Synthesis of Repair Materials and Methods for Reinforced Concrete and Prestressed Bridge Girders

Abstract

1. Introduction

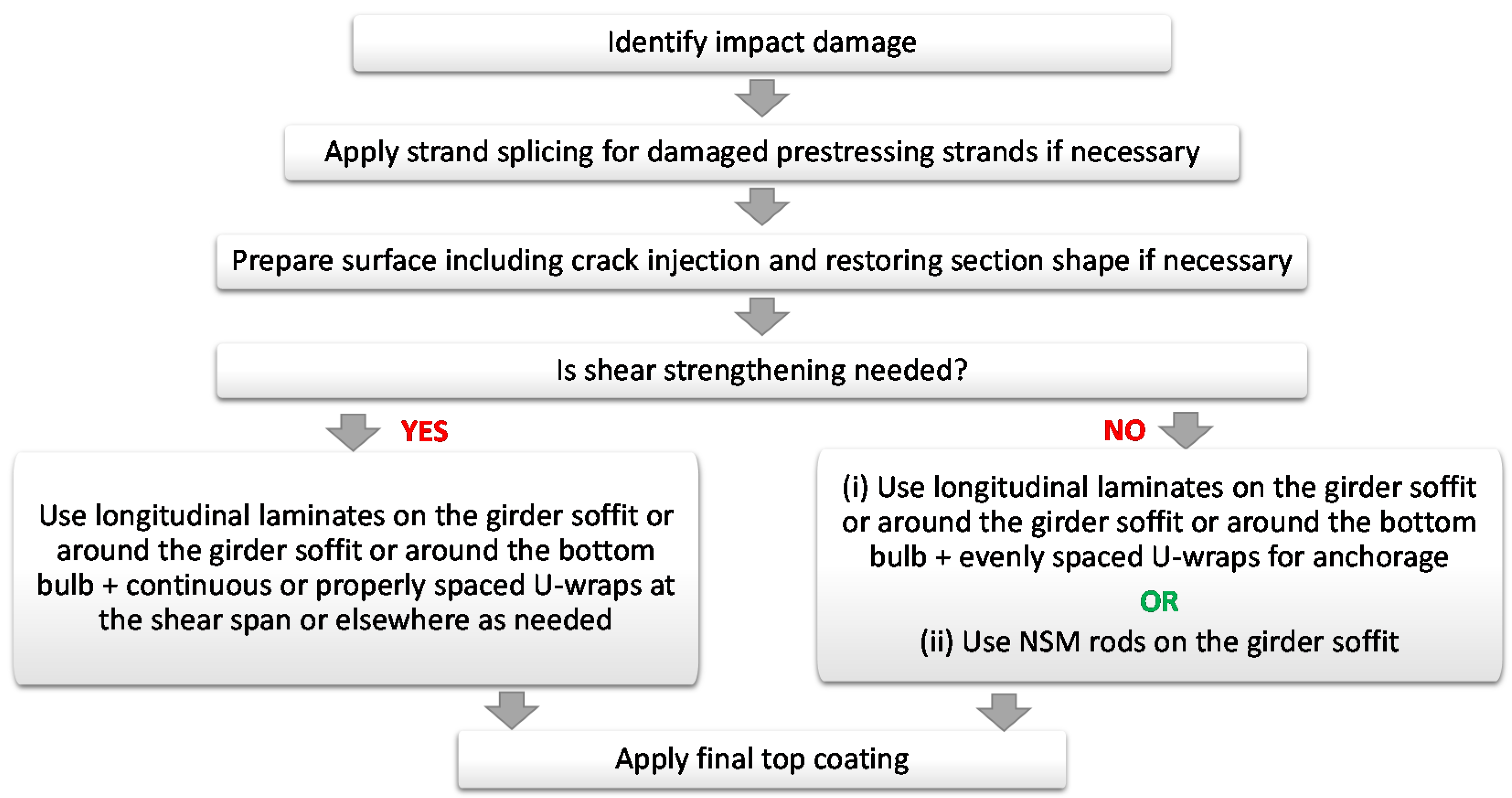

2. General Repair Procedure

2.1. Inspection and Monitoring

2.2. Decision #1: Choosing a Repair Material

2.2.1. Fiber-Reinforced Composites (Since 1980s)

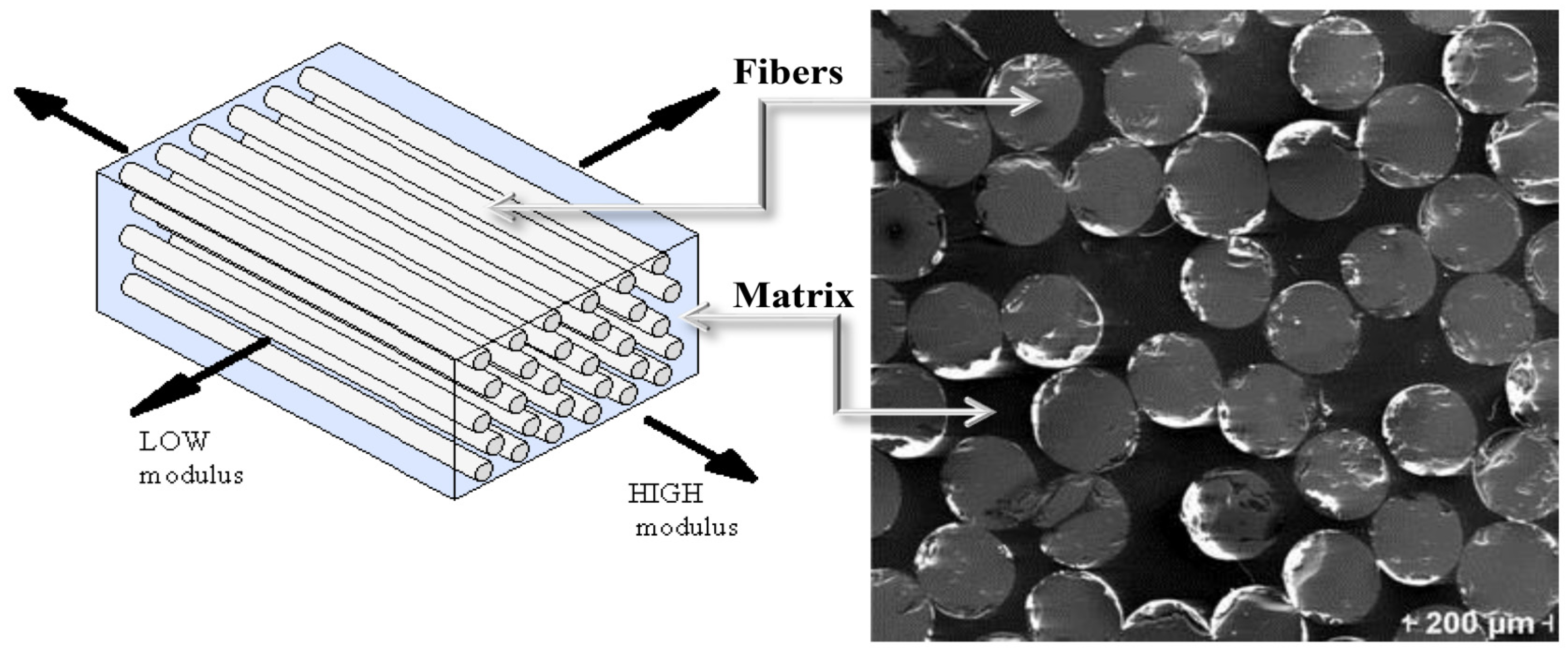

- Polymeric composites: Polymeric composites (also called fiber-reinforced polymers or FRP) are fibers embedded in a polymeric resin such as unsaturated polyester, epoxy, vinylester, phenolic, and polyurethane resins. Epoxy resins are the most common matrix in structural repair applications due to their characteristics such as good adhesive properties, low shrinkage during curing, and resistance to environmental degradation [1,33]. Popular fibers used are steel, basalt, carbon, and glass, which result in SFRP, BFRP, CFRP, and GFRP composites, respectively. The fibers and the resin work as a system together; the fibers provide load carrying capacity, high tensile strength, and rigidity, while the resin protects and transfers the load to the fibers and works like a binder to them [28,33,34]. However, one of the major limitations in using FRP materials as a repair or strengthening approach is the ductility of the element. The ductility of the concrete members strengthened with FRP materials decreases with the amount of FRP used. Therefore, a strengthening limit approach is often suggested in guidelines and codes in order to restrict the use of high amounts of FRP [35].

- Cement-based composites: Use of fibers with cementitious matrix instead of epoxy resin was proposed in the early 1980s, but did not gain that much attention until the late 1990s. Cementitious matrix has several advantages over conventional epoxy resins in terms of fire resistance, performance under ultraviolet (UV) radiation, permeability, thermal reversibility, and cost. Additionally, having similar mechanical, chemical, and physical properties as the concrete substrate is another advantage. Unlike the FRP installation safety requirement because of the characteristics of the used resins, installation of cementitious matrix can be done merely by simple troweling techniques and protective equipment for typical concrete applications. Further, unlike FRP, cementitious matrix can be applied to wet surfaces, and thus the project will not be affected by weather conditions as much. The different types of cement-based composites include sprayed concrete, textile-reinforced mortar (TRM), textile-reinforced concrete (TRC), fiber-reinforced concrete (FRC), fiber-reinforced cementitious mortar (FRCM), and mineral-based composites (MBC) [7,19,25,28,33,36,37,38]. However, one of the major concerns of such material (e.g., FRCM) is unknown long-term fatigue performance. Thus, FRCM should not yet be used as a repair alternative to bridges with a considerable level of damage and/or high traffic volume [33].

- Hybrid composites: Different fiber-based composites can be combined together as a hybrid to enhance the strengthening efficiency. For example, they can provide a progressive failure pattern to compensate for the loss of ductility that is observed in traditional fiber-reinforced materials [25]. Additionally, fiber-reinforced materials remain elastic up to failure. This is while hybrid materials can experience yielding as in steel. The modulus of elasticity of the fiber-reinforced material can be low or high depending on the fiber and the matrix utilized [25,38]. Examples of such material are CFRP rod panels (CRPs), CFRP-honeycomb (referred to as H-Lam-C), and GFRP-honeycomb (referred to as H-Lam-G) composites [39,40,41].

