2D Digital Image Correlation and Region-Based Convolutional Neural Network in Monitoring and Evaluation of Surface Cracks in Concrete Structural Elements

Abstract

1. Introduction

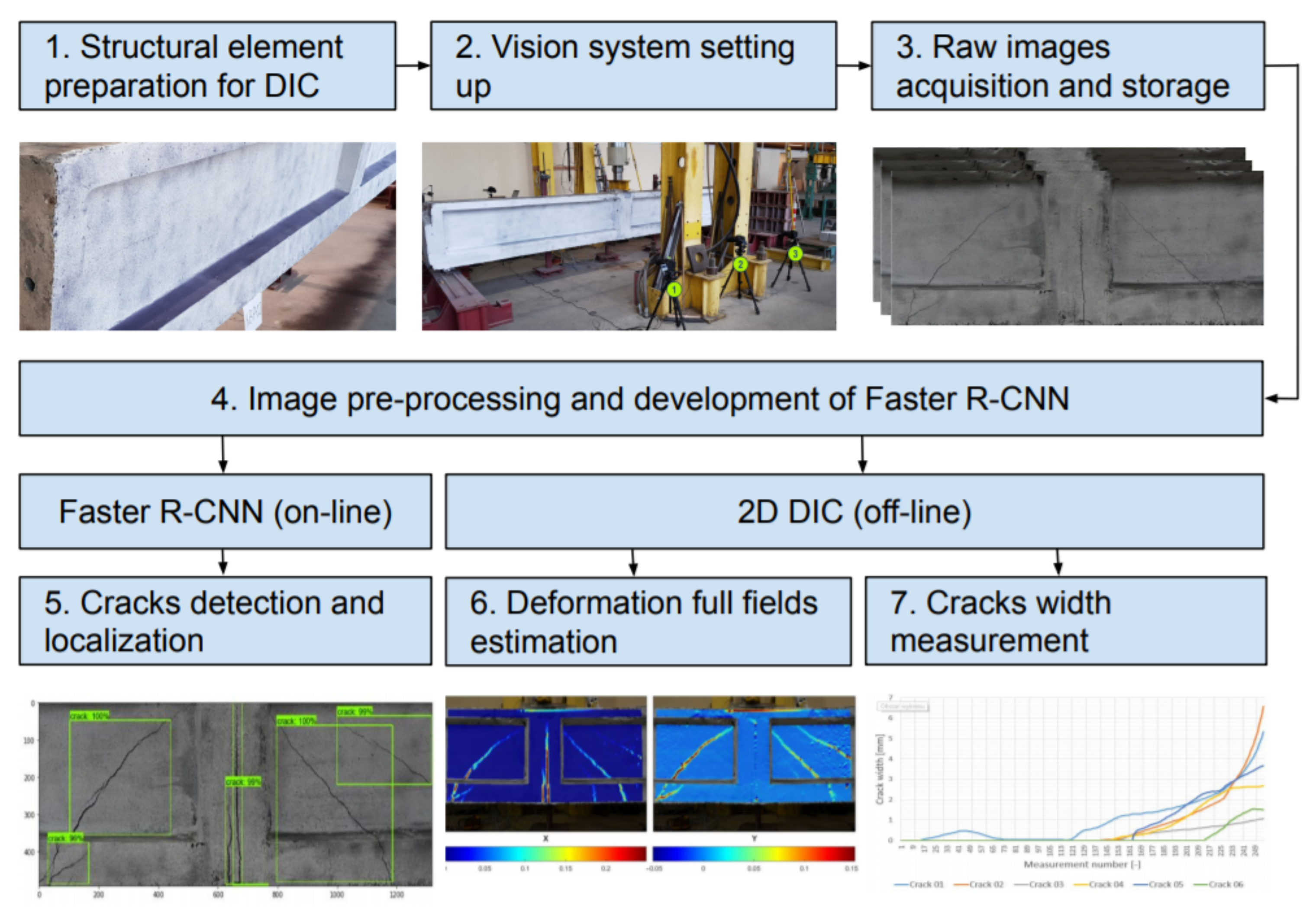

2. Methodology

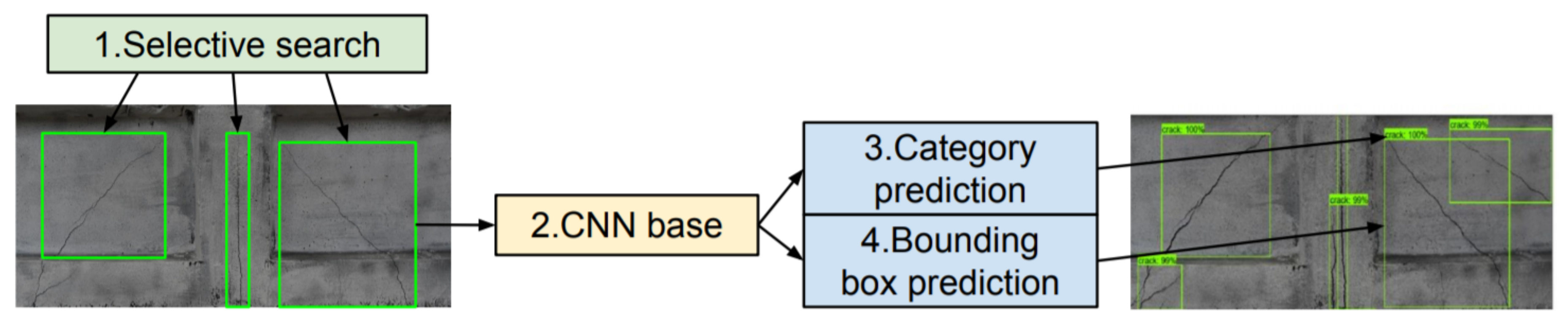

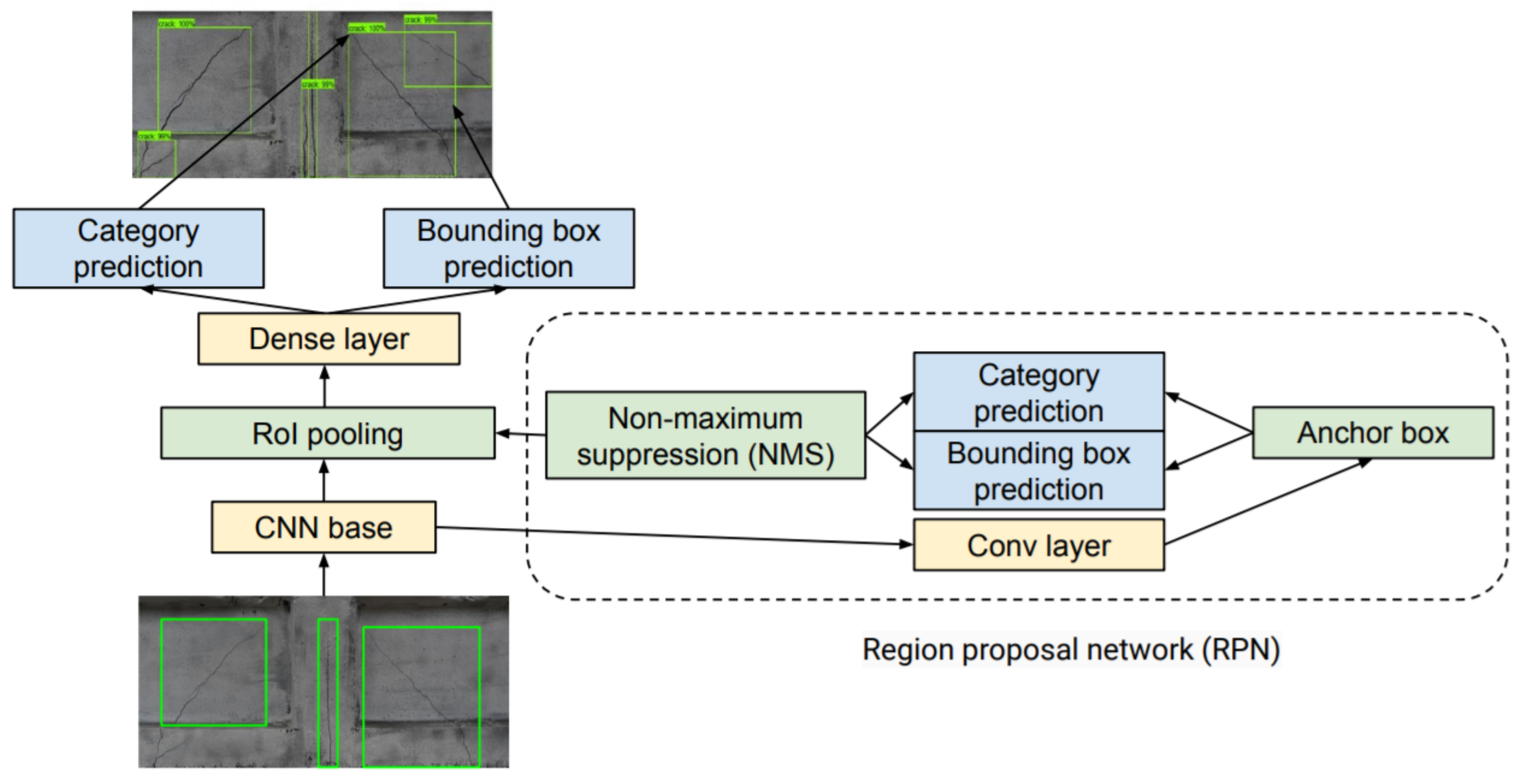

2.1. Region-Based Convolutional Neural Network

- a selective search on the input image to select proposed regions containing objects,

- a pre-trained CNN transforms each proposed region and computes the features extracted from the proposed regions,

- the extracted features and labeled category of each proposed region are combined to train support vector machine (SVM)-based classifiers for object classification,

- the extracted features and labeled bounding box of each proposed region are combined to train a linear regression model for bounding box prediction.

