Development of Unidirectional Cellular Structure with Multiple Pipe Layers and Characterisation of Its Mechanical Properties

Abstract

1. Introduction

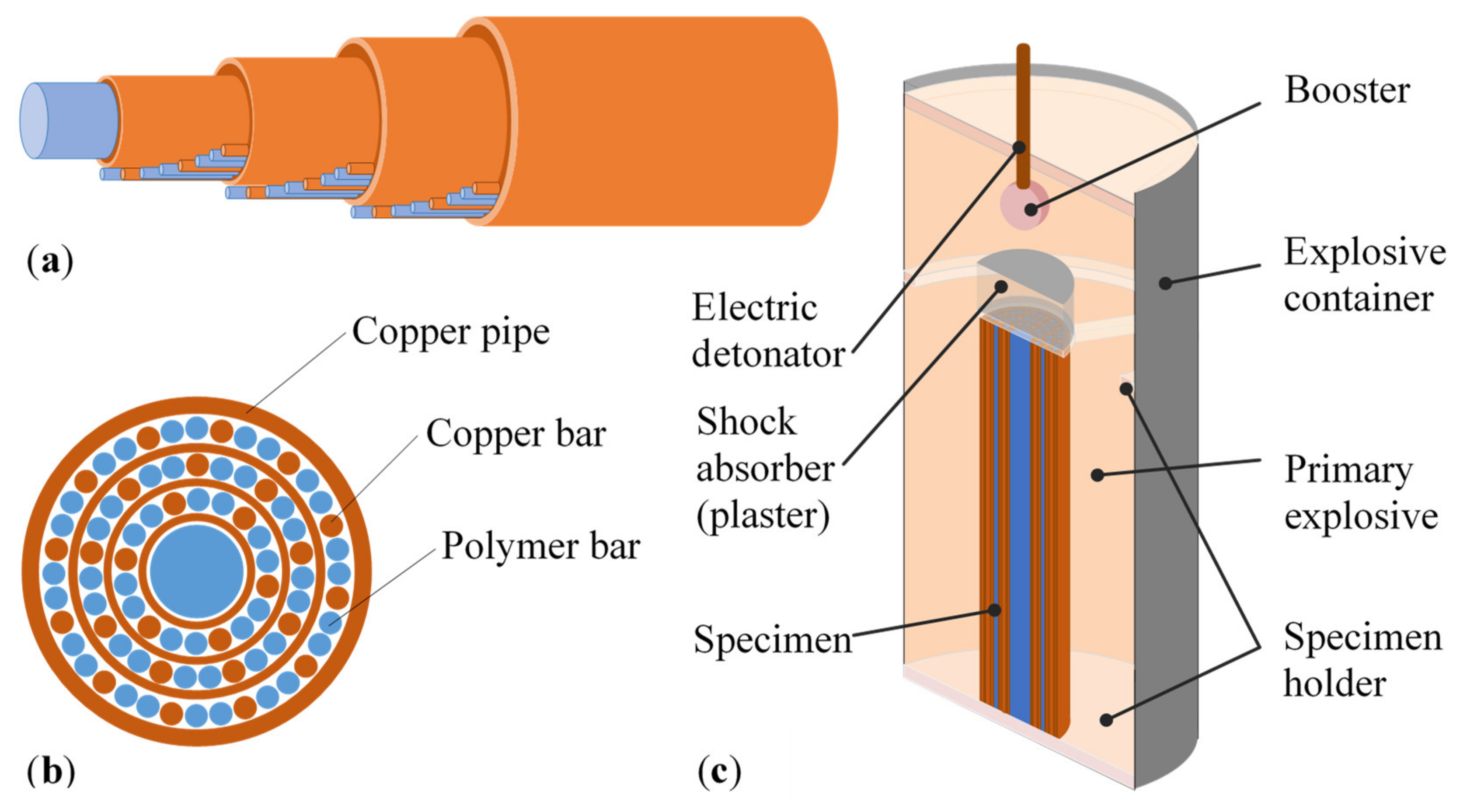

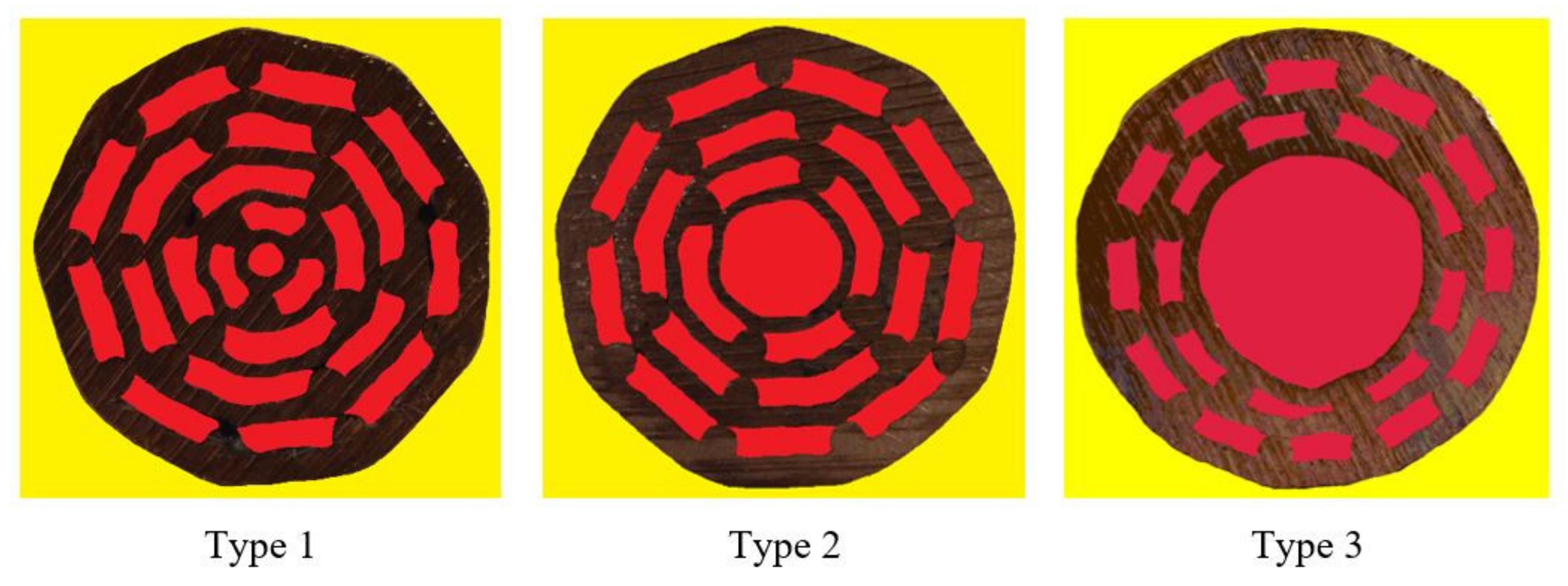

2. Materials and Fabrication of the Specimens

- Preparation of the specimen in the form of an assembly of metal pipes or bars, where the voids are filled with low-melting-point material (i.e., paraffin, polymer);

- Placement into the explosive container, where the specimen is surrounded by the primary explosive;

- Explosive compaction, with the main explosive detonated by the booster;

- Removal of the low-melting-point material by thermal treatment.

