Feasibility of Using a Prosthetic-Based Impression Template to Improve the Trueness and Precision of a Complete Arch Digital Impression on Four and Six Implants: An In Vitro Study

Abstract

1. Introduction

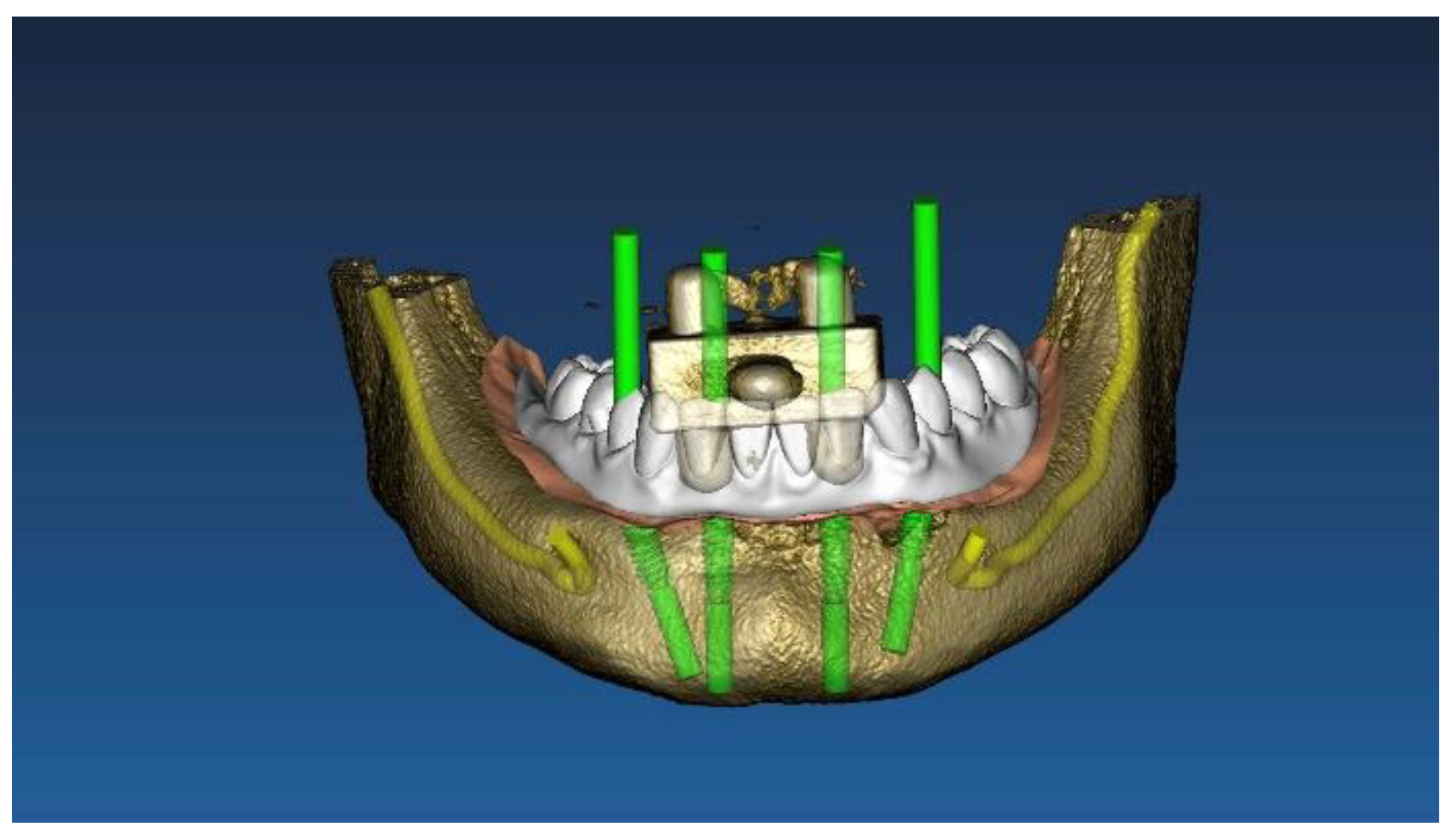

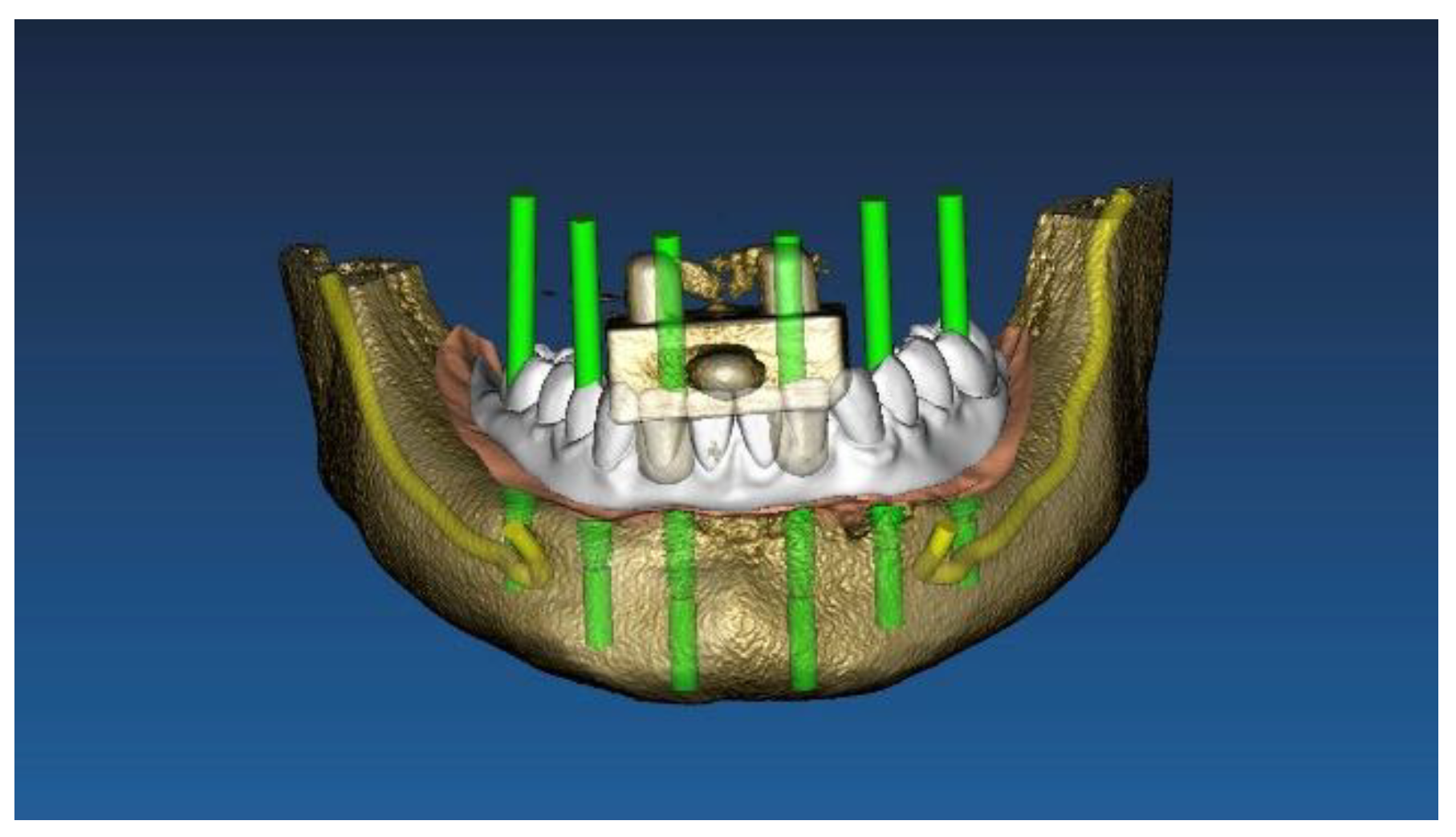

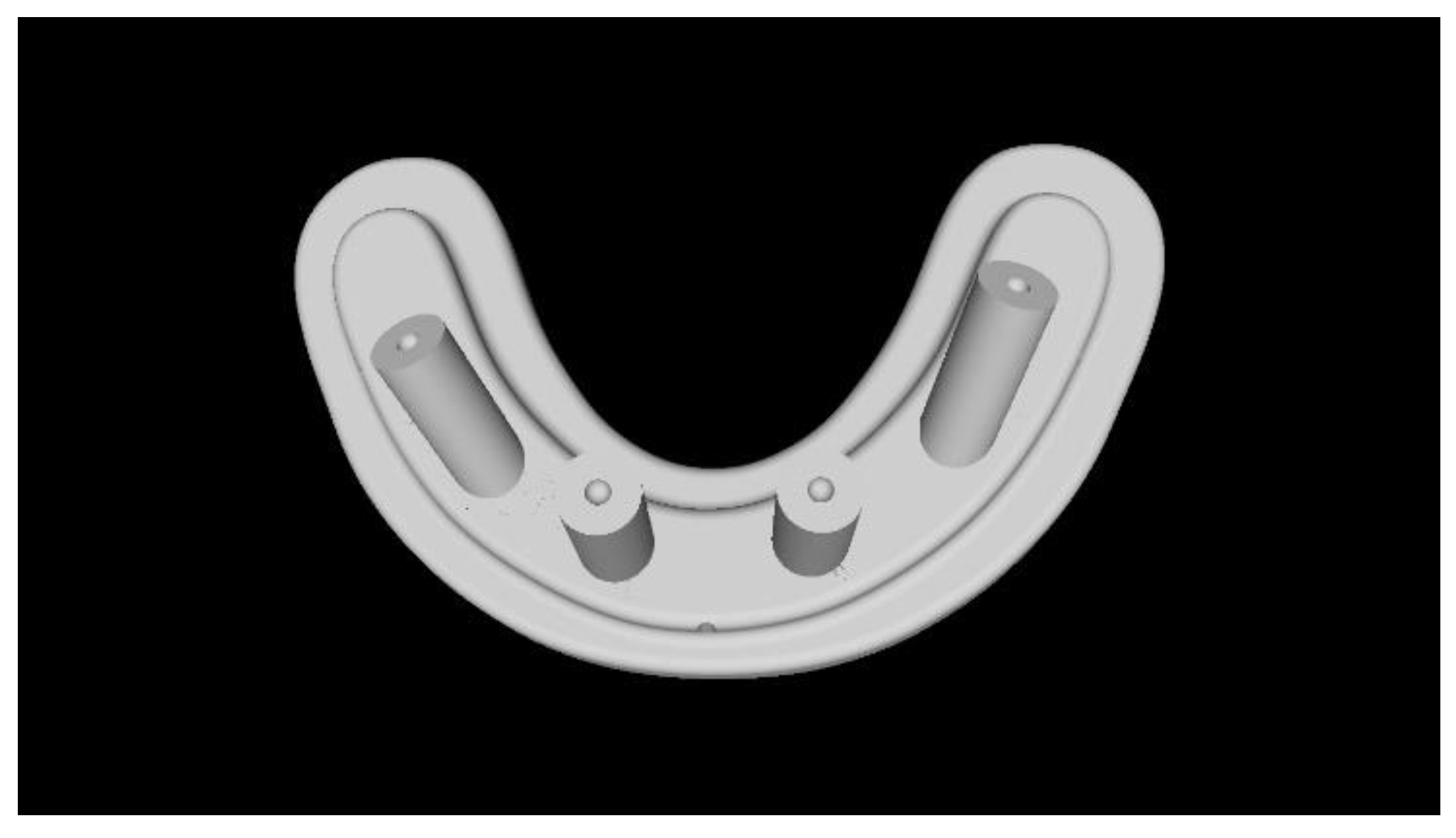