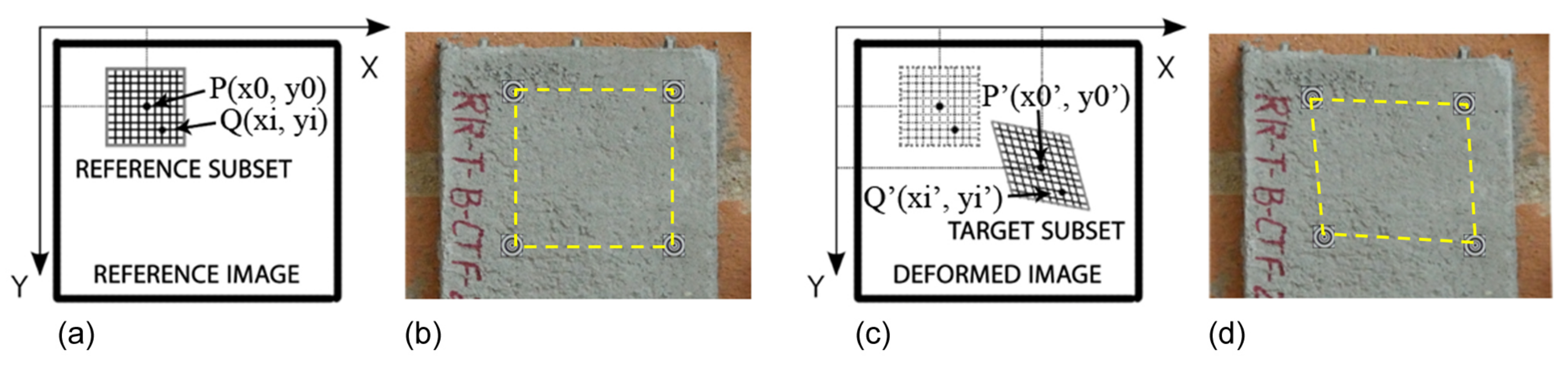

2.2. Digital Image Correlation

3. Model-Development Workflow for Crack Detection Based on Faster R-CNN

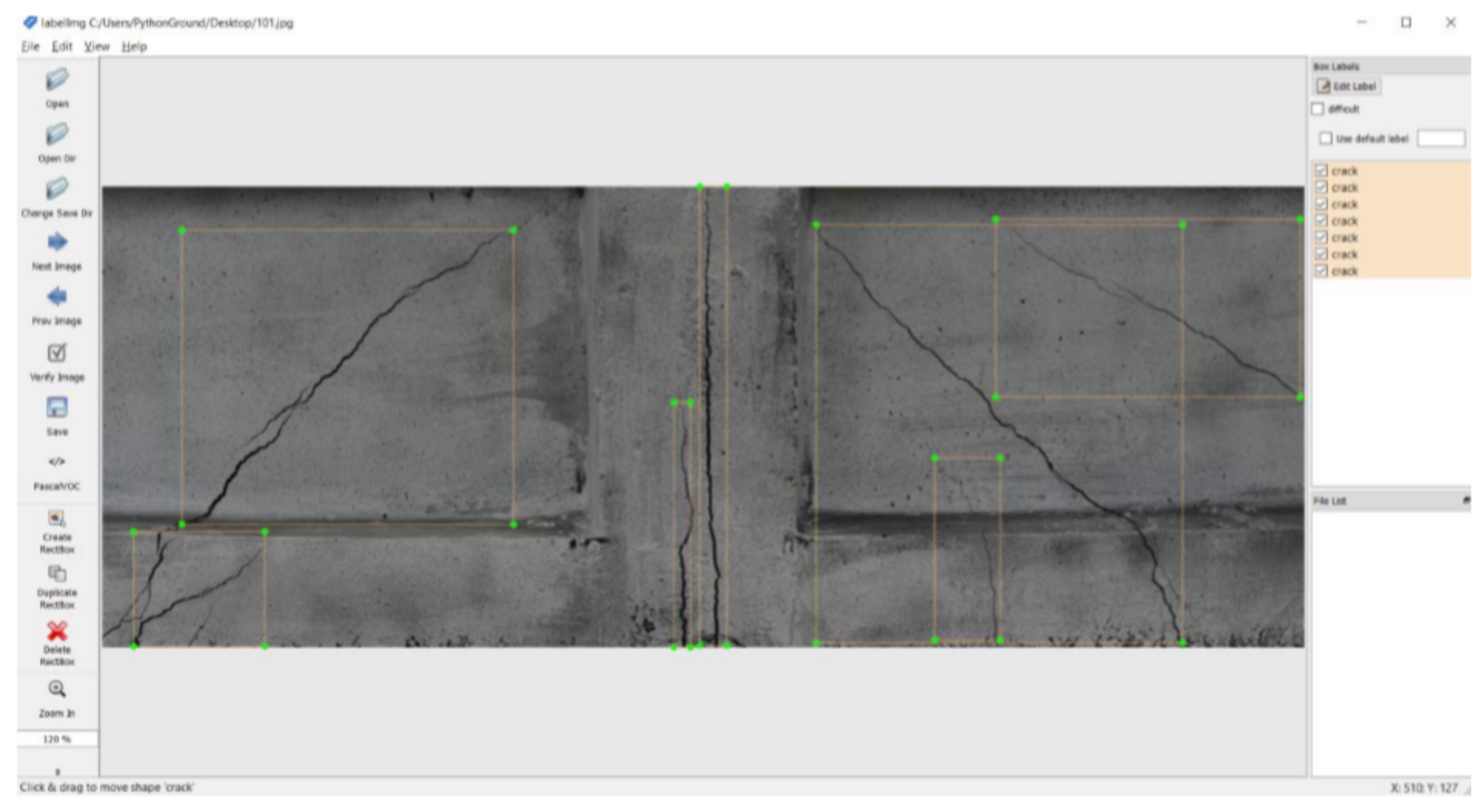

3.1. Dataset Collection and Annotation

3.2. Model Development

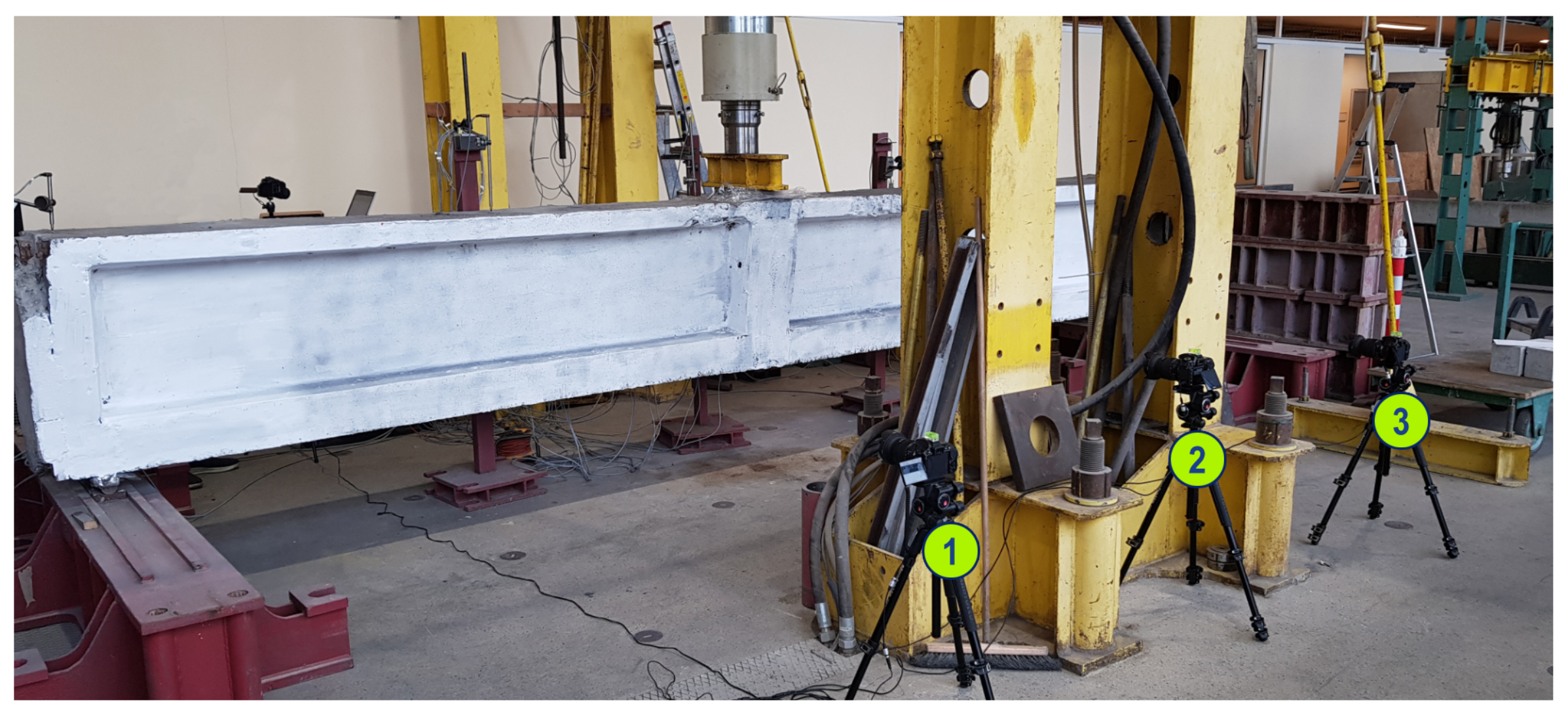

4. Experiments

5. Results and Discussion

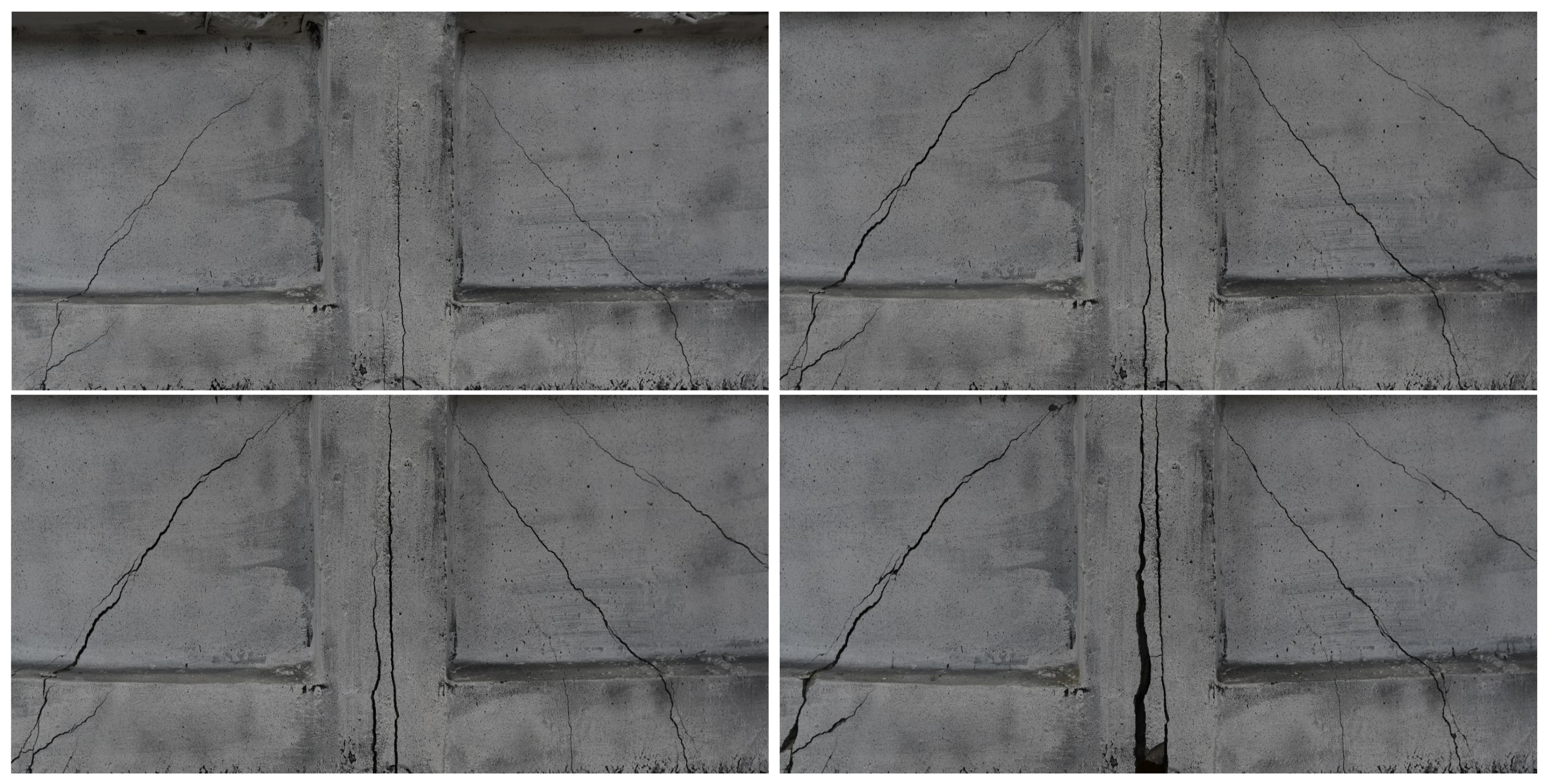

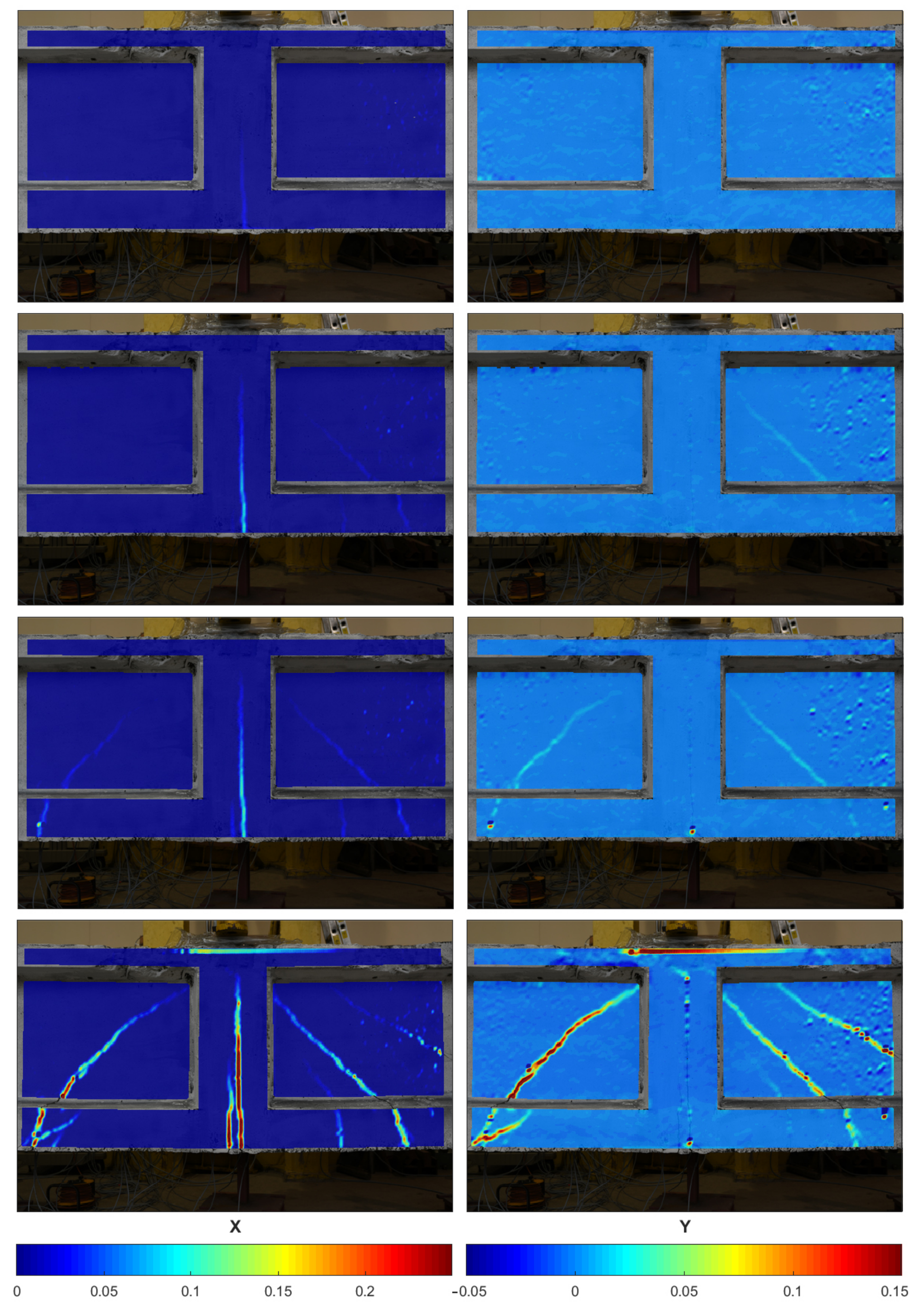

5.1. Monitoring of Beam Side Surface Deformation Fields

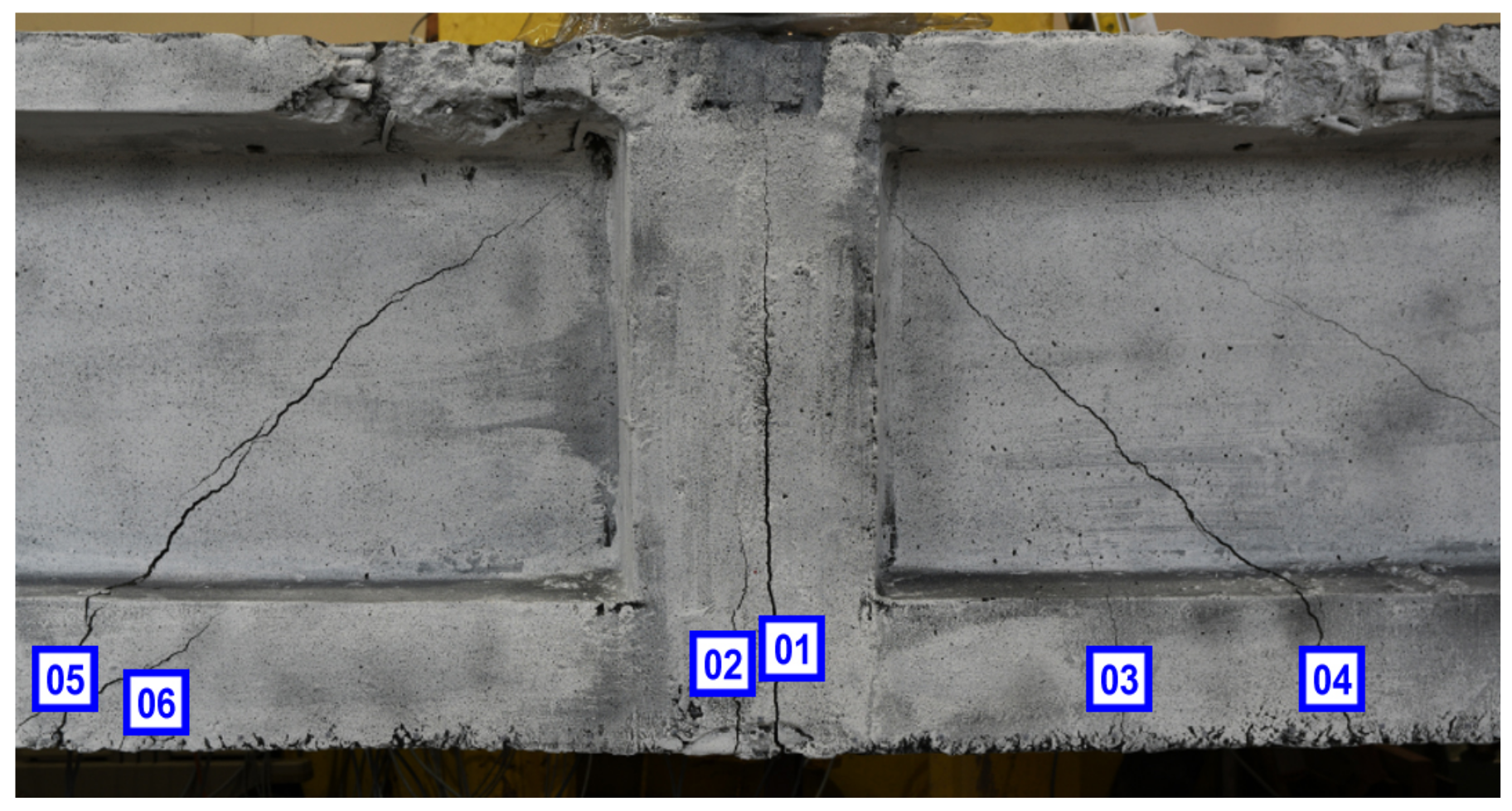

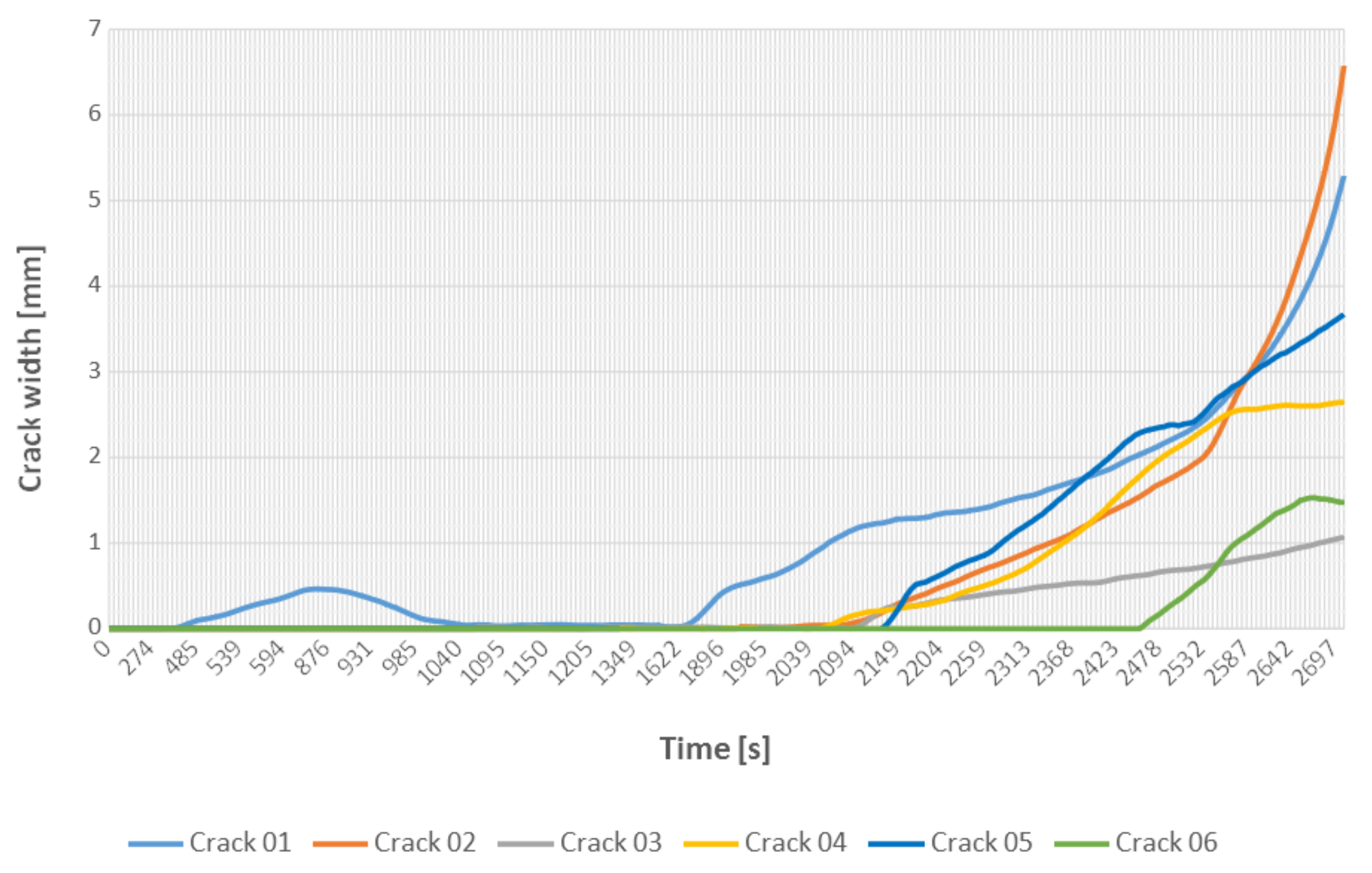

5.2. Assessment of Crack Width

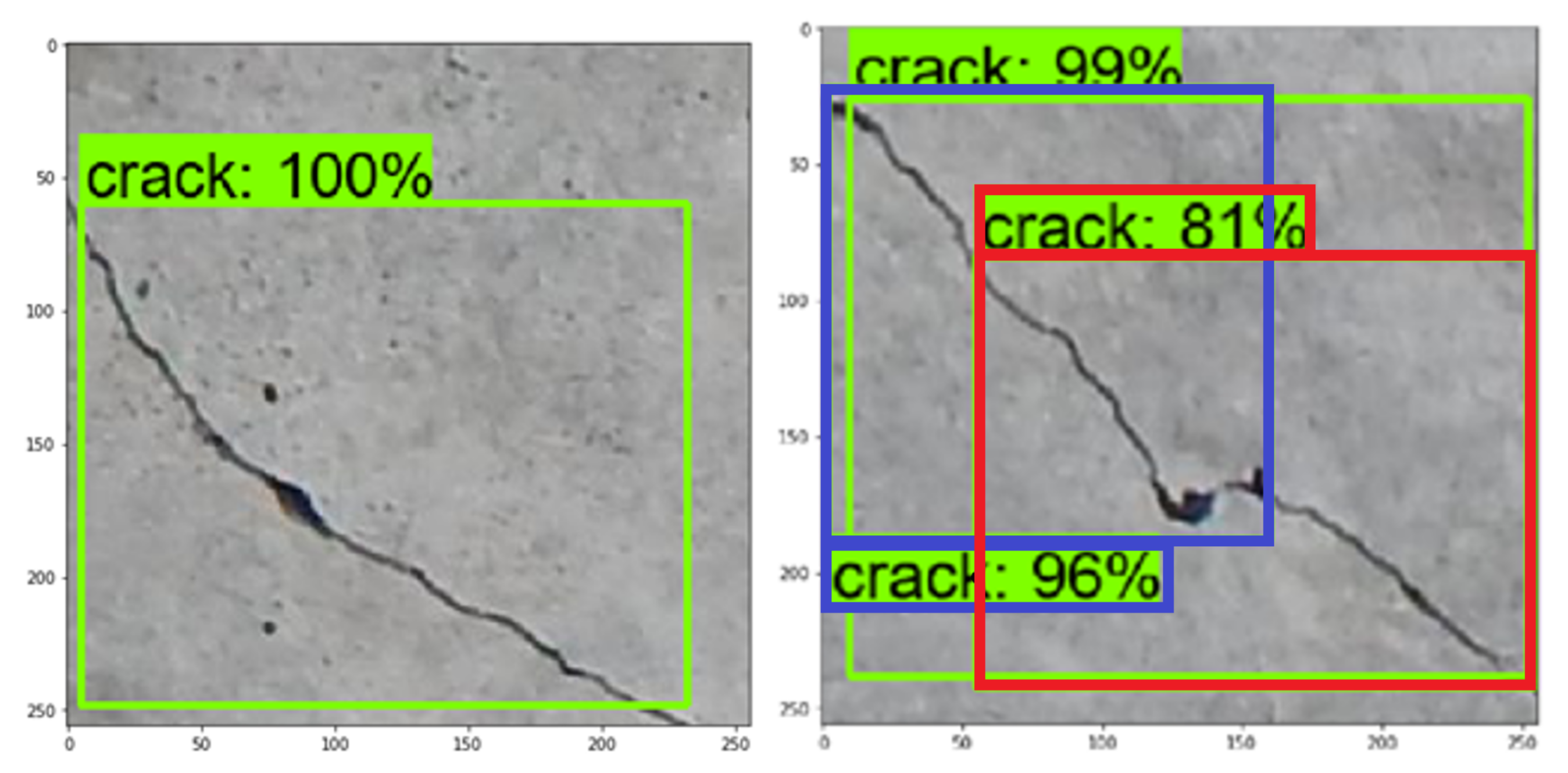

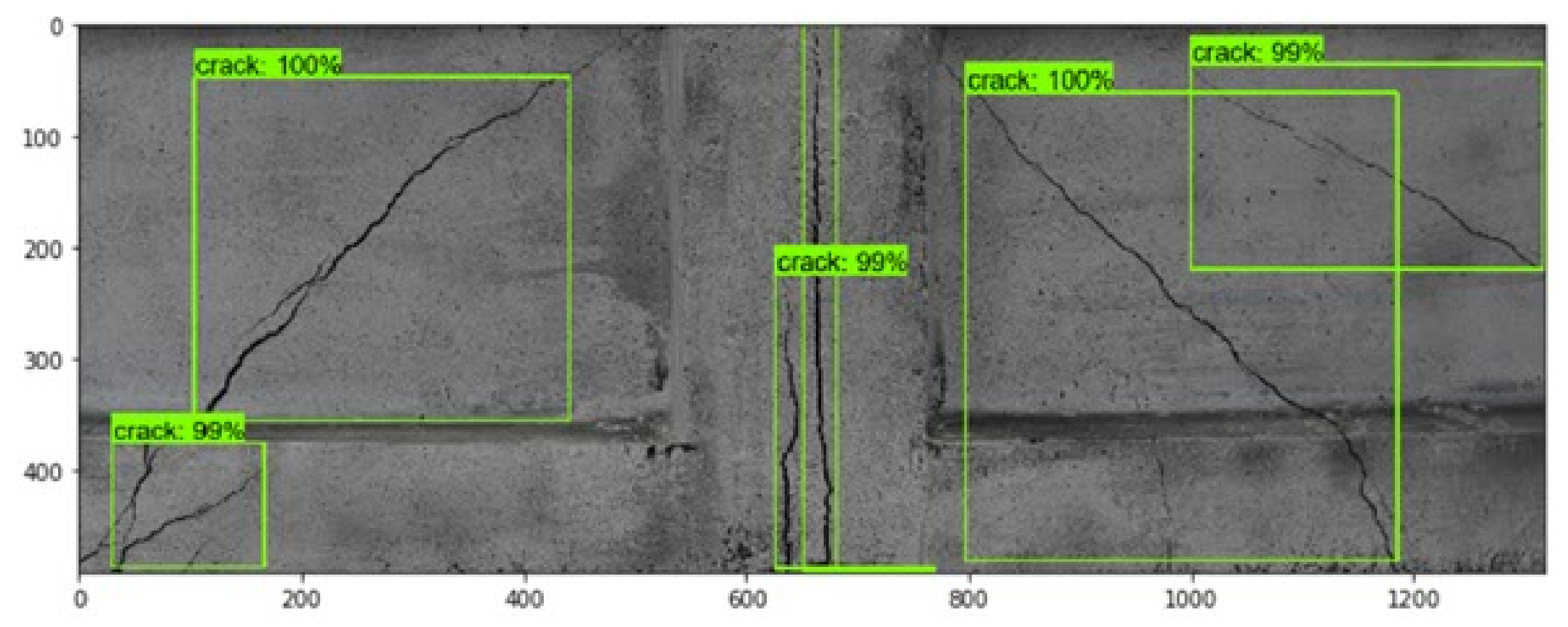

5.3. Cracks Detection and Localization

