High Temperature Mechanical Properties of a Vented Ti-6Al-4V Honeycomb Sandwich Panel

Abstract

:1. Introduction

2. Experimental Procedure

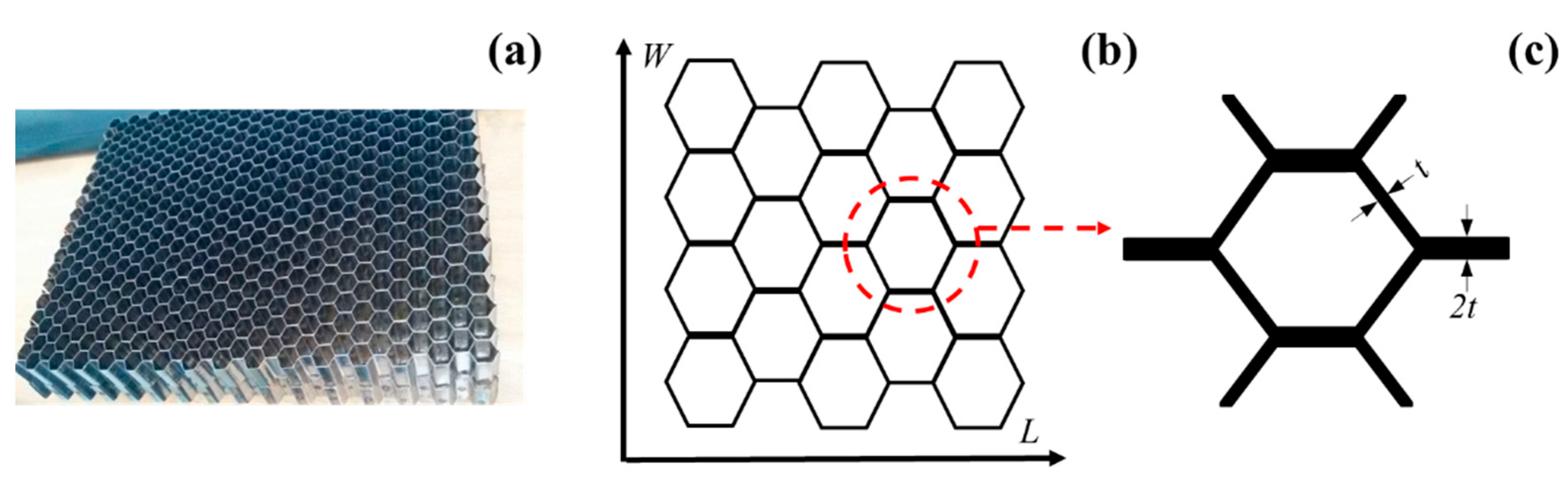

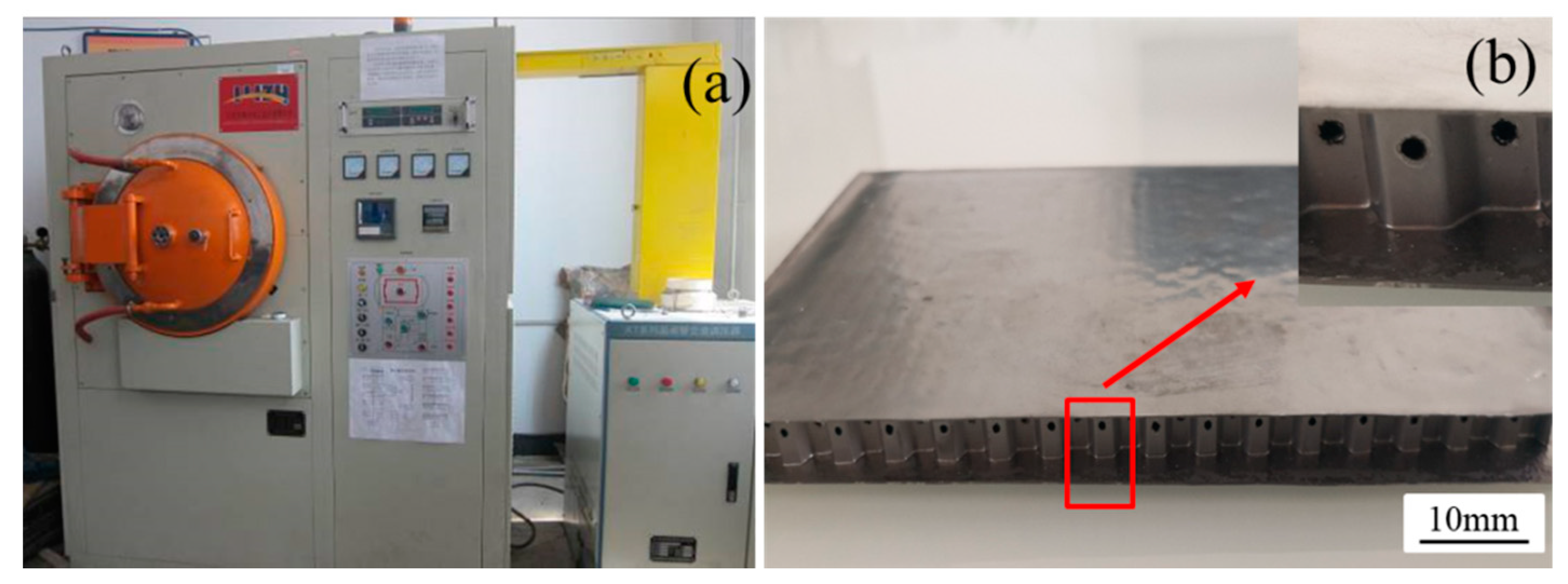

2.1. Metal Honeycomb Sandwich Panel Preparation

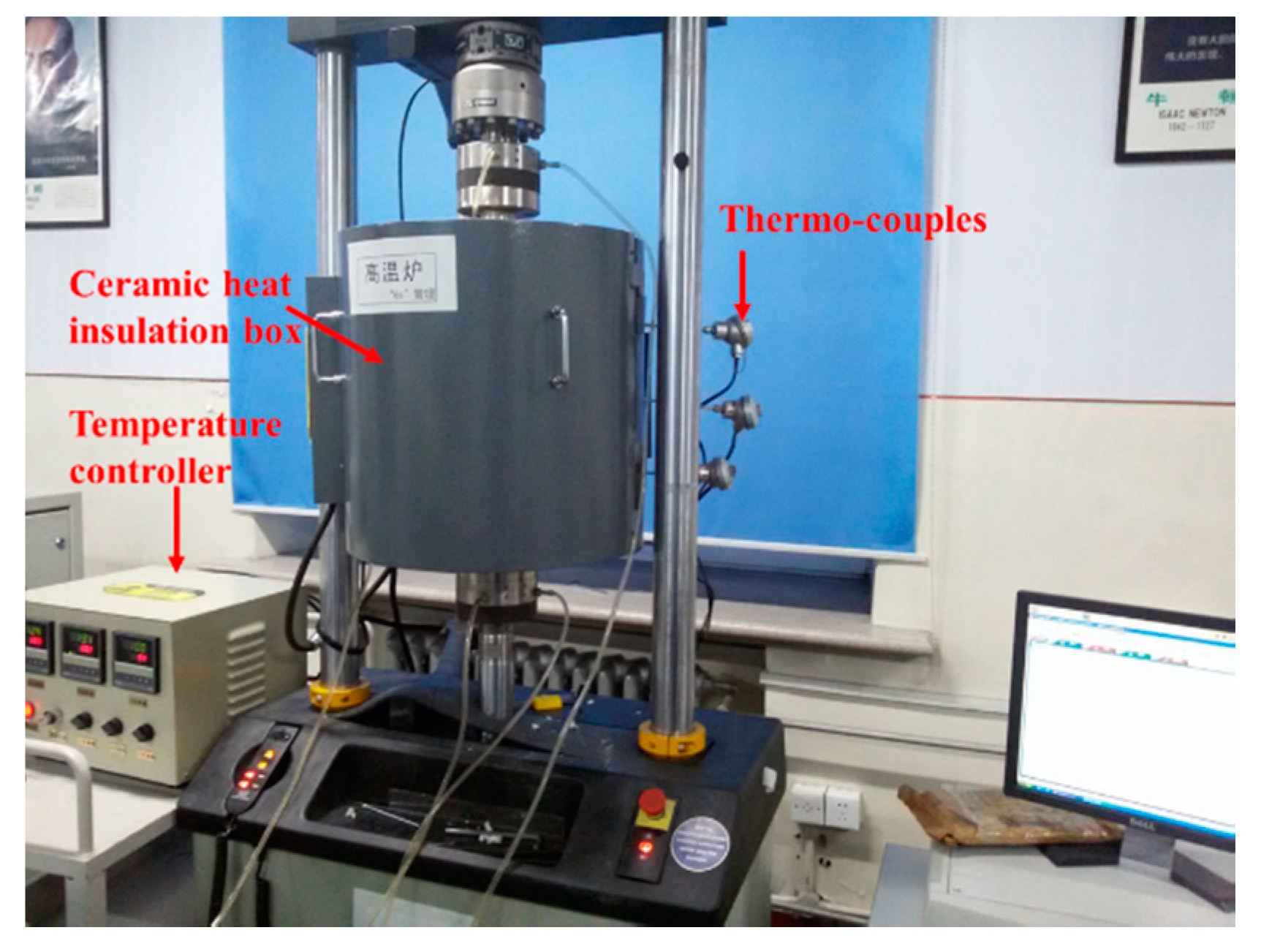

2.2. Flatwise Compression Test

2.3. Three-Point Bending Test

