Binder Jetting Additive Manufacturing of High Porosity 316L Stainless Steel Metal Foams

Abstract

1. Introduction

2. Materials and Methods

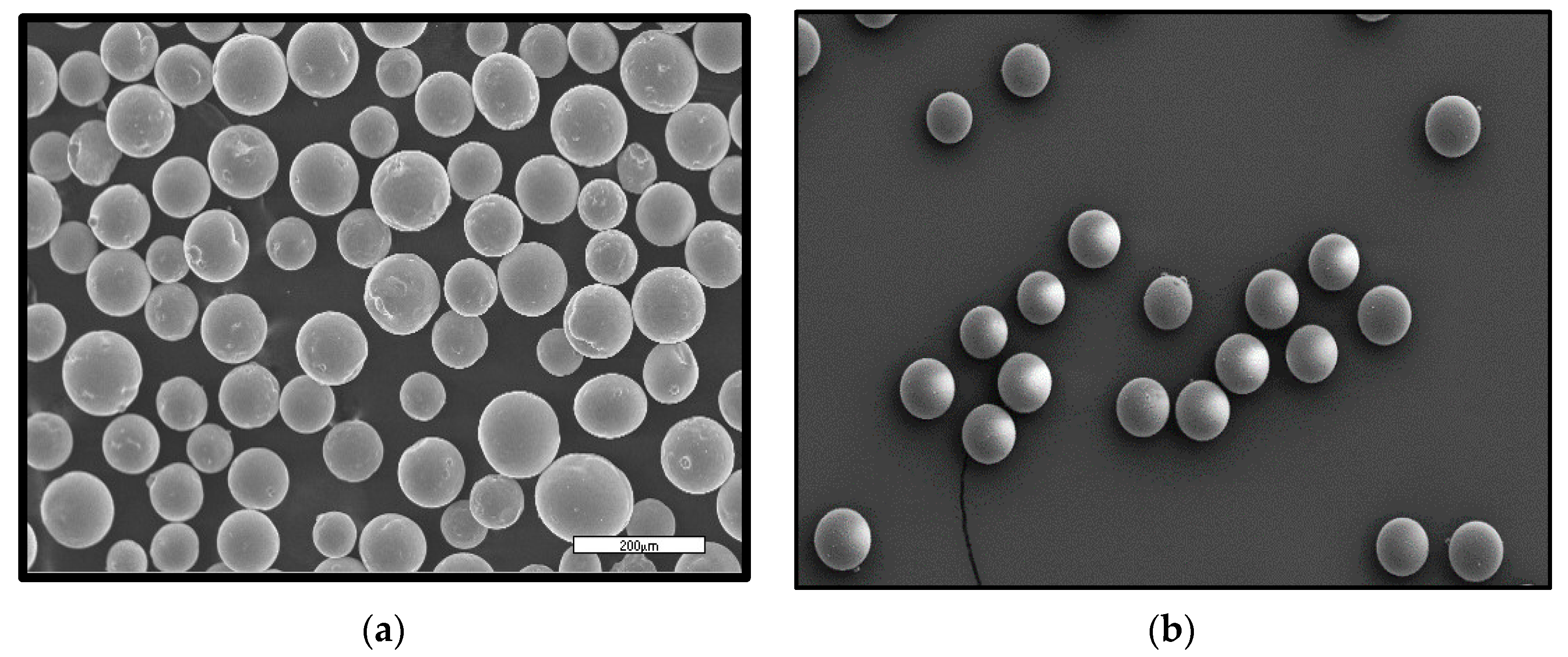

2.1. Feedstock

2.2. Feedstock Characteristics

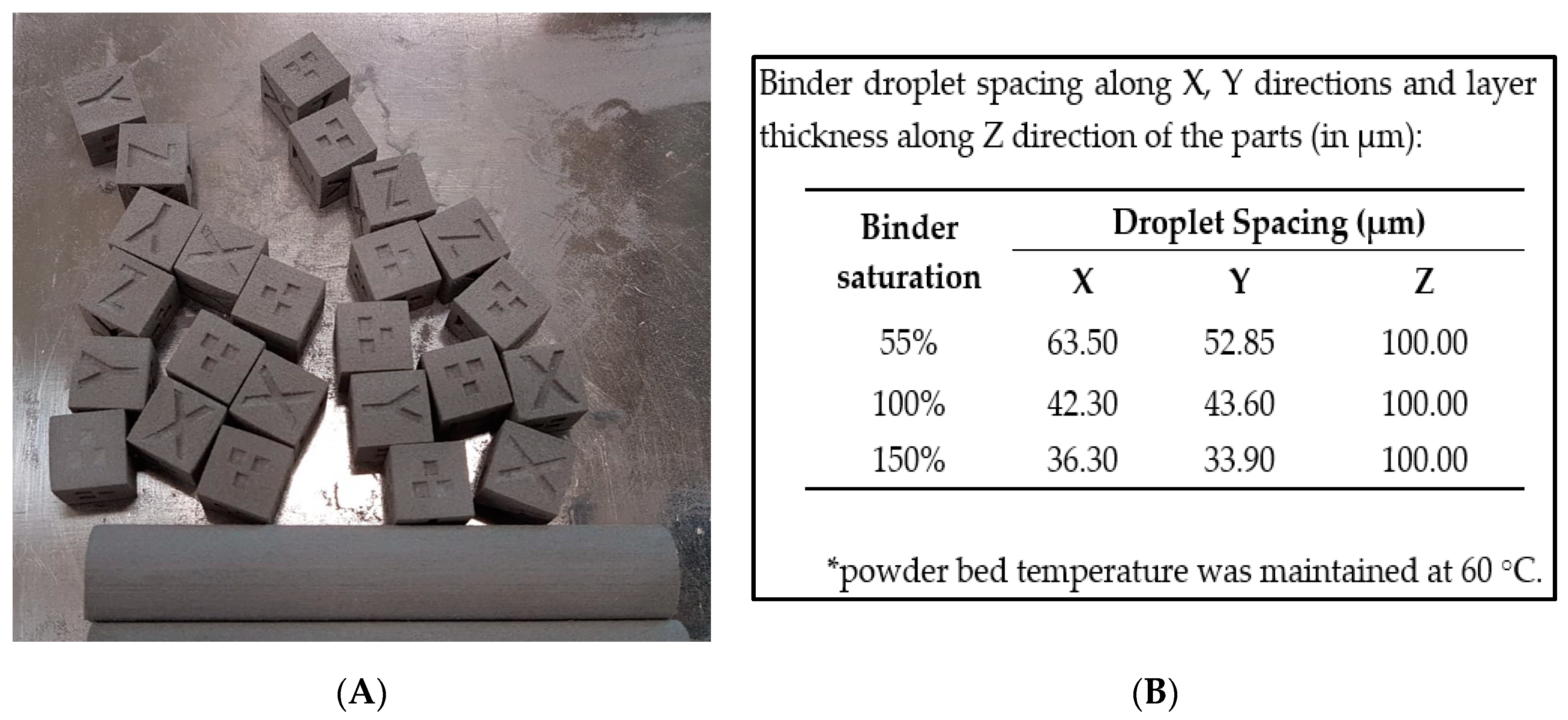

2.3. Three-Dimensional Printing of High Porosity 316L Stainless Steel Via Binder Jetting

2.4. Part Characterization

3. Results and Discussion

3.1. Feedstock Characteristics

3.2. Part Characteristics

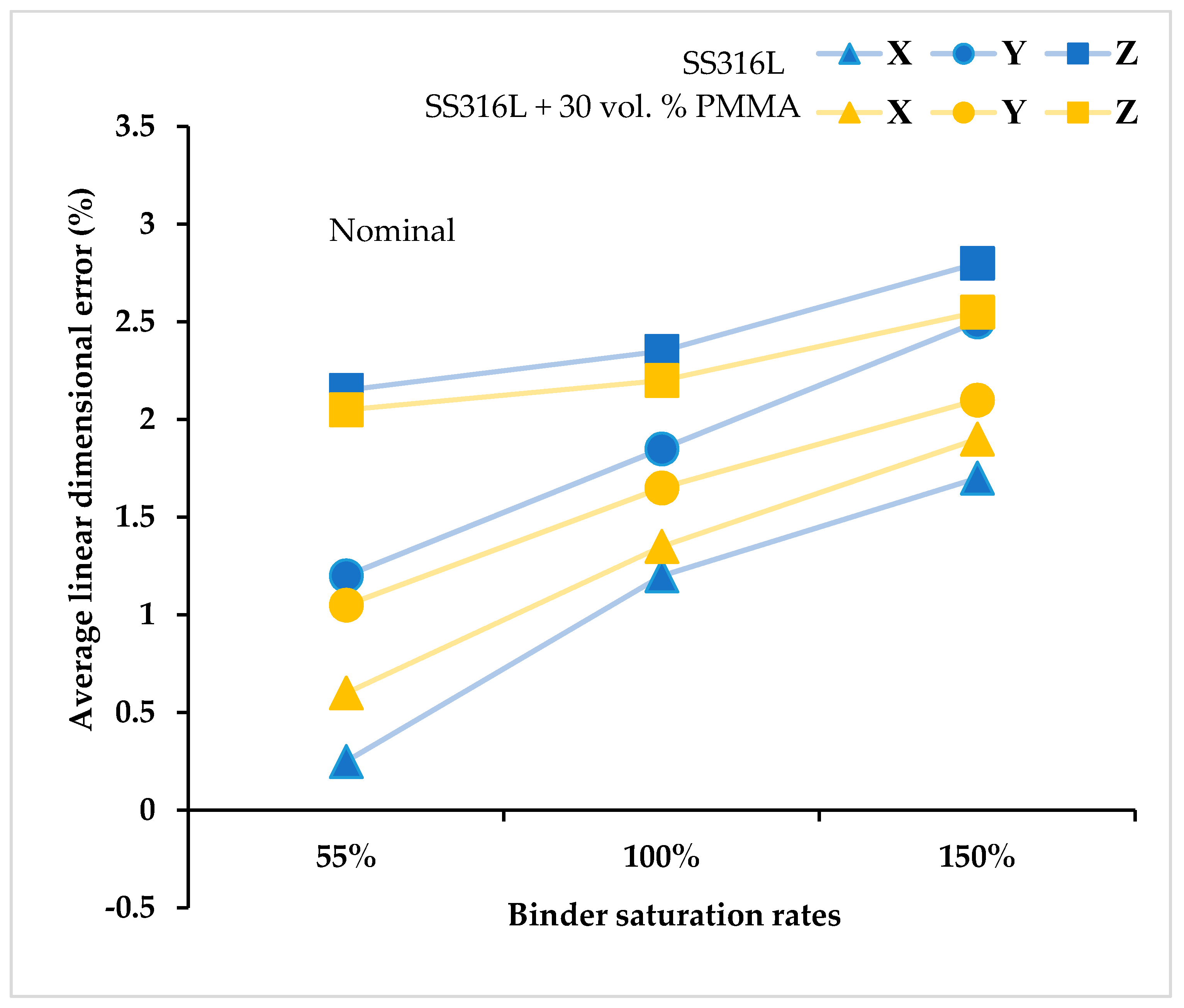

3.2.1. Effect of Binder Saturation Rates on The Dimensional Accuracy of The as-Printed SS316L Parts

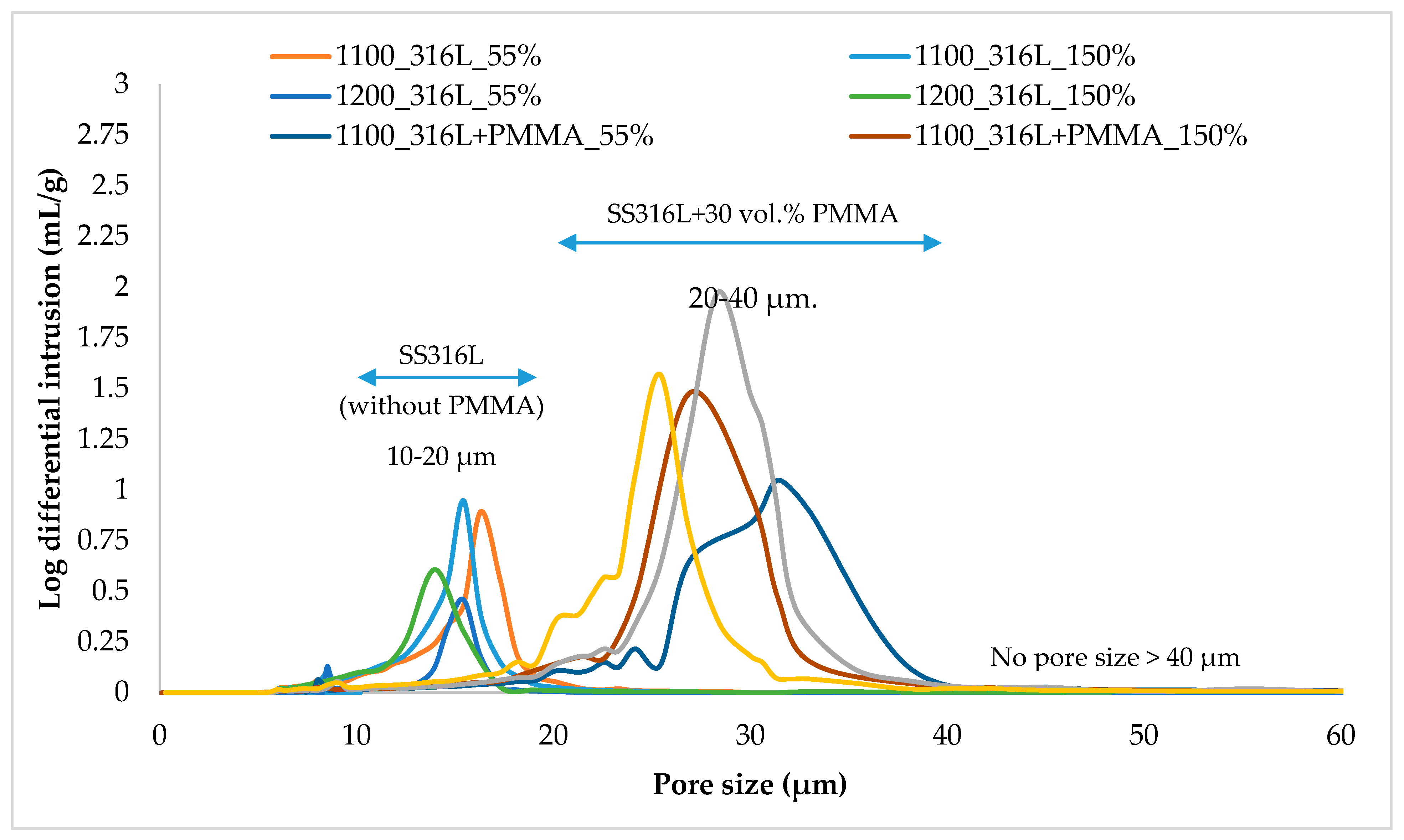

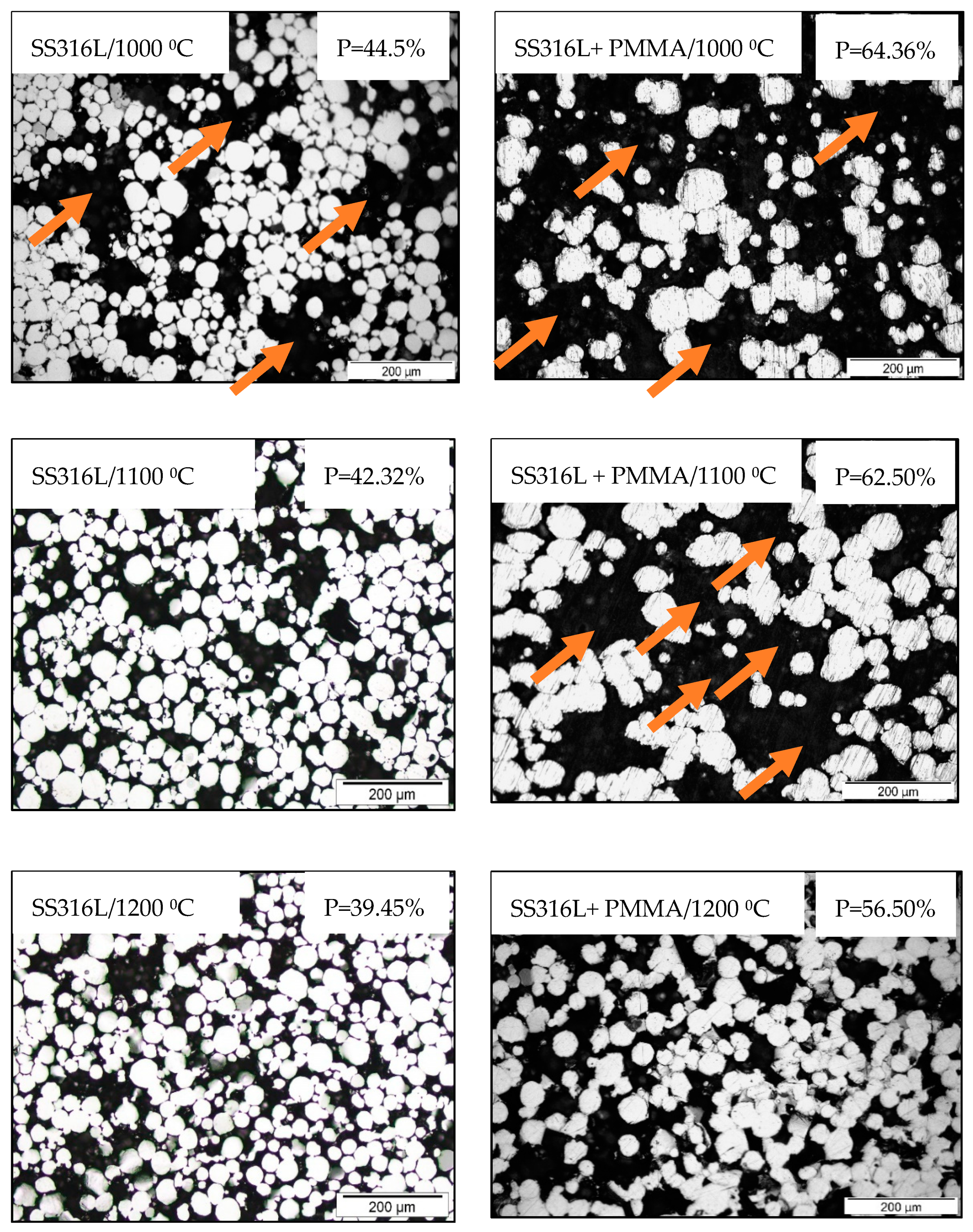

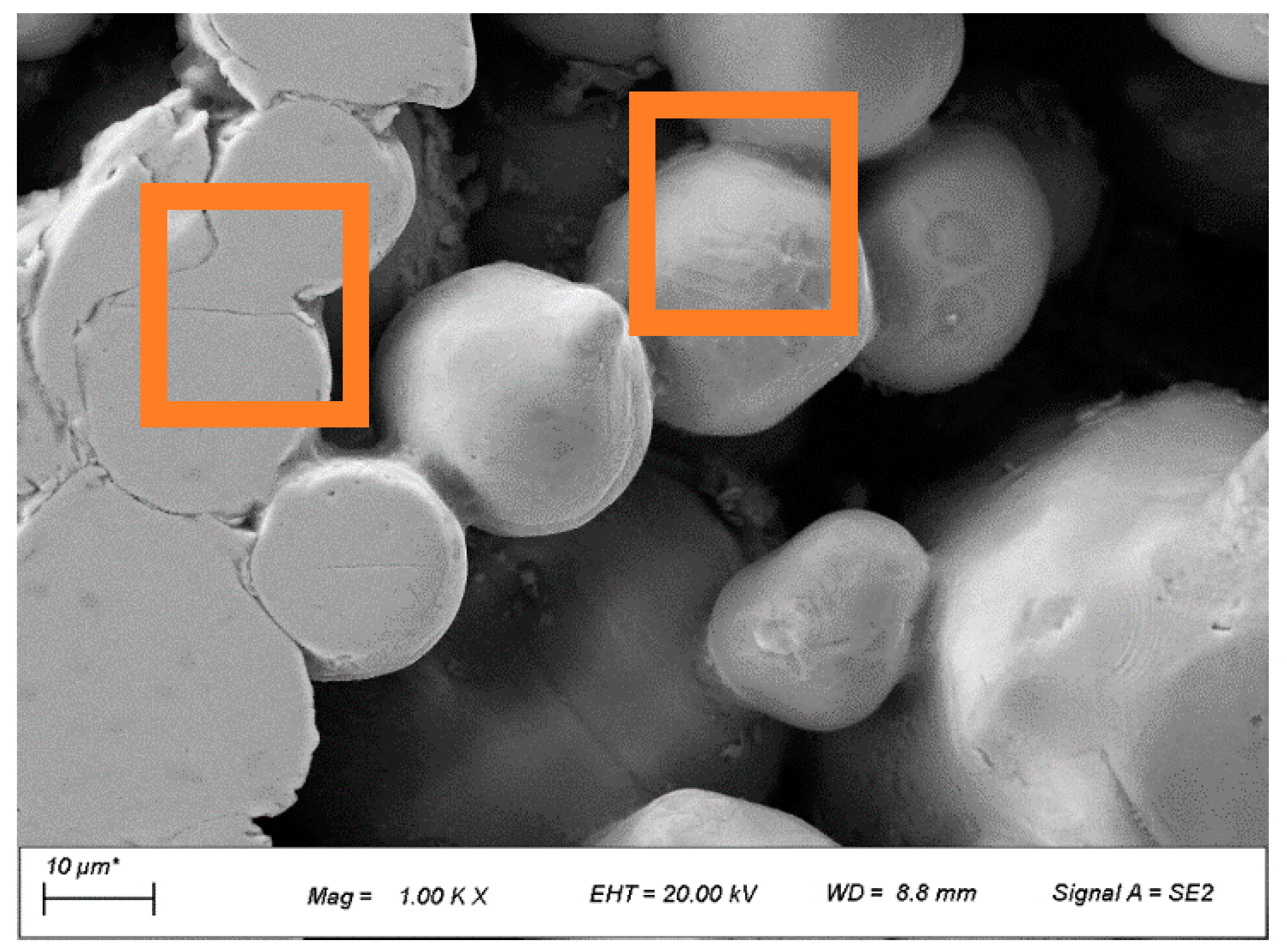

3.2.2. Results of Porosity Measurements

3.2.3. Results of Chemical Analysis

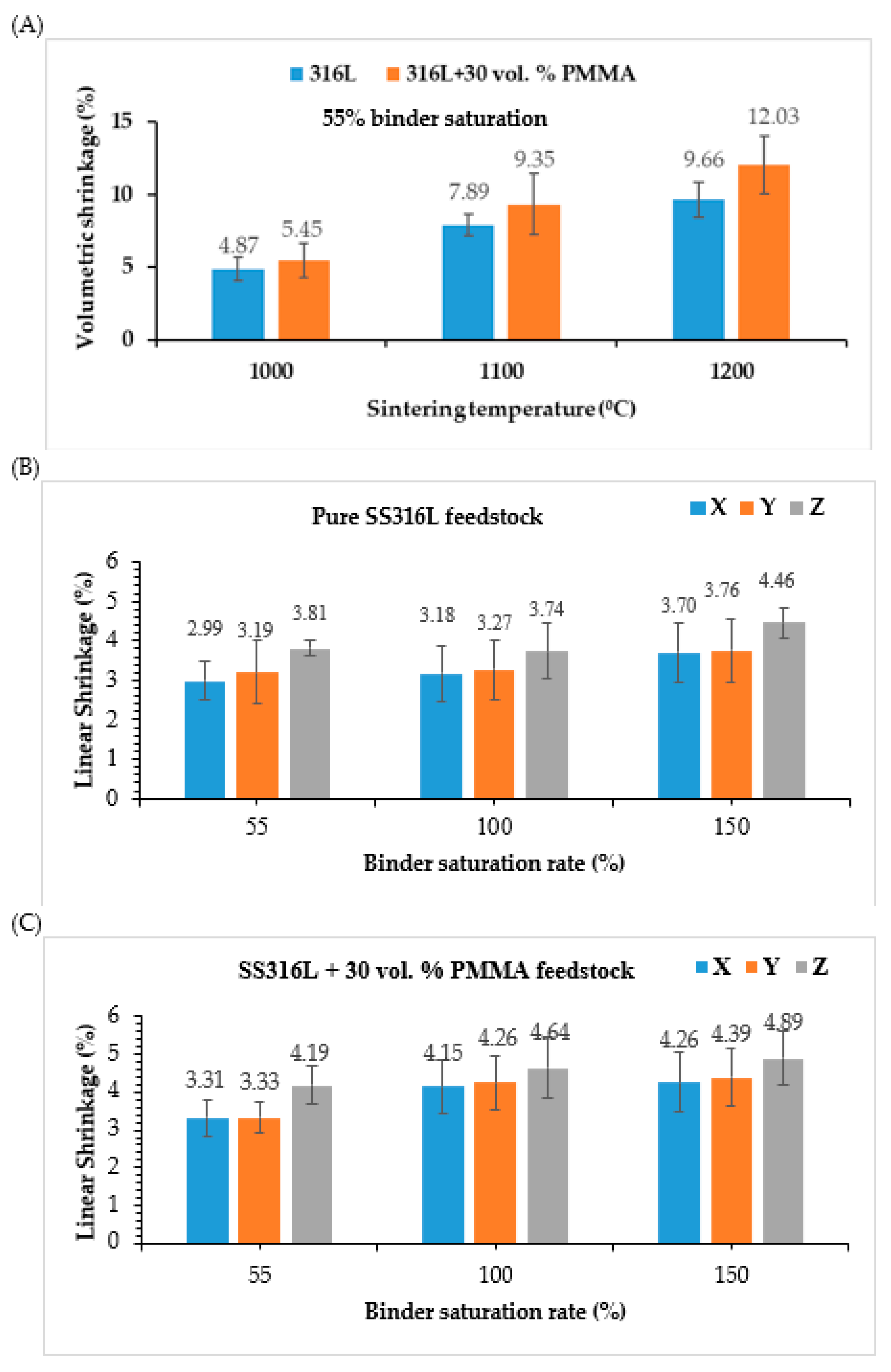

3.2.4. Results of Shrinkage Measurements

3.2.5. Results of Dynamic Young’s Modulus and Compression Properties

4. Conclusions