6. Summary and Final Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Derkowski, W.; Walczak, R. Problem of condition assessment of precast, post-tensioned concrete crane beams in an extended period of use. In Concrete—Innovations in Materials, Design and Structures, Proceedings of the FIB Symposium 2019, Kraków, Poland 27–29 May 2019; Derkowski, W., Ed.; International Federation for Structural Concrete: Lausanne, Switzerland, 2019; pp. 1507–1514. [Google Scholar]

- Solem, J.E. Programming Computer Vision with Python: Tools and Algorithms for Analyzing Images; O’Reilly Media, Inc.: Newton, MA, USA, 2012. [Google Scholar]

- Szeliski, R. Computer Vision: Algorithms and Applications; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Valença, J.; Dias-da Costa, D.; Júlio, E. Characterisation of concrete cracking during laboratorial tests using image processing. Construct. Build. Mater. 2012, 28, 607–615. [Google Scholar] [CrossRef]

- Azimi, M.; Eslamlou, A.D.; Pekcan, G. Data-Driven Structural Health Monitoring and Damage Detection through Deep Learning: State-of-the-Art Review. Sensors 2020, 20, 2778. [Google Scholar] [CrossRef] [PubMed]

- Spencer, B.F.J.; Hoskere, V.; Narazaki, Y. Advances in computer vision-based civil infrastructure inspection and monitoring. Engineering 2019, 5, 199–222. [Google Scholar] [CrossRef]

- Pan, B. Digital image correlation for surface deformation measurement: Historical developments, recent advances and future goals. Meas. Sci. Technol. 2018, 29, 082001. [Google Scholar] [CrossRef]

