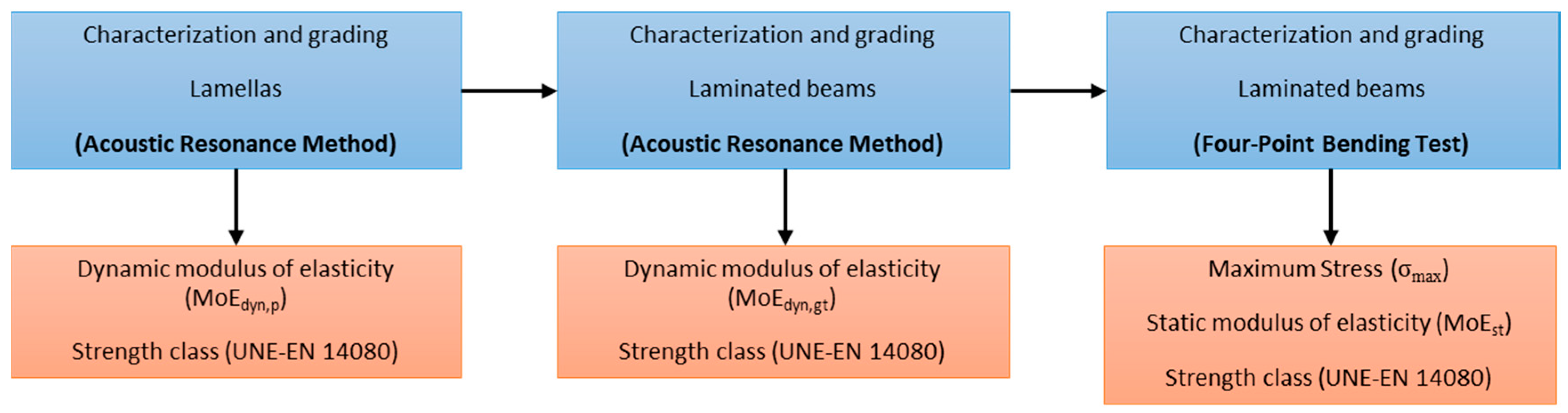

2.3. Dynamic Modulus of Elasticity of Planks: Acoustic Resonance Testing

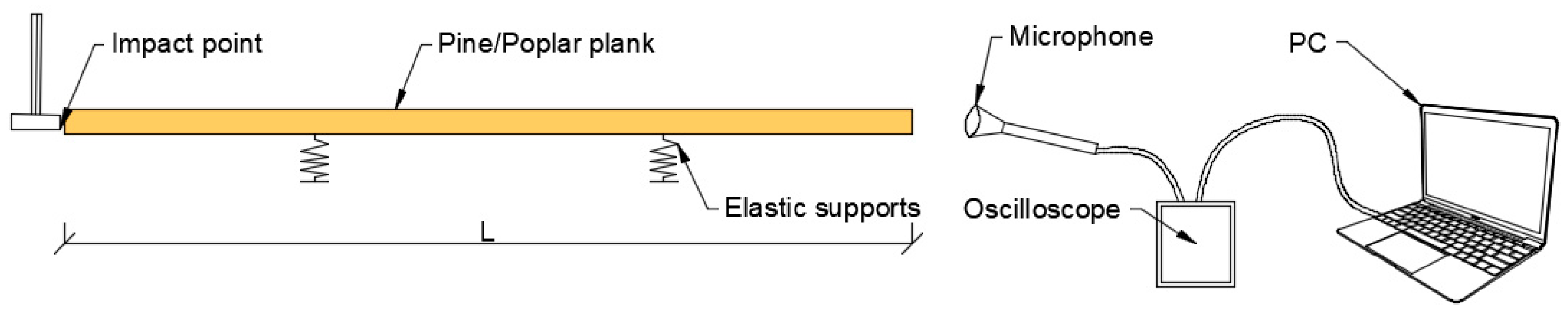

All the planks were subjected to an ART [

20,

21] in a flatwise orientation by placing them on two elastic supports and hitting them with a hammer (

Figure 2). Response vibration signals along the longitudinal direction were collected with a t.bonne MM-1 Thomann microphone (Thomman GmbH, Burgebrach, Germany) and transduced to an electrical signal recorded with a Picoscope

® 4424 oscilloscope with 80 MS/s (Pico Technology, Cambridgeshire, UK). The fundamental resonance frequency f

1 of each plank was obtained by means of spectral analysis. Using this frequency and the density of each plank (ρ

p), the dynamic elastic modulus (MoE

dyn,p) can be estimated as follows:

where L is the plank length, and v is the propagation velocity of the stationary elastic wave. Furthermore, a correction of the dynamic elastic modulus (MoE

dyn,p,12) from the real MC

p measured with a digital moisture meter to the MC = 12% was carried out according to the standard [

