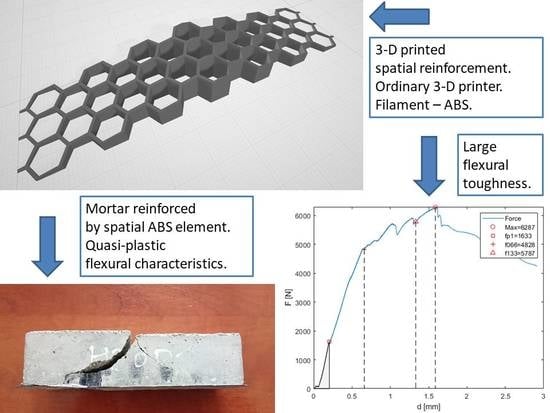

Effect of 3D Printed Spatial Reinforcement on Flexural Characteristics of Conventional Mortar

Abstract

1. Introduction

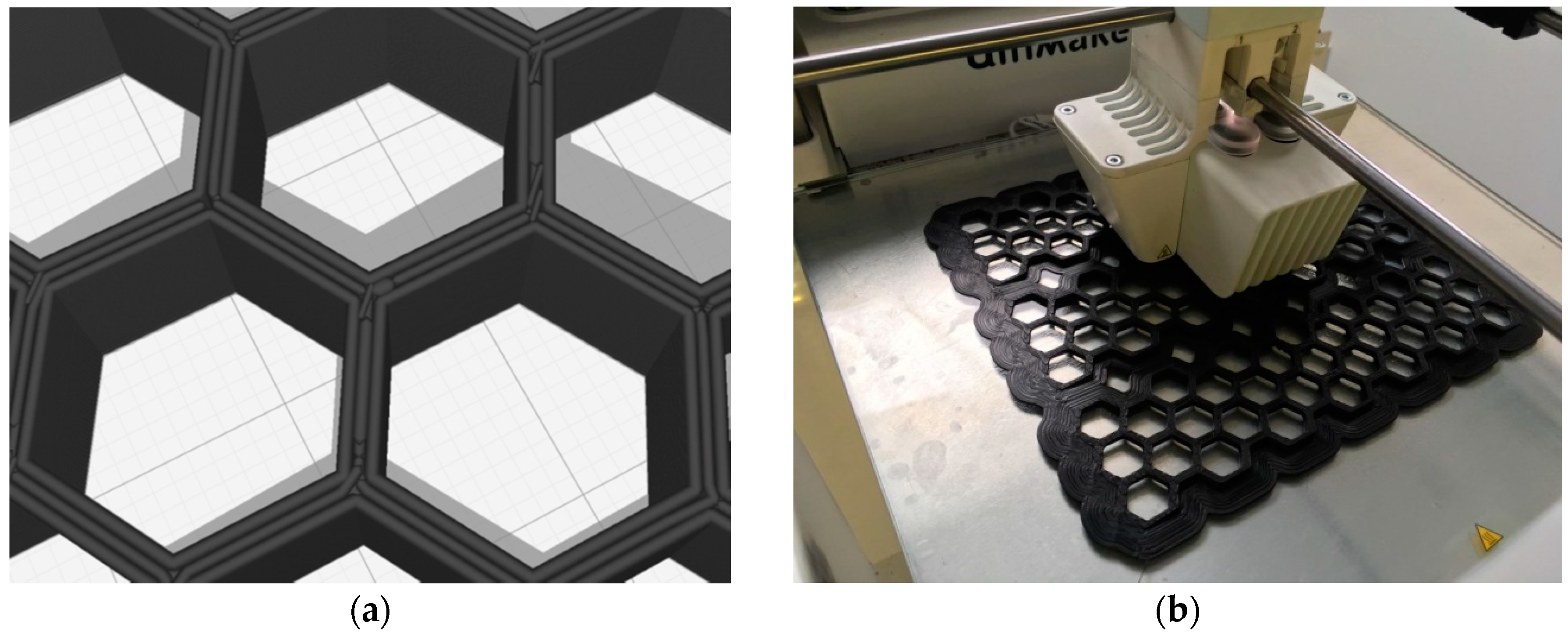

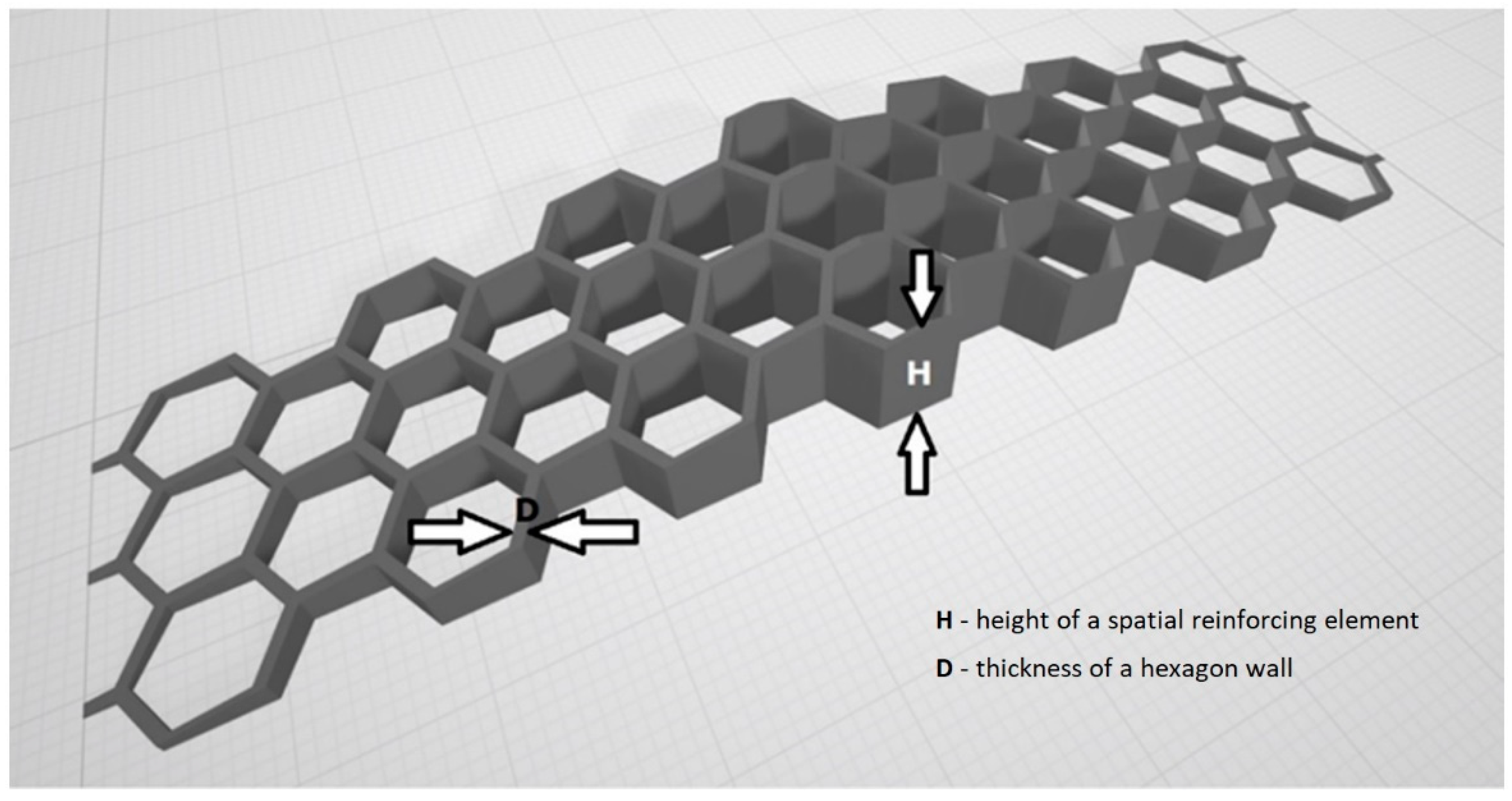

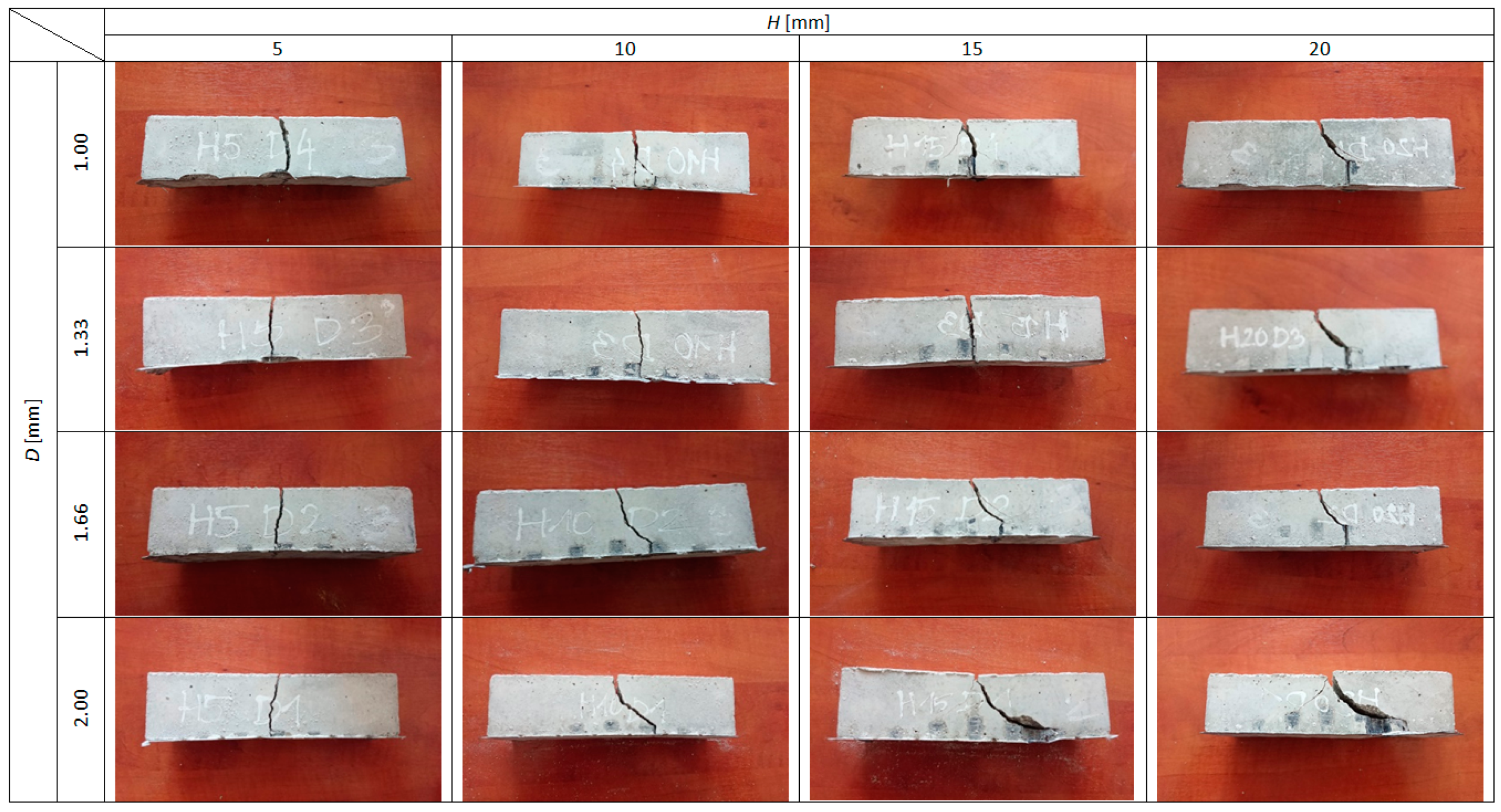

2. Materials and Methods

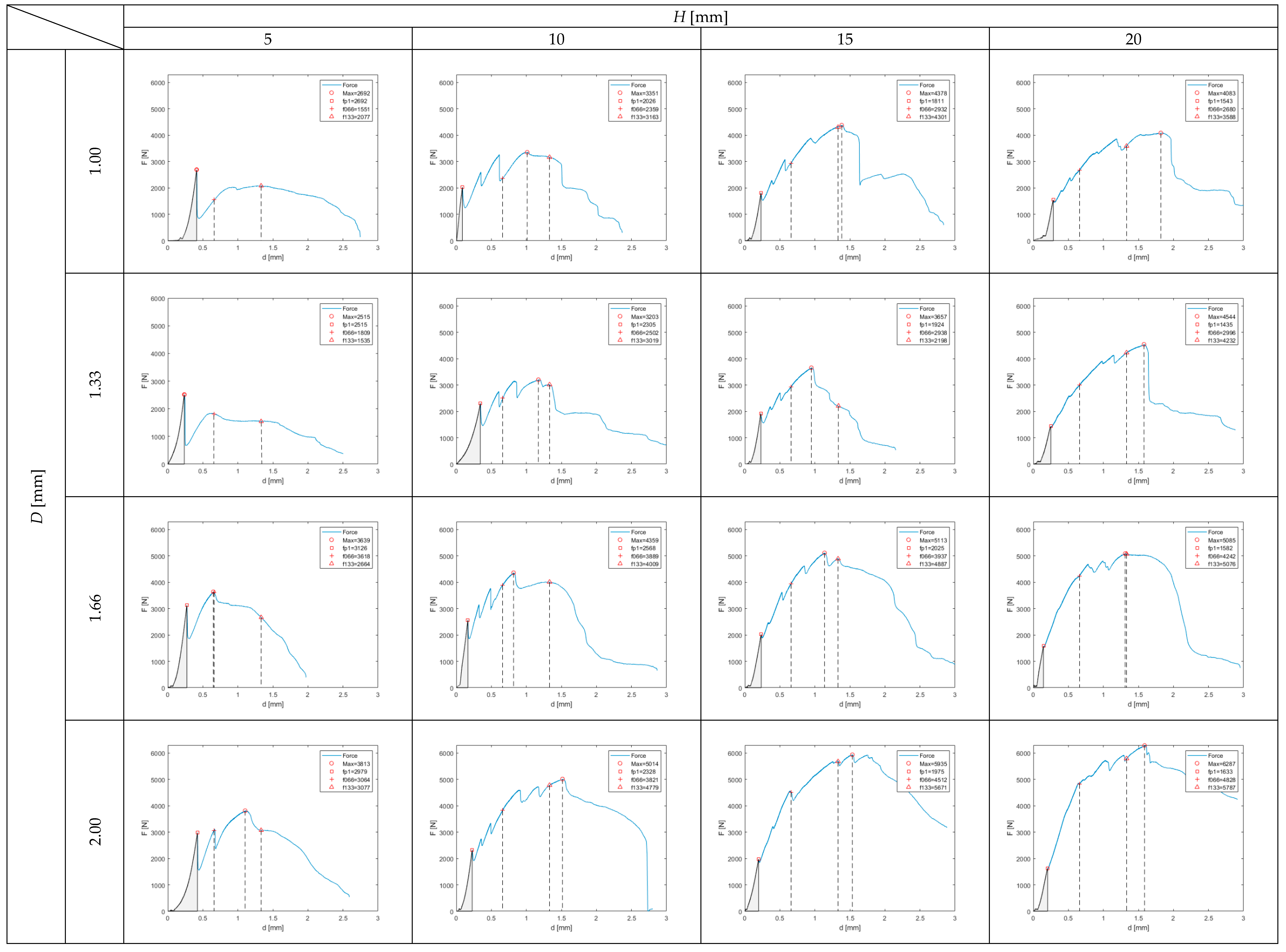