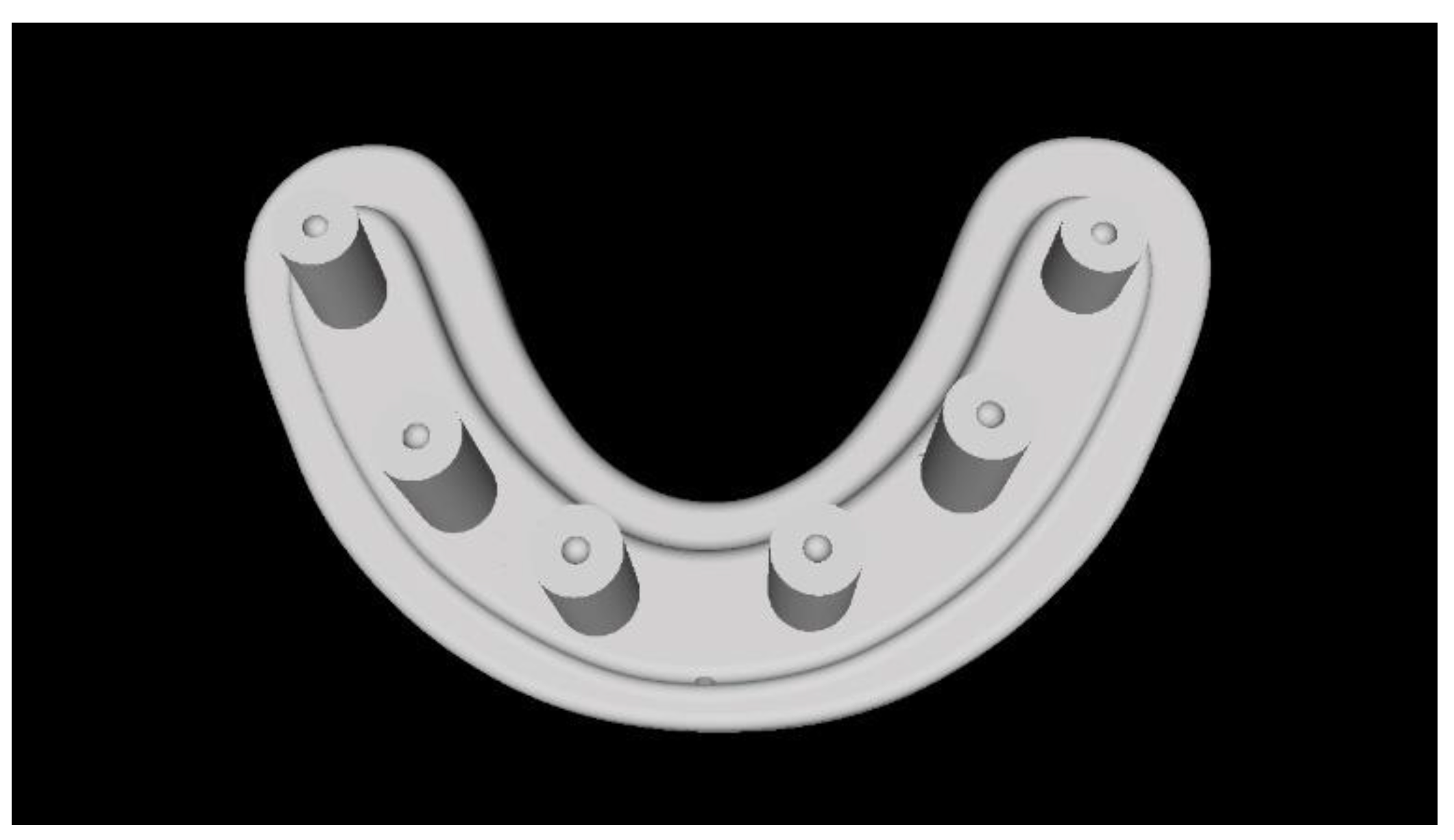

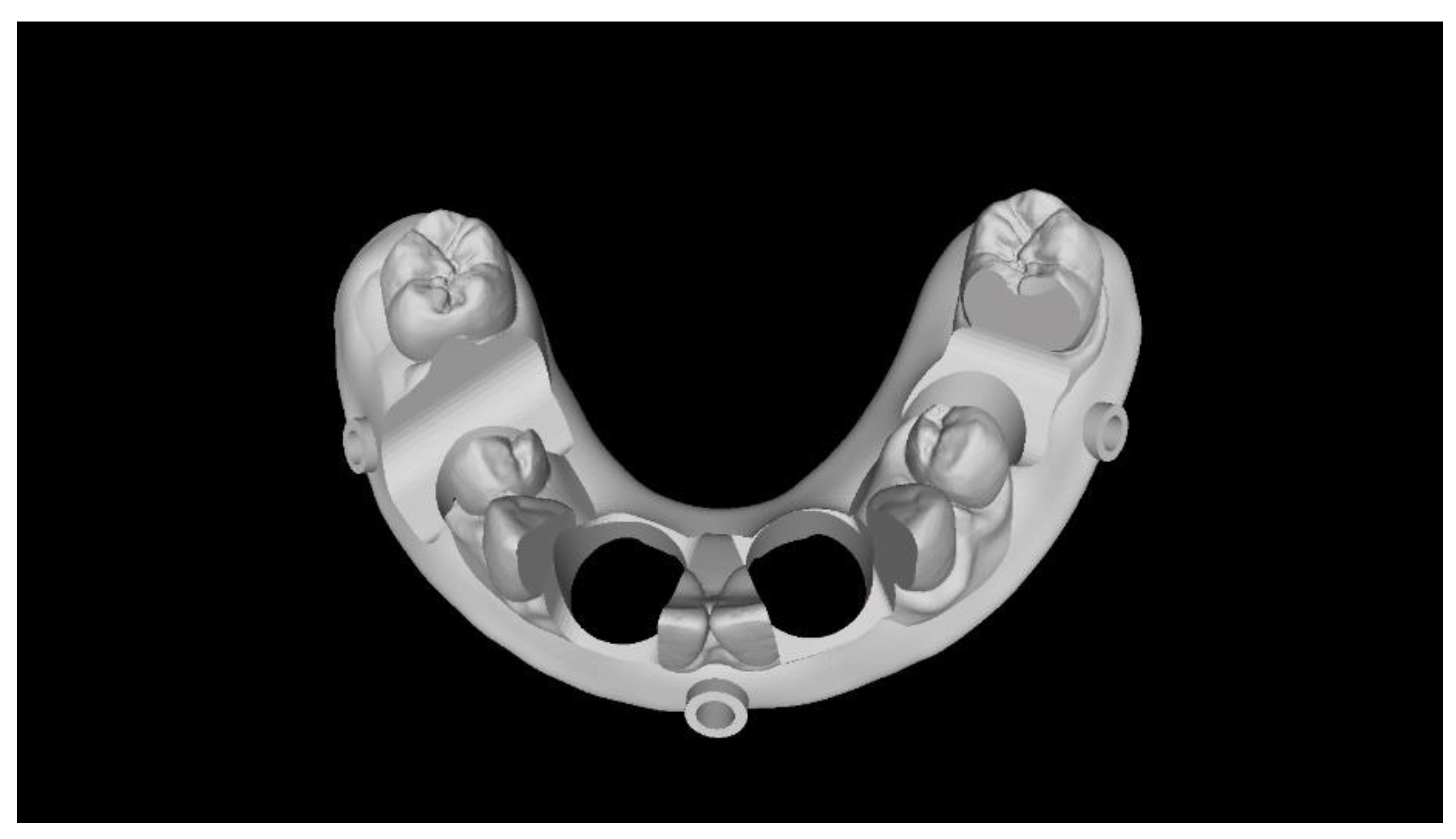

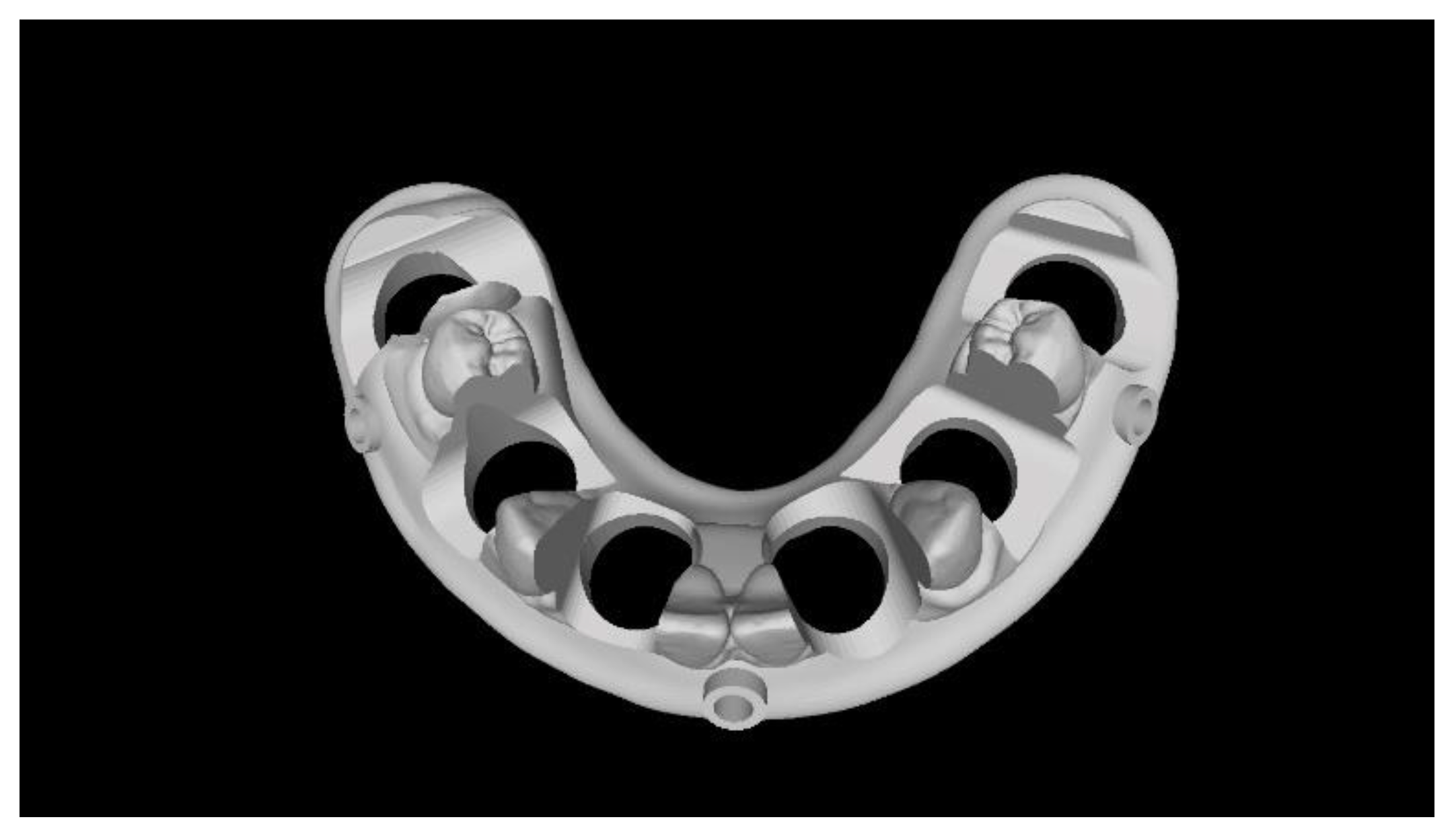

2. Materials and Methods

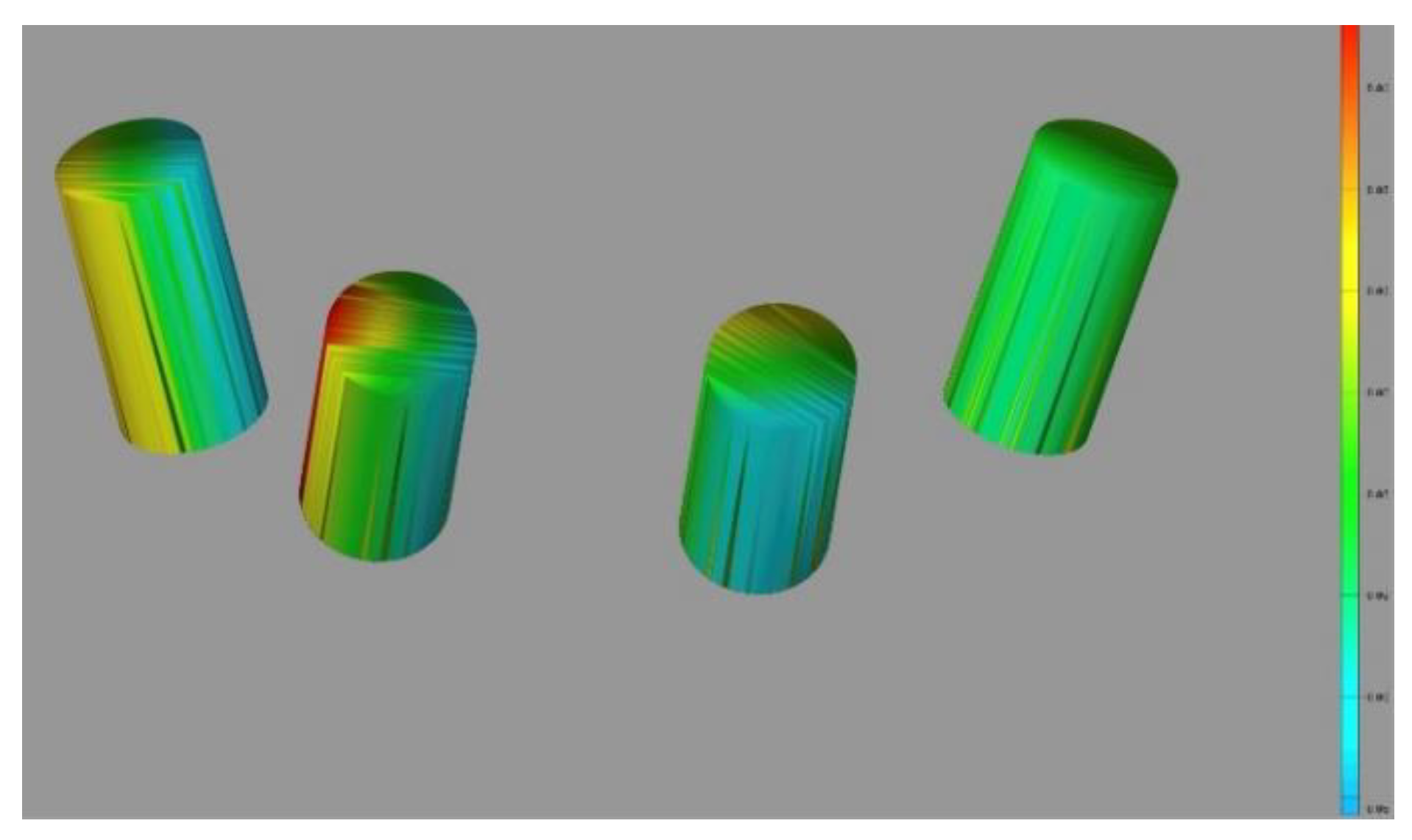

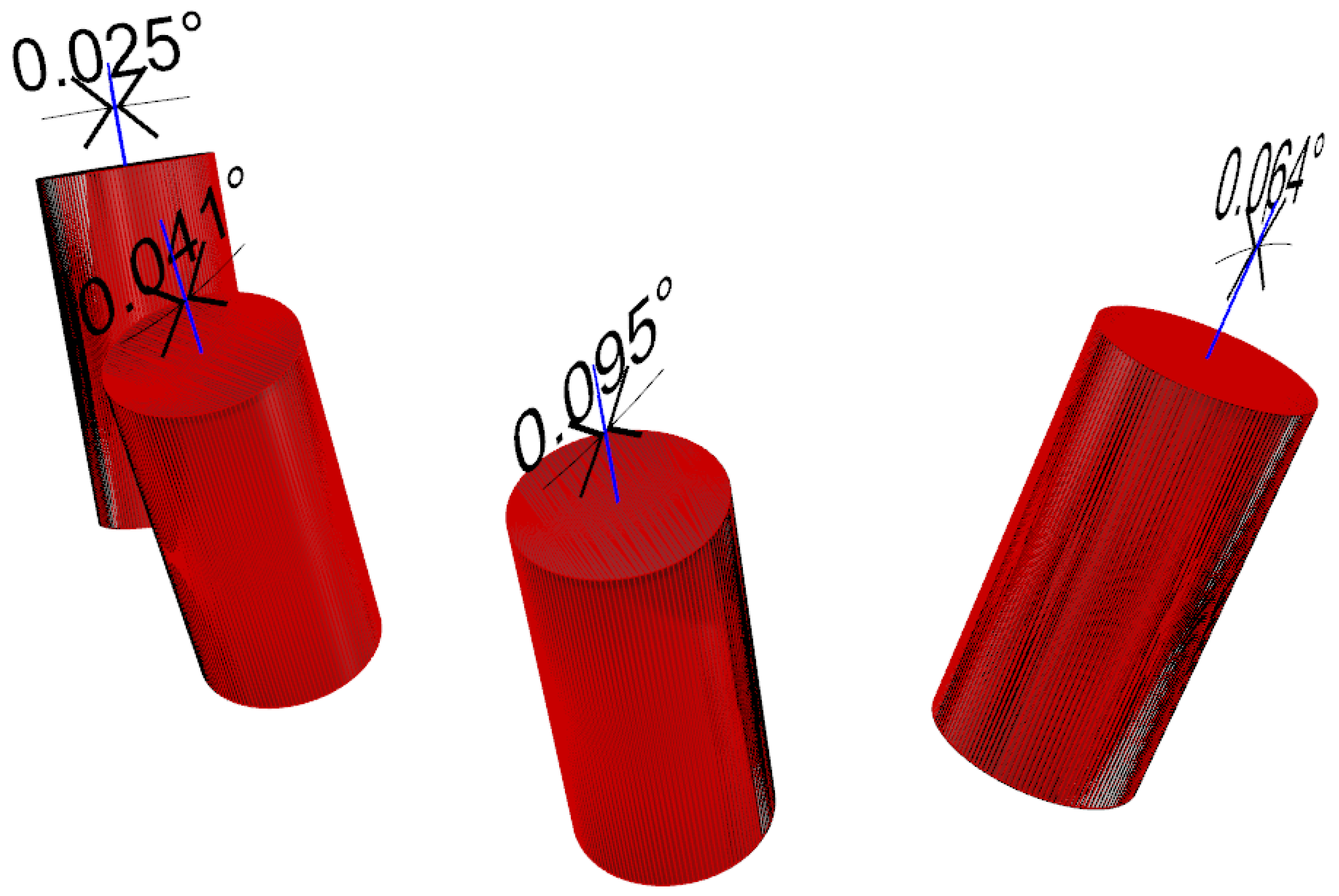

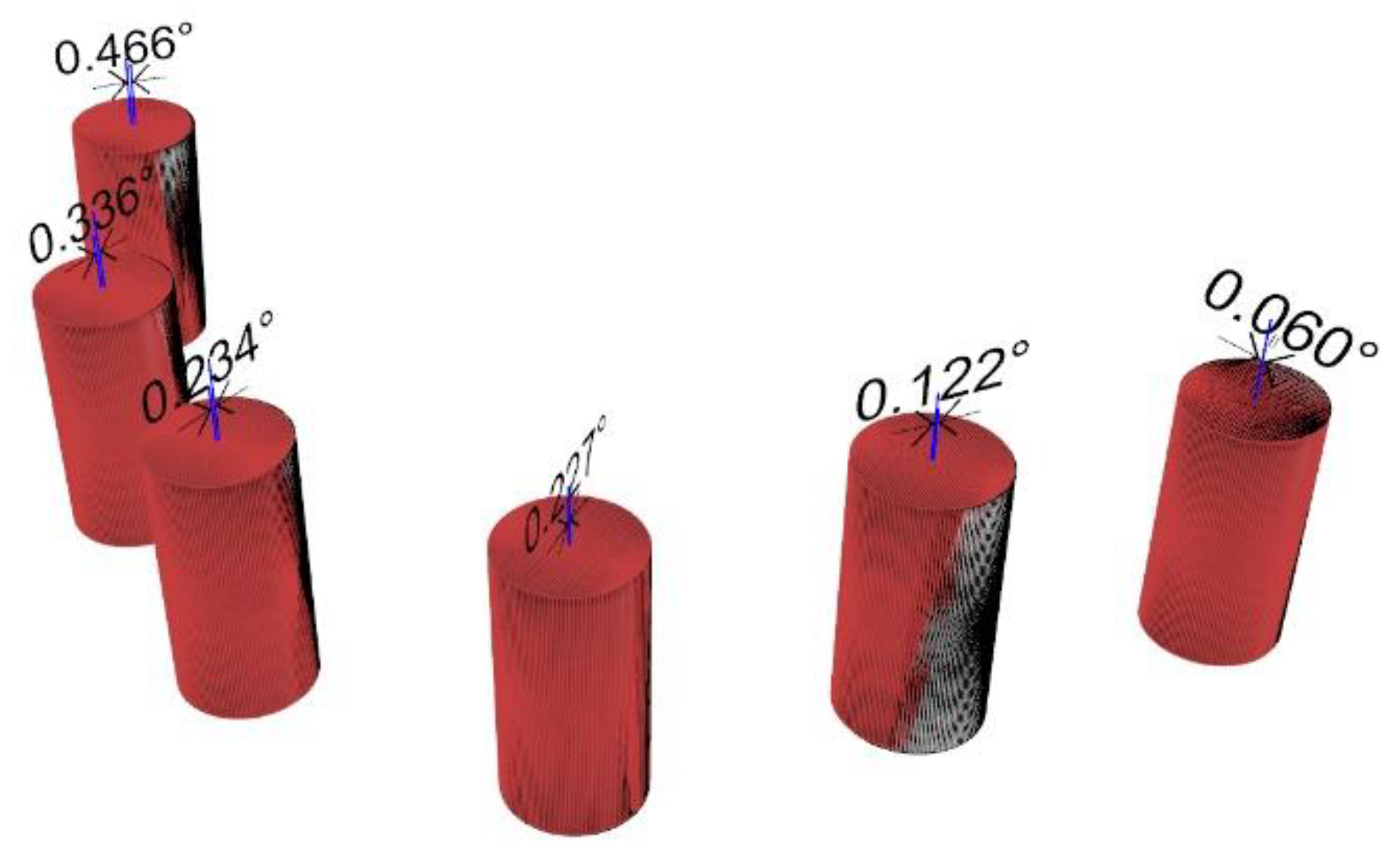

