Prediction of Structural Performance of Vinyl Ester Polymer Concrete Using FEM Elasto-Plastic Model

Abstract

1. Introduction

2. Materials and Methods

2.1. Polymer Concrete Composition

2.1.1. Vinyl-Ester Resin

2.1.2. Fine and Coarse Aggregates

2.1.3. Microfiller

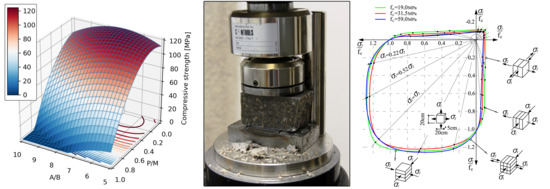

2.1.4. Mix Design

- A/B [g/g]—aggregate to binder ratio by mass;

- B/M [g/g]—microfiller to binder ratio by mass;

- P/M [g/g]—waste powder to microfiller mass ratio.

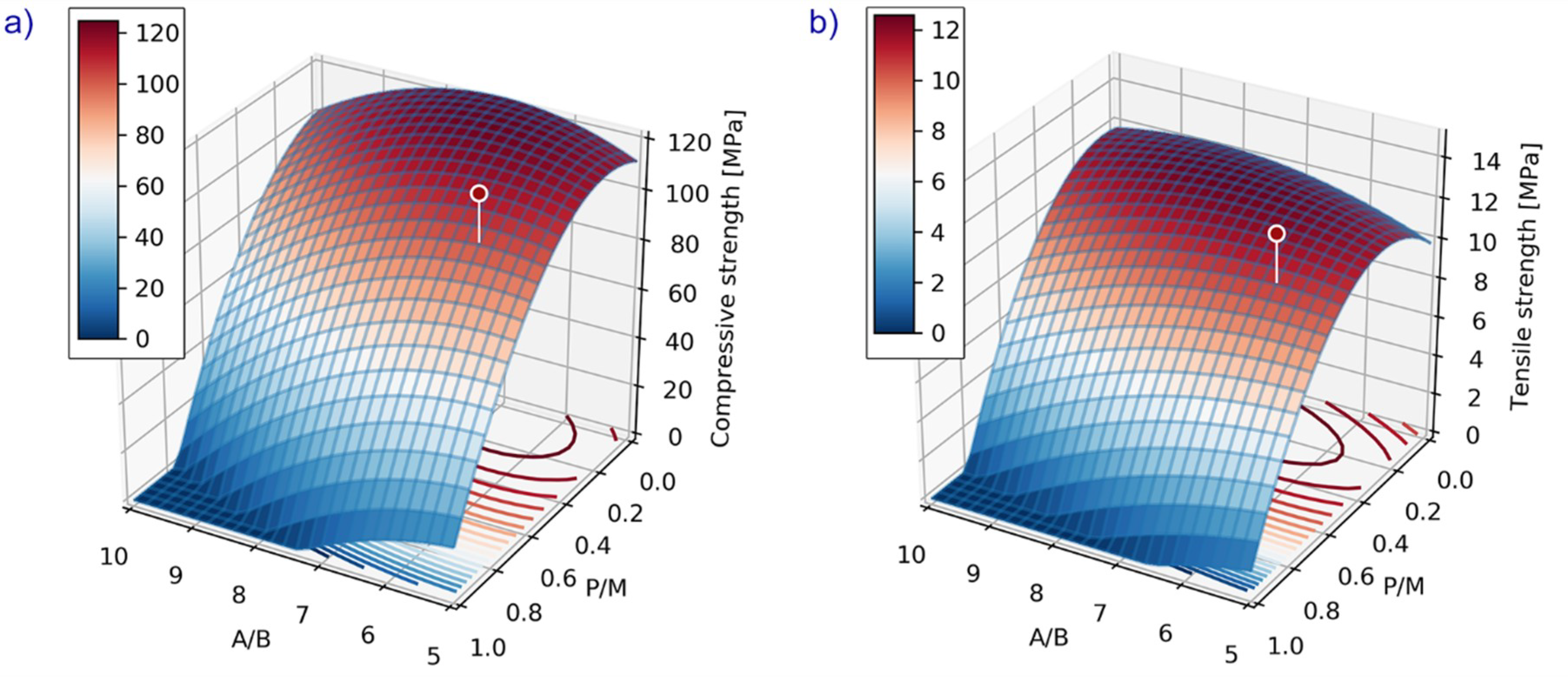

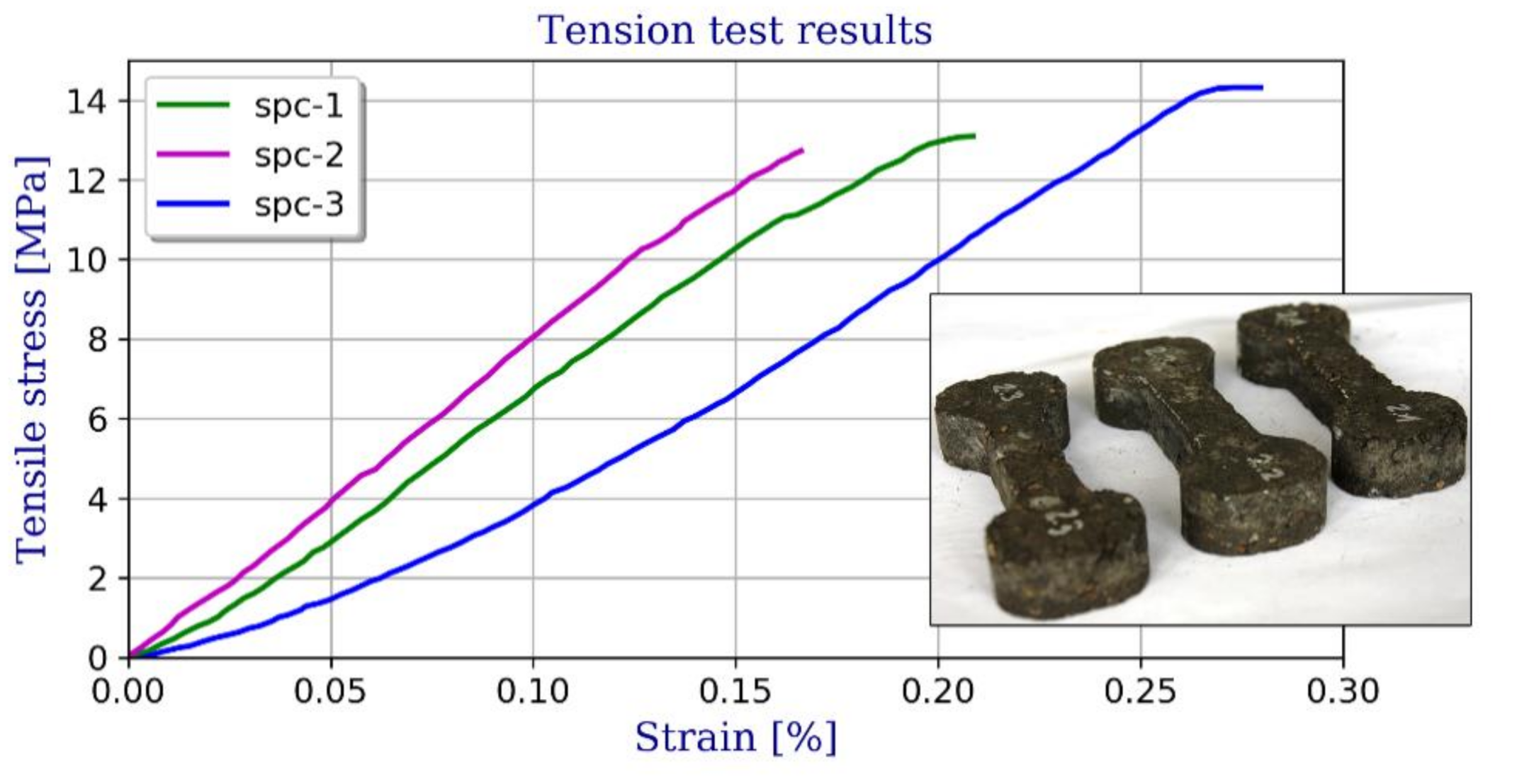

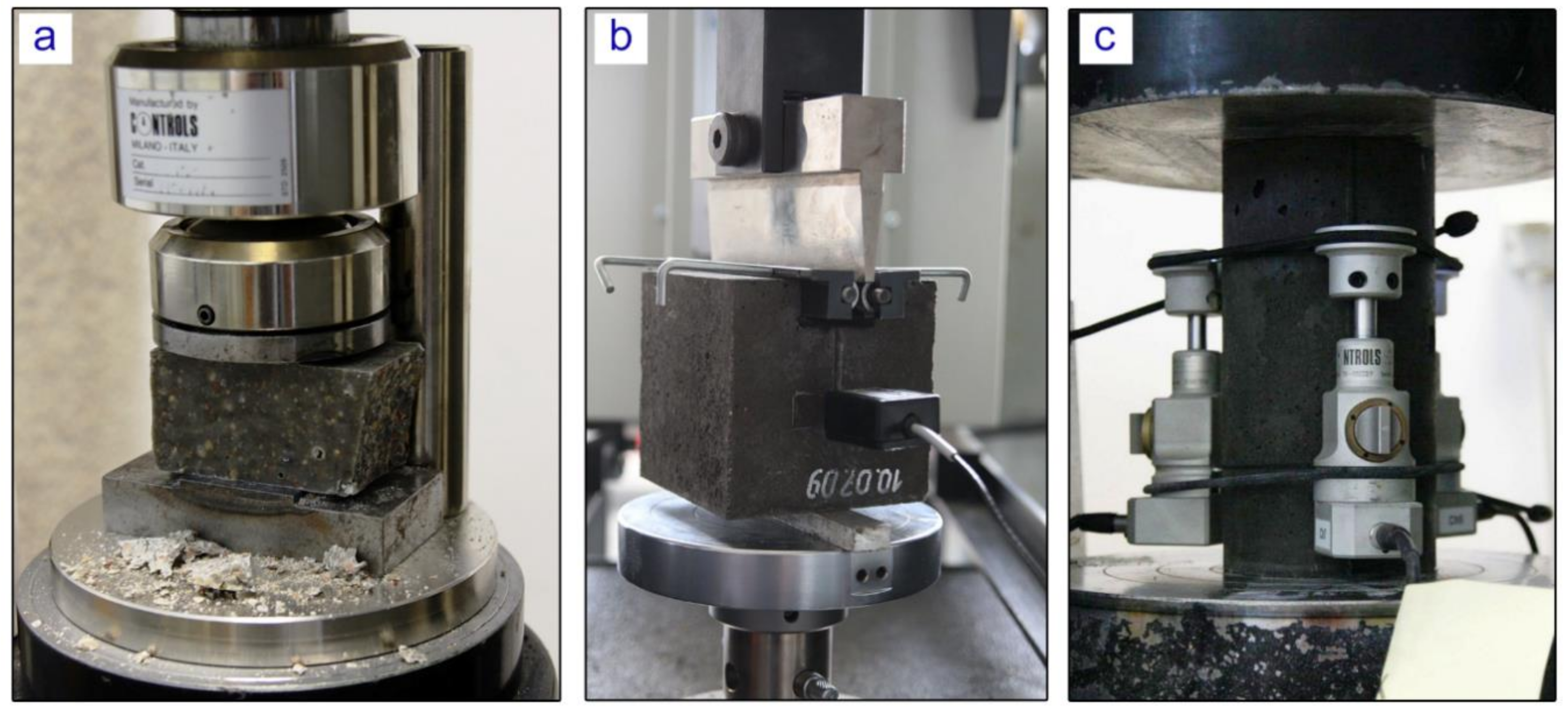

2.2. Material Characterization

2.3. Development of the Finite Element Model

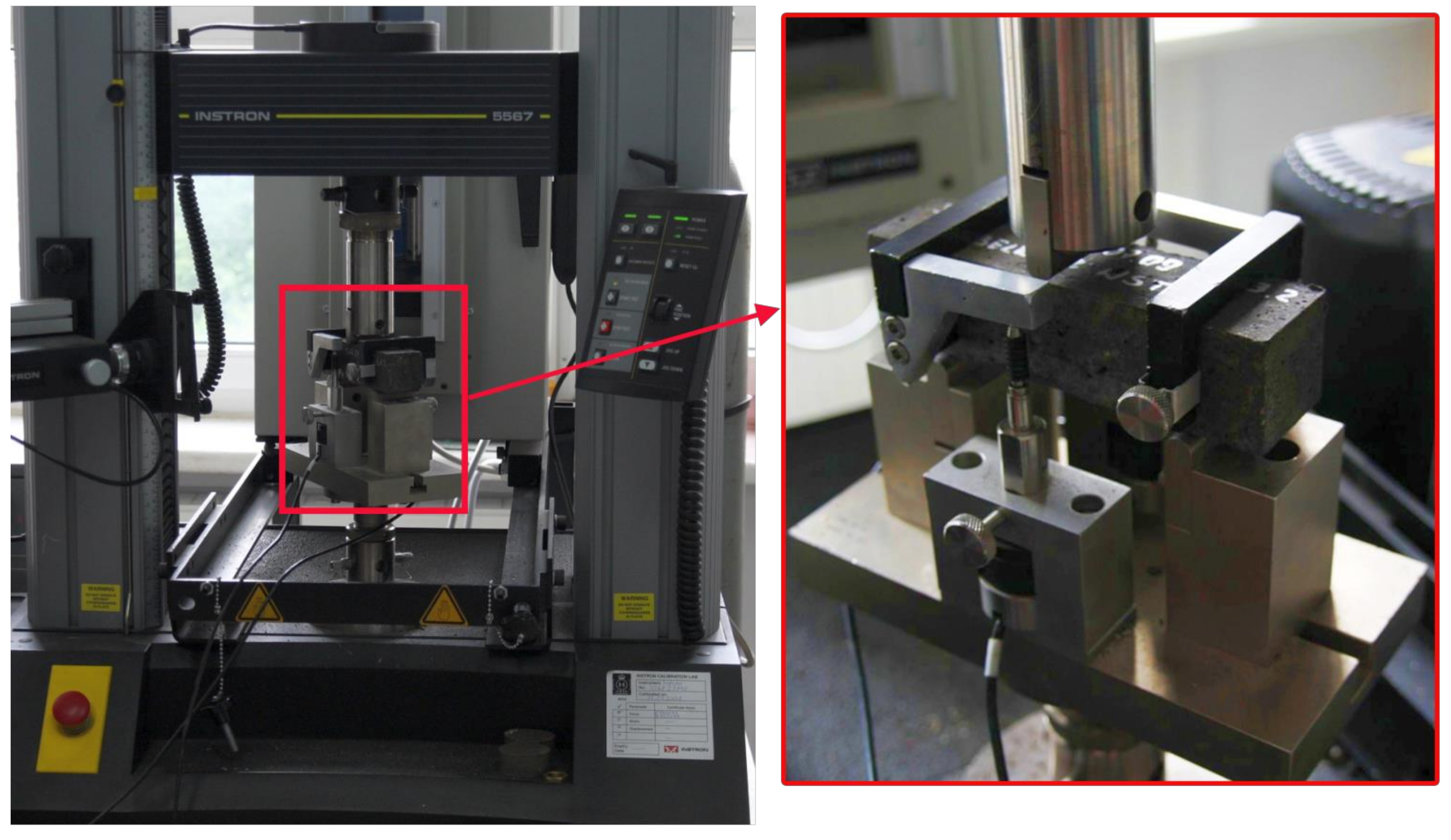

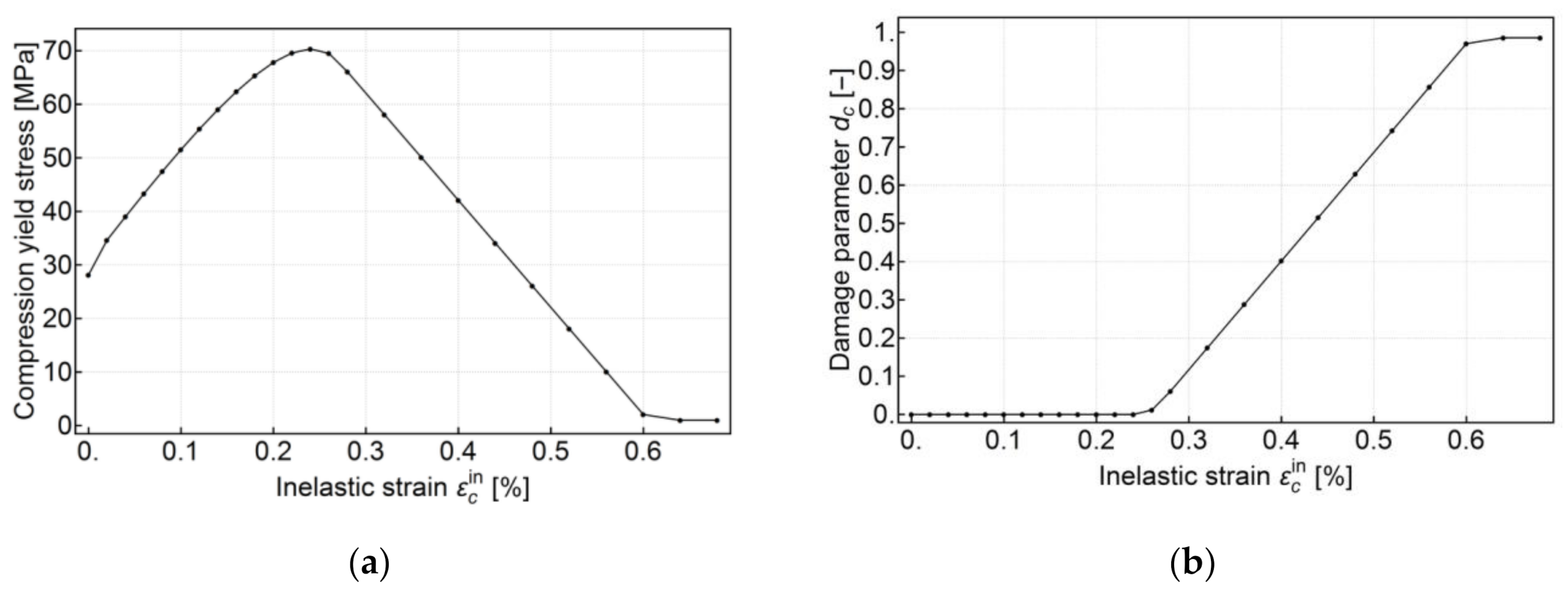