3. Methods

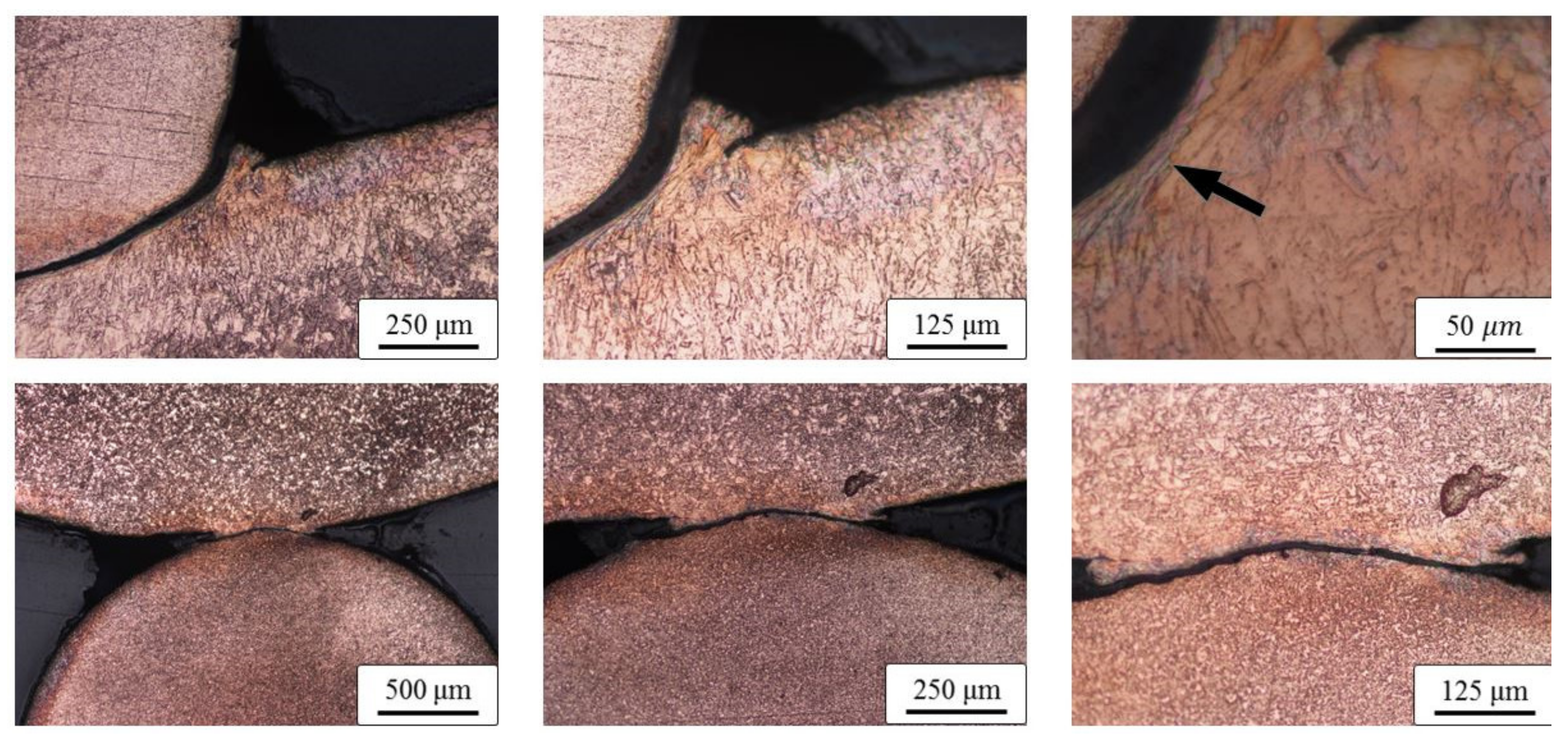

3.1. Metallography

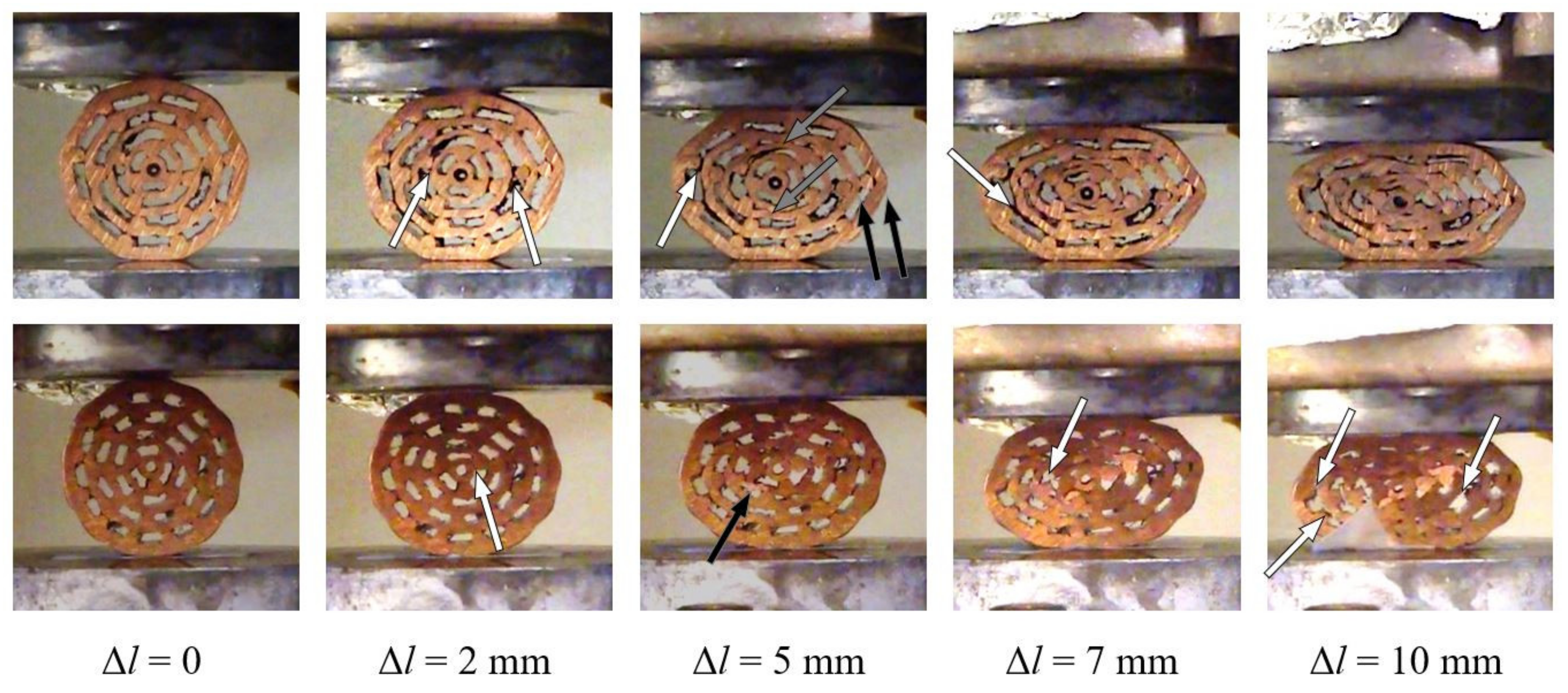

3.2. Compressive Testing

4. Results of a Metallographic Investigation

5. Results of Compressive Testing

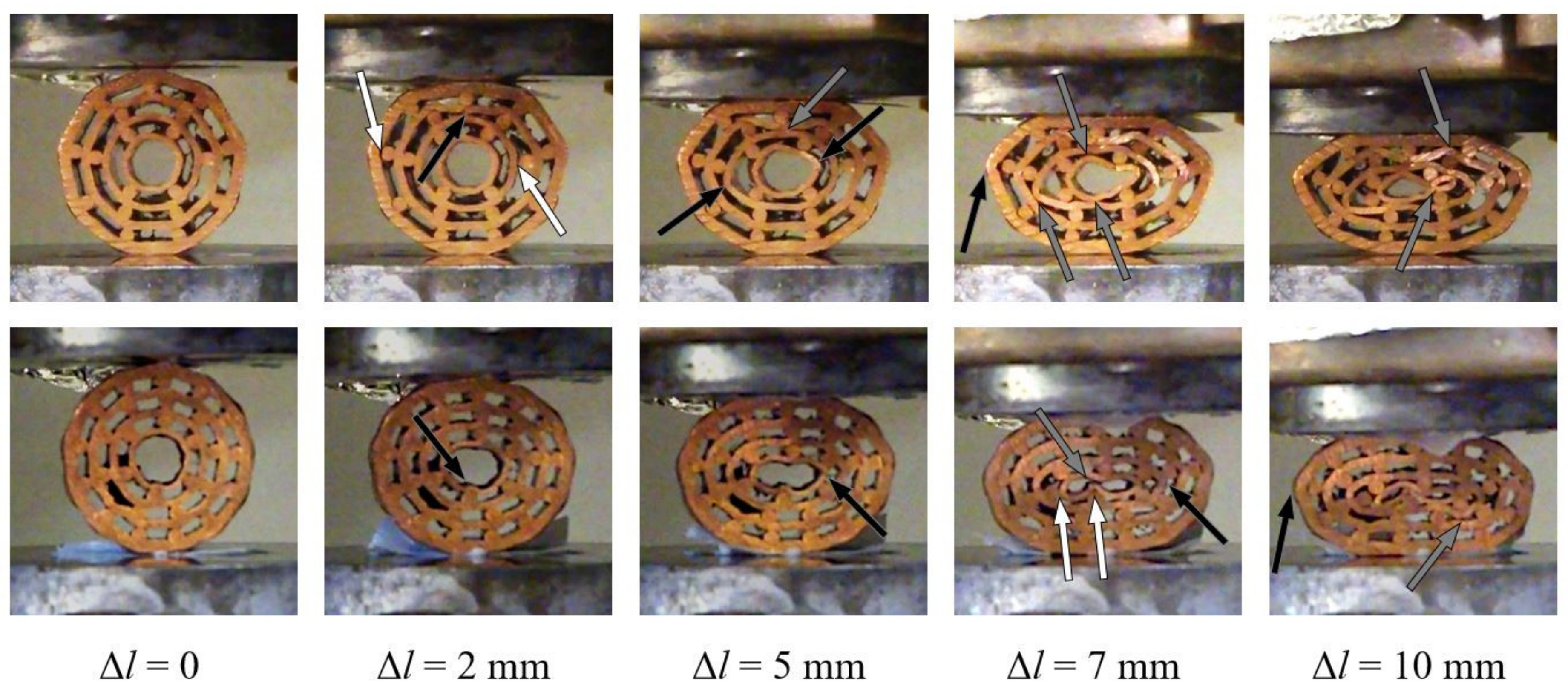

5.1. Type 1 Specimens

5.2. Type 2 Specimens

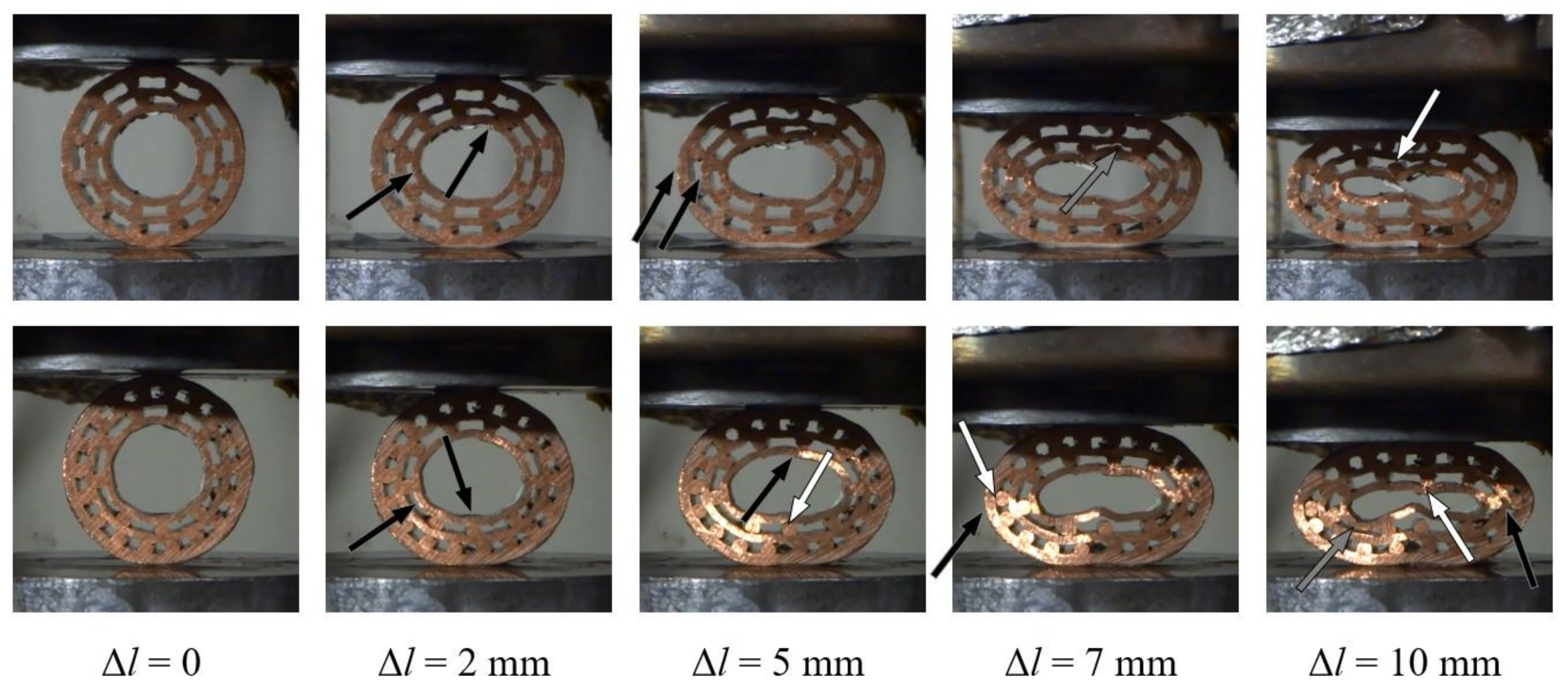

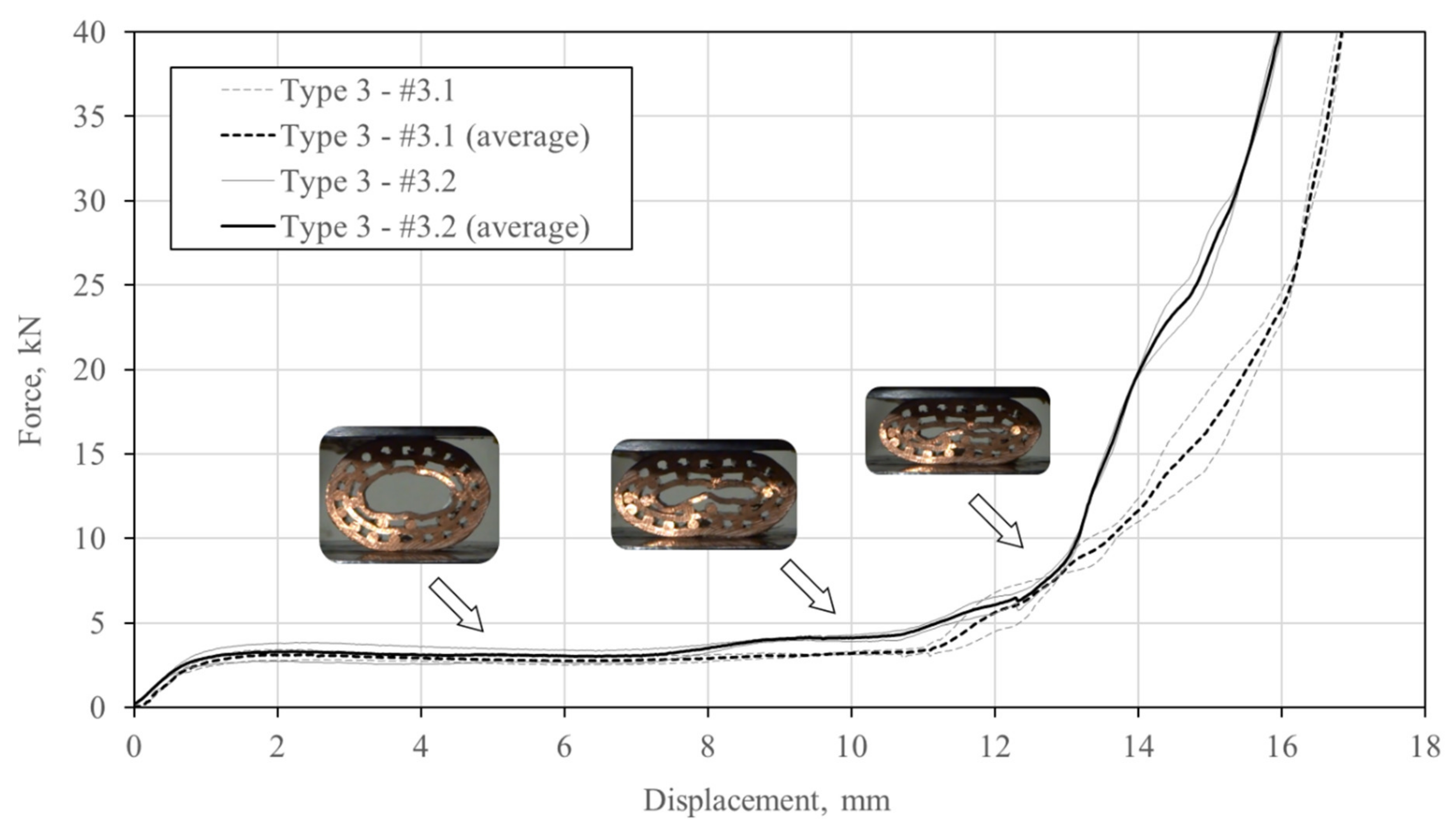

5.3. Type 3 Specimens

