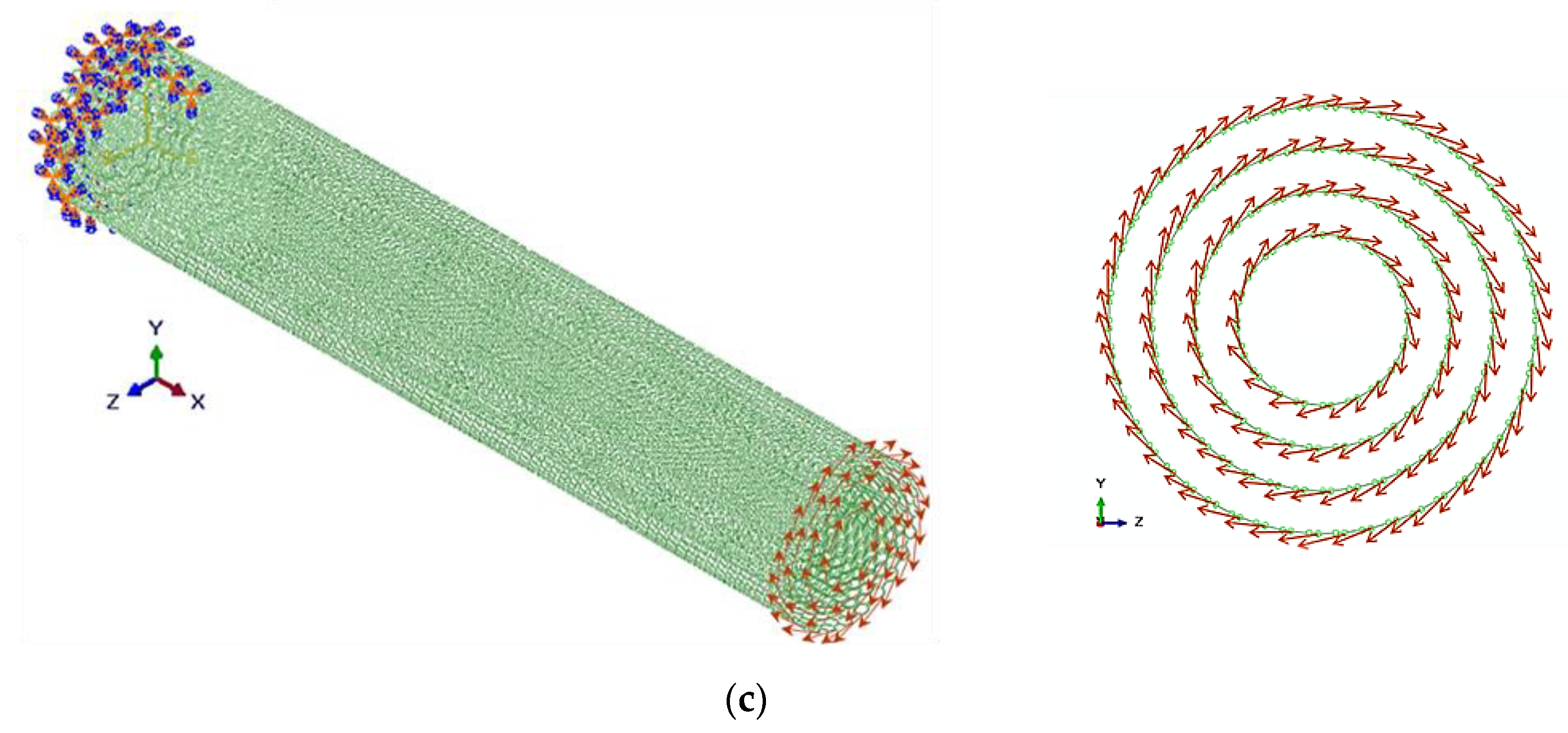

2. Geometric Definition

3. Numerical Simulation and Analysis

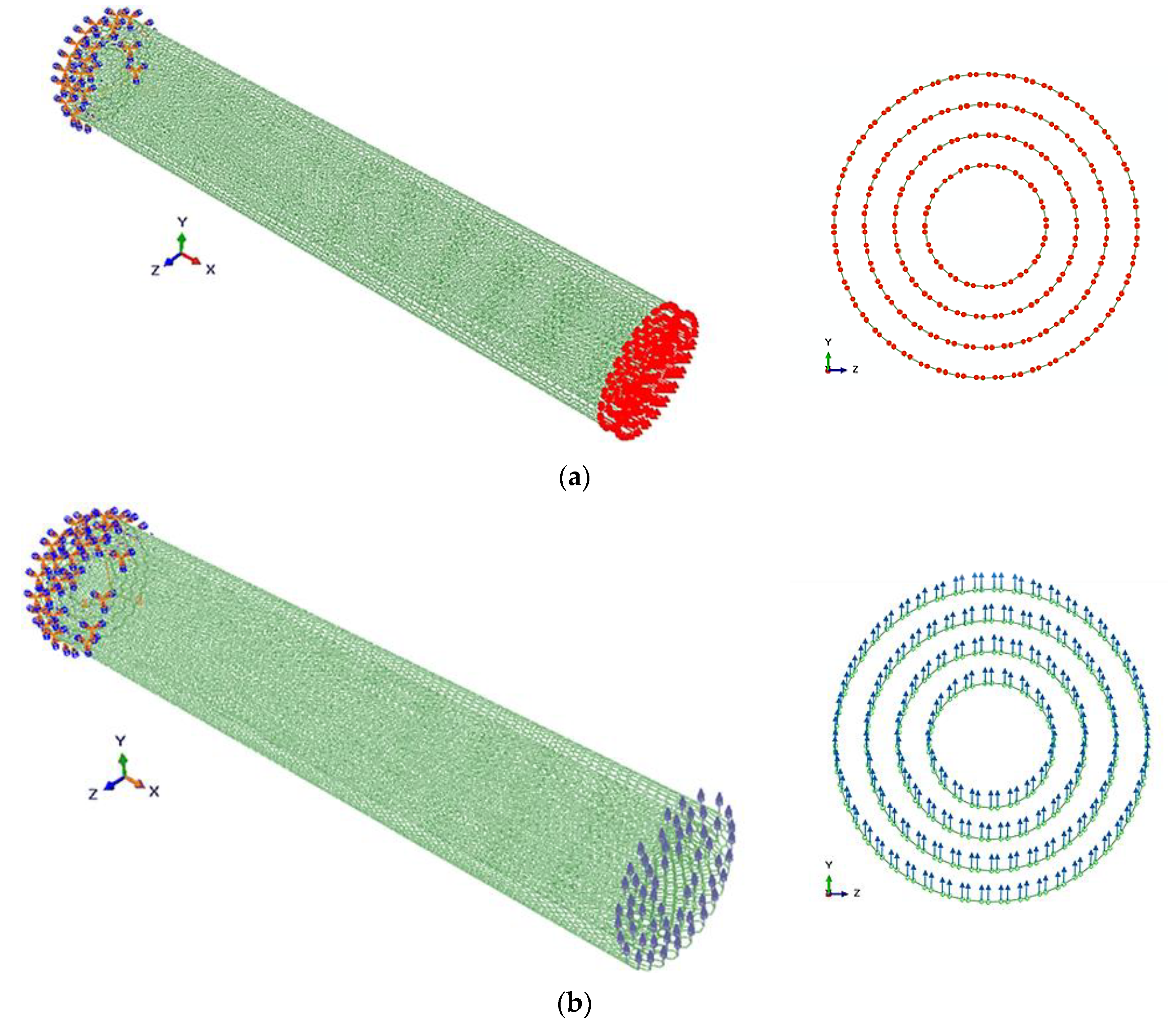

3.1. Configurations and FE Modelling of MWCNT

3.2. Loading Conditions

3.3. Elastic Moduli of MWCNTs

4. Results and Discussion

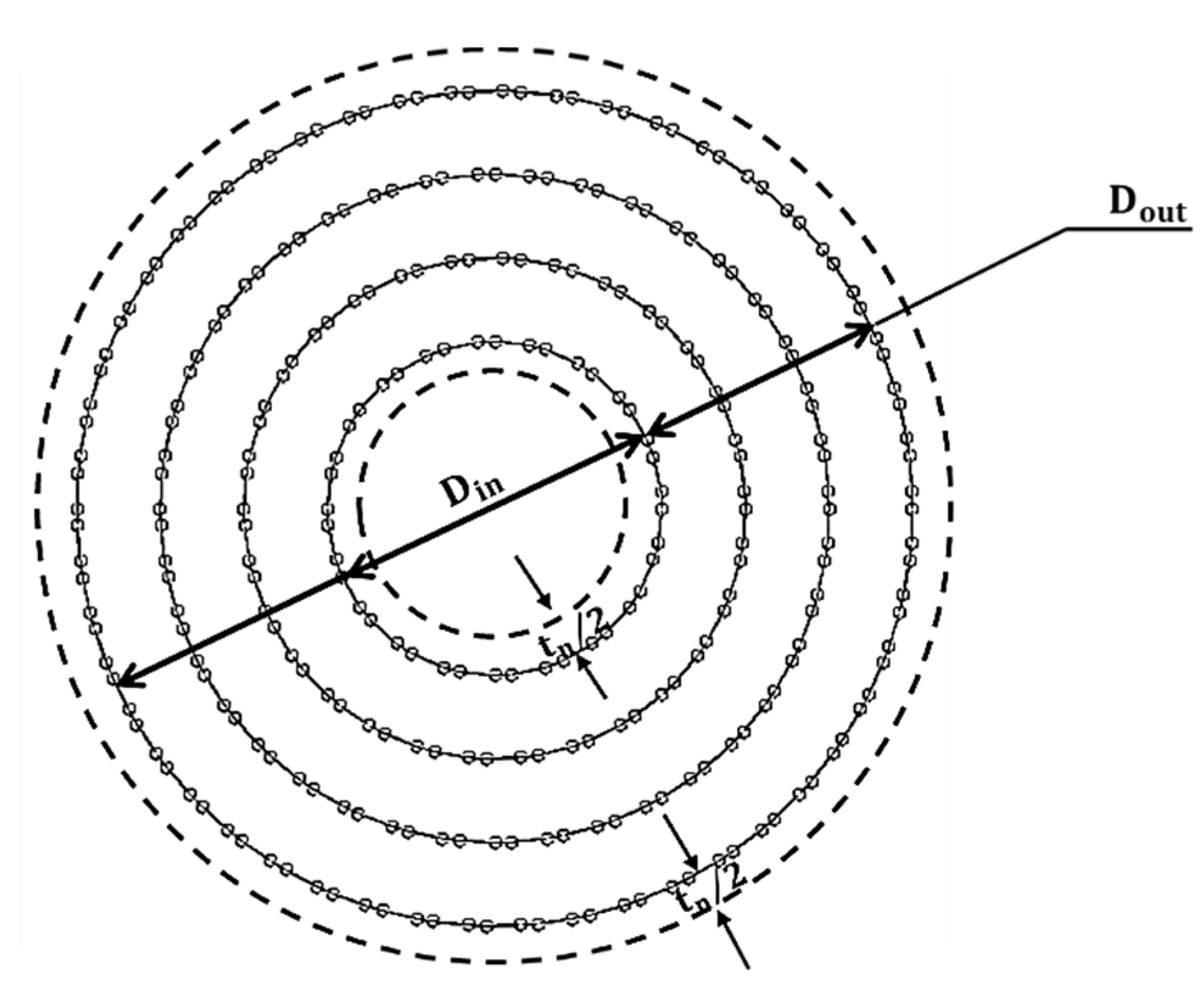

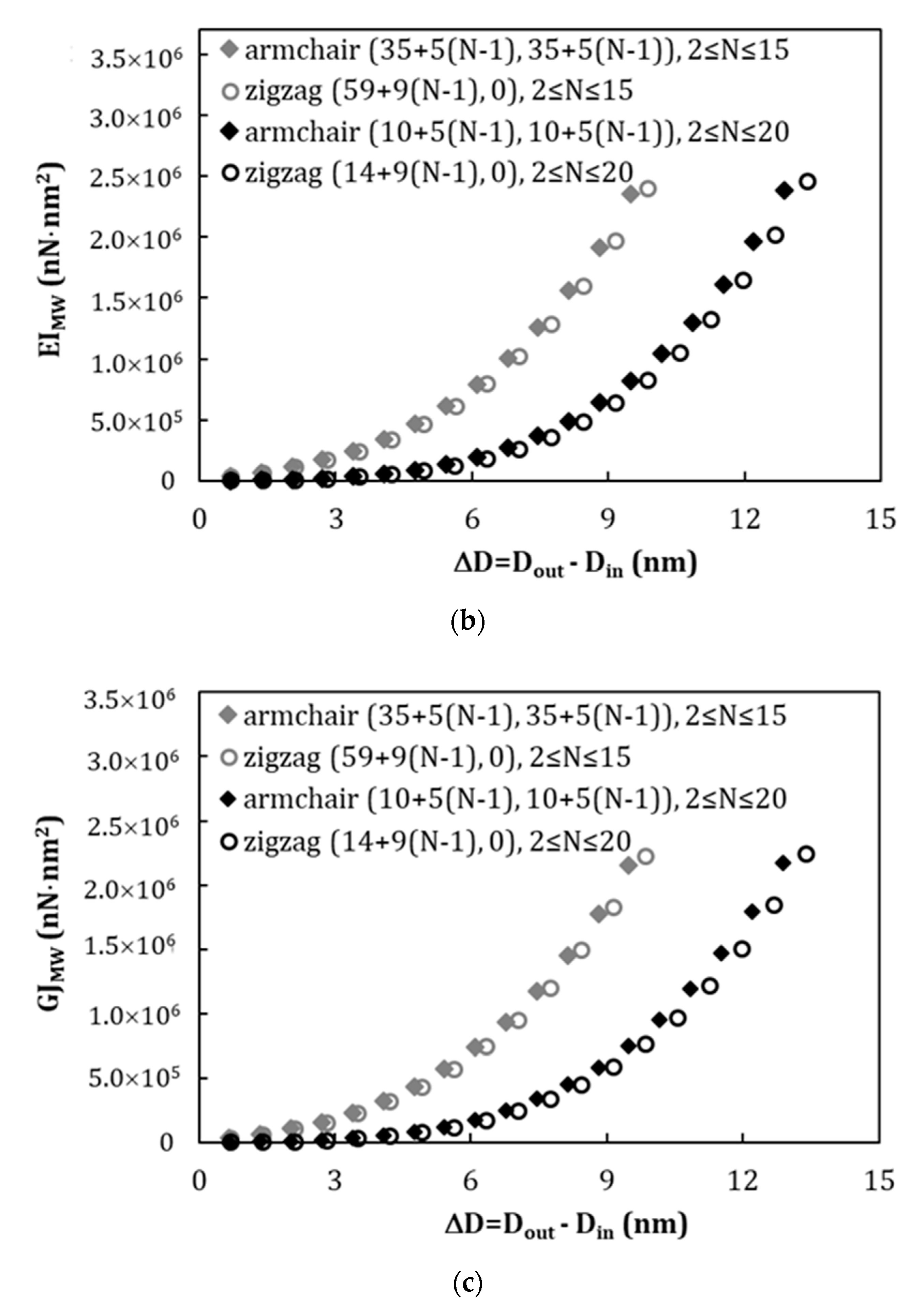

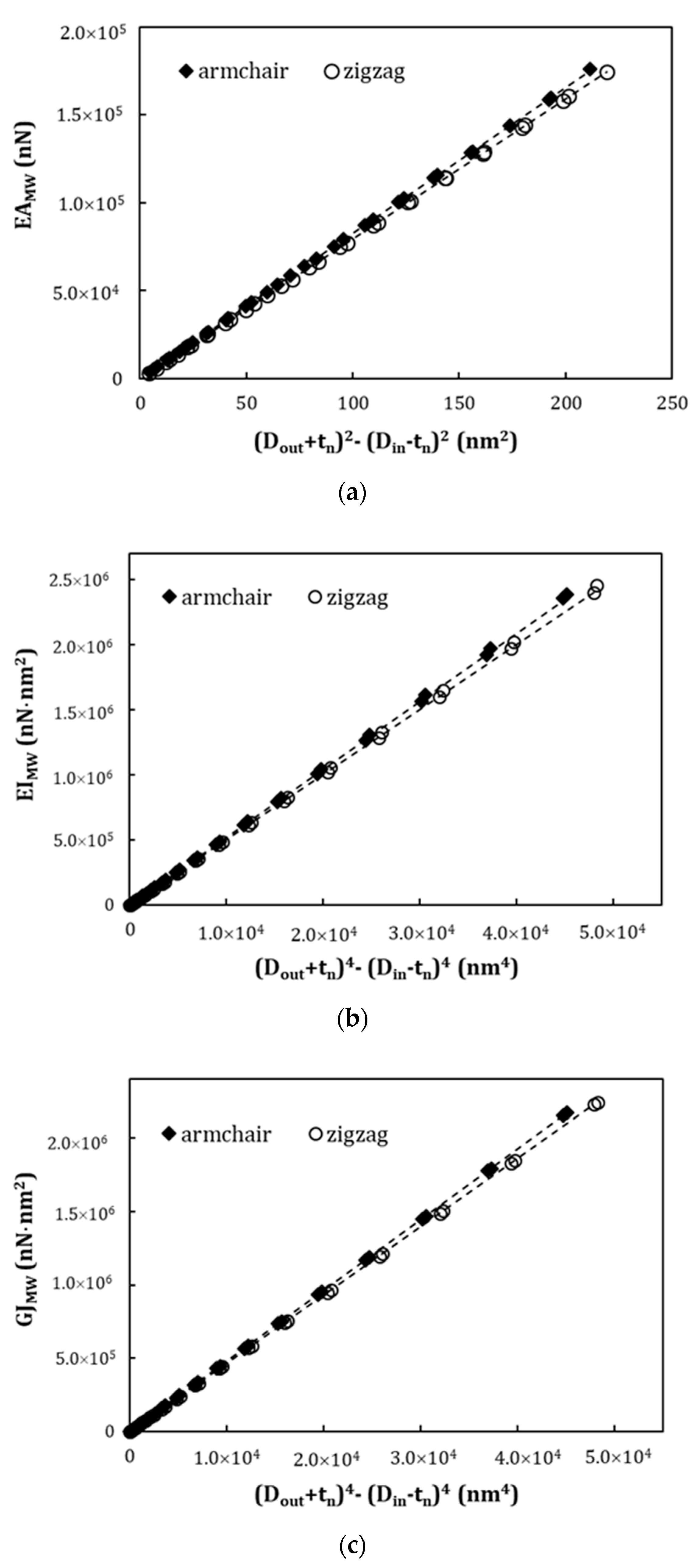

4.1. Rigidities of MWCNTs

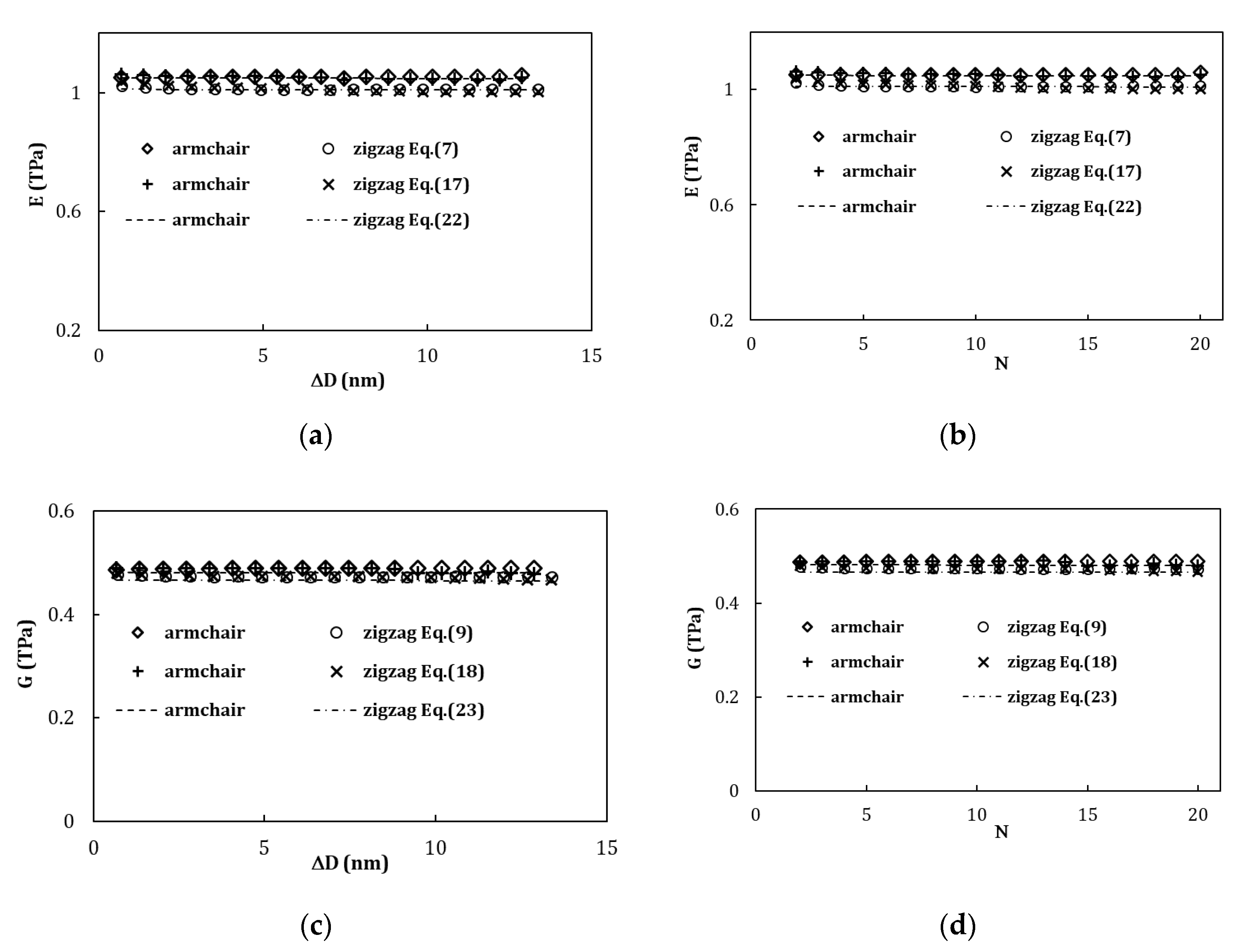

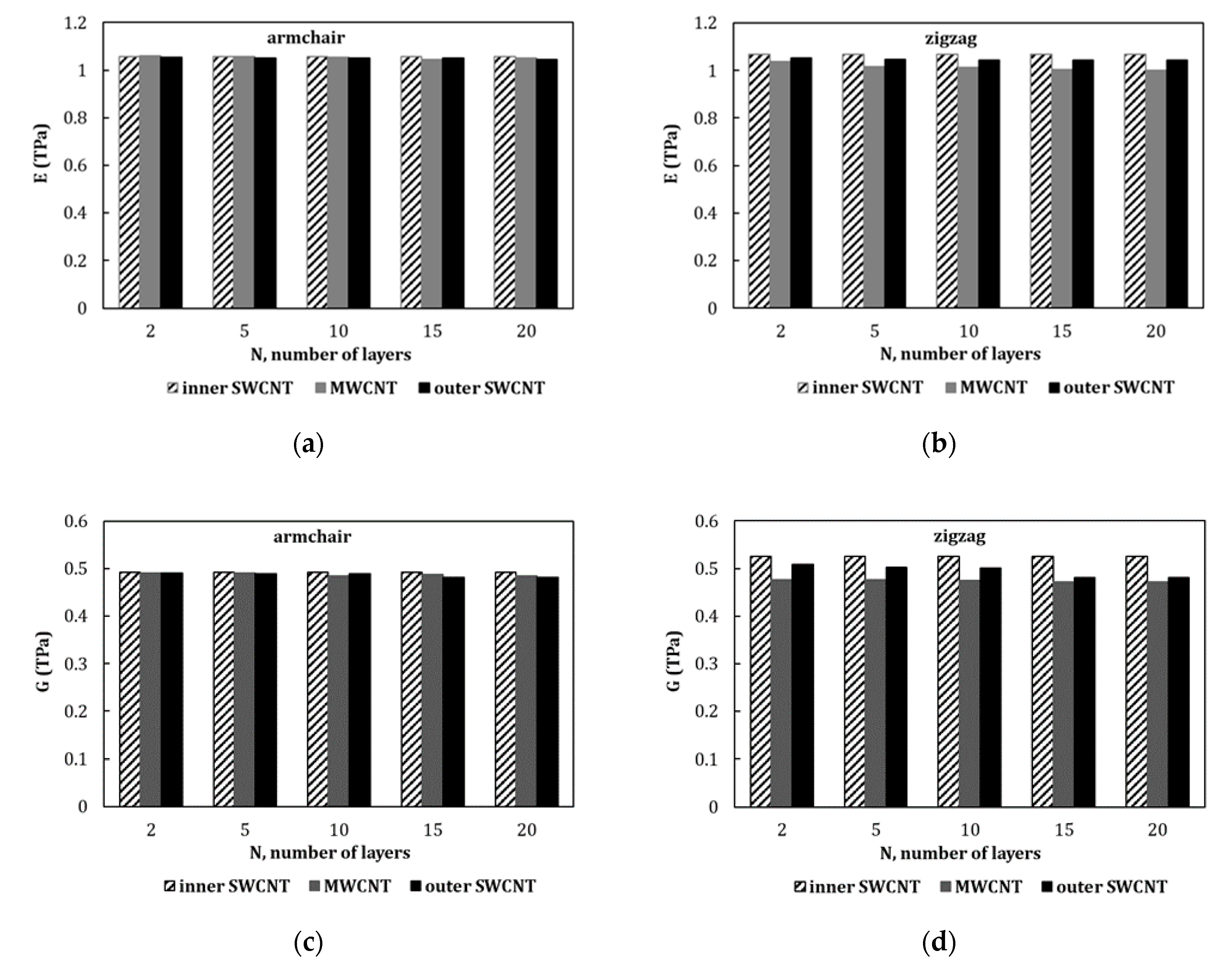

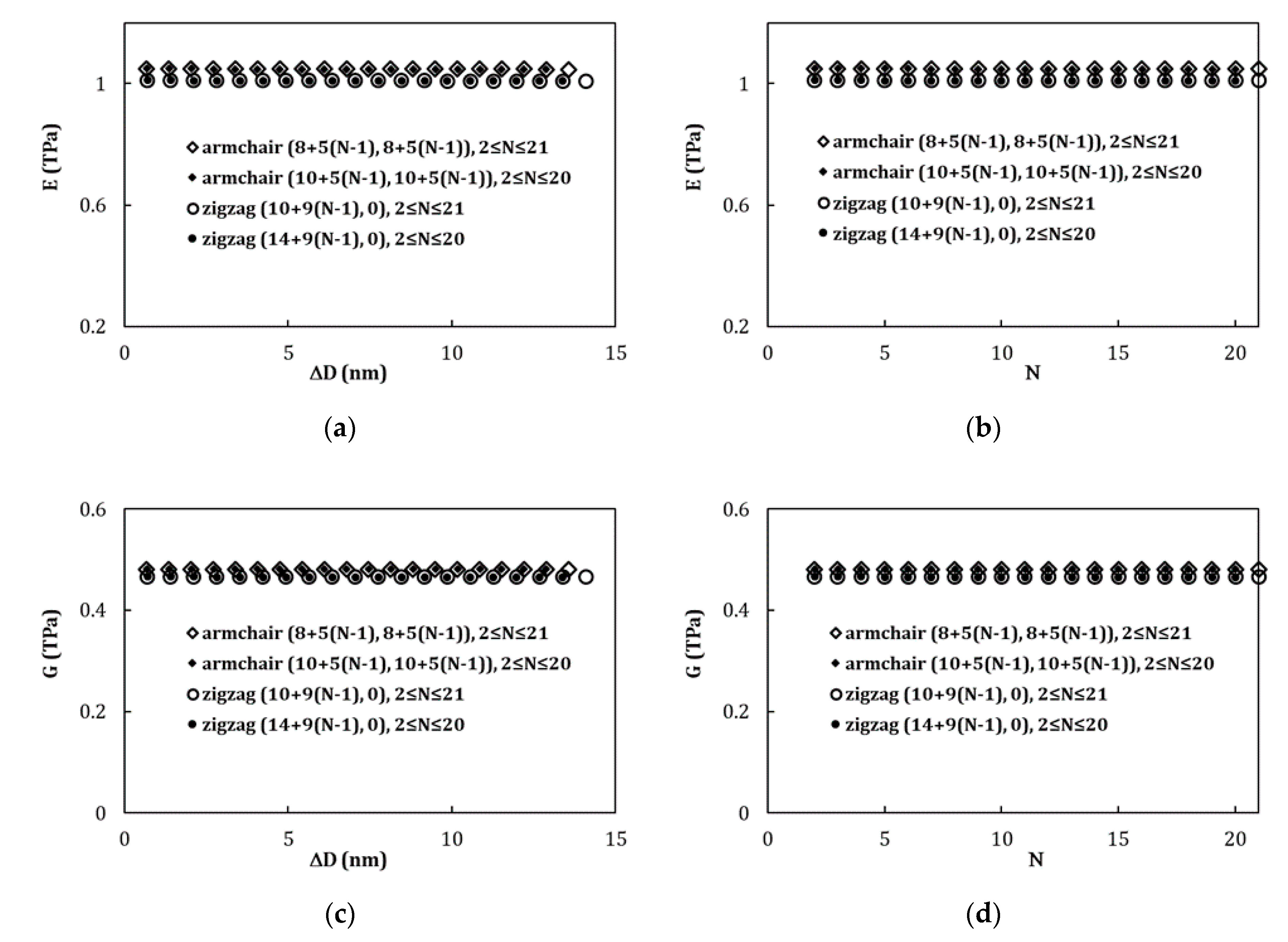

4.2. Young’s and Shear Moduli of MWCNTs

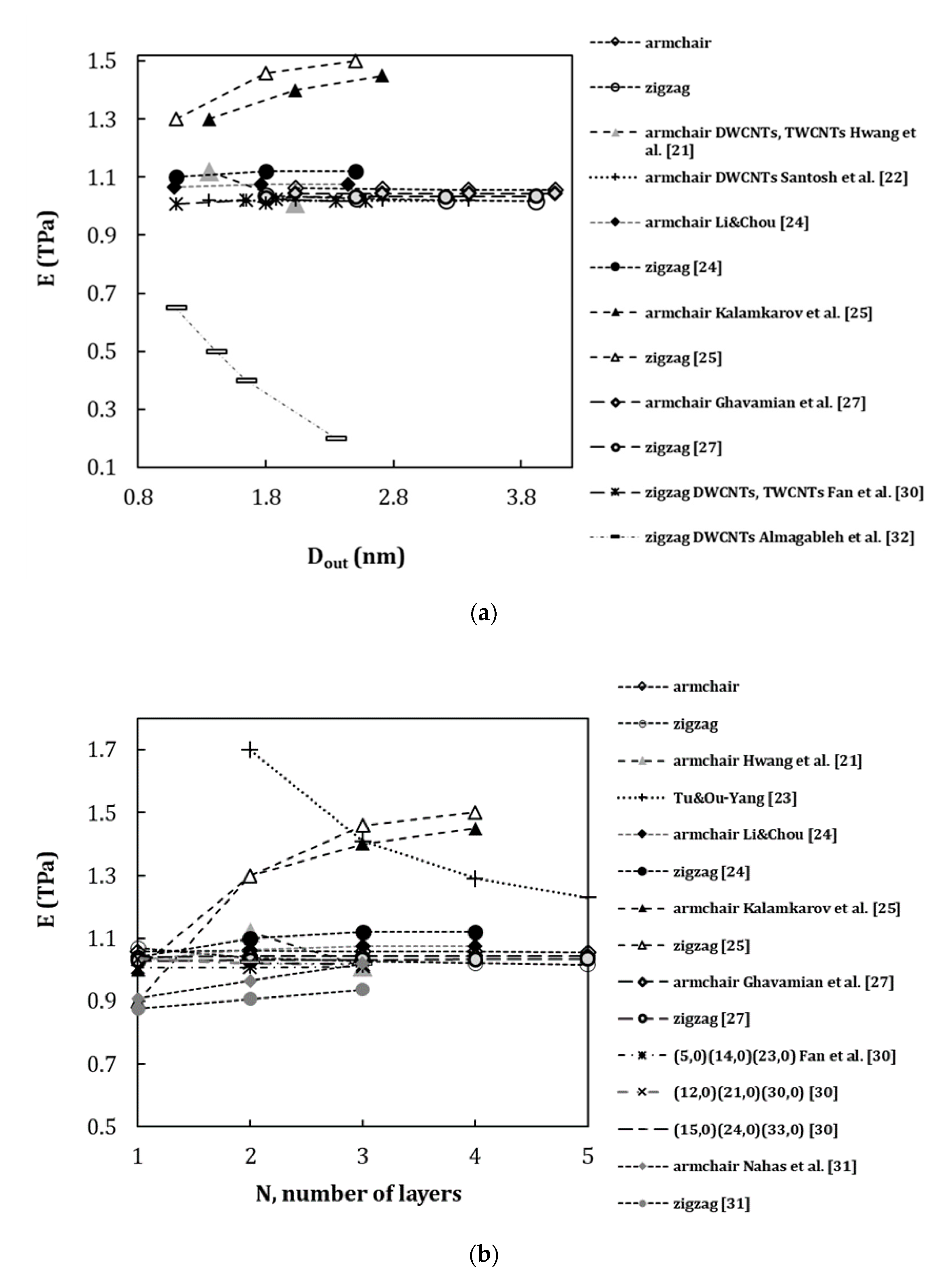

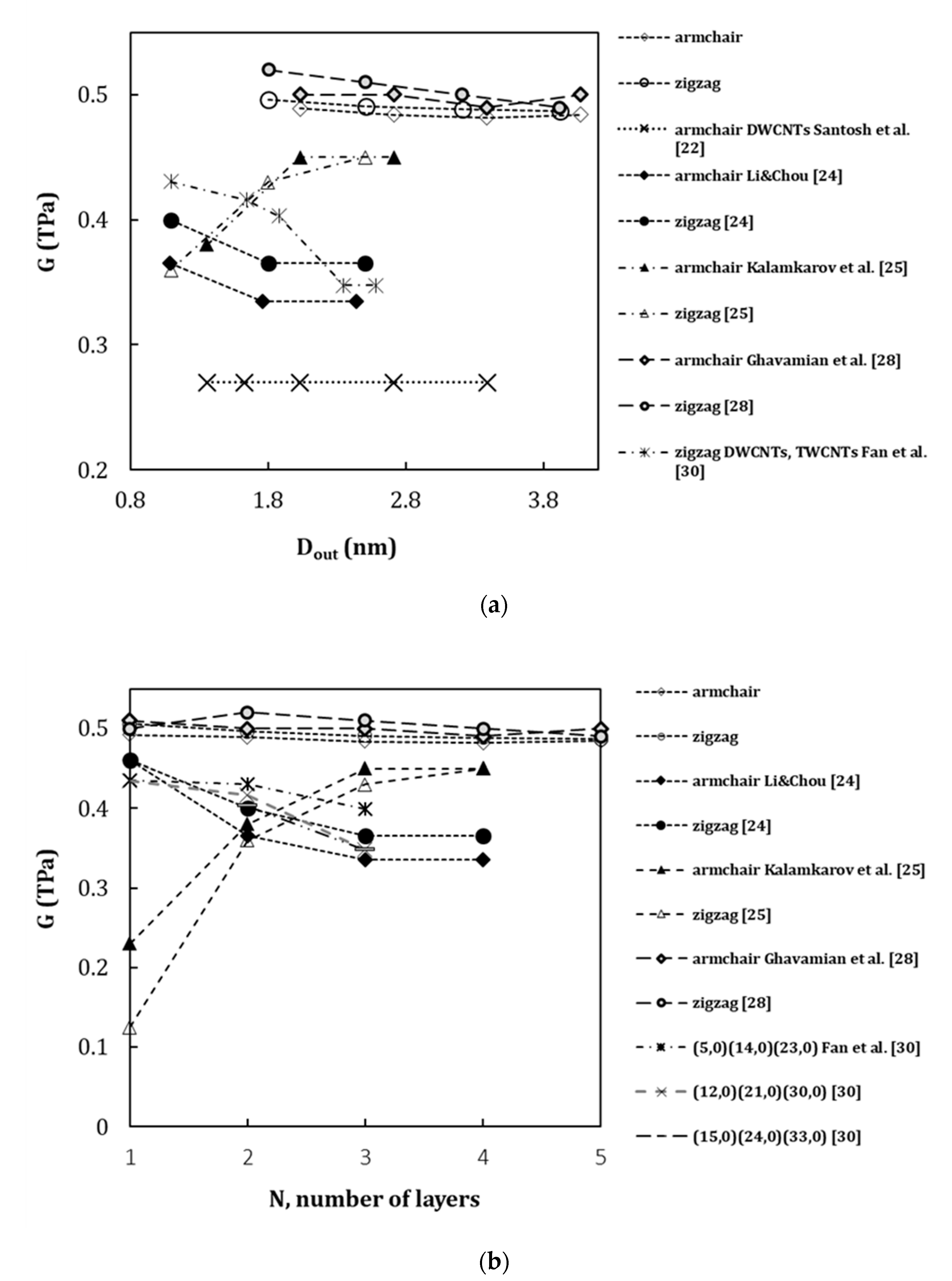

4.3. Comparison with Literature Results

5. Conclusions