2.3.1. Concrete Damaged Plasticity Constitutive Model

2.3.2. Finite Element Model of the Manhole Cover

3. Results

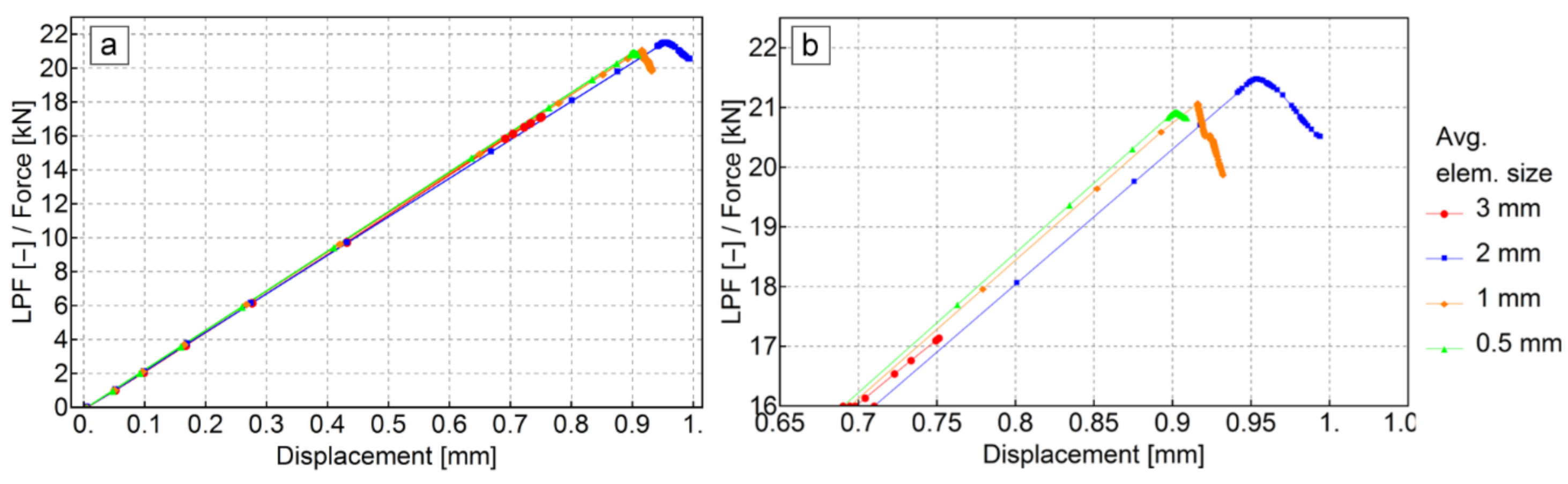

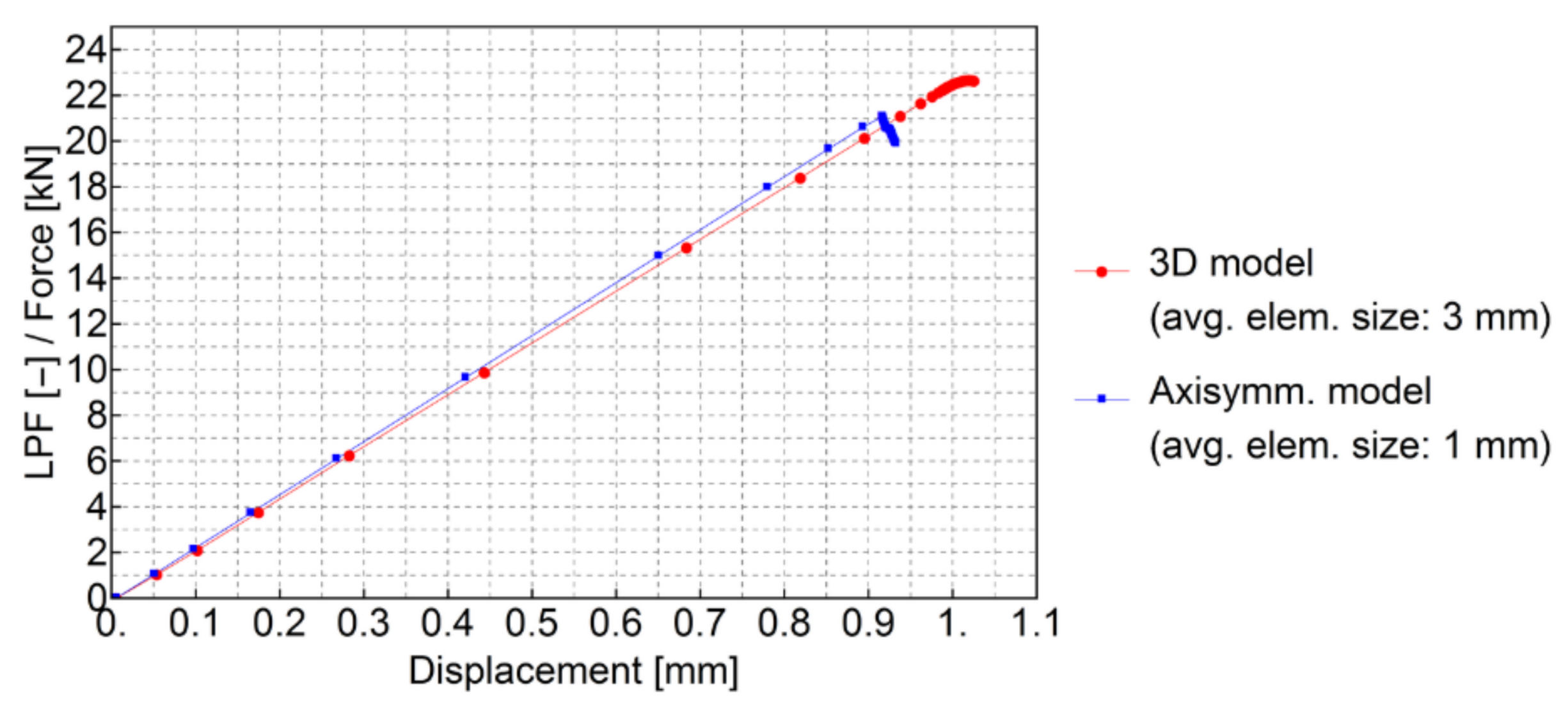

3.1. Mesh Convergence Test and Internal Energy Comparison

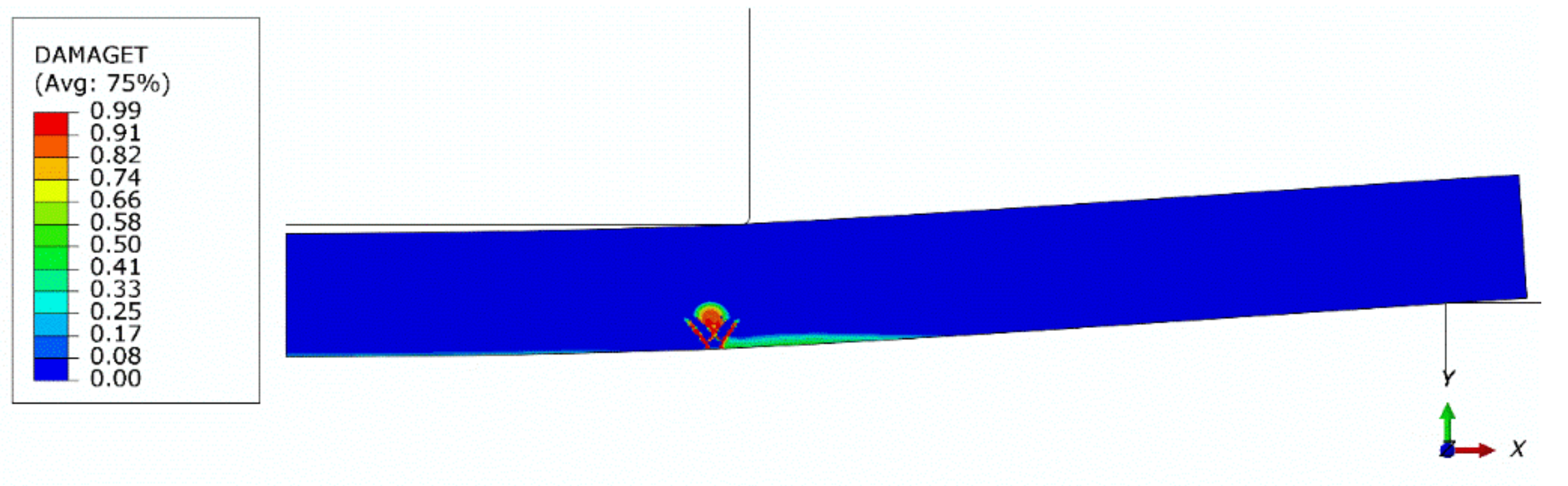

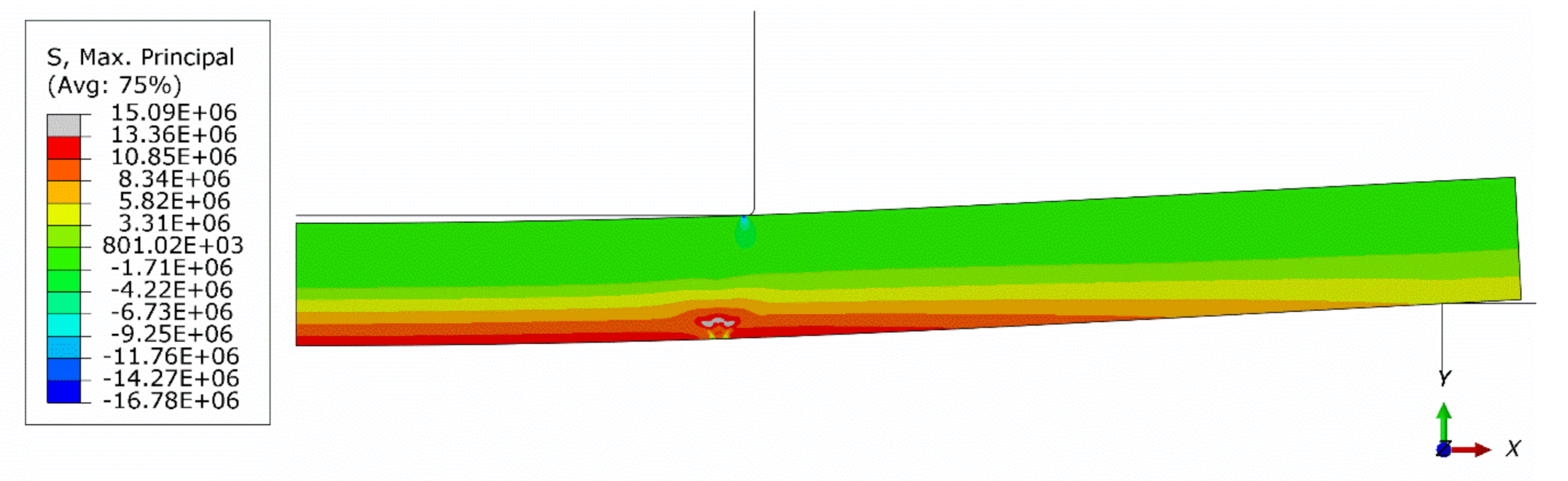

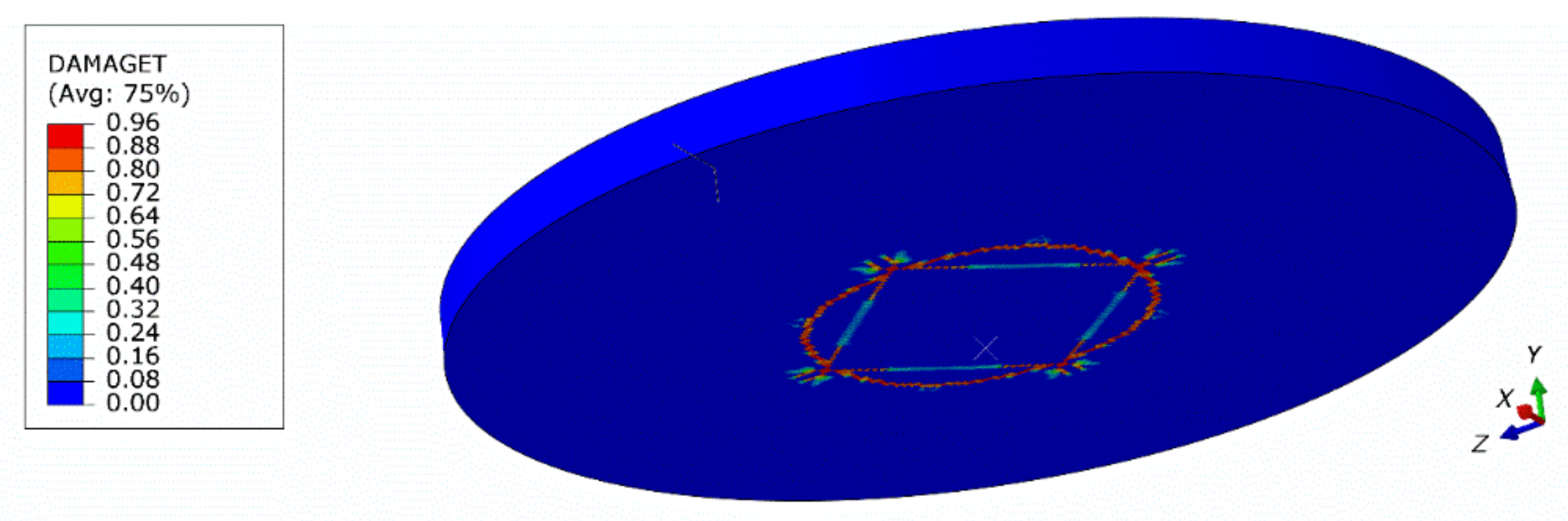

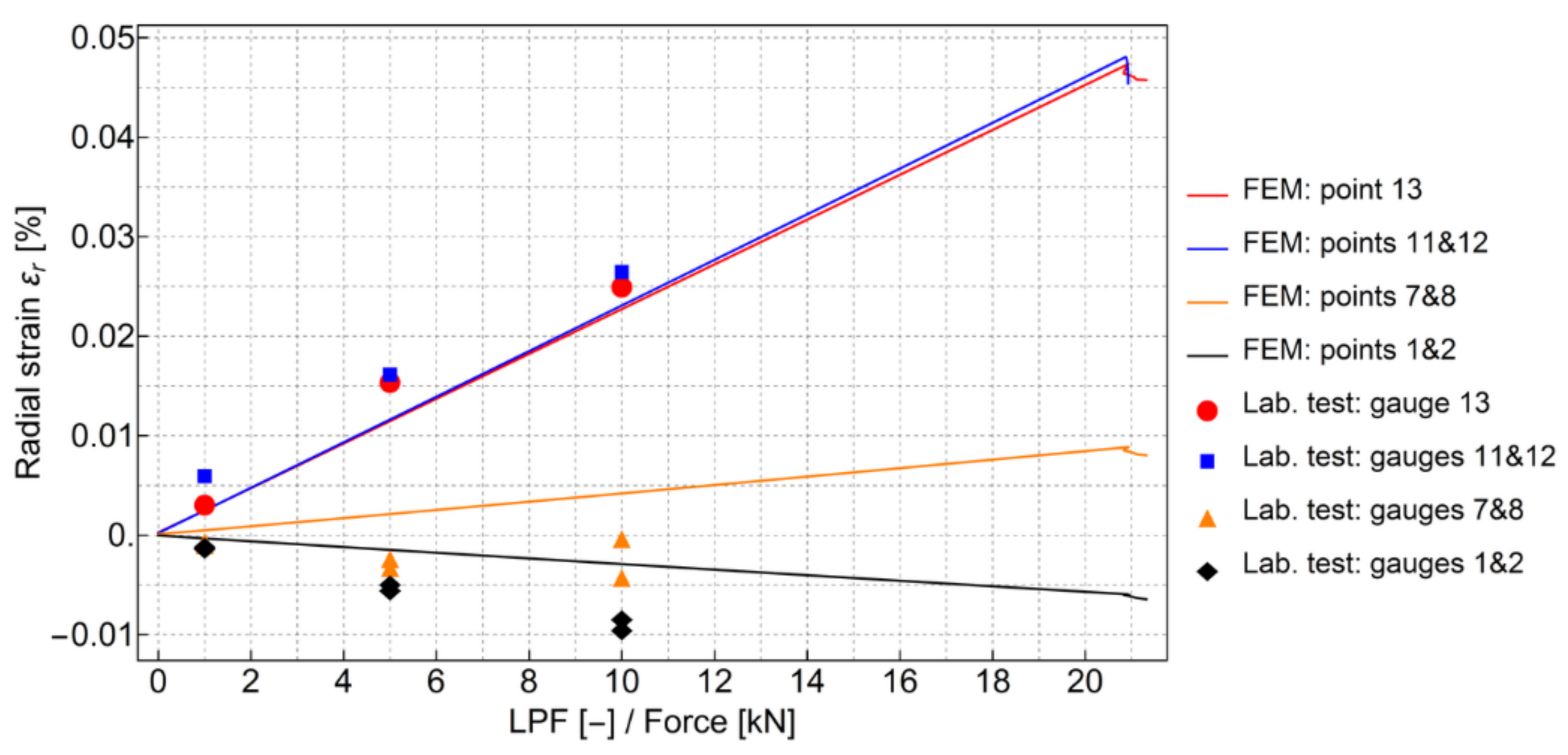

3.2. Stress–Strain Analysis

4. Discussion

5. Conclusions

- The concrete damage plasticity (CDP) material model can be successfully adopted to simulate the nonlinear mechanical behavior of polymer concrete.

- The CDP model takes many parameters and finding these parameters based on standard laboratory test data is not straightforward. The authors showed a clear procedure of finding CDP model input data based on standard laboratory tests.