25] as

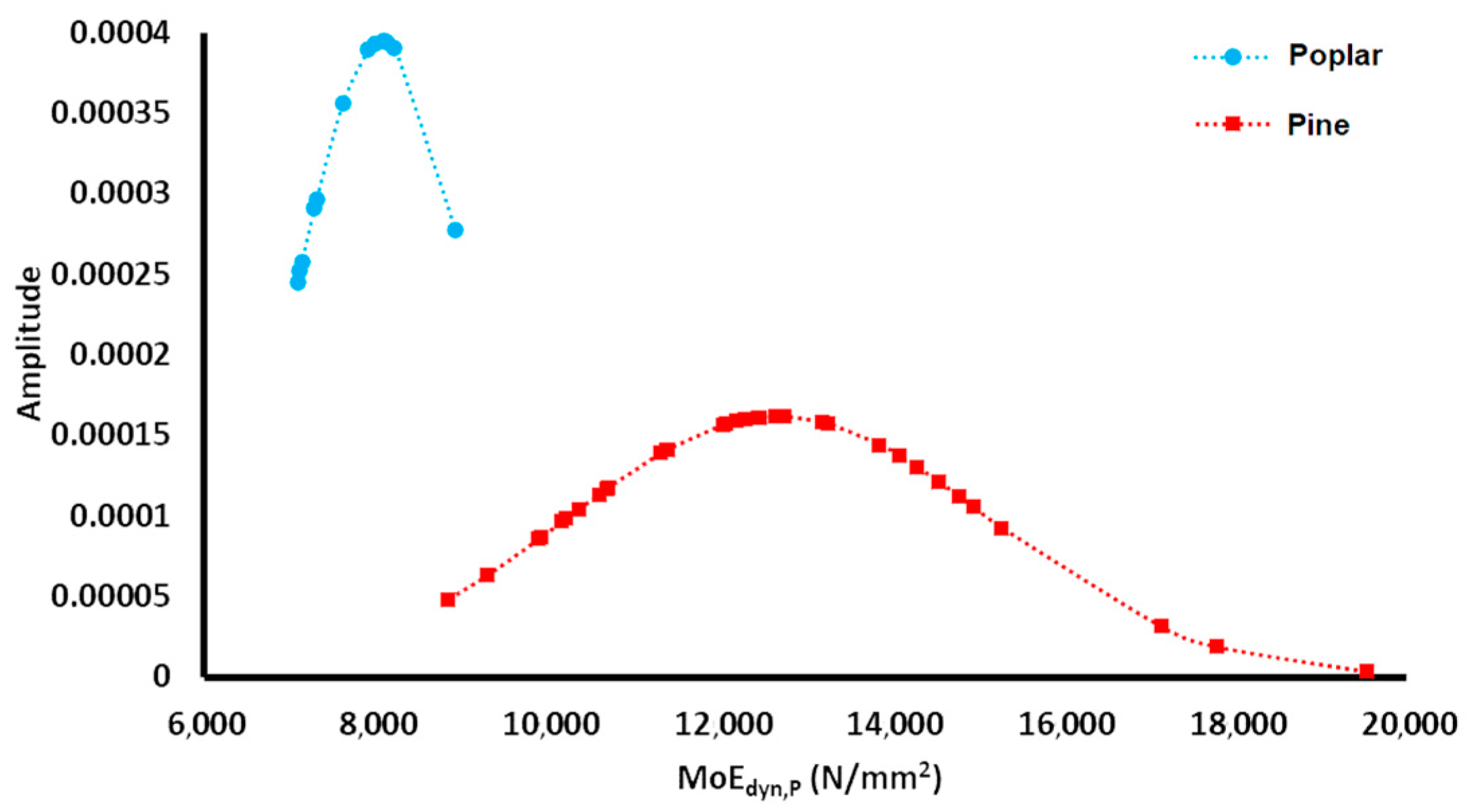

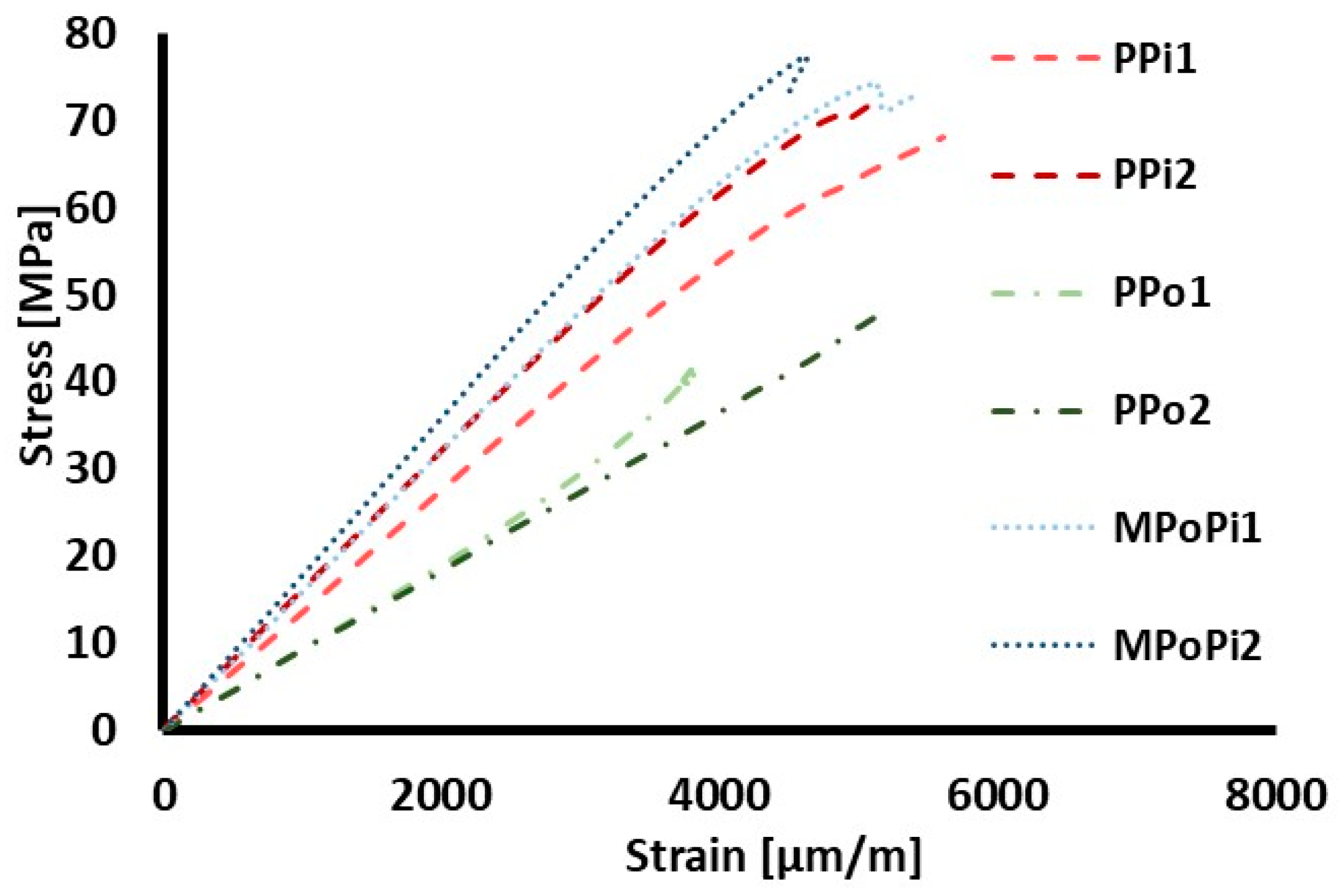

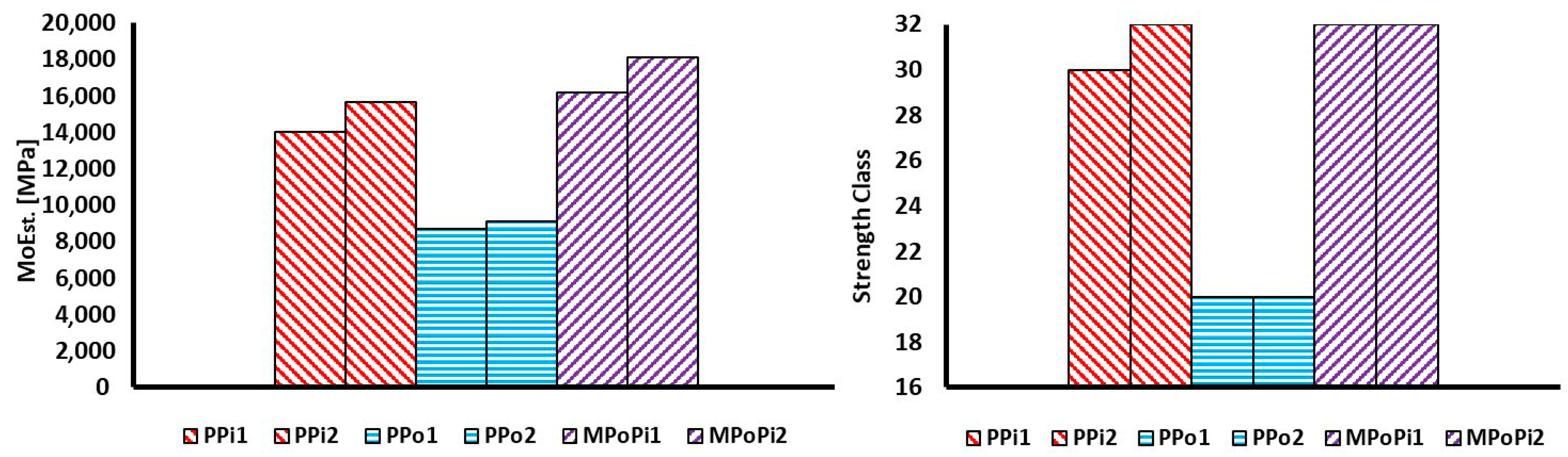

Figure 3 depicts the dynamic modulus of elasticity of all the planks. Results for poplar and pine follow normal distributions, with smaller values of the dynamic elastic modulus and a more reduced deviation values for the case of poplar timber compared with pine.