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tallarico, M. Computerization and Digital Workflow in Medicine: Focus on Digital Dentistry. Materials 2020, 13, 2172. [Google Scholar] [CrossRef]

- Tallarico, M.; Erta, X.; Kim, J.Y.; Cocchi, F.; Martinolli, M.; Adem, A.; Meloni, S.M. Accuracy of computer-assisted template-based implant placement using conventional impression and scan model or intraoral digital impression: A randomised controlled trial with 1 year of follow-up. Int. J. Oral Implantol. 2019, 12, 197–206. [Google Scholar]

- Mangano, F.; Mangano, C.; Margiani, B.; Admakin, O. Combining Intraoral and Face Scans for the Design and Fabrication of Computer-Assisted Design/Computer-Assisted Manufacturing (CAD/CAM) Polyether-Ether-Ketone (PEEK) Implant-Supported Bars for Maxillary Overdentures. Scanning 2019, 2019, 4274715. [Google Scholar] [CrossRef]

- Mangano, F.; Hauschild, U.; Veronesi, G.; Imburgia, M.; Mangano, C.; Admakin, O. Trueness and precision of 5 intraoral scanners in the impressions of single and multiple implants: A comparative in vitro study. BMC Oral Health 2019, 19, 101. [Google Scholar] [CrossRef]

- Vandeweghe, S.; Vervack, V.; Dierens, M.; De Bruyn, H. Accuracy of digital impressions of multiple dental implants: An in vitro study. Clin. Oral Implant. Res. 2017, 28, 648–653. [Google Scholar] [CrossRef]