- Isothermal sintering temperature plays a vital role in controlling the porosity of SS316L parts; porosity increased with decreasing sintering temperatures, whereas varying binder saturation rates affected the porosity values by only ±2%. Through pores-by-processing approach (present study), porosity of 40%–45% was achieved.

- With the addition of 30 vol. % of PMMA powders to the SS316L feedstock, the porosity values of parts sintered up to 1200 °C (2 h, each) increased significantly to 57%–61%.

- Mercury porosimetry results indicated pore sizes of 10–20 µm for the parts fabricated with pure SS316L feedstock and 20–40 µm for the parts fabricated with SS316L + 30 vol. % PMMA feedstock, respectively, with no pore size >40 µm.

- All the parts exhibited anisotropic shrinkage especially along the Z direction predominantly due to the mismatch between the set layer thickness (100 µm) and X & Y binder droplet spacing that varies based on the set binder saturation rates.

- The dynamic Young’s modulus and compression properties of the SS316L stainless steel parts increased with increasing relative density (or decreasing porosity). The SS316L parts fabricated by using pure SS316L feedstock sintered at 1200 °C exhibited the maximum overall compressive properties with 0.2% compressive yield strength of 52.7 MPa, ultimate compressive strength of 520 MPa, fracture strain of 36.4%, and energy absorption of 116.7 MJ/m3, respectively.

- Low Young’s modulus values in the range of 2–29 GPa could be achieved. The Young’s modulus and compression properties of the binder jet SS316L parts were found to be on par with that of the conventionally processed SS316L parts and even surpassed those having similar porosities and matched to that of the cancellous bone types.

- The final chemical composition of the sintered SS316L parts exactly matched the chemical composition of starting SS316L powders with no C, H and O contaminations confirming binder jetting process route to be contamination-free and ideal for fabricating porous austenitic 316L stainless. An optimum binder saturation rate of 55% was found to be more favourable to fabricate contamination-free SS316L parts with high dimensional accuracy.

Author Contributions

Funding

Conflicts of Interest

References