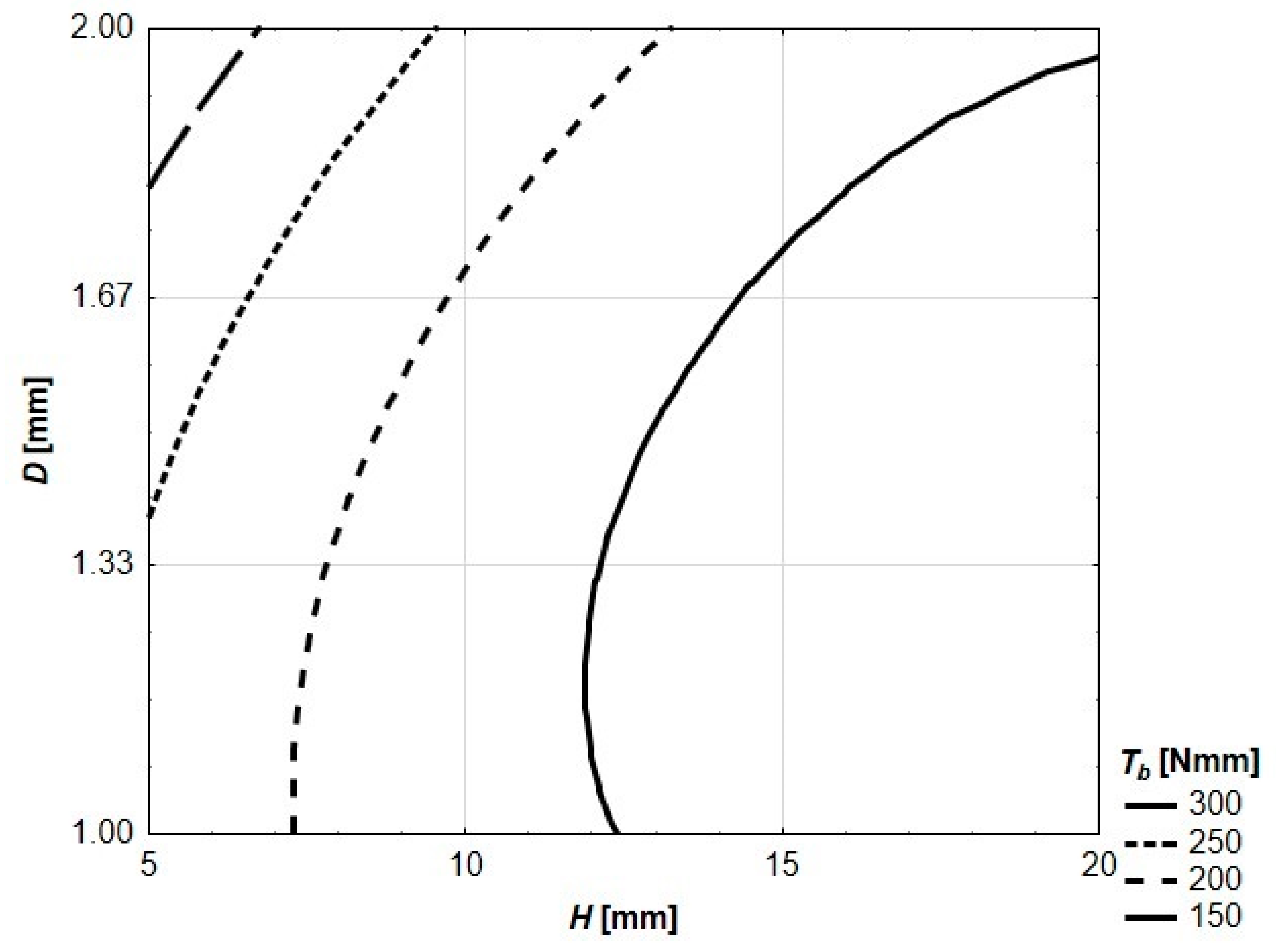

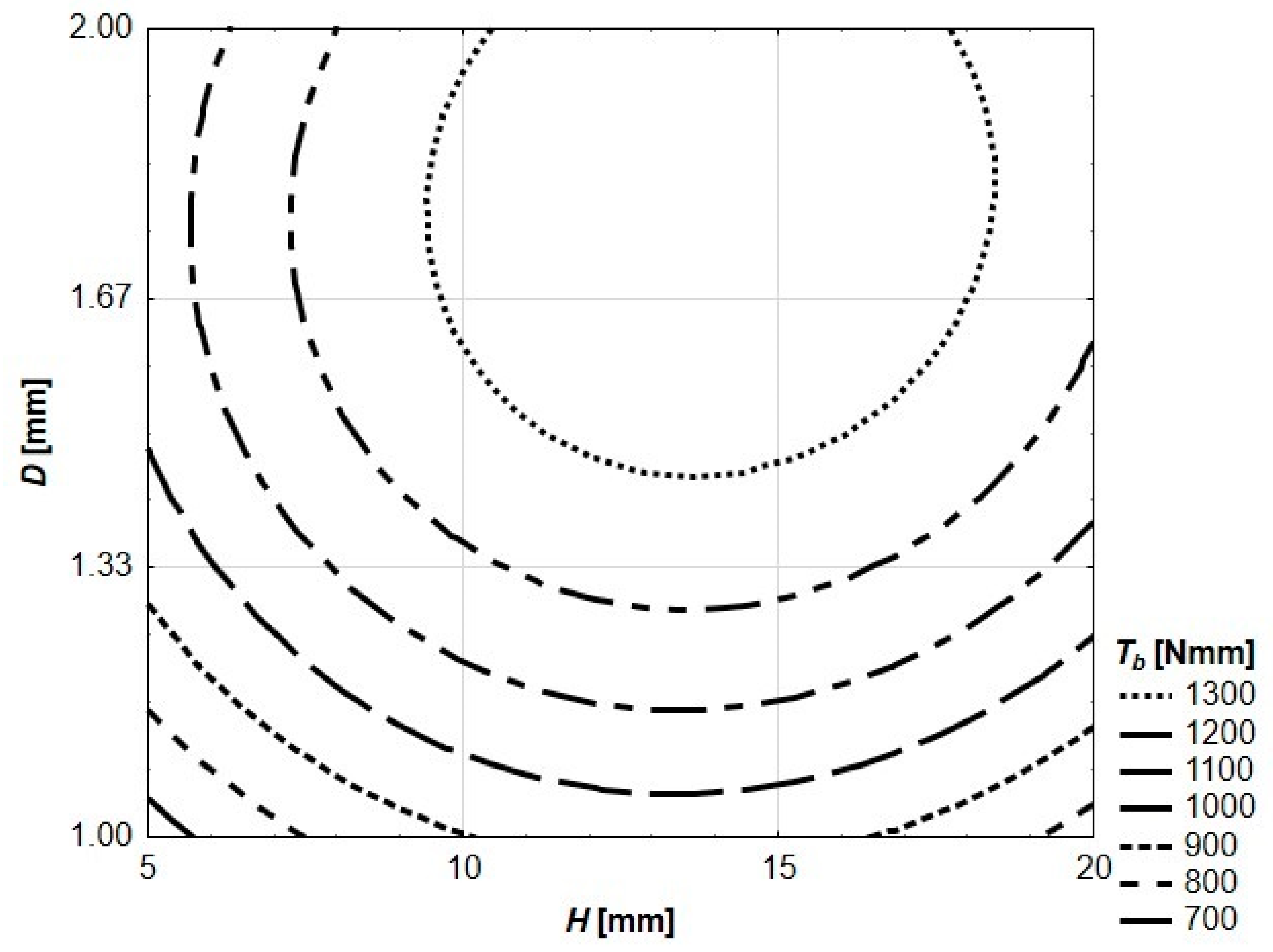

3. Results and Discussion

4. Conclusions

- It is possible to efficiently reinforce cement mortar by spatial 3D printed polymer elements.

- The shape and size of a spatial 3D printed element influence in a very wide range the flexural behavior of a prism specimen.