3. Results and Discussion

3.1. Microstructure of the Brazed Joint

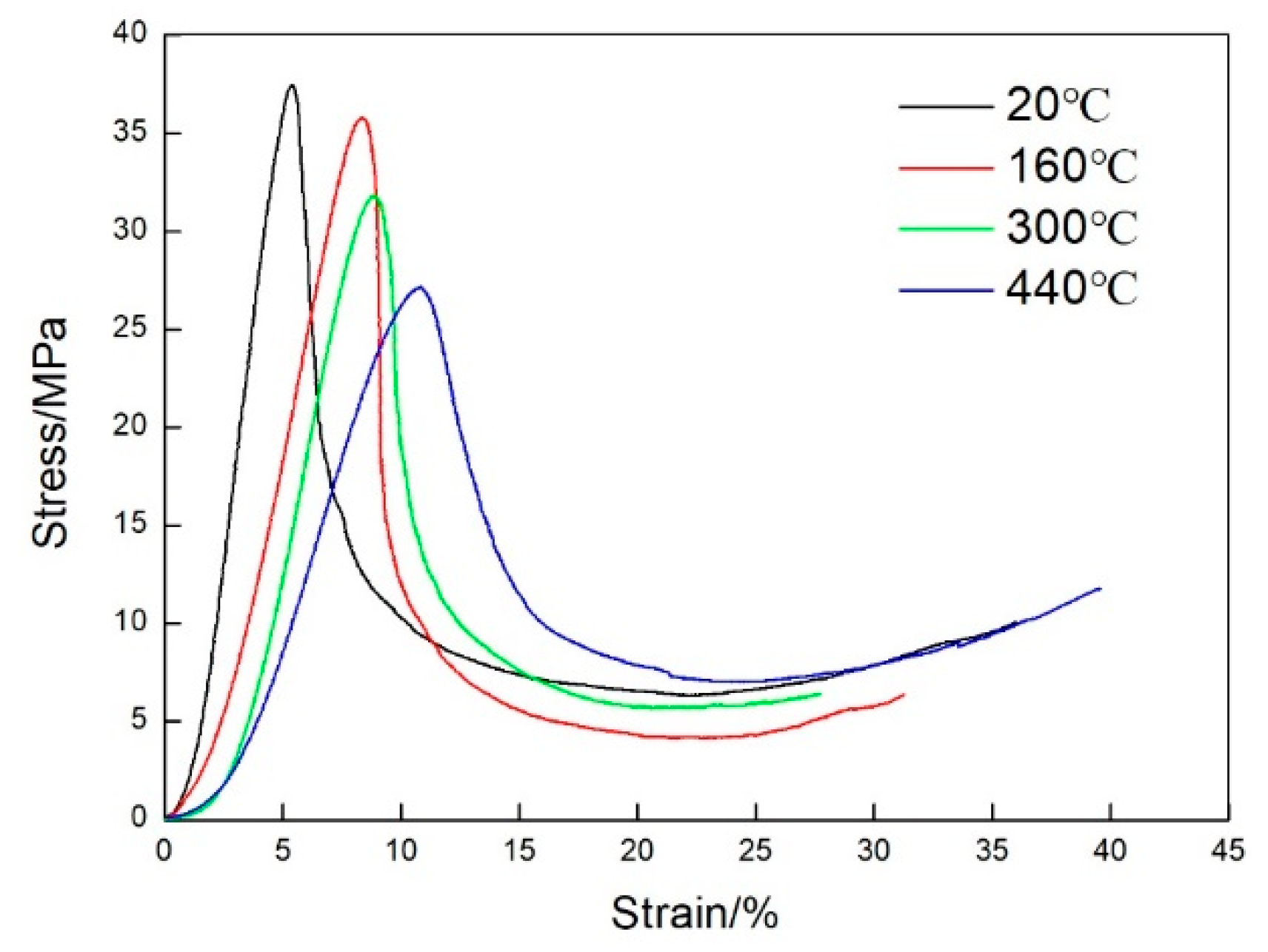

3.2. Flatwise Compressive Properties of the Vented Honeycomb Sandwich Panels

3.3. Three-Point Bending Properties of the Vented Honeycomb Sandwich Panels

4. Conclusions

- (1)

- The elements of the Ti-6Al-4V metal and the 35Ti-35Zr-15Cu-15Ni brazing filler metal diffuse to each other and react at the interface between the honeycomb core and the face-sheets during the brazing process, which makes a positive influence on the interface bonding performance of the vented metal honeycomb sandwich panels. Compared to the interaction between the face-sheets and the brazing filler, the diffusion and reaction between the honeycomb core and the brazing filler are stronger.