- Gray, G.T., III; Livescu, V.; Rigg, P.A.; Trujillo, C.P.; Cady, C.M.; Chen, S.-R.; Carpenter, J.S.; Lienert, T.J.; Fensin, S.J. Structure/property (constitutive and spallation response) of additively manufactured 316L stainless steel. Acta Mater. 2017, 138, 140–149. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, T.; Fleck, N.A.; Hutchinson, J.W.; Wadley, H.N.G.; Gibson, L.J. Metal Foams: A Design Guide; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Lewis, G. Properties of open-cell porous metals and alloys for orthopaedic applications. J. Mater. Sci. Mater. Med. 2013, 24, 2293–2325. [Google Scholar] [CrossRef] [PubMed]

- Singh, D.; Singh, R.; Boparai, K.S.; Farina, I.; Feo, L.; Verma, A.K. In-vitro studies of SS 316 L biomedical implants prepared by FDM, vapor smoothing and investment casting. Compos. Part B Eng. 2018, 132, 107–114. [Google Scholar] [CrossRef]

- Jha, S.; Rubow, K.L. Sintered Metal Filters for Hot and Corrosive Liquid and Gas Applications. In Proceedings of the 8th World Filtration Congress, Brighton, UK, 4 August 2000; pp. 317–320. [Google Scholar]