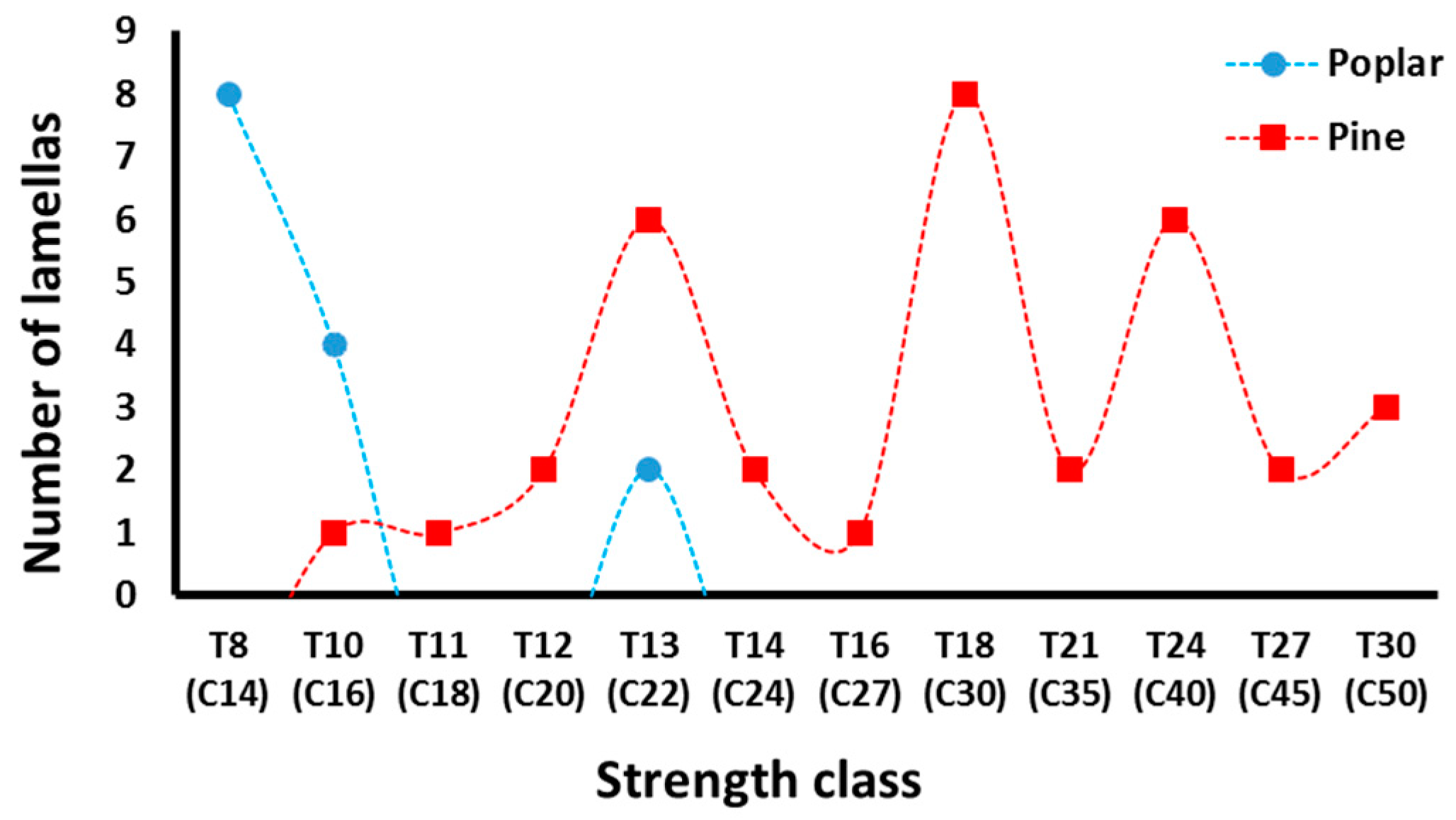

2.5. Glulam Timber Samples

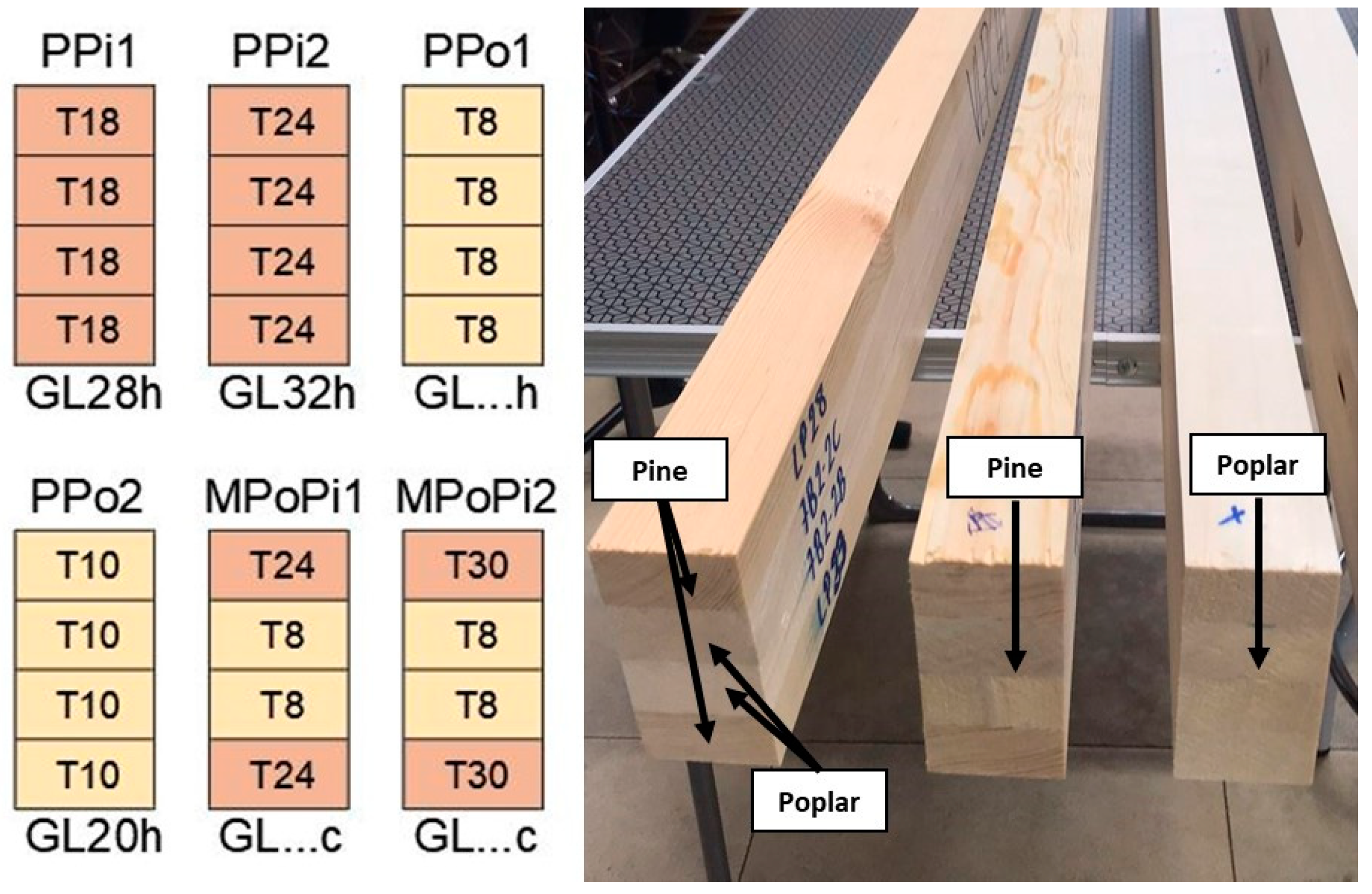

Three different types of 4-layers laminated timber were designed and compared; single-species poplar (PPo), single-species pine (PPi) and mixed poplar/pine (MPoPi) as shown in

Figure 5. Two samples were manufactured for each type. Based on the T strength class of the planks and the recommendations for homogeneous timber given by Table 2 in Section 5.1.4.3 from reference [

26], different layouts were set up for the case of pine or poplar single-species layouts used as control specimens.

Figure 5 indicates also the GL strength class theoretically assigned by the mentioned standard (named in this paper as “design class”), except for the case of poplar/pine mixed timber because the standard does not consider multispecies layouts, and for the PPo1 sample due to the very low out-standard strength class of the poplar planks (T8). It should be also noticed that the pine planks of the single-species pine control sample PPi2 and mixed sample MPoPi1 have the same design class—T24. Thus, its mutual comparison can be used to evaluate the influence of the substitution of inner pine planks by poplar ones.

The planks were glued to each other by using the polyurethane resin PUR-20 from Bakar

® (Bakar, Vizcaya, Spain) with an amount of adhesive of 350 g/m

2, applying a constant pressure of 6 × 10

−7 MPa during 4 h without using any finger joints. The elaboration process was carried out following the requirements of the standard [

26]-(Annex I). During the elaboration process the temperature and humidity of the room (HR) was of 20 °C and 40%. As indicated by the standard, the time between mechanization and gluing of the planks was lower than 24 h. The resulting dimensions of the samples were b = 40 mm, h = 80 mm, and L = 1230 mm.