- A linear relationship was established between the tensile rigidity of MWCNTs and the squares of the diameters of the outer and inner layers; Also, a linear relationship relates the bending and torsional rigidities of MWCNTs with the fourth powers of the diameters of the outer and inner layers.

- These linear relationships allow to obtain equations for easy analytical evaluation of the Young’s and shear moduli of armchair and zigzag MWCNT structures.

- Equations (22) and (23) offer two robust methods suitable for low-resource assessment to the Young’s and shear moduli of armchair and zigzag MWCNTs. They allow easily characterize the elastic moduli of nonchiral MWCNTs, whatever their inner and outer diameters, and the number of walls. This can be particularly useful, when understanding and modelling the mechanical behavior of MWCNT reinforced materials and MWCNT-based complex structures.

- The Young’s and shear moduli of armchair and zigzag MWCNTs are approximately constant with increasing difference between diameters of the outer and inner layers and, consequently, the number of layers. The Young’s and shear moduli of the zigzag structures are lower than for the armchair structures.

- The current values of the Young’s and shear moduli are in good agreement with various results available in the literature, obtained taking into account the van der Waals interactions between layers. This point out an appropriateness of using of the simplified model for evaluation of the elastic properties of the MWCNT structures.

Author Contributions

Funding

Conflicts of Interest

References

- Iijima, S.; Ichihashi, T. Single-shell carbon nanotubes of 1-nm diameter. Nature 1993, 363, 603–605. [Google Scholar]

- Kurita, H.; Estili, M.; Kwon, H.; Miyazaki, T.; Zhou, W.; Silvain, J.F.; Kawasaki, A. Load-bearing contribution of multi-walled carbon nanotubes on tensile response of aluminium. Compos. Part A Appl. Sci. Manuf. 2015, 68, 133–139. [Google Scholar] [CrossRef]

- WanderWal, R.L. Carbon nanotube synthesis in a flame using laser ablation for in situ catalyst generation. Appl. Phys. A Mater. Sci. Process. 2003, 77, 885–889. [Google Scholar] [CrossRef]

- Eatemadi, A.; Daraee, H.; Karimkhanloo, H.; Kouhi, M.; Zarghami, N.; Akbarzadeh, A.; Abasi, M.; Hanifehpour, Y.; Joo, S.W. Carbon nanotubes: Properties, synthesis, purification, and medical applications. Nanoscale Res. Lett. 2014, 9, 393. [Google Scholar] [CrossRef] [PubMed]

- Nam, I.W.; Souri, H.; Lee, H.K. Percolation threshold and piezoresistive response of multi-wall carbon nanotube/cement composites. Smart Struct. Syst. 2016, 18, 217–231. [Google Scholar] [CrossRef]

- Hajnayeb, A.; Khadem, S.E. An analytical study on the nonlinear vibration of a double walled carbon nanotube. Struct. Eng. Mech. 2015, 54, 987–998. [Google Scholar] [CrossRef]

- Rakrak, K.; Zidour, M.; Heireche, H.; Bousahla, A.A.; Chemi, A. Free vibration analysis of chiral double-walled carbon nanotube using non-local elasticity theory. Adv. Nano Res. 2016, 4, 31. [Google Scholar] [CrossRef]