- Manonukul, A.; Muenya, N.; Léaux, F.; Amaranan, S. Effects of replacing metal powder with powder space holder on metal foam produced by metal injection moulding. J. Mater. Process. Technol. 2010, 210, 529–535. [Google Scholar] [CrossRef]

- Mutlu, I.; Oktay, E. Characterization of 17-4 PH stainless steel foam for biomedical applications in simulated body fluid and artificial saliva environments. Mater. Sci. Eng. C 2013, 33, 1125–1131. [Google Scholar] [CrossRef] [PubMed]

- Neville, B.; Rabiei, A. Composite metal foams processed through powder metallurgy. Mater. Des. 2008, 29, 388–396. [Google Scholar] [CrossRef]

- Mondal, D.P.; Jain, H.; Das, S.; Jha, A. Stainless steel foams made through powder metallurgy route using NH4HCO3 as space holder. Mater. Des. 2015, 88, 430–437. [Google Scholar] [CrossRef]

- Gülsoy, H.Ö.; German, R.M. Production of micro-porous austenitic stainless steel by powder injection molding. Scr. Mater. 2008, 58, 295–298. [Google Scholar] [CrossRef]

- Laptev, A.M.; Daudt, N.F.; Guillon, O.; Bram, M. Increased Shape Stability and Porosity of Highly Porous Injection-Molded Titanium Parts. Adv. Eng. Mater. 2015, 17, 1579–1587. [Google Scholar] [CrossRef]