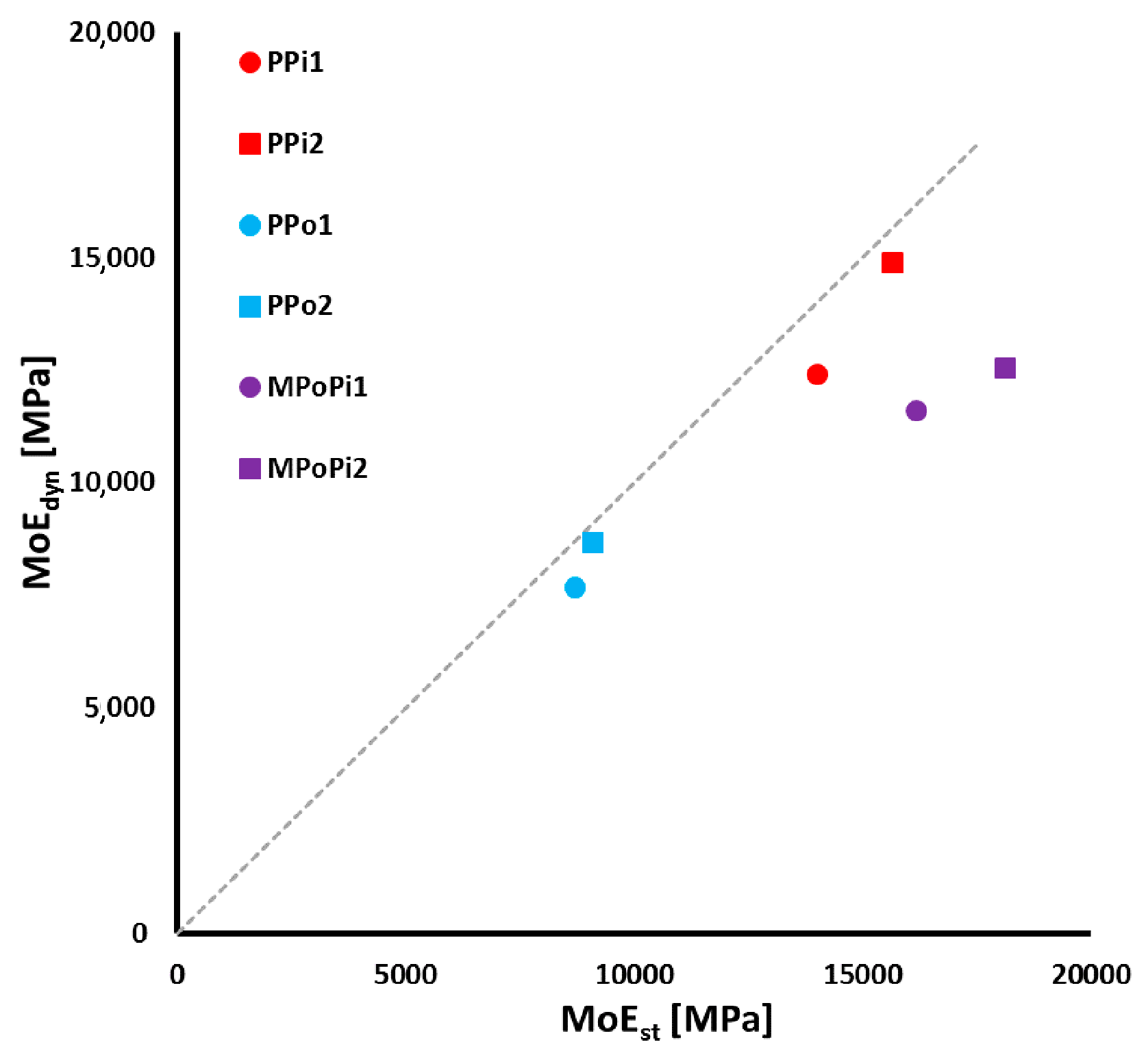

2.8. Bending Test

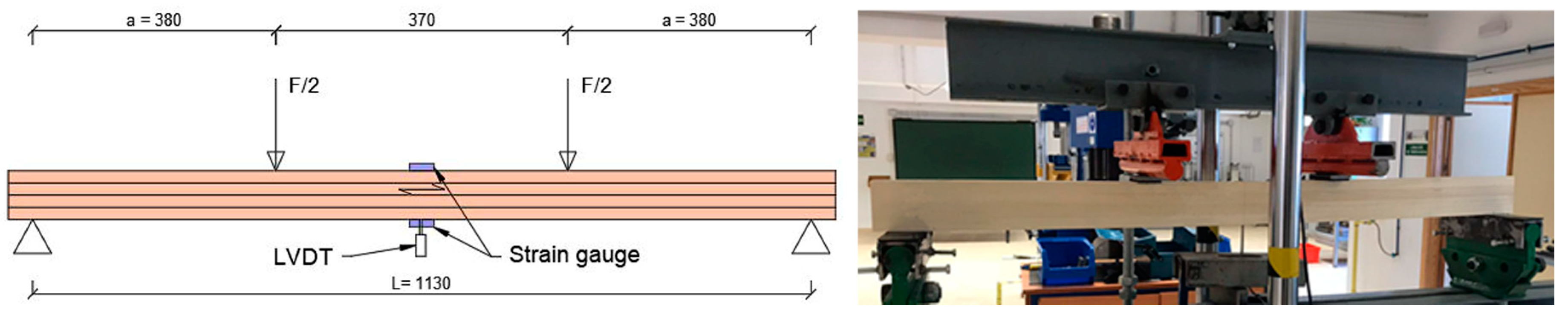

Following the standard [

24], a monotonic four-point bending test was performed for each particular sample (see