2.2.2. Steel (Since the 1960s)

2.2.3. Other Materials

2.3. Decision #2: Choosing a Repair Method

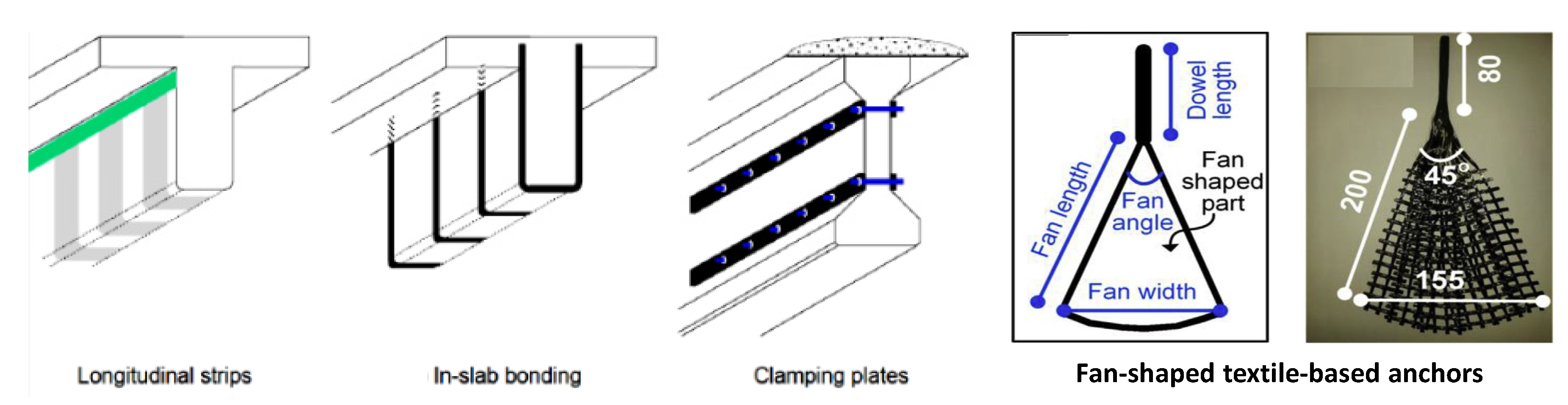

2.3.1. Externally Bonded (EB) Techniques

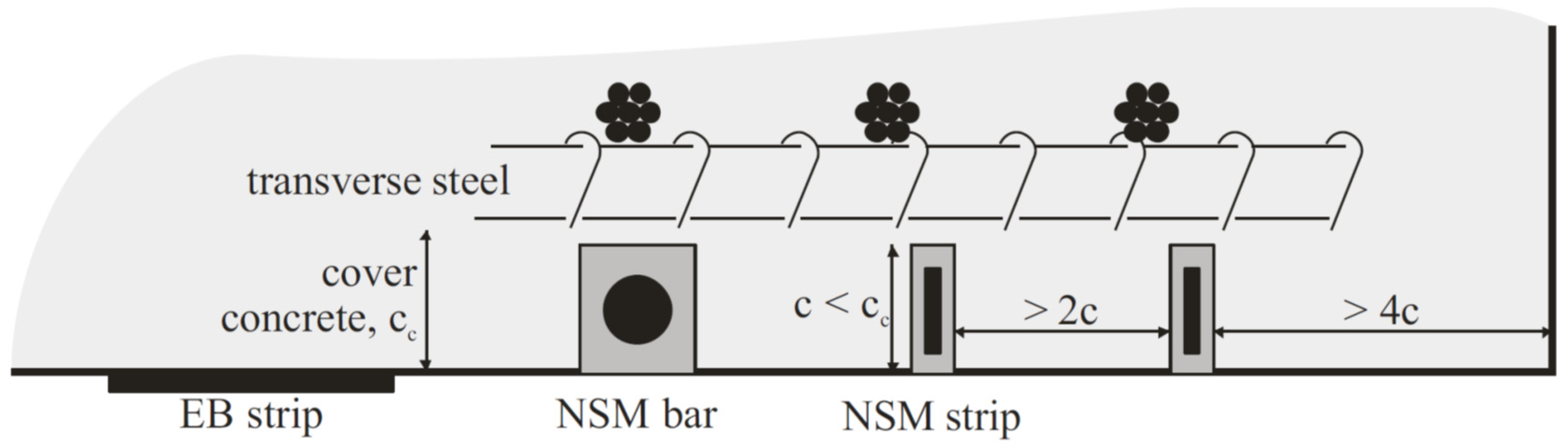

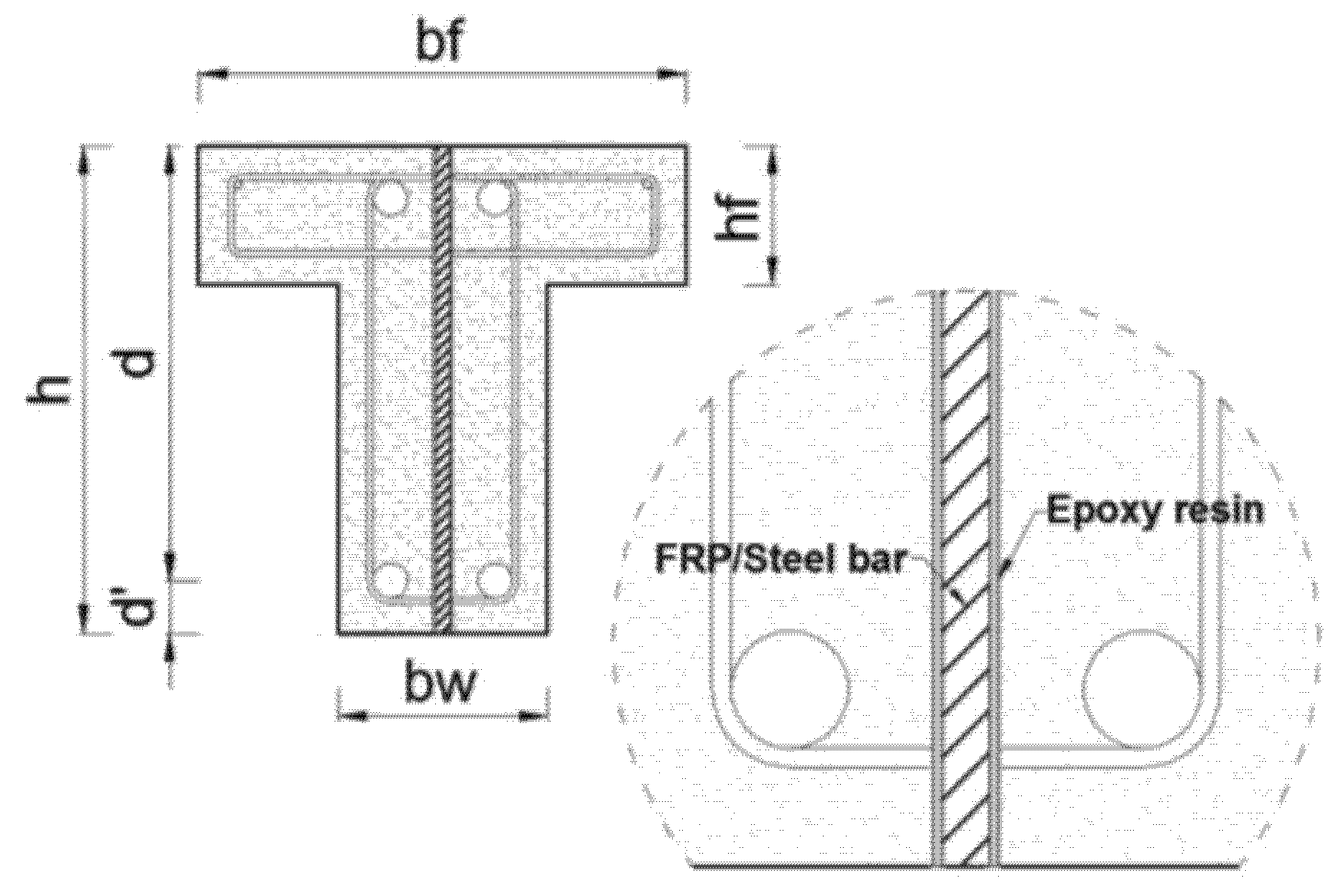

2.3.2. Near-Surface Mounted (NSM) Techniques

2.3.3. Embedded Reinforcement

2.4. Surface Preparation

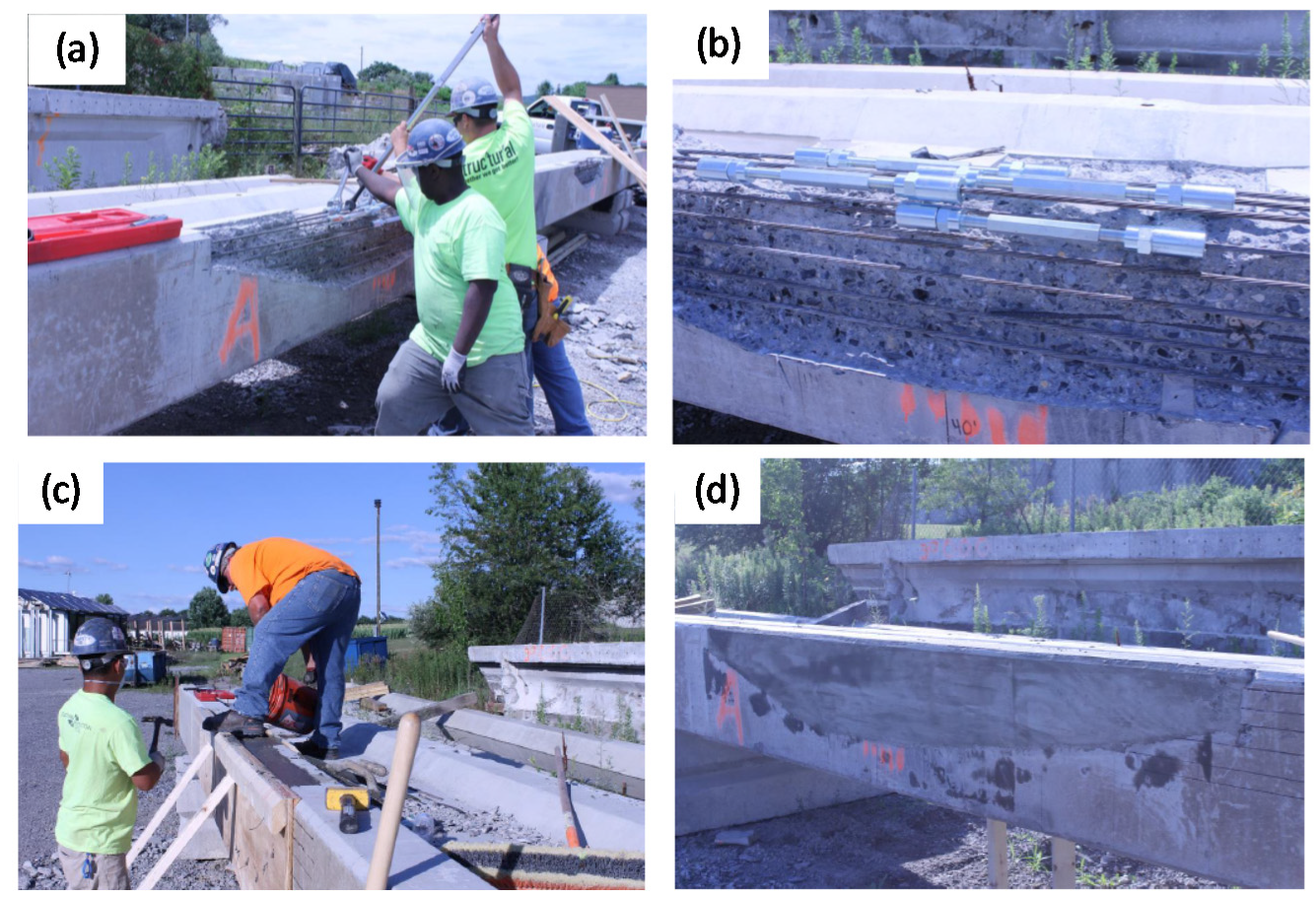

2.4.1. Removal of All Unsound Concrete

2.4.2. Select a Patching Method (If Needed)

2.4.3. Surface Polishing (Roughening)

2.4.4. Cleaning

2.4.5. Priming

2.5. Repair Design

- AASHTO Guide Specifications for Design of Bonded FRP Systems for Repair and Strengthening of Concrete Bridge Elements (latest version is 2013).

- AC125 Acceptance Criteria for Concrete and Reinforced and Unreinforced Masonry Strengthening Using Externally Bonded Fiber-Reinforced Polymer (FRP) Composite Systems (latest version is 2012). AC125 is issued by ICC Evaluation Service to establish minimum requirements for the issuance of evaluation reports on FRP composite systems under the 2012, 2009, and 2006 International Building Code (IBC) and the 1997 Uniform Building Code (UBC).

- ACI 440.3R Guide Test Methods for Fiber-Reinforced Polymers (FRPs) for Reinforcing or Strengthening Concrete Structures (latest version is 2004).

- ACI 440R Report on Fiber-Reinforced Polymer (FRP) Reinforcement for Concrete Structures (latest version is 2007).

- ACI SP-215 Field Applications of FRP Reinforcement: Case Studies (latest version is 2003).

- ISIS Design Manual No. 4, FRP Rehabilitation of Reinforced Concrete Structures, issued by the Canadian Network of Centers of Excellence on Intelligent Sensing for Innovative Structures (latest version is 2008).