- Mirzaei-Aliabadi, M.; Paydar, M.H. A novel process for manufacturing porous 316 L stainless steel with uniform pore distribution. Mater. Des. 2017, 121, 442–449. [Google Scholar] [CrossRef]

- Xie, Z.K.; Yamada, Y.; Banno, T. Fabrication of Micro Porous Aluminum by Powder Sintering. Mater. Sci. Forum 2007, 539, 2778–2781. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, X.Y.; Long, B. Fabrication of Stainless Steel Foams Using Polymeric Sponge Impregnation Technology. Adv. Mater. Res. 2014, 1035, 219–224. [Google Scholar] [CrossRef]

- Jain, H.; Kumar, R.; Gupta, G.; Mondal, D.P. Microstructure, mechanical and EMI shielding performance in open cell austenitic stainless steel foam made through PU foam template. Mater. Chem. Phys. 2020, 241, 122273. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Du, M.; Xie, Z. 316L Stainless Steel with Gradient Porosity Fabricated by Selective Laser Melting. J. Mater. Eng. Perform. 2009, 19, 666–671. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S.; Christensen, A. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 2010, 3, 249–259. [Google Scholar] [CrossRef]

- Farina, I.; Goodall, R.; Hernández-Nava, E.; Di Filippo, A.; Colangelo, F.; Fraternali, F. Design, microstructure and mechanical characterization of Ti6Al4V reinforcing elements for cement composites with fractal architecture. Mater. Des. 2019, 172, 107758. [Google Scholar] [CrossRef]

- Xie, F.; He, X.; Cao, S.; Qu, X. Structural and mechanical characteristics of porous 316L stainless steel fabricated by indirect selective laser sintering. J. Mater. Process. Technol. 2013, 213, 838–843. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Process. Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Stoffregen, H.; Fischer, J.; Siedelhofer, C.; Abele, E. Selective laser melting of porous structures. In Solid Freeform Fabrication Proceedings; University of Texas at Austin: Austin, TX, USA, 2011; pp. 680–695. [Google Scholar]

- Filters, Reusable Respirators with 3D Printed Metal, (n.d.). Available online: https://www.materialstoday.com/additive-manufacturing/news/reusable-respirators-with-3d-printed-metal-filters/ (accessed on 11 May 2020).

- Chou, D.-T.; Wells, D.; Hong, D.H.; Lee, B.; Kuhn, H.; Kumta, P. Novel processing of iron–manganese alloy-based biomaterials by inkjet 3-D printing. Acta Biomater. 2013, 9, 8593–8603. [Google Scholar] [CrossRef]

- Basalah, A.; Shanjani, Y.; Esmaeili, S.; Toyserkani, E. Characterizations of additive manufactured porous titanium implants†. J. Biomed. Mater. Res. Part B Appl. Biomater. 2012, 100, 1970–1979. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Wang, N.; Maskomani, S.; Lu, S.; Anantharajan, S.K.; Dheen, S.T.; Nai, S.M.L.; Fuh, J.Y.H.; Wei, J.; Kumar, A.S.; et al. Fabrication of Ti + Mg composites by three-dimensional printing of porous Ti and subsequent pressureless infiltration of biodegradable Mg. Mater. Sci. Eng. C 2020, 108, 110478. [Google Scholar] [CrossRef]

- Barui, S.; Panda, A.K.; Naskar, S.; Kuppuraj, R.; Basu, S.; Basu, B. 3D inkjet printing of biomaterials with strength reliability and cytocompatibility: Quantitative process strategy for Ti-6Al-4V. Biomaterials 2019, 213, 119212. [Google Scholar] [CrossRef]

- El-Hajje, A.; Kolos, E.C.; Wang, J.K.; Maleksaeedi, S.; He, Z.; Wiria, F.E.; Choong, C.; Ruys, A.J. Physical and mechanical characterisation of 3D-printed porous titanium for biomedical applications. J. Mater. Sci. Mater. Electron. 2014, 25, 2471–2480. [Google Scholar] [CrossRef] [PubMed]

- Miyanaji, H.; Ma, D.; Atwater, M.A.; Darling, K.A.; Hammond, V.H.; Williams, C.B. Binder jetting additive manufacturing of copper foam structures. Addit. Manuf. 2020, 32, 100960. [Google Scholar] [CrossRef]

- Sheydaeian, E.; Toyserkani, E. A system for selectively encapsulating porogens inside the layers during additive manufacturing: From conceptual design to the first prototype. J. Manuf. Process. 2017, 26, 330–338. [Google Scholar] [CrossRef]

- Rishmawi, I.; Salarian, M.; Vlasea, M. Tailoring green and sintered density of pure iron parts using binder jetting additive manufacturing. Addit. Manuf. 2018, 24, 508–520. [Google Scholar] [CrossRef]

- Xu, Z.; Zhu, Z.; Wang, P.; Meenashisundaram, G.K.; Nai, S.M.L.; Wei, J. Fabrication of porous CoCrFeMnNi high entropy alloy using binder jetting additive manufacturing. Addit. Manuf. 2020, 35, 101441. [Google Scholar] [CrossRef]

- ASTM B213-17. Standard Test Methods for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM B212-17. Standard Test Method for Apparent Density of Free-Flowing Metal Powders Using the Hall Flowmeter Funnel; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTMB527-15. Standard Test Method for Tap Density of Metal Powders and Compounds; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTMB923-16. Standard Test Method for Metal Powder Skeletal Density by Helium or Nitrogen Pycnometry; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Washburn, E.W. Note on a Method of Determining the Distribution of Pore Sizes in a Porous Material. Proc. Natl. Acad. Sci. USA 1921, 7, 115–116. [Google Scholar] [CrossRef] [PubMed]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [PubMed]

- ASTME1876-15. Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTME9-19. Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Hausner, H.H. Friction Conditions in a Mass of Metal Powder; Polytechnic Institute of Broklyn University of California: Los Angeles, CA, USA, 1967; Volume 3, pp. 7–13. [Google Scholar]

- Stanford, M.K.; DellaCorte, C.; Daniel, E. Particle Morphology Effects on Flow Characteristics of PS304 Plasma Spray Coating Feedstock Powder Blend. Available online: Ntrs.nasa.gov (accessed on 1 May 2020).