- The CDP model was originally developed for the description of cement concrete. For polymer concrete, the authors proposed how to make necessary assumptions regarding the post-failure behavior.

- The authors showed that PC can be considered for the design of manhole covers. In this study, manhole cover made of plain PC showed too little structural capacity. However, in the authors’ opinion, the numerical approach presented here can still be considered as a valuable design tool (e.g., for manhole covers made of reinforced PC). The numerical solution can be used to choose the type and geometry of the reinforcement, which will be the subject of future studies. Evaluating the application of a certain material model and formulating necessarily steps for finding material parameters is an important milestone before proceeding to the reinforcement design, as it can significantly limit the number of laboratory tests.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fowler, D.W. Polymers in concrete: A vision for the 21st century. Cem. Concr. Compos. 1999, 21, 449–452. [Google Scholar] [CrossRef]

- Leonardi, L.; Pique, T.M.; Leizerow, T.; Balzamo, H.; Bernal, C.; Vazquez, A.; Agaliotis, E. Design and Assessment of a Lightweight Polymer Concrete Utility Manhole. Adv. Mater. Sci. Eng. 2019, 2019, 5234719. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Van Erp, G.; Aravinthan, T.; Ghabraie, K. Evaluation of an Innovative Composite Railway Sleeper for a Narrow-Gauge Track under Static Load. J. Compos. Constr. 2018, 22. [Google Scholar] [CrossRef]