Figure 6). Due to the plank sizes and in order to avoid torsion effects caused by a small base of the samples, a 14h ratio was set, scaling the standard arrangement. Displacement control ratio was set at 4 mm/min, in order to fulfill the requirements of the aforementioned standard. A 100 kN-capacity testing machine (Equipos de ensayo Controls S.A., Toledo, Spain) was used. Two strain gauges were glued at the mid-spam section of the sample on the bottom and top faces, in order to measure the maximum tensile and compression strains, respectively. The span between supports was set as 1130 mm. The maximum stress σ

max was calculated as

where M

max = F

max a/2 is the maximum bending moment and W is the section modulus (see

Figure 6 for the meaning of a). Similarly, the static modulus of elasticity MoE

st was calculated by using the stress-tensile strain curve, as the slope in the linear range between 20–40% of the maximum stress. Moreover, the global modulus of elasticity MoE

st,g was also obtained according to Section 10.3 from reference [

24], as

by using the load–displacement (L–

) curve, in the same load range as MoE

st (20–40% of the maximum load). The displacement was measured by means of a LVDT placed as shown in

Figure 7.

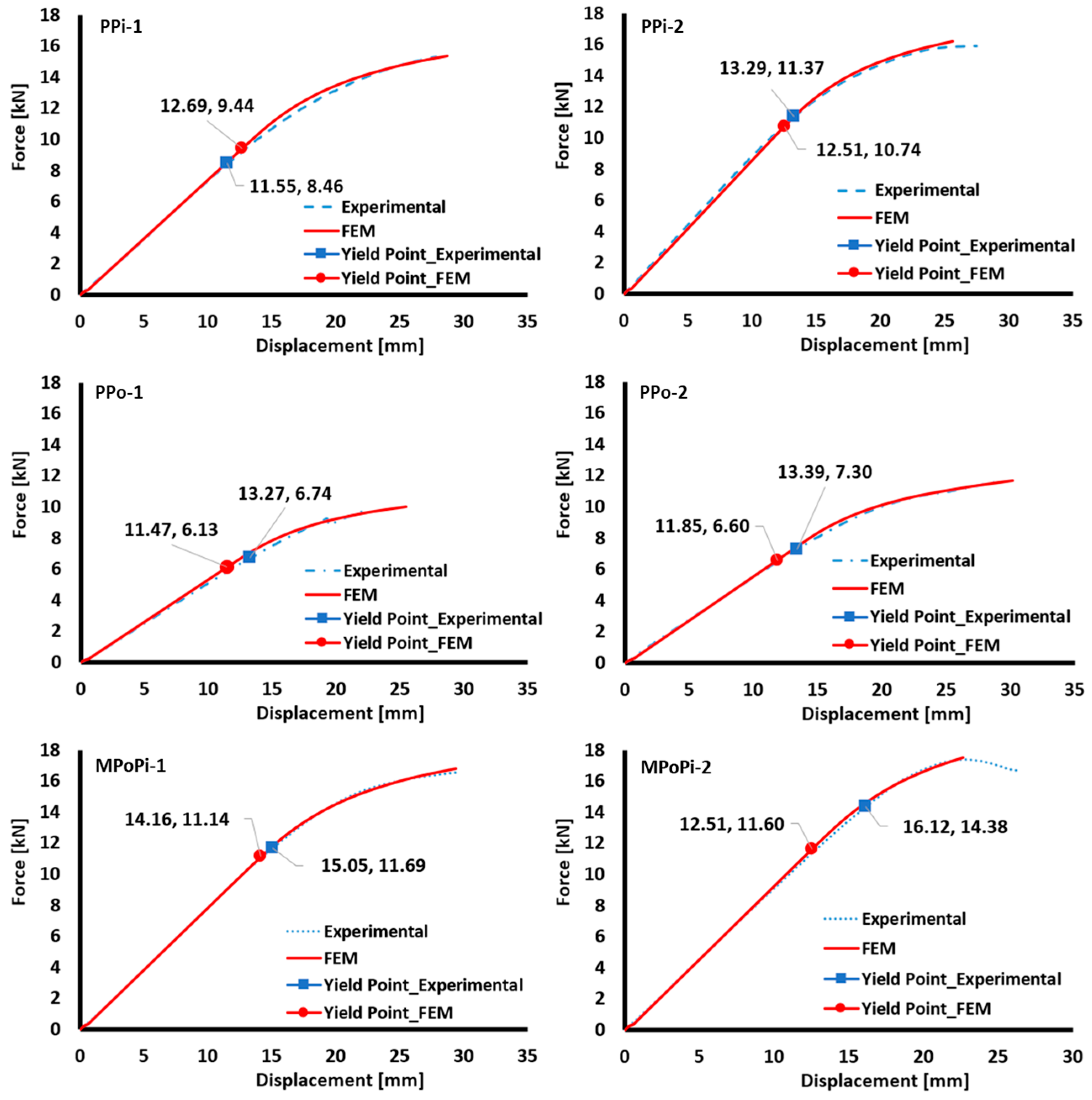

2.10. Numerical Modelling

A three-dimensional finite element model (3D-FEM) was developed into the open source finite element code Salome Meca

® (Version 2019, Code Aster, France) [

29] to evaluate the behavior of the manufactured glulam timber subjected to four-point bending test. The samples were modeled as elasto-plastic solids and nonlinear analyses were performed using a linear elasto-plastic constitutive model with hardening. The constitutive model received as input parameters the elastic modulus, shear modulus and Poisson ratio for the linear elastic part, and the yield stresses for the plastic part with hardening. The 3D-FEM model consists of one piece with a rectangular cross-section and four simply supported solid rollers (see

Figure 7). Bottom rollers represent the supports and top ones the points of application of the loads in the testing machine. In order to get accurate results with reasonable computational cost, an analysis of convergence of results dependent of element size was carried out. An optimum size of 8 mm was achieved and the sample was meshed into 9240 eight-node brick elements having a total number of 11,935 nodes. Each roller was meshed into 1648 six-node wedge elements with a total number of 1109 of nodes, allowing a proper adaptation to the cylindrical shape. The right subfigure in

Figure 7 shows the defined mesh for the supports and load cells in detail. The average radial size for each element was 2.75 mm and an outermost size of 5.85 mm was adopted, resulting in a total roller diameter of 30 mm. Due to the set-up of the experimental part, four-point bending test, the material definition of the 3D-FEM model was considered to be isotropic. In this case, the specimen is working mainly in the longitudinal direction without any transverse constraints and the mechanical properties in the longitudinal direction are the most relevant for this analysis. The isotropic model also implies an intermediate-low computational cost without important influence in the results. Rollers for the experimental test were made of steel so, in consequence, the elastic modulus of 210 GPa and the Poisson’s ratio of 0.3 were considered.