- Bouilly, D.; Cabana, J.; Meunier, F.; Desjardins-Carriere, M.; Lapointe, F.; Gagnon, P.; Larouche, F.L.; Adam, E.; Paillet, M.; Martel, R. Wall-selective probing of double-walled carbon nanotubes using covalent functionalization RID G-7589-2011. ACS Nano 2011, 5, 4927–4934. [Google Scholar] [CrossRef]

- Green, A.A.; Hersam, M.C. Properties and application of double-walled carbon nanotubes sorted by outer-wall electronic type. ACS Nano 2011, 5, 1459–1467. [Google Scholar] [CrossRef]

- Morimoto, T.; Kuno, A.; Yajima, S.; Ishibashi, K.; Tsuchiya, K.; Yajima, H. Effective energy gap of the double-walled carbon nanotubes with field effect transistors ambipolar characteristics. Appl. Phys. Lett. 2012, 100, 043107. [Google Scholar] [CrossRef]

- Dong, X.; Fu, D.; Xu, Y.; Wei, J.; Shi, Y.; Chen, P.; Li, L.J. Label-free electronic detection of DNA using simple double-walled carbon nanotube resistors. J. Phys. Chem. C 2008, 112, 9891–9895. [Google Scholar] [CrossRef]

- Li, S.; Yu, Z.; Yen, S.-F.; Tang, W.C.; Burke, P.J. Carbon nanotube transistor operation at 2.6 GHz. Nano Lett. 2004, 4, 753–756. [Google Scholar] [CrossRef]

- Meunier, V.; Buongiorno Nardelli, M.; Roland, C.; Bernholc, J. Structural and electronic properties of carbon nanotube tapers. J. Phys. Rev. B 2001, 64, 195419. [Google Scholar] [CrossRef]

- Lassagne, B.; Bachtold, A. Carbon nanotube electromechanical resonator for ultrasensitive mass/force sensing. C. R. Phys. 2010, 11, 355–361. [Google Scholar] [CrossRef]

- Hierold, C.; Jungen, A.; Stampfer, C.; Helbling, T. Nano electromechanical sensors based on carbon nanotubes. Sens. Actuat. A 2007, 136, 51–61. [Google Scholar] [CrossRef]

- Sani, A.; Darbari, S.; Abdi, Y.; Arzi, E. Using bent carbon nanotubes for the fabrication of electromechanical switches. Carbon 2012, 50, 3635–3640. [Google Scholar] [CrossRef]

- Pantano, A. Effects of mechanical deformation on electronic transport through multiwall carbon nanotubes. Int. J. Solids Struct. 2017, 122, 33–41. [Google Scholar] [CrossRef]

- Li, C.; Chou, T.W. A structural mechanics approach for the analysis of carbon nanotubes. Int. J. Solids Struct. 2003, 40, 2487–2499. [Google Scholar] [CrossRef]

- Tserpes, K.I.; Papanikos, P. Finite element modeling of single-walled carbon nanotubes. Compos. Part B Eng. 2005, 36, 468–477. [Google Scholar] [CrossRef]

- Sakharova, N.A.; Pereira, A.F.G.; Antunes, J.M.; Brett, C.M.A.; Fernandes, J.V. Mechanical characterization of single-walled carbon nanotubes. Numerical simulation study. Compos. Part B Eng. 2015, 75, 73–85. [Google Scholar] [CrossRef]

- Hwang, C.C.; Wang, Y.C.; Kuo, Q.Y.; Lu, J.M. Molecular dynamics study of multi-walled carbon nanotubes under uniaxial loading. Phys. E Low Dimens. Syst. Nanostruct. 2010, 42, 775–778. [Google Scholar] [CrossRef]

- Santosh, M.; Maiti, P.K.; Sood, A.K. Elastic properties of boron nitride nanotubes and their comparison with carbon nanotubes. J. Nanosci. Nanotech. 2009, 9, 5425–5430. [Google Scholar] [CrossRef] [PubMed]

- Tu, Z.; Ou-Yang, Z. Single-walled and multiwalled carbon nanotubes viewed as elastic tubes with the effective Young’s moduli dependent on layer number. Phys. Rev. B 2002, 65, 233407. [Google Scholar] [CrossRef]

- Li, C.; Chou, T.W. Elastic moduli of multi-walled carbon nanotubes and the effect of van der Waals forces. Comp. Sci. Tech. 2003, 63, 1517–1524. [Google Scholar] [CrossRef]

- Kalamkarov, A.L.; Georgiades, A.V.; Rokkam, S.K.; Veedu, V.P.; Ghasemi-Nejhad, M.N. Analytical and numerical techniques to predict carbon nanotubes properties. Int. J. Solids Struct. 2006, 43, 6832–6854. [Google Scholar] [CrossRef]

- Rahmandoust, M.; Öchsner, A. On finite element modeling of single- and multi-walled carbon nanotubes. J. Nanosci. Nanotechnol. 2012, 12, 8129–8136. [Google Scholar] [CrossRef] [PubMed]

- Ghavamian, A.; Rahmandoust, M.; Öchsner, A. A numerical evaluation of the influence of defects on the elastic modulus of single and multi-walled carbon nanotubes. Comp. Mater. Sci. 2012, 62, 110–116. [Google Scholar] [CrossRef]

- Ghavamian, A.; Rahmandoust, M.; Öchsner, A. On the determination of the shear modulus of carbon nanotubes. Compos. Part B Eng. 2013, 44, 52–59. [Google Scholar] [CrossRef]

- Rouhi, S.; Nikkar, A.; Ansari, R. Finite element investigation of the elastic modulus of concentric boron nitride and carbon multi-walled nanotubes. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 34. [Google Scholar] [CrossRef]

- Fan, C.W.; Liu, Y.Y.; Hwu, C. Finite element simulation for estimating the mechanical properties of multi-walled carbon nanotubes. Appl. Phys. A 2009, 95, 819–831. [Google Scholar] [CrossRef]

- Nahas, M.N.; Abd-Rabou, M. Finite element modeling of multi-walled carbon nanotubes. Int. J. Eng. Technol. 2010, 10, 63–71. [Google Scholar]

- Almagableh, A.; Omari, M.A.; Sevostianov, I. Modeling of anisotropic elastic properties of multi-walled zigzag carbon nanotubes. Int. J. Eng. Sci. 2019, 144, 103127. [Google Scholar] [CrossRef]

- Sakharova, N.A.; Pereira, A.F.G.; Antunes, C.M.A.; Fernandes, J.V. Numerical simulation on the mechanical behaviour of the multi-walled carbon nanotubes. J. Nano Res. 2017, 47, 106–119. [Google Scholar] [CrossRef]

- Wang, C.G.; Liu, Y.P.; Al-Ghalith, J.; Dumitica, T.; Wadee, M.K.; Tan, H.F. Buckling behavior of carbon nanotubes under bending: From ripple to kink. Carbon 2016, 102, 224–235. [Google Scholar] [CrossRef]

- Sarvestani, H.Y.; Naghashpour, A. Analytical and numerical investigations on buckling behavior of nanotube structures. Acta Mech. 2015, 226, 3695–3705. [Google Scholar] [CrossRef]

- Chang, T.; Li, G.; Guo, X. Elastic axial buckling of carbon nanotubes via a molecular mechanics model. Carbon 2005, 43, 287–294. [Google Scholar] [CrossRef]

- Ru, C.Q. Effect of van der Waals forces on axial buckling of a double-walled carbon nanotube. J. Appl. Phys. 2000, 87, 7227–7231. [Google Scholar] [CrossRef]

- Ghavamian, A.; Öchsner, A. Numerical investigation on the influence of defects on the buckling behavior of single-and multi-walled carbon nanotubes. Phys. E Low Dimens. Syst. Nanostruct. 2012, 46, 241–249. [Google Scholar] [CrossRef]

- Yao, X.; Han, Q.; Xin, H. Bending buckling behaviors of single- and multi-walled carbon nanotubes. Comp. Mater. Sci. 2008, 43, 579–590. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Saito, R. Physics of carbon nanotubes. Carbon 1995, 33, 883–891. [Google Scholar] [CrossRef]