- Fowler, D.W. Concrete-polymer materials: How far have we come, and where do we need to go? In Proceedings of the International Congress on Polymers in Concrete (ICPIC 2018), Washington, DC, USA, 29 April–1 May 2018; pp. 3–13. [Google Scholar] [CrossRef]

- Czarnecki, L. Polymer concretes. Cem. Wapno Beton 2010, 15, 63–85. [Google Scholar]

- Bedi, R.; Chandra, R.; Singh, S.P. Mechanical properties of polymer concrete. Hindawi J. Compos. 2013. [Google Scholar] [CrossRef]

- San Jose, J.T.; Ramirez Ortiz, J.L. A study of the mechanical properties of polyester concrete. In Proceedings of the Infrastructure Regeneration and Rehabilitation Improving the Quality of Life through Better Construction: A Vision for the Next Millennium, Sheffield, UK, 28 June–2 July 1999; pp. 477–486. Available online: https://www.worldcat.org/title/infrastucture-regeneration-and-rehabilitation-improving-the-quality-of-life-through-better-construction-a-vision-for-the-next-millennium-proceedings-of-international-conference-held-at-the-university-of-sheffield-28-june-2-july-1999/oclc/708566963 (accessed on 9 September 2020).

- Jo, B.W.; Park, S.K.; Kim, D.K. Mechanical properties of nano-MMT reinforced polymer composite and polymer concrete. Constr. Build. Mater. 2008, 22, 14–20. [Google Scholar] [CrossRef]

- Orak, S. Investigation of vibration damping on polymer concrete with polyester resin. Cem. Concr. Res. 2000, 30, 171–174. [Google Scholar] [CrossRef]

- Mendis, P. Commercial applications and property requirements for epoxies in construction. Spec. Publ. 1985, 89, 127–140. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Ferreira, A.J.M. Assessment of fracture properties of epoxy polymer concrete reinforced with short carbon and glass fibers. Constr. Build. Mater. 2004, 18, 523–528. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Wong, H.S.; Abousnina, R.; AlAjarmeh, O.S.; Zhuge, Y.; Schubel, P. Optimal design for epoxy polymer concrete based on mechanical properties and durability aspects. Constr. Build. Mater. 2020, 232, 117229. [Google Scholar] [CrossRef]

- Choi, N.W.; Ohama, Y. Development and testing of polystyrene mortars using waste EPS solution-based binders. Constr. Build. Mater. 2004, 18, 235–241. [Google Scholar] [CrossRef]