2.6. Application of the Repair Material

2.6.1. EB Technique

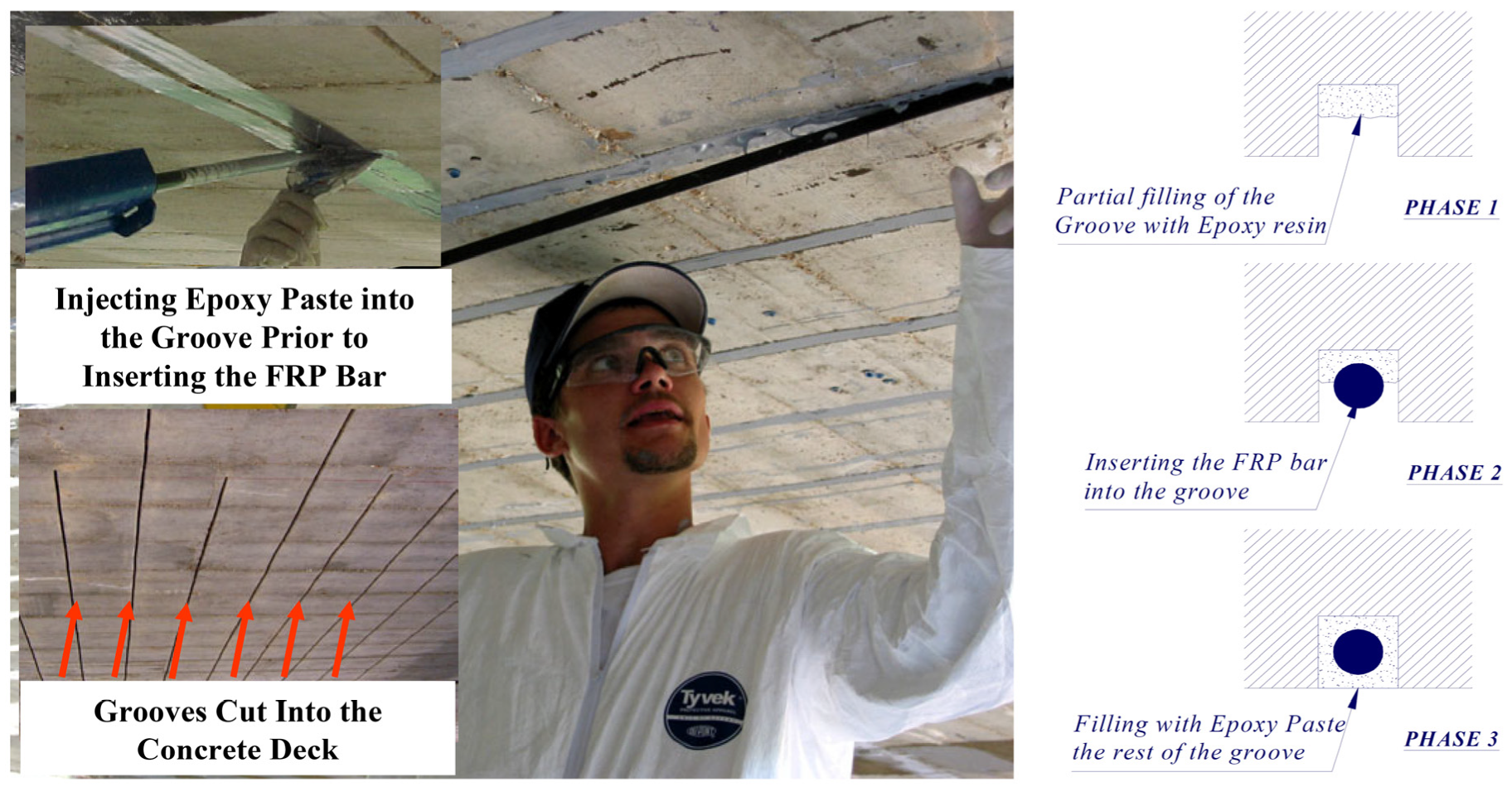

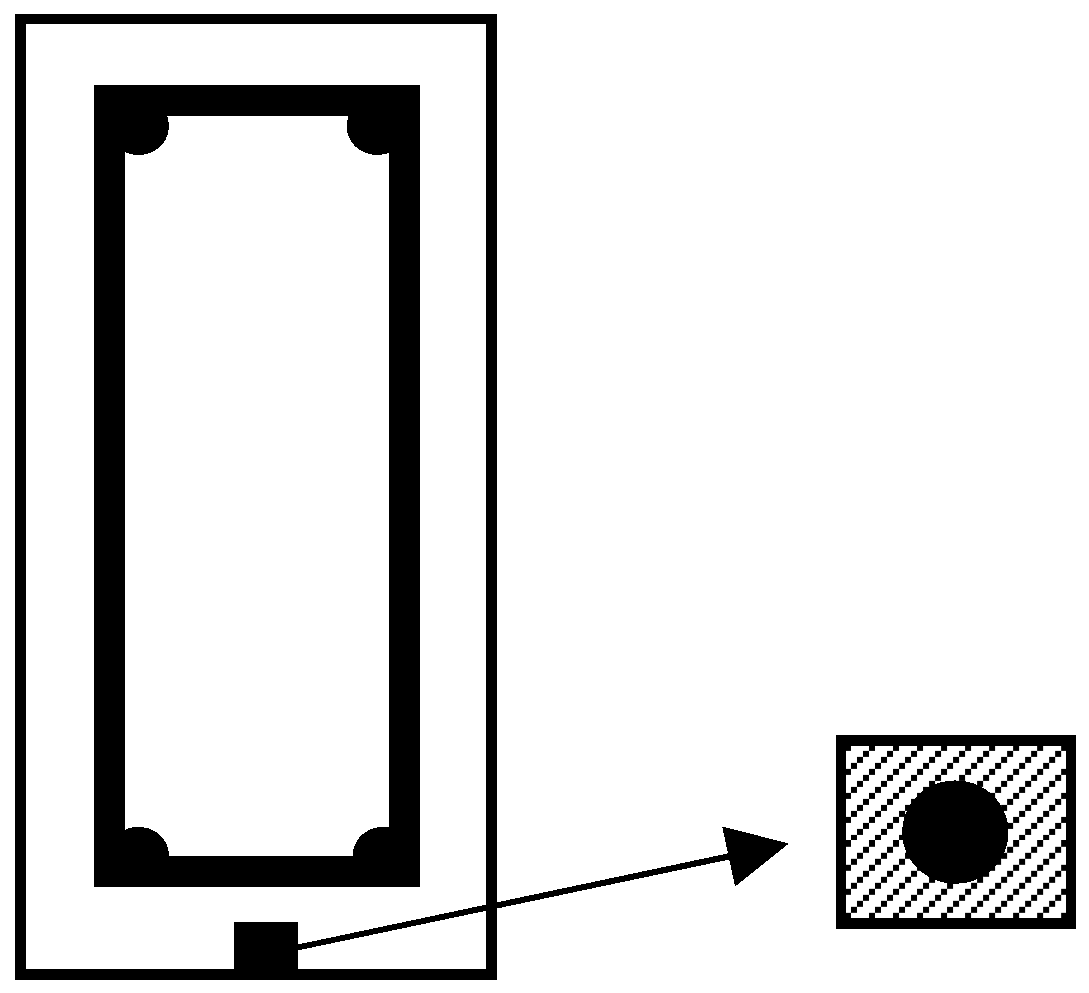

2.6.2. NSM Technique

2.7. Prestressing of the Repair Material (Optional)

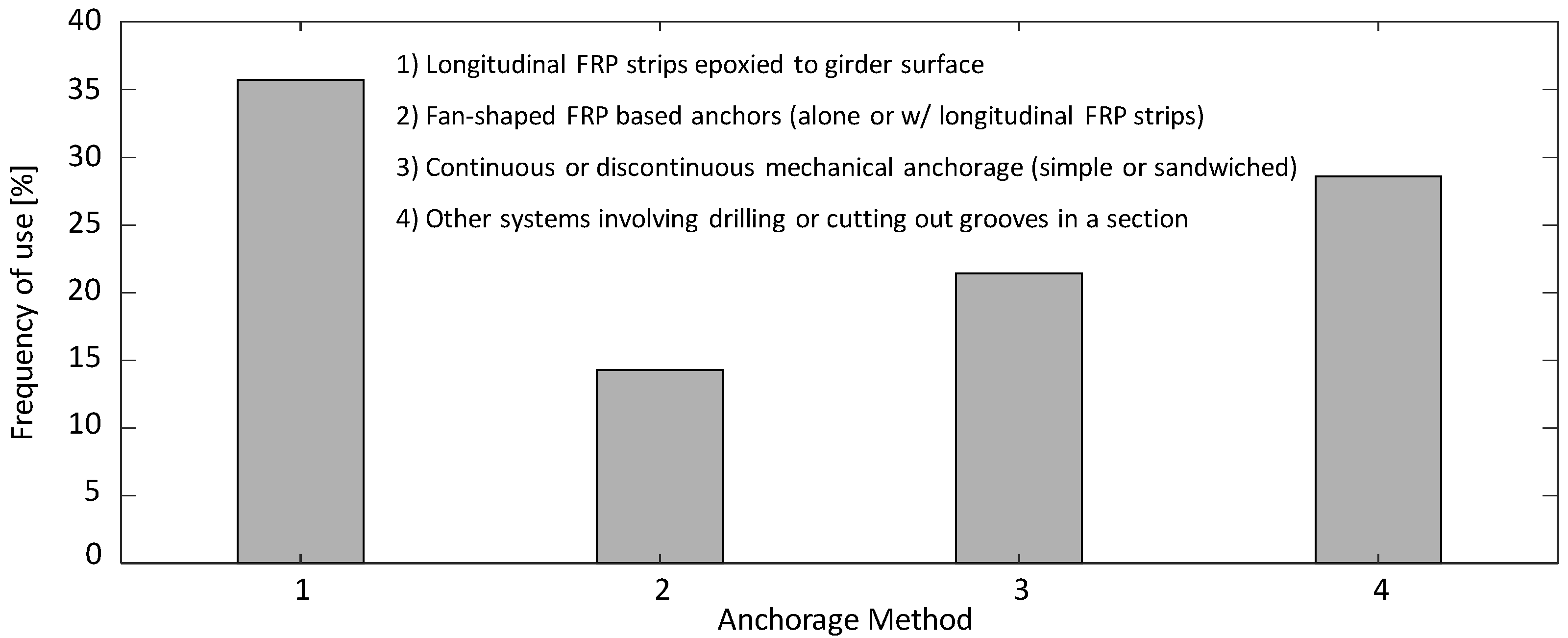

2.8. Anchorage System

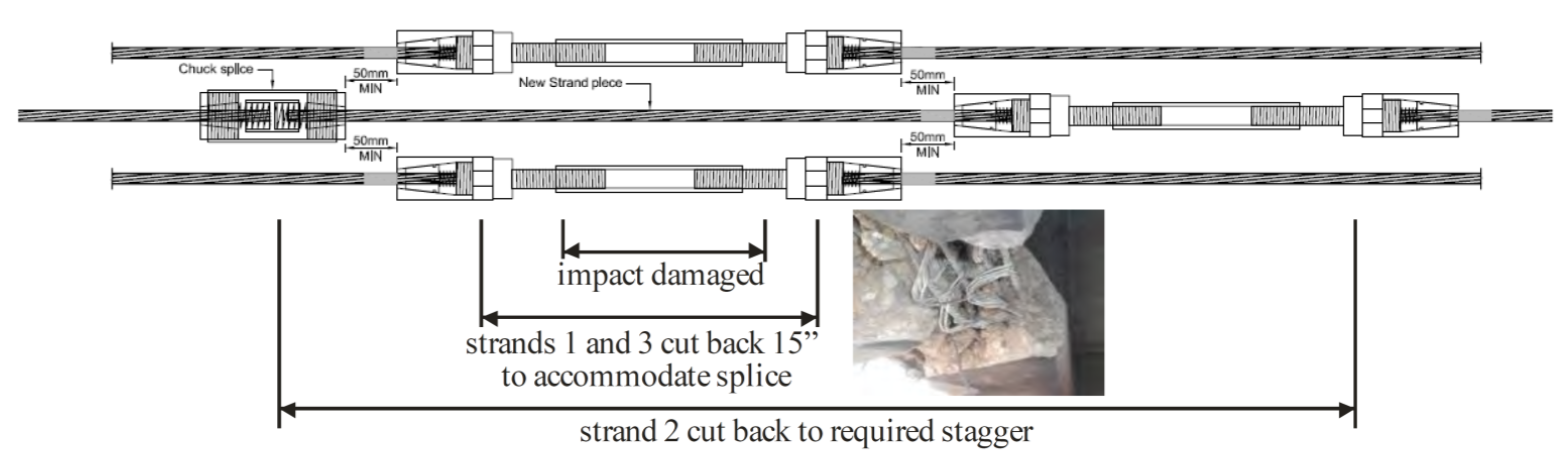

2.9. Strand Splicing (If Needed)

3. Repair for Shear

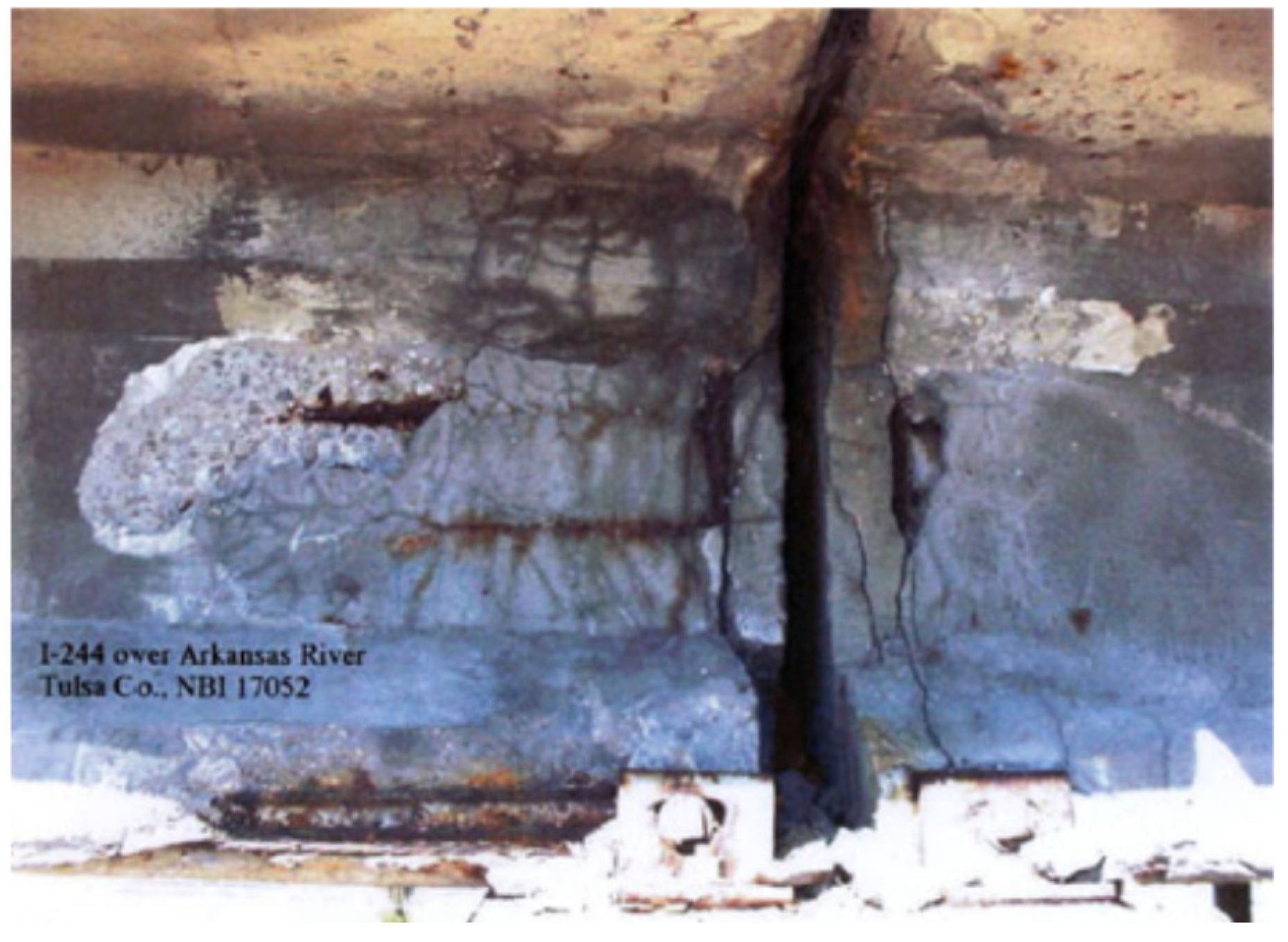

3.1. Main Causes of Damage

3.2. Common Solutions

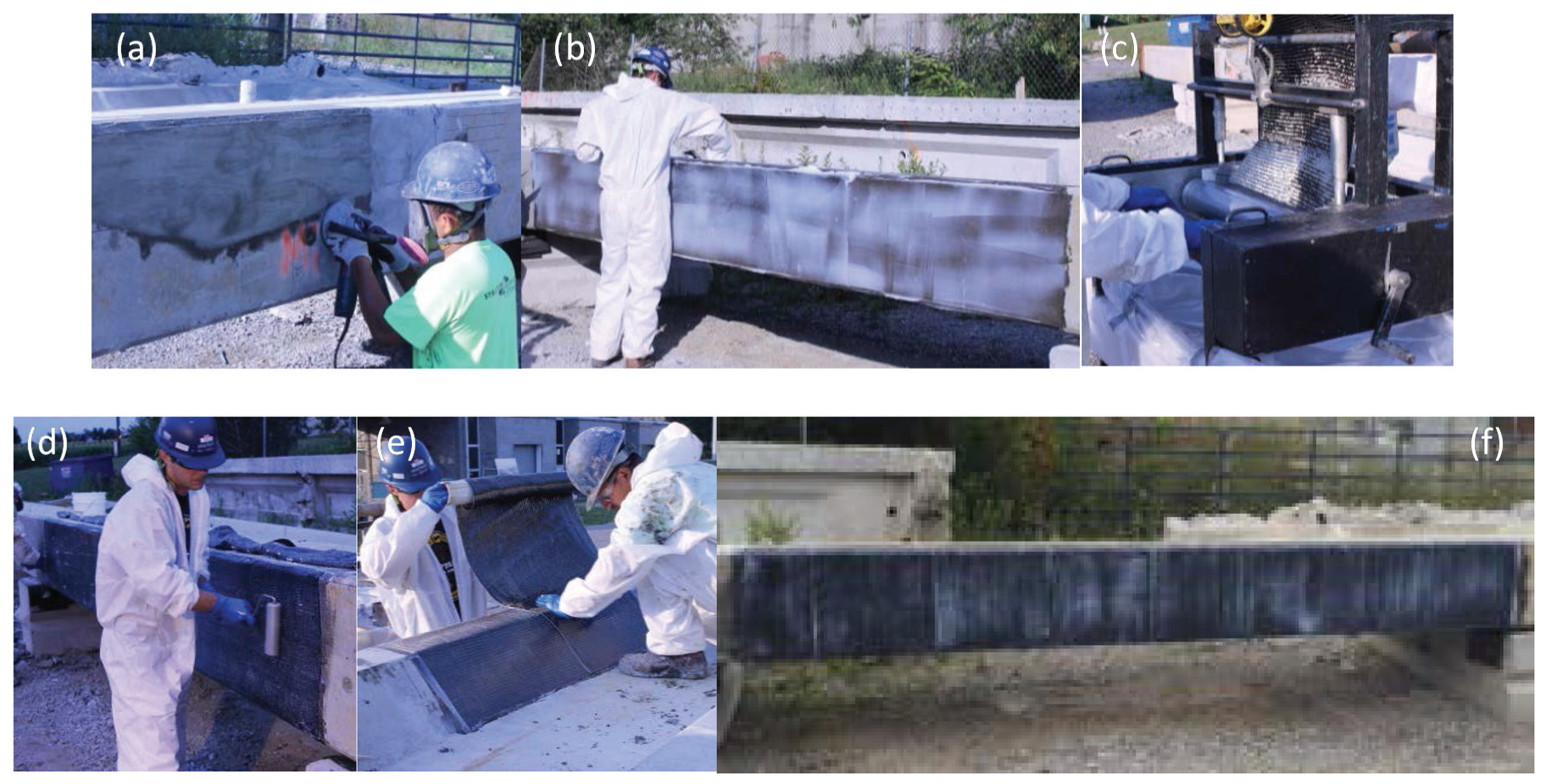

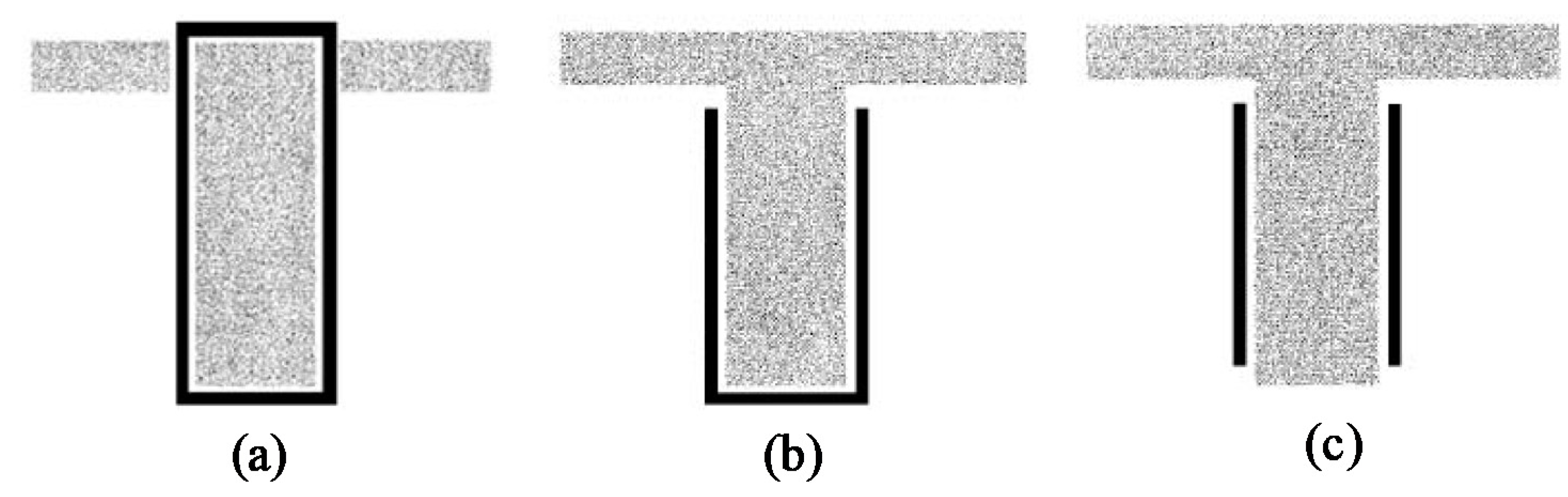

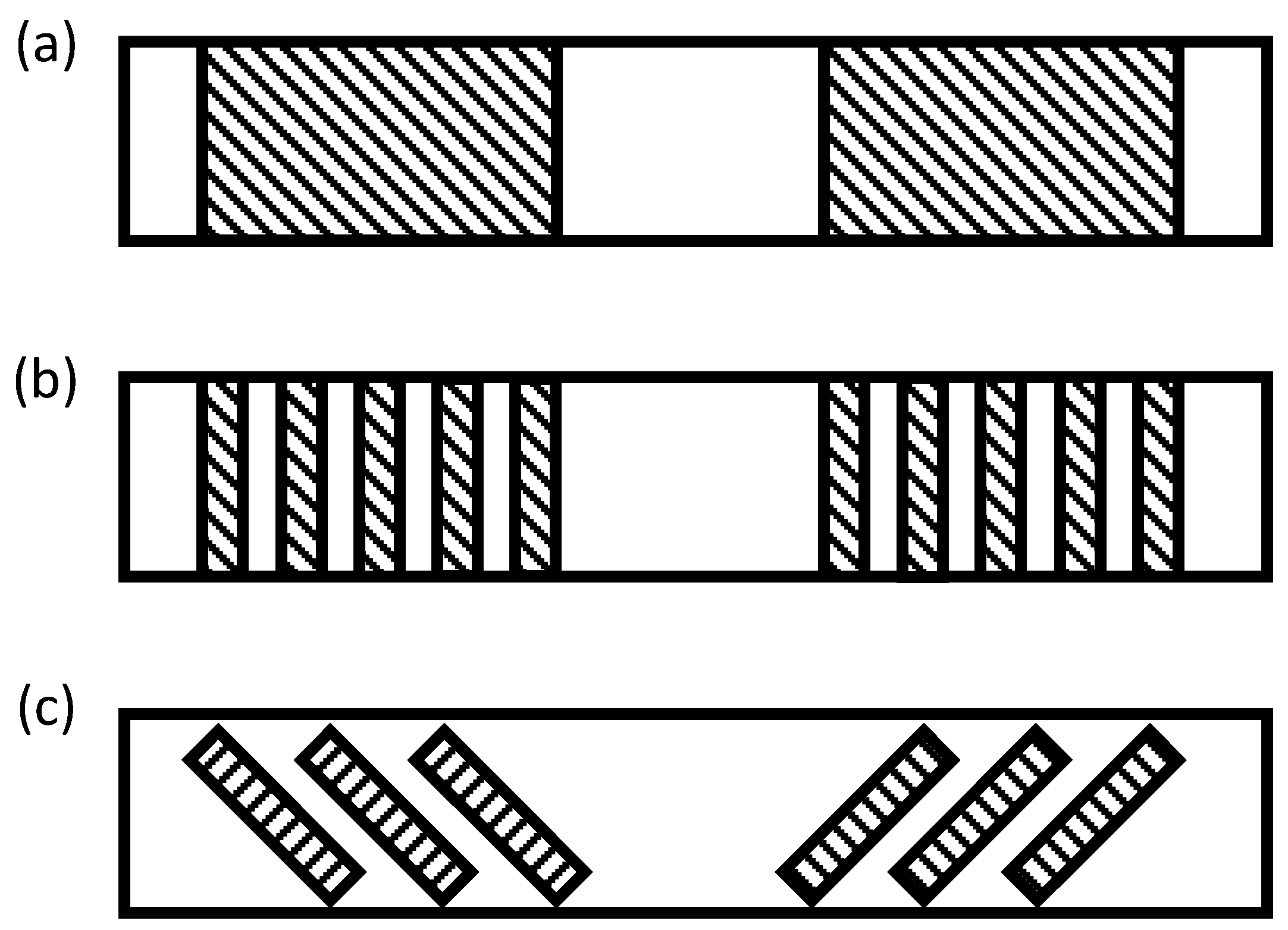

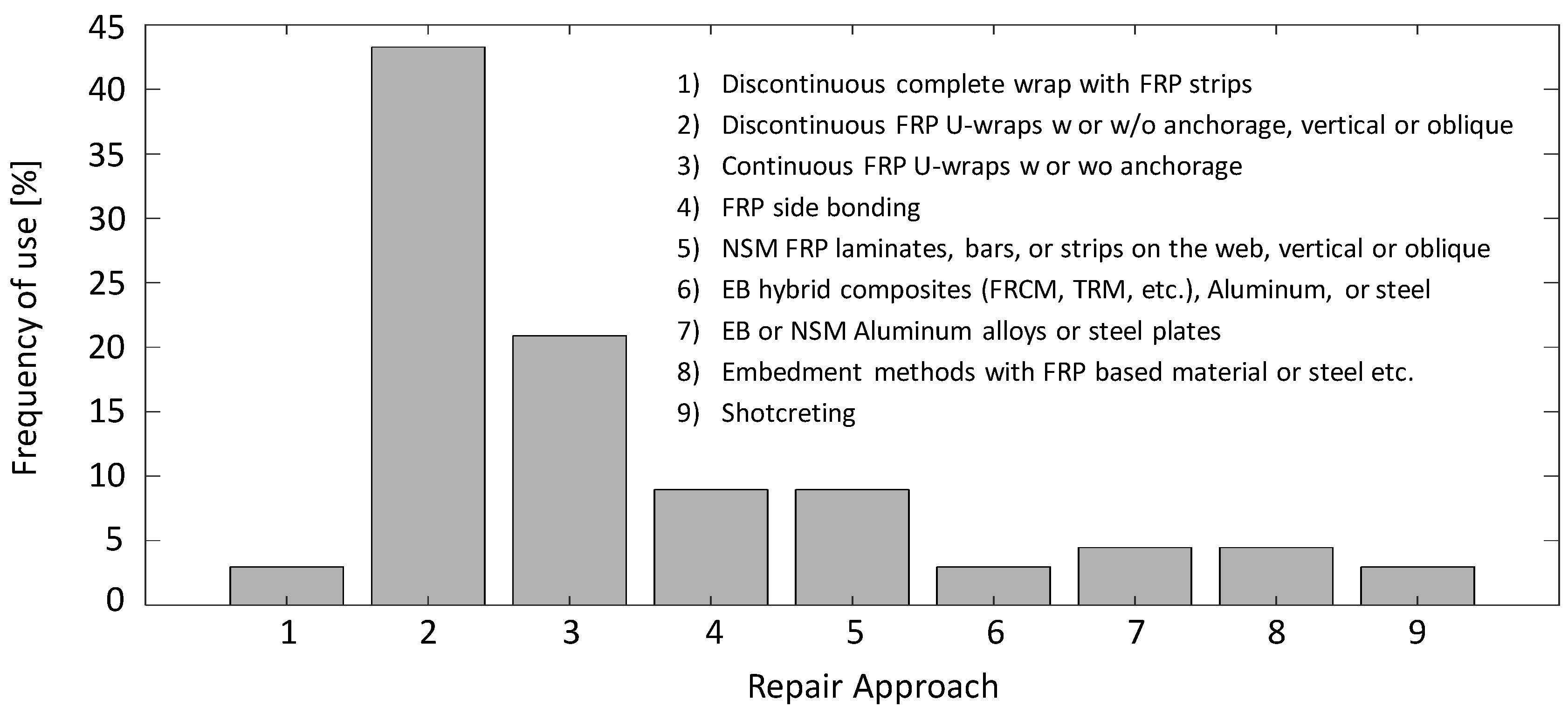

3.2.1. EB Technique

3.2.2. NSM Technique

3.2.3. Deep Embedment Method

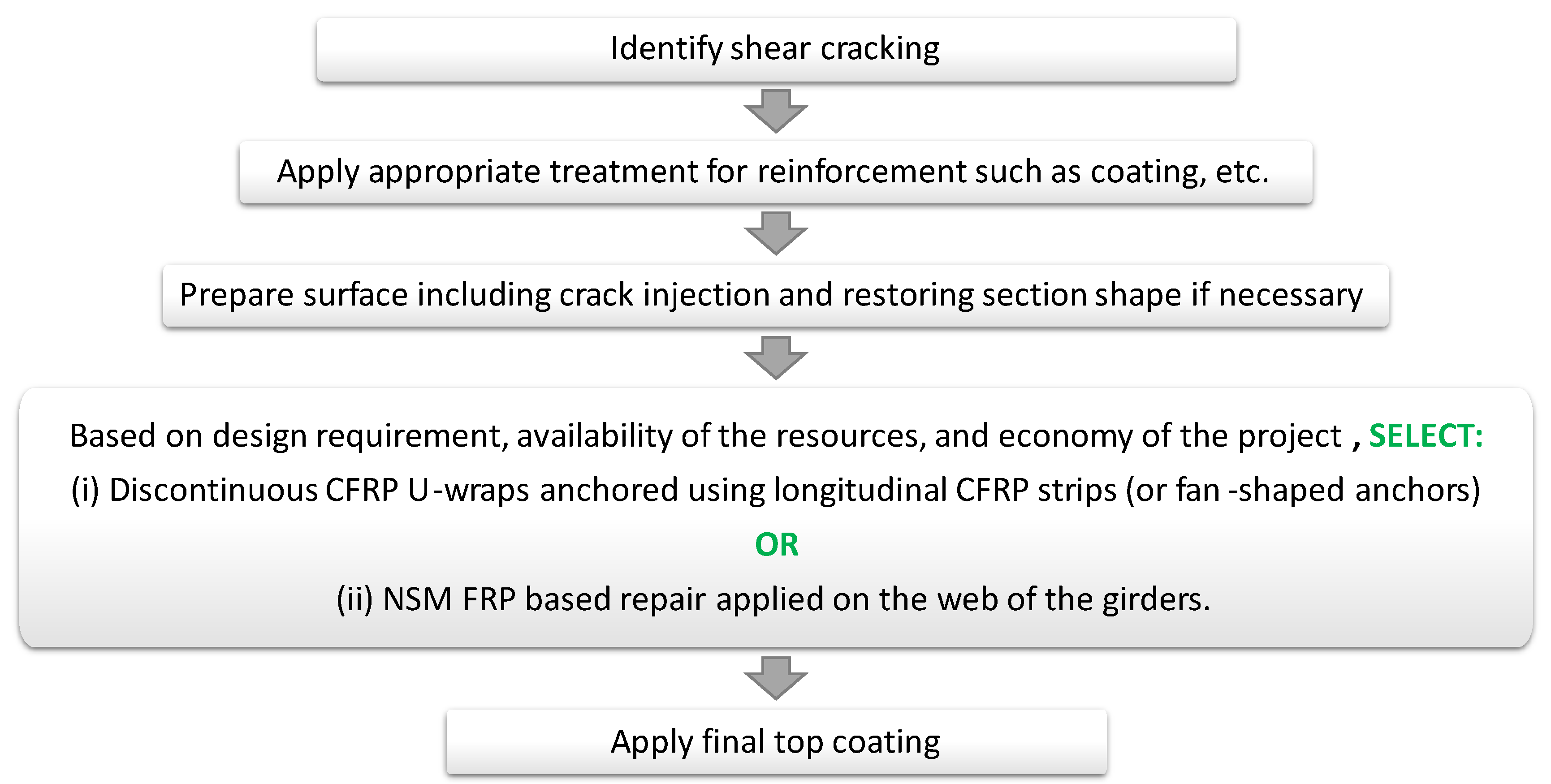

3.3. Recommendations

4. Repair for Flexure

4.1. Main Causes of Damage

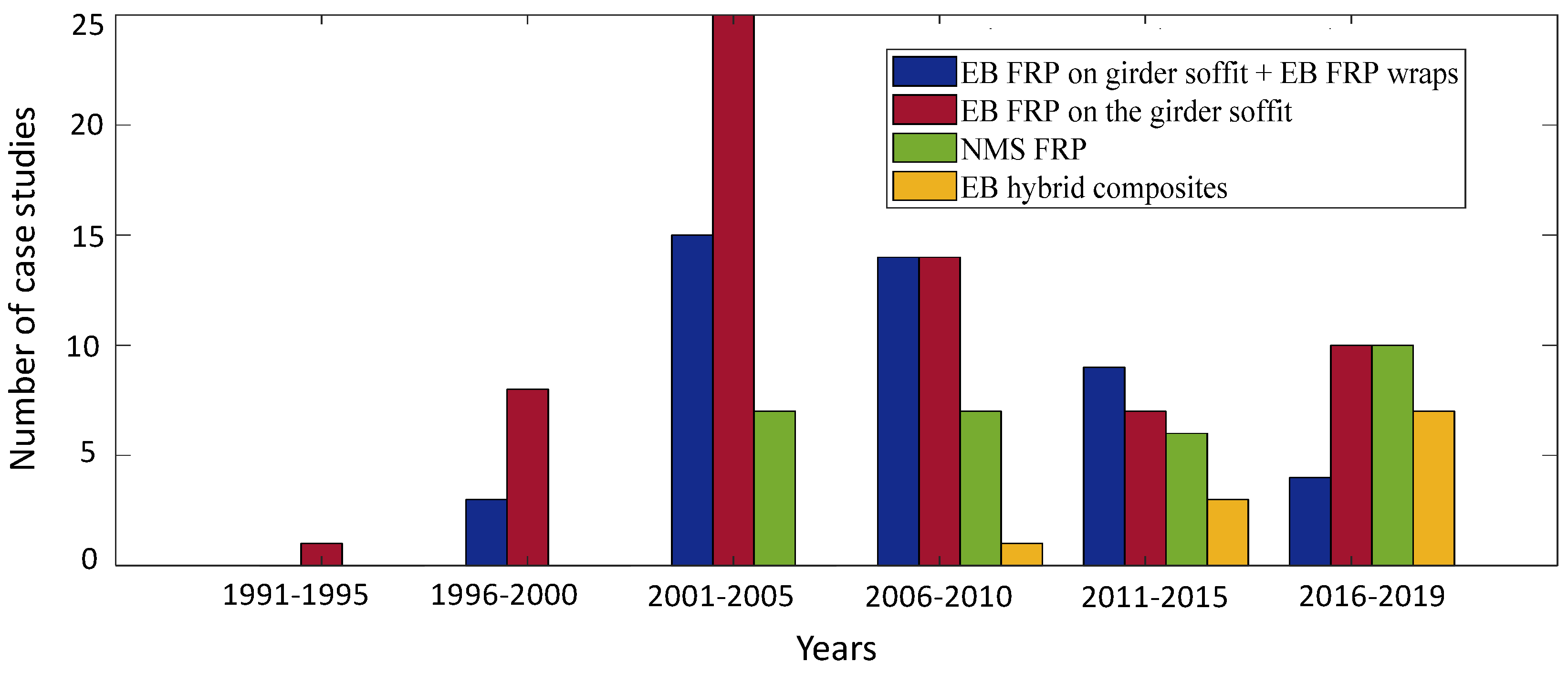

4.2. Common Solutions

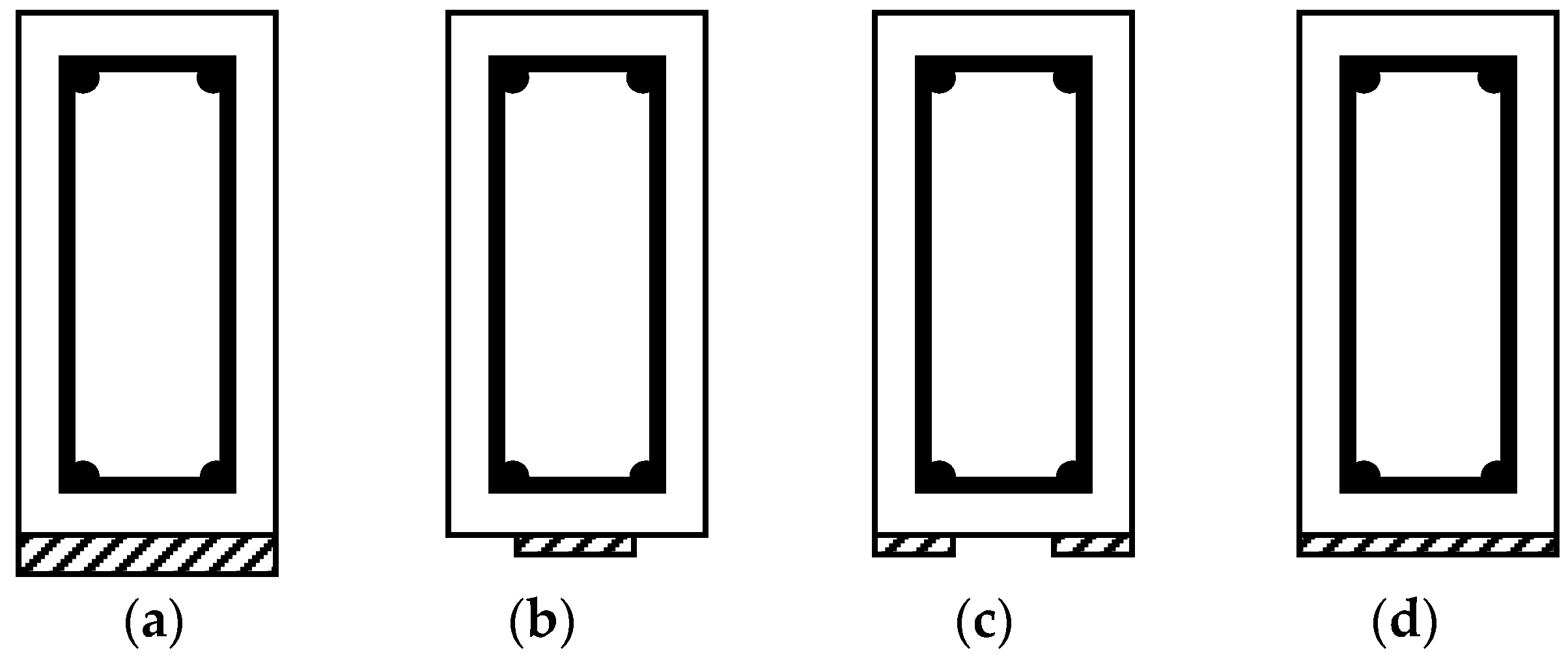

4.2.1. EB Technique

4.2.2. NSM Technique

4.3. Recommendations

5. Repair for Fire Damage

5.1. Main Causes of Damage

5.2. Common Solutions

5.3. Recommendations

6. Concluding Statement

Author Contributions

Funding

Conflicts of Interest

References

- Sobieck, T.; Atadero, R.; Mahmoud, H. Predicting Fatigue Service Life Extension of RC Bridges with Externally Bonded CFRP Repairs; Mountain Plains Consortium, Department of Civil and Environmental Engineering, Colorado State University: Fort Collins, CO, USA, 2015. [Google Scholar]

- Pough, K.; Mayhorn, D.; Prinz, G.S.; Floyd, R. Evaluation and Repair of Existing Bridges in Extreme Environments; School of Civil Engineering and Environmental Science, University of Oklahoma: Norman, Oklahoma, 2016. [Google Scholar]

- Baggio, D.; Soudki, K.; Noel, M. Strengthening of shear critical RC beams with various FRP systems. Constr. Build. Mater. 2014, 66, 634–644. [Google Scholar] [CrossRef]

- Huston, D.R. Cost-Effective and Rapid Concrete Repair Techniques; Final report; Vermont Agency of Transportation, Materials and Research Section. School of Engineering, The University of Vermont: Burlington, VT, USA, 2016. [Google Scholar]

- Motavalli, M.; Czaderski, C. FRP composites for retrofitting of existing civil structures in Europe: State-of-the-art review. In Proceedings of the International Conference of Composites & Polycon. American Composites Manufacturers Association, Tampa, FL, USA, 17 October 2007. [Google Scholar]

- Yazdani, N.; Montero, M.A. Structural performance of impact damaged and repaired concrete bridge girder using GFRP rebars. Innov. Infrastruct. Solut. 2016, 1, 34. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Koutas, L.N.; Bournas, D.A. Shear strengthening of full-scale RC T-beams using textile-reinforced mortar and textile-based anchors. Compos. Part B Eng. 2016, 95, 225–239. [Google Scholar] [CrossRef]

- Foster, R.M.; Brindley, M.; Lees, J.M.; Ibell, T.J.; Morley, C.T.; Darby, A.P.; Evernden, M.C. Experimental investigation of reinforced concrete T-beams strengthened in shear with externally bonded CFRP sheets. J. Compos. Constr. 2016, 21, 04016086. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Abu-Obeidah, A.S.; Hawileh, R.A.; Rasheed, H.A. Shear strengthening of reinforced concrete beams using externally-bonded aluminum alloy plates: An experimental study. Constr. Build. Mater. 2016, 128, 24–37. [Google Scholar] [CrossRef]

- Qapo, M.; Dirar, S.; Yang, J.; Elshafie, M.Z. Nonlinear finite element modelling and parametric study of CFRP shear-strengthened prestressed concrete girders. Constr. Build. Mater. 2015, 76, 245–255. [Google Scholar] [CrossRef]

- Cai, C.; Xia, M. Repairing/Strengthening of Bridges with Post-Tensioned FRP Materials and Performance Evaluation; Report; Louisiana Transportation Research Center: Baton Rouge, LA, USA, 2015. [Google Scholar]