- (2)

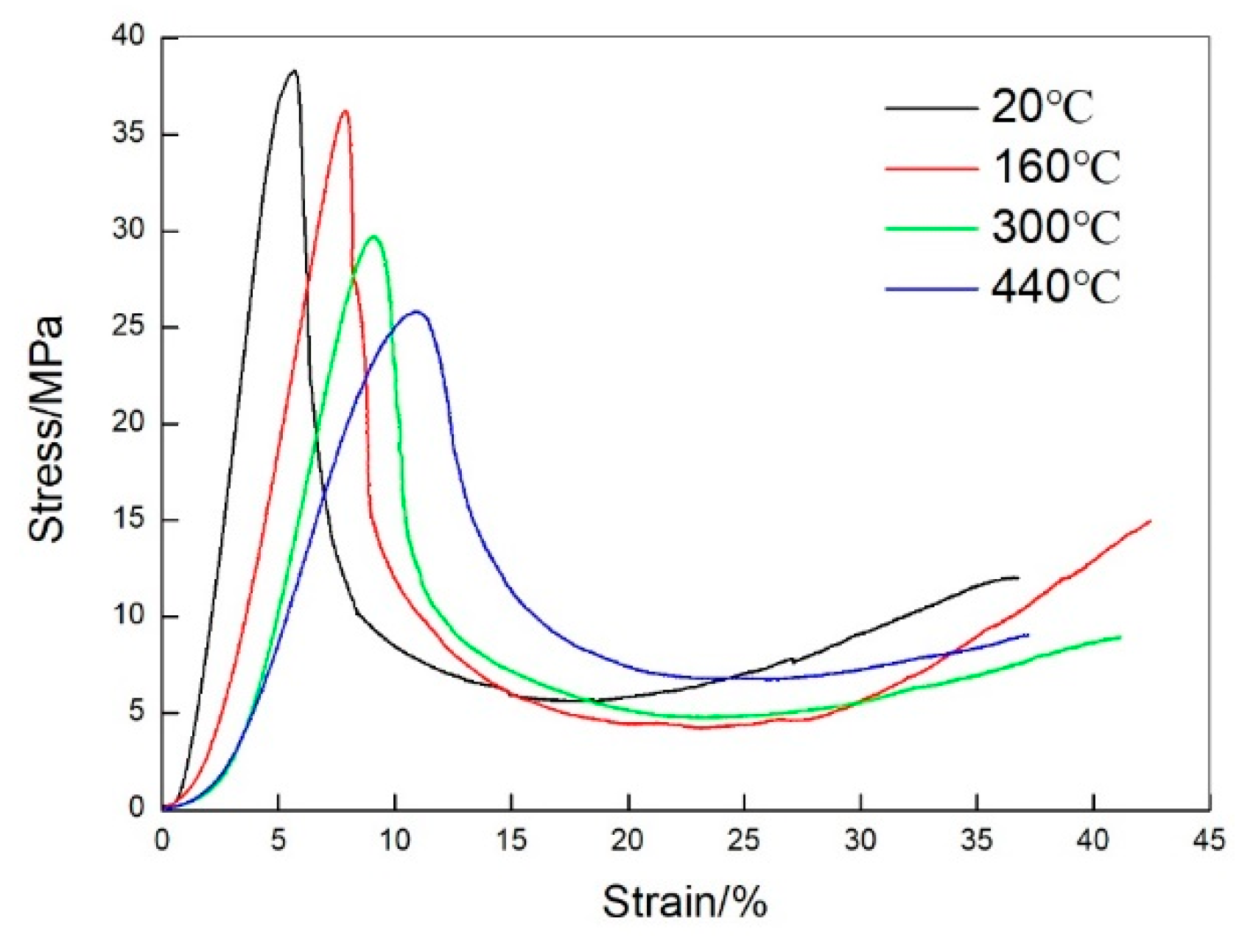

- Compared to the flatwise compression properties of the vented honeycomb sandwich panels at 20 °C, the compression strength shows 5.5%, 15.2%, and 27.8% reduction, and the elastic modulus decreases by 30.3%, 35%, and 56.4% for sandwich panels at 160, 300, and 440 °C, respectively. Compression buckling failure of the honeycomb core occurs at about one-quarter the thickness of the cell walls. The holes punched on the honeycomb core have not led to the decrease of the flatwise compression performance of the Ti-6Al-4V honeycomb sandwich panels in this study.