- Kharissova, O.V.; Kharisov, B.I. Variations of interlayer spacing in carbon nanotubes. RSC Adv. 2014, 58, 30807–30815. [Google Scholar] [CrossRef]

- Kiang, C.-H.; Endo, M.; Ajayan, P.M.; Dresselhaus, G.; Dresselhaus, M.S. Size effects in carbon nanotubes. Phys. Rev. Lett. 1998, 81, 1869–1872. [Google Scholar]

- Melchor, S.; Dobado, J.A. CoNTub: An algorithm for connecting two arbitrary carbon nanotubes. J. Chem. Inf. Comput. Sci. 2004, 44, 1639–1646. [Google Scholar] [PubMed]

- Cornell, W.D.; Cieplak, P.; Bayly, C.I.; Gould, I.R.; Merz, K.M.; Ferguson, D.M.; Spellmeyer, D.C.; Fox, T.; Caldwell, J.W.; Kollman, P.A. A second generation force-field for the simulation of proteins, nucleic acids and organic molecules. J. Am. Chem. Soc. 1995, 117, 5179–5197. [Google Scholar]

- Jorgensen, W.L.; Severance, D.L. Aromatic-aromatic interactions—Free energy profiles for the benzene dimer in water chloroform and liquid benzene. J. Am. Chem. Soc. 1990, 112, 4768–4774. [Google Scholar]

- Treacy, M.; Ebbesen, T.; Gibson, J. Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 1996, 381, 678–680. [Google Scholar]

- Kashyap, K.T.; Patil, R.G. On Young’s modulus of multi-walled carbon nanotubes. Bull. Mater. Sci. 2008, 31, 185–187. [Google Scholar]

| Parameter | Value | Formulation |

|---|---|---|

| Bond stretching force constant, [44] | 6.52 × 10−7 N nm−1 | – |

| Bond bending force constant, [44] | 8.76 × 10−10 N⋅nm⋅rad−2 | – |

| Torsional resistance force constant, [44,45] | 2.78 × 10−10 N⋅nm⋅rad−2 | – |

| Carbon–carbon (C–C) bond/beam length () | 0.1421 nm | – |

| Diameter (d) | 0.147 nm | |

| Cross section area, | 0.01688 nm2 | |

| Moment of inertia, | 2.269 × 10−5 nm4 | |

| Polar moment of inertia, | 4.537 × 10−5⋅nm4 | |

| Young’s modulus, | 5488 GPa | |

| Shear modulus, | 870.7 GPa | |

| Rigidity, | 92.65 nN | [24] |

| Rigidity, | 0.1245 nN⋅nm2 | [24] |

| Rigidity, | 0.0395 nN⋅nm2 | [24] |

| Interlay. Spacing, | Inner Layer Diameter, [nm] | N, Number of Layers | Outer Layer Diameter, [nm] | ||

|---|---|---|---|---|---|

| 0.339 | 1.356 | 2 | (10 + 5(N − 1), 10 + 5(N−1)), N = 2 to 20 | (10,10) (15,15) | 2.034 |

| 3 | (10,10) (15,15) (20,20) | 2.713 | |||

| 4 | (10,10) (15,15) … (25,25) | 3.390 | |||

| 5 | (10,10) (15,15) … (30,30) | 4.068 | |||

| 6 | (10,10) (15,15) … (35,35) | 4.746 | |||

| 7 | (10,10) (15,15) … (40,40) | 5.424 | |||

| 8 | (10,10) (15,15) … (45,45) | 6.101 | |||

| 9 | (10,10) (15,15) … (50,50) | 6.780 | |||

| 10 | (10,10) (15,15) … (55,55) | 7.457 | |||

| 11 | (10,10) (15,15) … (60,60) | 8.136 | |||

| 12 | (10,10) (15,15) … (65,65) | 8.814 | |||

| 13 | (10,10) (15,15) … (70,70) | 9.492 | |||

| 14 | (10,10) (15,15) … (75,75) | 10.170 | |||

| 15 | (10,10) (15,15) … (80,80) | 10.848 | |||

| 16 | (10,10) (15,15) … (85,85) | 11.526 | |||

| 17 | (10,10) (15,15) … (90,90) | 12.204 | |||

| 18 | (10,10) (15,15) … (95,95) | 12.882 | |||

| 19 | (10,10) (15,15) … (100,100) | 13.560 | |||

| 20 | (10,10) (15,15) … (105,105) | 14.238 | |||

| 4.746 | 2 | (35 + 5(N − 1), 35 + 5(N − 1)), N = 2 to 15 | (35,35) (40,40) | 5.424 | |

| 3 | (35,35) (40,40) (45,45) | 6.102 | |||

| 4 | (35,35) (40,40) … (50,50) | 6.780 | |||

| 5 | (35,35) (40,40) … (55,55) | 7.458 | |||

| 6 | (35,35) (40,40) … (60,60) | 8.136 | |||

| 7 | (35,35) (40,40) … (65,65) | 8.814 | |||

| 8 | (35,35) (40,40) … (70,70) | 9.492 | |||

| 9 | (35,35) (40,40) … (75,75) | 10.170 | |||

| 10 | (35,35) (40,40) … (80,80) | 10.848 | |||

| 11 | (35,35) (40,40) … (85,85) | 11.526 | |||

| 12 | (35,35) (40,40) … (90,90) | 12.204 | |||

| 13 | (35,35) (40,40) … (95,95) | 12.882 | |||

| 14 | (35,35) (40,40) … (100,100) | 13.560 | |||

| 15 | (35,35) (40,40) … (105,105) | 14.238 | |||

| Interlay. Spacing, | Inner Layer Diameter, [nm] | N, Number of Layers | Outer Layer Diameter, [nm] | ||

|---|---|---|---|---|---|

| 0.352 | 1.096 | 2 | (14 + 9(N − 1), 0), N = 2 to 20 | (14,0) (23,0) | 1.802 |

| 3 | (14,0) (23,0) (32,0) | 2.507 | |||

| 4 | (14,0) (23,0) … (41,0) | 3.212 | |||

| 5 | (14,0) (23,0) … (50,0) | 3.916 | |||

| 6 | (14,0) (23,0) … (59,0) | 4.618 | |||

| 7 | (14,0) (23,0) … (68,0) | 5.323 | |||

| 8 | (14,0) (23,0) … (77,0) | 6.027 | |||

| 9 | (14,0) (23,0) … (86,0) | 6.732 | |||

| 10 | (14,0) (23,0) … (95,0) | 7.436 | |||

| 11 | (14,0) (23,0) … (104,0) | 8.142 | |||

| 12 | (14,0) (23,0) … (113,0) | 8.847 | |||

| 13 | (14,0) (23,0) … (122,0) | 9.551 | |||

| 14 | (14,0) (23,0) … (131,0) | 10.256 | |||

| 15 | (14,0) (23,0) … (140,0) | 10.960 | |||

| 16 | (14,0) (23,0) … (149,0) | 11.665 | |||

| 17 | (14,0) (23,0) … (158,0) | 12.370 | |||

| 18 | (14,0) (23,0) … (167,0) | 13.074 | |||

| 19 | (14,0) (23,0) … (176,0) | 13.779 | |||

| 20 | (14,0) (23,0) … (185,0) | 14.483 | |||

| 4.619 | 2 | (59 + 9(N − 1), 0), N = 2 to 15 | (59,0) (68,0) | 5.324 | |

| 3 | (59,0) (68,0) (77,0) | 6.028 | |||

| 4 | (59,0) (68,0) … (86,0) | 6.733 | |||

| 5 | (59,0) (68,0) … (95,0) | 7.437 | |||

| 6 | (59,0) (68,0) … (104,0) | 8.142 | |||

| 7 | (59,0) (68,0) … (113,0) | 8.847 | |||

| 8 | (59,0) (68,0) … (122,0) | 9.551 | |||

| 9 | (59,0) (68,0) … (131,0) | 10.256 | |||

| 10 | (59,0) (68,0) … (140,0) | 10.960 | |||

| 11 | (59,0) (68,0) … (149,0) | 11.665 | |||

| 12 | (59,0) (68,0) … (158,0) | 12.370 | |||

| 13 | (59,0) (68,0) … (167,0) | 13.074 | |||

| 14 | (59,0) (68,0) … (176,0) | 13.779 | |||

| 15 | (59,0) (68,0) … (185,0) | 14.483 | |||

| Type of MWCNT | Parameter | ||

|---|---|---|---|

| Armchair | 827.24 | 52.34 | 48.02 |

| Zigzag | 796.91 | 50.37 | 46.44 |

| MWCNT Type | Inner Layer Diameter, [nm] | N, Number of Layers | Outer Layer Diameter, [nm] | ||