- Farghal, O.A. Fatigue behavior of RC T-beams strengthened in shear with CFRP sheets. Ain Shams Eng. J. 2014, 5, 667–680. [Google Scholar] [CrossRef][Green Version]

- Chai, H.; Majeed, A.A.; Allawi, A.A. Torsional analysis of multicell concrete box girders strengthened with CFRP using a modified softened truss model. J. Bridge Eng. 2014, 20, B4014001. [Google Scholar] [CrossRef]

- Cerullo, D.; Sennah, K.; Azimi, H.; Lam, C.; Fam, A.; Tharmabala, B. Experimental study on full-scale pretensioned bridge girder damaged by vehicle impact and repaired with fiber-reinforced polymer technology. J. Compos. Constr. 2013, 17, 662–672. [Google Scholar] [CrossRef]

- Harries, K.A.; Kasan, J.; Miller, R.; Brinkman, R. Updated Research for Collision Damage and Repair of Prestressed Concrete Beams. In National Cooperative Highway Research Program (NCHRP); Final Report; University of Pittsburgh, Pittsburgh, PA and University of Cincinnati: Cincinnati, OH, USA, 2012. [Google Scholar]

- Lee, H.; Jung, W.T.; Chung, W. Field test of an old RC bridge before and after NSM strengthening. Compos. Struct. 2018, 202, 793–801. [Google Scholar] [CrossRef]

- Pino, V.; Nanni, A.; Arboleda, D.; Roberts-Wollmann, C.; Cousins, T. Repair of damaged prestressed concrete girders with FRP and FRCM composites. J. Compos. Constr. 2017, 21, 04016111. [Google Scholar] [CrossRef]

- Radlinska, A.; Yost, J.; McCarthy, L.; Matzke, J.; Nagel, F. Coatings and Treatments for Beam Ends; Pennsylvania Department of Transportation: Villanova, PA, USA, 2012. [Google Scholar]

- Jones, M. Repair of Impact Damaged Prestressed Bridge Girders with Strand Splices and Fabric Reinforced Cementitious Matrix Systems. Master’s Thesis, Virginia Tech, Blacksburg, VA, USA, 2015. [Google Scholar]

- Valikhani, A.; Azizinamini, A. Experimental Investigation of High Performing Protective Shell Used for Retrofitting Bridge Elements; Final report; Department of Civil and Environmental Engineering, Florida International University: Miami, FL, USA, 2018. [Google Scholar]

- Ramseyer, C.; Kang, T.H.-K. Post-damage repair of prestressed concrete girders. Int. J. Concrete Struct. Mater. 2012, 6, 199–207. [Google Scholar] [CrossRef]

- Abedin, M.; Mehrabi, A.B. Novel approaches for fracture detection in steel girder bridges. Infrastructures 2019, 4, 42. [Google Scholar] [CrossRef]

- Abedin, M.; Farhangdoust, S.; Mehrabi, A. Fracture detection in steel girder bridges using self-powered wireless sensors. In Proceedings of the In Risk-Based Bridge Engineering: Proceedings of the 10th New York City Bridge Conference, New York City, NY, USA, 26–27 August 2019; p. 216. [Google Scholar]

- Graeff, M.K. The Repair of Laterally Damaged Concrete Bridge Girders Using Carbon Fiber Reinforcing Polymers (CFRP). Master’s Thesis, University of North Florida, College of Computing, Engineering, & Construction, Jacksonville, FL, USA, 2012. [Google Scholar]

- Qeshta, I.M.; Shafigh, P.; Jumaat, M.Z. Research progress on the flexural behaviour of externally bonded RC beams. Arch. Civ. Mech. Eng. 2016, 16, 982–1003. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.M. Strengthening of reinforced concrete beams by using fiber-reinforced polymer composites: A review. J. Build. Eng. 2019, 25, 100798. [Google Scholar] [CrossRef]

- Banjara, N.K.; Ramanjaneyulu, K. Investigations on behaviour of flexural deficient and CFRP strengthened reinforced concrete beams under static and fatigue loading. Constr. Build. Mater. 2019, 201, 746–762. [Google Scholar] [CrossRef]

- Andrawes, B.; Shaw, I.; Zhao, H. Repair & Strengthening of Distressed/Damaged Ends of Prestressed Beams with FRP Composites; Illinois Center for Transportation/Illinois Department of Transportation: Champaign County, IL, USA, 2018. [Google Scholar]