- (3)

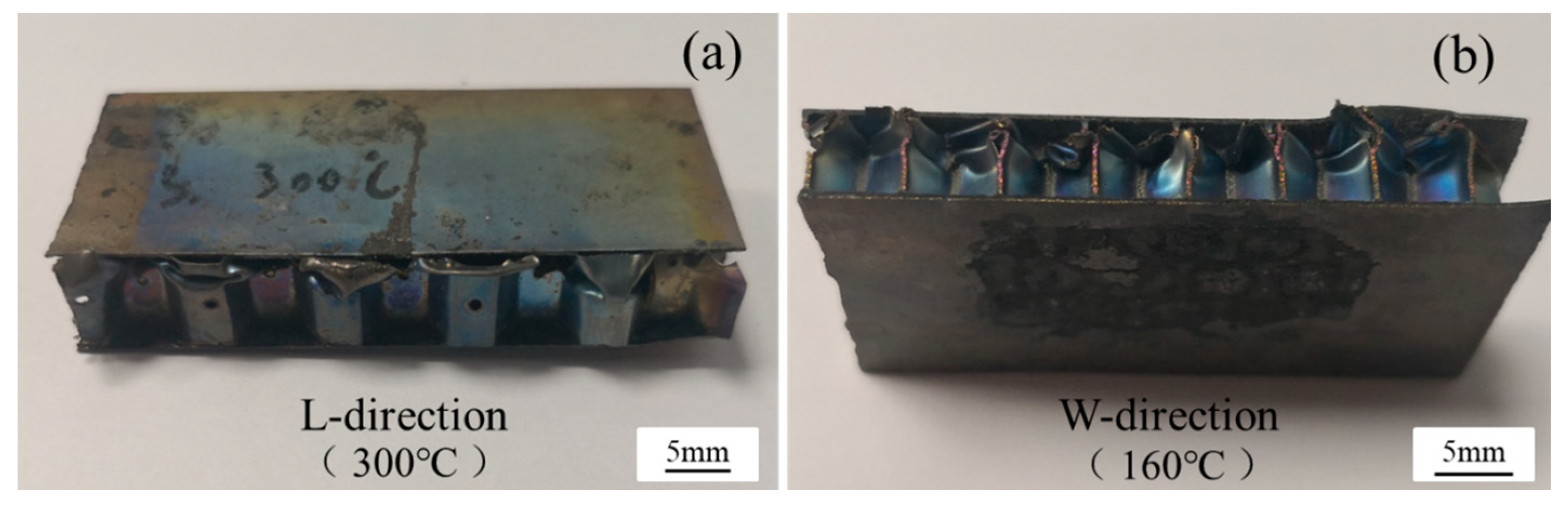

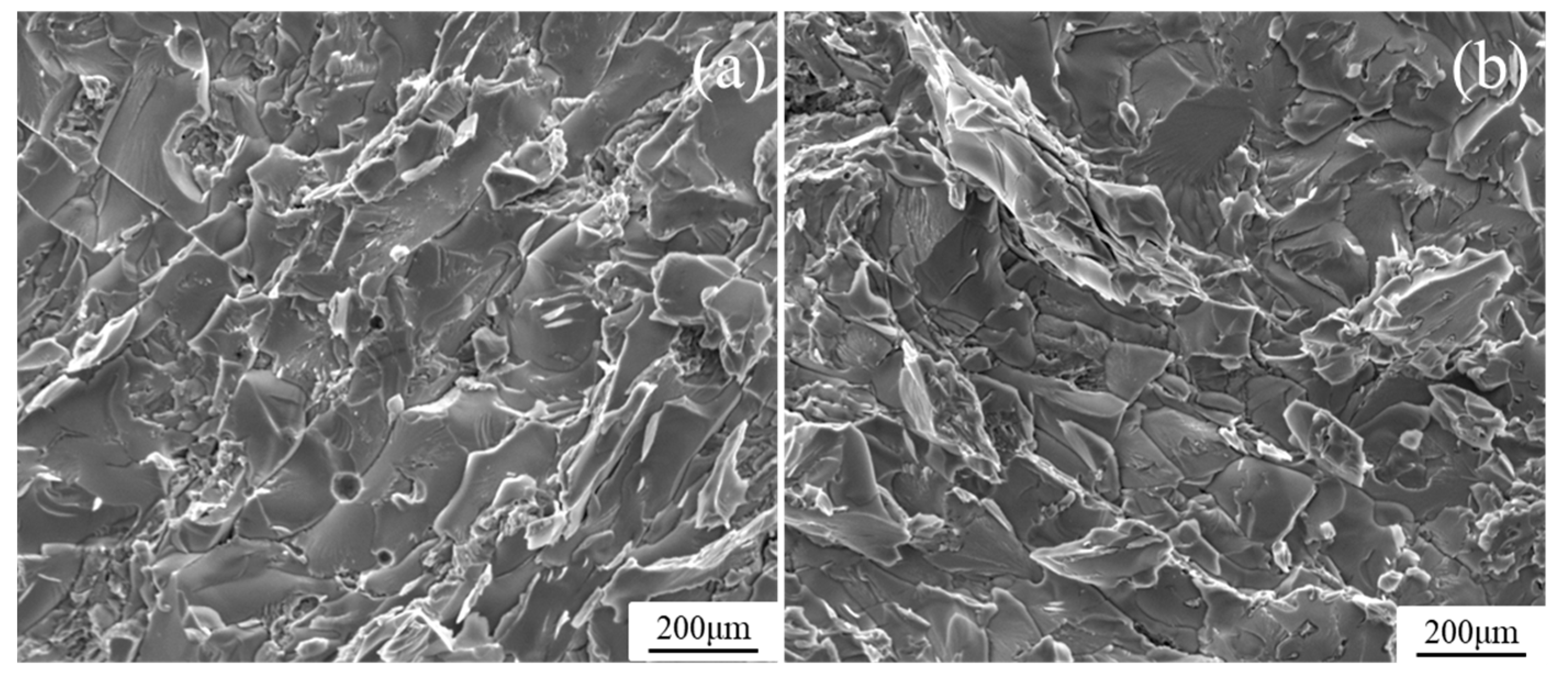

- The flexural strength of the vented honeycomb sandwich panels decreases with temperature increasing, while the deflection is increased. The flexural strength and deflection of the L-direction sandwich panels is larger than that of the W-direction sandwich panels at the same temperature. The sandwich panels show a brittle fracture behavior at lower temperature, the failure modes mainly include the face-sheet tensile breaking and the debonding between the honeycomb core and the face-sheets. The ductile failure of the sandwich panels occurs resulting from the compression crushing of the honeycomb core and the local buckling failure of the face-sheets at higher temperature. The plastic deformation ability of the material is great enough to change the failure mode of the structure from brittle into ductile at 440 °C.

Author Contributions

Funding

Conflicts of Interest

References

- Pydah, A.; Batra, R.C. Blast loading of bumper shielded hybrid two-core Miura-ori/honeycomb core sandwich plates. Thin Walled Struct. 2018, 129, 45–57. [Google Scholar] [CrossRef]

- Giglio, M.; Gilioli, A.; Manes, A. Numerical investigation of a three-point bending test on sandwich panels with aluminum face-sheets and Nomex™ honeycomb core. Comput. Mater. Sci. 2012, 56, 69–78. [Google Scholar] [CrossRef]