|---|---|---|---|---|---|

| Armchair | 1.085 | 2 | (8 + 5(N − 1), 8 + 5(N − 1)), N = 2 to 21 | (8,8) (13,13) | 1.763 |

| 3 | (8,8) (13,13) (18,18) | 2.441 | |||

| 4 | (8,8) (13,13) … (23,23) | 3.119 | |||

| 5 | (8,8) (13,13) … (28,28) | 3.797 | |||

| 6 | (8,8) (13,13) … (33,33) | 4.475 | |||

| 7 | (8,8) (13,13) … (38,38) | 5.153 | |||

| 8 | (8,8) (13,13) … (43,43) | 5.831 | |||

| 9 | (8,8) (13,13) … (48,48) | 6.509 | |||

| 10 | (8,8) (13,13) … (53,53) | 7.187 | |||

| 11 | (8,8) (13,13) … (58,58) | 7.865 | |||

| 12 | (8,8) (13,13) … (63,63) | 8.543 | |||

| 13 | (8,8) (13,13) … (68,68) | 9.221 | |||

| 14 | (8,8) (13,13) … (73,73) | 9.899 | |||

| 15 | (8,8) (13,13) … (78,78) | 10.577 | |||

| 16 | (8,8) (13,13) … (83,83) | 11.255 | |||

| 17 | (8,8) (13,13) … (88,88) | 11.933 | |||

| 18 | (8,8) (13,13) … (93,93) | 12.611 | |||

| 19 | (8,8) (13,13) … (98,98) | 13.289 | |||

| 20 | (8,8) (13,13) … (103,103) | 13.967 | |||

| 21 | (8,8) (13,13) … (108,108) | 14.645 | |||

| Zigzag | 0.783 | 2 | (10 + 9(N − 1), 0), N = 2 to 21 | (10,0) (19,0) | 1.487 |

| 3 | (10,0) (19,0) (28,0) | 2.192 | |||

| 4 | (10,0) (19,0) … (37,0) | 2.897 | |||

| 5 | (10,0) (19,0) … (46,0) | 3.601 | |||

| 6 | (10,0) (19,0) … (55,0) | 4.306 | |||

| 7 | (10,0) (19,0) … (64,0) | 5.010 | |||

| 8 | (10,0) (19,0) … (73,0) | 5.715 | |||

| 9 | (10,0) (19,0) … (82,0) | 6.420 | |||

| 10 | (10,0) (19,0) … (91,0) | 7.124 | |||

| 11 | (10,0) (19,0) … (100,0) | 7.829 | |||

| 12 | (10,0) (19,0) … (109,0) | 8.533 | |||

| 13 | (10,0) (19,0) … (118,0) | 9.238 | |||

| 14 | (10,0) (19,0) … (127,0) | 9.943 | |||

| 15 | (10,0) (19,0) … (136,0) | 10.647 | |||

| 16 | (10,0) (19,0) … (145,0) | 11.352 | |||

| 17 | (10,0) (19,0) … (154,0) | 12.056 | |||

| 18 | (10,0) (19,0) … (163,0) | 12.761 | |||

| 19 | (10,0) (19,0) … (172,0) | 13.466 | |||

| 20 | (10,0) (19,0) … (181,0) | 14.170 | |||

| 21 | (10,0) (19,0) … (190,0) | 14.875 | |||

| Reference | Method | Interlayer Spacing, | Approach for the vdW Interactions between Layers | MWCNT Type * | Max. Number of Layers, N | Young’s Modulus, TPa | Shear Modulus, TPa |

|---|---|---|---|---|---|---|---|

| Hwang et al. [21] | MD: empirical Tersoff three-body potential | 0.339 | Empirical Tersoff three-body potential | Armchair (5,5)(10,10), (10,10)(15,15) | 2 | 0.85–1.16 | – |

| Armchair (5,5)(10,10)(15,15) | 3 | 0.85–1.12 | |||||

| Santosh et al. [22] | MD: force- constant approach | 0.340 | Force-constant approach | Armchair (5,5)(10,10), (7,7)(12,12), (10,10)(15,15), (15,15)(20,20), (20,20)(25,25) | 2 | 1.02 | 0.27 |

| Tu and Ou-Yang [23] | CM: classic shell theory | 0.340 | – | – | 100 | 1.70–1.05 | – |

| Li and Chou [24] | NCM: beams | 0.339 | Truss rods | Armchair (3,3)(8,8)(13,13)(18,18) | 4 | 1.05–1.10 | 0.33–0.48 |

| 0.352 | Zigzag (5,0)(14,0)(23,0)(32,0) | 1.05–1.12 | 0.33–0.36 | ||||

| Kalamkarov et al. [25] | 0.339 | Springs | Armchair (5,5)(10,10)(15,15)(20,20) | 4 | 1.00–1.45 | 0.44–0.47 | |

| 0.352 | Zigzag (5, 0)(14, 0)(23, 0)(32, 0) | 0.96–1.50 | 0.44–0.47 | ||||

| Fan et al. [30] | 0.352 | Springs: interlayer pressure | Zigzag (5,0)(14,0)(23,0) | 3 | 1.007–1.011 | 0.430–0.398 | |

| (12,0)(21, 0)(30,0) | 1.021–1.017 | 0.415–0.347 | |||||

| (15,0)(24, 0)(33,0) | 1.023–1.018 | 0.402–0.347 | |||||

| Nahas and Abd-Rabou [31] | – | Beams | Armchair | 3 | 0.98–1.02 | – | |

| Zigzag | 0.876–0.937 | ||||||

| Ghavamian et al. [27] | NCM: beams | 0.339 | Springs | Armchair (10,10)(15,15)…(30,30) | 5 | 1.040–1.044 | – |

| 0.352 | Zigzag (14,0)(23,0)…(50,0) | 1.030–1.035 | |||||

| Ghavamian et al. [28] | 0.339 | Springs | Armchair (10,10)(15,15)…(30,30) | 5 | – | 0.50 | |

| 0.352 | Zigzag (14,0)(23,0)…(50,0) | ||||||

| Almagableh et al. [32] | NCM: pseudo-rectangular beams | 0.340 | Nonlinear solid elements | Zigzag (5,0)(14,0), (9,0)(18,0), (12,0)(21,0), (21,0)(30,0) | 2 | 0.65–0.2 | – |

| Treacy et al. [46] | TEM: amplitude of intrinsic thermal vibrations | – | – | Unidentified type | – | 1.8 ± 0.9 | – |

| Kashyap and Patil [47] | TEM image +analytical | – | – | Unidentified type | – | 0.9 | |

| Current results | NCM: beams | 0.339 | – | Armchair (10,10)(15,15)…(105,105) | 20 | 1.061–1.051 | 0.479–0.484 |

| 0.352 | Zigzag (14,0) (23,0)…(185,0) | 1.069–1.012 | 0.475–0.471 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakharova, N.A.; Pereira, A.F.G.; Antunes, J.M.; Fernandes, J.V. Mechanical Characterization of Multiwalled Carbon Nanotubes: Numerical Simulation Study. Materials 2020, 13, 4283. https://doi.org/10.3390/ma13194283

Sakharova NA, Pereira AFG, Antunes JM, Fernandes JV. Mechanical Characterization of Multiwalled Carbon Nanotubes: Numerical Simulation Study. Materials. 2020; 13(19):4283. https://doi.org/10.3390/ma13194283

Chicago/Turabian StyleSakharova, Nataliya A., André F. G. Pereira, Jorge M. Antunes, and José V. Fernandes. 2020. "Mechanical Characterization of Multiwalled Carbon Nanotubes: Numerical Simulation Study" Materials 13, no. 19: 4283. https://doi.org/10.3390/ma13194283

APA StyleSakharova, N. A., Pereira, A. F. G., Antunes, J. M., & Fernandes, J. V. (2020). Mechanical Characterization of Multiwalled Carbon Nanotubes: Numerical Simulation Study. Materials, 13(19), 4283. https://doi.org/10.3390/ma13194283