In coherence with the experimental test, bottom rollers were restrained to move in any direction and the top rollers (points of load application) were constrained to remain horizontal, while being able to rotate and moving vertically during the simulation. Previous authors [

23] use similar numerical setups without modelling contact interactions from supports and loads cells. Further, a contact restriction between roller and the laminated specimen surface was prescribed. Definition of contact requires the description contact candidates which comprise the slave and master surfaces [

30]. The contact formulation, applied to the simulation, are normal and frictional penalties [

31] due to their ability to soften the nonlinearities induced by contact. The mechanical stiffness of penalty springs was calibrated to 1 × 10

9 kN/m according to the guidelines given in [

32], while the friction coefficient was set to 0.3, which is a common value for the friction for steel surfaces. In order to simulate the whole experimental process and to improve the convergence of the contacts, the load increases linearly and is applied in the center of gravity of each top roller.

The set of nonlinear equations from the finite element model was solved with a direct full Newton nonlinear solver. The solution provides the displacements, elastic/plastic stresses and strains at each increment. A set of nodes located at the bottom face of the mid-span, in the same positions as LVDTs, was used to obtain the deflection during the simulation.

Moreover, in order to obtain the mechanical properties for the FEM model, a calibration process was carried out. It consisted of running the analysis using a starting value of elastic modulus, equal to the one determined through the experimental part (MoE

st), and then the elastic and plastic parameters as the yielding stress (σ

y) were adjusted to fit the experimental patterns. In order to compute a reasonable shear modulus (G), MoE

st is enforced to be equal to MoE

st,g in Equation (6). The rest of known parameters from Equation (6) represent: L, the span of the sample; a, the distance between the supports and its nearest point of load application; b, the base of the sample; h, the height of the sample; L20 and L40, the load at 20% and 40% of the maximum load, respectively; and

20 and

40, the corresponding displacement registered with de LVDT at that load values. Thus, the only unknown to be solved is the value of the shear modulus G. The Poisson’s ratio (ν) was set as 0.37 by means of tests performed in [

33]. Two calibration processes were carried out by considering G or not, thus obtaining the calibrated modulus of elasticity MoE

FEM,G and MoE

FEM, respectively. In both cases, the calibration procedure was considered to be finished when the difference between numerical and experimental stiffness in the elastic regime was lower than 5%. Increments of applied load,

, and corresponding displacements,

, were used to compute the stiffness K applying the following relation:

Stiffness of the samples was computed between 15 and 35% of the elastic range, based on the force–displacement relationship, for both the numerical and experimental part.