- Harnessing existing standards dedicated for reinforced concrete, fiber-reinforced concrete and ferrocement for testing and analysis of mortar prism specimen with spatial 3D printed plastic-reinforced elements is not feasible.

- Some elements of existing standards (e.g., flexural toughness) can be adopted for the testing and analysis of mortar prism specimens with spatial 3D printed polymer reinforcing elements.

- The shape and size of the 3D printed polymer reinforcing elements should be further developed to optimize their efficiency.

- Tests on larger specimens and full-scale structural elements (e.g., beams, columns) should be conducted.

Author Contributions

Funding

Conflicts of Interest

References

- Kruth, J.P.; Leu, M.C.; Nakagawa, T. Progress in additive manufacturing and rapid prototyping. CIRP Ann. Manuf. Technol. 1998. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012. [Google Scholar] [CrossRef]

- Shakor, P.; Sanjayan, J.; Nazari, A.; Nejadi, S. Modified 3D printed powder to cement-based material and mechanical properties of cement scaffold used in 3D printing. Constr. Build. Mater. 2017. [Google Scholar] [CrossRef]

- Shakor, P.; Nejadi, S.; Paul, G.; Malek, S. Review of emerging additive manufacturing technologies in 3d printing of cementitious materials in the construction industry. Front. Built Environ. 2019. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016. [Google Scholar] [CrossRef]