- Zhao, J.; Sang, Y.; Duan, F. The state of the art of two-dimensional digital image correlation computational method. Eng. Rep. 2019, 1, e12038. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.; Maguire, M. Comparison of deep convolutional neural networks and edge detectors for image-based crack detection in concrete. Construct. Build. Mater. 2018, 186, 1031–1045. [Google Scholar] [CrossRef]

- Sutton, M.; Orteu, J.J.; Shreier, H. Image Correlation for Shape, Motion and Deformation Measurements; Springer: Berlin, Germany, 2009. [Google Scholar]

- Khoo, S.W.; Karuppanan, S.; Tan, C.S. A review of surface deformation and strain measurement using two-dimensional digital image correlation. Metrol. Meas. Syst. 2016, 23, 461–480. [Google Scholar] [CrossRef]

- Mróz, K.; Tekieli, M.; Hager, I. Feasibility Study of Digital Image Correlation in Determining Strains in Concrete Exposed to Fire. Materials 2020, 13, 2516. [Google Scholar] [CrossRef]

- Helm, J.D. Digital image correlation for specimens with multiple growing cracks. Exp. Mech. 2008, 48, 753–762. [Google Scholar] [CrossRef]

- Rui, L.; Zappa, E.; Collina, A. Vision-based measurement of crack generation and evolution during static testing of concrete sleepers. Eng. Fract. Mech. 2020, 224, 106715. [Google Scholar] [CrossRef]

- Gehri, N.; Mata-Falcón, J.; Kaufmann, W. Automated crack detection and measurement based on digital image correlation. Construct. Build. Mater. 2020, 256, 119383. [Google Scholar] [CrossRef]