6. Comparison

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ashby, M.F.; Evans, A.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W.; Wadley, H.N.G. Metal Foams: A Design Guide; Elsevier Science: Burlington, MA, USA, 2000. [Google Scholar]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Lehmhus, D.; Vesenjak, M.; De Schampheleire, S.; Fiedler, T. From Stochastic Foam to Designed Structure: Balancing Cost and Performance of Cellular Metals. Materials 2017, 10, 922. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Ren, Z. Auxetic Cellular Materials—A Review. Strojniški Vestnik—J. Mech. Eng. 2016, 62, 485–493. [Google Scholar] [CrossRef]

- Imbalzano, G.; Tran, P.; Ngo, T.; Lee, P.V.S. Three-dimensional modelling of auxetic sandwich panels for localised impact resistance. J. Sandw. Struct. Mater. 2015, 19, 291–316. [Google Scholar] [CrossRef]

- Garcia-Moreno, F. Commercial Applications of Metal Foams: Their Properties and Production. Materials 2016, 9, 85. [Google Scholar] [CrossRef]

- Shapovalov, V. Porous metals. MRS Bull. 1994, 19, 24–29. [Google Scholar] [CrossRef]

- Nakajima, H. Fabrication, properties and application of porous metals with directional pores. Prog. Mater. Sci. 2007, 52, 1091–1173. [Google Scholar] [CrossRef]