- Foo, C.C.; Chai, G.B.; Seah, L.K. A model to predict low-velocity impact response and damage in sandwich composites. Compos. Sci. Technol. 2008, 68, 1348–1356. [Google Scholar] [CrossRef]

- Wang, B.; Wu, L.Z.; Ma, L. Low-velocity impact characteristics and residual tensile strength of carbon fiber composite lattice core sandwich structures. Compos. Part B Eng. 2011, 42, 891–897. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, M.; Stocchi, A. Mechanical behaviors of carbon fiber composite sandwich columns with three-dimensional honeycomb cores under in-plane compression. Compos. Part B Eng. 2014, 60, 350–358. [Google Scholar] [CrossRef]

- Gusarova, I.A.; Man’ko, T.A.; Derevyanko, I.I.; Potapov, A.M.; Buiskikh, K.P.; Barilo, V.G. Study on metal heat-protective structures of reusable aerospace vehicles. Strength Mater. 2019, 51, 852–859. [Google Scholar] [CrossRef]

- Elrefaey, A.; Tillmann, W. Brazing of titanium to steel with different filler metals. Analysis and comparison. J. Mater. Sci. 2010, 45, 4332–4338. [Google Scholar] [CrossRef]

- Ganjeh, E.; Sarkhosh, H. Microstructural, mechanical and fractographical study of Titanium-CP and Ti-6Al-4V similar brazing with Ti-based filler. Mater. Sci. Eng. A. 2013, 559, 119–129. [Google Scholar] [CrossRef]