- Murthy, A.R.; Karihaloo, B.; Rani, P.V.; Priya, D.S. Fatigue behaviour of damaged RC beams strengthened with ultra high performance fibre reinforced concrete. Int. J. Fatigue 2018, 116, 659–668. [Google Scholar] [CrossRef]

- Qapo, M.; Dirar, S.; Jemaa, Y. Finite element parametric study of reinforced concrete beams shear-strengthened with embedded FRP bars. Compos. Struct. 2016, 149, 93–105. [Google Scholar] [CrossRef]

- Huang, H.; Wang, W.W.; Dai, J.G.; Brigham, J.C. Fatigue behavior of reinforced concrete beams strengthened with externally bonded prestressed CFRP sheets. J. Compos. Constr. 2016, 21, 04016108. [Google Scholar] [CrossRef]

- Tsai, C.; Alaywan, W. I-10 Girder Repair Using Post-Tensioned Steel Rods and Carbon Fiber Composite Cables (CFCC); Final report; Louisiana Department of Transportation and Development 1201 Capitol Access Road: Baton Rouge, LA, USA, 2018. [Google Scholar]

- Pino, V.; Nanni, A. Research on Concrete Applications for Sustainable Transportation; Research on Concrete Applications for Sustainable Transportation, University of Miami: Miami-Dade County, FL, USA, 2015. [Google Scholar]

- Eamon, C.D.; Wu, H.-C.; Makkawy, A.A.; Siavashi, S. Design and Construction Guidelines for Strengthening Bridges Using Fiber Reinforced Polymers (FRP); Michigan Department of Transportation. Office of Research Administration, Wayne State University: Detroit, MI, USA, 2014. [Google Scholar]

- Oudah, F.; El-Hacha, R. A new ductility model of reinforced concrete beams strengthened using fiber reinforced polymer reinforcement. Compos. Part B Eng. 2012, 43, 3338–3347. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kang, J.-Y.; Park, J.-S.; Jung, W.-T. Effect of Corrosion Damage on Service Response of Bridge Girders Strengthened with Posttensioned NSM CFRP Strips. J. Bridge Eng. 2015, 21, 04015031. [Google Scholar] [CrossRef]

- Mechtcherine, V. Novel cement-based composites for the strengthening and repair of concrete structures. Constr. Build. Mater. 2013, 41, 365–373. [Google Scholar] [CrossRef]

- Gangi, M. Evaluation of Repair Techniques for Impact-Damaged Prestressed Beams; Final report; Virginia Department of Transportation, The Charles E. Via, Jr. Department of Civil and Environmental Engineering, Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 2018. [Google Scholar]

- Mosallam, A.; Elsanadedy, H.M.; Almusallam, T.H.; Al-Salloum, Y.A.; Alsayed, S.H. Structural evaluation of reinforced concrete beams strengthened with innovative bolted/bonded advanced frp composites sandwich panels. Compos. Struct. 2015, 124, 421–440. [Google Scholar] [CrossRef]

- Jawdhari, A.; Harik, I.; Fam, A. Behavior of reinforced concrete beams strengthened with CFRP rod panels CRP 195. Structures 2018, 16, 239–253. [Google Scholar] [CrossRef]

- Peiris, A.; Harik, I. Carbon fiber–reinforced polymer rod panels for strengthening concrete bridges. Adv. Struct. Eng. 2018, 21, 557–570. [Google Scholar] [CrossRef]

- Zhang, Y. Repair and Strengthening of Reinforced Concrete Beams; Ohio State University: Columbus, OH, USA, 2012. [Google Scholar]

- Radlińska, A.; McCarthy, L.M.; Matzke, J.; Nagel, F. Synthesis of DOT use of beam end protection for extending the life of bridges. Int. J. Concr. Struct. Mater. 2014, 8, 185–199. [Google Scholar] [CrossRef]

- Małek, M.; Łasica, W.; Jackowski, M.; Kadela, M. Effect of waste glass addition as a replacement for fine aggregate on properties of mortar. Materials 2020, 13, 3189. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Characteristics of recycled polypropylene fibers as an addition to concrete fabrication based on portland cement. Materials 2020, 13, 1827. [Google Scholar] [CrossRef] [PubMed]