- Xia, M.; Nematollahi, B.; Sanjayan, J. Influence of Binder Saturation Level on Compressive Strength and Dimensional Accuracy of Powder-Based 3D Printed Geopolymer. Mater. Sci. Forum 2018, 939, 177–183. [Google Scholar] [CrossRef]

- Lanzetta, M.; Sachs, E. Improved surface finish in 3D printing using bimodal powder distribution. Rapid Prototyp. J. 2003, 9, 157–166. [Google Scholar] [CrossRef]

- Soltman, D.; Subramanian, V. Inkjet-Printed Line Morphologies and Temperature Control of the Coffee Ring Effect. Langmuir 2008, 24, 2224–2231. [Google Scholar] [CrossRef]

- Maleksaeedi, S.; Meenashisundaram, G.K.; Lu, S.; Salehi, M.; Wei, J. Hybrid Binder to Mitigate Feed Powder Segregation in the Inkjet 3D Printing of Titanium Metal Parts. Metals 2018, 8, 322. [Google Scholar] [CrossRef]

- Patirupanusara, P.; Suwanpreuk, W.; Rubkumintara, T.; Suwanprateeb, J. Effect of binder content on the material properties of polymethyl methacrylate fabricated by three dimensional printing technique. J. Mater. Process. Technol. 2008, 207, 40–45. [Google Scholar] [CrossRef]

- Rajabi, J.; Muhamad, N.; Sulong, A.B.; Fayyaz, A.; Raza, M.R. The effect of nano-sized stainless steel powder addition on mechanical and physical properties of micropowder injection molded part. Mater. Des. 2014, 63, 223–232. [Google Scholar] [CrossRef]

- Ziaee, M.; Tridas, E.M.; Crane, N. Binder-Jet Printing of Fine Stainless Steel Powder with Varied Final Density. JOM 2016, 69, 592–596. [Google Scholar] [CrossRef]

- German, R. Thermodynamics of sintering. Sinter. Adv. Mater. 2010, 3–32. [Google Scholar] [CrossRef]

- German, R. Coarsening in Sintering: Grain Shape Distribution, Grain Size Distribution, and Grain Growth Kinetics in Solid-Pore Systems. Crit. Rev. Solid State Mater. Sci. 2010, 35, 263–305. [Google Scholar] [CrossRef]

- Dewidar, M.M.; A Khalil, K.; Lim, J.; Khalil, K.A. Processing and mechanical properties of porous 316L stainless steel for biomedical applications. Trans. Nonferrous Met. Soc. China 2007, 17, 468–473. [Google Scholar] [CrossRef]

- Ashby, M.F.; Gibson, L.J. Cellular Solids: Structure and Properties; The Press Syndicate of University of Cambridge: Cambridge, UK, 1997; pp. 175–231. [Google Scholar]

- Schade, C.T.; Schaberl, J.; Ridgway, P.A. Development of Stainless Steel and High Alloy Powders. Adv. Powder Metall. Part. Mater. 2002, 2, 148–153. [Google Scholar]

- Wen, C.; Mabuchi, M.; Yamada, Y.; Shimojima, K.; Chino, Y.; Asahina, T. Processing of biocompatible porous Ti and Mg. Scr. Mater. 2001, 45, 1147–1153. [Google Scholar] [CrossRef]

- Evans, F.G. Mechanical Properties of Bone; Charles C. Thomas: Springfield, IL, USA, 1973. [Google Scholar]

- Essa, K.; Jamshidi, P.; Zou, J.; Attallah, M.M.; Hassanin, H. Porosity control in 316L stainless steel using cold and hot isostatic pressing. Mater. Des. 2018, 138, 21–29. [Google Scholar] [CrossRef]

| Materials | Space Holder/Foaming Agent | Applications | Printing Systems | Porosity | Pore Interconnectivity | Average Pore Diameter |

|---|---|---|---|---|---|---|

| Fe-30Mn [23] | – | Biomedical | ExOne Lab | 36.3% | – | 500 µm & 1 mm |

| Pure Ti [24] | PVA | Biomedical | ZCorp 310 plus | 31–43% | – | – |

| Ti + Mg [25] | PVA | Biomedical | ZCorp 310 plus | 3D printed Ti: 41.33% | 82.5% | 97 ± 26 µm |

| Ti + Mg: 7.56% | – | – | ||||

| Ti-6Al-4V [26] | – | Biomedical | Spectrum Z510 | As printed: 52% | 99.8% | 8.9 µm |

| As sintered: 28% | 98.4% | 12.5 µm | ||||

| Pure Ti [27] | PVA | Biomedical | ZCorp 310 plus | Ti + 5% PVA: 32.2–52.7% | – | Median 20 µm |

| Copper [28] | CuO | Electrical, biomedical | ExOne R2 | 41.6–58.1% | – | – |

| Pure Ti [29] | Paraffin/wax progen | Biomedical | PIM integrated binder jet 3D printer | 35–40% | – | 0.37 mm–0.47 mm |

| Iron [30] | PVA | Biomedical and tooling | ZPrint 310 plus | 64.5–91.3% | – | – |

| CoCrFeNiMn [31] | – | Filtration | Innovent, ExOne | 34–40% | 87%–89% | 1 µm–100 µm |

| Elements | As Received SS316L Powders | Sintered SS316L Parts Using Two Types of Feedstock | |||

|---|---|---|---|---|---|

| 55% Binder Saturation | 150% Binder Saturation | ||||

| Pure SS316L | SS316L + 30 vol. % PMMA | Pure SS316L | SS316L + 30 vol. % PMMA | ||

| C 1 | 0.03 | 0.03 | 0.03 | 0.03 | 0.07 |

| Mn | 1.10 | 1.09 | 1.10 | 1.10 | 1.09 |

| Si | 0.74 | 0.73 | 0.74 | 0.74 | 0.73 |

| P | 0.034 | 0.036 | 0.036 | 0.034 | 0.036 |

| S 1 | 0.003 | 0.002 | 0.002 | 0.003 | 0.002 |

| Cr | 16.74 | 16.73 | 16.73 | 16.74 | 16.73 |

| Mo | 2.44 | 2.38 | 2.38 | 2.44 | 2.38 |

| Ni | 12.97 | 12.77 | 12.77 | 12.97 | 12.77 |

| Cu | 0.10 | 0.11 | 0.11 | 0.10 | 0.11 |

| Co | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

| Nb | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| V | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| W | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| O 2 | 0.034 | 0.33 | 0.033 | 0.34 | 0.033 |