- Tallarico, M.; Canullo, L.; Caneva, M.; Ozcan, M. Microbial colonization at the implant-abutment interface and its possible influence on periimplantitis: A systematic review and meta-analysis. J. Prosthodont. Res. 2017, 61, 233–241. [Google Scholar] [CrossRef] [PubMed]

- Tallarico, M.; Kim, Y.J.; Cocchi, F.; Martinolli, M.; Meloni, S.M. Accuracy of newly developed sleeve-designed templates for insertion of dental implants: A prospective multicenters clinical trial. Clin. Implant. Dent. Relat. Res. 2018, 11, 203–206. [Google Scholar] [CrossRef] [PubMed]

- Tallarico, M.; Martinolli, M.; Kim, Y.-J.; Cocchi, F.; Meloni, S.M.; Alushi, A.; Xhanarim, E. Accuracy of Computer-Assisted Template-Based Implant Placement Using Two Different Surgical Templates Designed with or without Metallic Sleeves: A Randomized Controlled Trial. Dent. J. 2019, 7, 41. [Google Scholar] [CrossRef] [PubMed]

- Cervino, G.; Fiorillo, L.; Arzukanyan, A.V.; Spagnuolo, G.; Cicciu, M. Dental Restorative Digital Workflow: Digital Smile Design from Aesthetic to Function. Dent. J. 2019, 7, 30. [Google Scholar] [CrossRef]

- Jacobs, R.; Salmon, B.; Codari, M.; Hassan, B.; Bornstein, M.M. Cone beam computed tomography in implant dentistry: Recommendations for clinical use. BMC Oral Health 2018, 18, 88. [Google Scholar] [CrossRef]

- Lee, J.H.; Yun, J.H.; Han, J.S.; Yeo, I.L.; Yoon, H.I. Repeatability of Intraoral Scanners for Complete Arch Scan of Partially Edentulous Dentitions: An In Vitro Study. J. Clin. Med. 2019, 8, 1187. [Google Scholar] [CrossRef] [PubMed]

- Lo Russo, L.; Caradonna, G.; Troiano, G.; Salamini, A.; Guida, L.; Ciavarella, D. Three- dimensional differences between intraoral scans and conventional impressions of edentulous jaws: A clinical study. J. Prosthet. Dent. 2020, 123, 264–268. [Google Scholar] [CrossRef]

- Papaspyridakos, P.; Gallucci, G.; Chen, C.; Hanssen, S.; Naert, I.; Vandenberghe, B. Digital versus conventional implant impressions for edentulous patients: Accuracy outcomes. Clin. Oral Implant. Res. 2016, 27, 465–472. [Google Scholar] [CrossRef] [PubMed]

- Amin, S.; Weber, H.; Finkelman, M.; El Rafie, K.; Kudara, Y.; Papaspyridakos, P. Digital vs. conventional full-arch implant impressions: A comparative study. Clin. Oral Implant. Res. 2017, 28, 1360–1367. [Google Scholar] [CrossRef] [PubMed]

- Di Fiore, A.; Meneghello, R.; Graiff, L.; Savio, G.; Vigolo, P.; Monaco, C.; Stellini, E. Full arch digital scanning systems performances for implant-supported fixed dental prostheses: A comparative study of 8 intraoral scanners. J. Prosthodont. Res. 2019, 63, 396–403. [Google Scholar] [CrossRef]

- Pesce, P.; Pera, F.; Setti, P.; Menini, M. Precision and accuracy of a digital impression scanner in full-arch implant rehabilitation. Int. J. Prosthodont. 2018, 31, 171–175. [Google Scholar] [CrossRef]

- Albdour, E.A.; Shaheen, E.; Vranckx, M.; Mangano, F.G.; Politis, C.; Jacobs, R. A novel in vivo method to evaluate trueness of digital impressions. BMC Oral Health 2018, 18, 117. [Google Scholar] [CrossRef]

- Nedelcu, R.; Olsson, P.; Nyström, I.; Rydén, J.; Thor, A. Accuracy and precision of 3 intraoral scanners and accuracy of conventional impressions: A novel in vivo analysis method. J. Dent. 2018, 69, 110–118. [Google Scholar] [CrossRef]

- Tallarico, M.; Schiappa, D.; Schipani, F.; Cocchi, F.; Annucci, M.; Xhanari, E. Improved fully digital work- flow to rehabilitate an edentulous patient with an implant overdenture in 4 appointments: A case report. J. Oral Sci. Rehabil. 2017, 3, 38–46. [Google Scholar]

- Tallarico, M.; Xhanari, E.; Martinolli, M.; Baldoni, E.; Meloni, S.M. Extraoral chairside digitalization: Clinical reports on a new digital protocol for surgical and prosthetic treatment of completely edentulous patients. J. Oral Sci. Rehabil. 2018, 22, 1–5. [Google Scholar]

- Tallarico, M.; Canullo, L.; Pisano, M.; Penarrocha-Oltra, D.; Peñarrocha-Diago, M.; Meloni, S.M. An up to 7-Year Retrospective Analysis of Biologic and Technical Complication with the All-on-4 Concept. J. Oral Implantol. 2016, 42, 265–271. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://goodcalculators.com/one-way-anova-calculator/ (accessed on 15 June 2020).

- Available online: https://www.socscistatistics.com/effectsize/default3.aspx (accessed on 15 June 2020).

- Available online: https://www.danielsoper.com/statcalc/calculator.aspx?id=49 (accessed on 15 June 2020).

- Available online: https://www.socscistatistics.com/tests/fisher/default2.aspx (accessed on 15 June 2020).