- Harries, K.A.; Kasan, J.; Brinkman, R. Guide To Recommended Practice For The Repair Of Impact-Damaged Prestressed Concrete Bridge Girders; Guide; National Cooperative Highway Research Program, Transportation Research Board of The National Academies. University of Pittsburgh, Pittsburgh PA and University of Cincinnati: Cincinnati, OH, USA, 2012. [Google Scholar]

- Belarbi, A.; Bae, S.-W.; Brancaccio, A. Behavior of full-scale RC T-beams strengthened in shear with externally bonded FRP sheets. Constr. Build. Mater. 2012, 32, 27–40. [Google Scholar] [CrossRef]

- Beneberu, E.; Yazdani, N. Residual strength of CFRP strengthened prestressed concrete bridge girders after hydrocarbon fire exposure. Eng. Struct. 2019, 184, 1–14. [Google Scholar] [CrossRef]

- Beneberu, E.; Yazdani, N. Performance of CFRP-Strengthened Concrete Bridge Girders under Combined Live Load and Hydrocarbon Fire. J. Bridge Eng. 2018, 23, 04018042. [Google Scholar] [CrossRef]

- Yang, J.; Wang, L. Experimental research on flexural behaviors of damaged PRC beams strengthened with NSM CFRP strips. Constr. Build. Mater. 2018, 190, 265–275. [Google Scholar] [CrossRef]

- El-Saikaly, G.; Godat, A.; Chaallal, O. New anchorage technique for FRP shear-strengthened RC T-beams using CFRP rope. J. Compos. Constr. 2014, 19, 04014064. [Google Scholar] [CrossRef]

- Belarbi, A. Design of FRP Systems for Strengthening Concrete Girders in Shear; Center for Transportation Infrastructure and Safety/NUTC program, Missouri University of Science and Technology, 220 Engineering Research Lab: Rolla, MO, USA, 2011; Volume 678. [Google Scholar]

- Lee, H.Y.; Jung, W.T.; Chung, W. Flexural strengthening of reinforced concrete beams with pre-stressed near surface mounted CFRP systems. Compos. Struct. 2017, 163, 1–12. [Google Scholar] [CrossRef]

- Lee, H.; Jung, W.T.; Chung, W. Post-tension near-surface mounted strengthening system for reinforced concrete beams with changes in concrete condition. Compos. Part B Eng. 2019, 161, 514–529. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z.; Shah, S. Strengthening of RC beams using prestressed fiber reinforced polymers–A review. Constr. Build. Mater. 2015, 82, 235–256. [Google Scholar] [CrossRef]

- Kasan, J.L.; Harries, K.A.; Miller, R.; Brinkman, R.J. Limits of application of externally bonded CFRP repairs for impact-damaged prestressed concrete girders. J. Compos. Constr. 2012, 18, A4013013. [Google Scholar] [CrossRef]

- Valerio, P.; Ibell, T.J.; Darby, A.P. Deep embedment of FRP for concrete shear strengthening. Proc. Inst. Civ. Eng. Struct. Build. 2009, 162, 311–321. [Google Scholar] [CrossRef]

- Raicic, V.; Ibell, T.J.; Darby, A.; Evernden, M.; Orr, J.J. Deep embedment shear strengthening of continuous reinforced concrete T-beams. In Proceedings of the 11th fib International PhD Symposium in Civil Engineering, Tokyo, Japan, 29–31 August 2016; The University of Tokyo: Tokyo, Japan, 2016. [Google Scholar]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R. Fatigue performance of near-surface mounted CFRP strips embedded in concrete girders using cementitious adhesive made with graphene oxide. Constr. Build. Mater. 2017, 148, 632–647. [Google Scholar] [CrossRef]

- Bullock, W.O.; Barnes, R.W.; Schindler, A.K. Repair of Cracked Prestressed Concrete Girders, I-565, Huntsville, Alabama; Auburn University. Highway Research Center, Department of Civil Engineering, 238 Harbert Engineering Center: Auburn, AL, USA, 2011. [Google Scholar]

- Alkhrdaji, T. Strengthening of Concrete Structures Using FRP Composites. Struct. Mag. 2015, 12, 18–20. [Google Scholar]

- Rteil, A.; Soudki, K. CFRP Repair of Corroded Girder: Four Years of Service. Spec. Publ. 2011, 277, 176–191. [Google Scholar]

- Choo, C.C.; Peiris, A.; Harik, I.E. Repair Using Steel Fiber Reinforced Polymer on US 150 Bridges; Final report; Kentucky Transportation Center, College of Engineering, University of Kentucky: Lexington, KY, USA, 2013. [Google Scholar]

- Dong, J.; Wang, Q.; Guan, Z. Structural behaviour of RC beams externally strengthened with FRP sheets under fatigue and monotonic loading. Eng. Struct. 2012, 41, 24–33. [Google Scholar] [CrossRef]

- Yang, D.; Merrill, B.; Bradberry, T. Texas’ use of CFRP to repair concrete bridges. Spec. Publ. 2011, 277, 39–57. [Google Scholar]

- Williams, G.; Higgins, C. Fatigue of diagonally cracked RC girders repaired with CFRP. J. Bridge Eng. 2008, 13, 24–33. [Google Scholar] [CrossRef]

- Michels, J.; Staśkiewicz, M.; Czaderski, C.; Kotynia, R.; Harmanci, Y.E.; Motavalli, M. Prestressed CFRP strips for concrete bridge girder retrofitting: Application and static loading test. J. Bridge Eng. 2016, 21, 04016003. [Google Scholar] [CrossRef]

- Qin, S.; Dirar, S.; Yang, J.; Chan, A.H.; Elshafie, M. CFRP shear strengthening of reinforced-concrete T-beams with corroded shear links. J. Compos. Constr. 2014, 19, 04014081. [Google Scholar] [CrossRef]

- Mahdavi, G.; Nasrollahzadeh, K.; Hariri-Ardebili, M. Optimal FRP jacket placement in RC frame structures towards a resilient seismic design. Sustainability 2019, 11, 6985. [Google Scholar] [CrossRef]

- Pino, V.A. Fabric Reinforced Cementitious Matrix (FRCM) Composites as A Repair System for Transportation Infrastructure. Ph.D. Thesis, University of Miami, Miami-Dade County, FL, USA, 2016. [Google Scholar]

- Jung, W.T.; Keum, M.S.; Park, J.S.; Kang, J.Y.; Park, Y.H.; Chung, W.; Kim, Y.J. Composite strengthening of a bridge. Concr. Int. 2017, 39, 48–53. [Google Scholar]

- Galati, N.; Boschetto, G.; Tan, K.Y.; Nanni, A.; Galecki, G. Strengthening of impacted prestressed concrete bridge I-girder using prestressed near surface mounted C-FRP bars. In Proceedings of the 2nd International Congress, Naples, Italy, 5–8 June 2006. [Google Scholar]

- Bae, S.-W.; Belarbi, A. Behavior of various anchorage systems used for shear strengthening of concrete structures with externally bonded FRP sheets. J. Bridge Eng. 2012, 18, 837–847. [Google Scholar] [CrossRef]

- Gangi, M.J. Analytical Modeling of the Repair Impact-Damaged Prestressed Concrete Bridge Girders; Virginia Tech: Blacksburg, VI, USA, 2015. [Google Scholar]

- Kasan, J.L.; Harries, K.A.; Miller, R.; Brinkman, R.J. Repair of prestressed-concrete girders combining internal strand splicing and externally bonded CFRP techniques. J. Bridge Eng. 2014, 19, 200–209. [Google Scholar] [CrossRef]

- Manos, G.; Stavroy, D.; Dimosthenous, M.; Kourtides, B. Experimental and analytical investigation of repaired and strengthened reinforced concrete structural elements utilizing CFRP. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. paper No. 91. [Google Scholar]

- Murphy, M.; Belarbi, A.; Bae, S.-W. Behavior of prestressed concrete I-girders strengthened in shear with externally bonded fiber-reinforced-polymer sheets. PCI J. 2012, 57, 63–82. [Google Scholar] [CrossRef]

- Mofidi, A.; Chaallal, O. Shear strengthening of RC beams with externally bonded FRP composites: Effect of strip-width-to-strip-spacing ratio. J. Compos. Constr. 2011, 15, 732–742. [Google Scholar] [CrossRef]

- Kang, T.H.-K.; Ary, M.I. Shear-strengthening of reinforced & prestressed concrete beams using FRP: Part II—Experimental investigation. Int. J. Concr. Struct. Mater. 2012, 6, 49–57. [Google Scholar]

- Shaw, I.; Andrawes, B. Repair of damaged end regions of PC beams using externally bonded FRP shear reinforcement. Constr. Build. Mater. 2017, 148, 184–194. [Google Scholar] [CrossRef]

- Bae, S.-W.; Murphy, M.; Mirmiran, A.; Belarbi, A. Behavior of RC T-beams strengthened in shear with CFRP under cyclic loading. J. Bridge Eng. 2013, 18, 99–109. [Google Scholar] [CrossRef]

- Azimi, H.; Sennah, K. Parametric effects on evaluation of an impact-damaged prestressed concrete bridge girder repaired by externally bonded carbon-fiber-reinforced polymer sheets. J. Perform. Constr. Facil. 2013, 29, 04014147. [Google Scholar] [CrossRef]

- You, Y.-M.; Ayoub, A.; Belarbi, A. Three-dimensional nonlinear finite-element analysis of prestressed concrete beams strengthened in shear with FRP composites. J. Compos. Constr. 2011, 15, 896–907. [Google Scholar] [CrossRef]

- Petty, D.A.; Barr, P.J.; Osborn, G.P.; Halling, M.W.; Brackus, T.R. Carbon fiber shear retrofit of forty-two-year-old AASHTO I-shaped girders. J. Compos. Constr. 2011, 15, 773–781. [Google Scholar] [CrossRef]

- Higgins, C.C.; Howell, D.A.; Smith, M.T.; Senturk, A.E. Shear Repair Methods for Conventionally Reinforced Concrete Girders and Bent Caps: Final Report; Oregon Department of Transportation Research Section, School of Civil and Construction Engineering, Oregon State University: Corvallis, OR, USA, December 2009. [Google Scholar]

- Wang, Y.-C.; Lee, M.-G.; Chen, B. Experimental study of FRP-strengthened RC bridge girders subjected to fatigue loading. Compos. Struct. 2007, 81, 491–498. [Google Scholar] [CrossRef]

- Higgins, C.; Williams, G.; Elkins, L. Capabilities of Diagonally-Cracked Girders Repaired with CFRP.; Oregon Department of Transportation: Salem, OR, USA, 2006. [Google Scholar]

- Masoud, S.; Soudki, K.; Topper, T. Postrepair fatigue performance of FRP-repaired corroded RC beams: Experimental and analytical investigation. J. Compos. Constr. 2005, 9, 441–449. [Google Scholar] [CrossRef]

- Hag-Elsafi, O.; Alampalli, S.; Kunin, J. Application of FRP laminates for strengthening of a reinforced-concrete T-beam bridge structure. Compos. Struct. 2001, 52, 453–466. [Google Scholar] [CrossRef]

- Deniaud, C.; Cheng, J.R. Shear behavior of reinforced concrete T-beams with externally bonded fiber-reinforced polymer sheets. Struct. J. 2001, 98, 386–394. [Google Scholar]

- Hutchinson, R.L. The Use of Externally Bonded CFRP Sheets for Shear Strengthening of I-Shaped Prestressed Concrete Bridge Girders. Ph.D. Dissertation, Structural Engineering Division, Department of Civil and Geological Engineering, University of Manitoba, Winnipeg, MB, Canada, 2000. [Google Scholar]

- Hutchinson, R.; Rizkalla, S. Shear Strengthening of AASHTO Bridge Girders Using CFRP Sheets. ACI Spec. Publ. 1999, 188, 945–958. [Google Scholar]

- Czaderski, C.; Motavalli, M. Fatigue behaviour of CFRP L-shaped plates for shear strengthening of RC T-beams. Compos. Part B Eng. 2004, 35, 279–290. [Google Scholar] [CrossRef]

- El-Saikaly, G.; Chaallal, O. Fatigue behavior of RC T-beams strengthened in shear with EB CFRP L-shaped laminates. Compos. Part B Eng. 2015, 68, 100–112. [Google Scholar] [CrossRef]

- Dirar, S.; Lees, J.; Morley, C. Precracked reinforced concrete T-beams repaired in shear with bonded carbon fiber-reinforced polymer sheets. ACI Struct. J. 2012, 109, 215–224. [Google Scholar]

- El-Saikaly, G.; Chaallal, O. Extending the fatigue life of reinforced concrete T-beams strengthened in shear with externally bonded FRP: Upgrading versus repairing. J. Compos. Constr. 2015, 19, 04014027. [Google Scholar] [CrossRef]

- Dirar, S.; Lees, J.M.; Morley, C. Phased nonlinear finite-element analysis of precracked RC T-beams repaired in shear with CFRP sheets. J. Compos. Constr. 2012, 17, 476–487. [Google Scholar] [CrossRef]

- Galal, K.; Mofidi, A. Shear strengthening of RC T-beams using mechanically anchored unbonded dry carbon fiber sheets. J. Perform. Constr. Facil. 2009, 24, 31–39. [Google Scholar] [CrossRef]

- Bousselham, A.; Chaallal, O. Behavior of reinforced concrete T-beams strengthened in shear with carbon fiber-reinforced polymer-An experimental study. ACI Struct. J. 2006, 103, 339. [Google Scholar]

- Chaallal, O.; Shahawy, M.; Hassan, M. Performance of reinforced concrete T-girders strengthened in shear with carbon fiber-reinforced polymer fabric. Struct. J. 2002, 99, 335–343. [Google Scholar]

- Kachlakev, D.; McCurry, D. Behavior of full-scale reinforced concrete beams retrofitted for shear and flexural with FRP laminates. Compos. Part B Eng. 2000, 31, 445–452. [Google Scholar] [CrossRef]

- Naaman, A.E. Repair and Strengthening of Reinforced Concrete Beams Using Cfrp Laminates; Report; University of Michigan, Department of Civil and Environmental Engineering: Ann Arbor, MI, USA, 1999. [Google Scholar]

- Norris, T.; Saadatmanesh, H.; Ehsani, M.R. Shear and flexural strengthening of R/C beams with carbon fiber sheets. J. Struct. Eng. 1997, 123, 903–911. [Google Scholar] [CrossRef]

- Panda, K.; Bhattacharyya, S.; Barai, S. Shear strengthening of RC T-beams with externally side bonded GFRP sheet. J. Reinf. Plast. Compos. 2011, 30, 1139–1154. [Google Scholar] [CrossRef]

- Pantelides, C.P.; Reaveley, L.D.; Burningham, C.A. Repair of Prestressed Concrete Girder Ends and Girder Collision Repair; Final report; Utah Department of Transportation, University of Utah, Department of Civil and Environmental Engineering: Salt Lake City, UT, USA, 2010. [Google Scholar]

- Durham, S.A.; Heymsfield, E.; Jones, J.X. Retrofitting precast bridge beams with carbon fiber-reinforced polymer strips for shear capacity. J. Perform. Constr. Facil. 2009, 23, 219–226. [Google Scholar] [CrossRef]

- Simpson, I.; Jim, W.; Harik, I.E.; Chiaw, C.C. Shear Repair of P/C Box Beams Using Carbon Fiber Reinforced Polymer (CFRP) Fabric; Final report; Kentucky Transportation Center, College of Engineering, University of Kentucky: Lexington, KY, USA, 2006. [Google Scholar]

- Dias, S.; Barros, J. NSM shear strengthening technique with CFRP laminates applied in high-strength concrete beams with or without pre-cracking. Compos. Part B Eng. 2012, 43, 290–301. [Google Scholar] [CrossRef]

- Goebel, J.H.; Johnson, B.A.; Higgins, C. Strength and Durability of Near-Surface Mounted CFRP Bars for Shear Strengthening Reinforced Concrete Bridge Girders; Oregon Department of Transportation Research Section: Salem, OR, USA, 2012. [Google Scholar]

- Islam, A.A. Effective methods of using CFRP bars in shear strengthening of concrete girders. Eng. Struct. 2009, 31, 709–714. [Google Scholar] [CrossRef]

- Phillips, S.E.; Parretti, R.; Peterman, R.; Nanni, A. Joint Kdot-Modot: Evaluation Of Frp Repair Method For Cracked Pc Bridge Members; Final report; Center for Infrastructure Engineering Studies/UTC program, University of Missouri, Rolla 223 Engineering Research Lab: Rolla, MO, USA, 2004. [Google Scholar]

- Barnes, R.; Baglin, P.; Mays, G.; Subedi, N. External steel plate systems for the shear strengthening of reinforced concrete beams. Eng. Struct. 2001, 23, 1162–1176. [Google Scholar] [CrossRef]

- Shield, C.; Bergson, P. BR27568–Experimental Shear Capacity Comparison Between Repaired and Unrepaired Girder Ends; Final report; Minnesota Department of Transportation, Civil, Environmental and Geo- Engineering University of Minnesota: Minneapolis, MN, USA, 2018. [Google Scholar]

- Pilarski, P. Affordable Bridge Girder End Repair Method Restores Concrete Beams to Original Strength; Technical summary; Minnesota Department of Transportation, Reserach Services and Library: St Paul, MN, USA, 2018. [Google Scholar]

- TexasDOT. 2015. Available online: https://www.youtube.com/watch?v=Ommd8_JOEV0&list=PL5JY3er6Wwbj6eMw7TWUK7l6XBkZRPyPe (accessed on 5 June 2020).