- Kovačič, A.; Borovinšek, M.; Vesenjak, M.; Ren, Z. Indirect Reconstruction of Pore Morphology for Parametric Computational Characterization of Unidirectional Porous Iron. Materials 2018, 11, 193. [Google Scholar] [CrossRef] [PubMed]

- Kujime, T.; Nakajima, H. Investigation of the Mechanical Properties of Lotus-Type Porous Carbon Steel Made by Continuous Zone Melting Technique. Mater. Sci. Forum 2010, 638, 1866–1871. [Google Scholar] [CrossRef]

- Fiedler, T.; Veyhl, C.; Belova, I.V.; Tane, M.; Nakajima, H.; Bernthaler, T.; Merkel, M.; Öchsner, A.; Murch, G.E. On the Anisotropy of Lotus-Type Porous Copper. Adv. Eng. Mater. 2011, 14, 144–152. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, X.; Yan, X.; Meng, A.; Tan, C. A System of Back-to-back Multi-stage Radial Turbine. Chinese Patent 201220059417.1, 21 February 2012. [Google Scholar]

- Crossland, B. Explosive Welding of Metals and Its Application; Oxford University Press: New York, NY, USA, 1982. [Google Scholar]

- Vesenjak, M.; Hokamoto, K.; Anzel, I.; Sato, A.; Tsunoda, R.; Krstulović-Opara, L.; Ren, Z. Influence of the explosive treatment on the mechanical properties and microstructure of copper. Mater. Des. 2015, 75, 85–94. [Google Scholar] [CrossRef]

- Nishi, M.; Oshita, M.; Ulbin, M.; Vesenjak, M.; Ren, Z.; Hokamoto, K. Computational Analysis of the Explosive Compaction Fabrication Process of Cylindrical Uni-directional Porous Copper. Met. Mater. Int. 2018, 24, 1143–1148. [Google Scholar] [CrossRef]

- Vesenjak, M.; Hokamoto, K.; Sakamoto, M.; Nishi, T.; Krstulović-Opara, L.; Ren, Z. Mechanical and microstructural analysis of unidirectional porous (UniPore) copper. Mater. Des. 2016, 90, 867–880. [Google Scholar] [CrossRef]

- Hokamoto, K.; Shimomiya, K.; Nishi, M.; Krstulović-Opara, L.; Vesenjak, M.; Ren, Z. Fabrication of unidirectional porous-structured aluminum through explosive compaction using cylindrical geometry. J. Mater. Process. Technol. 2018, 251, 262–266. [Google Scholar] [CrossRef]

- Nishi, M.; Tanaka, S.; Vesenjak, M.; Ren, Z.; Hokamoto, K. Experimental and computational analysis of the uni-directional porous (UniPore) copper mechanical response at high-velocity impact. Int. J. Impact Eng. 2020, 136, 103409. [Google Scholar] [CrossRef]

- Fiedler, T.; Borovinšek, M.; Hokamoto, K.; Vesenjak, M. High-performance thermal capacitors made by explosion forming. Int. J. Heat Mass Transf. 2015, 83, 366–371. [Google Scholar] [CrossRef]

- Vesenjak, M.; Hokamoto, K.; Matsumoto, S.; Marumo, Y.; Ren, Z. Uni-directional porous metal fabricated by rolling of copper sheet and explosive compaction. Mater. Lett. 2016, 170, 39–43. [Google Scholar] [CrossRef]

- Utsunomiya, H.; Koh, H.; Miyamoto, J.; Sakai, T. High-Strength Porous Copper by Cold-Extrusion. Adv. Eng. Mater. 2008, 10, 826–829. [Google Scholar] [CrossRef]

- Utsunomiya, H.; Tsuruoka, H. Porasu-kinzokuno-sosei-kakou. Sokezai 2012, 53, 14–19. (In Japanese) [Google Scholar]

- Osakada, K.; Limb, M.; Mellor, P. Hydrostatic extrusion of composite rods with hard cores. Int. J. Mech. Sci. 1973, 15, 291–307. [Google Scholar] [CrossRef]

- Hokamoto, K.; Vesenjak, M.; Ren, Z. Fabrication of cylindrical uni-directional porous metal with explosive compaction. Mater. Lett. 2014, 137, 323–327. [Google Scholar] [CrossRef]

- Meyers, M.A.; Murr, L.E. Shock Waves and High-Strain-Rate Phenomena Effects in Metals; Springer US: New York, NY, USA, 1981. [Google Scholar]