- Ghosh, A.; Favier, J.J.; Harper, M.C. Solar sintering on lunar regolith simulant (JSC-1) for 3D printing. Proc. Int. Astronaut. Congr. IAC 2016, 2, 1195–1203. [Google Scholar]

- Wilhelm, S.; Curbach, M. Review of possible mineral materials and production techniques for a building material on the moon. Struct. Concr. 2014. [Google Scholar] [CrossRef]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012. [Google Scholar] [CrossRef]

- Zhu, B.; Pan, J.; Nematollahi, B.; Zhou, Z.; Zhang, Y.; Sanjayan, J. Development of 3D printable engineered cementitious composites with ultra-high tensile ductility for digital construction. Mater. Des. 2019. [Google Scholar] [CrossRef]

- Shakor, P.; Nejadi, S.; Paul, G. A study into the effect of different nozzles shapes and fibre-reinforcement in 3D printed mortar. Materials. 2019, 12, 1708. [Google Scholar] [CrossRef] [PubMed]

- Forsythe, P.F. The Producttivity of Steel Reinforcement Placement in Australian Construction. In Proceedings of the ICEC IX World Congress, Milan, Italy, 20–22 October 2014. [Google Scholar]

- Jaimes, W.; Maroufi, S. Sustainability in steelmaking. Curr. Opin. Green Sustain. Chem. 2020. [Google Scholar] [CrossRef]

- Sudiajeng, L.; Mudhina, M.; Intara, I.W.; Jaya, I.M.; Aryawan, I.G.M.O.; Sutapa, I.K. Work Posture Analyses for Ergonomics Working Condition Improvement of Concrete Work Practices. In Proceedings of the 2018 International Conference on Applied Science and Technology iCAST 2018, Sulawesi Utara, Indonesia, 26–27 September 2018. [Google Scholar] [CrossRef]

- Schuelke-Leech, B.A. A model for understanding the orders of magnitude of disruptive technologies. Technol. Forecast. Soc. Chang. 2018. [Google Scholar] [CrossRef]

- Tiberti, G.; Germano, F.; Mudadu, A.; Plizzari, G.A. An overview of the flexural post-cracking behavior of steel fiber reinforced concrete. Struct. Concr. 2018. [Google Scholar] [CrossRef]

- Balaji, S.; Thirugnanam, G.S. Behaviour of reinforced concrete beams with SIFCON at various locations in the beam. KSCE J. Civ. Eng. 2018. [Google Scholar] [CrossRef]

- Katzer, J.; Szatkiewicz, T. Properties of concrete elements with 3-D printed formworks which substitute steel reinforcement. Constr. Build. Mater. 2019. [Google Scholar] [CrossRef]

- Habib, F.N.; Iovenitti, P.; Masood, S.H.; Nikzad, M. Cell geometry effect on in-plane energy absorption of periodic honeycomb structures. Int. J. Adv. Manuf. Technol. 2018. [Google Scholar] [CrossRef]

- Song, G.H.; Jing, S.K.; Zhao, F.L.; Wang, Y.D.; Xing, H.; Zhou, J.T. Design Optimization of Irregular Cellular Structure for Additive Manufacturing. Chin. J. Mech. Eng. (Engl. Ed.) 2017. [Google Scholar] [CrossRef]

- Niu, J.; Choo, H.L.; Sun, W.; Mok, S.H. Numerical study on load-bearing capabilities of beam-like lattice structures with three different unit cells. Int. J. Mech. Mater. Des. 2018. [Google Scholar] [CrossRef]

- Cement—Determination of Strength. In EN 196-1: 2016 Method of Testing Cement—Part 1: Determination of Strength; Comite Europeen de Normalisation: Brussels, Belgium, 2016; Chapter 13.

- Katzer, J. Median diameter as a grading characteristic for fine aggregate cement composite designing. Constr. Build. Mater. 2012, 35. [Google Scholar] [CrossRef]

- BS-EN197-1: Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Br. Stand. 2011, 4, 191–197.