- Kasan, J.L. On the Repair of Impact Damaged Prestressed Concrete Bridge Girders; University of Pittsburgh: Pittsburgh, PA, USA, 2012. [Google Scholar]

- ElSafty, A.; Graeff, M.K.; Fallaha, S. Behavior of laterally damaged prestressed concrete bridge girders repaired with CFRP laminates under static and fatigue loading. Int. J. Concr. Struct. Mater. 2014, 8, 43–59. [Google Scholar] [CrossRef]

- Fu, C.C.; Burhouse, J.R.; Chang, G.-L. Overheight vehicle collisions with highway bridges. Transp. Res. Rec. 2004, 1865, 80–88. [Google Scholar] [CrossRef]

- Harries, K.A.; Kasan, J.; Aktas, J. Repair Methods for Prestressed Girder Bridges; Final report; Department of Transportation: Pittsburgh, PA, USA, 2009. [Google Scholar]

- ElSafty, A.; Graeff, M.K. The Repair of Damaged Bridge Girders with Carbon Fiber Reinforced Polymer “CFRP” Laminates; Final report; School of Engineering, College of computing, Engineering, and Construction, University of NOrth Florida: Jacksonville, FL, USA, 2012. [Google Scholar]

- Davalos, J.F.; Chen, A.; Ray, I.; Levan, J.R. Comprehensive study on using externally bonded FRP composites for the rehabilitation of reinforced concrete T-beam bridges. J. Infrastruct. Syst. 2011, 18, 89–102. [Google Scholar] [CrossRef]

- Shen, D.; Deng, S.; Zhang, J.; Wang, W.; Jiang, G. Behavior of reinforced concrete box beam with initial cracks repaired with basalt fiber-reinforced polymer sheet. J. Reinf. Plast. Compos. 2015, 34, 1540–1554. [Google Scholar] [CrossRef]

- Shen, D.; Zeng, X.; Zhang, J.; Zhou, B.; Wang, A.W. Behavior of RC box beam strengthened with basalt FRP using end anchorage with grooving. J. Compos. Mater. 2019, 53, 3307–3324. [Google Scholar] [CrossRef]

- Kabir, M.I.; Subhani, M.; Shrestha, R.; Samali, B. Experimental and theoretical analysis of severely damaged concrete beams strengthened with CFRP. Constr. Build. Mater. 2018, 178, 161–174. [Google Scholar] [CrossRef]

- Mahal, M.; Täljsten, B.; Blanksvärd, T. Experimental performance of RC beams strengthened with FRP materials under monotonic and fatigue loads. Constr. Build. Mater. 2016, 122, 126–139. [Google Scholar] [CrossRef]

- Choo, C.C.; Peiris, A.; Harik, I.E. Repair of I-65 Expressway Bridges Using Carbon Fiber Reinforced Polymer (CFRP) Composites; Final report; Kentucky transportation center, College of Engineering, University of Kentucky: Lexington, KY, USA, 2013. [Google Scholar]

- Ray, I.; Parish, G.C.; Davalos, J.F.; Chen, A. Effect of concrete substrate repair methods for beams aged by accelerated corrosion and strengthened with CFRP. J. Aerosp. Eng. 2010, 24, 227–239. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Prota, A.; Manfredi, G.; Cosenza, E. FRP strengthening of full-scale PC girders. J. Compos. Constr. 2010, 14, 510–520. [Google Scholar] [CrossRef]

- Davalos, J.F.; Chen, A.; Ray, I.; Levan, J.R. Rehabilitation of Reinforced Concrete T-Beam Structures Using Externally Bonded FRP Composites. In Proceedings of the Earth and Space 2010: Engineering, Science, Construction, and Operations in Challenging Environments, Honolulu, HI, USA, 14–17 March 2010; pp. 649–663. [Google Scholar]

- Davalos, J.F.; Chen, A.; Ray, I.; Justice, A.; Anderson, M. District 3–0 Investigation of Fiber Wrap Technology for Bridge Repair and Rehabilitation (Phase III); Final report; Pennsylvania Department of Transportation. Bureau of Planning and Research, West Virginia University: Morgantown, WV, USA, 2010. [Google Scholar]

- Rosenboom, O.; Walter, C.; Rizkalla, S. Strengthening of prestressed concrete girders with composites: Installation, design and inspection. Constr. Build. Mater. 2009, 23, 1495–1507. [Google Scholar] [CrossRef]

- Rosenboom, O.; Rizkalla, S.H. Experimental study of intermediate crack debonding in fiber-reinforced polymer strengthened beams. ACI Struct. J. 2008, 105, 41. [Google Scholar]

- Kim, Y.J.; Wight, R.G.; Green, M.F. Flexural strengthening of RC beams with prestressed CFRP sheets: Development of nonmetallic anchor systems. J. Compos. Constr. 2008, 12, 35–43. [Google Scholar] [CrossRef]

- Rosenboom, O.; Rizkalla, S. Analytical modeling of flexural debonding in CFRP strengthened reinforced or prestressed concrete beams. In Proceedings of the 8th International Symposium on Fiber Reinforced Polymer Reinforcement for Concrete Structures (FRPRCS-8), Patras, Greece, 16 July 2007. [Google Scholar]

- Rosenboom, O.; Hassan, T.K.; Rizkalla, S. Flexural behavior of aged prestressed concrete girders strengthened with various FRP systems. Constr. Build. Mater. 2007, 21, 764–776. [Google Scholar] [CrossRef]

- Larson, K.H.; Rasheed, H.A.; Peterman, R.J. Evaluating Fiber Reinforced Polymer Repair Method for Cracked Prestressed Concrete Bridge Members Subjected to Repeated Loadings Phase 2; Final report; Kansas Department of Transportation, Kansas State University: Manhattan, KS, USA, 2007. [Google Scholar]

- Toutanji, H.; Zhao, L.; Zhang, Y. Flexural behavior of reinforced concrete beams externally strengthened with CFRP sheets bonded with an inorganic matrix. Eng. Struct. 2006, 28, 557–566. [Google Scholar] [CrossRef]

- Toutanji, H.; Zhao, L.; Deng, Y.; Zhang, Y.; Balaguru, P. Cyclic behavior of RC beams strengthened with carbon fiber sheets bonded by inorganic matrix. J. Mater. Civ. Eng. 2006, 18, 28–35. [Google Scholar] [CrossRef]

- Rosenboom, O.; Rizkalla, S. Behavior of prestressed concrete strengthened with various CFRP systems subjected to fatigue loading. J. Compos. Constr. 2006, 10, 492–502. [Google Scholar] [CrossRef]

- Rizkalla, S.; Rosenboom, O.; Miller, A. Value Engineering and Cost Effectiveness of Various Fiber Reinforced Polymer (Frp) Repair Systems; Final report; North Carolina Department of Transportation. Research and Analysis Group, Department of Civil Engineering, North Carolina State University: Raleigh, NC, USA, 2006. [Google Scholar]

- Larson, K.H.; Peterman, R.J.; Rasheed, H.A. Strength-fatigue behavior of fiber reinforced polymer strengthened prestressed concrete T-beams. J. Compos. Constr. 2005, 9, 313–326. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Nanni, A.; Prota, A.; Cosenza, E. Repair of bridge girders with composites: Experimental and analytical validation. ACI Struct. J. 2005, 102, 639. [Google Scholar]

- Brena, S.F.; Benouaich, M.A.; Kreger, M.E.; Wood, S.L. Fatigue tests of reinforced concrete beams strengthened using carbon fiber-reinforced polymer composites. ACI Struct. J. 2005, 102, 305. [Google Scholar]

- Wipf, T.; Klaiber, F.; Rhodes, J.; Kempers, B. Effective Structural Concrete Repair: Repair of Impact Damaged Prestressed Concrete Beams with Carbon Fiber Reinforced Polymer (CFRP); Final report; Department of Civil, Construction, and Environmental Engineering, Iowa Department of Transportation, Iwoa State University: Ames, IA, USA, 2004; Volume 12, p. 2014. [Google Scholar]

- Rosenboom, O.; Hassan, T.; Mirmiran, A.; Rizkalla, S. Static and fatigue performance of 40 year old prestressed concrete girders strengthened with various CFRP systems. In Proceedings of the 2nd International Conference on FRP Composite in Civil Engineering (CICE 2004), Adelaide, Australia, 8–10 December 2004. [Google Scholar]

- Reed, C.E.; Peterman, R.J. Evaluation of prestressed concrete girders strengthened with carbon fiber reinforced polymer sheets. J. Bridge Eng. 2004, 9, 185–192. [Google Scholar] [CrossRef]

- Nanni, A. Strengthening of an Impact-Damaged PC Girder. 2004. Available online: https://cdn.ymaws.com/www.icri.org/resource/resmgr/crb/2004mayjun/CRBMayJune04_Nanni.pdf (accessed on 5 June 2020).

- Tumialan, J.; Huang, P.; Nanni, A. Strengthening of an Impacted PC Girder on Bridge A10062, St. Louis County, Missouri; Technical report; Missouri Department of Transportation, Center for Infrastructure Engineering Studies: Rolla, MO, USA, 2001. [Google Scholar]

- Spadea, G.; Swamy, R.; Bencardino, F. Strength and ductility of RC beams repaired with bonded CFRP laminates. J. Bridge Eng. 2001, 6, 349–355. [Google Scholar] [CrossRef]

- Schiebel, S.; Parretti, R.; Nanni, A. Repair and strengthening of impacted PC girders on Bridge; Final report; MoDOT Research Development and Technology, Co-Force America, Inc.: Jackson County, MI, USA, 2001. [Google Scholar]

- Nanni, A.; Huang, P.; Tumialan, J. Strengthening of impact-damaged bridge girder using FRP Laminates. In Proceedings of the Ninth International Conference on Structural Faults and Repair, The Commonwealth Institute, Kensington, London, UK, 4–6 July 2001. [Google Scholar]

- Masoud, S.; Soudki, K.; Topper, T. CFRP-strengthened and corroded RC beams under monotonic and fatigue loads. J. Compos. Constr. 2001, 5, 228–236. [Google Scholar] [CrossRef]

- Martinola, G.; Meda, A.; Plizzari, G.A.; Rinaldi, Z. Strengthening and repair of RC beams with fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 731–739. [Google Scholar] [CrossRef]

- Arduini, M.; Napolitano, P.; Gottardo, R. Strengthening of casilina bridge with carbon fibre reinforced polymer sheets. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2002, 216, 157–165. [Google Scholar] [CrossRef]

- El-Tawil, S.; Ogunc, C.; Okeil, A.; Shahawy, M. Static and fatigue analyses of RC beams strengthened with CFRP laminates. J. Compos. Constr. 2001, 5, 258–267. [Google Scholar] [CrossRef]

- Shahawy, M.; Chaallal, O.; Beitelman, T.E.; El-Saad, A. Flexural strengthening with carbon fiber-reinforced polymer composites of preloaded full-scale girders. Struct. J. 2001, 98, 735–742. [Google Scholar]

- Charalambidi, B.G.; Rousakis, T.C.; Karabinis, A.I. Fatigue behavior of large-scale reinforced concrete beams strengthened in flexure with fiber-reinforced polymer laminates. J. Compos. Constr. 2016, 20, 04016035. [Google Scholar] [CrossRef]

- Dias-da-Costa, D.; Neves, L.; Gomes, S.; Hadigheh, S.; Fernandes, P. Time-dependent reliability analyses of prestressed concrete girders strengthened with CFRP laminates. Eng. Struct. 2019, 196, 109297. [Google Scholar] [CrossRef]

- Song, L.; Hou, J. Fatigue assessment model of corroded RC beams strengthened with prestressed CFRP sheets. Int. J. Concr. Struct. Mater. 2017, 11, 247–259. [Google Scholar] [CrossRef]

- Maghsoudi, M.; Maghsoudi, A. Experimental and Theoretical Serviceability of Strengthened and Nonstrengthened Unbonded Posttensioned Indeterminate I-Beams. J. Bridge Eng. 2017, 22, 05017006. [Google Scholar] [CrossRef]

- Chen, C.; Cheng, L. Predicting flexural fatigue performance of RC beams strengthened with externally bonded FRP due to FRP debonding. J. Bridge Eng. 2017, 22, 04017082. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, J.; Shang, S.; Liu, Y.; Cai, C. Experimental study of flexural fatigue performance of reinforced concrete beams strengthened with prestressed CFRP plates. Eng. Struct. 2016, 127, 62–72. [Google Scholar] [CrossRef]

- Gao, P.; Gu, X.; Mosallam, A.S. Flexural behavior of preloaded reinforced concrete beams strengthened by prestressed CFRP laminates. Compos. Struct. 2016, 157, 33–50. [Google Scholar] [CrossRef]

- Bigaud, D.; Ali, O. Time-variant flexural reliability of RC beams with externally bonded CFRP under combined fatigue-corrosion actions. Reliab. Eng. Syst. Saf. 2014, 131, 257–270. [Google Scholar] [CrossRef]

- Wang, W.-W.; Dai, J.-G.; Harries, K.A. Performance evaluation of RC beams strengthened with an externally bonded FRP system under simulated vehicle loads. J. Bridge Eng. 2013, 18, 76–82. [Google Scholar] [CrossRef]

- Dong, Y.; Ansari, F.; Karbhari, V.M. Fatigue performance of reinforced concrete beams with externally bonded CFRP reinforcement. Struct. Infrastruct. Eng. 2011, 7, 229–241. [Google Scholar] [CrossRef]