- Tallarico, M.; Caneva, M.; Baldini, N.; Gatti, F.; Duvina, M.; Billi, M.; Iannello, G.; Piacentini, G.; Meloni, S.; Cicciù, M. Patient-centered rehabilitation of single, partial, and complete edentulism with cemented- or screw-retained fixed dental prosthesis: The First Osstem Advanced Dental Implant Research and Education Center Consensus Conference 2017. Eur. J. Dent. 2018, 12, 617. [Google Scholar] [CrossRef] [PubMed]

- Papaspyridakos, P.; Chen, Y.W.; Alshawaf, B.; Kang, K.; Finkelman, M.; Chronopoulos, V.; Weber, H.P. Digital workflow: In vitro accuracy of 3D printed casts generated from complete-arch digital implant scans. J. Prosthet. Dent. 2020. [Google Scholar] [CrossRef] [PubMed]

- Jemt, T. In Vivo measurements of precision of fit involving implant-supported prostheses in the edentulous jaw. Int. J. Oral Maxillofac. Implant. 1996, 11, 151–158. [Google Scholar]

- Jemt, T.; Book, K. Prosthesis misfit and marginal bone loss in edentulous implant patients. Int. J. Oral Maxillofac. Implant. 1996, 11, 620–625. [Google Scholar]

- Papaspyridakos, P.; Benic, G.I.; Hogsett, V.L.; White, G.S.; Lal, K.; Gallucci, G.O. Accuracy of implant casts generated with splinted and non-splinted impression techniques for edentulous patients: An optical scanning study. Clin. Oral Implant. Res. 2012, 23, 676–681. [Google Scholar] [CrossRef]

- Pozzi, A.; Tallarico, M.; Mangani, F.; Barlattani, A. Different implant impression techniques for edentulous patients treated with CAD/CAM complete-arch prostheses: A randomised controlled trial reporting data at 3 year post-loading. Eur. J. Oral. Implantol. 2013, 6, 325–340. [Google Scholar]

- Venezia, P.; Torsello, F.; Santomauro, V.; Dibello, V.; Cavalcanti, R. Full Digital Workflow for the Treatment of an Edentulous Patient with Guided Surgery, Immediate Loading and 3D-Printed Hybrid Prosthesis: The BARI Technique 2.0. A Case Report. Int. J. Environ. Res. Public Health 2019, 16, 5160. [Google Scholar] [CrossRef]

- Ahmed, W.M.; Verhaeghe, T.V.; McCullagh, A.P.G. Maxillary complete-arch implant-supported restoration: A digital scanning and maxillomandibular relationship workflow. J. Prosthet. Dent. 2020. [Google Scholar] [CrossRef]

- Meloni, S.M.; Lumbau, A.; Baldoni, E.; Pisano, M.; Spano, G.; Massarelli, O.; Tallarico, M. Platform switching versus regular platform single implants: 5-year post-loading results from a randomised controlled trial. Int. J. Oral Implantol. 2020, 13, 43–52. [Google Scholar]

- Tallarico, M.; Scrascia, R.; Annucci, M.; Meloni, S.M.; Lumbau, A.I.; Koshovari, A.; Xhanari, E.; Martinolli, M. Errors in Implant Positioning Due to Lack of Planning: A Clinical Case Report of New Prosthetic Materials and Solutions. Materials 2020, 13, 1883. [Google Scholar] [CrossRef] [PubMed]

- Meloni, S.M.; Spano, G.; Ceruso, F.M.; Gargari, M.; Lumbau, A.; Baldoni, E.; Massarelli, O.; Pisano, M.; Tallarico, M. Upper jaw implant restoration on six implants with flapless guided template surgery and immediate loading: 5 years results of a prospective case series. ORAL Implantol. 2020, 12, 151–160. [Google Scholar] [CrossRef]

- Kim, J.; Amelya, A.; Shin, Y.; Shim, J. Accuracy of intraoral digital impressions using an artificial landmark. J. Prosthet. Dent. 2017, 117, 755–761. [Google Scholar] [CrossRef] [PubMed]

- Cicciù, M.; Bramanti, E.; Cecchetti, F.; Scappaticci, L.; Guglielmino, E.; Risitano, G. Fem and Von Mises analyses of different dental implant shapes for masticatory loading distribution. ORAL Implantol. 2014, 7, 1–10. [Google Scholar]

- Cicciù, M.; Cervino, G.; Milone, D.; Risitano, D. FEM Investigation of the Stress Distribution over Mandibular Bone Due to Screwed Overdenture Positioned on Dental Implants. Materials 2018, 11, 1512. [Google Scholar] [CrossRef] [PubMed]

| Test | Control | Difference | p-Value | |

|---|---|---|---|---|

| Four | 0.134 ± 0.053 (0.016–0.090) | 0.252 ± 0.068 (0.021–0.115) | 0.118 ± 0.077 (0.024–0.131) | 0.002 |

| Six | 0.100 ± 0.029 (0.009–0.049) | 0.373 ± 0.117 (0.036–0.198) | (0.273 ± 0.111 (0.034–0.188) | 0.000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tallarico, M.; Lumbau, A.I.; Scrascia, R.; Demelas, G.; Sanseverino, F.; Amarena, R.; Meloni, S.M. Feasibility of Using a Prosthetic-Based Impression Template to Improve the Trueness and Precision of a Complete Arch Digital Impression on Four and Six Implants: An In Vitro Study. Materials 2020, 13, 3543. https://doi.org/10.3390/ma13163543

Tallarico M, Lumbau AI, Scrascia R, Demelas G, Sanseverino F, Amarena R, Meloni SM. Feasibility of Using a Prosthetic-Based Impression Template to Improve the Trueness and Precision of a Complete Arch Digital Impression on Four and Six Implants: An In Vitro Study. Materials. 2020; 13(16):3543. https://doi.org/10.3390/ma13163543

Chicago/Turabian StyleTallarico, Marco, Aurea Immacolata Lumbau, Roberto Scrascia, Gianluca Demelas, Franco Sanseverino, Rocco Amarena, and Silvio Mario Meloni. 2020. "Feasibility of Using a Prosthetic-Based Impression Template to Improve the Trueness and Precision of a Complete Arch Digital Impression on Four and Six Implants: An In Vitro Study" Materials 13, no. 16: 3543. https://doi.org/10.3390/ma13163543

APA StyleTallarico, M., Lumbau, A. I., Scrascia, R., Demelas, G., Sanseverino, F., Amarena, R., & Meloni, S. M. (2020). Feasibility of Using a Prosthetic-Based Impression Template to Improve the Trueness and Precision of a Complete Arch Digital Impression on Four and Six Implants: An In Vitro Study. Materials, 13(16), 3543. https://doi.org/10.3390/ma13163543