- Vesenjak, M.; Nishi, M.; Nishi, T.; Marumo, Y.; Krstulović-Opara, L.; Ren, Z.; Hokamoto, K. Fabrication and Mechanical Properties of Rolled Aluminium Unidirectional Cellular Structure. Metals 2020, 10, 770. [Google Scholar] [CrossRef]

| Layer No. | Layer Material | Type 1 | Type 2 | Type 3 | |||

|---|---|---|---|---|---|---|---|

| #1.1 | #1.2 | #2.1 | #2.2 | #3.1 | #3.2 | ||

| 1 | Cu pipe (do/di/t) | 30/27/1.5 | 30/27/1.5 | 30/27/1.5 | 30/27/1.5 | 30/27/1.5 | 30/27/1.5 |

| 2 | No. of Cu (acryl) bars | 9 (27) | 12 (24) | 9 (27) | 12 (24) | 12 (24) | 18 (18) |

| 3 | Cu pipe (do/di/t) | 22/20/1 | 22/20/1 | 22/20/1 | 22/20/1 | 22/20/1 | 22/20/1 |

| 4 | No. of Cu (acryl) bars | 6 (21) | 9 (18) | 6 (21) | 9 (18) | 9 (18) | 9 (18) |

| 5 | Cu pipe (do/di/t) | 16/14/1 | 16/14/1 | 16/14/1 | 16/14/1 | 16/14/1 | 16/14/1 |

| 6 | No. of Cu (acryl) bars | 4 (14) | 6 (12) | 4 (14) | 6 (12) | 0 (1) | 0 (1) |

| 7 | Cu pipe (do/di/t) | 10/8/1 | 10/8/1 | 10/8/1 | 10/8/1 | - | - |

| 8 | No. of Cu (acryl) bars | 3 (6) | 3 (6) | 0 (1) | 0 (1) | - | - |

| 9 | Cu pipe (do/di/t) | 4/2/1 | 4/2/1 | - | - | - | - |

| 10 | No. of Cu (acryl) bars | 0 (1) | 0 (1) | - | - | - | - |

| Theoretical porosity [%] | 37.7 | 32.2 | 41.5 | 36.5 | 49.3 | 44.3 | |

| Actual porosity [%] | 36.5 | 30.3 | 40.4 | 35.9 | 44.4 | 43.2 | |

| Type 1 | Type 2 | Type 3 | UniPore | UniPore | ||||

|---|---|---|---|---|---|---|---|---|

| #1.1 | #1.2 | #2.1 | #2.2 | #3.1 | #3.2 | Original | Rolled | |

| Porosity (%) | 36.5 | 30.3 | 40.4 | 35.9 | 44.4 | 43.2 | 49 | 42 |

| Force plateau (kN) | 2.74 | 4.96 | 3.05 | 4.11 | 3.06 | 3.20 | 4.19 | 2.92 |

| Energy absorption up to displacement of 5 mm (J) | 13.05 | 23.52 | 14.04 | 18.69 | 13.50 | 14.46 | 20.91 | 13.71 |

| Energy absorption up to displacement of 10 mm (J) | 46.67 | 88.90 | 35.63 | 49.84 | 28.12 | 31.59 | 44.98 | 40.06 |

| Densification (mm) | 4.9 | 3.4 | 11.9 | 8.9 | 11.3 | 10.4 | 11.5 | 8.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vesenjak, M.; Nakashima, Y.; Hokamoto, K.; Ren, Z.; Marumo, Y. Development of Unidirectional Cellular Structure with Multiple Pipe Layers and Characterisation of Its Mechanical Properties. Materials 2020, 13, 3880. https://doi.org/10.3390/ma13173880

Vesenjak M, Nakashima Y, Hokamoto K, Ren Z, Marumo Y. Development of Unidirectional Cellular Structure with Multiple Pipe Layers and Characterisation of Its Mechanical Properties. Materials. 2020; 13(17):3880. https://doi.org/10.3390/ma13173880

Chicago/Turabian StyleVesenjak, Matej, Yutaka Nakashima, Kazuyuki Hokamoto, Zoran Ren, and Yasuo Marumo. 2020. "Development of Unidirectional Cellular Structure with Multiple Pipe Layers and Characterisation of Its Mechanical Properties" Materials 13, no. 17: 3880. https://doi.org/10.3390/ma13173880

APA StyleVesenjak, M., Nakashima, Y., Hokamoto, K., Ren, Z., & Marumo, Y. (2020). Development of Unidirectional Cellular Structure with Multiple Pipe Layers and Characterisation of Its Mechanical Properties. Materials, 13(17), 3880. https://doi.org/10.3390/ma13173880