- Chmielewska, B.; Czarnecki, L.; Šušteršič, J.; Zajc, A. The influence of silane coupling agents on the polymer mortar. Cem. Concr. Compos. 2006, 28, 803–810. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Taylor, R.L. The Finite Element Method, Volume 2: Solid Mechanics; Butterworth-Heinemann: Oxford, UK, 2000. [Google Scholar]

- Peters, S.T. Handbook of Composites; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Garbacz, A.; Sokołowska, J. Concrete-like polymer composites with fly ashes—Comparative study. Constr. Build. Mater. 2013, 38, 689–699. [Google Scholar] [CrossRef]

- Clifton, J.R.; Czarnecki, L.; Łukowski, P. Application of material model in optimization of polymer concretes. In Proceedings of the International Congress on Polymers in Concrete, Oostende, Belgium, 1995; Volume 293. [Google Scholar]

- Lokuge, W.; Aravinthan, T. Effect of fly ash on the behavior of polymer concrete with different types of resin. Mater. Des. 2013, 51, 175–181. [Google Scholar] [CrossRef]

- Brühwiler, E.; Wittmann, F.H. The wedge splitting test, a new method of performing stable fracture mechanics tests. Eng. Fract. Mech. 1990, 35, 117–125. [Google Scholar] [CrossRef]

- Dassault Systèmes. Abaqus Analysis User’s Manual, 2016; Dassault Systèmes: Vélizy-Villacoublay, France, 2016. [Google Scholar]

- Lubliner, J.; Oliver, J.; Oller, S.; Oñate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Kupfer, H.; Hilsdorf, H.K.; Rusch, H. Behavior of concrete under biaxial stresses. ACI J. 1969, 66, 656–666. [Google Scholar]

- Papanikolaou, V.K.; Kappos, A.J. Confinement-sensitive plasticity constitutive model for concrete in triaxial compression. Int. J. Solids Struct. 2007, 44, 7021–7048. [Google Scholar] [CrossRef]

- Wei, S.; Mau, S.T.; Vipulanandan, C. Mechanical behavior of confined polymer concrete. Cem. Concr. Res. 1992, 22, 621–630. [Google Scholar] [CrossRef]

- EN 1992-1-1:2004, Eurocode 2: Design of concrete structures - Part 1-1: General rules and rules for buildings, European Standard. 2004. Available online: https://eurocodes.jrc.ec.europa.eu/showpage.php?id=132 (accessed on 9 September 2020).

- Markowski, Ł; Andrzej, G.; Artur, Z. Theoretical Foundations of Civil Engineering: Polish-Ukrainian-Lithuanian; Oficyna Wydawnicza Politechniki Warszawskiej: Warszawa, Poland, 2010; Volume 18, pp. 371–378. [Google Scholar]

- Powell, G.; Simons, J. Improved iterative strategy for nonlinear structures. Int. J. Numer. Methods Eng. 1981, 17, 1455–1467. [Google Scholar] [CrossRef]

| Property | Test Method | Value |

|---|---|---|

| Viscosity (25 °C) | DIN 53015 | 350 ± 50 mPa·s |

| Gelling time (25 °C) | ISO 2535 | 30 ± 5 min |

| Flexural strength | ISO 178 | 110 MPa |

| Tensile strength | ISO 527 | 75 MPa |

| Elasticity modulus | ISO 527 | 3500 MPa |

| Extension | ISO 527 | 2.8% |

| Heat deflection temperature | ISO 75 | 95 °C |

| Barcol hardness | ASTM D 2583 | 35 °B |

| Component | Function | Content (% of Resin Mass) |

|---|---|---|

| Cobalt naphthenate 1% | Accelerant | 0.6 |

| Dimethylaniline 10% | Accelerant | 1.21 |

| Benzoyl peroxide | Hardener | 1.97 |

| Sand and Gravel | Resin | Fly Ash | Quartz Powder |

|---|---|---|---|

| 1314 kg | 329 kg | 328.5 kg | 328.5 kg |

| Test | Unit | Result | Standard Deviation |

|---|---|---|---|

| Compression (beam) | N/mm2 | 109.40 | 4.00 |

| Compression (cube) | N/mm2 | 93.10 | 1.19 |

| Compression (cylinder) | N/mm2 | 70.35 | 7.59 |

| Bending | N/mm2 | 24.33 | 1.31 |

| Tension | N/mm2 | 13.76 | 0.68 |

| WST | N/m | 17.68 | 0.39 |

| Young’s modulus | kN/mm2 | 21.80 | 1.090 |

| ρ [kg/m3] | E [GPa] | ν [–] | K [–] | χ [–] | ψ [°] | fb0/fc0 [–] | μ [s] |

|---|---|---|---|---|---|---|---|

| 2400 | 21.802 | 0.2 | 0.667 | 0.2 | 36 | 1.05 | 0.005 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Józefiak, K.; Michalczyk, R. Prediction of Structural Performance of Vinyl Ester Polymer Concrete Using FEM Elasto-Plastic Model. Materials 2020, 13, 4034. https://doi.org/10.3390/ma13184034

Józefiak K, Michalczyk R. Prediction of Structural Performance of Vinyl Ester Polymer Concrete Using FEM Elasto-Plastic Model. Materials. 2020; 13(18):4034. https://doi.org/10.3390/ma13184034

Chicago/Turabian StyleJózefiak, Kazimierz, and Rafał Michalczyk. 2020. "Prediction of Structural Performance of Vinyl Ester Polymer Concrete Using FEM Elasto-Plastic Model" Materials 13, no. 18: 4034. https://doi.org/10.3390/ma13184034

APA StyleJózefiak, K., & Michalczyk, R. (2020). Prediction of Structural Performance of Vinyl Ester Polymer Concrete Using FEM Elasto-Plastic Model. Materials, 13(18), 4034. https://doi.org/10.3390/ma13184034