- Kozicki, J.; Tejchman, J. Experimental investigations of strain localization in concrete using Digital Image Correlation (DIC) technique. Arch. Hydro Eng. Environ. Mech. 2007, 54, 3–24. [Google Scholar]

- Skarżyński, Ł.; Syroka, E.; Tejchman, J. Measurements and calculations of the width of the fracture process zones on the surface of notched concrete beams. Strain 2011, 47, 319–332. [Google Scholar]

- Lacidogna, G.; Piana, G.; Accornero, F.; Carpinteri, A. Multi-technique damage monitoring of concrete beams: Acoustic Emission, Digital Image Correlation, Dynamic Identification. Construct. Build. Mater. 2020, 242, 118114. [Google Scholar] [CrossRef]

- Gkantou, M.; Muradov, M.; Kamaris, G.S.; Hashim, K.; Atherton, W.; Kot, P. Novel Electromagnetic Sensors Embedded in Reinforced Concrete Beams for Crack Detection. Sensors 2019, 19, 5175. [Google Scholar] [CrossRef] [PubMed]

- Cha, Y.J.; Choi, W.; Suh, G.; Mahmoudkhani, S.; Büyüköztürk, O. Autonomous structural visual inspection using region-based deep learning for detecting multiple damage types. Comput. Aided Civ. Infrastruc. Eng. 2018, 33, 731–747. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, J. Real-time crack assessment using deep neural networks with wall-climbing unmanned aerial system. Comput. Aided Civ. Infrastruc. Eng. 2020, 35, 549–564. [Google Scholar] [CrossRef]

- Roberts, R.; Giancontieri, G.; Inzerillo, L.; Di Mino, G. Towards Low-Cost Pavement Condition Health Monitoring and Analysis Using Deep Learning. Appl. Sci. 2020, 10, 319. [Google Scholar] [CrossRef]

- Deng, L.; Hong-Hu, C.; Shi, P.; Wang, W.; Kong, X. Region-Based CNN Method with Deformable Modules for Visually Classifying Concrete Cracks. Appl. Sci. 2020, 10, 2528. [Google Scholar] [CrossRef]

- Słoński, M.; Schabowicz, K.; Krawczyk, E. Detection of Flaws in Concrete Using Ultrasonic Tomography and Convolutional Neural Networks. Materials 2020, 13, 1557. [Google Scholar] [CrossRef]

- Zhang, A.; Lipton, Z.C.; Li, M.; Smola, A.J. Dive into Deep Learning. 2020. Available online: https://d2l.ai (accessed on 3 August 2020).

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich feature hierarchies for accurate object detection and semantic segmentation. arXiv 2013, arXiv:1311.2524. [Google Scholar]

- Girshick, R. Fast R-CNN. arXiv 2015, arXiv:1504.08083. [Google Scholar]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. arXiv 2015, arXiv:1506.01497. [Google Scholar] [CrossRef] [PubMed]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Szegedy, C.; Vanhoucke, V.; Ioffe, S.; Shlens, J.; Wojna, Z. Rethinking the inception architecture for computer vision. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 26 June–1 July 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 2818–2826. [Google Scholar]

- Huang, J.; Rathod, V.; Sun, C.; Zhu, M.; Korattikara, A.; Fathi, A.; Fischer, I.; Wojna, Z.; Song, Y.; Guadarrama, S.; et al. Speed/accuracy trade-offs for modern convolutional object detectors. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 7310–7311. [Google Scholar]

- Abadi, M.; Agarwal, A.; Barham, P.; Brevdo, E.; Chen, Z.; Citro, C.; Corrado, G.S.; Davis, A.; Dean, J.; Devin, M.; et al. TensorFlow: Large-Scale Machine Learning on Heterogeneous Systems. 2015. Available online: tensorflow.org (accessed on 12 June 2020).

- Peters, W.; Ranson, W. Digital imaging techniques in experimental stress analysis. Opt. Eng. 1982, 21, 427–431. [Google Scholar] [CrossRef]

- Sutton, M.; Wolters, W.; Peters, W.; Ranson, W.; McNeill, S. Determination of displacements using an improved digital correlation method. Image Vis. Comput. 1983, 1, 133–139. [Google Scholar] [CrossRef]

- Olufsen, S.N.; Andersen, M.E.; Fagerholt, E. μDIC: An open-source toolkit for digital image correlation. SoftwareX 2020, 11, 100391. [Google Scholar] [CrossRef]

- Tekieli, M. A Vision-Based Measurement System for the Analysis of Structural Element Deformation Fields. Ph.D. Thesis, Faculty of Civil Engineering, Cracow University of Technology, Kraków, Poland, 2019. [Google Scholar]

- Lin, T. LabelImg. Available online: https://github.com/tzutalin/labelImg (accessed on 4 May 2020).

- Tekieli, M.; Słoński, M. Particle filtering for computer vision-based identification of frame model parameters. Comput. Assis. Methods Eng. Sci. 2014, 21, 39–48. [Google Scholar]

- Tekieli, M.; Słoński, M. Digital image correlation and Bayesian filtering in inverse analysis of structures. In Recent Advances in Civil Engineering: Computational Methods; Cecot, W., Ed.; Publishing House of Cracow University of Technology: Kraków, Poland, 2015; pp. 111–124. [Google Scholar]

- Bełda, P. Reinforced Concrete Element Crack Detection by Application of Convolutional Neural Network Using the TensorFlow Library. Master’s Thesis, Cracow University of Technology, Kraków, Poland, 2019. (In Polish). [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Słoński, M.; Tekieli, M. 2D Digital Image Correlation and Region-Based Convolutional Neural Network in Monitoring and Evaluation of Surface Cracks in Concrete Structural Elements. Materials 2020, 13, 3527. https://doi.org/10.3390/ma13163527

Słoński M, Tekieli M. 2D Digital Image Correlation and Region-Based Convolutional Neural Network in Monitoring and Evaluation of Surface Cracks in Concrete Structural Elements. Materials. 2020; 13(16):3527. https://doi.org/10.3390/ma13163527

Chicago/Turabian StyleSłoński, Marek, and Marcin Tekieli. 2020. "2D Digital Image Correlation and Region-Based Convolutional Neural Network in Monitoring and Evaluation of Surface Cracks in Concrete Structural Elements" Materials 13, no. 16: 3527. https://doi.org/10.3390/ma13163527

APA StyleSłoński, M., & Tekieli, M. (2020). 2D Digital Image Correlation and Region-Based Convolutional Neural Network in Monitoring and Evaluation of Surface Cracks in Concrete Structural Elements. Materials, 13(16), 3527. https://doi.org/10.3390/ma13163527