- Jing, Y.J.; Yue, X.S.; Gao, X.Q.; Su, D.Y.; Hou, J.B. The influence of Zr content on the performance of Ti-Zr-Cu-Ni brazing filler. Mater. Sci. Eng. A. 2016, 678, 190–196. [Google Scholar] [CrossRef]

- Fatemi, J.; Lemmen, M. Effective thermal mechanical properties of honeycomb core panels for hot structure applications. J. Spacecr. Rocket. 2009, 46, 514–525. [Google Scholar] [CrossRef]

- Petley, D.H.; Jones, S.C. Thermal management for a Mach 5 cruise aircraft using endothermic fuel. J. Aircr. 1992, 29, 384–389. [Google Scholar] [CrossRef]

- Lee, H.S.; Hong, S.H.; Lee, J.R.; Kim, Y.K. Mechanical behavior and failure process during compressive and shear deformation of honeycomb composite at elevated temperatures. J. Mater. Sci. 2002, 37, 1265–1272. [Google Scholar] [CrossRef]

- Li, Z.; Wang, T.; Jiang, Y.; Wang, L.; Liu, D. Design-oriented crushing analysis of hexagonal honeycomb core under in-plane compression. Compos. Struct. 2018, 187, 129–138. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, Z.; Tian, H.; Yao, S.; Zhou, W. Theoretical assessment methodology on axial compressed hexagonal honeycomb’s energy absorption capability. Mech. Adv. Mater. Struct. 2016, 23, 503–512. [Google Scholar] [CrossRef]

- Lee, S.M.; Tsotsis, T.K. Indentation failure behavior of honeycomb sandwich panels. Compos. Sci. Technol. 2000, 60, 1147–1159. [Google Scholar] [CrossRef]

- Wang, Z.G.; Liu, J.F. Numerical and theoretical analysis of honeycomb structure filled with circular aluminum tubes subjected to axial compression. Compos. Part B Eng. 2019, 165, 626–635. [Google Scholar] [CrossRef]

- Wang, Z.G.; Liu, J.F.; Hui, D. Mechanical behaviors of inclined cell honeycomb structure subjected to compression. Compos. Part B. Eng. 2017, 110, 307–314. [Google Scholar] [CrossRef]

- Zhou, G.; Hill, M.; Loughlan, J.; Hookham, N. Damage characteristics of composite honeycomb sandwich panels in bending under quasi-static loading. J. Sandw. Struct. Mater. 2006, 8, 55–90. [Google Scholar] [CrossRef]

- Sun, G.; Huo, X.; Chen, D.; Li, Q. Experimental and numerical study on honeycomb sandwich panels under bending and in-panel compression. Mater. Des. 2017, 133, 154–168. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Morganti, S.; Prota, A.; Reali, A. Statistical finite element analysis of the buckling behavior of honeycomb structures. Compos. Struct. 2013, 105, 240–255. [Google Scholar] [CrossRef]

- Jang, W.Y.; Kyriakides, S. On the buckling and crushing of expanded honeycomb. Int. J. Mech. Sci. 2015, 91, 81–90. [Google Scholar] [CrossRef]

- Chen, T.J.; Huang, J.S. Creep-buckling of hexagonal honeycombs with dual imperfections. Compos. Struct. 2009, 89, 143–150. [Google Scholar] [CrossRef]

- Bai, Y.; Yu, K.; Zhao, J.; Zhao, R. Experimental and simulation investigation of temperature effects on modal characteristics of composite honeycomb structure. Compos. Struct. 2018, 201, 816–827. [Google Scholar] [CrossRef]

- Erickson, M.D.; Kallmeyer, A.R.; Kellogg, K.G. Effect of temperature on the lowvelocity impact behavior of composite sandwich panels. J. Sandw. Struct. Mater. 2016, 7, 245–264. [Google Scholar] [CrossRef]

- Shang, L.; Xue, Q.C.; Yang, D.C.; Zou, G.P.; Li, Y. High temperature mechanical properties of tc4 titanium alloy honeycomb panel. Rare Metal Mat. Eng. 2018, 47, 567–573. [Google Scholar]

- Okada, R.; Kortschot, M.T. The role of the resin fillet in the delamination of honeycomb sandwich structures. Compos. Sci. Technol. 2002, 62, 1811–1819. [Google Scholar] [CrossRef]

- Glaessgen, E.H.; Reeder, J.R.; Sleight, D.W.; Wang, J.T.; Raju, I.S.; Harris, C.E. Debonding failure of sandwich-composite cryogenic fuel tank with internal core pressure. J. Spacecr. Rocket. 2005, 42, 613–627. [Google Scholar] [CrossRef]