- Hornakova, M.; Katzer, J.; Kobaka, J.; Konecny, P. Lightweight SFRC Benefitting from a Pre-Soaking and Internal Curing Process. Materials. 2019, 12, 4152. [Google Scholar] [CrossRef] [PubMed]

- Zarzycki, P.K.; Katzer, J. Multivariate Comparison of Lunar Soil Simulants. J. Aerosp. Eng. 2019. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS. Materials 2015, 5834–5846. [Google Scholar] [CrossRef]

- Rocha, C.R.; Perez, A.R.T.; Roberson, D.A.; Shemelya, C.M.; Macdonald, E.; Wicker, R.B. Novel ABS-based binary and ternary polymer blends for material extrusion 3D printing. J. Mater. Res. 2014. [Google Scholar] [CrossRef]

- De Sá, J.P.M. Applied Statistics Using SPSS, STATISTICA, MATLAB and R; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar] [CrossRef]

- Katzer, J.; Domski, J. Optimization of fibre reinforcement for waste aggregate cement composite. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Rorabacher, D.B. Statistical Treatment for Rejection of Deviant Values: Critical Values of Dixon’s “Q” Parameter and Related Subrange Ratios at the 95% Confidence Level. Anal. Chem. 1991. [Google Scholar] [CrossRef]

- Katzer, J. Strength performance comparison of mortars made with waste fine aggregate and ceramic fume. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Toniolo, G.; Di Prisco, M. Reinforced Concrete Design to Eurocode 2; Springer: Berlin, Germany, 2017. [Google Scholar] [CrossRef]

- Kaish, A.B.M.A.; Jamil, M.; Raman, S.N.; Zain, M.F.M.; Nahar, L. Ferrocement composites for strengthening of concrete columns: A review. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- Di Prisco, M.; Plizzari, G.; Vandewalle, L. Fibre reinforced concrete: New design perspectives. Mater. Struct. Constr. 2009. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Dhang, N.; Gupta, A.P. Toughness characterization of steel fiber-reinforced concrete by JSCE approach. Cem. Concr. Res. 2000. [Google Scholar] [CrossRef]

- Thiel, A. ULS and SLS design of CLT and its implementation in the CLTdesigner. In Focus Solid Timber Solutions-European Conference on Cross Laminated Timber; University of Bath: Lambas, UK, 2013. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament. J. Clean. Prod. 2014. [Google Scholar] [CrossRef]

| Ingredient | Amount [g] | Density [g/cm3] | Volume [cm3] |

|---|---|---|---|

| Standardized sand | 1350 | 2.65 | 509.4 |

| Portland cement | 450 | 3.10 | 145.1 |

| Tap water | 225 | 1.00 | 225.0 |

| Density [kg/cm3] | Melting Point [°C] | Diameter [mm] | Thermal Decomposition [°C] | |||

|---|---|---|---|---|---|---|

| 1100 | +225 | 2.85 | >+280 | |||

| Tensile modulus [MPa] | Tensile stress at yield [MPa] | Tensile stress at break [MPa] | Elongation at yield [%] | Elongation at break [%] | Flexural strength [MPa] | Flexural modulus [MPa] |

| 1681.5 | 39.0 | 33.9 | 3.5 | 4.8 | 70.5 | 2070.0 |

| H [mm] | |||||

| 5 | 10 | 15 | 20 | ||

| D [mm] | 1.00 | 1.25 | 2.25 | 3.2 | 4.17 |

| 1.33 | 1.42 | 3.55 | 3.71 | 4.87 | |

| 1.66 | 2.07 | 3.60 | 5.09 | 6.60 | |

| 2.00 | 2.35 | 4.18 | 5.98 | 7.80 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katzer, J.; Szatkiewicz, T. Effect of 3D Printed Spatial Reinforcement on Flexural Characteristics of Conventional Mortar. Materials 2020, 13, 3133. https://doi.org/10.3390/ma13143133

Katzer J, Szatkiewicz T. Effect of 3D Printed Spatial Reinforcement on Flexural Characteristics of Conventional Mortar. Materials. 2020; 13(14):3133. https://doi.org/10.3390/ma13143133

Chicago/Turabian StyleKatzer, Jacek, and Tomasz Szatkiewicz. 2020. "Effect of 3D Printed Spatial Reinforcement on Flexural Characteristics of Conventional Mortar" Materials 13, no. 14: 3133. https://doi.org/10.3390/ma13143133

APA StyleKatzer, J., & Szatkiewicz, T. (2020). Effect of 3D Printed Spatial Reinforcement on Flexural Characteristics of Conventional Mortar. Materials, 13(14), 3133. https://doi.org/10.3390/ma13143133