| N 3 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| H 3 | 0.0013 | 0.0017 | 0.0017 | 0.0013 | 0.0017 |

| Fe | Balance | Balance | Balance | Balance | Balance |

| Powder Samples | Flowability Characteristics | Density Characteristics (g/cm3) | Hausner Ratio, HR (B/A) | Powder Packing Factor p.f (%) | |||

|---|---|---|---|---|---|---|---|

| Hall Flow Rate (s. 50 g−1) | Apparent (A) | Tapped (B) | True (C) | Apparent p.f (A/C) × 100 | Tapped p.f (B/C) × 100 | ||

| As received SS316L powders | 18 s 18′ | 4.601 | 4.928 | 7.929 | 1.071 | 58.02 | 62.15 |

| SS316L + 30 vol. % PMMA | 28 s 11′ | 3.054 | 3.720 | 5.953 | 1.218 | 51.30 | 62.48 |

| Part Name | Porosity (%) | Average Pore Size (µm) |

|---|---|---|

| 1100_316L_55% | 42.50 ± 3.0 | 16.30 ± 1.50 |

| 1100_316L_150% | 42.70 ± 2.5 | 15.45 ± 0.70 |

| 1200_316L_55% | 38.70 ± 2.0 | 15.45 ± 1.00 |

| 1200_316L_150% | 38.20 ± 2.0 | 13.95 ± 1.50 |

| 1100_316L+PMMA_55% | 60.45 ± 3.0 | 28.35 ± 3.50 |

| 1100_316L+PMMA_150% | 58.60 ± 2.5 | 26.85 ± 2.00 |

| 1200_316L+PMMA_55% | 58.65 ± 3.0 | 30.60 ± 3.50 |

| 1200_316L+PMMA_150% | 56.10 ± 3.5 | 25.44 ± 2.50 |

| Part Description | Sintering Temperature [°C] | Total Porosity [%] | Density [g/cm3] | Average Pore Size [µm] | Dynamic Young’s Modulus [GPa] | 0.2%CYS [MPa] | Specific Compressive Strength [MPa/(g/cm3)] | UCS [MPa] | Fracture Strain [%] | Work of Fracture or Energy Absorption [MJ/m3] |

|---|---|---|---|---|---|---|---|---|---|---|

| SS316L (Present study) | 1000 | 45.33 | 4.3736 | 16 ± 2 | 10.52 ± 0.02 | 26.4 ± 2 | 6.03 | 47.3 ± 5 | 5.17 ± 1 | 2.4 ± 0.5 |

| 1100 | 44.08 | 4.4736 | 19.38 ± 0.03 | 34.7 ± 2 | 7.75 | 172.6 ± 12 | 24.09 ± 2 | 26.4 ± 3 | ||

| 1200 | 40.32 | 4.7744 | 28.66 ± 0.03 | 52.70 ± 5 | 11.05 | 520 ± 10 | 36.4 ± 2 | 116.7 ± 8 | ||

| SS316L + 30 vol % PMMA (Present study) | 1000 | 61.18 | 3.1056 | 28 ± 2 | 1.99 ± 0.02 | Very fragile parts failed at low compressive loading | ||||

| 1100 | 60.20 | 3.1840 | 3.81 ± 0.02 | 12.6 ± 2 | 3.95 | 34.9 ± 3 | 13.29 ± 3 | 3.9 ± 0.5 | ||

| 1200 | 57.67 | 3.3864 | 4.13 ± 0.03 | 16.2 ± 3 | 4.78 | 75.4 ± 5 | 27.3 ± 2 | 13.8 ± 1 | ||

| Femoral head [55] | – | – | – | – | 2.9 | 68 | – | – | – | – |

| Femoral condyle [55] | – | – | – | – | 4.9 | 32 | – | – | – | – |

| Vertebra [55] | – | – | – | – | 1.5 | 4.1 | – | – | – | – |

| SS316L 1 [19] | 1100 | 57 | – | 160 | 1.58 | 15.5 | 4.50 | – | – | – |

| SS316L 1 [19] | 1200 | 45 | – | – | 3.27 | 36.3 | 8.25 | – | – | – |

| SS316L 1 [19] | 1300 | 30 | – | 35 | 6.64 | 52.8 | 9.42 | – | – | – |

| SS316L 1 [51] | 1150 | 46 | – | – | – | 25 | 5.78 | – | – | – |

| SS316L 2 [12] | 1200 | 71.5 | – | 1750–2350 | 1.05 | 14.1 | 6.18 | – | – | – |

| SS316L 2 [12] | 1200 | 64.8 | – | 2.03 | 28.8 | 10.22 | – | – | – | |

| SS316L 3 [56] | 920 (103 MPa) | 25.4 | – | 10–57 | 18 | 110 | 16.77 | – | 25 | – |

| Austenitic Steel foam 4 [15] | 1200 | 68 | 2.56 | 350–400 | 7.31 | 10.5 | 4.101 | – | – | 3.5 ± 0.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meenashisundaram, G.K.; Xu, Z.; Nai, M.L.S.; Lu, S.; Ten, J.S.; Wei, J. Binder Jetting Additive Manufacturing of High Porosity 316L Stainless Steel Metal Foams. Materials 2020, 13, 3744. https://doi.org/10.3390/ma13173744

Meenashisundaram GK, Xu Z, Nai MLS, Lu S, Ten JS, Wei J. Binder Jetting Additive Manufacturing of High Porosity 316L Stainless Steel Metal Foams. Materials. 2020; 13(17):3744. https://doi.org/10.3390/ma13173744

Chicago/Turabian StyleMeenashisundaram, Ganesh Kumar, Zhengkai Xu, Mui Ling Sharon Nai, Shenglu Lu, Jyi Sheuan Ten, and Jun Wei. 2020. "Binder Jetting Additive Manufacturing of High Porosity 316L Stainless Steel Metal Foams" Materials 13, no. 17: 3744. https://doi.org/10.3390/ma13173744

APA StyleMeenashisundaram, G. K., Xu, Z., Nai, M. L. S., Lu, S., Ten, J. S., & Wei, J. (2020). Binder Jetting Additive Manufacturing of High Porosity 316L Stainless Steel Metal Foams. Materials, 13(17), 3744. https://doi.org/10.3390/ma13173744