- Anders, M.; Zebrine, D.; Centea, T.; Nutt, S.R. Process diagnostics for cocure of sandwich structures using in situ visualization. Compos. Part A Appl. Sci. Manuf. 2019, 116, 24–35. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, Q.; Chen, S.; Yu, X.; Li, H.; Wang, T. Compressive crushing of novel aluminum hexagonal honeycombs with perforations: experimental and numerical investigations. Int. J. Solids. Struct. 2017, 126–127, 187–195. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Zhu, F.; Wu, G.Y.; Zhao, L.M. Response of aluminium corrugated sandwich panels under air blast loadings: experiment and numerical simulation. Int. J. Impact Eng. 2014, 65, 79–88. [Google Scholar] [CrossRef]

- Cai, L.C.; Zhang, D.Y.; Zhou, S.H.; Xu, W. Investigation on mechanical properties and equivalent model of aluminum honeycomb sandwich panels. J. Mater. Eng. Perform. 2018, 27, 6585–6596. [Google Scholar] [CrossRef]

| Al | V | Fe | Si | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|

| 5.5–6.8 | 3.5–4.5 | ≤0.30 | ≤0.15 | ≤0.10 | ≤0.05 | ≤0.015 | ≤0.20 | Bal. a |

| Zone | Al | Zr | Ti | V | Ni | Cu |

|---|---|---|---|---|---|---|

| 1 | 6.43 | 0 | 87.86 | 5.71 | 0 | 0 |

| 2 | 10.61 | 0.76 | 78.03 | 7.68 | 1.51 | 1.51 |

| 3 | 12.24 | 1.06 | 81.72 | 2.39 | 1.32 | 1.26 |

| 4 | 4.51 | 15.12 | 62.03 | 4.6 | 4.58 | 9.15 |

| 5 | 3.31 | 24.28 | 37.95 | 1.67 | 14.91 | 17.88 |

| 6 | 2.69 | 17.85 | 57.04 | 1.41 | 8.11 | 12.9 |

| 20 °C | 160 °C | 300 °C | 440 °C | |

|---|---|---|---|---|

| σ/MPa | 38.29 ± 1.6 | 36.20 ± 1.5 | 32.47 ± 1.4 | 27.63 ± 1.2 |

| E/MPa | 943.87 ± 17 | 657.81 ± 15 | 613.97 ± 13 | 411.85 ± 13 |

| 20 °C | 160 °C | 300 °C | 440 °C | |

|---|---|---|---|---|

| σ/MPa | 37.49 ± 1.5 | 35.80 ± 1.4 | 31.81 ± 1.5 | 27.16 ± 1.3 |

| E/MPa | 940.49 ± 16 | 634.61 ± 18 | 604.01 ± 14 | 397.67 ± 15 |

| Temperature | Core Orientation | Defletion (Max)/mm | Load (Max)/N | Main Failure Modes |

|---|---|---|---|---|

| Room temperature | W | 1.6 | 5427 | upper face-sheet wrinkling; lower face-sheet cracking |

| L | 1.63 | 6279 | lower face-sheet cracking; core cracking | |

| 160 °C | W | 1.74 | 4276 | upper face-sheet/core debonding |

| L | 1.81 | 5126 | lower face-sheet cracking; upper face-sheet buckling | |

| 300 °C | W | 1.91 | 3616 | lower face-sheet/core debonding |

| L | 1.96 | 3764 | core and the upper face-sheet buckling | |

| 440 °C | W | 4.97 | 3076 | core and the upper face-sheet buckling; overall buckling |

| L | 5.7 | 3389 | core and the upper face-sheet buckling; overall buckling |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, L.; Wu, Y.; Fang, Y.; Li, Y. High Temperature Mechanical Properties of a Vented Ti-6Al-4V Honeycomb Sandwich Panel. Materials 2020, 13, 3008. https://doi.org/10.3390/ma13133008

Shang L, Wu Y, Fang Y, Li Y. High Temperature Mechanical Properties of a Vented Ti-6Al-4V Honeycomb Sandwich Panel. Materials. 2020; 13(13):3008. https://doi.org/10.3390/ma13133008

Chicago/Turabian StyleShang, Lei, Ye Wu, Yuchao Fang, and Yao Li. 2020. "High Temperature Mechanical Properties of a Vented Ti-6Al-4V Honeycomb Sandwich Panel" Materials 13, no. 13: 3008. https://doi.org/10.3390/ma13133008

APA StyleShang, L., Wu, Y., Fang, Y., & Li, Y. (2020). High Temperature Mechanical Properties of a Vented Ti-6Al-4V Honeycomb Sandwich Panel. Materials, 13(13), 3008. https://doi.org/10.3390/ma13133008