- Al-Rousan, R.; Issa, M. Fatigue performance of reinforced concrete beams strengthened with CFRP sheets. Constr. Build. Mater. 2011, 25, 3520–3529. [Google Scholar] [CrossRef]

- Al-Hammoud, R.; Soudki, K.; Topper, T.H. Fatigue flexural behavior of corroded reinforced concrete beams repaired with CFRP sheets. J. Compos. Constr. 2010, 15, 42–51. [Google Scholar] [CrossRef]

- Pellegrino, C.; Modena, C. Flexural Strengthening of Real-Scale RC and PRC Beams with End-Anchored Pretensioned FRP Laminates. ACI Struct. J. 2009, 106. [Google Scholar]

- Galal, K.; Mofidi, A. Strengthening RC beams in flexure using new hybrid FRP sheet/ductile anchor system. J. Compos. Constr. 2009, 13, 217–225. [Google Scholar] [CrossRef]

- Ekenel, M.; Myers, J.J. Fatigue performance of CFRP strengthened RC beams under environmental conditioning and sustained load. J. Compos. Constr. 2009, 13, 93–102. [Google Scholar] [CrossRef]

- Kim, Y.J.; Green, M.F.; Fallis, G.J. Repair of bridge girder damaged by impact loads with prestressed CFRP sheets. J. Bridge Eng. 2008, 13, 15–23. [Google Scholar] [CrossRef]

- Kim, Y.J.; Shi, C.; Green, M.F. Ductility and cracking behavior of prestressed concrete beams strengthened with prestressed CFRP sheets. J. Compos. Constr. 2008, 12, 274–283. [Google Scholar] [CrossRef]

- Gheorghiu, C.; Labossiere, P.; Proulx, J. Response of CFRP-strengthened beams under fatigue with different load amplitudes. Constr. Build. Mater. 2007, 21, 756–763. [Google Scholar] [CrossRef]

- Czaderski, C.; Motavalli, M. 40-Year-old full-scale concrete bridge girder strengthened with prestressed CFRP plates anchored using gradient method. Compos. Part B Eng. 2007, 38, 878–886. [Google Scholar] [CrossRef]

- Aidoo, J.; Harries, K.A.; Petrou, M.F. Full-scale experimental investigation of repair of reinforced concrete interstate bridge using CFRP materials. J. Bridge Eng. 2006, 11, 350–358. [Google Scholar] [CrossRef]

- Wenwei, W.; Guo, L. Experimental study and analysis of RC beams strengthened with CFRP laminates under sustaining load. Int. J. Solids Struct. 2006, 43, 1372–1387. [Google Scholar] [CrossRef]

- Rasheed, H.A.; Larson, K.H.; Peterman, R.J. Analysis and design procedure for FRP-strengthened prestressed concrete T-Girders considering strength and fatigue. J. Compos. Constr. 2006, 10, 419–432. [Google Scholar] [CrossRef]

- Ekenel, M.; Rizzo, A.; Myers, J.J.; Nanni, A. Flexural fatigue behavior of reinforced concrete beams strengthened with FRP fabric and precured laminate systems. J. Compos. Constr. 2006, 10, 433–442. [Google Scholar] [CrossRef]

- Dawood, M.; Rosenboom, O.; Rizkalla, S. Repair and Strengthening of Highway Bridges with FRP. In Proceedings of the International Conference on Bridge Management Systems-Monitoring Assessment and Rehabilitation, Cairo, Egypt, 21–23 March 2006; pp. 1–16. [Google Scholar]

- Osenboom, O.; Rizkalla, S. Fatigue behavior of prestressed concrete bridge girders strengthened with various CFRP systems. Spec. Publ. 2005, 230, 597–612. [Google Scholar]

- Quattlebaum, J.B.; Harries, K.A.; Petrou, M.F. Comparison of three flexural retrofit systems under monotonic and fatigue loads. J. Bridge Eng. 2005, 10, 731–740. [Google Scholar] [CrossRef]

- Gussenhoven, R.; Brena, S. Fatigue behavior of reinforced concrete beams strengthened with different FRP laminate configurations. ACI Spec. Publ. SP 2005, 230, 613–630. [Google Scholar]

- Ekenel, M.; Rizzo, A.; Myers, J.; Nanni, A. Effect of fatigue loading on flexural performance of reinforced concrete beams strengthened with FRP fabric and pre-cured laminate systems. In Proceedings of the Third International Conference on Composites in Construction, Hong Kong, China, 7–9 December 2005; pp. 405–412. [Google Scholar]

- Carolin, A.; Täljsten, B.; Hejll, A. Concrete beams exposed to live loading during carbon fiber reinforced polymer strengthening. J. Compos. Constr. 2005, 9, 178–186. [Google Scholar] [CrossRef]

- Carmichael, B.M.; Barnes, R.W. Repair of the Uphapee Creek Bridge with FRP Laminates; Final report; Research Project 930-466; Alabama Department of Transportation: Montgomery, AL, USA, 2005. [Google Scholar]

- Reed, C.E.; Peterman, R.J.; Rasheed, H.A. Evaluating FRP Repair Method for Cracked Prestressed Concrete Bridge Members Subjected to Repeated Loadings Phase 1; Final report; Kansas Department of Transportation, Bureau of Materials and Research, Kansas State University: Manhattan, KA, USA, 2005. [Google Scholar]

- Pham, H.; Al-Mahaidi, R. Experimental investigation into flexural retrofitting of reinforced concrete bridge beams using FRP composites. Compos. Struct. 2004, 66, 617–625. [Google Scholar] [CrossRef]

- Aidoo, J. Flexural Retrofit of Reinforced Concrete Bridge Girders Using Three Cfrp Systems; University of South Carolina: Columbia, SC, USA, 2004. [Google Scholar]

- Ekenel, M.; Stephen, V.; Myers, J.; Zoughi, R. Microwave NDE of RC beams strengthened with CFRP laminates containing surface defects and tested under cyclic loading. In Electrical and Computer Engineering; University of Missouri-Rolla: Rolla, MO, USA, 2004; Volume 65409, pp. 1–8. [Google Scholar]

- Aidoo, J.; Harries, K.A.; Petrou, M.F. Fatigue behavior of carbon fiber reinforced polymer-strengthened reinforced concrete bridge girders. J. Compos. Constr. 2004, 8, 501–509. [Google Scholar] [CrossRef]

- Heffernan, P.; Erki, M. Fatigue behavior of reinforced concrete beams strengthened with carbon fiber reinforced plastic laminates. J. Compos. Constr. 2004, 8, 132–140. [Google Scholar] [CrossRef]

- Bank, L.C.; Oliva, M.G.; Arora, D.; Borowicz, D.T. Rapid Strengthening of Reinforced Concrete Bridges; Final report; Wisconsin Department of Transportation, Department of Civil and Environmental Engineering, University of Wisconsin-Madison: Madison, WI, USA, 2003. [Google Scholar]

- Hassan, T.; Rizkalla, S. Investigation of bond in concrete structures strengthened with near surface mounted carbon fiber reinforced polymer strips. J. Compos. Constr. 2003, 7, 248–257. [Google Scholar] [CrossRef]

- Rizkalla, S.; Hassan, T. Effectiveness of FRP for strengthening concrete bridges. Struct. Eng. Int. 2002, 12, 89–95. [Google Scholar] [CrossRef]

- Wight, R.; Green, M.; Erki, M. Prestressed FRP sheets for poststrengthening reinforced concrete beams. J. Compos. Constr. 2001, 5, 214–220. [Google Scholar] [CrossRef]

- White, T.W.; Soudki, K.A.; Erki, M.-A. Response of RC beams strengthened with CFRP laminates and subjected to a high rate of loading. J. Compos. Constr. 2001, 5, 153–162. [Google Scholar] [CrossRef]

- Senthilnath, P.; Belarbi, A.; Myers, J.J. Performance of CFRP strengthened reinforced concrete (RC) beams in the presence of delaminations and lap splices under fatigue loading. In Proceedings of the International Conference in Construction(CCC-2001), Porto, Portugal, 10–12 October 2001; pp. 323–328. [Google Scholar]

- Sebastian, W.M. Significance of midspan debonding failure in FRP-plated concrete beams. J. Struct. Eng. 2001, 127, 792–798. [Google Scholar] [CrossRef]

- Rahimi, H.; Hutchinson, A. Concrete beams strengthened with externally bonded FRP plates. J. Compos. Constr. 2001, 5, 44–56. [Google Scholar] [CrossRef]

- Papakonstantinou, C.G.; Petrou, M.F.; Harries, K.A. Fatigue behavior of RC beams strengthened with GFRP sheets. J. Compos. Constr. 2001, 5, 246–253. [Google Scholar] [CrossRef]

- Lamanna, A.J.; Bank, L.C.; Scott, D.W. Flexural strengthening of reinforced concrete beams using fasteners and fiber-reinforced polymer strips. ACI Struct. J. 2001, 98, 368–376. [Google Scholar]

- Barnes, R.A.; Mays, G.C. Fatigue performance of concrete beams strengthened with CFRP plates. J. Compos. Constr. 1999, 3, 63–72. [Google Scholar] [CrossRef]

- Erki, M.; Meier, U. Impact loading of concrete beams externally strengthened with CFRP laminates. J. Compos. Constr. 1999, 3, 117–124. [Google Scholar] [CrossRef]

- Garden, H.; Hollaway, L.; Thorne, A. The strengthening and deformation behaviour of reinforced concrete beams upgraded using prestressed composite plates. Mater. Struct. 1998, 31, 247–258. [Google Scholar] [CrossRef]

- Garden, H.; Hollaway, L. An experimental study of the failure modes of reinforced concrete beams strengthened with prestressed carbon composite plates. Compos. Part B Eng. 1998, 29, 411–424. [Google Scholar] [CrossRef]

- El-Hacha, R. Strengthening of Concrete Members with Advanced Composite Materials. Master’s Thesis, Concordia University, Montreal, QC, Canada, 1997. [Google Scholar]

- Varastehpour, H.; Hamelin, P. Strengthening of concrete beams using fiber-reinforced platics. Mater. Struct. 1997, 30, 160–166. [Google Scholar] [CrossRef]

- Heffernan, C.P. Fatigue Behaviour of Reinforced Concrete Beams Strengthened wlth CFRP Laminates; Royal Military College of Canada: Kingston, ON, Canada, 1997. [Google Scholar]

- Saadatmanesh, H.; Ehsani, M.R. RC beams strengthened with GFRP plates. I: Experimental study. J. Struct. Eng. 1991, 117, 3417–3433. [Google Scholar] [CrossRef]

- Miller, A.D. Repair of Impact-Damaged Prestressed Concrete Bridge. Girders Using Carbon Fiber Reinforced Polymer (CFRP) Materials. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2006. [Google Scholar]

- Hawileh, R.A. Nonlinear finite element modeling of RC beams strengthened with NSM FRP rods. Constr. Build. Mater. 2012, 27, 461–471. [Google Scholar] [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R. Performance of RC beams rehabilitated with NSM CFRP strips using innovative high-strength self-compacting cementitious adhesive (IHSSC-CA) made with graphene oxide. Compos. Struct. 2017, 160, 392–407. [Google Scholar] [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R. Assessment of residual strength of concrete girders rehabilitated using NSM CFRP with cementitious adhesive made with graphene oxide after exposure to fatigue loading. Constr. Build. Mater. 2017, 153, 402–422. [Google Scholar] [CrossRef]

- Oudah, F.; El-Hacha, R. Fatigue behavior of RC beams strengthened with prestressed NSM CFRP rods. Compos. Struct. 2012, 94, 1333–1342. [Google Scholar] [CrossRef]

- Oudah, F.; El-Hacha, R. Performance of RC beams strengthened using prestressed NSM-CFRP strips subjected to fatigue loading. J. Compos. Constr. 2011, 16, 300–307. [Google Scholar] [CrossRef]

- El-Hacha, R.; Gaafar, M. Flexural strengthening of reinforced concrete beams using prestressed, near-surfacemounted CFRP bars. PCI J. 2011, 56, 134–151. [Google Scholar] [CrossRef]

- Badawi, M.; Soudki, K. Fatigue behavior of RC beams strengthened with NSM CFRP rods. J. Compos. Constr. 2009, 13, 415–421. [Google Scholar] [CrossRef]

- Badawi, M.A. Monotonic and fatigue flexural behaviour of RC beams strengthened with prestressed NSM CFRP rods. Ph.D. Dissertation, University of Waterloo, Waterloo, ON, Canada, 2007. [Google Scholar]

- Nordin, H.; Täljsten, B. Concrete beams strengthened with prestressed near surface mounted CFRP. J. Compos. Constr. 2006, 10, 60–68. [Google Scholar] [CrossRef]

- El-Hacha, R.; Rizkalla, S.H. Near-surface-mounted fiber-reinforced polymer reinforcements for flexural strengthening of concrete structures. Struct. J. 2004, 101, 717–726. [Google Scholar]

- Hassan, T.; Rizkalla, S. Bond mechanism of NSM FRP bars for flexural strengthening of concrete structures. ACI Struct. J. 2004, 101, 830–839. [Google Scholar]

- Babaeidarabad, S.; Loreto, G.; Nanni, A. Flexural strengthening of RC beams with an externally bonded fabric-reinforced cementitious matrix. J. Compos. Constr. 2014, 18, 04014009. [Google Scholar] [CrossRef]

- Pino, V.; Akbari Hadad, H.; De Caso y Basalo, F.; Nanni, A.; Ali Ebead, U.; El Refai, A. Performance of FRCM-strengthened RC beams subject to fatigue. J. Bridge Eng. 2017, 22, 04017079. [Google Scholar] [CrossRef]

- Picard, A.; Massicotte, B.; Boucher, E. Strengthening of reinforced concrete beams with composite materials: Theoretical study. Compos. Struct. 1995, 33, 63–75. [Google Scholar] [CrossRef]

| Damage Classification [15] | ||||

|---|---|---|---|---|

| Minor | Moderate | Severe | ||

| Severe I | Sever II | Severe III | ||

| Damage does not affect member capacity | Damage does not affect member capacity | Requires structural repair | Requires structural repair | Damage is too expensive |

| Repairs are for preventative or aesthetic purposes | Repair is done to prevent further deterioration | Repair is done to restore ultimate limit state | Repair is done to restore both the ultimate limit state and the service limit state | The member must be replaced |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghaffary, A.; Moustafa, M.A. Synthesis of Repair Materials and Methods for Reinforced Concrete and Prestressed Bridge Girders. Materials 2020, 13, 4079. https://doi.org/10.3390/ma13184079

Ghaffary A, Moustafa MA. Synthesis of Repair Materials and Methods for Reinforced Concrete and Prestressed Bridge Girders. Materials. 2020; 13(18):4079. https://doi.org/10.3390/ma13184079

Chicago/Turabian StyleGhaffary, Azin, and Mohamed A. Moustafa. 2020. "Synthesis of Repair Materials and Methods for Reinforced Concrete and Prestressed Bridge Girders" Materials 13, no. 18: 4079. https://doi.org/10.3390/ma13184079

APA StyleGhaffary, A., & Moustafa, M. A. (2020). Synthesis of Repair Materials and Methods for Reinforced Concrete and Prestressed Bridge Girders. Materials, 13(18), 4079. https://doi.org/10.3390/ma13184079